Interior lighting DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 604 of 2627

DRIVER DOOR MODULE SWITCH TESTS

LEFT FRONT DOWN PINS9&12

RIGHT FRONT UP PINS3&9

RIGHT FRONT DOWN PINS6&9

LEFT REAR UP PINS4&9

LEFT REAR DOWN PINS9&10

RIGHT REAR UP PINS2&9

RIGHT REAR DOWN PINS1&9

POWER WINDOW LOCKOUT SWITCH

SWITCH POSITION CONTINUITY BETWEEN

OFF (SWITCH BUTTON

RAISED - NOT

DEPRESSED)PIN 9 OF CONNECTOR

C-1&PIN8OF

CONNECTOR C-2

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door trim panel (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(3) Remove the driver door module from the trim

panel bezel.

INSTALLATION

(1) Install driver door module to trim panel bezel.

(2) Install door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION).

(3) Connect battery negative cable.

REMOTE KEYLESS ENTRY

MODULE

DESCRIPTION

When an RKE lock message is sent to the instru-

ment cluster, the instrument cluster actuates the

door locks, the interior lighting is turned off, the

horn chirps (if this feature is enabled), the park

lamps flash (if this feature is enabled) and, if the

vehicle is so equipped, the Vehicle Theft Security

System (VTSS) is armed. When an RKE unlock mes-

sage is sent to the instrument cluster, the instrument

cluster actuates the driver side front door (or all

doors if this feature is enabled) unlock, the interior

lighting is turned on and, if the vehicle is so

equipped, the VTSS is disarmed.

When an RKE panic message is sent to the instru-

ment cluster, the instrument cluster actuates the

driver side front door (or all doors if this feature is

enabled) unlock, the interior lighting is turned on

and, if the vehicle is so equipped, the VTSS is dis-

armed. The panic message will also cause the exte-

rior lamps (including the headlights) to flash, andthe horn to sound for about three minutes, or until a

second panic message is sent to the instrument clus-

ter. A vehicle speed of about 25.7 kilometers-per-hour

(15 miles-per-hour) will also cancel the panic event.

Refer to the owner's manual for more information

on the features, use and operation of the RKE sys-

tem.

OPERATION

Whenever the vehicle battery power is interrupted,

the Remote Keyless Module (RKE) Module will retain

all vehicle access codes in its memory. When replac-

ing or adding a key fob transmitter (maximum of 4) a

DRB IIItscan tool is required to program the RKE

Module to accept the new Vehicle Access Code if a

customer owned transmitter is not available.

If a functioning transmitter is available, (Refer to 8

- ELECTRICAL/POWER LOCKS/KEYLESS ENTRY

TRANSMITTER - STANDARD PROCEDURE)

DIAGNOSIS AND TESTING - REMOTE KEYLESS

ENTRY MODULE

The most reliable, efficient, and accurate means to

diagnose the power lock system requires the use of a

DRBIIItscan tool and the proper Diagnostic Proce-

dures manual.

Refer to the appropriate wiring information.

