heating & air conditioning DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1319 of 2627

(19) Disconnect throttle and speed control cables.

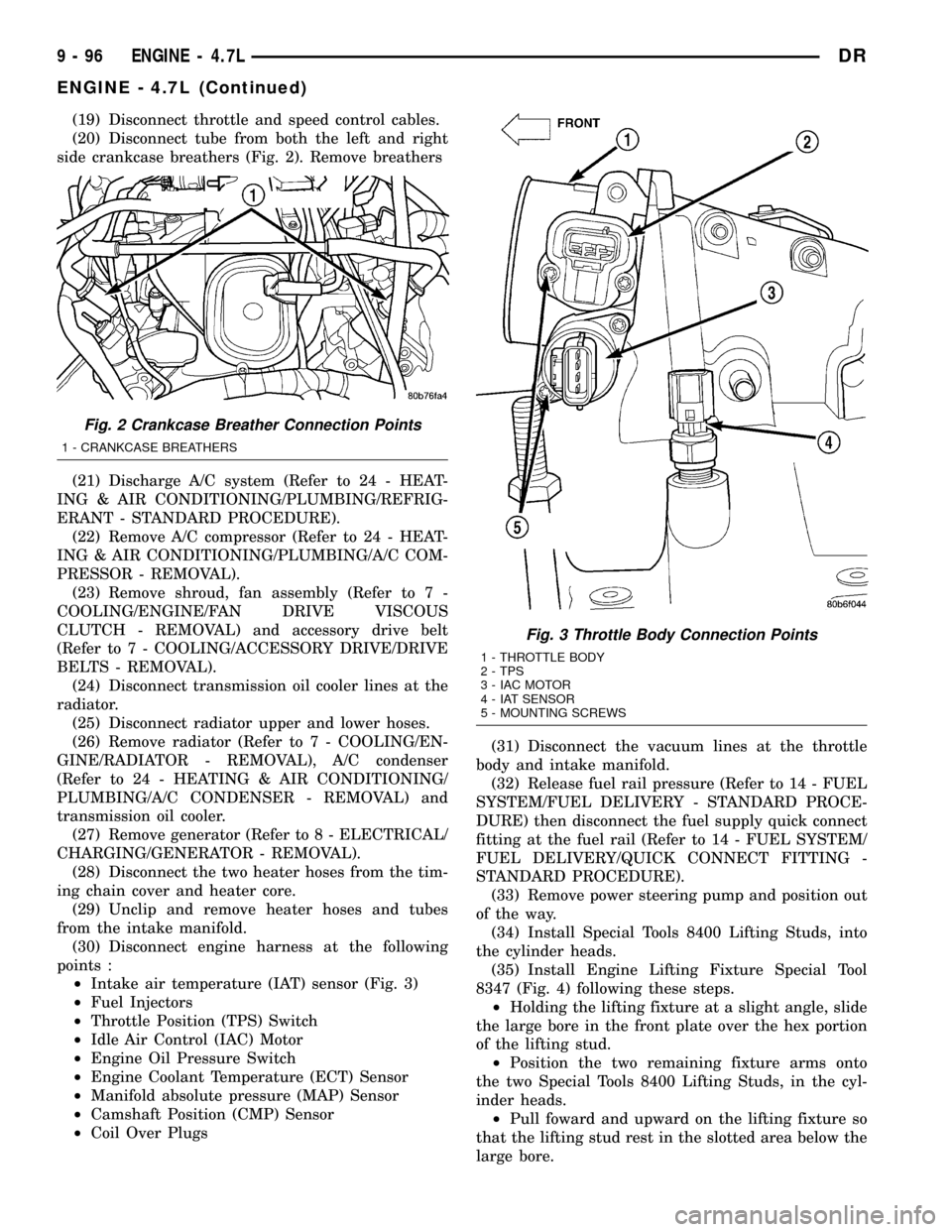

(20) Disconnect tube from both the left and right

side crankcase breathers (Fig. 2). Remove breathers

(21) Discharge A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/REFRIG-

ERANT - STANDARD PROCEDURE).

(22) Remove A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - REMOVAL).

(23) Remove shroud, fan assembly (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL) and accessory drive belt

(Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - REMOVAL).

(24) Disconnect transmission oil cooler lines at the

radiator.

(25) Disconnect radiator upper and lower hoses.

(26) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL), A/C condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL) and

transmission oil cooler.

(27) Remove generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).

(28) Disconnect the two heater hoses from the tim-

ing chain cover and heater core.

(29) Unclip and remove heater hoses and tubes

from the intake manifold.

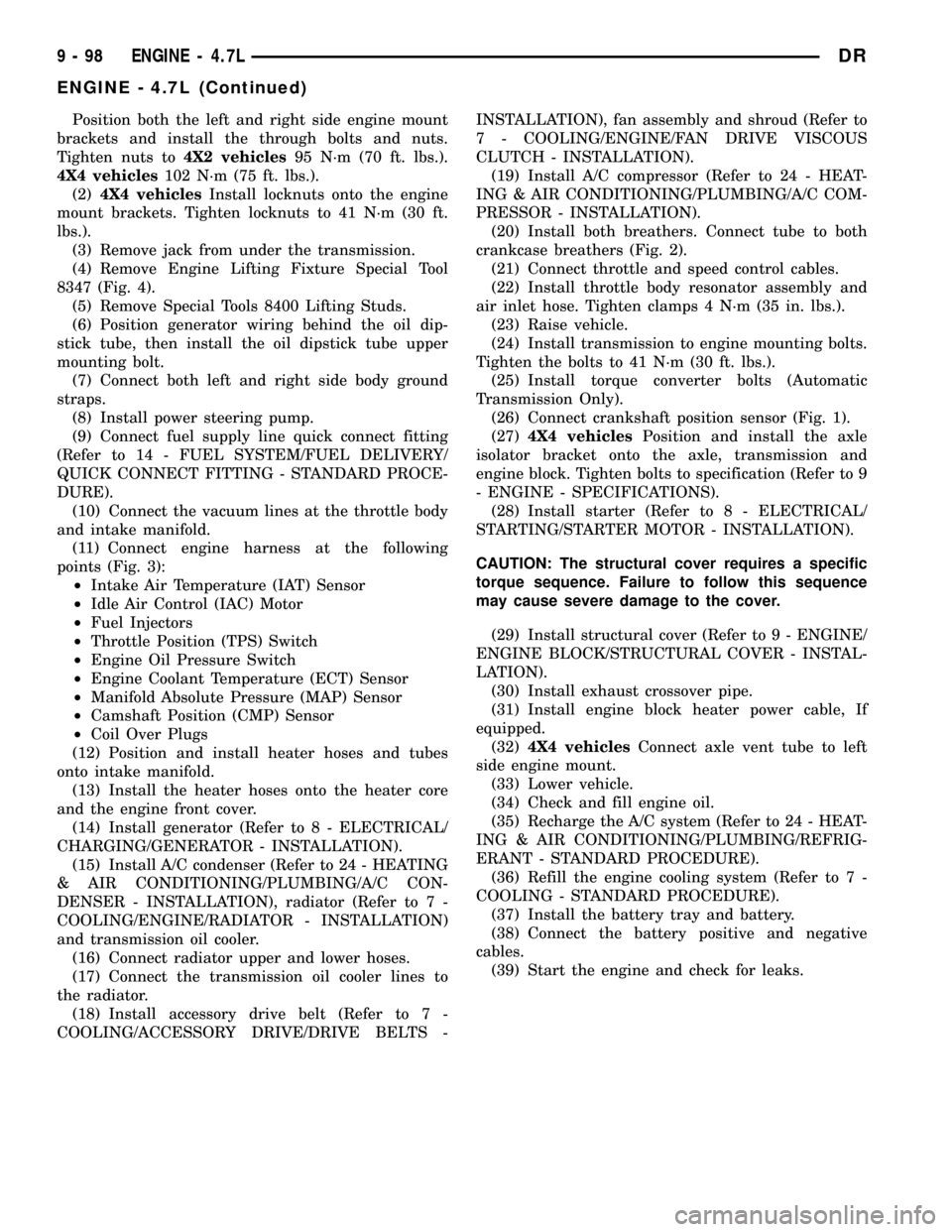

(30) Disconnect engine harness at the following

points :

²Intake air temperature (IAT) sensor (Fig. 3)

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold absolute pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs(31) Disconnect the vacuum lines at the throttle

body and intake manifold.

