Engine Installation DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 306 of 2627

CONDITION POSSIBLE CAUSES CORRECTION

Partial engagement of clutch disc.

One side of disc is worn and the

other side is glazed and lightly

worn.1. Clutch pressure plate position

incorrect.1. Replace clutch disc and cover.

2. Clutch cover, spring, or release

fingers bent or distorted.2. Replace clutch disc and cover.

3. Clutch disc damaged or

distorted.2. Replace clutch disc.

4. Clutch misalignment. 4. Check alignment and runout of

flywheel, disc, pressure plate, andùr

clutch housing. Correct as

necessary.

SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Slave Cylinder Nuts 23 17 -

Clutch Master Cylinder

Nuts28 21 -

Pressure Plate Bolts - V6

&V850 37 -

Pressure Plate Bolts - V10 30 22.5 -

Pressure Plate Bolts -

Diesel30 22.5 -

Release Bearing Pivot 23 17 -

Flywheel Bolts 95 70 -

CLUTCH DISC

REMOVAL

(1) Support engine with wood block and adjustable

jack stand, to prevent strain on engine mounts.

(2) Remove transmission and transfer case, if

equipped.

(3) If pressure plate will be reused, mark the posi-

tion on flywheel with paint or scriber (Fig. 1). Also

note location marks on the pressure next to the bolt

holes. The mark will be a L or a circle with an X in

it.

(4) Insert clutch alignment tool through clutch disc

and into pilot bushing, to hold disc in place while

removing bolts.

(5) Loosen pressure plate bolts evenly, a few

threads at a time and in a diagonal pattern to pre-

vent warping the plate.

(6) Remove bolts completely and remove pressure

plate, disc and alignment tool.

INSTALLATION

(1) Check runout and free operation of new clutch

disc.

(2) Lubricate crankshaft pilot bearing with a NLGI

- 2 rated grease.

(3) Install clutch alignment tool in clutch disc hub

with the raised side of hub is facing away from the

flywheel.

NOTE: Flywheel side is imprinted on the disc face.

(4) Install alignment tool in pilot bearing and posi-

tion disc on the flywheel.

(5) Position pressure plate over disc and onto the

flywheel (Fig. 2).

(6) Align and hold pressure plate in position and

install bolts finger tight.

(7) Tighten bolts evenly and a few threads at a

time in a diagonal pattern.

CAUTION: Bolts must be tightened evenly and to

specified torque to avoid warping pressure plate

cover.

DRCLUTCH 6 - 5

CLUTCH (Continued)

Page 310 of 2627

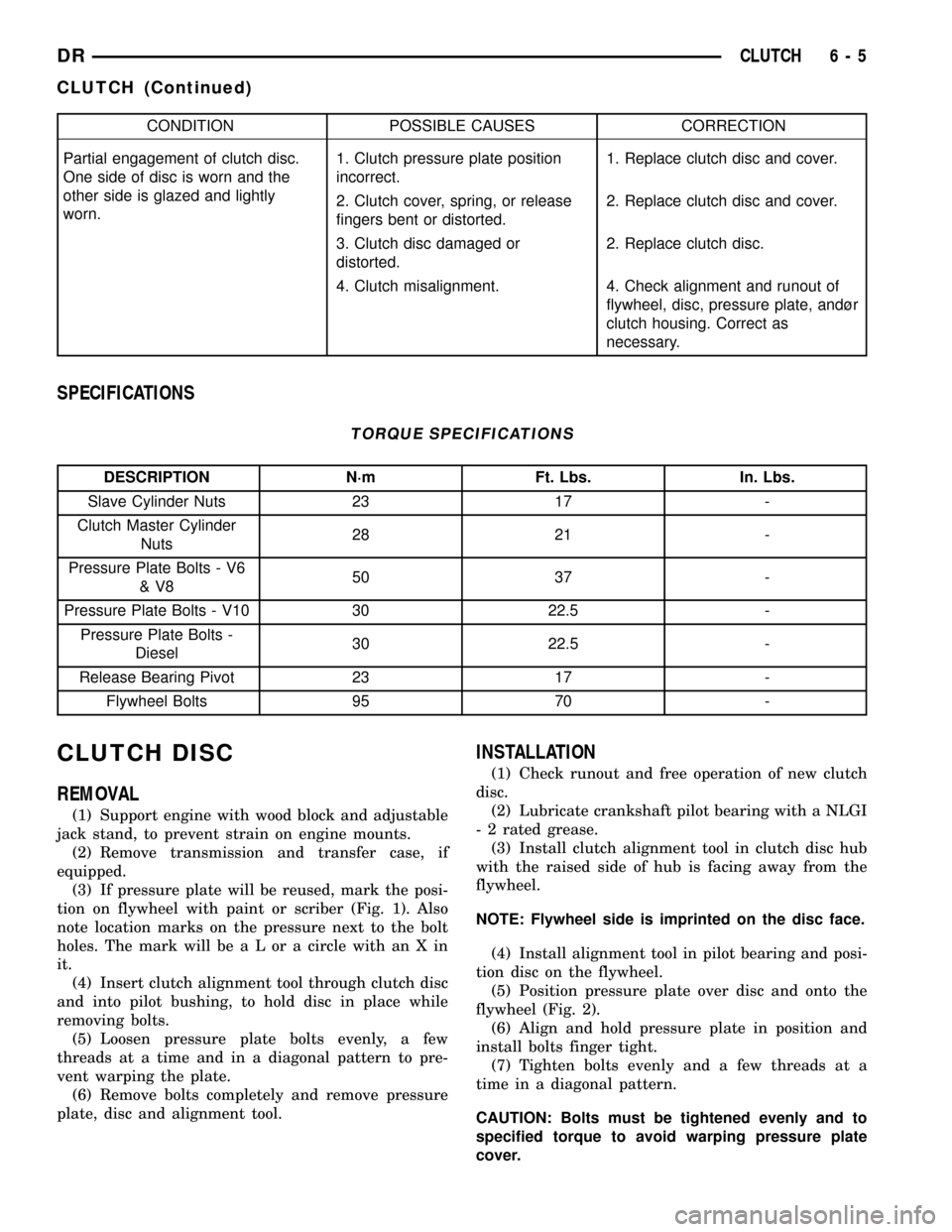

To correct this example (Fig. 11) the shims needed

between the clutch housing and transmission are:

²0.009 in. at the 0.000 corner

²0.012 in. at the ±0.003 corner

²0.013 in. at the ±0.004 corner

After installing the clutch assembly and housing,

tighten the housing bolts nearest the alignment dow-

els first.

