fuse block DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 744 of 2627

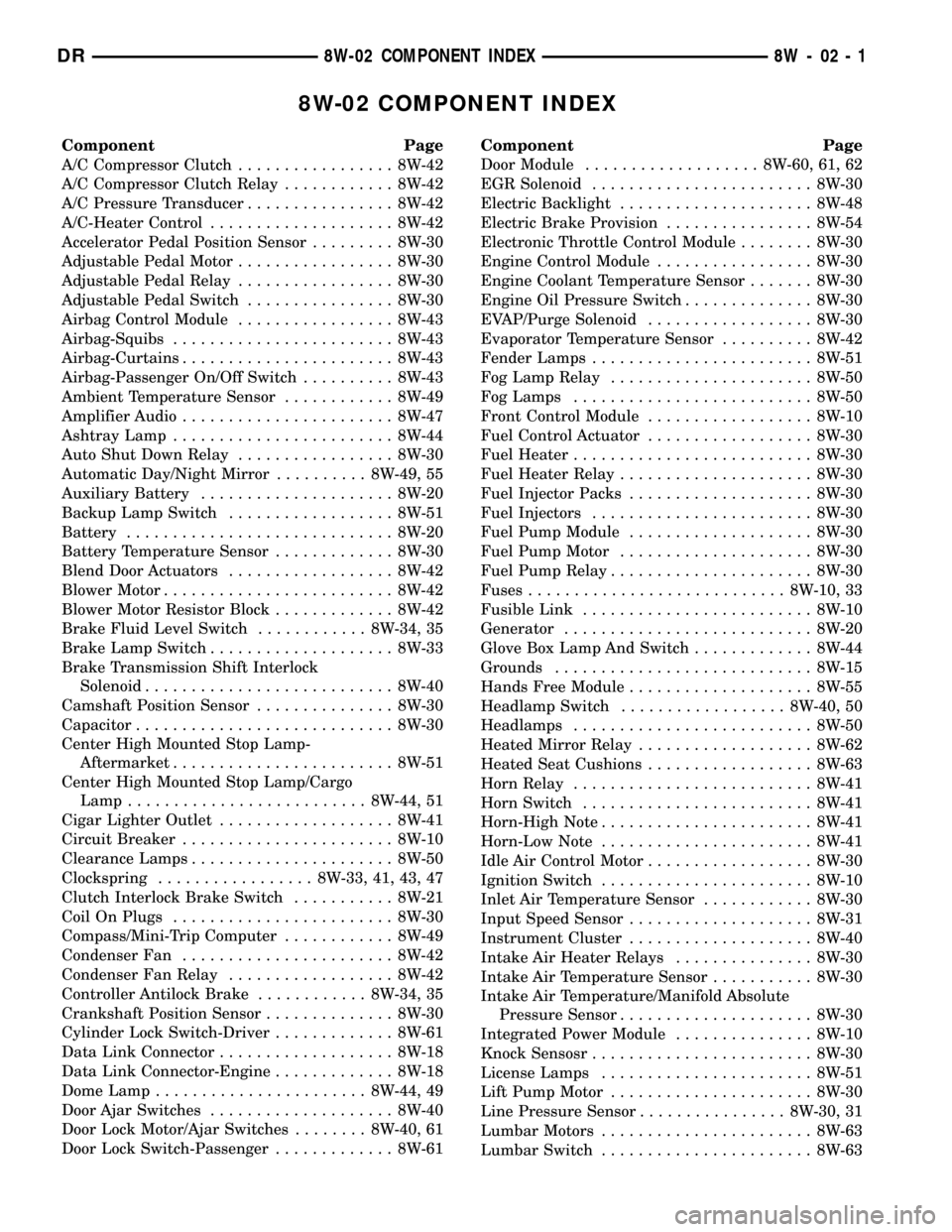

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch................. 8W-42

A/C Compressor Clutch Relay............ 8W-42

A/C Pressure Transducer................ 8W-42

A/C-Heater Control.................... 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Adjustable Pedal Motor................. 8W-30

Adjustable Pedal Relay................. 8W-30

Adjustable Pedal Switch................ 8W-30

Airbag Control Module................. 8W-43

Airbag-Squibs........................ 8W-43

Airbag-Curtains....................... 8W-43

Airbag-Passenger On/Off Switch.......... 8W-43

Ambient Temperature Sensor............ 8W-49

Amplifier Audio....................... 8W-47

Ashtray Lamp........................ 8W-44

Auto Shut Down Relay................. 8W-30

Automatic Day/Night Mirror.......... 8W-49, 55

Auxiliary Battery..................... 8W-20

Backup Lamp Switch.................. 8W-51

Battery............................. 8W-20

Battery Temperature Sensor............. 8W-30

Blend Door Actuators.................. 8W-42

Blower Motor......................... 8W-42

Blower Motor Resistor Block............. 8W-42

Brake Fluid Level Switch............ 8W-34, 35

Brake Lamp Switch.................... 8W-33

Brake Transmission Shift Interlock

Solenoid........................... 8W-40

Camshaft Position Sensor............... 8W-30

Capacitor............................ 8W-30

Center High Mounted Stop Lamp-

Aftermarket........................ 8W-51

Center High Mounted Stop Lamp/Cargo

Lamp.......................... 8W-44, 51

Cigar Lighter Outlet................... 8W-41

Circuit Breaker....................... 8W-10

Clearance Lamps...................... 8W-50

Clockspring................. 8W-33, 41, 43, 47

Clutch Interlock Brake Switch........... 8W-21

Coil On Plugs........................ 8W-30

Compass/Mini-Trip Computer............ 8W-49

Condenser Fan....................... 8W-42

Condenser Fan Relay.................. 8W-42

Controller Antilock Brake............ 8W-34, 35

Crankshaft Position Sensor.............. 8W-30

Cylinder Lock Switch-Driver............. 8W-61

Data Link Connector................... 8W-18

Data Link Connector-Engine............. 8W-18

Dome Lamp....................... 8W-44, 49

Door Ajar Switches.................... 8W-40

Door Lock Motor/Ajar Switches........ 8W-40, 61

Door Lock Switch-Passenger............. 8W-61Component Page

Door Module................... 8W-60, 61, 62

EGR Solenoid........................ 8W-30

Electric Backlight..................... 8W-48

Electric Brake Provision................ 8W-54

Electronic Throttle Control Module........ 8W-30

Engine Control Module................. 8W-30

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Pressure Switch.............. 8W-30

