height adjustment DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 141 of 2627

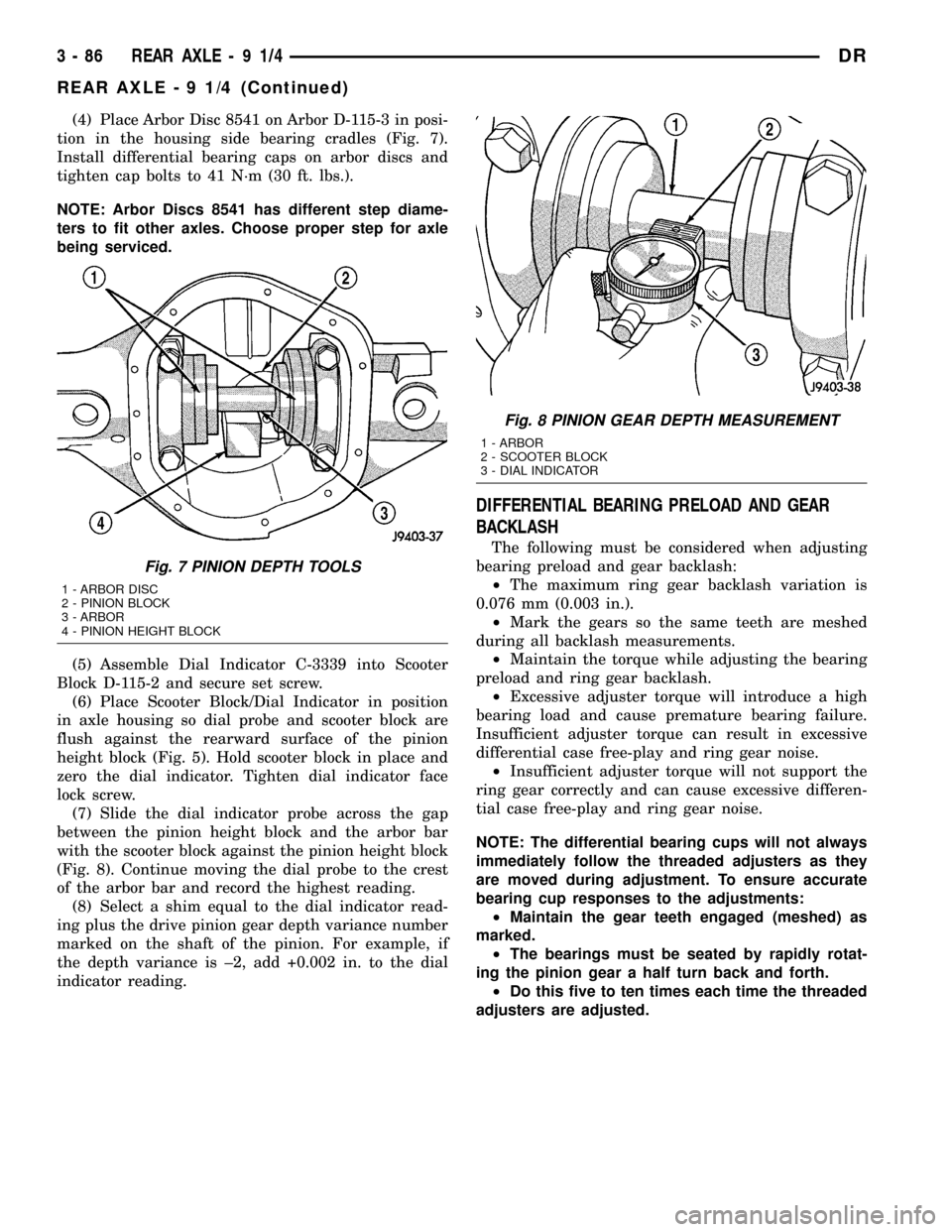

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 9). Move scooter

block till dial indicator crests the arbor, then record

the highest reading.

(9) Select a shim equal to the dial indicator read-

ing.

(10) Install the select shim between the rear pin-

ion bearing and the pinion gear head.