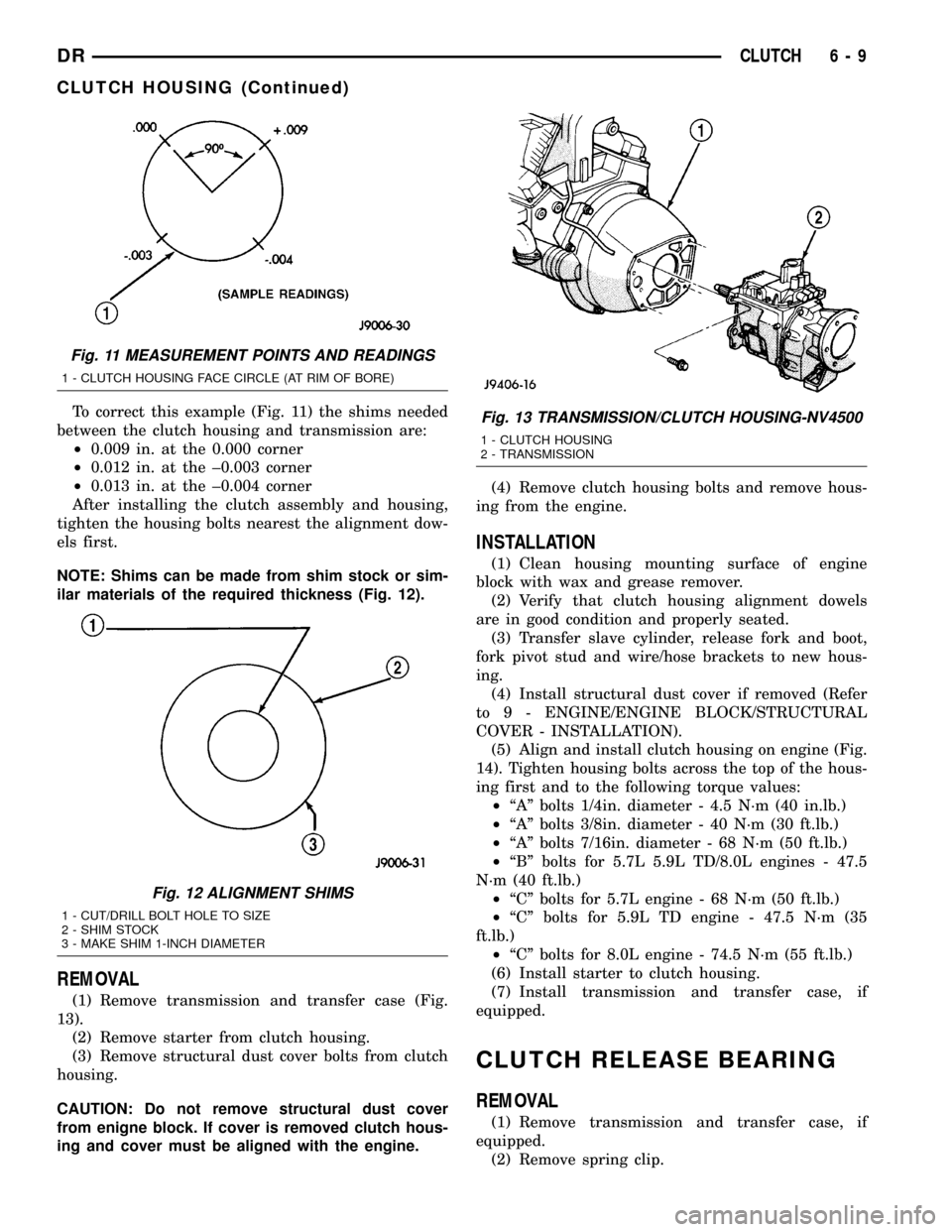

NOTE: Shims can be made from shim stock or sim-

ilar materials of the required thickness (Fig. 12).

REMOVAL

(1) Remove transmission and transfer case (Fig.

13).

(2) Remove starter from clutch housing.

(3) Remove structural dust cover bolts from clutch

housing.

CAUTION: Do not remove structural dust cover

from enigne block. If cover is removed clutch hous-

ing and cover must be aligned with the engine.(4) Remove clutch housing bolts and remove hous-

ing from the engine.

INSTALLATION

(1) Clean housing mounting surface of engine

block with wax and grease remover.

(2) Verify that clutch housing alignment dowels

are in good condition and properly seated.

(3) Transfer slave cylinder, release fork and boot,

fork pivot stud and wire/hose brackets to new hous-

ing.

(4) Install structural dust cover if removed (Refer

to 9 - ENGINE/ENGINE BLOCK/STRUCTURAL

COVER - INSTALLATION).

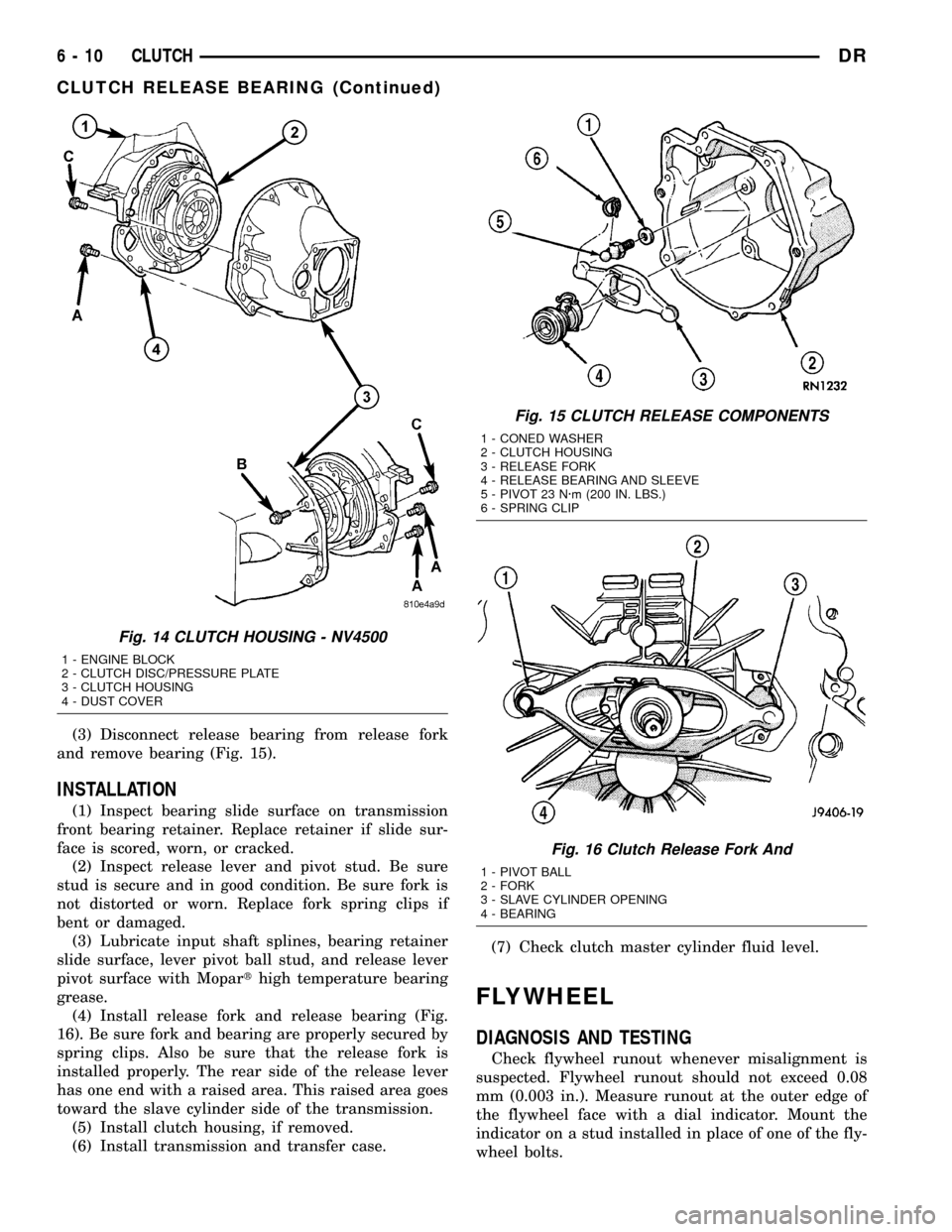

(5) Align and install clutch housing on engine (Fig.