(32) Release fuel rail pressure (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - STANDARD PROCE-

DURE) then disconnect the fuel supply quick connect

fitting at the fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/QUICK CONNECT FITTING -

STANDARD PROCEDURE).

(33) Remove power steering pump and position out

of the way.

(34) Install Special Tools 8400 Lifting Studs, into

the cylinder heads.

(35) Install Engine Lifting Fixture Special Tool

8347 (Fig. 4) following these steps.

²Holding the lifting fixture at a slight angle, slide

the large bore in the front plate over the hex portion

of the lifting stud.

²Position the two remaining fixture arms onto

the two Special Tools 8400 Lifting Studs, in the cyl-

inder heads.

²Pull foward and upward on the lifting fixture so

that the lifting stud rest in the slotted area below the

large bore.

Fig. 2 Crankcase Breather Connection Points

1 - CRANKCASE BREATHERS

Fig. 3 Throttle Body Connection Points

1 - THROTTLE BODY

2 - TPS

3 - IAC MOTOR

4 - IAT SENSOR

5 - MOUNTING SCREWS

9 - 96 ENGINE - 4.7LDR

ENGINE - 4.7L (Continued)

Page 1321 of 2627

Position both the left and right side engine mount

brackets and install the through bolts and nuts.

Tighten nuts to4X2 vehicles95 N´m (70 ft. lbs.).

4X4 vehicles102 N´m (75 ft. lbs.).

(2)4X4 vehiclesInstall locknuts onto the engine

mount brackets. Tighten locknuts to 41 N´m (30 ft.

lbs.).

(3) Remove jack from under the transmission.

(4) Remove Engine Lifting Fixture Special Tool

8347 (Fig. 4).

(5) Remove Special Tools 8400 Lifting Studs.

(6) Position generator wiring behind the oil dip-

stick tube, then install the oil dipstick tube upper

mounting bolt.

(7) Connect both left and right side body ground

straps.

(8) Install power steering pump.

(9) Connect fuel supply line quick connect fitting

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

QUICK CONNECT FITTING - STANDARD PROCE-

DURE).

(10) Connect the vacuum lines at the throttle body

and intake manifold.

(11) Connect engine harness at the following

points (Fig. 3):

²Intake Air Temperature (IAT) Sensor

²Idle Air Control (IAC) Motor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

(12) Position and install heater hoses and tubes

onto intake manifold.

(13) Install the heater hoses onto the heater core

and the engine front cover.

(14) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

(15) Install A/C condenser (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/A/C CON-

DENSER - INSTALLATION), radiator (Refer to 7 -

COOLING/ENGINE/RADIATOR - INSTALLATION)

and transmission oil cooler.

(16) Connect radiator upper and lower hoses.

(17) Connect the transmission oil cooler lines to

the radiator.

(18) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -INSTALLATION), fan assembly and shroud (Refer to

7 - COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - INSTALLATION).

(19) Install A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - INSTALLATION).

(20) Install both breathers. Connect tube to both

crankcase breathers (Fig. 2).

(21) Connect throttle and speed control cables.

(22) Install throttle body resonator assembly and

air inlet hose. Tighten clamps 4 N´m (35 in. lbs.).

(23) Raise vehicle.

(24) Install transmission to engine mounting bolts.

Tighten the bolts to 41 N´m (30 ft. lbs.).

(25) Install torque converter bolts (Automatic

Transmission Only).

(26) Connect crankshaft position sensor (Fig. 1).

(27)4X4 vehiclesPosition and install the axle

isolator bracket onto the axle, transmission and

engine block. Tighten bolts to specification (Refer to 9

- ENGINE - SPECIFICATIONS).

(28) Install starter (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - INSTALLATION).

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

(29) Install structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION).

(30) Install exhaust crossover pipe.

(31) Install engine block heater power cable, If

equipped.

(32)4X4 vehiclesConnect axle vent tube to left

side engine mount.

(33) Lower vehicle.

(34) Check and fill engine oil.

(35) Recharge the A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/REFRIG-

ERANT - STANDARD PROCEDURE).

(36) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(37) Install the battery tray and battery.

(38) Connect the battery positive and negative

cables.

(39) Start the engine and check for leaks.

9 - 98 ENGINE - 4.7LDR

ENGINE - 4.7L (Continued)

Page 1414 of 2627

(6) Remove the viscous fan/drive (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - REMOVAL).

(7) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(8) Remove the upper crossmember and top core

support.

NOTE: It is not necessary to drain A/C system for

engine removal.

(9) Remove the A/C compressor with the lines

attached. Secure compressor out of the way.

(10) Remove generator assembly (Refer to 8 -

ELECTRICAL/CHARGING/GENERATOR -

REMOVAL).

(11) Remove the intake manifold and IAFM as an

assembly(Refer to 9 - ENGINE/MANIFOLDS/IN-

TAKE MANIFOLD - REMOVAL).

(12) Disconnect the heater hoses.

NOTE: It is not necessary to disconnect P/S hoses

from pump, for P/S pump removal.

(13) Remove the power steering pump and set

aside.

(14) Disconnect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(15) Raise and support the vehicle on a hoist and

drain the engine oil.

(16) Remove engine front mount thru-bolt nuts.

(17) Remove right side axle retaining bolts.

(18) Disconnect the transmission oil cooler lines

from their retainers at the oil pan bolts.

(19) Disconnect exhaust pipe at manifolds.

(20) Disconnect the starter wires. Remove starter

motor (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - REMOVAL).

(21) Remove the structural dust cover and trans-

mission inspection cover,(Refer to 9 - ENGINE/EN-

GINE BLOCK/STRUCTURAL COVER - REMOVAL).

(22) Remove drive plate to converter bolts (Auto-

matic transmission equipped vehicles).

(23) Remove transmission bell housing to engine

block bolts.

(24) Lower the vehicle.

(25) Install engine lift fixture, special tool # 8984.

(26) Separate engine from transmission, remove

engine from vehicle, and install engine assembly on a

repair stand.

INSTALLATION

(1) Install engine lift fixture Special tool # 8984.

(2) Position the engine in the engine compartment.

(3) Lower engine into compartment and align

engine with transmission:²Manual Transmission: Align clutch disc assem-

bly (if disturbed). Install transmission input shaft

into clutch disc while mating engine and transmis-

sion surfaces. Install two transmission to engine

block mounting bolts finger tight.