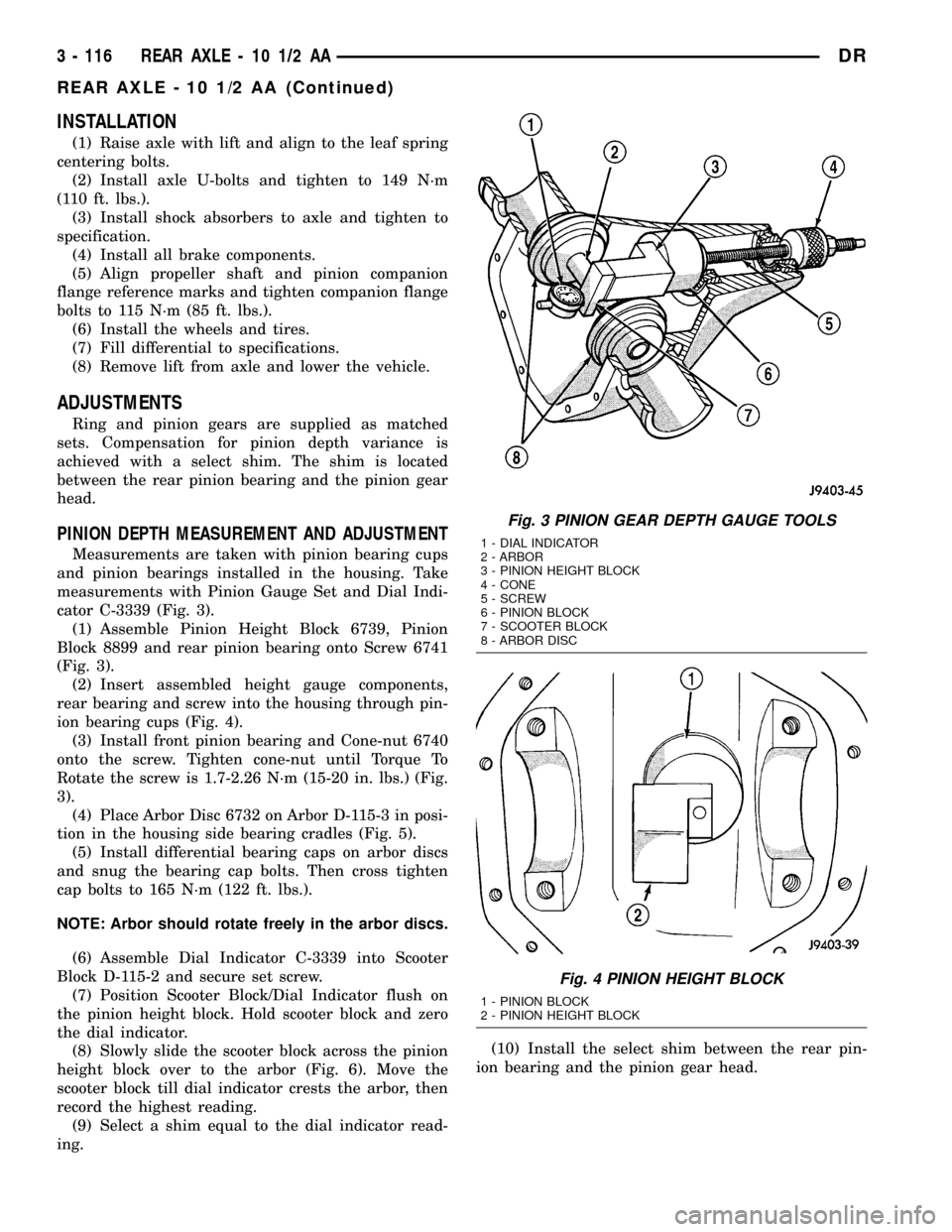

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 10).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(6) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(7) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(8) Rotate the pinion several times to seat the dif-

ferential bearings.

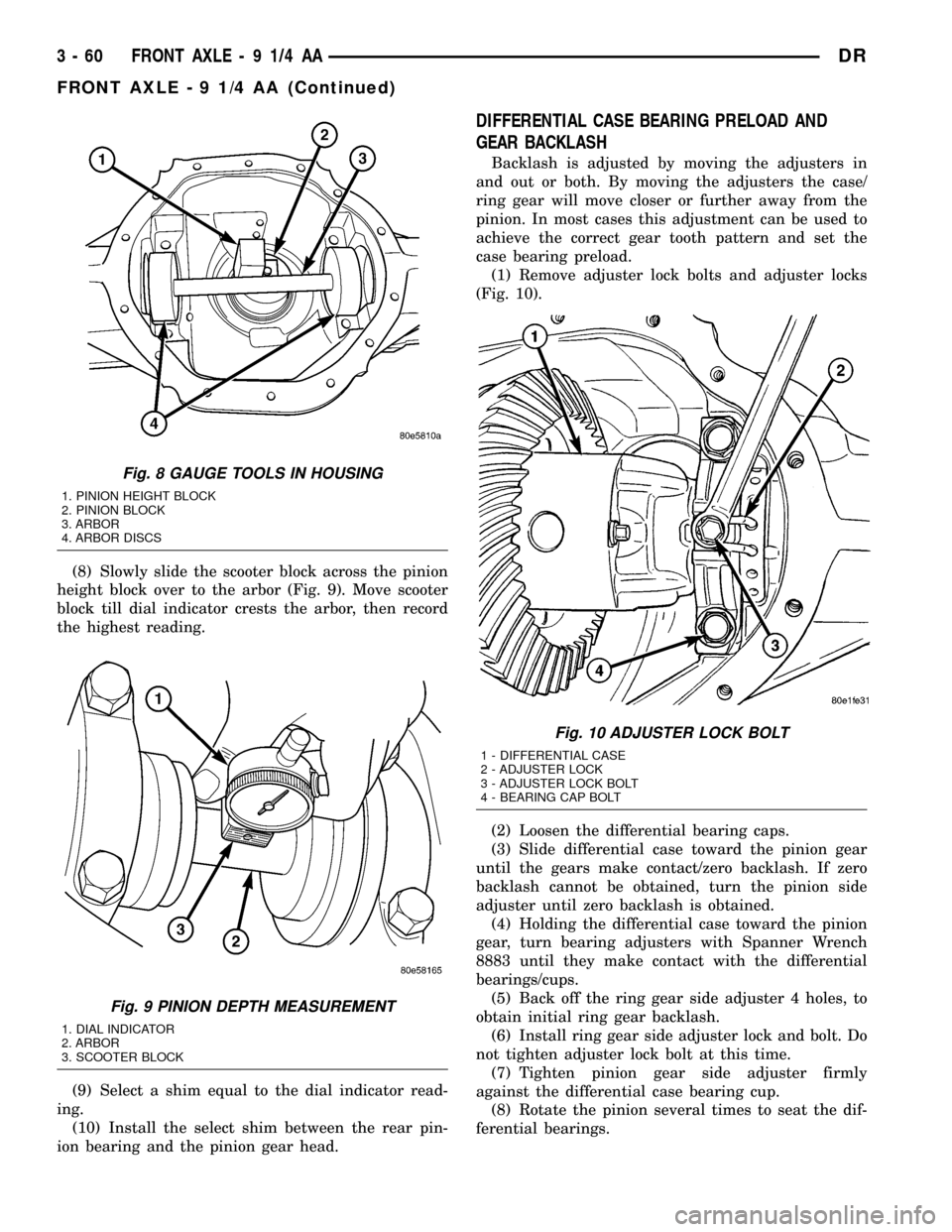

Fig. 8 GAUGE TOOLS IN HOUSING

1. PINION HEIGHT BLOCK

2. PINION BLOCK

3. ARBOR

4. ARBOR DISCS

Fig. 9 PINION DEPTH MEASUREMENT

1. DIAL INDICATOR

2. ARBOR

3. SCOOTER BLOCK

Fig. 10 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

3 - 60 FRONT AXLE - 9 1/4 AADR

FRONT AXLE - 9 1/4 AA (Continued)

Page 167 of 2627

(4) Place Arbor Disc 8541 on Arbor D-115-3 in posi-

tion in the housing side bearing cradles (Fig. 7).

Install differential bearing caps on arbor discs and

tighten cap bolts to 41 N´m (30 ft. lbs.).

NOTE: Arbor Discs 8541 has different step diame-

ters to fit other axles. Choose proper step for axle

being serviced.

(5) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(6) Place Scooter Block/Dial Indicator in position

in axle housing so dial probe and scooter block are

flush against the rearward surface of the pinion

height block (Fig. 5). Hold scooter block in place and

zero the dial indicator. Tighten dial indicator face

lock screw.

(7) Slide the dial indicator probe across the gap

between the pinion height block and the arbor bar

with the scooter block against the pinion height block

(Fig. 8). Continue moving the dial probe to the crest

of the arbor bar and record the highest reading.