14). Tighten housing bolts across the top of the hous-

ing first and to the following torque values:

²ªAº bolts 1/4in. diameter - 4.5 N´m (40 in.lb.)

²ªAº bolts 3/8in. diameter - 40 N´m (30 ft.lb.)

²ªAº bolts 7/16in. diameter - 68 N´m (50 ft.lb.)

²ªBº bolts for 5.7L 5.9L TD/8.0L engines - 47.5

N´m (40 ft.lb.)

²ªCº bolts for 5.7L engine - 68 N´m (50 ft.lb.)

²ªCº bolts for 5.9L TD engine - 47.5 N´m (35

ft.lb.)

²ªCº bolts for 8.0L engine - 74.5 N´m (55 ft.lb.)

(6) Install starter to clutch housing.

(7) Install transmission and transfer case, if

equipped.

CLUTCH RELEASE BEARING

REMOVAL

(1) Remove transmission and transfer case, if

equipped.

(2) Remove spring clip.

Fig. 11 MEASUREMENT POINTS AND READINGS

1 - CLUTCH HOUSING FACE CIRCLE (AT RIM OF BORE)

Fig. 12 ALIGNMENT SHIMS

1 - CUT/DRILL BOLT HOLE TO SIZE

2 - SHIM STOCK

3 - MAKE SHIM 1-INCH DIAMETER

Fig. 13 TRANSMISSION/CLUTCH HOUSING-NV4500

1 - CLUTCH HOUSING

2 - TRANSMISSION

DRCLUTCH 6 - 9

CLUTCH HOUSING (Continued)

Page 311 of 2627

(3) Disconnect release bearing from release fork

and remove bearing (Fig. 15).

INSTALLATION

(1) Inspect bearing slide surface on transmission

front bearing retainer. Replace retainer if slide sur-

face is scored, worn, or cracked.

(2) Inspect release lever and pivot stud. Be sure

stud is secure and in good condition. Be sure fork is

not distorted or worn. Replace fork spring clips if

bent or damaged.

(3) Lubricate input shaft splines, bearing retainer

slide surface, lever pivot ball stud, and release lever

pivot surface with Moparthigh temperature bearing

grease.

(4) Install release fork and release bearing (Fig.

16). Be sure fork and bearing are properly secured by

spring clips. Also be sure that the release fork is

installed properly. The rear side of the release lever

has one end with a raised area. This raised area goes

toward the slave cylinder side of the transmission.

(5) Install clutch housing, if removed.

(6) Install transmission and transfer case.(7) Check clutch master cylinder fluid level.

FLYWHEEL

DIAGNOSIS AND TESTING

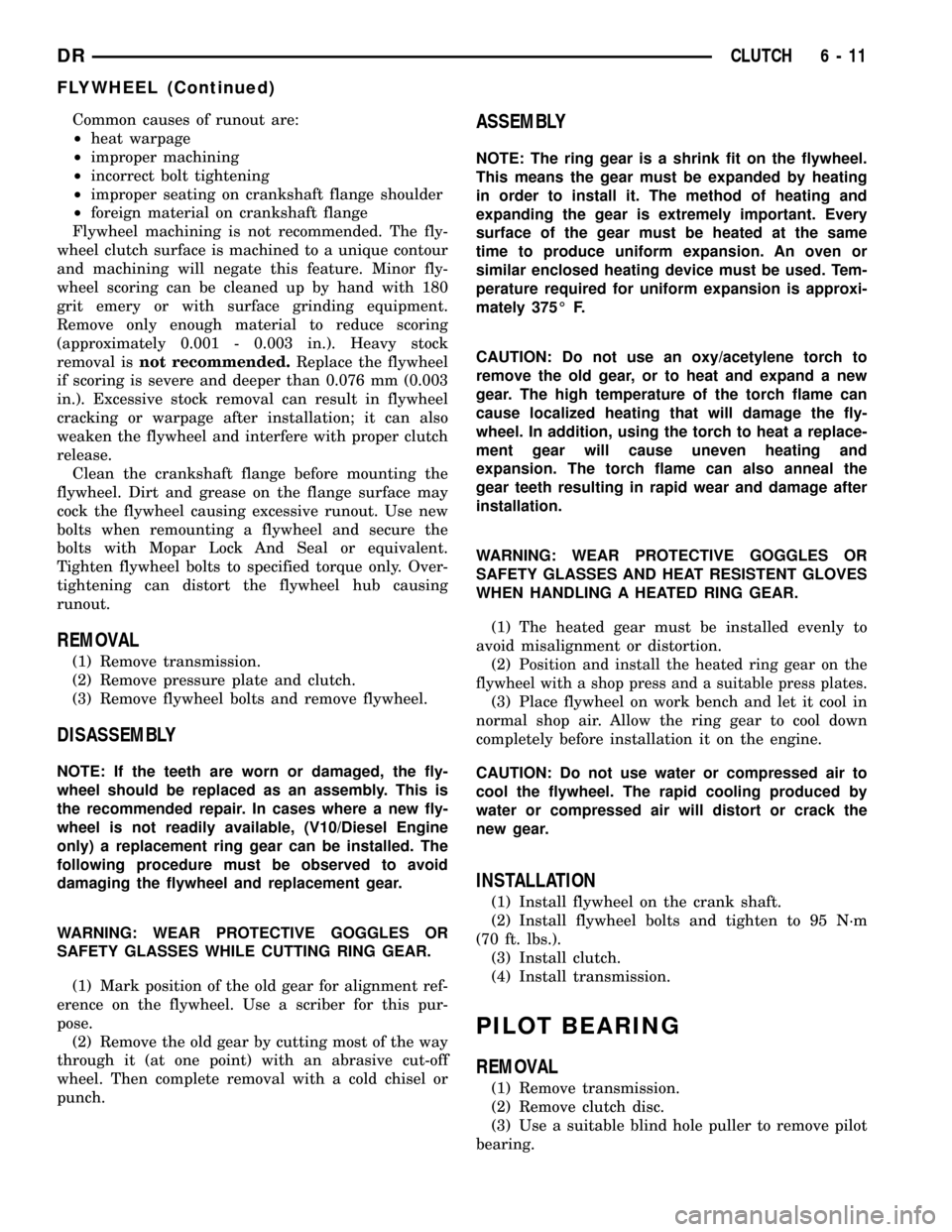

Check flywheel runout whenever misalignment is

suspected. Flywheel runout should not exceed 0.08

mm (0.003 in.). Measure runout at the outer edge of

the flywheel face with a dial indicator. Mount the

indicator on a stud installed in place of one of the fly-

wheel bolts.

