oil level DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 28 of 2627

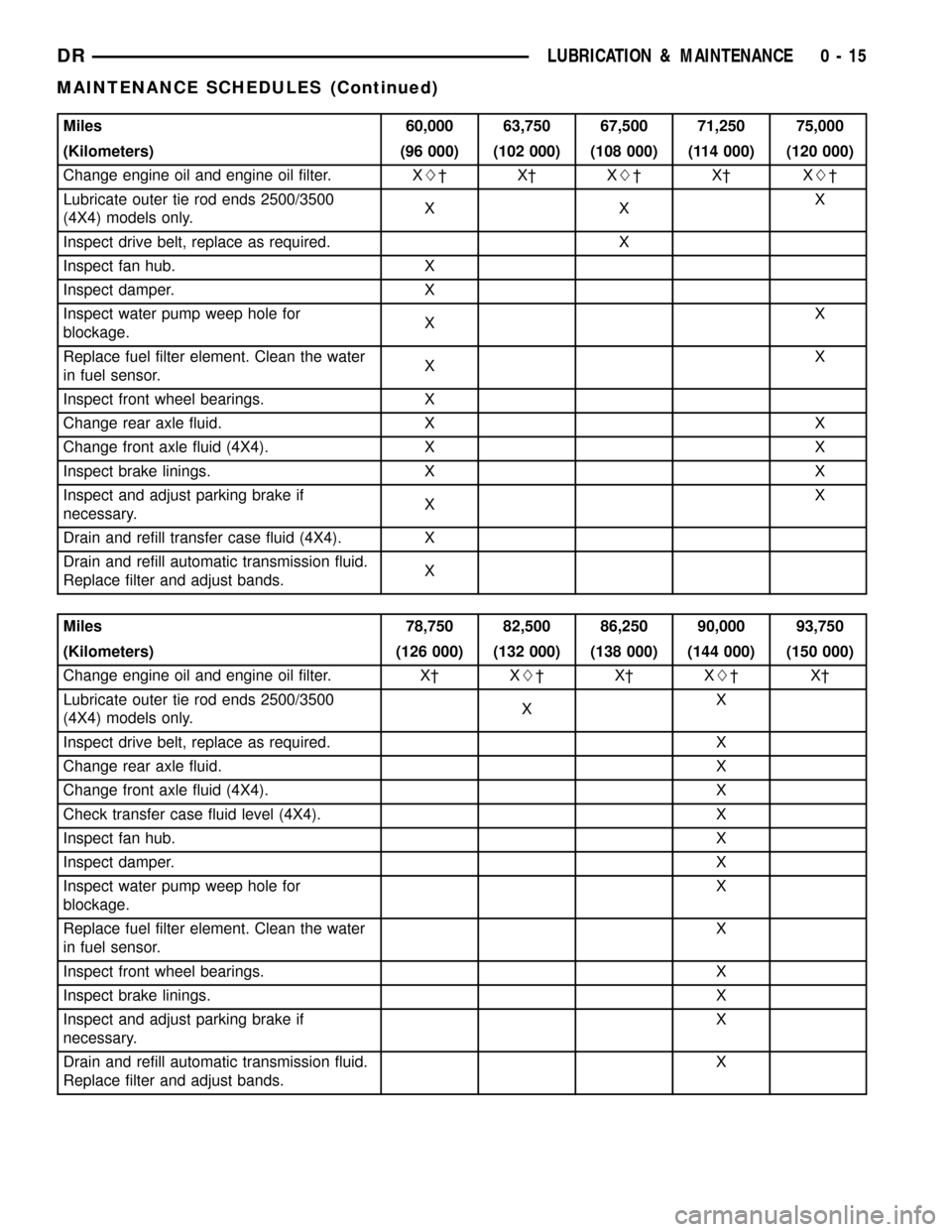

Miles 60,000 63,750 67,500 71,250 75,000

(Kilometers) (96 000) (102 000) (108 000) (114 000) (120 000)

Change engine oil and engine oil filter. XL²X²XL²X² XL²

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XXX

Inspect drive belt, replace as required. X

Inspect fan hub. X

Inspect damper. X

Inspect water pump weep hole for

blockage.XX

Replace fuel filter element. Clean the water

in fuel sensor.XX

Inspect front wheel bearings. X

Change rear axle fluid. X X

Change front axle fluid (4X4). X X

Inspect brake linings. X X

Inspect and adjust parking brake if

necessary.XX

Drain and refill transfer case fluid (4X4). X

Drain and refill automatic transmission fluid.