(8) Select a shim equal to the dial indicator read-

ing plus the drive pinion gear depth variance number

marked on the shaft of the pinion. For example, if

the depth variance is ±2, add +0.002 in. to the dial

indicator reading.

DIFFERENTIAL BEARING PRELOAD AND GEAR

BACKLASH

The following must be considered when adjusting

bearing preload and gear backlash:

²The maximum ring gear backlash variation is

0.076 mm (0.003 in.).

²Mark the gears so the same teeth are meshed

during all backlash measurements.

²Maintain the torque while adjusting the bearing

preload and ring gear backlash.

²Excessive adjuster torque will introduce a high

bearing load and cause premature bearing failure.

Insufficient adjuster torque can result in excessive

differential case free-play and ring gear noise.

²Insufficient adjuster torque will not support the

ring gear correctly and can cause excessive differen-

tial case free-play and ring gear noise.

NOTE: The differential bearing cups will not always

immediately follow the threaded adjusters as they

are moved during adjustment. To ensure accurate

bearing cup responses to the adjustments:

²Maintain the gear teeth engaged (meshed) as

marked.

²The bearings must be seated by rapidly rotat-

ing the pinion gear a half turn back and forth.

²Do this five to ten times each time the threaded

adjusters are adjusted.

Fig. 7 PINION DEPTH TOOLS

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 8 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

3 - 86 REAR AXLE-91/4DR

REAR AXLE - 9 1/4 (Continued)

Page 197 of 2627

INSTALLATION

(1) Raise axle with lift and align to the leaf spring

centering bolts.

(2) Install axle U-bolts and tighten to 149 N´m

(110 ft. lbs.).

(3) Install shock absorbers to axle and tighten to

specification.

(4) Install all brake components.

(5) Align propeller shaft and pinion companion

flange reference marks and tighten companion flange

bolts to 115 N´m (85 ft. lbs.).

(6) Install the wheels and tires.

(7) Fill differential to specifications.

(8) Remove lift from axle and lower the vehicle.

ADJUSTMENTS

Ring and pinion gears are supplied as matched

sets. Compensation for pinion depth variance is

achieved with a select shim. The shim is located

between the rear pinion bearing and the pinion gear

head.

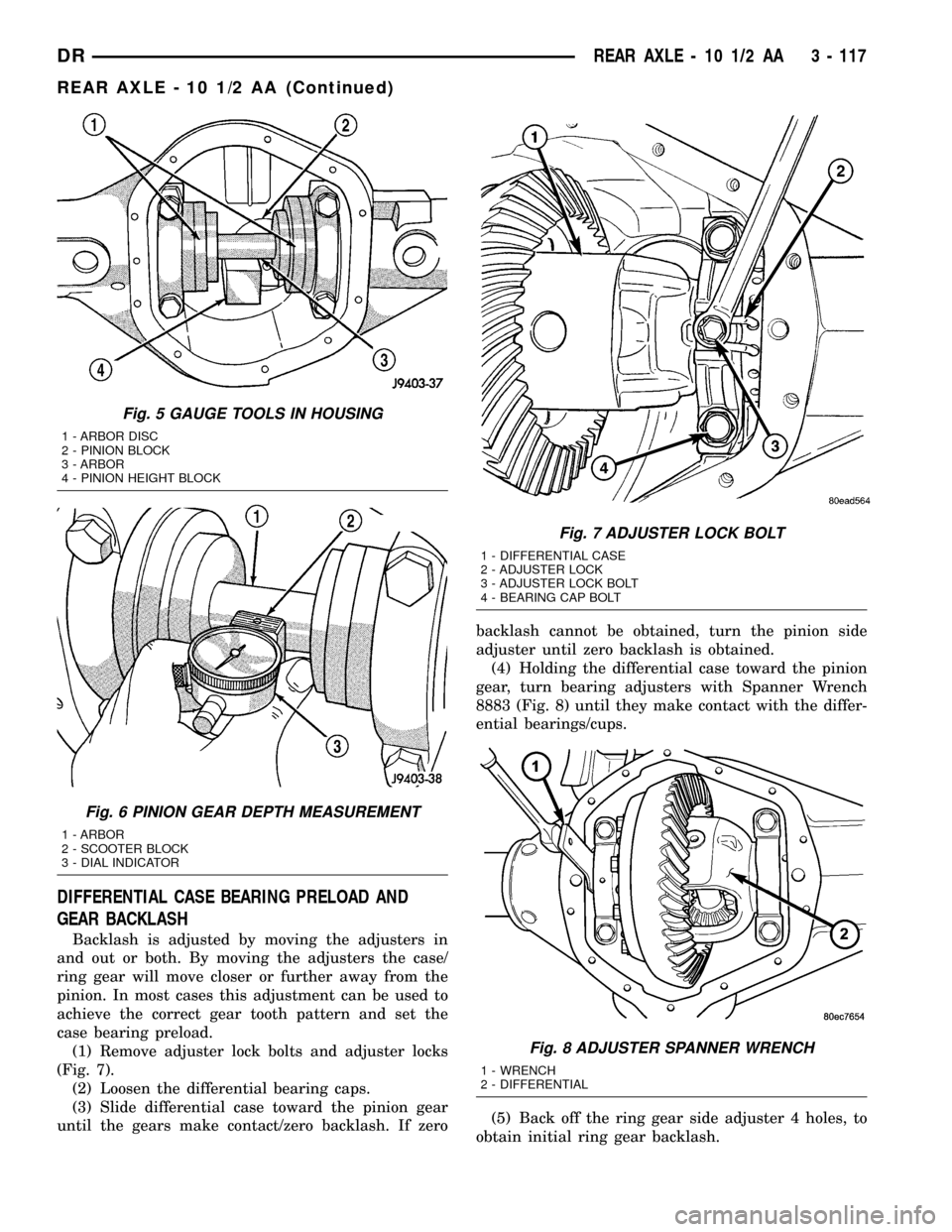

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

cator C-3339 (Fig. 3).

(1) Assemble Pinion Height Block 6739, Pinion

Block 8899 and rear pinion bearing onto Screw 6741

(Fig. 3).

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through pin-

ion bearing cups (Fig. 4).

(3) Install front pinion bearing and Cone-nut 6740

onto the screw. Tighten cone-nut until Torque To

Rotate the screw is 1.7-2.26 N´m (15-20 in. lbs.) (Fig.

3).

(4) Place Arbor Disc 6732 on Arbor D-115-3 in posi-

tion in the housing side bearing cradles (Fig. 5).

(5) Install differential bearing caps on arbor discs

and snug the bearing cap bolts. Then cross tighten

cap bolts to 165 N´m (122 ft. lbs.).