Fig. 14 CLUTCH HOUSING - NV4500

1 - ENGINE BLOCK

2 - CLUTCH DISC/PRESSURE PLATE

3 - CLUTCH HOUSING

4 - DUST COVER

Fig. 15 CLUTCH RELEASE COMPONENTS

1 - CONED WASHER

2 - CLUTCH HOUSING

3 - RELEASE FORK

4 - RELEASE BEARING AND SLEEVE

5 - PIVOT 23 N´m (200 IN. LBS.)

6 - SPRING CLIP

Fig. 16 Clutch Release Fork And

1 - PIVOT BALL

2 - FORK

3 - SLAVE CYLINDER OPENING

4 - BEARING

6 - 10 CLUTCHDR

CLUTCH RELEASE BEARING (Continued)

Page 312 of 2627

Common causes of runout are:

²heat warpage

²improper machining

²incorrect bolt tightening

²improper seating on crankshaft flange shoulder

²foreign material on crankshaft flange

Flywheel machining is not recommended. The fly-

wheel clutch surface is machined to a unique contour

and machining will negate this feature. Minor fly-

wheel scoring can be cleaned up by hand with 180

grit emery or with surface grinding equipment.

Remove only enough material to reduce scoring

(approximately 0.001 - 0.003 in.). Heavy stock

removal isnot recommended.Replace the flywheel

if scoring is severe and deeper than 0.076 mm (0.003

in.). Excessive stock removal can result in flywheel

cracking or warpage after installation; it can also

weaken the flywheel and interfere with proper clutch

release.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout. Use new

bolts when remounting a flywheel and secure the

bolts with Mopar Lock And Seal or equivalent.

Tighten flywheel bolts to specified torque only. Over-

tightening can distort the flywheel hub causing

runout.

REMOVAL

(1) Remove transmission.

(2) Remove pressure plate and clutch.

(3) Remove flywheel bolts and remove flywheel.

DISASSEMBLY

NOTE: If the teeth are worn or damaged, the fly-

wheel should be replaced as an assembly. This is

the recommended repair. In cases where a new fly-

wheel is not readily available, (V10/Diesel Engine

only) a replacement ring gear can be installed. The

following procedure must be observed to avoid

damaging the flywheel and replacement gear.

WARNING: WEAR PROTECTIVE GOGGLES OR

SAFETY GLASSES WHILE CUTTING RING GEAR.

(1) Mark position of the old gear for alignment ref-

erence on the flywheel. Use a scriber for this pur-

pose.

(2) Remove the old gear by cutting most of the way

through it (at one point) with an abrasive cut-off

wheel. Then complete removal with a cold chisel or

punch.

ASSEMBLY

NOTE: The ring gear is a shrink fit on the flywheel.

This means the gear must be expanded by heating

in order to install it. The method of heating and

expanding the gear is extremely important. Every

surface of the gear must be heated at the same

time to produce uniform expansion. An oven or

similar enclosed heating device must be used. Tem-

perature required for uniform expansion is approxi-

mately 375É F.

CAUTION: Do not use an oxy/acetylene torch to

remove the old gear, or to heat and expand a new

gear. The high temperature of the torch flame can

cause localized heating that will damage the fly-

wheel. In addition, using the torch to heat a replace-

ment gear will cause uneven heating and

expansion. The torch flame can also anneal the

gear teeth resulting in rapid wear and damage after

installation.

WARNING: WEAR PROTECTIVE GOGGLES OR

SAFETY GLASSES AND HEAT RESISTENT GLOVES

WHEN HANDLING A HEATED RING GEAR.

(1) The heated gear must be installed evenly to

avoid misalignment or distortion.

(2)

Position and install the heated ring gear on the

flywheel with a shop press and a suitable press plates.

(3) Place flywheel on work bench and let it cool in

normal shop air. Allow the ring gear to cool down

completely before installation it on the engine.

CAUTION: Do not use water or compressed air to

cool the flywheel. The rapid cooling produced by

water or compressed air will distort or crack the

new gear.

INSTALLATION

(1) Install flywheel on the crank shaft.

(2) Install flywheel bolts and tighten to 95 N´m

(70 ft. lbs.).

(3) Install clutch.

(4) Install transmission.

PILOT BEARING

REMOVAL

(1) Remove transmission.

(2) Remove clutch disc.

(3) Use a suitable blind hole puller to remove pilot

bearing.

DRCLUTCH 6 - 11

FLYWHEEL (Continued)

Page 313 of 2627

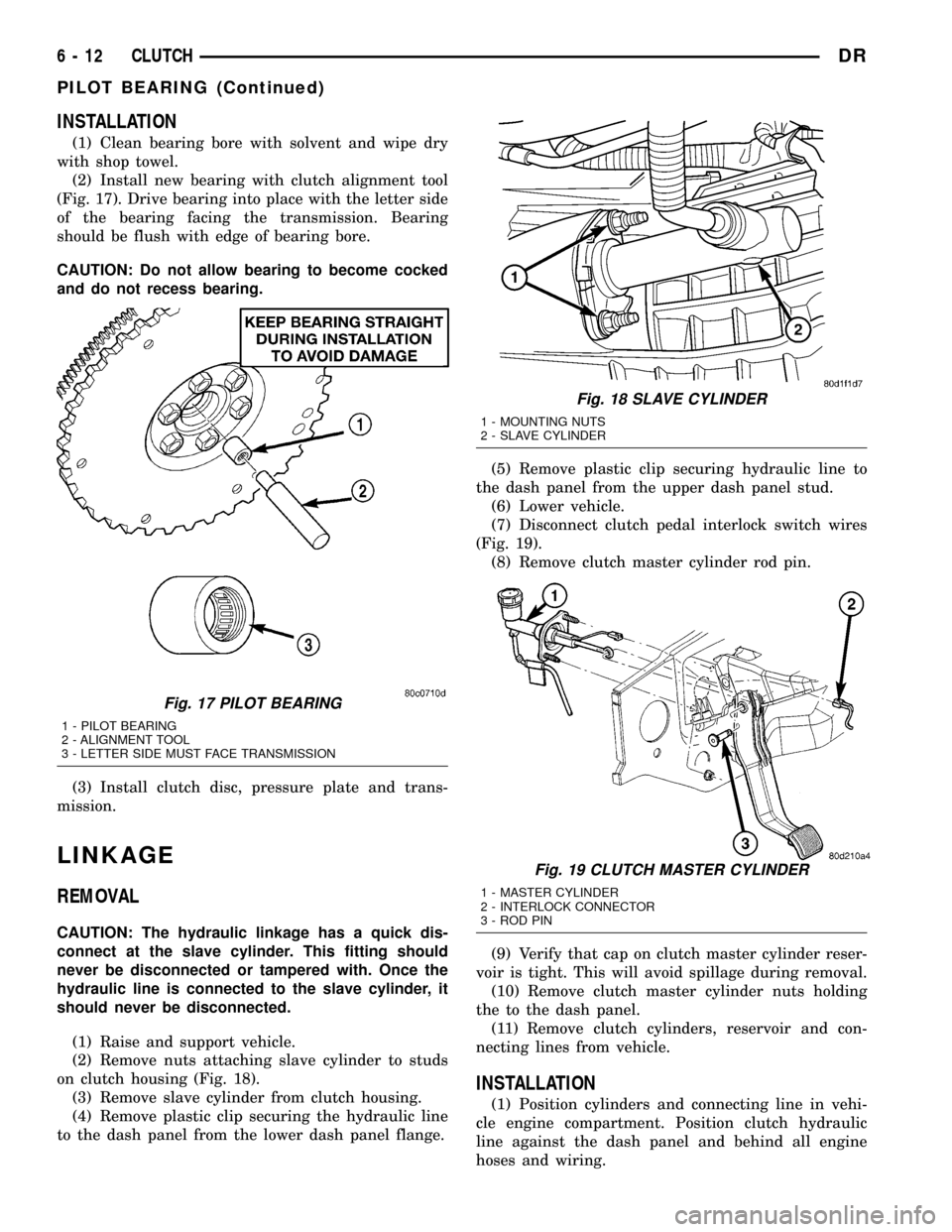

INSTALLATION

(1) Clean bearing bore with solvent and wipe dry

with shop towel.