Replace filter and adjust bands.X

Miles 78,750 82,500 86,250 90,000 93,750

(Kilometers) (126 000) (132 000) (138 000) (144 000) (150 000)

Change engine oil and engine oil filter. X² XL²X²XL²X²

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XX

Inspect drive belt, replace as required. X

Change rear axle fluid. X

Change front axle fluid (4X4). X

Check transfer case fluid level (4X4). X

Inspect fan hub.X

Inspect damper.X

Inspect water pump weep hole for

blockage.X

Replace fuel filter element. Clean the water

in fuel sensor.X

Inspect front wheel bearings. X

Inspect brake linings.X

Inspect and adjust parking brake if

necessary.X

Drain and refill automatic transmission fluid.

Replace filter and adjust bands.X

DRLUBRICATION & MAINTENANCE 0 - 15

MAINTENANCE SCHEDULES (Continued)

Page 30 of 2627

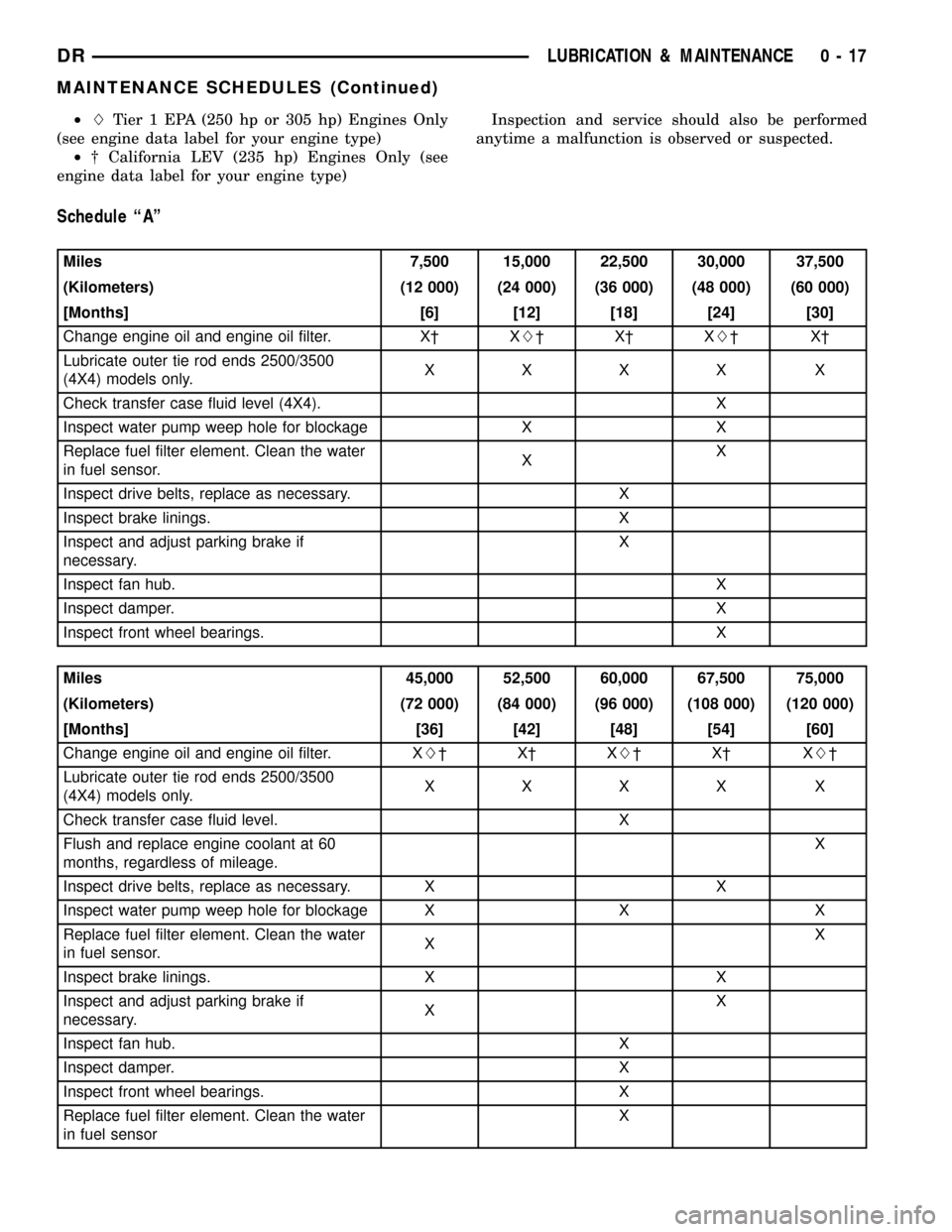

²LTier 1 EPA (250 hp or 305 hp) Engines Only

(see engine data label for your engine type)