NOTE: Arbor should rotate freely in the arbor discs.

(6) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(7) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 6). Move the

scooter block till dial indicator crests the arbor, then

record the highest reading.

(9) Select a shim equal to the dial indicator read-

ing.(10) Install the select shim between the rear pin-

ion bearing and the pinion gear head.

Fig. 3 PINION GEAR DEPTH GAUGE TOOLS

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

Fig. 4 PINION HEIGHT BLOCK

1 - PINION BLOCK

2 - PINION HEIGHT BLOCK

3 - 116 REAR AXLE - 10 1/2 AADR

REAR AXLE - 10 1/2 AA (Continued)

Page 198 of 2627

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 7).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zerobacklash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 (Fig. 8) until they make contact with the differ-

ential bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

Fig. 5 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 6 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 7 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 8 ADJUSTER SPANNER WRENCH

1 - WRENCH

2 - DIFFERENTIAL

DRREAR AXLE - 10 1/2 AA 3 - 117

REAR AXLE - 10 1/2 AA (Continued)

Page 225 of 2627

INSTALLATION

(1) Raise axle with lift and align to the leaf spring

centering bolts.

(2) Install axle U-bolts and tighten to 149 N´m

(110 ft. lbs.).

(3) Install shock absorbers to axle and tighten to

specification.

(4) Install all brake components.

(5) Align propeller shaft and pinion companion

flange reference marks and tighten companion flange

bolts to 115 N´m (85 ft. lbs.).

(6) Install the wheels and tires.

(7) Fill differential to specifications.

(8) Remove lift from axle and lower the vehicle.

ADJUSTMENTS

Ring and pinion gears are supplied as matched

sets. Compensation for pinion depth variance is

achieved with a select shim, located between the rear

pinion bearing and pinion gear head.

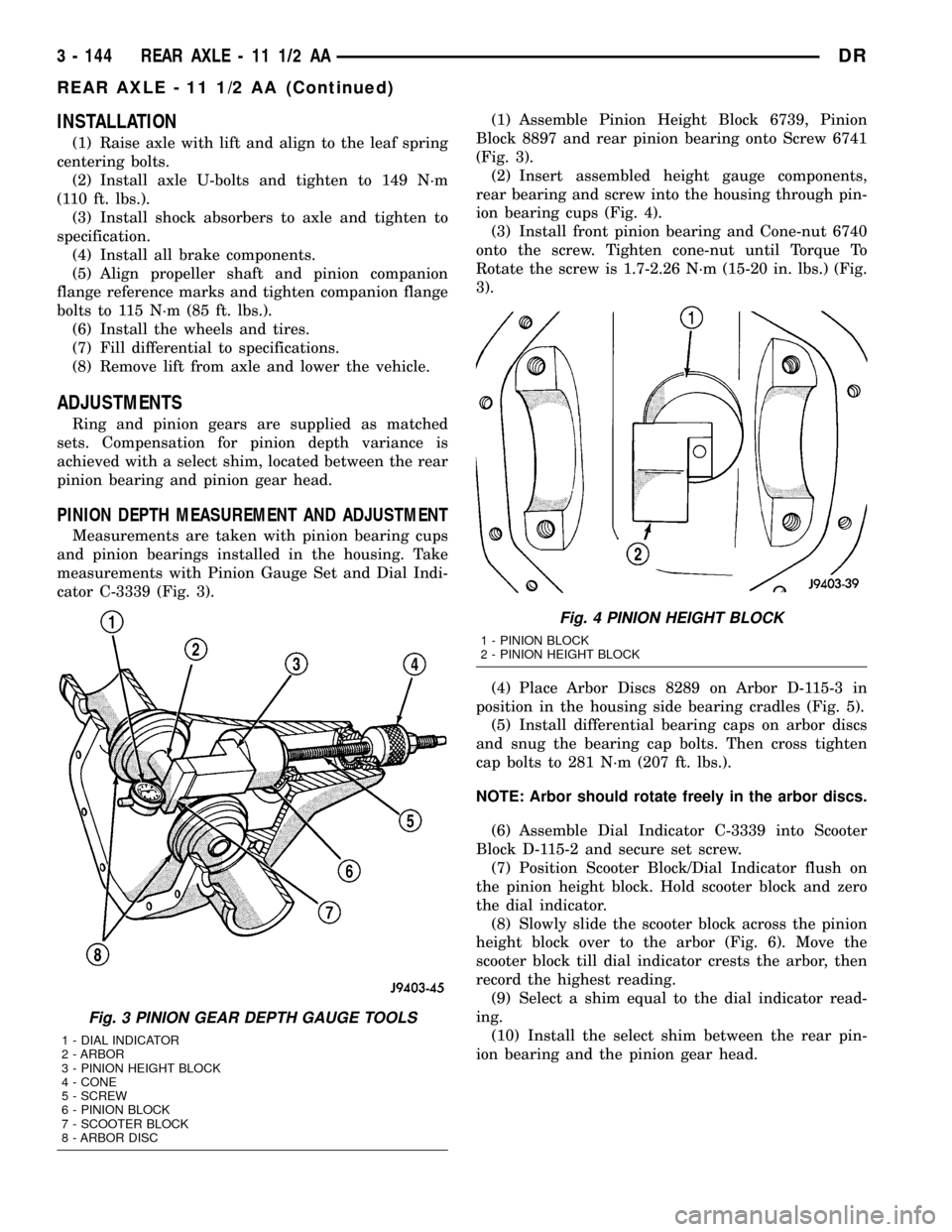

PINION DEPTH MEASUREMENT AND ADJUSTMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

cator C-3339 (Fig. 3).(1) Assemble Pinion Height Block 6739, Pinion

Block 8897 and rear pinion bearing onto Screw 6741

(Fig. 3).