(2) Install new bearing with clutch alignment tool

(Fig. 17). Drive bearing into place with the letter side

of the bearing facing the transmission. Bearing

should be flush with edge of bearing bore.

CAUTION: Do not allow bearing to become cocked

and do not recess bearing.

(3) Install clutch disc, pressure plate and trans-

mission.

LINKAGE

REMOVAL

CAUTION: The hydraulic linkage has a quick dis-

connect at the slave cylinder. This fitting should

never be disconnected or tampered with. Once the

hydraulic line is connected to the slave cylinder, it

should never be disconnected.

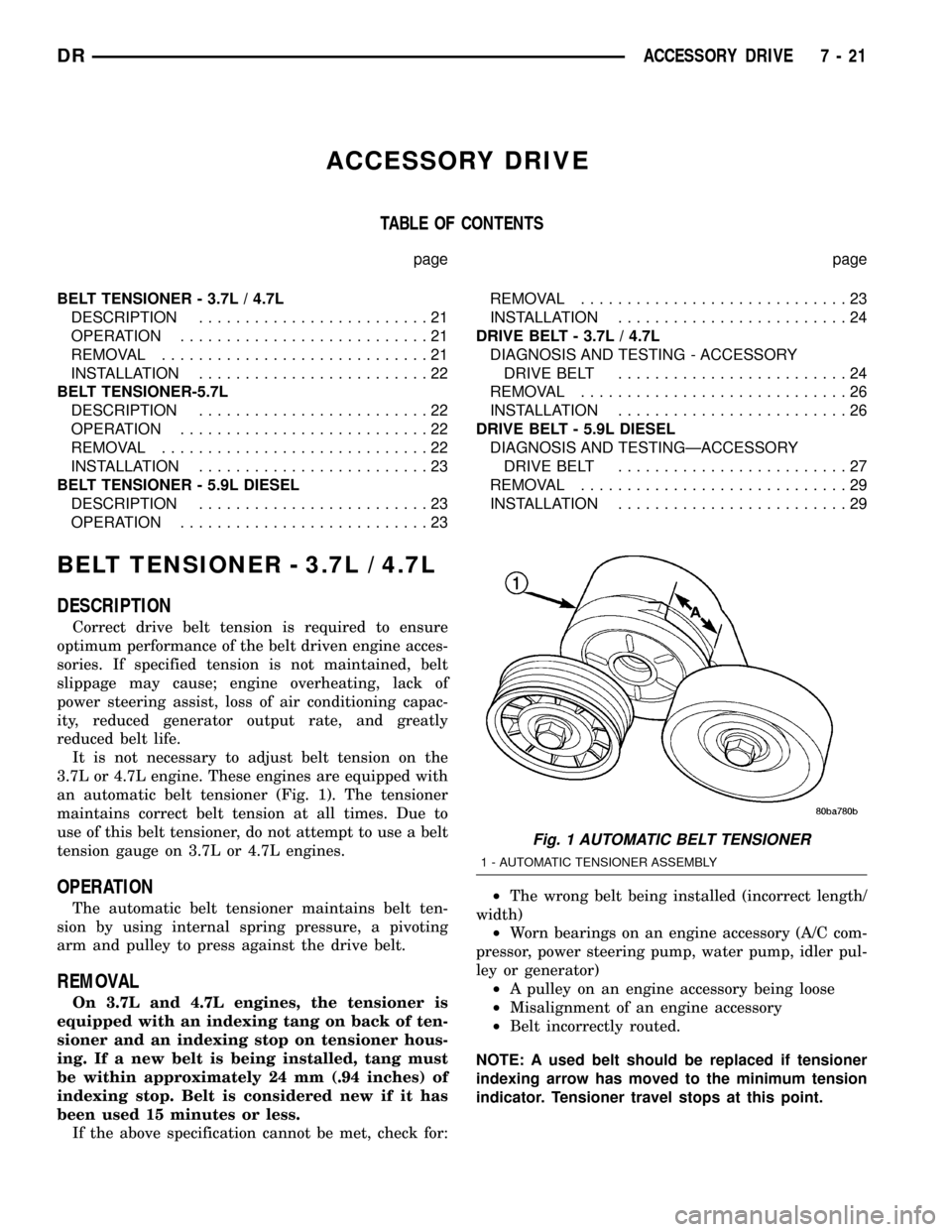

(1) Raise and support vehicle.

(2) Remove nuts attaching slave cylinder to studs

on clutch housing (Fig. 18).

(3) Remove slave cylinder from clutch housing.

(4) Remove plastic clip securing the hydraulic line

to the dash panel from the lower dash panel flange.(5) Remove plastic clip securing hydraulic line to

the dash panel from the upper dash panel stud.