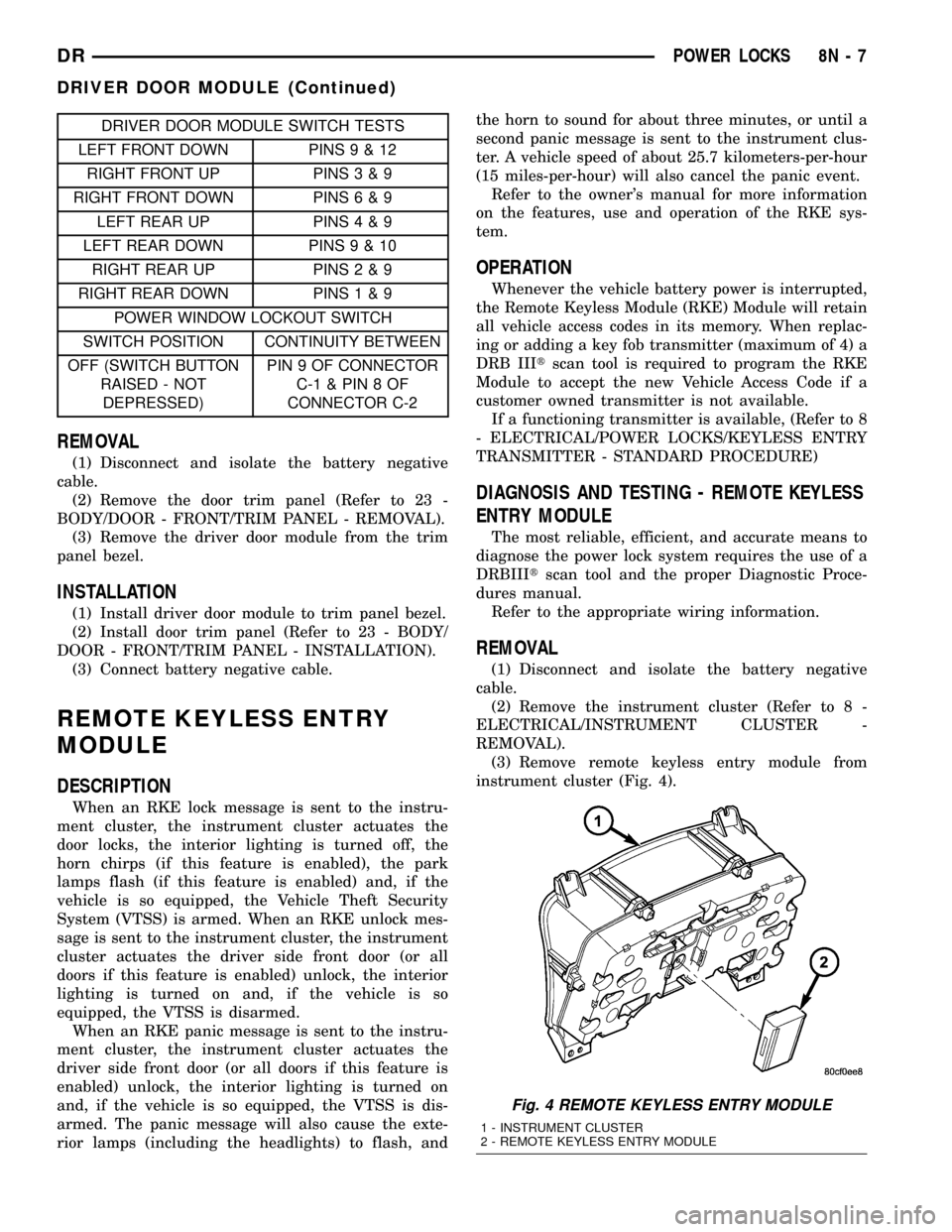

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER -

REMOVAL).

(3) Remove remote keyless entry module from

instrument cluster (Fig. 4).

Fig. 4 REMOTE KEYLESS ENTRY MODULE

1 - INSTRUMENT CLUSTER

2 - REMOTE KEYLESS ENTRY MODULE

DRPOWER LOCKS 8N - 7

DRIVER DOOR MODULE (Continued)

Page 726 of 2627

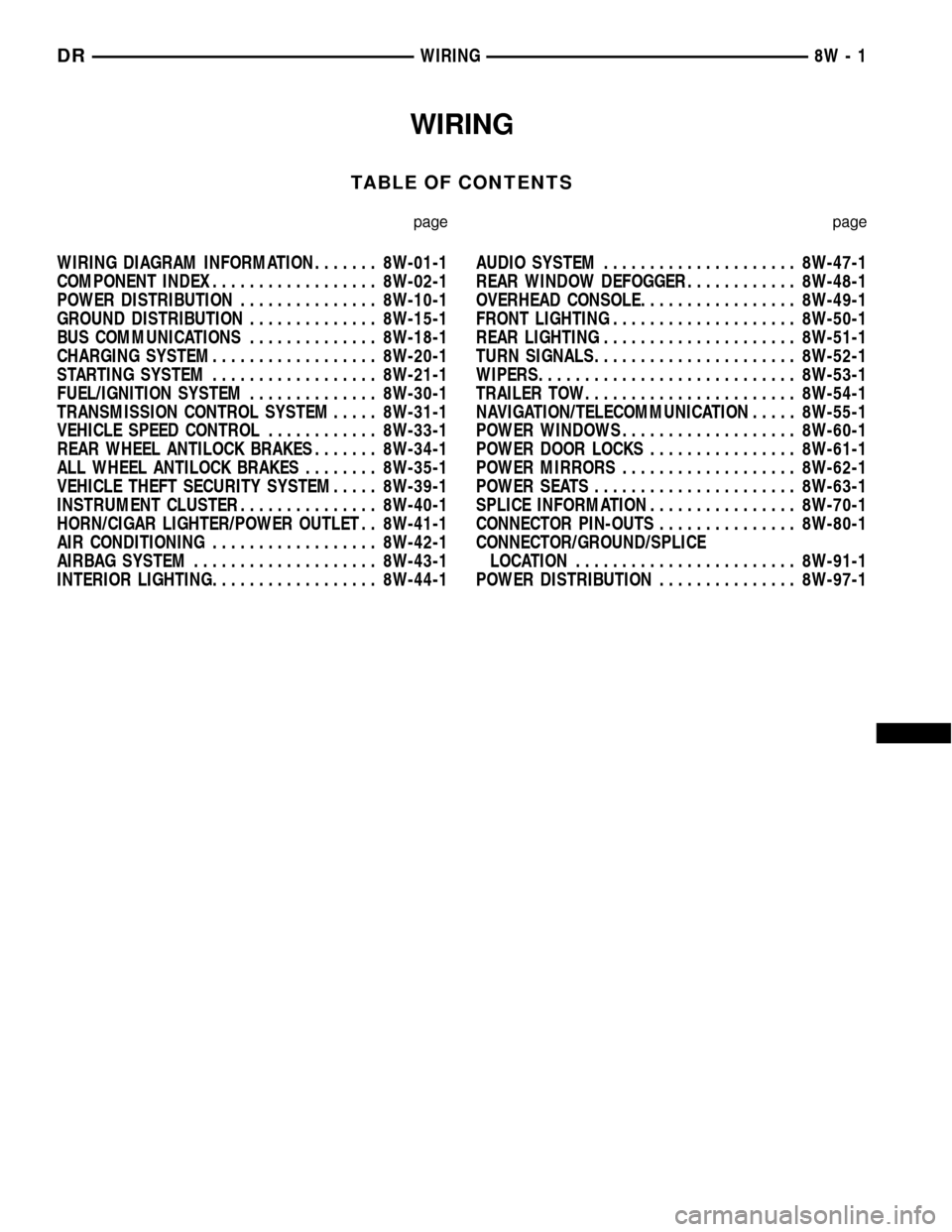

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

REAR WHEEL ANTILOCK BRAKES....... 8W-34-1

ALL WHEEL ANTILOCK BRAKES........ 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING.................. 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

NAVIGATION/TELECOMMUNICATION..... 8W-55-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION............... 8W-97-1 DRWIRING 8W - 1