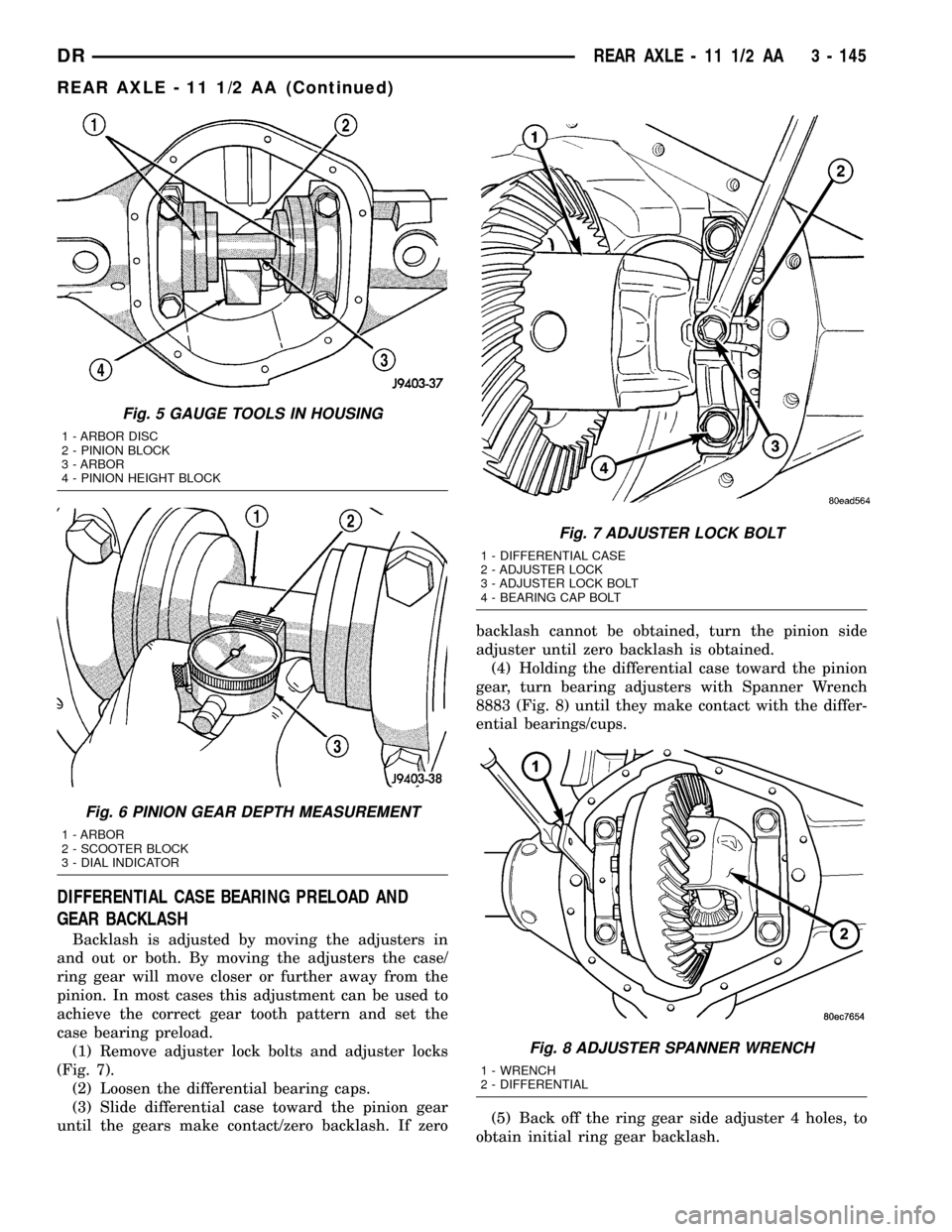

(2) Insert assembled height gauge components,

rear bearing and screw into the housing through pin-

ion bearing cups (Fig. 4).

(3) Install front pinion bearing and Cone-nut 6740

onto the screw. Tighten cone-nut until Torque To

Rotate the screw is 1.7-2.26 N´m (15-20 in. lbs.) (Fig.

3).

(4) Place Arbor Discs 8289 on Arbor D-115-3 in

position in the housing side bearing cradles (Fig. 5).

(5) Install differential bearing caps on arbor discs

and snug the bearing cap bolts. Then cross tighten

cap bolts to 281 N´m (207 ft. lbs.).

NOTE: Arbor should rotate freely in the arbor discs.

(6) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(7) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 6). Move the

scooter block till dial indicator crests the arbor, then

record the highest reading.

(9) Select a shim equal to the dial indicator read-

ing.

(10) Install the select shim between the rear pin-

ion bearing and the pinion gear head.

Fig. 3 PINION GEAR DEPTH GAUGE TOOLS

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

Fig. 4 PINION HEIGHT BLOCK

1 - PINION BLOCK

2 - PINION HEIGHT BLOCK

3 - 144 REAR AXLE - 11 1/2 AADR

REAR AXLE - 11 1/2 AA (Continued)

Page 226 of 2627

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 7).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zerobacklash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 (Fig. 8) until they make contact with the differ-

ential bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

Fig. 5 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 6 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 7 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 8 ADJUSTER SPANNER WRENCH

1 - WRENCH

2 - DIFFERENTIAL

DRREAR AXLE - 11 1/2 AA 3 - 145

REAR AXLE - 11 1/2 AA (Continued)

Page 252 of 2627

normal and should not be mistaken for contam-

ination.

(a) If fluid level is abnormally low, look for evi-

dence of leaks at calipers, wheel cylinders, brake

lines, and master cylinder.

(b) If fluid appears contaminated, drain out a

sample to examine. System will have to be flushed

if fluid is separated into layers, or contains a sub-

stance other than brake fluid. The system seals

and cups will also have to be replaced after flush-

ing. Use clean brake fluid to flush the system.

(4) Check parking brake operation. Verify free

movement and full release of cables and pedal. Also

note if vehicle was being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for

being loose or for bind condition. Do not road test

until condition is corrected.

(6) Check booster vacuum check valve and hose.

(7) If components checked appear OK, road test

the vehicle.

ROAD TESTING

(1) If complaint involved low brake pedal, pump

pedal and note if it comes back up to normal height.

(2) Check brake pedal response with transmission

in Neutral and engine running. Pedal should remain

firm under constant foot pressure.

(3) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as low pedal, hard pedal, fade, pedal pulsa-

tion, pull, grab, drag, noise, etc.

(4) Attempt to stop the vehicle with the parking

brake only and note grab, drag, noise, etc.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak or

fluid contamination. The leak point could be at a

brake line, fitting, hose, or caliper/wheel cylinder. If

leakage is severe, fluid will be evident at or around

the leaking component.

Internal leakage (seal by-pass) in the master cylin-

der caused by worn or damaged piston cups, may

also be the problem cause.

An internal leak in the ABS or RWAL system may

also be the problem with no physical evidence.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up worn linings,

rotors, drums, or rear brakes out of adjustment are

the most likely causes. The proper course of action isto inspect and replace all worn component and make

the proper adjustments.

SPONGY PEDAL

A spongy pedal is most often caused by air in the

system. However, thin brake drums or substandard

brake lines and hoses can also cause a spongy pedal.