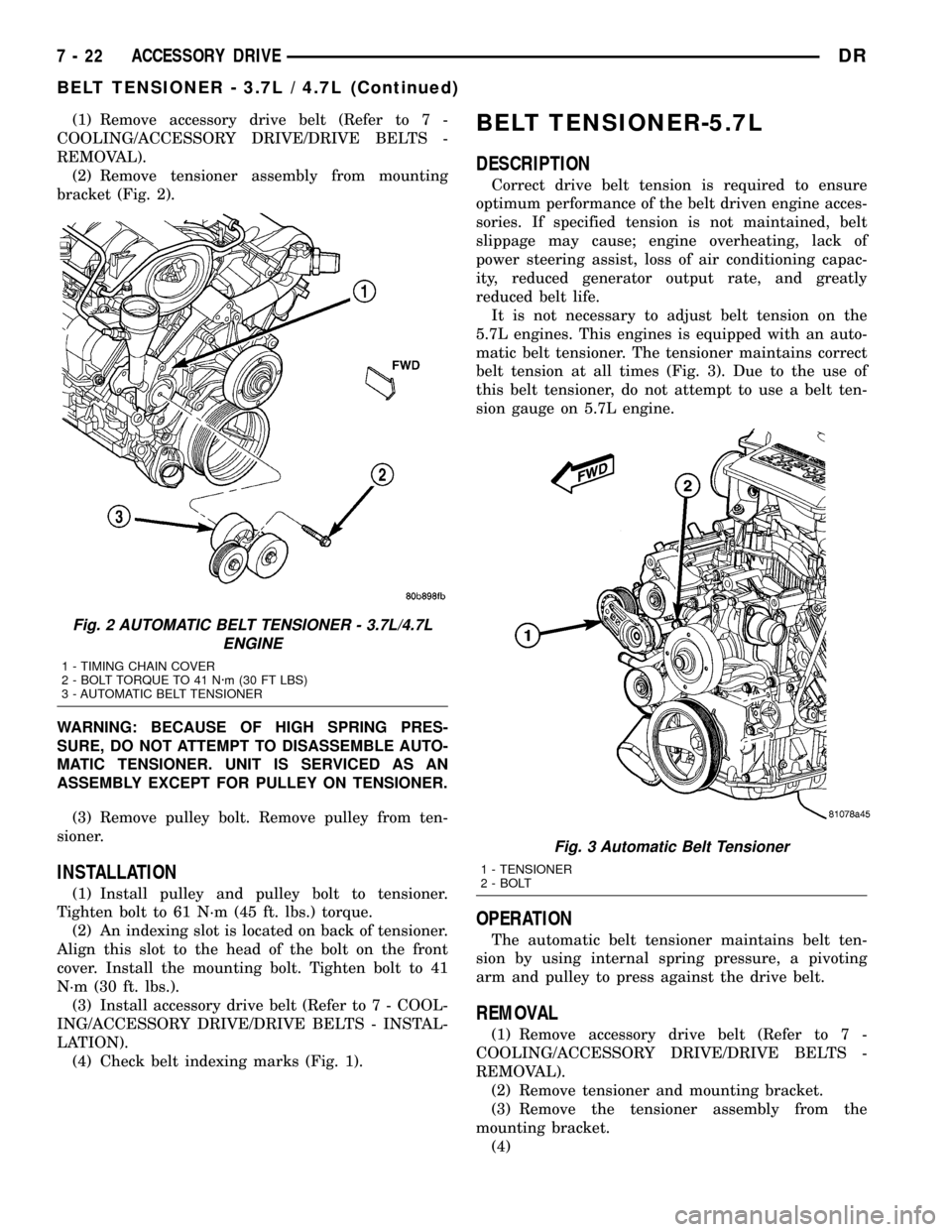

(6) Lower vehicle.

(7) Disconnect clutch pedal interlock switch wires

(Fig. 19).

(8) Remove clutch master cylinder rod pin.

(9) Verify that cap on clutch master cylinder reser-

voir is tight. This will avoid spillage during removal.

(10) Remove clutch master cylinder nuts holding

the to the dash panel.

(11) Remove clutch cylinders, reservoir and con-

necting lines from vehicle.

INSTALLATION

(1) Position cylinders and connecting line in vehi-

cle engine compartment. Position clutch hydraulic

line against the dash panel and behind all engine

hoses and wiring.

Fig. 17 PILOT BEARING

1 - PILOT BEARING

2 - ALIGNMENT TOOL

3 - LETTER SIDE MUST FACE TRANSMISSION

Fig. 18 SLAVE CYLINDER

1 - MOUNTING NUTS

2 - SLAVE CYLINDER

Fig. 19 CLUTCH MASTER CYLINDER

1 - MASTER CYLINDER

2 - INTERLOCK CONNECTOR

3 - ROD PIN

6 - 12 CLUTCHDR

PILOT BEARING (Continued)

Page 336 of 2627

ACCESSORY DRIVE

TABLE OF CONTENTS

page page

BELT TENSIONER - 3.7L / 4.7L

DESCRIPTION.........................21

OPERATION...........................21

REMOVAL.............................21

INSTALLATION.........................22

BELT TENSIONER-5.7L

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................23

BELT TENSIONER - 5.9L DIESEL

DESCRIPTION.........................23

OPERATION...........................23REMOVAL.............................23

INSTALLATION.........................24

DRIVE BELT - 3.7L / 4.7L

DIAGNOSIS AND TESTING - ACCESSORY

DRIVE BELT.........................24

REMOVAL.............................26

INSTALLATION.........................26

DRIVE BELT - 5.9L DIESEL

DIAGNOSIS AND TESTINGÐACCESSORY

DRIVE BELT.........................27

REMOVAL.............................29

INSTALLATION.........................29

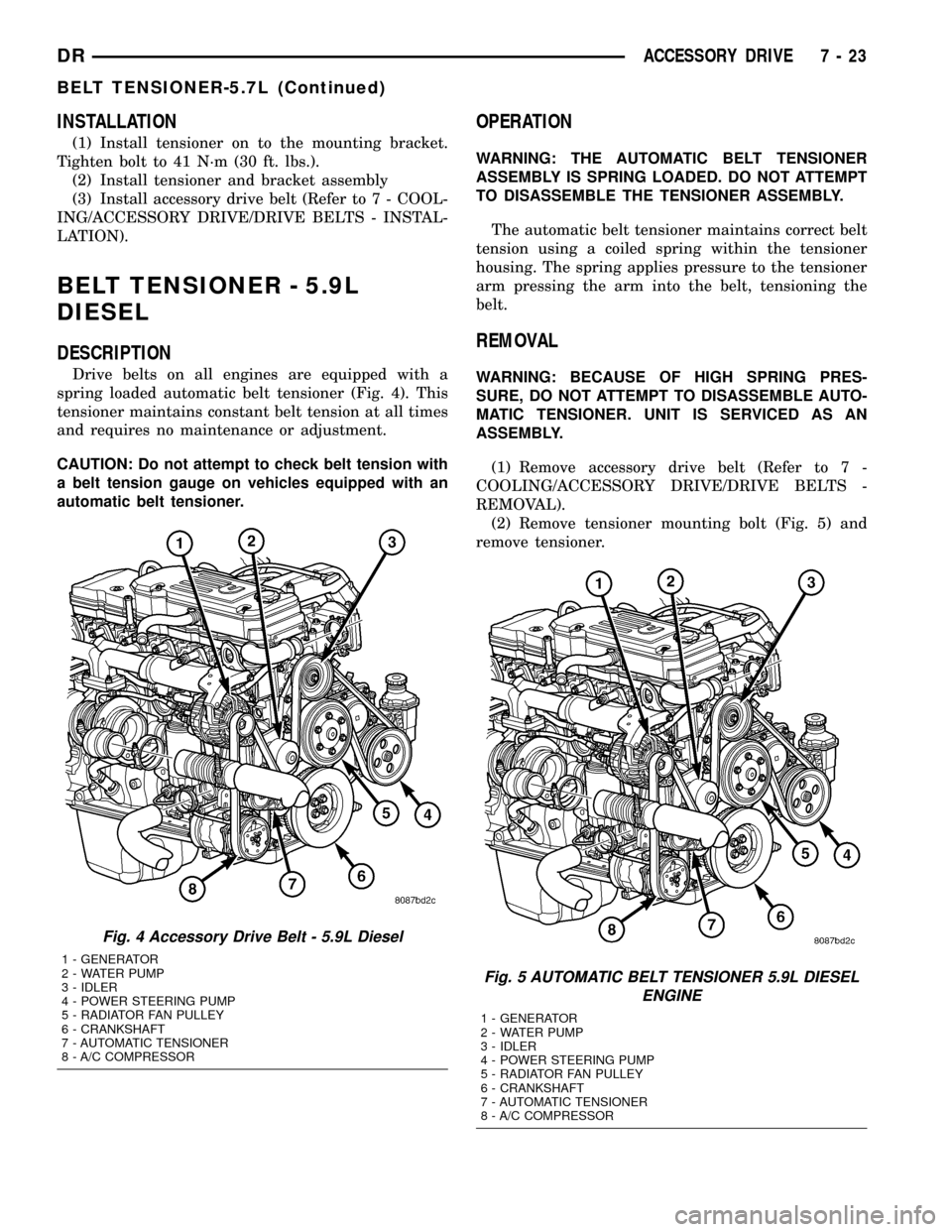

BELT TENSIONER - 3.7L / 4.7L

DESCRIPTION

Correct drive belt tension is required to ensure

optimum performance of the belt driven engine acces-

sories. If specified tension is not maintained, belt

slippage may cause; engine overheating, lack of

power steering assist, loss of air conditioning capac-

ity, reduced generator output rate, and greatly

reduced belt life.