EVAP/Purge Solenoid.................. 8W-30

Evaporator Temperature Sensor.......... 8W-42

Fender Lamps........................ 8W-51

Fog Lamp Relay...................... 8W-50

Fog Lamps.......................... 8W-50

Front Control Module.................. 8W-10

Fuel Control Actuator.................. 8W-30

Fuel Heater.......................... 8W-30

Fuel Heater Relay..................... 8W-30

Fuel Injector Packs.................... 8W-30

Fuel Injectors........................ 8W-30

Fuel Pump Module.................... 8W-30

Fuel Pump Motor..................... 8W-30

Fuel Pump Relay...................... 8W-30

Fuses............................ 8W-10, 33

Fusible Link......................... 8W-10

Generator........................... 8W-20

Glove Box Lamp And Switch............. 8W-44

Grounds............................ 8W-15

Hands Free Module.................... 8W-55

Headlamp Switch.................. 8W-40, 50

Headlamps.......................... 8W-50

Heated Mirror Relay................... 8W-62

Heated Seat Cushions.................. 8W-63

Horn Relay.......................... 8W-41

Horn Switch......................... 8W-41

Horn-High Note....................... 8W-41

Horn-Low Note....................... 8W-41

Idle Air Control Motor.................. 8W-30

Ignition Switch....................... 8W-10

Inlet Air Temperature Sensor............ 8W-30

Input Speed Sensor.................... 8W-31

Instrument Cluster.................... 8W-40

Intake Air Heater Relays............... 8W-30

Intake Air Temperature Sensor........... 8W-30

Intake Air Temperature/Manifold Absolute

Pressure Sensor..................... 8W-30

Integrated Power Module............... 8W-10

Knock Sensosr........................ 8W-30

License Lamps....................... 8W-51

Lift Pump Motor...................... 8W-30

Line Pressure Sensor................ 8W-30, 31

Lumbar Motors....................... 8W-63

Lumbar Switch....................... 8W-63

DR8W-02 COMPONENT INDEX 8W - 02 - 1

Page 954 of 2627

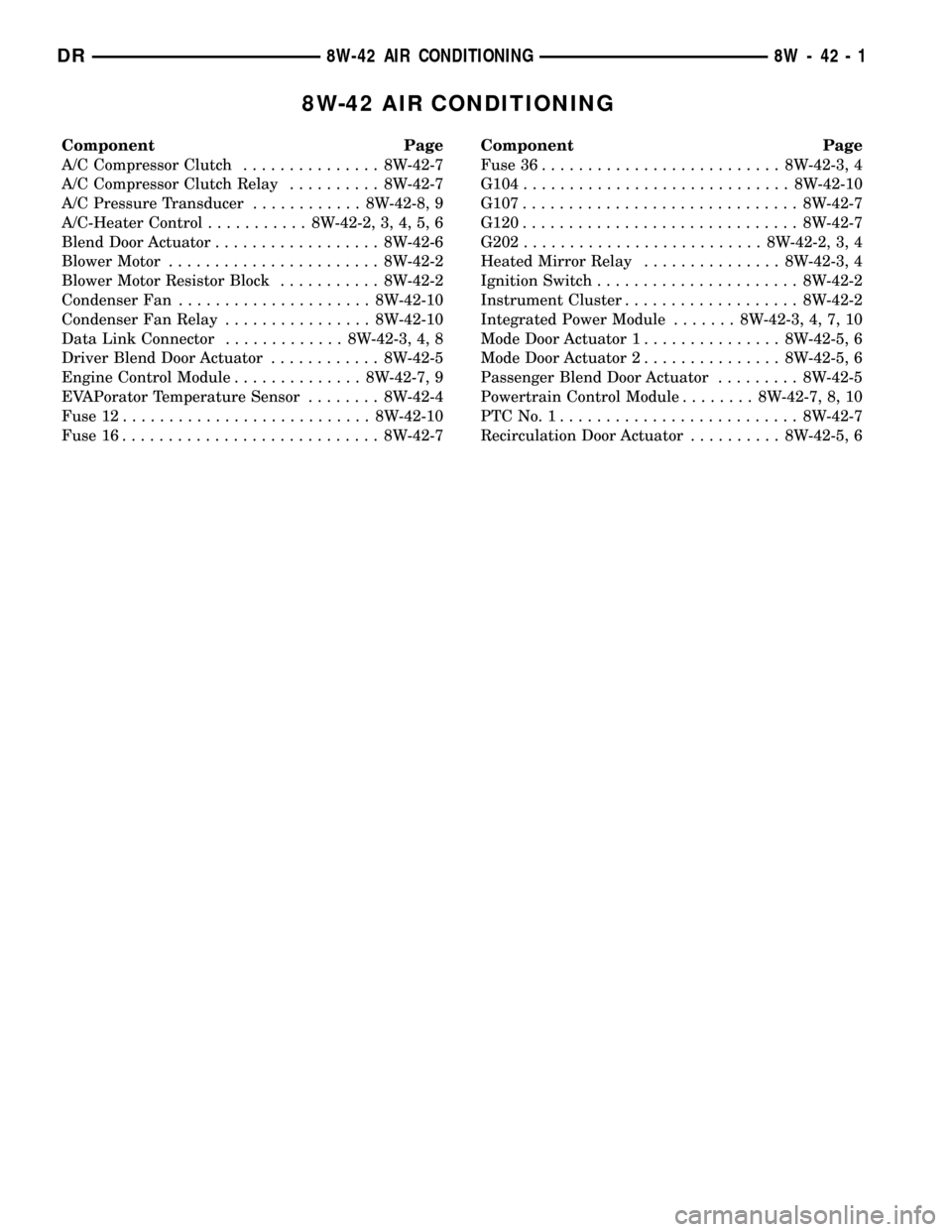

8W-42 AIR CONDITIONING

Component Page

A/C Compressor Clutch............... 8W-42-7

A/C Compressor Clutch Relay.......... 8W-42-7

A/C Pressure Transducer............ 8W-42-8, 9

A/C-Heater Control........... 8W-42-2, 3, 4, 5, 6

Blend Door Actuator.................. 8W-42-6

Blower Motor....................... 8W-42-2

Blower Motor Resistor Block........... 8W-42-2

Condenser Fan..................... 8W-42-10

Condenser Fan Relay................ 8W-42-10

Data Link Connector............. 8W-42-3, 4, 8

Driver Blend Door Actuator............ 8W-42-5

Engine Control Module.............. 8W-42-7, 9

EVAPorator Temperature Sensor........ 8W-42-4

Fuse 12........................... 8W-42-10

Fuse 16............................ 8W-42-7Component Page

Fuse 36.......................... 8W-42-3, 4

G104............................. 8W-42-10

G107.............................. 8W-42-7

G120.............................. 8W-42-7

G202.......................... 8W-42-2, 3, 4

Heated Mirror Relay............... 8W-42-3, 4