The proper course of action is to bleed the system,

and replace thin drums and substandard quality

brake hoses if suspected.

HARD PEDAL OR HIGH PEDAL EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster or check valve or a

vacuum hose could also be faulty.

PEDAL PULSATION

Pedal pulsation is caused by components that are

loose, or beyond tolerance limits.

The primary cause of pulsation are disc brake

rotors with excessive lateral runout or thickness vari-

ation, or out of round brake drums. Other causes are

loose wheel bearings or calipers and worn, damaged

tires.

NOTE: Some pedal pulsation may be felt during

ABS activation.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at one

wheel, all wheels, fronts only, or rears only.

Drag is a product of incomplete brake shoe release.

Drag can be minor or severe enough to overheat the

linings, rotors and drums.

Minor drag will usually cause slight surface char-

ring of the lining. It can also generate hard spots in

rotors and drums from the overheat-cool down pro-

cess. In most cases, the rotors, drums, wheels and

tires are quite warm to the touch after the vehicle is

stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors and

drums to the point of replacement. The wheels, tires

and brake components will be extremely hot. In

severe cases, the lining may generate smoke as it

chars from overheating.

Common causes of brake drag are:

²Seized or improperly adjusted parking brake

cables.

²Loose/worn wheel bearing.

²Seized caliper or wheel cylinder piston.

²Caliper binding on corroded bushings or rusted

slide surfaces.

²Loose caliper mounting.

DRBRAKES - BASE 5 - 3

BRAKES - BASE (Continued)

Page 1253 of 2627

TESTING VALVE SPRINGS

NOTE: Whenever the valves are removed from the

cylinder head it is recommended that the valve

springs be inspected and tested for reuse.

Inspect the valve springs for physical signs of wear or

damage. Turn table of tool C-647 until surface is in line

with the 40.12 mm (1.579 in.) mark on the threaded

stud and the zero mark on the front. Place spring over

the stud on the table and lift compressing lever to set

tone device. Pull on torque wrench until a Ping is

heard. Take reading on torque wrench at this instant.

Multiply this reading by two. This will give the spring

load at test length. Fractional measurements are indi-

cated on the table for finer adjustments. Refer to Spec-

ifications Section to obtain specified height and

allowable tensions. Replace any springs that do not

meet specifications (Fig. 19).

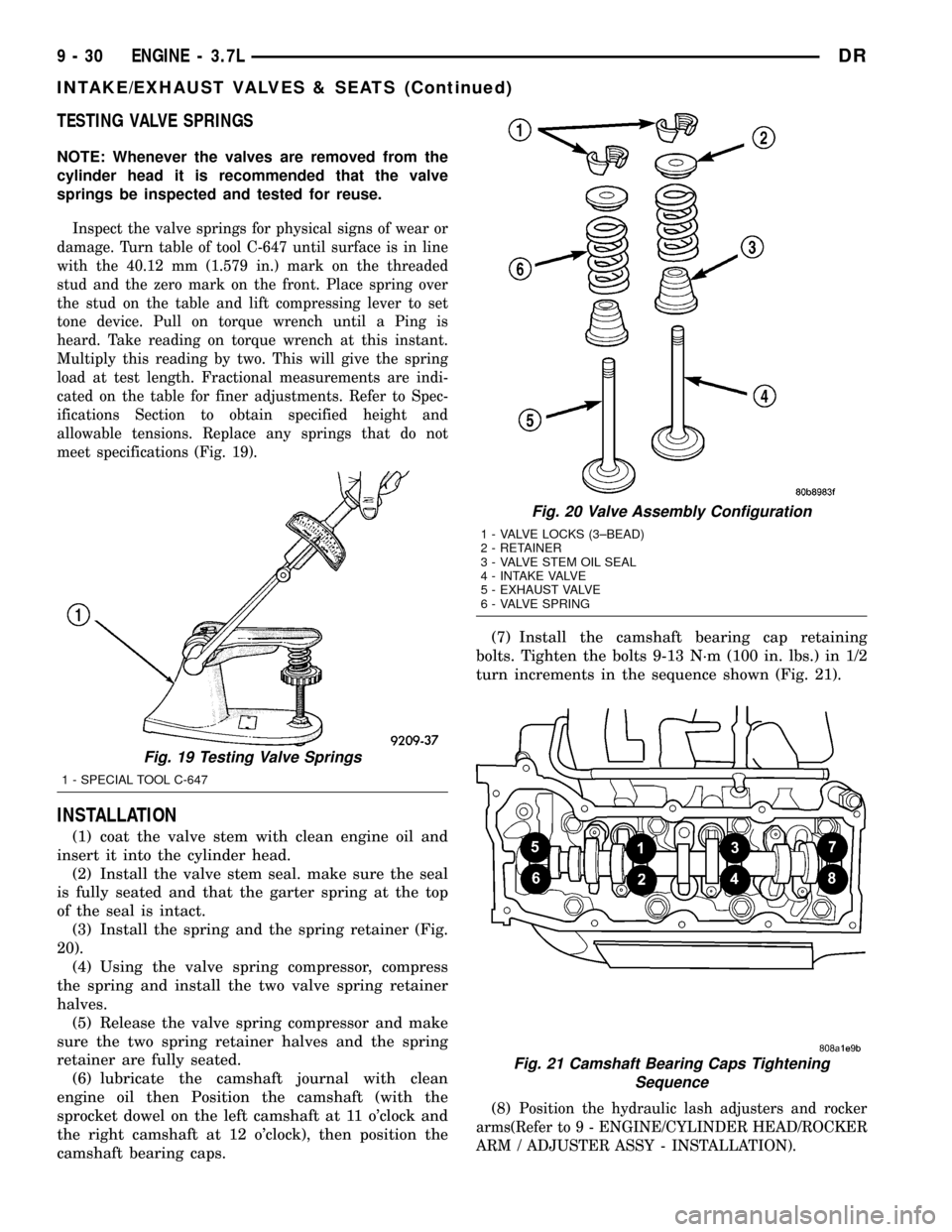

INSTALLATION

(1) coat the valve stem with clean engine oil and

insert it into the cylinder head.

(2) Install the valve stem seal. make sure the seal

is fully seated and that the garter spring at the top

of the seal is intact.

(3) Install the spring and the spring retainer (Fig.

20).

(4) Using the valve spring compressor, compress

the spring and install the two valve spring retainer

halves.

(5) Release the valve spring compressor and make

sure the two spring retainer halves and the spring

retainer are fully seated.