²Automatic Transmission: Mate engine and trans-

mission and install two transmission to engine block

mounting bolts finger tight.

(4) Position the thru-bolt into the support cushion

brackets.

(5) Lower engine assembly until engine mount

through bolts rest in mount perches.

(6) Install remaining transmission to engine block

mounting bolts and tighten.

(7) Tighten engine mount through bolts.

(8) Install drive plate to torque converter bolts.

(Automatic transmission models)

(9) Install the structural dust cover and transmis-

sion dust cover,(Refer to 9 - ENGINE/ENGINE

BLOCK/STRUCTURAL COVER - INSTALLATION).

(10) Install the starter and connect the starter

wires (Refer to 8 - ELECTRICAL/STARTING/

STARTER MOTOR - INSTALLATION).

(11) Install exhaust pipe to manifold.

(12) Lower the vehicle.

(13) Remove engine lift fixture, special tool # 8984.

(14) Connect the fuel supply line (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/QUICK CON-

NECT FITTING - STANDARD PROCEDURE).

(15) Reinstall the power steering pump.

(16) Connect the heater hoses.

(17) Install the intake manifold.

(18) Using a new gasket, install throttle body

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE BODY - INSTALLATION).

(19) Install the generator and wire connections

(Refer to 8 - ELECTRICAL/CHARGING/GENERA-

TOR - INSTALLATION).

(20) Install a/c compressor and lines (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION).

(21) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(22) Install upper radiator support crossmember.

(23) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(24) Connect the radiator lower hose.

(25) Connect the transmission oil cooler lines to

the radiator.

(26) Install the fan shroud.

(27) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(28) Connect the radiator upper hose.

(29) Install the washer bottle.

(30) Connect the transmission cooler lines.

DRENGINE - 5.7L 9 - 191

ENGINE - 5.7L (Continued)

Page 1491 of 2627

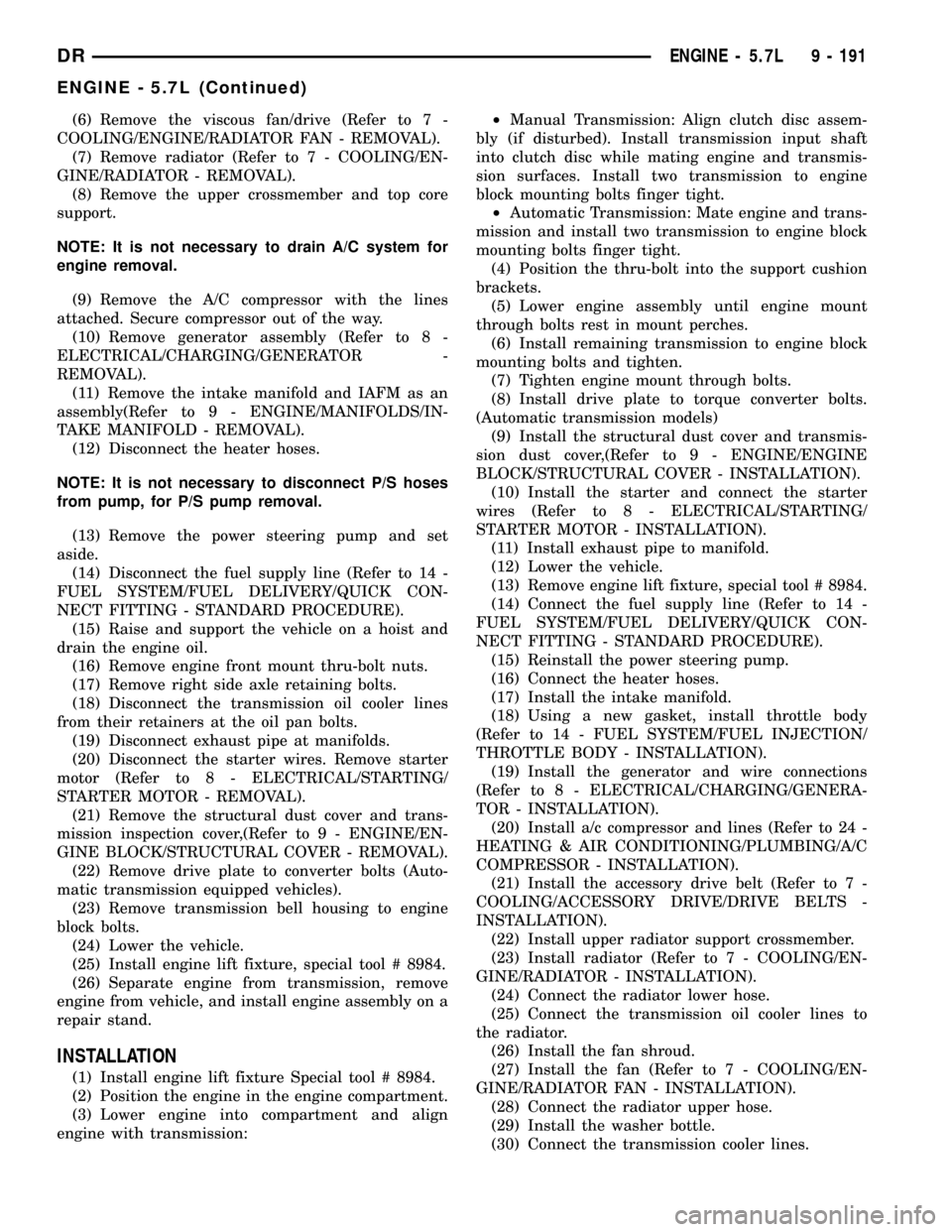

Inspect the cylinder bores for damage or excessive

wear.

Measure the cylinder bores (Fig. 54). If the cylin-

der bores exceed the limit, (Refer to 9 - ENGINE/EN-

GINE BLOCK - STANDARD PROCEDURE).

BORE SPECIFICATIONS

BORE DIAMETER

Min. 102.000 mm (4.0157 in.)

Max. 102.116 mm (4.0203 in.)

OUT OF ROUNDNESS

Max. 0.038 mm (0.0015 in.)

TAPER

Max. 0.076 mm (.003 in.)

Inspect the camshaft bores for scoring or excessive

wear.

Measure the camshaft bores (Refer to 9 - ENGINE

- SPECIFICATIONS).

If a bore exceeds the limit, (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - STANDARD PROCEDURE).

Inspect the tappet bores for scoring or excessive

wear.

Measure tappet bore from bottom of block. Mini-

mum tappet bore diameter 16.000 mm (0.0630 in.).

Maximum tappet bore 16.055 mm. (0.632 in.).

If out of limits, replace the cylinder block.

CAMSHAFT & BEARINGS (IN

BLOCK)

REMOVAL

REMOVALÐCAMSHAFT BEARINGS

NOTE: Measure the diameter of each bore. If the

camshaft bore for the first or rear cam bushing is

worn beyond the limit, install a new service bush-

ing. Inspect the rest of the camshaft bores for dam-

age or excessive wear.If the bores without a

bushing are worn beyond the limit, the engine must

be removed for machining and installation of ser-

vice bushings. If badly worn, replace the cylinder

block.

(1) Remove the camshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

(2) Remove the bushing from the No.1 bore and

No.7 using a universal cam bushing tool.

(3) Mark the cylinder block so you can align the oil

hole in the cylinder block with the oil hole in the

bushing.

REMOVAL - CAMSHAFT

(1) Disconnect both battery negative cables.