Ignition Switch...................... 8W-42-2

Instrument Cluster................... 8W-42-2

Integrated Power Module....... 8W-42-3, 4, 7, 10

Mode Door Actuator 1............... 8W-42-5, 6

Mode Door Actuator 2............... 8W-42-5, 6

Passenger Blend Door Actuator......... 8W-42-5

Powertrain Control Module........ 8W-42-7, 8, 10

PTCNo.1.......................... 8W-42-7

Recirculation Door Actuator.......... 8W-42-5, 6

DR8W-42 AIR CONDITIONING 8W - 42 - 1

Page 1062 of 2627

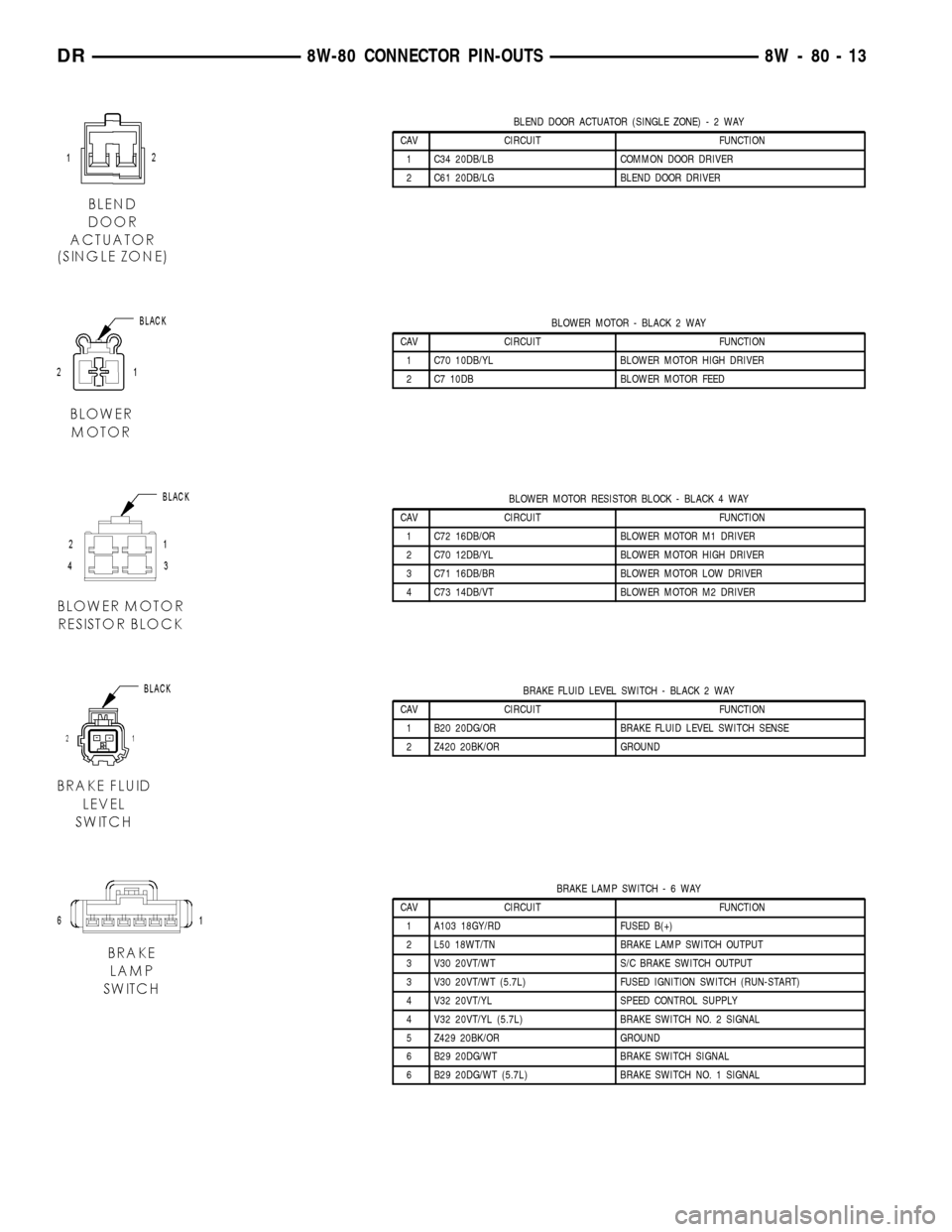

BLEND DOOR ACTUATOR (SINGLE ZONE)-2WAY

CAV CIRCUIT FUNCTION

1 C34 20DB/LB COMMON DOOR DRIVER

2 C61 20DB/LG BLEND DOOR DRIVER

BLOWER MOTOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 C70 10DB/YL BLOWER MOTOR HIGH DRIVER

2 C7 10DB BLOWER MOTOR FEED

BLOWER MOTOR RESISTOR BLOCK - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 C72 16DB/OR BLOWER MOTOR M1 DRIVER

2 C70 12DB/YL BLOWER MOTOR HIGH DRIVER

3 C71 16DB/BR BLOWER MOTOR LOW DRIVER

4 C73 14DB/VT BLOWER MOTOR M2 DRIVER

BRAKE FLUID LEVEL SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 B20 20DG/OR BRAKE FLUID LEVEL SWITCH SENSE

2 Z420 20BK/OR GROUND

BRAKE LAMP SWITCH-6WAY

CAV CIRCUIT FUNCTION

1 A103 18GY/RD FUSED B(+)

2 L50 18WT/TN BRAKE LAMP SWITCH OUTPUT

3 V30 20VT/WT S/C BRAKE SWITCH OUTPUT

3 V30 20VT/WT (5.7L) FUSED IGNITION SWITCH (RUN-START)

4 V32 20VT/YL SPEED CONTROL SUPPLY

4 V32 20VT/YL (5.7L) BRAKE SWITCH NO. 2 SIGNAL

5 Z429 20BK/OR GROUND

6 B29 20DG/WT BRAKE SWITCH SIGNAL

6 B29 20DG/WT (5.7L) BRAKE SWITCH NO. 1 SIGNAL

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 13

Page 1217 of 2627

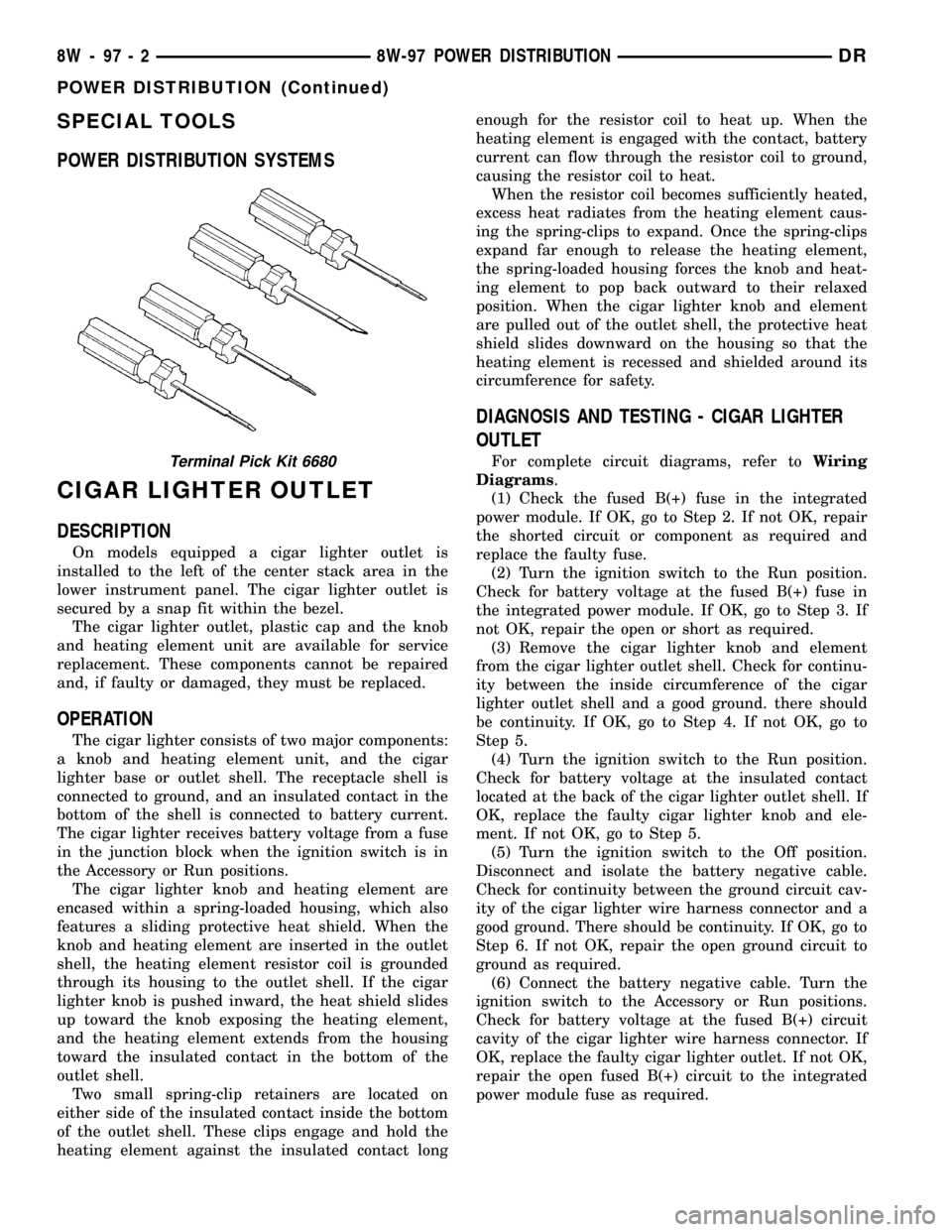

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS

CIGAR LIGHTER OUTLET

DESCRIPTION

On models equipped a cigar lighter outlet is

installed to the left of the center stack area in the

lower instrument panel. The cigar lighter outlet is

secured by a snap fit within the bezel.

The cigar lighter outlet, plastic cap and the knob

and heating element unit are available for service

replacement. These components cannot be repaired

and, if faulty or damaged, they must be replaced.

OPERATION

The cigar lighter consists of two major components:

a knob and heating element unit, and the cigar

lighter base or outlet shell. The receptacle shell is

connected to ground, and an insulated contact in the

bottom of the shell is connected to battery current.

The cigar lighter receives battery voltage from a fuse

in the junction block when the ignition switch is in

the Accessory or Run positions.

The cigar lighter knob and heating element are

encased within a spring-loaded housing, which also

features a sliding protective heat shield. When the

knob and heating element are inserted in the outlet

shell, the heating element resistor coil is grounded

through its housing to the outlet shell. If the cigar

lighter knob is pushed inward, the heat shield slides

up toward the knob exposing the heating element,

and the heating element extends from the housing

toward the insulated contact in the bottom of the

outlet shell.