(6) lubricate the camshaft journal with clean

engine oil then Position the camshaft (with the

sprocket dowel on the left camshaft at 11 o'clock and

the right camshaft at 12 o'clock), then position the

camshaft bearing caps.(7) Install the camshaft bearing cap retaining

bolts. Tighten the bolts 9-13 N´m (100 in. lbs.) in 1/2

turn increments in the sequence shown (Fig. 21).

(8)

Position the hydraulic lash adjusters and rocker

arms(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - INSTALLATION).

Fig. 19 Testing Valve Springs

1 - SPECIAL TOOL C-647

Fig. 20 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

Fig. 21 Camshaft Bearing Caps Tightening

Sequence

9 - 30 ENGINE - 3.7LDR

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1347 of 2627

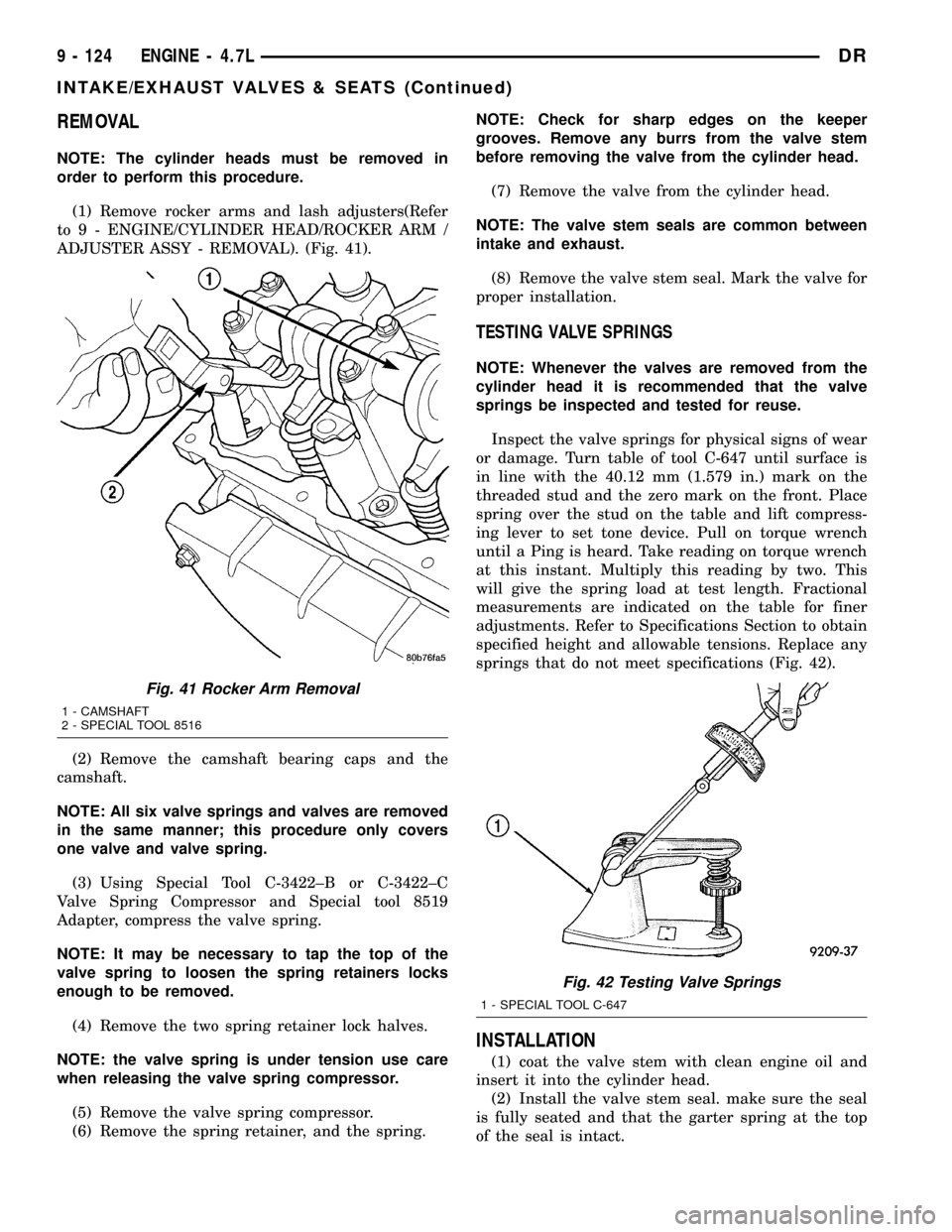

REMOVAL

NOTE: The cylinder heads must be removed in

order to perform this procedure.

(1) Remove rocker arms and lash adjusters(Refer

to 9 - ENGINE/CYLINDER HEAD/ROCKER ARM /

ADJUSTER ASSY - REMOVAL). (Fig. 41).

(2) Remove the camshaft bearing caps and the

camshaft.

NOTE: All six valve springs and valves are removed

in the same manner; this procedure only covers

one valve and valve spring.

(3) Using Special Tool C-3422±B or C-3422±C

Valve Spring Compressor and Special tool 8519

Adapter, compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

(4) Remove the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(5) Remove the valve spring compressor.

(6) Remove the spring retainer, and the spring.NOTE: Check for sharp edges on the keeper

grooves. Remove any burrs from the valve stem

before removing the valve from the cylinder head.

(7) Remove the valve from the cylinder head.

NOTE: The valve stem seals are common between

intake and exhaust.

(8) Remove the valve stem seal. Mark the valve for

proper installation.

TESTING VALVE SPRINGS

NOTE: Whenever the valves are removed from the

cylinder head it is recommended that the valve

springs be inspected and tested for reuse.

Inspect the valve springs for physical signs of wear

or damage. Turn table of tool C-647 until surface is

in line with the 40.12 mm (1.579 in.) mark on the

threaded stud and the zero mark on the front. Place

spring over the stud on the table and lift compress-

ing lever to set tone device. Pull on torque wrench

until a Ping is heard. Take reading on torque wrench

at this instant. Multiply this reading by two. This

will give the spring load at test length. Fractional

measurements are indicated on the table for finer

adjustments. Refer to Specifications Section to obtain

specified height and allowable tensions. Replace any

springs that do not meet specifications (Fig. 42).

INSTALLATION

(1) coat the valve stem with clean engine oil and

insert it into the cylinder head.

(2) Install the valve stem seal. make sure the seal

is fully seated and that the garter spring at the top

of the seal is intact.