(2) Recover A/C refrigerant (if A/C equipped) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE).

(3) Raise vehicle on hoist.

(4) Drain engine coolant into container suitable for

re-use (Refer to 7 - COOLING - STANDARD PROCE-

DURE).

(5) Lower vehicle.

(6) Remove radiator upper hose.

(7) Remove viscous fan/drive assembly and fan

shroud (Refer to 7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL).

(8) Disconnect the coolant recovery bottle hose

from the radiator filler neck.

(9) Disconnect lower radiator hose from radiator

outlet.

(10)Automatic Transmission models:Discon-

nect transmission oil cooler lines from front of radia-

tor using Special Tool 6931 (unless equipped with

finger-release disconnect).

(11) Remove radiator mounting screws and lift

radiator out of engine compartment.

(12) Remove upper radiator support panel.

(13) If A/C equipped, disconnect A/C condenser

refrigerant lines.

(14) Disconnect charge air cooler piping from the

cooler inlet and outlet.

Fig. 54 Cylinder Bore Diameter

9 - 268 ENGINE 5.9L DIESELDR

ENGINE BLOCK (Continued)

Page 1542 of 2627

CAUTION: Do not apply more than 138 kPa (20 psi)

air pressure to the charge air cooler system, sever

damage to the charge air cooler system may occur.

(3) Connect a regulated air supply to air fitting on

Tool 9022 Adapter. Set air pressure to a Maximum of

138 kPa (20 psi).

(4) Using soapy water check the rubber sleeves,

charge air cooler and intake manifold for leaks.

REMOVAL

WARNING: IF THE ENGINE WAS JUST TURNED

OFF, THE AIR INTAKE SYSTEM TUBES MAY BE

HOT.

(1) Disconnect the battery negative cables.

(2) Discharge the A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE) and remove the A/C condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL) (if A/C

equipped).

(3) Remove the transmission auxiliary cooler

(Refer to 7 - COOLING/TRANSMISSION/TRANS

COOLER - REMOVAL).

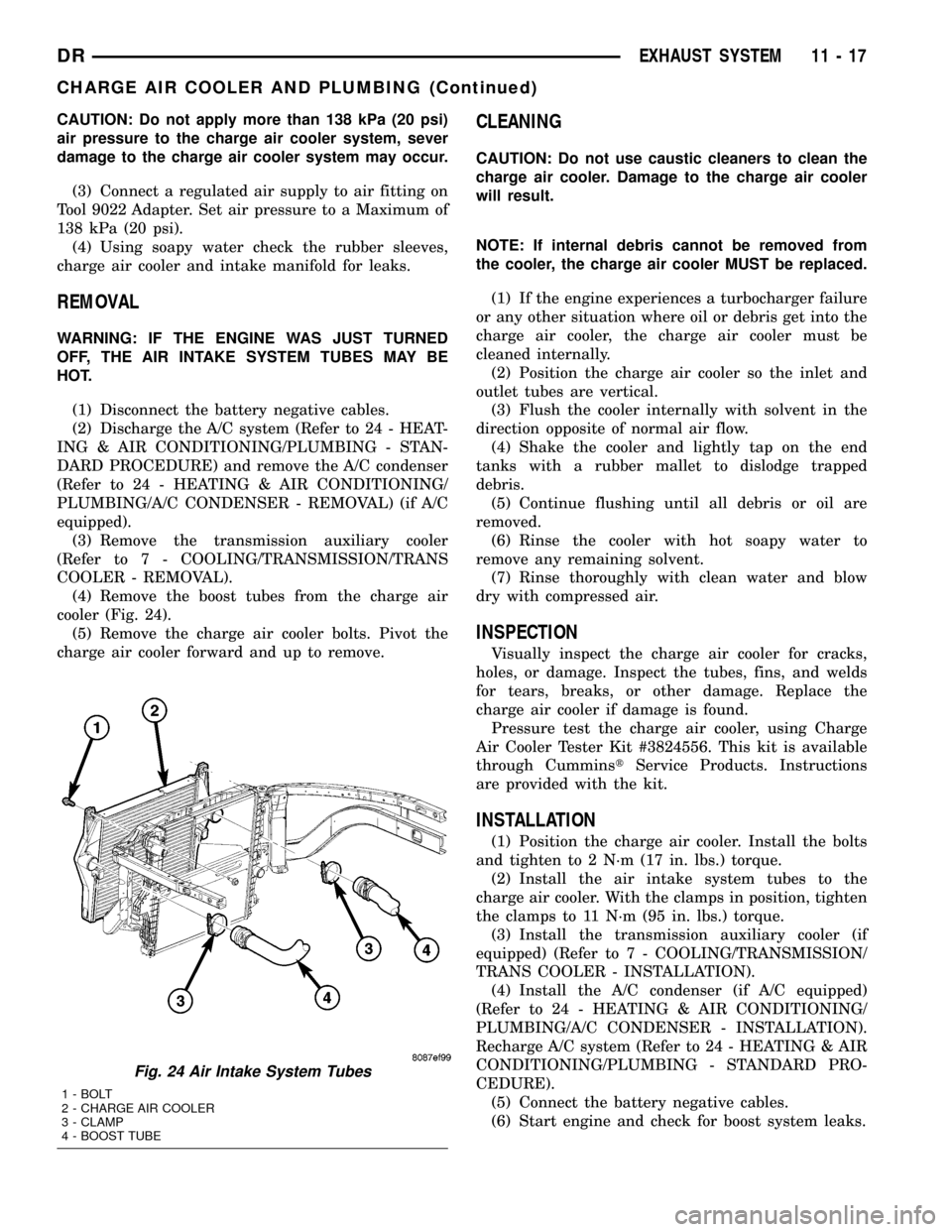

(4) Remove the boost tubes from the charge air

cooler (Fig. 24).

(5) Remove the charge air cooler bolts. Pivot the

charge air cooler forward and up to remove.

CLEANING

CAUTION: Do not use caustic cleaners to clean the

charge air cooler. Damage to the charge air cooler

will result.

NOTE: If internal debris cannot be removed from

the cooler, the charge air cooler MUST be replaced.

(1) If the engine experiences a turbocharger failure

or any other situation where oil or debris get into the

charge air cooler, the charge air cooler must be

cleaned internally.

(2) Position the charge air cooler so the inlet and

outlet tubes are vertical.

(3) Flush the cooler internally with solvent in the

direction opposite of normal air flow.

(4) Shake the cooler and lightly tap on the end

tanks with a rubber mallet to dislodge trapped

debris.

(5) Continue flushing until all debris or oil are

removed.

(6) Rinse the cooler with hot soapy water to

remove any remaining solvent.

(7) Rinse thoroughly with clean water and blow

dry with compressed air.

INSPECTION

Visually inspect the charge air cooler for cracks,

holes, or damage. Inspect the tubes, fins, and welds

for tears, breaks, or other damage. Replace the

charge air cooler if damage is found.

Pressure test the charge air cooler, using Charge

Air Cooler Tester Kit #3824556. This kit is available

through CumminstService Products. Instructions

are provided with the kit.

INSTALLATION

(1) Position the charge air cooler. Install the bolts

and tighten to 2 N´m (17 in. lbs.) torque.

(2) Install the air intake system tubes to the

charge air cooler. With the clamps in position, tighten

the clamps to 11 N´m (95 in. lbs.) torque.