Page 733 of 2627

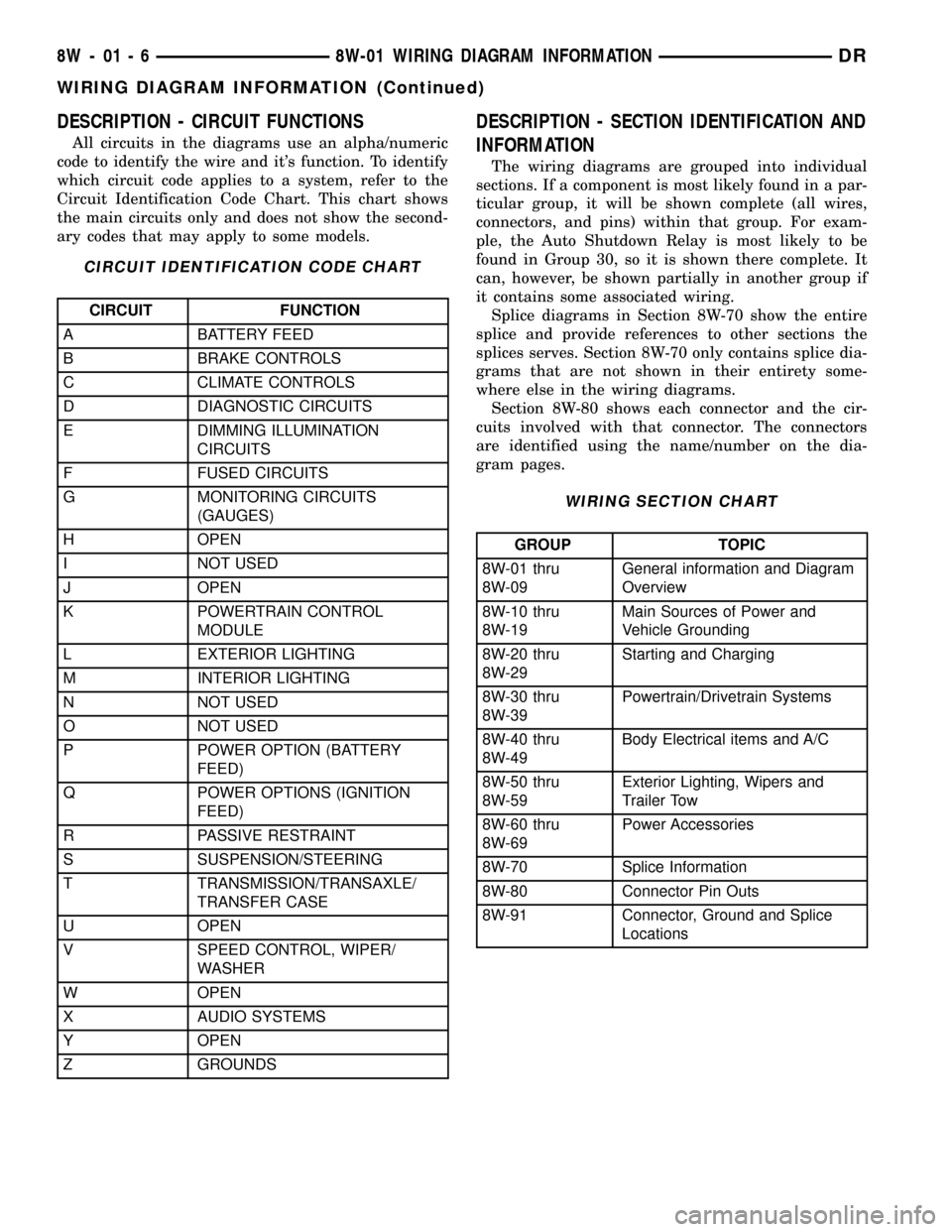

DESCRIPTION - CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and it's function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION

CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS

(GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL

MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY

FEED)

Q POWER OPTIONS (IGNITION

FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/

WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru

8W-09General information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

8W - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONDR

WIRING DIAGRAM INFORMATION (Continued)