Two small spring-clip retainers are located on

either side of the insulated contact inside the bottom

of the outlet shell. These clips engage and hold the

heating element against the insulated contact longenough for the resistor coil to heat up. When the

heating element is engaged with the contact, battery

current can flow through the resistor coil to ground,

causing the resistor coil to heat.

When the resistor coil becomes sufficiently heated,

excess heat radiates from the heating element caus-

ing the spring-clips to expand. Once the spring-clips

expand far enough to release the heating element,

the spring-loaded housing forces the knob and heat-

ing element to pop back outward to their relaxed

position. When the cigar lighter knob and element

are pulled out of the outlet shell, the protective heat

shield slides downward on the housing so that the

heating element is recessed and shielded around its

circumference for safety.

DIAGNOSIS AND TESTING - CIGAR LIGHTER

OUTLET

For complete circuit diagrams, refer toWiring

Diagrams.

(1) Check the fused B(+) fuse in the integrated

power module. If OK, go to Step 2. If not OK, repair

the shorted circuit or component as required and

replace the faulty fuse.

(2) Turn the ignition switch to the Run position.

Check for battery voltage at the fused B(+) fuse in

the integrated power module. If OK, go to Step 3. If

not OK, repair the open or short as required.

(3) Remove the cigar lighter knob and element

from the cigar lighter outlet shell. Check for continu-

ity between the inside circumference of the cigar

lighter outlet shell and a good ground. there should

be continuity. If OK, go to Step 4. If not OK, go to

Step 5.

(4) Turn the ignition switch to the Run position.

Check for battery voltage at the insulated contact

located at the back of the cigar lighter outlet shell. If

OK, replace the faulty cigar lighter knob and ele-

ment. If not OK, go to Step 5.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Check for continuity between the ground circuit cav-

ity of the cigar lighter wire harness connector and a

good ground. There should be continuity. If OK, go to

Step 6. If not OK, repair the open ground circuit to

ground as required.

(6) Connect the battery negative cable. Turn the

ignition switch to the Accessory or Run positions.

Check for battery voltage at the fused B(+) circuit

cavity of the cigar lighter wire harness connector. If

OK, replace the faulty cigar lighter outlet. If not OK,

repair the open fused B(+) circuit to the integrated

power module fuse as required.Terminal Pick Kit 6680

8W - 97 - 2 8W-97 POWER DISTRIBUTIONDR

POWER DISTRIBUTION (Continued)

Page 1857 of 2627

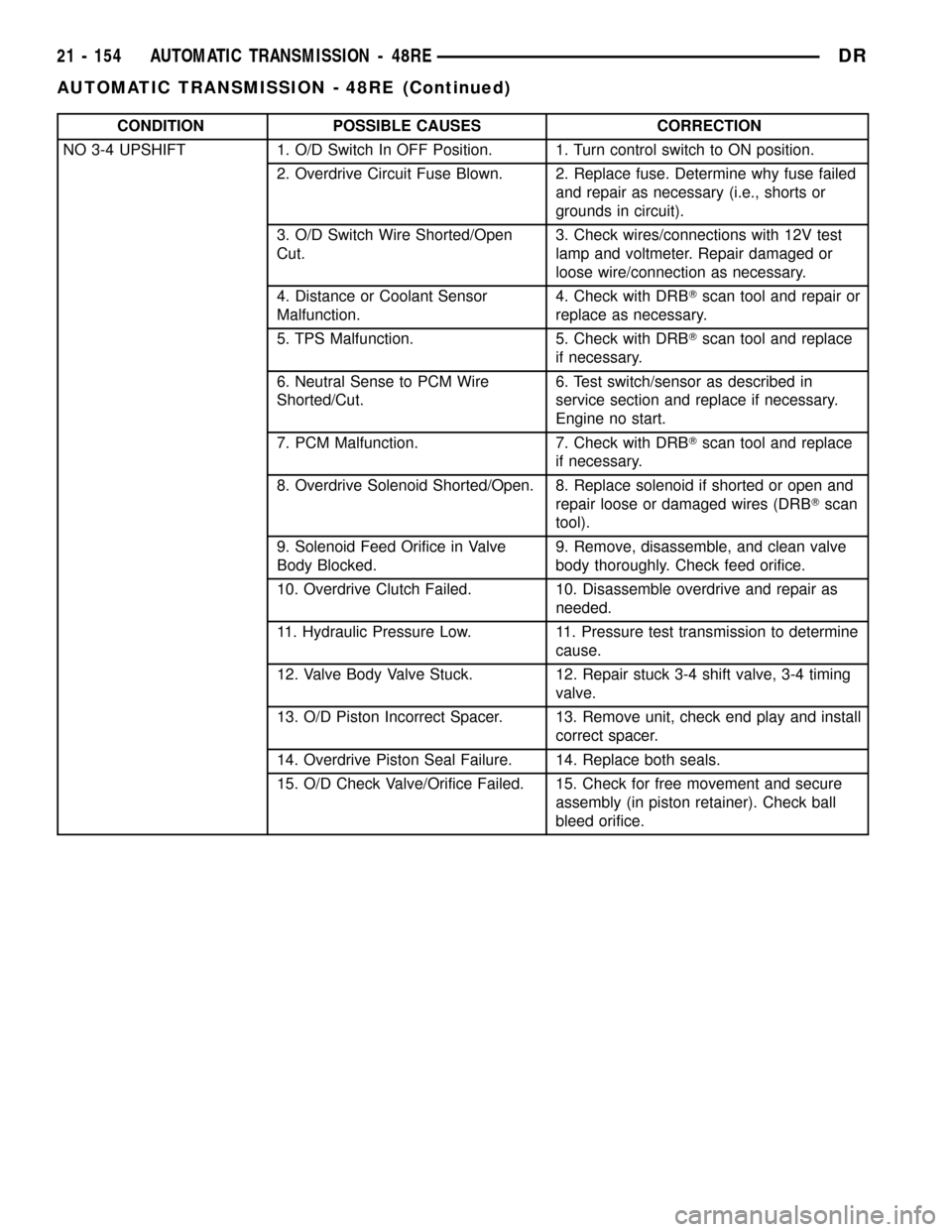

CONDITION POSSIBLE CAUSES CORRECTION

NO 3-4 UPSHIFT 1. O/D Switch In OFF Position. 1. Turn control switch to ON position.

2. Overdrive Circuit Fuse Blown. 2. Replace fuse. Determine why fuse failed

and repair as necessary (i.e., shorts or

grounds in circuit).

3. O/D Switch Wire Shorted/Open

Cut.3. Check wires/connections with 12V test

lamp and voltmeter. Repair damaged or

loose wire/connection as necessary.

4. Distance or Coolant Sensor

Malfunction.4. Check with DRBTscan tool and repair or

replace as necessary.

5. TPS Malfunction. 5. Check with DRBTscan tool and replace

if necessary.

6. Neutral Sense to PCM Wire

Shorted/Cut.6. Test switch/sensor as described in

service section and replace if necessary.

Engine no start.

7. PCM Malfunction. 7. Check with DRBTscan tool and replace

if necessary.

8. Overdrive Solenoid Shorted/Open. 8. Replace solenoid if shorted or open and

repair loose or damaged wires (DRBTscan

tool).

9. Solenoid Feed Orifice in Valve

Body Blocked.9. Remove, disassemble, and clean valve

body thoroughly. Check feed orifice.

10. Overdrive Clutch Failed. 10. Disassemble overdrive and repair as

needed.

11. Hydraulic Pressure Low. 11. Pressure test transmission to determine

cause.

12. Valve Body Valve Stuck. 12. Repair stuck 3-4 shift valve, 3-4 timing

valve.

13. O/D Piston Incorrect Spacer. 13. Remove unit, check end play and install

correct spacer.

14. Overdrive Piston Seal Failure. 14. Replace both seals.

15. O/D Check Valve/Orifice Failed. 15. Check for free movement and secure

assembly (in piston retainer). Check ball

bleed orifice.