(3) Install the transmission auxiliary cooler (if

equipped) (Refer to 7 - COOLING/TRANSMISSION/

TRANS COOLER - INSTALLATION).

(4) Install the A/C condenser (if A/C equipped)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - INSTALLATION).

Recharge A/C system (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE).

(5) Connect the battery negative cables.

(6) Start engine and check for boost system leaks.

Fig. 24 Air Intake System Tubes

1 - BOLT

2 - CHARGE AIR COOLER

3 - CLAMP

4 - BOOST TUBE

DREXHAUST SYSTEM 11 - 17

CHARGE AIR COOLER AND PLUMBING (Continued)

Page 1554 of 2627

STANDARD PROCEDURE - HYDROFORM

FENDER RAIL REPAIR

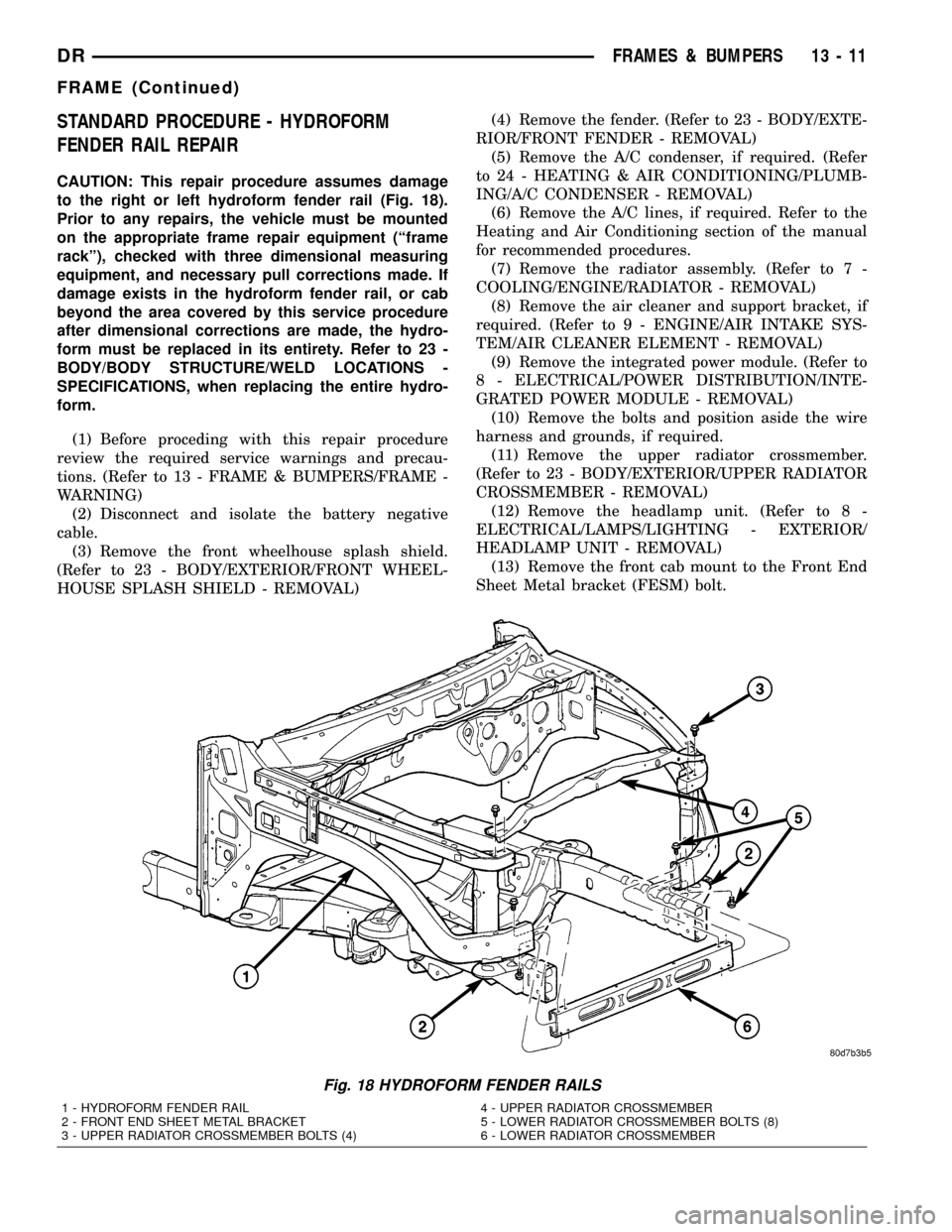

CAUTION: This repair procedure assumes damage

to the right or left hydroform fender rail (Fig. 18).

Prior to any repairs, the vehicle must be mounted

on the appropriate frame repair equipment (ªframe

rackº), checked with three dimensional measuring

equipment, and necessary pull corrections made. If

damage exists in the hydroform fender rail, or cab

beyond the area covered by this service procedure

after dimensional corrections are made, the hydro-

form must be replaced in its entirety. Refer to 23 -

BODY/BODY STRUCTURE/WELD LOCATIONS -

SPECIFICATIONS, when replacing the entire hydro-

form.

(1) Before proceding with this repair procedure

review the required service warnings and precau-

tions. (Refer to 13 - FRAME & BUMPERS/FRAME -

WARNING)

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the front wheelhouse splash shield.

(Refer to 23 - BODY/EXTERIOR/FRONT WHEEL-

HOUSE SPLASH SHIELD - REMOVAL)(4) Remove the fender. (Refer to 23 - BODY/EXTE-

RIOR/FRONT FENDER - REMOVAL)

(5) Remove the A/C condenser, if required. (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/A/C CONDENSER - REMOVAL)

(6) Remove the A/C lines, if required. Refer to the

Heating and Air Conditioning section of the manual

for recommended procedures.

(7) Remove the radiator assembly. (Refer to 7 -

COOLING/ENGINE/RADIATOR - REMOVAL)

(8) Remove the air cleaner and support bracket, if

required. (Refer to 9 - ENGINE/AIR INTAKE SYS-

TEM/AIR CLEANER ELEMENT - REMOVAL)

(9) Remove the integrated power module. (Refer to

8 - ELECTRICAL/POWER DISTRIBUTION/INTE-

GRATED POWER MODULE - REMOVAL)

(10) Remove the bolts and position aside the wire

harness and grounds, if required.

(11) Remove the upper radiator crossmember.

(Refer to 23 - BODY/EXTERIOR/UPPER RADIATOR

CROSSMEMBER - REMOVAL)

(12) Remove the headlamp unit. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP UNIT - REMOVAL)

(13) Remove the front cab mount to the Front End

Sheet Metal bracket (FESM) bolt.

Fig. 18 HYDROFORM FENDER RAILS

1 - HYDROFORM FENDER RAIL

2 - FRONT END SHEET METAL BRACKET

3 - UPPER RADIATOR CROSSMEMBER BOLTS (4)4 - UPPER RADIATOR CROSSMEMBER

5 - LOWER RADIATOR CROSSMEMBER BOLTS (8)

6 - LOWER RADIATOR CROSSMEMBER

DRFRAMES & BUMPERS 13 - 11

FRAME (Continued)

Page 1555 of 2627

(14) Remove the bolts attaching the lower radiator

crossmember to the hydroform fender rail. (Fig. 18)

CAUTION: Do not use any flame or plasma cutting

equipment to cut the frame in this procedure. The

inaccurate and high temperatures achieved during

flame or plasma cutting will change the metal char-

acteristics and may weaken the frame and/or repair

location.