It is not necessary to adjust belt tension on the

3.7L or 4.7L engine. These engines are equipped with

an automatic belt tensioner (Fig. 1). The tensioner

maintains correct belt tension at all times. Due to

use of this belt tensioner, do not attempt to use a belt

tension gauge on 3.7L or 4.7L engines.

OPERATION

The automatic belt tensioner maintains belt ten-

sion by using internal spring pressure, a pivoting

arm and pulley to press against the drive belt.

REMOVAL

On 3.7L and 4.7L engines, the tensioner is

equipped with an indexing tang on back of ten-

sioner and an indexing stop on tensioner hous-

ing. If a new belt is being installed, tang must

be within approximately 24 mm (.94 inches) of

indexing stop. Belt is considered new if it has

been used 15 minutes or less.

If the above specification cannot be met, check for:²The wrong belt being installed (incorrect length/

width)

²Worn bearings on an engine accessory (A/C com-

pressor, power steering pump, water pump, idler pul-

ley or generator)

²A pulley on an engine accessory being loose

²Misalignment of an engine accessory

²Belt incorrectly routed.

NOTE: A used belt should be replaced if tensioner

indexing arrow has moved to the minimum tension

indicator. Tensioner travel stops at this point.

Fig. 1 AUTOMATIC BELT TENSIONER

1 - AUTOMATIC TENSIONER ASSEMBLY

DRACCESSORY DRIVE 7 - 21

Page 337 of 2627

(1) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove tensioner assembly from mounting

bracket (Fig. 2).

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY EXCEPT FOR PULLEY ON TENSIONER.

(3) Remove pulley bolt. Remove pulley from ten-

sioner.

INSTALLATION

(1) Install pulley and pulley bolt to tensioner.

Tighten bolt to 61 N´m (45 ft. lbs.) torque.

(2) An indexing slot is located on back of tensioner.

Align this slot to the head of the bolt on the front

cover. Install the mounting bolt. Tighten bolt to 41

N´m (30 ft. lbs.).

(3) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(4) Check belt indexing marks (Fig. 1).

BELT TENSIONER-5.7L

DESCRIPTION

Correct drive belt tension is required to ensure

optimum performance of the belt driven engine acces-

sories. If specified tension is not maintained, belt

slippage may cause; engine overheating, lack of

power steering assist, loss of air conditioning capac-

ity, reduced generator output rate, and greatly

reduced belt life.

It is not necessary to adjust belt tension on the

5.7L engines. This engines is equipped with an auto-

matic belt tensioner. The tensioner maintains correct

belt tension at all times (Fig. 3). Due to the use of

this belt tensioner, do not attempt to use a belt ten-

sion gauge on 5.7L engine.

OPERATION

The automatic belt tensioner maintains belt ten-

sion by using internal spring pressure, a pivoting

arm and pulley to press against the drive belt.

REMOVAL

(1) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove tensioner and mounting bracket.

(3) Remove the tensioner assembly from the

mounting bracket.

(4)

Fig. 2 AUTOMATIC BELT TENSIONER - 3.7L/4.7L

ENGINE

1 - TIMING CHAIN COVER

2 - BOLT TORQUE TO 41 N´m (30 FT LBS)

3 - AUTOMATIC BELT TENSIONER

Fig. 3 Automatic Belt Tensioner

1 - TENSIONER

2 - BOLT

7 - 22 ACCESSORY DRIVEDR

BELT TENSIONER - 3.7L / 4.7L (Continued)

Page 338 of 2627

INSTALLATION

(1) Install tensioner on to the mounting bracket.

Tighten bolt to 41 N´m (30 ft. lbs.).

(2) Install tensioner and bracket assembly

(3) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

BELT TENSIONER - 5.9L

DIESEL

DESCRIPTION

Drive belts on all engines are equipped with a

spring loaded automatic belt tensioner (Fig. 4). This

tensioner maintains constant belt tension at all times

and requires no maintenance or adjustment.

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner.

OPERATION

WARNING: THE AUTOMATIC BELT TENSIONER

ASSEMBLY IS SPRING LOADED. DO NOT ATTEMPT

TO DISASSEMBLE THE TENSIONER ASSEMBLY.

The automatic belt tensioner maintains correct belt

tension using a coiled spring within the tensioner

housing. The spring applies pressure to the tensioner

arm pressing the arm into the belt, tensioning the

belt.

REMOVAL

WARNING: BECAUSE OF HIGH SPRING PRES-

SURE, DO NOT ATTEMPT TO DISASSEMBLE AUTO-

MATIC TENSIONER. UNIT IS SERVICED AS AN

ASSEMBLY.

(1) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove tensioner mounting bolt (Fig. 5) and

remove tensioner.

Fig. 4 Accessory Drive Belt - 5.9L Diesel

1 - GENERATOR

2 - WATER PUMP

3 - IDLER

4 - POWER STEERING PUMP

5 - RADIATOR FAN PULLEY

6 - CRANKSHAFT

7 - AUTOMATIC TENSIONER

8 - A/C COMPRESSOR

Fig. 5 AUTOMATIC BELT TENSIONER 5.9L DIESEL

ENGINE

1 - GENERATOR

2 - WATER PUMP

3 - IDLER

4 - POWER STEERING PUMP

5 - RADIATOR FAN PULLEY

6 - CRANKSHAFT

7 - AUTOMATIC TENSIONER

8 - A/C COMPRESSOR

DRACCESSORY DRIVE 7 - 23

BELT TENSIONER-5.7L (Continued)

Page 341 of 2627

CONDITION POSSIBLE CAUSES CORRECTION

CORD EDGE FAILURE

(Tensile member exposed at edges

of belt or separated from belt body)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Belt contacting stationary object 2. Replace belt