21 - 154 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 2491 of 2627

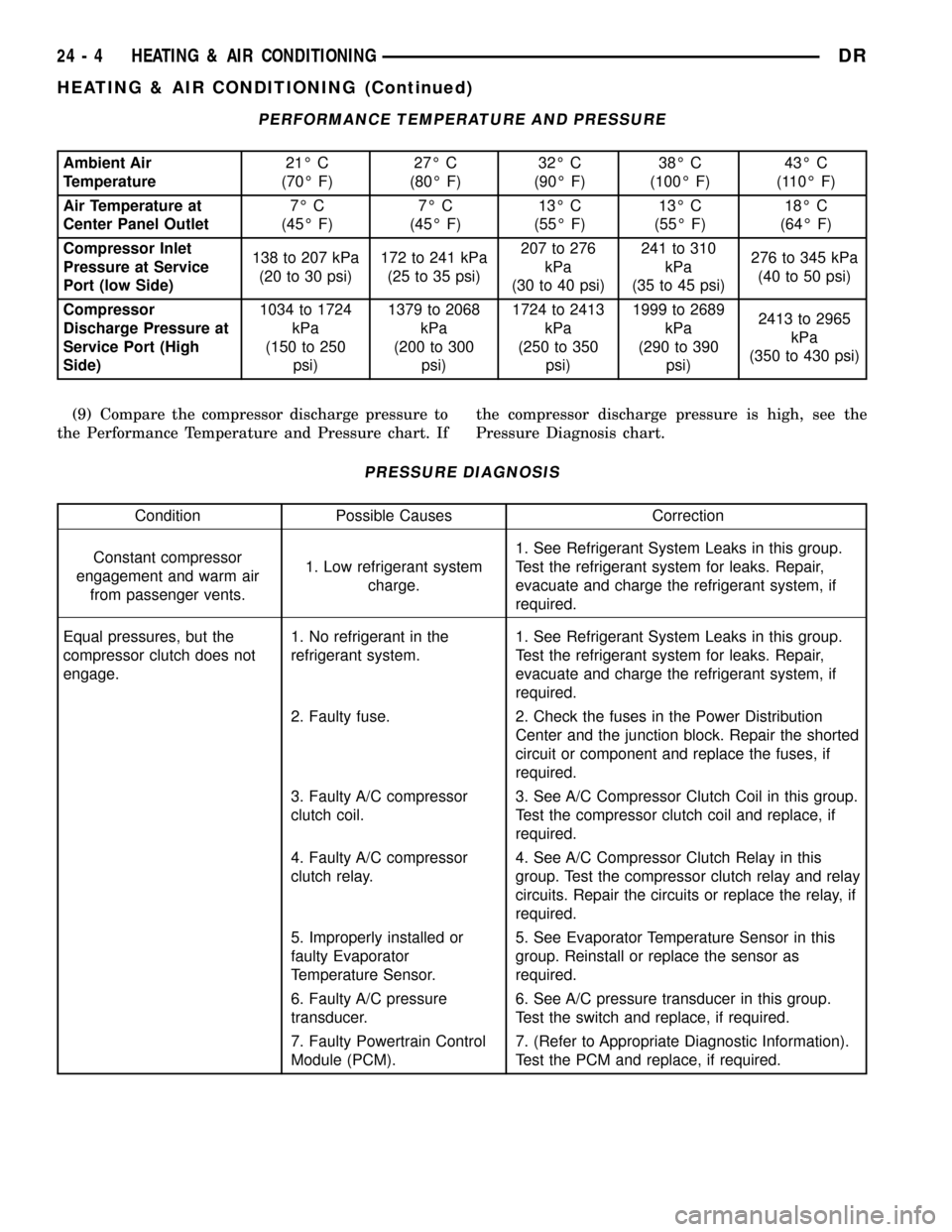

PERFORMANCE TEMPERATURE AND PRESSURE

Ambient Air

Temperature21É C

(70É F)27É C

(80É F)32É C

(90É F)38É C

(100É F)43É C

(110É F)

Air Temperature at

Center Panel Outlet7É C

(45É F)7É C

(45É F)13É C

(55É F)13É C

(55É F)18É C

(64É F)

Compressor Inlet

Pressure at Service

Port (low Side)138 to 207 kPa

(20 to 30 psi)172 to 241 kPa

(25 to 35 psi)207 to 276

kPa

(30 to 40 psi)241 to 310

kPa

(35 to 45 psi)276 to 345 kPa

(40 to 50 psi)

Compressor

Discharge Pressure at

Service Port (High

Side)1034 to 1724

kPa

(150 to 250

psi)1379 to 2068

kPa

(200 to 300

psi)1724 to 2413

kPa

(250 to 350

psi)1999 to 2689

kPa

(290 to 390

psi)2413 to 2965

kPa

(350 to 430 psi)

(9) Compare the compressor discharge pressure to

the Performance Temperature and Pressure chart. Ifthe compressor discharge pressure is high, see the

Pressure Diagnosis chart.

PRESSURE DIAGNOSIS

Condition Possible Causes Correction

Constant compressor

engagement and warm air

from passenger vents.1. Low refrigerant system

charge.1. See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

Equal pressures, but the

compressor clutch does not

engage.1. No refrigerant in the

refrigerant system.1. See Refrigerant System Leaks in this group.

Test the refrigerant system for leaks. Repair,

evacuate and charge the refrigerant system, if

required.

2. Faulty fuse. 2. Check the fuses in the Power Distribution

Center and the junction block. Repair the shorted

circuit or component and replace the fuses, if

required.

3. Faulty A/C compressor

clutch coil.3. See A/C Compressor Clutch Coil in this group.

Test the compressor clutch coil and replace, if

required.

4. Faulty A/C compressor

clutch relay.4. See A/C Compressor Clutch Relay in this

group. Test the compressor clutch relay and relay

circuits. Repair the circuits or replace the relay, if

required.

5. Improperly installed or

faulty Evaporator

Temperature Sensor.5. See Evaporator Temperature Sensor in this

group. Reinstall or replace the sensor as

required.

6. Faulty A/C pressure

transducer.6. See A/C pressure transducer in this group.

Test the switch and replace, if required.

7. Faulty Powertrain Control

Module (PCM).7. (Refer to Appropriate Diagnostic Information).

Test the PCM and replace, if required.

24 - 4 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)