(15) Using a reciprocating saw or equivalent, cut

the fender rail and shotgun at a straight and square

section of the hydroform and remove.

(16) Smooth and square the cut edges.

(17) Using the damaged structure as a reference

cut the service part at the same location as the first

cut. Smooth and square the cut edges.

NOTE: The repair structure should butt up to the

remaining structure and provide the same overall

vehicle geometry.

(18) Fabricate 51 mm (2.0 in.) long repair inserts

using scrap from the old structure or the replacement

part. It will be necessary to split the inserts on each

of their four sides to fit into the hydroform.

(19) Remove any paint or e-coat from the inserts

and also to the interior and exterior of the hydro-

forms.

(20) Cut plug weld holes as described below.

²On the upper rail, cut one 13 mm (0.5 in.) hole

on each side of the rail, 25 mm (1.0 in.) from the butt

joint of the tubes.

²On the lower rail, cut one 13 mm (0.5 in.) hole

on the top and bottom sides of the rail 25 mm (1.0

in.) from the butt joint of the tube.

²On the lower rail, cut two 13 mm (0.5 in.) holes

on the inner and outer sides of the rail 25 mm (1.0

in.) from the butt joint of the tube.

CAUTION: Shield the surrounding area and compo-

nents from exposure to the welding spatter and

heat.

(21) Install the insert 1º into the replacement part

and tack into place with a weld. (Refer to 13 -

FRAME & BUMPERS/FRAME - SPECIFICATIONS -

WELDING)

(22) Insert the service part into place and using

the appropriate measuring equipment, verify the

front end sheet metal bracket's location in all three

(X,Y, and Z) planes of space. (Fig. 19)

(23) Complete all 360É plug welds.

NOTE: Before the final welding, use three dimen-

sional measuring equipment to ensure the part is in

the correct location. Verify that tap plate extrusion

at the bottom of the vertical post lines up with theisolator and hole in the frame perch mount. Also

ensure the lower radiator closure tube is bolted into

the forward shotgun ends.

(24) Complete welding by making a 360É butt weld

around the fender rails.

(25) Metal finish the exposed welds on the hydro-

forms.

(26) Dress the welded area and apply corrosion

resistant coatings inside and out.

(a) Inside the rail, inject a creeping wax based

rust inhibitor compound to the inside of the hydro-

forms ensuring 100% coverage including the mat-

ing face between the fender rail sections and insert

such that corrosion protection is restored in the

internal cavity.

(b) Apply a durable top coat to the outside of the

repair area.

(27) Install the front cab mount bolt if previously

removed and tighten to 81 N´m (60 ft. lbs.).

(28) Install the lower radiator crossmember bolts

and tighten to 28 N´m (21 ft. lbs.).

(29) Install the headlamp unit. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - INSTALLATION)

(30) Install the upper radiator crossmember. (Refer

to 23 - BODY/EXTERIOR/UPPER RADIATOR

CROSSMEMBER - INSTALLATION)

(31) Install the wire harness and ground if previ-

ously removed and install the bolts.

(32) Install the integrated power module, if previ-

ously removed. (Refer to 8 - ELECTRICAL/POWER

DISTRIBUTION/INTEGRATED POWER MODULE -

INSTALLATION)

(33) Install the air cleaner bracket and air cleaner,

if previously removed. (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER ELEMENT -

INSTALLATION)

(34) Install the radiator assembly. (Refer to 7 -

COOLING/ENGINE/RADIATOR - INSTALLATION)

(35) Install the A/C lines, if previously removed.

Refer to the Heating and Air Conditioning section of

the manual for the recommended procedures.

(36) Install the A/C condenser, if previously

removed. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C CONDENSER - INSTAL-

LATION)

(37) Install the fender. (Refer to 23 - BODY/EXTE-

RIOR/FRONT FENDER - INSTALLATION)

(38) Install the front wheelhouse splash shield.

(Refer to 23 - BODY/EXTERIOR/FRONT WHEEL-

HOUSE SPLASH SHIELD - INSTALLATION)

(39) Reconnect the battery ground.

13 - 12 FRAMES & BUMPERSDR

FRAME (Continued)

Page 2488 of 2627

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION

DESCRIPTION - ENGINE COOLING

SYSTEM REQUIREMENTS...............1

DESCRIPTION - HEATER AND AIR

CONDITIONER........................1

OPERATION - HEATER AND AIR

CONDITIONER........................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE.......................3DIAGNOSIS AND TESTING - HEATER

PERFORMANCE TEST..................6

SPECIFICATIONS - A/C SYSTEM............7

CONTROLS.............................9

DISTRIBUTION..........................26

PLUMBING.............................41

HEATING & AIR

CONDITIONING

DESCRIPTION

DESCRIPTION - ENGINE COOLING SYSTEM

REQUIREMENTS

To maintain the performance level of the heating,

ventilation and air conditioning (HVAC) system, the

engine cooling system must be properly maintained.

The use of a bug screen is not recommended. Any

obstructions in front of the radiator or A/C condenser

will reduce the performance of the A/C and engine

cooling systems.

The engine cooling system includes the radiator,

thermostat, radiator hoses and the engine coolant

pump. Refer to Cooling for more information before

opening or attempting any service to the engine cool-

ing system.