Page 968 of 2627

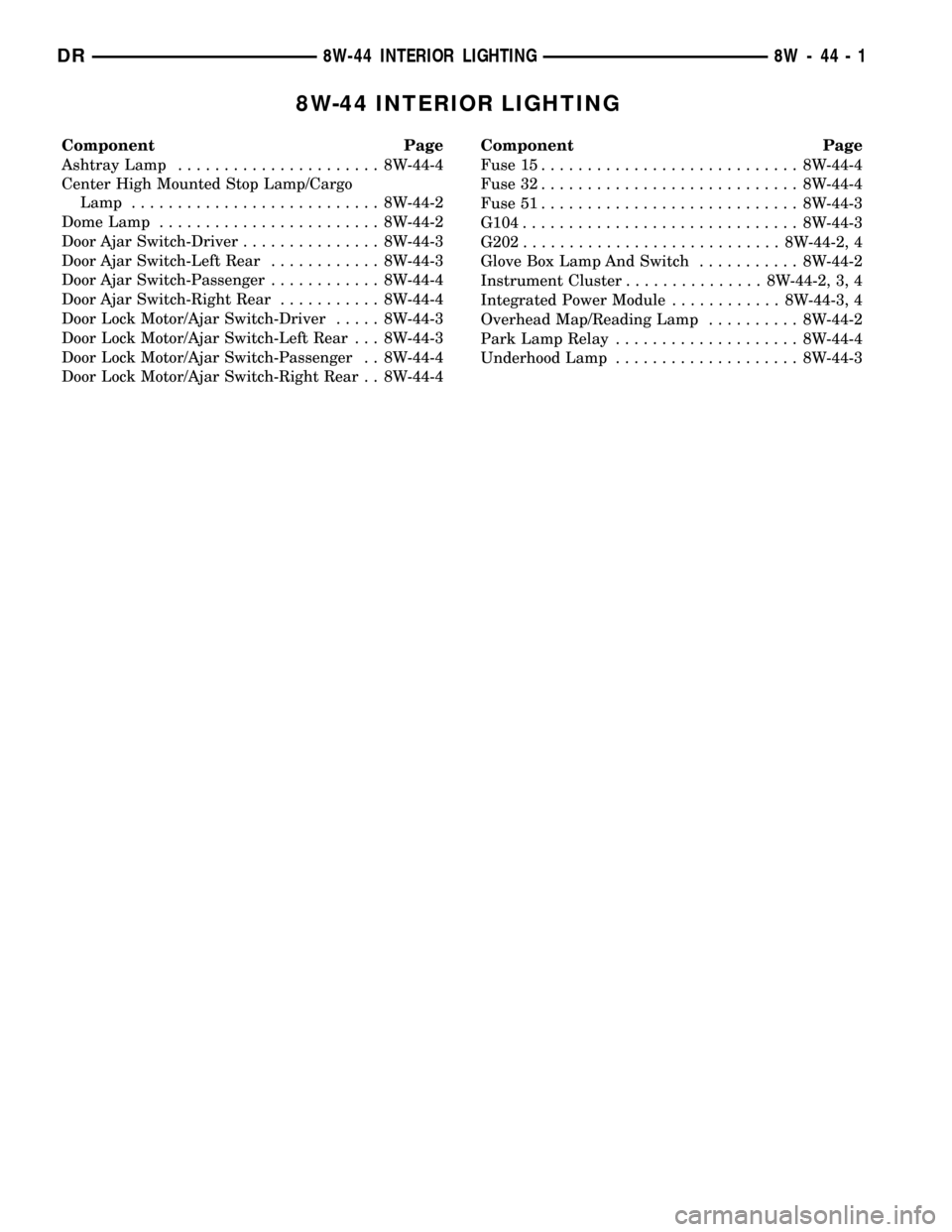

8W-44 INTERIOR LIGHTING

Component Page

Ashtray Lamp...................... 8W-44-4

Center High Mounted Stop Lamp/Cargo

Lamp........................... 8W-44-2

Dome Lamp........................ 8W-44-2

Door Ajar Switch-Driver............... 8W-44-3

Door Ajar Switch-Left Rear............ 8W-44-3

Door Ajar Switch-Passenger............ 8W-44-4

Door Ajar Switch-Right Rear........... 8W-44-4

Door Lock Motor/Ajar Switch-Driver..... 8W-44-3

Door Lock Motor/Ajar Switch-Left Rear . . . 8W-44-3

Door Lock Motor/Ajar Switch-Passenger . . 8W-44-4

Door Lock Motor/Ajar Switch-Right Rear . . 8W-44-4Component Page

Fuse 15............................ 8W-44-4

Fuse 32............................ 8W-44-4

Fuse 51............................ 8W-44-3

G104.............................. 8W-44-3

G202............................ 8W-44-2, 4

Glove Box Lamp And Switch........... 8W-44-2

Instrument Cluster............... 8W-44-2, 3, 4

Integrated Power Module............ 8W-44-3, 4

Overhead Map/Reading Lamp.......... 8W-44-2

Park Lamp Relay.................... 8W-44-4

Underhood Lamp.................... 8W-44-3

DR8W-44 INTERIOR LIGHTING 8W - 44 - 1

Page 1555 of 2627

(14) Remove the bolts attaching the lower radiator

crossmember to the hydroform fender rail. (Fig. 18)

CAUTION: Do not use any flame or plasma cutting

equipment to cut the frame in this procedure. The

inaccurate and high temperatures achieved during

flame or plasma cutting will change the metal char-

acteristics and may weaken the frame and/or repair

location.

(15) Using a reciprocating saw or equivalent, cut

the fender rail and shotgun at a straight and square

section of the hydroform and remove.

(16) Smooth and square the cut edges.

(17) Using the damaged structure as a reference

cut the service part at the same location as the first

cut. Smooth and square the cut edges.

NOTE: The repair structure should butt up to the

remaining structure and provide the same overall

vehicle geometry.

(18) Fabricate 51 mm (2.0 in.) long repair inserts

using scrap from the old structure or the replacement

part. It will be necessary to split the inserts on each

of their four sides to fit into the hydroform.

(19) Remove any paint or e-coat from the inserts

and also to the interior and exterior of the hydro-

forms.

(20) Cut plug weld holes as described below.

²On the upper rail, cut one 13 mm (0.5 in.) hole

on each side of the rail, 25 mm (1.0 in.) from the butt

joint of the tubes.

²On the lower rail, cut one 13 mm (0.5 in.) hole

on the top and bottom sides of the rail 25 mm (1.0

in.) from the butt joint of the tube.

²On the lower rail, cut two 13 mm (0.5 in.) holes

on the inner and outer sides of the rail 25 mm (1.0

in.) from the butt joint of the tube.

CAUTION: Shield the surrounding area and compo-

nents from exposure to the welding spatter and

heat.

(21) Install the insert 1º into the replacement part

and tack into place with a weld. (Refer to 13 -

FRAME & BUMPERS/FRAME - SPECIFICATIONS -

WELDING)

(22) Insert the service part into place and using

the appropriate measuring equipment, verify the

front end sheet metal bracket's location in all three

(X,Y, and Z) planes of space. (Fig. 19)

(23) Complete all 360É plug welds.

NOTE: Before the final welding, use three dimen-

sional measuring equipment to ensure the part is in

the correct location. Verify that tap plate extrusion

at the bottom of the vertical post lines up with theisolator and hole in the frame perch mount. Also

ensure the lower radiator closure tube is bolted into

the forward shotgun ends.

(24) Complete welding by making a 360É butt weld

around the fender rails.