Page 2497 of 2627

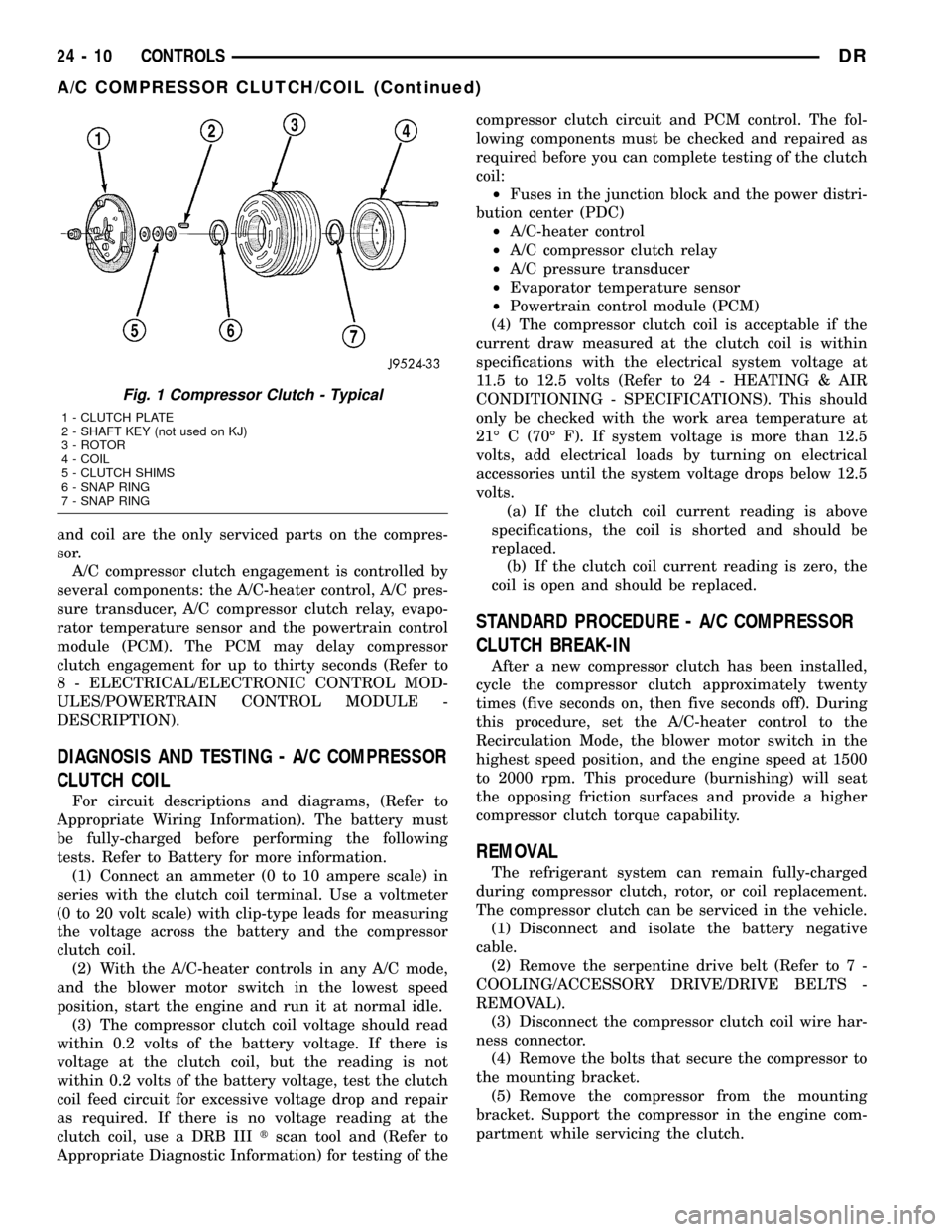

and coil are the only serviced parts on the compres-

sor.

A/C compressor clutch engagement is controlled by

several components: the A/C-heater control, A/C pres-

sure transducer, A/C compressor clutch relay, evapo-

rator temperature sensor and the powertrain control

module (PCM). The PCM may delay compressor

clutch engagement for up to thirty seconds (Refer to

8 - ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION).

DIAGNOSIS AND TESTING - A/C COMPRESSOR

CLUTCH COIL

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information). The battery must

be fully-charged before performing the following

tests. Refer to Battery for more information.

(1) Connect an ammeter (0 to 10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0 to 20 volt scale) with clip-type leads for measuring

the voltage across the battery and the compressor

clutch coil.

(2) With the A/C-heater controls in any A/C mode,

and the blower motor switch in the lowest speed

position, start the engine and run it at normal idle.

(3) The compressor clutch coil voltage should read

within 0.2 volts of the battery voltage. If there is

voltage at the clutch coil, but the reading is not

within 0.2 volts of the battery voltage, test the clutch

coil feed circuit for excessive voltage drop and repair

as required. If there is no voltage reading at the

clutch coil, use a DRB IIItscan tool and (Refer to

Appropriate Diagnostic Information) for testing of thecompressor clutch circuit and PCM control. The fol-

lowing components must be checked and repaired as

required before you can complete testing of the clutch

coil:

²Fuses in the junction block and the power distri-

bution center (PDC)

²A/C-heater control

²A/C compressor clutch relay

²A/C pressure transducer

²Evaporator temperature sensor

²Powertrain control module (PCM)

(4) The compressor clutch coil is acceptable if the

current draw measured at the clutch coil is within

specifications with the electrical system voltage at

11.5 to 12.5 volts (Refer to 24 - HEATING & AIR

CONDITIONING - SPECIFICATIONS). This should

only be checked with the work area temperature at

21É C (70É F). If system voltage is more than 12.5

volts, add electrical loads by turning on electrical

accessories until the system voltage drops below 12.5

volts.

(a) If the clutch coil current reading is above

specifications, the coil is shorted and should be

replaced.

(b) If the clutch coil current reading is zero, the

coil is open and should be replaced.

STANDARD PROCEDURE - A/C COMPRESSOR

CLUTCH BREAK-IN

After a new compressor clutch has been installed,

cycle the compressor clutch approximately twenty

times (five seconds on, then five seconds off). During

this procedure, set the A/C-heater control to the

Recirculation Mode, the blower motor switch in the

highest speed position, and the engine speed at 1500

to 2000 rpm. This procedure (burnishing) will seat

the opposing friction surfaces and provide a higher

compressor clutch torque capability.

REMOVAL

The refrigerant system can remain fully-charged

during compressor clutch, rotor, or coil replacement.

The compressor clutch can be serviced in the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(3) Disconnect the compressor clutch coil wire har-

ness connector.

(4) Remove the bolts that secure the compressor to

the mounting bracket.

(5) Remove the compressor from the mounting

bracket. Support the compressor in the engine com-

partment while servicing the clutch.

Fig. 1 Compressor Clutch - Typical

1 - CLUTCH PLATE

2 - SHAFT KEY (not used on KJ)

3 - ROTOR

4 - COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

24 - 10 CONTROLSDR

A/C COMPRESSOR CLUTCH/COIL (Continued)

Page 2515 of 2627

(5) Install the HVAC housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION)

BLOWER MOTOR

DESCRIPTION

The blower motor and blower wheel are located in

the passenger side end of the HVAC housing, below

the glove box. The blower motor controls the velocity

of air flowing through the HVAC housing by spinning

a squirrel cage-type blower wheel within the housing

at the selected speed. The blower motor and wheel

can be removed from the housing inside the vehicle

without removing the instrument panel or HVAC

housing.

OPERATION

The blower motor will only operate with the igni-

tion switch in the On position and the A/C-heater

mode control switch in any position, except Off. The

blower motor receives a fused battery feed circuit

through a fuse in the Power Distribution Center

(PDC) whenever the ignition switch is in the On posi-

tion. Blower motor speed is controlled by regulating

the ground path through or around the blower motor

resistor block and through the A/C-heater blower

motor switch.

The blower motor and blower motor wheel are ser-

viced only as a unit and cannot be repaired and, if

faulty or damaged, must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

BLOWER MOTOR INOPERATIVE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

Refer to the Blower Motor Electrical Diagnosis

chart for basic checks of the blower motor circuit

(Fig. 3).

BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 4).

24 - 28 DISTRIBUTIONDR

BLEND DOOR (Continued)