DESCRIPTION - HEATER AND AIR

CONDITIONER

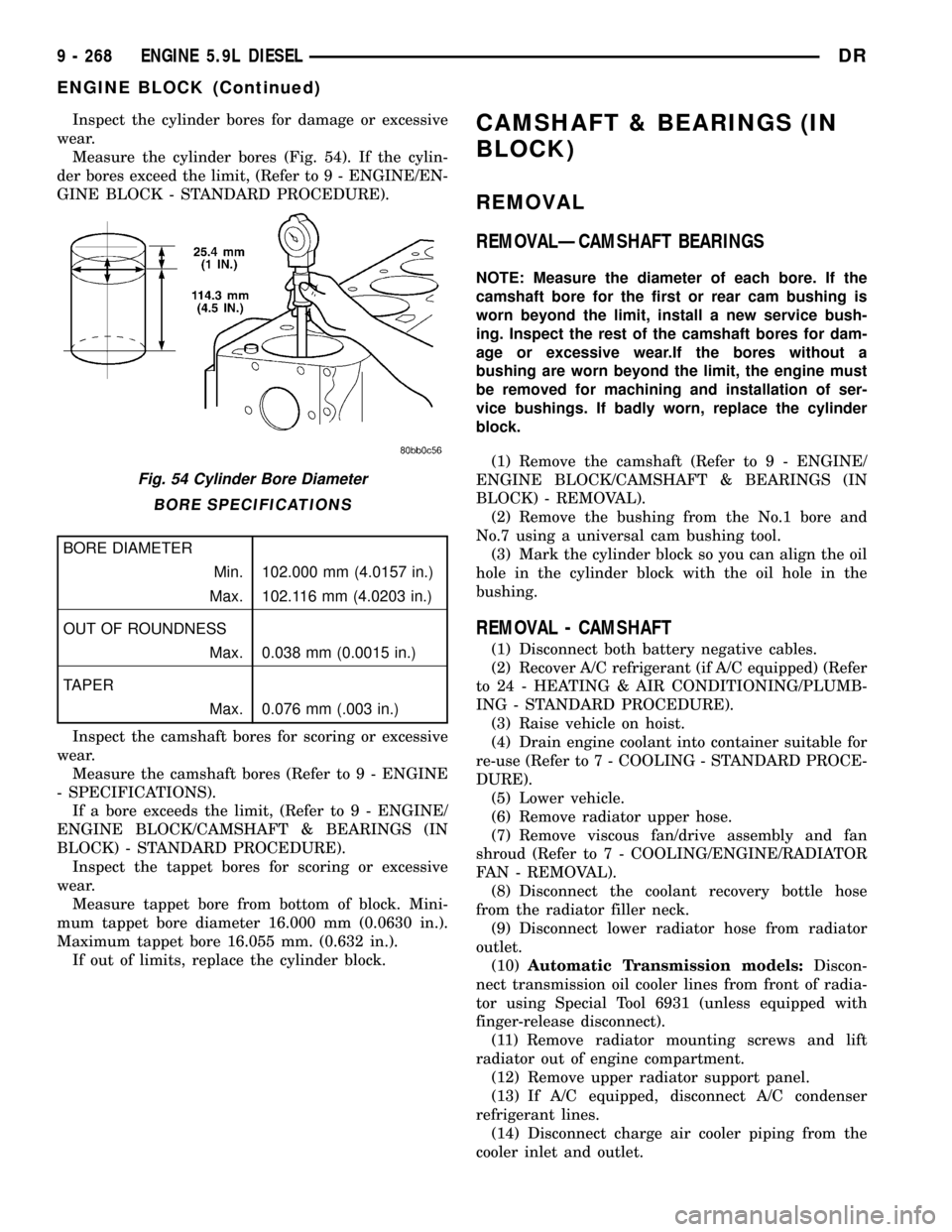

A manually controlled single zone type heating-air

conditioning system or a manually controlled dual

zone type heating-air conditioning system is available

on this model.

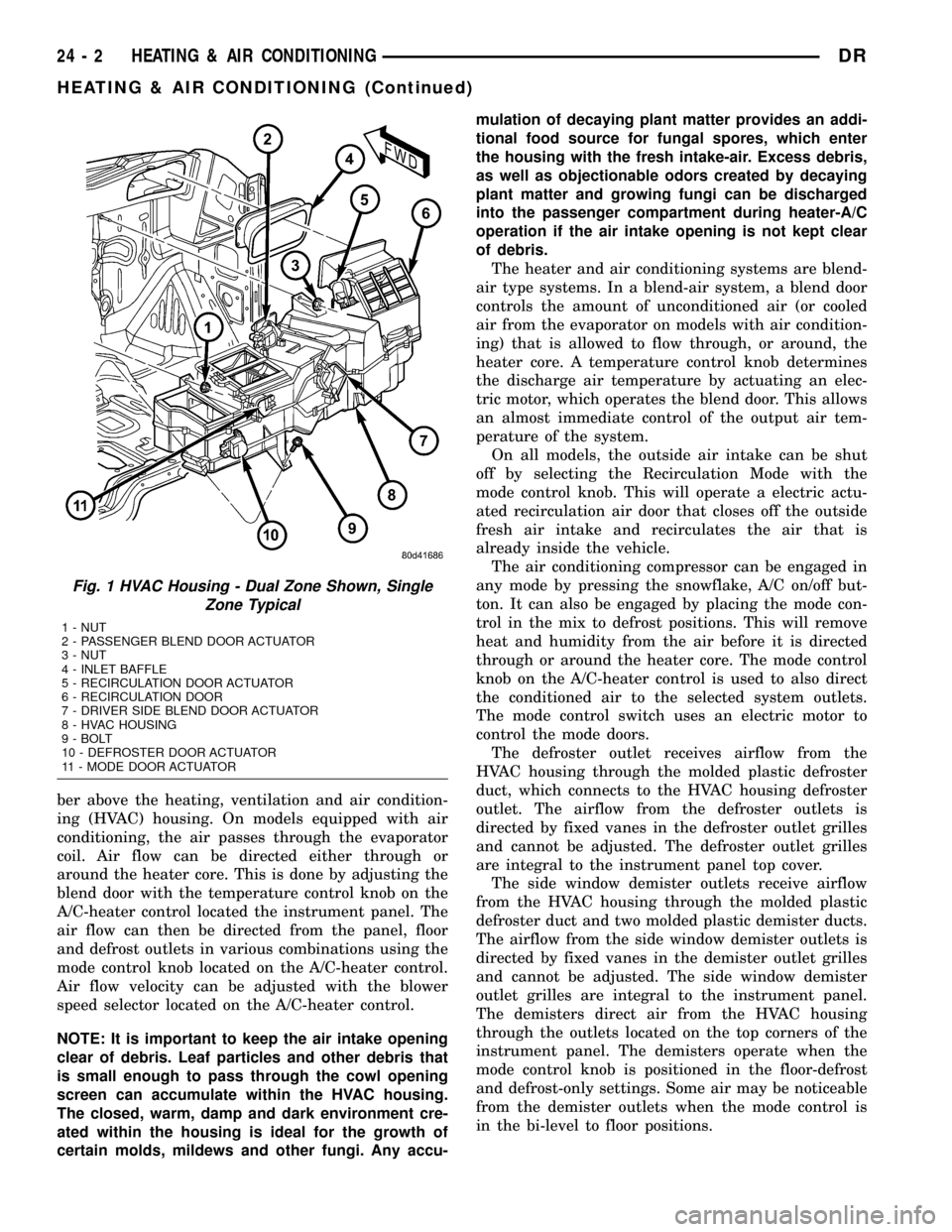

All vehicles are equipped with a common heater,

ventilation and air conditioning (HVAC) housing (Fig.

1). The system combines air conditioning, heating,

and ventilating capabilities in a single unit housing

mounted within the passenger compartment under

the instrument panel. The HVAC housing includes:

²Blower motor

²Blower motor resistor block²Heater core

²Evaporator coil

²Blend door and actuator

²Defrost door and actuator

²Mode door and actuator

²Recirculation door and actuator

Based upon the system and mode selected, condi-

tioned air can exit the HVAC housing through one or

a combination of the three main housing outlets:

defrost, panel or floor. The defrost outlet is located on

the top of the housing, the panel outlet is located on

the face of the housing and the floor outlet is located

on the bottom of the housing. Once the conditioned

air exits the unit housing, it is further directed

through molded plastic ducts to the various outlets in

the vehicle interior. These outlets and their locations

are as follows:

²Defroster Outlet- A single large defroster out-

let is located in the center of the instrument panel

top cover, near the base of the windshield.

²Side Window Demister Outlets- There are

two side window demister outlets, one is located at

each outboard end of the instrument panel top cover,

near the belt line at the A-pillars.

²Panel Outlets- There are four panel outlets in

the instrument panel, one located near each outboard

end of the instrument panel facing the rear of the

vehicle and two located near the top of the instru-

ment panel center bezel.

²Front Floor Outlets- There are two front floor

outlets, one located above each side of the floor panel

center tunnel near the dash panel.

OPERATION - HEATER AND AIR CONDITIONER

The heating and air conditioning systems pulls

outside (ambient) air through the cowl opening at the

base of the windshield, then into the plenum cham-

DRHEATING & AIR CONDITIONING 24 - 1

Page 2489 of 2627

ber above the heating, ventilation and air condition-

ing (HVAC) housing. On models equipped with air

conditioning, the air passes through the evaporator

coil. Air flow can be directed either through or

around the heater core. This is done by adjusting the

blend door with the temperature control knob on the

A/C-heater control located the instrument panel. The

air flow can then be directed from the panel, floor

and defrost outlets in various combinations using the

mode control knob located on the A/C-heater control.