(25) Metal finish the exposed welds on the hydro-

forms.

(26) Dress the welded area and apply corrosion

resistant coatings inside and out.

(a) Inside the rail, inject a creeping wax based

rust inhibitor compound to the inside of the hydro-

forms ensuring 100% coverage including the mat-

ing face between the fender rail sections and insert

such that corrosion protection is restored in the

internal cavity.

(b) Apply a durable top coat to the outside of the

repair area.

(27) Install the front cab mount bolt if previously

removed and tighten to 81 N´m (60 ft. lbs.).

(28) Install the lower radiator crossmember bolts

and tighten to 28 N´m (21 ft. lbs.).

(29) Install the headlamp unit. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - INSTALLATION)

(30) Install the upper radiator crossmember. (Refer

to 23 - BODY/EXTERIOR/UPPER RADIATOR

CROSSMEMBER - INSTALLATION)

(31) Install the wire harness and ground if previ-

ously removed and install the bolts.

(32) Install the integrated power module, if previ-

ously removed. (Refer to 8 - ELECTRICAL/POWER

DISTRIBUTION/INTEGRATED POWER MODULE -

INSTALLATION)

(33) Install the air cleaner bracket and air cleaner,

if previously removed. (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER ELEMENT -

INSTALLATION)

(34) Install the radiator assembly. (Refer to 7 -

COOLING/ENGINE/RADIATOR - INSTALLATION)

(35) Install the A/C lines, if previously removed.

Refer to the Heating and Air Conditioning section of

the manual for the recommended procedures.

(36) Install the A/C condenser, if previously

removed. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C CONDENSER - INSTAL-

LATION)

(37) Install the fender. (Refer to 23 - BODY/EXTE-

RIOR/FRONT FENDER - INSTALLATION)

(38) Install the front wheelhouse splash shield.

(Refer to 23 - BODY/EXTERIOR/FRONT WHEEL-

HOUSE SPLASH SHIELD - INSTALLATION)

(39) Reconnect the battery ground.

13 - 12 FRAMES & BUMPERSDR

FRAME (Continued)

Page 2363 of 2627

HEADLINER

REMOVAL

(1) Remove the a-pillar trim. (Refer to 23 - BODY/

INTERIOR/A-PILLAR TRIM - REMOVAL)

(2) Remove the upper b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

REMOVAL)

(3) Remove the upper c-pillar trim, if equipped.

(Refer to 23 - BODY/INTERIOR/C-PILLAR TRIM -

REMOVAL)

(4) Remove the coat hooks. (Refer to 23 - BODY/

INTERIOR/COAT HOOK - REMOVAL)

(5) Disconnect the headliner harness electrical con-

nector at the left a-pillar.

(6) Remove the dome lamp. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - INTERIOR/DOME

LAMP - REMOVAL)

(7) Remove the overhead console. (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOVAL)

(8) Remove the sun visors. (Refer to 23 - BODY/

INTERIOR/SUN VISOR - REMOVAL)

(9) Remove the sun visor supports. (Refer to 23 -

BODY/INTERIOR/SUN VISOR SUPPORT -

REMOVAL)

(10) Lower the headliner and disconnect the center

high mounted stop light.

(11) Lower the front of the headliner down to the

floor just in front of the instrument panel and

remove through the passenger door.

INSTALLATION

(1) Install the headliner into the vehicle through

the passenger door.

(2) Raise the headliner and insert the right side

above right side pillar trim pieces.

(3) Connect the center high mounted stop light

electrical connector.

(4) Install the sun visor supports. (Refer to 23 -

BODY/INTERIOR/SUN VISOR SUPPORT - INSTAL-

LATION)

(5) Install the coat hooks. (Refer to 23 - BODY/IN-

TERIOR/COAT HOOK - INSTALLATION)

(6) Install the sun visors. (Refer to 23 - BODY/IN-

TERIOR/SUN VISOR - INSTALLATION)

(7) Install the overhead console. (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - INSTALLA-

TION)

(8) Install the dome lamp. (Refer to 8 - ELECTRI-

CAL/LAMPS/LIGHTING - INTERIOR/DOME LAMP

- INSTALLATION)

(9) Connect the headliner harness electrical con-

nector at the left a-pillar.

(10) Install the upper c-pillar trim, if equipped.

(Refer to 23 - BODY/INTERIOR/C-PILLAR TRIM -

INSTALLATION)(11) Install the upper b-pillar trim. (Refer to 23 -

BODY/INTERIOR/B-PILLAR UPPER TRIM -

INSTALLATION)

(12) Install the upper a-pillar trim. (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM - INSTALLA-

TION)