Page 2605 of 2627

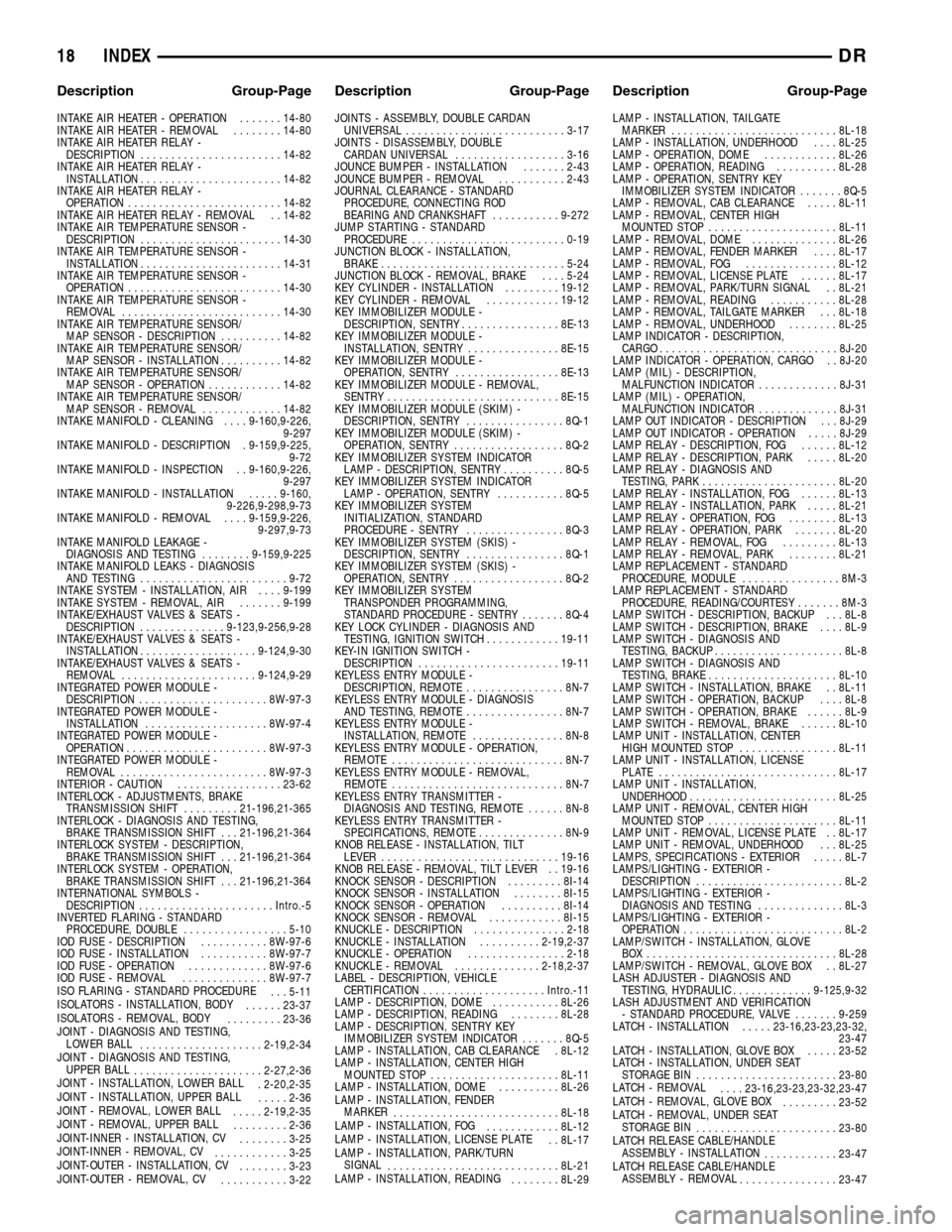

INTAKE AIR HEATER - OPERATION.......14-80

INTAKE AIR HEATER - REMOVAL........14-80

INTAKE AIR HEATER RELAY -

DESCRIPTION.......................14-82

INTAKE AIR HEATER RELAY -

INSTALLATION.......................14-82

INTAKE AIR HEATER RELAY -

OPERATION.........................14-82

INTAKE AIR HEATER RELAY - REMOVAL . . 14-82

INTAKE AIR TEMPERATURE SENSOR -

DESCRIPTION.......................14-30

INTAKE AIR TEMPERATURE SENSOR -

INSTALLATION.......................14-31

INTAKE AIR TEMPERATURE SENSOR -

OPERATION.........................14-30

INTAKE AIR TEMPERATURE SENSOR -

REMOVAL..........................14-30

INTAKE AIR TEMPERATURE SENSOR/

MAP SENSOR - DESCRIPTION..........14-82

INTAKE AIR TEMPERATURE SENSOR/

MAP SENSOR - INSTALLATION..........14-82

INTAKE AIR TEMPERATURE SENSOR/

MAP SENSOR - OPERATION............14-82

INTAKE AIR TEMPERATURE SENSOR/

MAP SENSOR - REMOVAL.............14-82

INTAKE MANIFOLD - CLEANING....9-160,9-226,

9-297

INTAKE MANIFOLD - DESCRIPTION . 9-159,9-225,

9-72

INTAKE MANIFOLD - INSPECTION . . 9-160,9-226,

9-297

INTAKE MANIFOLD - INSTALLATION.....9-160,

9-226,9-298,9-73

INTAKE MANIFOLD - REMOVAL....9-159,9-226,

9-297,9-73

INTAKE MANIFOLD LEAKAGE -

DIAGNOSIS AND TESTING........9-159,9-225

INTAKE MANIFOLD LEAKS - DIAGNOSIS

AND TESTING........................9-72

INTAKE SYSTEM - INSTALLATION, AIR....9-199

INTAKE SYSTEM - REMOVAL, AIR.......9-199

INTAKE/EXHAUST VALVES & SEATS -

DESCRIPTION..............9-123,9-256,9-28

INTAKE/EXHAUST VALVES & SEATS -

INSTALLATION...................9-124,9-30

INTAKE/EXHAUST VALVES & SEATS -

REMOVAL......................9-124,9-29

INTEGRATED POWER MODULE -

DESCRIPTION.....................8W-97-3

INTEGRATED POWER MODULE -

INSTALLATION....................8W-97-4

INTEGRATED POWER MODULE -

OPERATION.......................8W-97-3

INTEGRATED POWER MODULE -

REMOVAL........................8W-97-3

INTERIOR - CAUTION.................23-62

INTERLOCK - ADJUSTMENTS, BRAKE

TRANSMISSION SHIFT.........21-196,21-365

INTERLOCK - DIAGNOSIS AND TESTING,

BRAKE TRANSMISSION SHIFT . . . 21-196,21-364

INTERLOCK SYSTEM - DESCRIPTION,

BRAKE TRANSMISSION SHIFT . . . 21-196,21-364

INTERLOCK SYSTEM - OPERATION,

BRAKE TRANSMISSION SHIFT . . . 21-196,21-364

INTERNATIONAL SYMBOLS -

DESCRIPTION......................Intro.-5

INVERTED FLARING - STANDARD

PROCEDURE, DOUBLE.................5-10

IOD FUSE - DESCRIPTION...........8W-97-6

IOD FUSE - INSTALLATION...........8W-97-7

IOD FUSE - OPERATION.............8W-97-6

IOD FUSE - REMOVAL..............8W-97-7

ISO FLARING - STANDARD PROCEDURE

. . . 5-11

ISOLATORS - INSTALLATION, BODY

......23-37

ISOLATORS - REMOVAL, BODY

.........23-36

JOINT - DIAGNOSIS AND TESTING,

LOWER BALL

....................2-19,2-34

JOINT - DIAGNOSIS AND TESTING,

UPPER BALL

.....................2-27,2-36

JOINT - INSTALLATION, LOWER BALL

. 2-20,2-35

JOINT - INSTALLATION, UPPER BALL

.....2-36

JOINT - REMOVAL, LOWER BALL

.....2-19,2-35

JOINT - REMOVAL, UPPER BALL

.........2-36

JOINT-INNER - INSTALLATION, CV

........3-25

JOINT-INNER - REMOVAL, CV

............3-25

JOINT-OUTER - INSTALLATION, CV

........3-23

JOINT-OUTER - REMOVAL, CV

...........3-22JOINTS - ASSEMBLY, DOUBLE CARDAN

UNIVERSAL..........................3-17

JOINTS - DISASSEMBLY, DOUBLE

CARDAN UNIVERSAL..................3-16

JOUNCE BUMPER - INSTALLATION.......2-43

JOUNCE BUMPER - REMOVAL...........2-43

JOURNAL CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD

BEARING AND CRANKSHAFT...........9-272

JUMP STARTING - STANDARD

PROCEDURE.........................0-19

JUNCTION BLOCK - INSTALLATION,

BRAKE..............................5-24

JUNCTION BLOCK - REMOVAL, BRAKE....5-24

KEY CYLINDER - INSTALLATION.........19-12

KEY CYLINDER - REMOVAL............19-12

KEY IMMOBILIZER MODULE -

DESCRIPTION, SENTRY................8E-13

KEY IMMOBILIZER MODULE -

INSTALLATION, SENTRY...............8E-15

KEY IMMOBILIZER MODULE -

OPERATION, SENTRY.................8E-13

KEY IMMOBILIZER MODULE - REMOVAL,

SENTRY............................8E-15

KEY IMMOBILIZER MODULE (SKIM) -

DESCRIPTION, SENTRY................8Q-1

KEY IMMOBILIZER MODULE (SKIM) -

OPERATION, SENTRY..................8Q-2

KEY IMMOBILIZER SYSTEM INDICATOR

LAMP - DESCRIPTION, SENTRY..........8Q-5

KEY IMMOBILIZER SYSTEM INDICATOR

LAMP - OPERATION, SENTRY...........8Q-5

KEY IMMOBILIZER SYSTEM

INITIALIZATION, STANDARD

PROCEDURE - SENTRY................8Q-3

KEY IMMOBILIZER SYSTEM (SKIS) -

DESCRIPTION, SENTRY................8Q-1

KEY IMMOBILIZER SYSTEM (SKIS) -

OPERATION, SENTRY..................8Q-2

KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING,

STANDARD PROCEDURE - SENTRY.......8Q-4

KEY LOCK CYLINDER - DIAGNOSIS AND

TESTING, IGNITION SWITCH............19-11

KEY-IN IGNITION SWITCH -

DESCRIPTION.......................19-11

KEYLESS ENTRY MODULE -

DESCRIPTION, REMOTE................8N-7