Air flow velocity can be adjusted with the blower

speed selector located on the A/C-heater control.

NOTE: It is important to keep the air intake opening

clear of debris. Leaf particles and other debris that

is small enough to pass through the cowl opening

screen can accumulate within the HVAC housing.

The closed, warm, damp and dark environment cre-

ated within the housing is ideal for the growth of

certain molds, mildews and other fungi. Any accu-mulation of decaying plant matter provides an addi-

tional food source for fungal spores, which enter

the housing with the fresh intake-air. Excess debris,

as well as objectionable odors created by decaying

plant matter and growing fungi can be discharged

into the passenger compartment during heater-A/C

operation if the air intake opening is not kept clear

of debris.

The heater and air conditioning systems are blend-

air type systems. In a blend-air system, a blend door

controls the amount of unconditioned air (or cooled

air from the evaporator on models with air condition-

ing) that is allowed to flow through, or around, the

heater core. A temperature control knob determines

the discharge air temperature by actuating an elec-

tric motor, which operates the blend door. This allows

an almost immediate control of the output air tem-

perature of the system.

On all models, the outside air intake can be shut

off by selecting the Recirculation Mode with the

mode control knob. This will operate a electric actu-

ated recirculation air door that closes off the outside

fresh air intake and recirculates the air that is

already inside the vehicle.

The air conditioning compressor can be engaged in

any mode by pressing the snowflake, A/C on/off but-

ton. It can also be engaged by placing the mode con-

trol in the mix to defrost positions. This will remove

heat and humidity from the air before it is directed

through or around the heater core. The mode control

knob on the A/C-heater control is used to also direct

the conditioned air to the selected system outlets.

The mode control switch uses an electric motor to

control the mode doors.

The defroster outlet receives airflow from the

HVAC housing through the molded plastic defroster

duct, which connects to the HVAC housing defroster

outlet. The airflow from the defroster outlets is

directed by fixed vanes in the defroster outlet grilles

and cannot be adjusted. The defroster outlet grilles

are integral to the instrument panel top cover.

The side window demister outlets receive airflow

from the HVAC housing through the molded plastic

defroster duct and two molded plastic demister ducts.

The airflow from the side window demister outlets is

directed by fixed vanes in the demister outlet grilles

and cannot be adjusted. The side window demister

outlet grilles are integral to the instrument panel.

The demisters direct air from the HVAC housing

through the outlets located on the top corners of the

instrument panel. The demisters operate when the

mode control knob is positioned in the floor-defrost

and defrost-only settings. Some air may be noticeable

from the demister outlets when the mode control is

in the bi-level to floor positions.

Fig. 1 HVAC Housing - Dual Zone Shown, Single

Zone Typical

1 - NUT

2 - PASSENGER BLEND DOOR ACTUATOR

3 - NUT

4 - INLET BAFFLE

5 - RECIRCULATION DOOR ACTUATOR

6 - RECIRCULATION DOOR

7 - DRIVER SIDE BLEND DOOR ACTUATOR

8 - HVAC HOUSING

9 - BOLT

10 - DEFROSTER DOOR ACTUATOR

11 - MODE DOOR ACTUATOR

24 - 2 HEATING & AIR CONDITIONINGDR

HEATING & AIR CONDITIONING (Continued)

Page 2490 of 2627

The panel outlets receive airflow from the HVAC

housing through a molded plastic main panel duct,

center panel duct and two end panel ducts. The two

end panel ducts direct airflow to the left and right

instrument panel outlets, while the center panel duct

directs airflow to the two center panel outlets. Each

of these outlets can be individually adjusted to direct

the flow of air.

The floor outlets receive airflow from the HVAC

housing through the floor distribution duct. The front

floor outlets are integral to the molded plastic floor

distribution duct, which is secured to the bottom of

the housing. The floor outlets cannot be adjusted.

The air conditioner for all models is designed for

the use of non-CFC, R-134a refrigerant. The air con-

ditioning system has an evaporator to cool and dehu-

midify the incoming air prior to blending it with the

heated air. This air conditioning system uses a fixed

orifice tube in the liquid line near the condenser out-

let tube to meter refrigerant flow to the evaporator

coil. To maintain minimum evaporator temperature

and prevent evaporator freezing, a evaporator tem-

perature sensor is used. The JTEC control module is

programmed to respond to the evaporator tempera-

ture sensor input by cycling the air conditioning com-

pressor clutch as necessary to optimize air

conditioning system performance and to protect the

system from evaporator freezing.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to remove

heat and humidity from the air entering the passen-

ger compartment. The evaporator, located in the

HVAC housing, is cooled to temperatures near the

freezing point. As warm damp air passes over the

fins in the evaporator, moisture in the air condenses

to water, dehumidifying the air. Condensation on the

evaporator fins reduces the evaporators ability to

absorb heat. During periods of high heat and humid-

ity, an air conditioning system will be less effective.

With the instrument control set to Recirculation

mode, only air from the passenger compartment

passes through the evaporator. As the passenger com-

partment air dehumidifies, A/C performance levels

rise.

Humidity has an important bearing on the temper-

ature of the air delivered to the interior of the vehi-

cle. It is important to understand the effect that

humidity has on the performance of the air condition-

ing system. When humidity is high, the evaporator

has to perform a double duty. It must lower the air

temperature, and it must lower the temperature ofthe moisture in the air that condenses on the evapo-

rator fins. Condensing the moisture in the air trans-

fers heat energy into the evaporator fins and tubing.

This reduces the amount of heat the evaporator can

absorb from the air. High humidity greatly reduces

the ability of the evaporator to lower the temperature

of the air.

However, evaporator capacity used to reduce the

amount of moisture in the air is not wasted. Wring-

ing some of the moisture out of the air entering the

vehicle adds to the comfort of the passengers.

Although, an owner may expect too much from their

air conditioning system on humid days. A perfor-

mance test is the best way to determine whether the

system is performing up to standard. This test also

provides valuable clues as to the possible cause of

trouble with the air conditioning system.

PERFORMANCE TEST PROCEDURE

Review Safety Warnings and Cautions before per-

forming this procedure (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - WARNING) and

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - CAUTION). Air temperature in test

room and on vehicle must be 21É C (70É F) minimum

for this test.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) Connect a tachometer and a manifold gauge set

or A/C recycling/charging station.

(2) Set the A/C-heater mode control in the Recircu-

lation Mode position, the temperature control knob in

the full cool position, and the blower motor switch to

the highest speed position.

(3) Start the engine and hold at 1,000 rpm with

the A/C compressor clutch engaged.

(4) The engine should be warmed up to operating

temperature with the doors closed and windows

open.

(5) Insert a thermometer in the driver side center

panel A/C-heater outlet and operate the engine for

five minutes.

(6) The compressor clutch may cycle, depending

upon the ambient temperature and humidity.

(7) With the compressor clutch engaged, record the

discharge air temperature and the compressor dis-

charge pressure.

(8) If the discharge air temperature fails to meet

the specifications in the A/C Performance Tempera-

ture chart, refer to the Pressure Diagnosis chart.

DRHEATING & AIR CONDITIONING 24 - 3

HEATING & AIR CONDITIONING (Continued)