3. Pulley(s) out of tolerance 3. Replace pulley

4. Insufficient adhesion between

tensile member and rubber matrix4. Replace belt

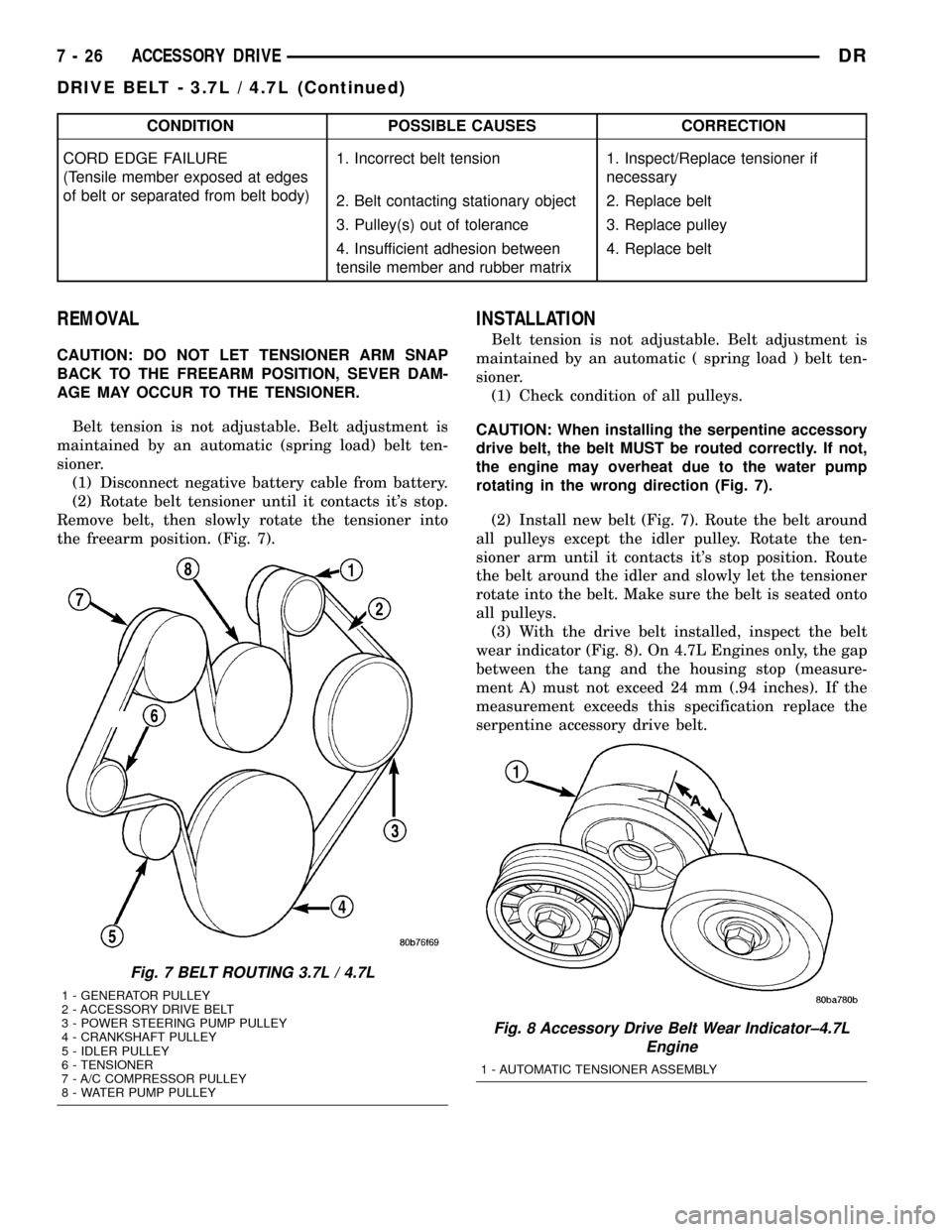

REMOVAL

CAUTION: DO NOT LET TENSIONER ARM SNAP

BACK TO THE FREEARM POSITION, SEVER DAM-

AGE MAY OCCUR TO THE TENSIONER.

Belt tension is not adjustable. Belt adjustment is

maintained by an automatic (spring load) belt ten-

sioner.

(1) Disconnect negative battery cable from battery.

(2) Rotate belt tensioner until it contacts it's stop.

Remove belt, then slowly rotate the tensioner into

the freearm position. (Fig. 7).

INSTALLATION

Belt tension is not adjustable. Belt adjustment is

maintained by an automatic ( spring load ) belt ten-

sioner.

(1) Check condition of all pulleys.

CAUTION: When installing the serpentine accessory

drive belt, the belt MUST be routed correctly. If not,

the engine may overheat due to the water pump

rotating in the wrong direction (Fig. 7).

(2) Install new belt (Fig. 7). Route the belt around

all pulleys except the idler pulley. Rotate the ten-

sioner arm until it contacts it's stop position. Route

the belt around the idler and slowly let the tensioner

rotate into the belt. Make sure the belt is seated onto

all pulleys.

(3) With the drive belt installed, inspect the belt

wear indicator (Fig. 8). On 4.7L Engines only, the gap

between the tang and the housing stop (measure-

ment A) must not exceed 24 mm (.94 inches). If the

measurement exceeds this specification replace the

serpentine accessory drive belt.

Fig. 7 BELT ROUTING 3.7L / 4.7L

1 - GENERATOR PULLEY

2 - ACCESSORY DRIVE BELT

3 - POWER STEERING PUMP PULLEY

4 - CRANKSHAFT PULLEY

5 - IDLER PULLEY

6 - TENSIONER

7 - A/C COMPRESSOR PULLEY

8 - WATER PUMP PULLEY

Fig. 8 Accessory Drive Belt Wear Indicator±4.7L

Engine

1 - AUTOMATIC TENSIONER ASSEMBLY

7 - 26 ACCESSORY DRIVEDR

DRIVE BELT - 3.7L / 4.7L (Continued)

Page 343 of 2627

CONDITION POSSIBLE CAUSES CORRECTION

LONGITUDAL BELT CRACKING 1. Belt has mistracked from pulley

groove1. Replace belt

2. Pulley groove tip has worn away

rubber to tensile member2. Replace belt

9GROOVE JUMPING9

(Belt does not maintain correct

position on pulley)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Pulley(s) not within design

tolerance2. Replace pulley(s)

3. Foreign object(s) in grooves 3. Remove foreign objects from

grooves

4. Pulley misalignment 4. Align component

5. Belt cordline is broken 5. Replace belt

BELT BROKEN

(Note: Identify and correct problem

before new belt is installed)1. Incorrect belt tension 1. Replace Inspect/Replace

tensioner if necessary

2. Tensile member damaged during

belt installation2. Replace belt

3. Severe misalignment 3. Align pulley(s)

4. Bracket, pulley, or bearing failure 4. Replace defective component

and belt

NOISE (Objectional squeal, squeak,

or rumble is heard or felt while drive

belt is in operation)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Bearing noise 2. Locate and repair

3. Belt misalignment 3. Align belt/pulley(s)

4. Belt to pulley mismatch 4. Install correct belt

5. Driven component induced

vibration5. Locate defective driven

component and repair

TENSION SHEETING FABRIC

FAILURE

(Woven fabric on outside,

circumference of belt has cracked or

separated from body of belt)1. Tension sheeting contacting

stationary object1. Correct rubbing condition

2. Excessive heat causing woven

fabric to age2. Replace belt

3. Tension sheeting splice has

fractured3. Replace belt

CORD EDGE FAILURE

(Tensile member exposed at edges

of belt or separated from belt body)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Belt contacting stationary object 2. Replace belt

3. Pulley(s) out of tolerance 3. Replace pulley

4. Insufficient adhesion between

tensile member and rubber matrix4. Replace belt

NOTE: The engine speed sensor face is very close

to the accessory drive belt. Inspect engine speed

sensor and wire harness for damage when acces-sory drive belt has been replaced due to failure or

abnormal conditions.

7 - 28 ACCESSORY DRIVEDR

DRIVE BELT - 5.9L DIESEL (Continued)