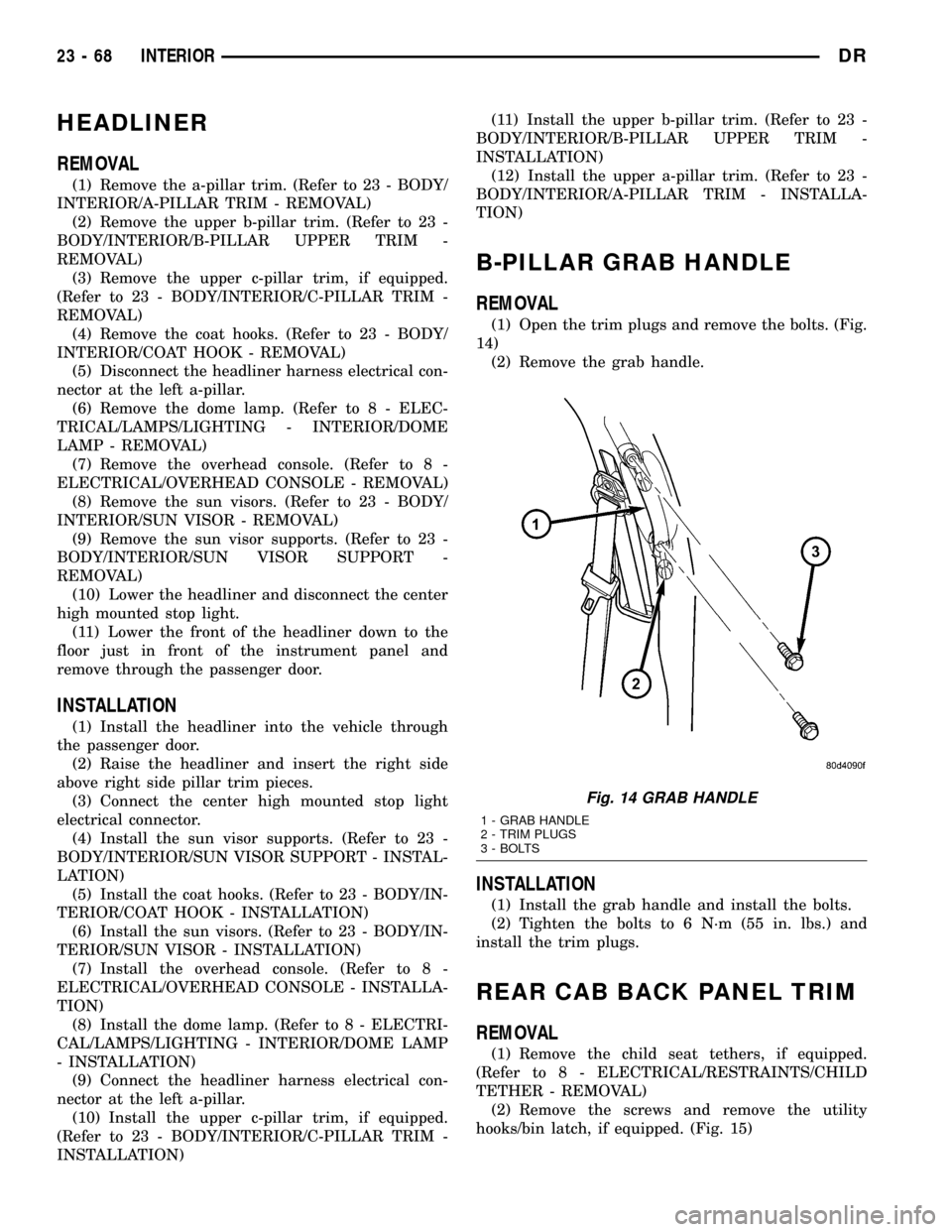

B-PILLAR GRAB HANDLE

REMOVAL

(1) Open the trim plugs and remove the bolts. (Fig.

14)

(2) Remove the grab handle.

INSTALLATION

(1) Install the grab handle and install the bolts.

(2) Tighten the bolts to 6 N´m (55 in. lbs.) and

install the trim plugs.

REAR CAB BACK PANEL TRIM

REMOVAL

(1) Remove the child seat tethers, if equipped.

(Refer to 8 - ELECTRICAL/RESTRAINTS/CHILD

TETHER - REMOVAL)

(2) Remove the screws and remove the utility

hooks/bin latch, if equipped. (Fig. 15)