KEYLESS ENTRY MODULE - DIAGNOSIS

AND TESTING, REMOTE................8N-7

KEYLESS ENTRY MODULE -

INSTALLATION, REMOTE...............8N-8

KEYLESS ENTRY MODULE - OPERATION,

REMOTE............................8N-7

KEYLESS ENTRY MODULE - REMOVAL,

REMOTE............................8N-7

KEYLESS ENTRY TRANSMITTER -

DIAGNOSIS AND TESTING, REMOTE......8N-8

KEYLESS ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE..............8N-9

KNOB RELEASE - INSTALLATION, TILT

LEVER.............................19-16

KNOB RELEASE - REMOVAL, TILT LEVER . . 19-16

KNOCK SENSOR - DESCRIPTION.........8I-14

KNOCK SENSOR - INSTALLATION........8I-15

KNOCK SENSOR - OPERATION..........8I-14

KNOCK SENSOR - REMOVAL............8I-15

KNUCKLE - DESCRIPTION...............2-18

KNUCKLE - INSTALLATION..........2-19,2-37

KNUCKLE - OPERATION................2-18

KNUCKLE - REMOVAL..............2-18,2-37

LABEL - DESCRIPTION, VEHICLE

CERTIFICATION....................Intro.-11

LAMP - DESCRIPTION, DOME...........8L-26

LAMP - DESCRIPTION, READING........8L-28

LAMP - DESCRIPTION, SENTRY KEY

IMMOBILIZER SYSTEM INDICATOR.......8Q-5

LAMP - INSTALLATION, CAB CLEARANCE . 8L-12

LAMP - INSTALLATION, CENTER HIGH

MOUNTED STOP.....................8L-11

LAMP - INSTALLATION, DOME..........8L-26

LAMP - INSTALLATION, FENDER

MARKER

...........................8L-18

LAMP - INSTALLATION, FOG

............8L-12

LAMP - INSTALLATION, LICENSE PLATE

. . 8L-17

LAMP - INSTALLATION, PARK/TURN

SIGNAL

............................8L-21

LAMP - INSTALLATION, READING

........8L-29LAMP - INSTALLATION, TAILGATE

MARKER...........................8L-18

LAMP - INSTALLATION, UNDERHOOD....8L-25

LAMP - OPERATION, DOME............8L-26

LAMP - OPERATION, READING..........8L-28

LAMP - OPERATION, SENTRY KEY

IMMOBILIZER SYSTEM INDICATOR.......8Q-5

LAMP - REMOVAL, CAB CLEARANCE.....8L-11

LAMP - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-11

LAMP - REMOVAL, DOME..............8L-26

LAMP - REMOVAL, FENDER MARKER....8L-17

LAMP - REMOVAL, FOG...............8L-12

LAMP - REMOVAL, LICENSE PLATE......8L-17

LAMP - REMOVAL, PARK/TURN SIGNAL . . 8L-21

LAMP - REMOVAL, READING...........8L-28

LAMP - REMOVAL, TAILGATE MARKER . . . 8L-18

LAMP - REMOVAL, UNDERHOOD........8L-25

LAMP INDICATOR - DESCRIPTION,

CARGO.............................8J-20

LAMP INDICATOR - OPERATION, CARGO . . 8J-20

LAMP (MIL) - DESCRIPTION,

MALFUNCTION INDICATOR.............8J-31

LAMP (MIL) - OPERATION,

MALFUNCTION INDICATOR.............8J-31

LAMP OUT INDICATOR - DESCRIPTION . . . 8J-29

LAMP OUT INDICATOR - OPERATION.....8J-29

LAMP RELAY - DESCRIPTION, FOG......8L-12

LAMP RELAY - DESCRIPTION, PARK.....8L-20

LAMP RELAY - DIAGNOSIS AND

TESTING, PARK......................8L-20

LAMP RELAY - INSTALLATION, FOG......8L-13

LAMP RELAY - INSTALLATION, PARK.....8L-21

LAMP RELAY - OPERATION, FOG........8L-13

LAMP RELAY - OPERATION, PARK.......8L-20

LAMP RELAY - REMOVAL, FOG.........8L-13

LAMP RELAY - REMOVAL, PARK........8L-21

LAMP REPLACEMENT - STANDARD

PROCEDURE, MODULE................8M-3

LAMP REPLACEMENT - STANDARD

PROCEDURE, READING/COURTESY.......8M-3

LAMP SWITCH - DESCRIPTION, BACKUP . . . 8L-8

LAMP SWITCH - DESCRIPTION, BRAKE....8L-9

LAMP SWITCH - DIAGNOSIS AND

TESTING, BACKUP.....................8L-8

LAMP SWITCH - DIAGNOSIS AND

TESTING, BRAKE.....................8L-10

LAMP SWITCH - INSTALLATION, BRAKE . . 8L-11

LAMP SWITCH - OPERATION, BACKUP....8L-8

LAMP SWITCH - OPERATION, BRAKE......8L-9

LAMP SWITCH - REMOVAL, BRAKE......8L-10

LAMP UNIT - INSTALLATION, CENTER

HIGH MOUNTED STOP................8L-11

LAMP UNIT - INSTALLATION, LICENSE

PLATE .............................8L-17

LAMP UNIT - INSTALLATION,

UNDERHOOD........................8L-25

LAMP UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP.....................8L-11

LAMP UNIT - REMOVAL, LICENSE PLATE . . 8L-17

LAMP UNIT - REMOVAL, UNDERHOOD . . . 8L-25

LAMPS, SPECIFICATIONS - EXTERIOR.....8L-7

LAMPS/LIGHTING - EXTERIOR -

DESCRIPTION........................8L-2

LAMPS/LIGHTING - EXTERIOR -

DIAGNOSIS AND TESTING..............8L-3

LAMPS/LIGHTING - EXTERIOR -

OPERATION..........................8L-2

LAMP/SWITCH - INSTALLATION, GLOVE

BOX ...............................8L-28

LAMP/SWITCH - REMOVAL, GLOVE BOX . . 8L-27

LASH ADJUSTER - DIAGNOSIS AND

TESTING, HYDRAULIC.............9-125,9-32

LASH ADJUSTMENT AND VERIFICATION

- STANDARD PROCEDURE, VALVE.......9-259

LATCH - INSTALLATION.....23-16,23-23,23-32,

23-47

LATCH - INSTALLATION, GLOVE BOX.....23-52

LATCH - INSTALLATION, UNDER SEAT

STORAGE BIN.......................23-80

LATCH - REMOVAL

....23-16,23-23,23-32,23-47

LATCH - REMOVAL, GLOVE BOX

.........23-52

LATCH - REMOVAL, UNDER SEAT

STORAGE BIN

.......................23-80

LATCH RELEASE CABLE/HANDLE

ASSEMBLY - INSTALLATION

............23-47

LATCH RELEASE CABLE/HANDLE

ASSEMBLY - REMOVAL

................23-47

18 INDEXDR

Description Group-Page Description Group-Page Description Group-Page