Fig. 41 Rocker Arm Removal

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

Fig. 42 Testing Valve Springs

1 - SPECIAL TOOL C-647

9 - 124 ENGINE - 4.7LDR

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1622 of 2627

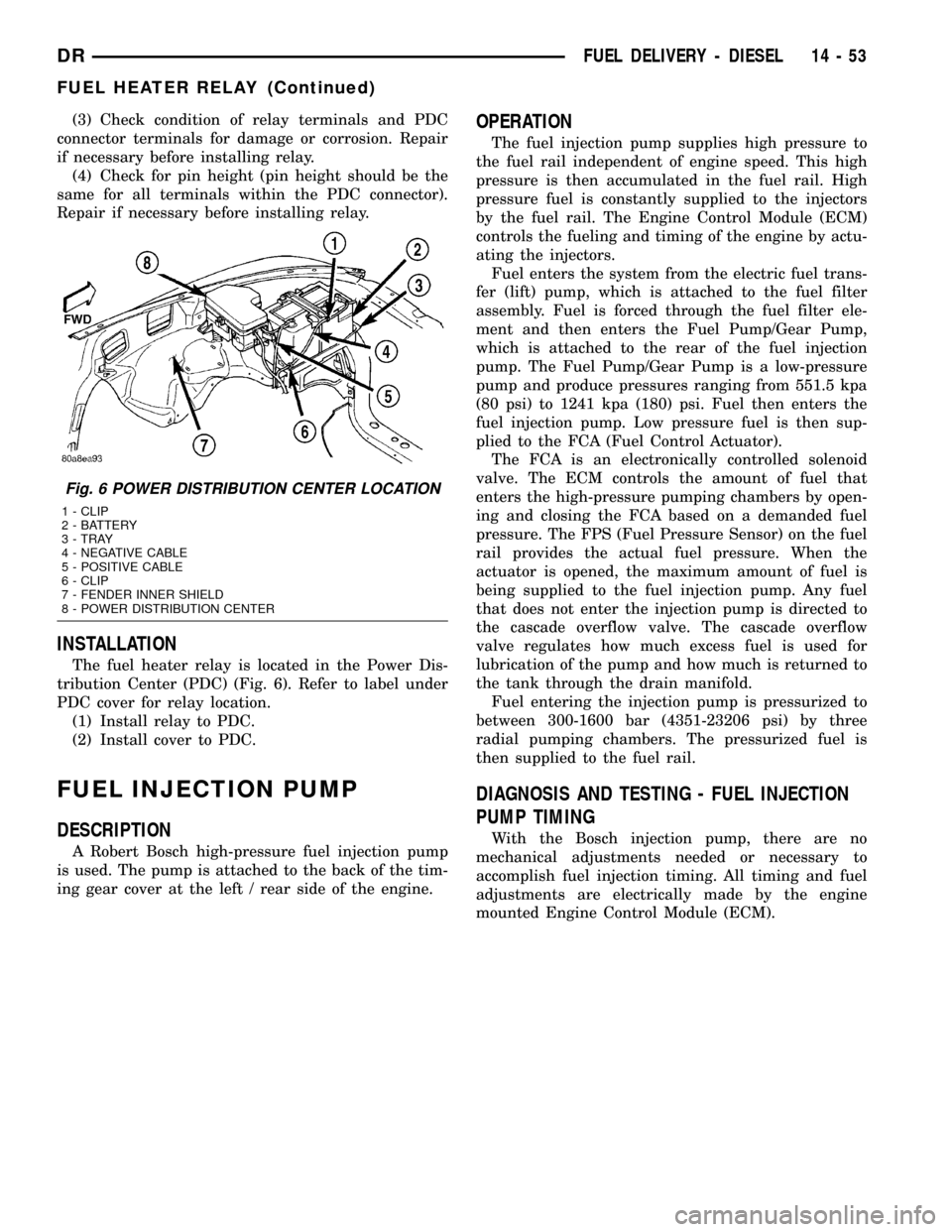

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel heater relay is located in the Power Dis-

tribution Center (PDC) (Fig. 6). Refer to label under

PDC cover for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

FUEL INJECTION PUMP

DESCRIPTION

A Robert Bosch high-pressure fuel injection pump

is used. The pump is attached to the back of the tim-

ing gear cover at the left / rear side of the engine.

OPERATION

The fuel injection pump supplies high pressure to

the fuel rail independent of engine speed. This high

pressure is then accumulated in the fuel rail. High

pressure fuel is constantly supplied to the injectors

by the fuel rail. The Engine Control Module (ECM)

controls the fueling and timing of the engine by actu-

ating the injectors.

Fuel enters the system from the electric fuel trans-

fer (lift) pump, which is attached to the fuel filter

assembly. Fuel is forced through the fuel filter ele-

ment and then enters the Fuel Pump/Gear Pump,

which is attached to the rear of the fuel injection

pump. The Fuel Pump/Gear Pump is a low-pressure

pump and produce pressures ranging from 551.5 kpa

(80 psi) to 1241 kpa (180) psi. Fuel then enters the

fuel injection pump. Low pressure fuel is then sup-

plied to the FCA (Fuel Control Actuator).

The FCA is an electronically controlled solenoid

valve. The ECM controls the amount of fuel that

enters the high-pressure pumping chambers by open-

ing and closing the FCA based on a demanded fuel

pressure. The FPS (Fuel Pressure Sensor) on the fuel

rail provides the actual fuel pressure. When the

actuator is opened, the maximum amount of fuel is

being supplied to the fuel injection pump. Any fuel

that does not enter the injection pump is directed to

the cascade overflow valve. The cascade overflow

valve regulates how much excess fuel is used for

lubrication of the pump and how much is returned to

the tank through the drain manifold.

Fuel entering the injection pump is pressurized to

between 300-1600 bar (4351-23206 psi) by three

radial pumping chambers. The pressurized fuel is

then supplied to the fuel rail.

DIAGNOSIS AND TESTING - FUEL INJECTION

PUMP TIMING

With the Bosch injection pump, there are no

mechanical adjustments needed or necessary to

accomplish fuel injection timing. All timing and fuel

adjustments are electrically made by the engine

mounted Engine Control Module (ECM).

Fig. 6 POWER DISTRIBUTION CENTER LOCATION

1 - CLIP

2 - BATTERY

3 - TRAY

4 - NEGATIVE CABLE

5 - POSITIVE CABLE

6 - CLIP

7 - FENDER INNER SHIELD

8 - POWER DISTRIBUTION CENTER

DRFUEL DELIVERY - DIESEL 14 - 53

FUEL HEATER RELAY (Continued)