Fig. 14 GRAB HANDLE

1 - GRAB HANDLE

2 - TRIM PLUGS

3 - BOLTS

23 - 68 INTERIORDR

Page 2605 of 2627

INTAKE AIR HEATER - OPERATION.......14-80

INTAKE AIR HEATER - REMOVAL........14-80

INTAKE AIR HEATER RELAY -

DESCRIPTION.......................14-82

INTAKE AIR HEATER RELAY -

INSTALLATION.......................14-82

INTAKE AIR HEATER RELAY -

OPERATION.........................14-82

INTAKE AIR HEATER RELAY - REMOVAL . . 14-82

INTAKE AIR TEMPERATURE SENSOR -

DESCRIPTION.......................14-30

INTAKE AIR TEMPERATURE SENSOR -

INSTALLATION.......................14-31

INTAKE AIR TEMPERATURE SENSOR -

OPERATION.........................14-30

INTAKE AIR TEMPERATURE SENSOR -

REMOVAL..........................14-30

INTAKE AIR TEMPERATURE SENSOR/

MAP SENSOR - DESCRIPTION..........14-82

INTAKE AIR TEMPERATURE SENSOR/

MAP SENSOR - INSTALLATION..........14-82

INTAKE AIR TEMPERATURE SENSOR/

MAP SENSOR - OPERATION............14-82

INTAKE AIR TEMPERATURE SENSOR/

MAP SENSOR - REMOVAL.............14-82

INTAKE MANIFOLD - CLEANING....9-160,9-226,

9-297

INTAKE MANIFOLD - DESCRIPTION . 9-159,9-225,

9-72

INTAKE MANIFOLD - INSPECTION . . 9-160,9-226,

9-297

INTAKE MANIFOLD - INSTALLATION.....9-160,

9-226,9-298,9-73

INTAKE MANIFOLD - REMOVAL....9-159,9-226,

9-297,9-73

INTAKE MANIFOLD LEAKAGE -

DIAGNOSIS AND TESTING........9-159,9-225

INTAKE MANIFOLD LEAKS - DIAGNOSIS

AND TESTING........................9-72

INTAKE SYSTEM - INSTALLATION, AIR....9-199

INTAKE SYSTEM - REMOVAL, AIR.......9-199

INTAKE/EXHAUST VALVES & SEATS -

DESCRIPTION..............9-123,9-256,9-28

INTAKE/EXHAUST VALVES & SEATS -

INSTALLATION...................9-124,9-30

INTAKE/EXHAUST VALVES & SEATS -

REMOVAL......................9-124,9-29

INTEGRATED POWER MODULE -

DESCRIPTION.....................8W-97-3

INTEGRATED POWER MODULE -

INSTALLATION....................8W-97-4

INTEGRATED POWER MODULE -

OPERATION.......................8W-97-3

INTEGRATED POWER MODULE -

REMOVAL........................8W-97-3

INTERIOR - CAUTION.................23-62

INTERLOCK - ADJUSTMENTS, BRAKE

TRANSMISSION SHIFT.........21-196,21-365

INTERLOCK - DIAGNOSIS AND TESTING,

BRAKE TRANSMISSION SHIFT . . . 21-196,21-364

INTERLOCK SYSTEM - DESCRIPTION,

BRAKE TRANSMISSION SHIFT . . . 21-196,21-364

INTERLOCK SYSTEM - OPERATION,

BRAKE TRANSMISSION SHIFT . . . 21-196,21-364

INTERNATIONAL SYMBOLS -

DESCRIPTION......................Intro.-5

INVERTED FLARING - STANDARD

PROCEDURE, DOUBLE.................5-10

IOD FUSE - DESCRIPTION...........8W-97-6

IOD FUSE - INSTALLATION...........8W-97-7

IOD FUSE - OPERATION.............8W-97-6

IOD FUSE - REMOVAL..............8W-97-7

ISO FLARING - STANDARD PROCEDURE

. . . 5-11

ISOLATORS - INSTALLATION, BODY

......23-37

ISOLATORS - REMOVAL, BODY

.........23-36

JOINT - DIAGNOSIS AND TESTING,

LOWER BALL

....................2-19,2-34

JOINT - DIAGNOSIS AND TESTING,

UPPER BALL

.....................2-27,2-36

JOINT - INSTALLATION, LOWER BALL

. 2-20,2-35

JOINT - INSTALLATION, UPPER BALL

.....2-36

JOINT - REMOVAL, LOWER BALL

.....2-19,2-35

JOINT - REMOVAL, UPPER BALL

.........2-36

JOINT-INNER - INSTALLATION, CV

........3-25

JOINT-INNER - REMOVAL, CV

............3-25

JOINT-OUTER - INSTALLATION, CV

........3-23

JOINT-OUTER - REMOVAL, CV

...........3-22JOINTS - ASSEMBLY, DOUBLE CARDAN

UNIVERSAL..........................3-17

JOINTS - DISASSEMBLY, DOUBLE

CARDAN UNIVERSAL..................3-16

JOUNCE BUMPER - INSTALLATION.......2-43

JOUNCE BUMPER - REMOVAL...........2-43

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD

BEARING AND CRANKSHAFT...........9-272

JUMP STARTING - STANDARD

PROCEDURE.........................0-19

JUNCTION BLOCK - INSTALLATION,

BRAKE..............................5-24

JUNCTION BLOCK - REMOVAL, BRAKE....5-24

KEY CYLINDER - INSTALLATION.........19-12

KEY CYLINDER - REMOVAL............19-12

KEY IMMOBILIZER MODULE -

DESCRIPTION, SENTRY................8E-13

KEY IMMOBILIZER MODULE -

INSTALLATION, SENTRY...............8E-15

KEY IMMOBILIZER MODULE -

OPERATION, SENTRY.................8E-13

KEY IMMOBILIZER MODULE - REMOVAL,

SENTRY............................8E-15

KEY IMMOBILIZER MODULE (SKIM) -

DESCRIPTION, SENTRY................8Q-1

KEY IMMOBILIZER MODULE (SKIM) -

OPERATION, SENTRY..................8Q-2

KEY IMMOBILIZER SYSTEM INDICATOR

LAMP - DESCRIPTION, SENTRY..........8Q-5

KEY IMMOBILIZER SYSTEM INDICATOR

LAMP - OPERATION, SENTRY...........8Q-5

KEY IMMOBILIZER SYSTEM

INITIALIZATION, STANDARD

PROCEDURE - SENTRY................8Q-3

KEY IMMOBILIZER SYSTEM (SKIS) -

DESCRIPTION, SENTRY................8Q-1

KEY IMMOBILIZER SYSTEM (SKIS) -

OPERATION, SENTRY..................8Q-2

KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING,

STANDARD PROCEDURE - SENTRY.......8Q-4

KEY LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH............19-11

KEY-IN IGNITION SWITCH -

DESCRIPTION.......................19-11

KEYLESS ENTRY MODULE -

DESCRIPTION, REMOTE................8N-7

KEYLESS ENTRY MODULE - DIAGNOSIS

AND TESTING, REMOTE................8N-7

KEYLESS ENTRY MODULE -

INSTALLATION, REMOTE...............8N-8

KEYLESS ENTRY MODULE - OPERATION,

REMOTE............................8N-7

KEYLESS ENTRY MODULE - REMOVAL,

REMOTE............................8N-7

KEYLESS ENTRY TRANSMITTER -

DIAGNOSIS AND TESTING, REMOTE......8N-8

KEYLESS ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE..............8N-9

KNOB RELEASE - INSTALLATION, TILT

LEVER.............................19-16

KNOB RELEASE - REMOVAL, TILT LEVER . . 19-16

KNOCK SENSOR - DESCRIPTION.........8I-14

KNOCK SENSOR - INSTALLATION........8I-15

KNOCK SENSOR - OPERATION..........8I-14

KNOCK SENSOR - REMOVAL............8I-15

KNUCKLE - DESCRIPTION...............2-18

KNUCKLE - INSTALLATION..........2-19,2-37

KNUCKLE - OPERATION................2-18

KNUCKLE - REMOVAL..............2-18,2-37

LABEL - DESCRIPTION, VEHICLE

CERTIFICATION....................Intro.-11

LAMP - DESCRIPTION, DOME...........8L-26

LAMP - DESCRIPTION, READING........8L-28

LAMP - DESCRIPTION, SENTRY KEY

IMMOBILIZER SYSTEM INDICATOR.......8Q-5

LAMP - INSTALLATION, CAB CLEARANCE . 8L-12

LAMP - INSTALLATION, CENTER HIGH

MOUNTED STOP.....................8L-11

LAMP - INSTALLATION, DOME..........8L-26

LAMP - INSTALLATION, FENDER

MARKER

...........................8L-18

LAMP - INSTALLATION, FOG

............8L-12

LAMP - INSTALLATION, LICENSE PLATE

. . 8L-17

LAMP - INSTALLATION, PARK/TURN

SIGNAL

............................8L-21

LAMP - INSTALLATION, READING

........8L-29LAMP - INSTALLATION, TAILGATE

MARKER...........................8L-18

LAMP - INSTALLATION, UNDERHOOD....8L-25

LAMP - OPERATION, DOME............8L-26

LAMP - OPERATION, READING..........8L-28

LAMP - OPERATION, SENTRY KEY

IMMOBILIZER SYSTEM INDICATOR.......8Q-5

LAMP - REMOVAL, CAB CLEARANCE.....8L-11

LAMP - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-11

LAMP - REMOVAL, DOME..............8L-26

LAMP - REMOVAL, FENDER MARKER....8L-17

LAMP - REMOVAL, FOG...............8L-12

LAMP - REMOVAL, LICENSE PLATE......8L-17

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-21

LAMP - REMOVAL, READING...........8L-28

LAMP - REMOVAL, TAILGATE MARKER . . . 8L-18

LAMP - REMOVAL, UNDERHOOD........8L-25

LAMP INDICATOR - DESCRIPTION,

CARGO.............................8J-20

LAMP INDICATOR - OPERATION, CARGO . . 8J-20

LAMP (MIL) - DESCRIPTION,

MALFUNCTION INDICATOR.............8J-31

LAMP (MIL) - OPERATION,

MALFUNCTION INDICATOR.............8J-31

LAMP OUT INDICATOR - DESCRIPTION . . . 8J-29

LAMP OUT INDICATOR - OPERATION.....8J-29

LAMP RELAY - DESCRIPTION, FOG......8L-12

LAMP RELAY - DESCRIPTION, PARK.....8L-20

LAMP RELAY - DIAGNOSIS AND

TESTING, PARK......................8L-20

LAMP RELAY - INSTALLATION, FOG......8L-13

LAMP RELAY - INSTALLATION, PARK.....8L-21

LAMP RELAY - OPERATION, FOG........8L-13

LAMP RELAY - OPERATION, PARK.......8L-20

LAMP RELAY - REMOVAL, FOG.........8L-13

LAMP RELAY - REMOVAL, PARK........8L-21

LAMP REPLACEMENT - STANDARD

PROCEDURE, MODULE................8M-3

LAMP REPLACEMENT - STANDARD

PROCEDURE, READING/COURTESY.......8M-3

LAMP SWITCH - DESCRIPTION, BACKUP . . . 8L-8

LAMP SWITCH - DESCRIPTION, BRAKE....8L-9

LAMP SWITCH - DIAGNOSIS AND

TESTING, BACKUP.....................8L-8

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE.....................8L-10

LAMP SWITCH - INSTALLATION, BRAKE . . 8L-11

LAMP SWITCH - OPERATION, BACKUP....8L-8

LAMP SWITCH - OPERATION, BRAKE......8L-9

LAMP SWITCH - REMOVAL, BRAKE......8L-10

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP................8L-11

LAMP UNIT - INSTALLATION, LICENSE

PLATE .............................8L-17

LAMP UNIT - INSTALLATION,

UNDERHOOD........................8L-25

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-11

LAMP UNIT - REMOVAL, LICENSE PLATE . . 8L-17

LAMP UNIT - REMOVAL, UNDERHOOD . . . 8L-25

LAMPS, SPECIFICATIONS - EXTERIOR.....8L-7

LAMPS/LIGHTING - EXTERIOR -

DESCRIPTION........................8L-2

LAMPS/LIGHTING - EXTERIOR -

DIAGNOSIS AND TESTING..............8L-3

LAMPS/LIGHTING - EXTERIOR -

OPERATION..........................8L-2

LAMP/SWITCH - INSTALLATION, GLOVE

BOX ...............................8L-28

LAMP/SWITCH - REMOVAL, GLOVE BOX . . 8L-27

LASH ADJUSTER - DIAGNOSIS AND

TESTING, HYDRAULIC.............9-125,9-32

LASH ADJUSTMENT AND VERIFICATION

- STANDARD PROCEDURE, VALVE.......9-259

LATCH - INSTALLATION.....23-16,23-23,23-32,

23-47

LATCH - INSTALLATION, GLOVE BOX.....23-52

LATCH - INSTALLATION, UNDER SEAT

STORAGE BIN.......................23-80

LATCH - REMOVAL

....23-16,23-23,23-32,23-47

LATCH - REMOVAL, GLOVE BOX

.........23-52

LATCH - REMOVAL, UNDER SEAT

STORAGE BIN

.......................23-80

LATCH RELEASE CABLE/HANDLE

ASSEMBLY - INSTALLATION

............23-47

LATCH RELEASE CABLE/HANDLE

ASSEMBLY - REMOVAL

................23-47

18 INDEXDR

Description Group-Page Description Group-Page Description Group-Page