²² California LEV (235 hp) Engines Only (see

engine data label for your engine type)Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Schedule ªAº

Miles 7,500 15,000 22,500 30,000 37,500

(Kilometers) (12 000) (24 000) (36 000) (48 000) (60 000)

[Months] [6] [12] [18] [24] [30]

Change engine oil and engine oil filter. X² XL²X²XL²X²

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XXXX X

Check transfer case fluid level (4X4). X

Inspect water pump weep hole for blockage X X

Replace fuel filter element. Clean the water

in fuel sensor.XX

Inspect drive belts, replace as necessary. X

Inspect brake linings. X

Inspect and adjust parking brake if

necessary.X

Inspect fan hub.X

Inspect damper.X

Inspect front wheel bearings. X

Miles 45,000 52,500 60,000 67,500 75,000

(Kilometers) (72 000) (84 000) (96 000) (108 000) (120 000)

[Months] [36] [42] [48] [54] [60]

Change engine oil and engine oil filter. XL²X²XL²X² XL²

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XXXX X

Check transfer case fluid level. X

Flush and replace engine coolant at 60

months, regardless of mileage.X

Inspect drive belts, replace as necessary. X X

Inspect water pump weep hole for blockage X X X

Replace fuel filter element. Clean the water

in fuel sensor.XX

Inspect brake linings. X X

Inspect and adjust parking brake if

necessary.XX

Inspect fan hub. X

Inspect damper. X

Inspect front wheel bearings. X

Replace fuel filter element. Clean the water

in fuel sensorX

DRLUBRICATION & MAINTENANCE 0 - 17

MAINTENANCE SCHEDULES (Continued)

Page 31 of 2627

![DODGE RAM 1500 1998 2.G User Guide Miles 82,500 90,000 97,500 100,000 105,000

(Kilometers) (132 000) (144 000) (156 000) (160 000) (168 000)

[Months] [66] [72] [78] [84]

Change engine oil and engine oil filter. X² XL²X² XL²

Lubrica DODGE RAM 1500 1998 2.G User Guide Miles 82,500 90,000 97,500 100,000 105,000

(Kilometers) (132 000) (144 000) (156 000) (160 000) (168 000)

[Months] [66] [72] [78] [84]

Change engine oil and engine oil filter. X² XL²X² XL²

Lubrica](/img/12/5702/w960_5702-30.png)

Miles 82,500 90,000 97,500 100,000 105,000

(Kilometers) (132 000) (144 000) (156 000) (160 000) (168 000)

[Months] [66] [72] [78] [84]

Change engine oil and engine oil filter. X² XL²X² XL²

Lubricate outer tie rod ends 2500/3500

(4X4) models only.XXXX X

Flush and replace engine coolant, if not

done at 60 mos.X

Check transfer case fluid level (4X4). X

Inspect drive belt, replace as required. X

Inspect fan hub. X

Inspect damper. X

Inspect water pump weep hole for

blockage.XX

Replace fuel filter element. Clean the water

in fuel sensor.XX

Inspect front wheel bearings. X

Inspect brake linings. X

Inspect and adjust parking brake if

necessary.X

Drain and refill automatic transmission fluid.

Replace filter and adjust bands.X

Miles 112,500 120,000 127,500 135,000 142,500 150,000

(Kilometers) (181 000) (193 000) (205 000) (217 000) (229 000) (241 000)

[Months] [90] [96] [102] [108] [114] [150]

Change engine oil and engine

oil filter.X² XL²X²XL²X² XL²

Lubricate outer tie rod ends

2500/3500 (4X4) models only.XXXXX X

Flush and replace engine

coolant, if it has been 160

000 km (100, 000 miles) or 60

months since last change.X

Inspect drive belt, replace as

required.XX

Drain and refill transfer case

fluid (4X4).X

Check tranfer case fluid level

(4X4).X

Inspect fan hub. X X

Inspect damper. X X

Inspect water pump weep

hole for blockage.XXX

Replace fuel filter element.

Clean the water in fuel

sensor.XXX

0 - 18 LUBRICATION & MAINTENANCEDR

MAINTENANCE SCHEDULES (Continued)

Page 178 of 2627

(10) If rotating torque is low, use Holder 6719 to

hold the companion flange and tighten pinion nut in

6.8 N´m (5 ft. lbs.) increments until proper rotating

torque is achieved.

NOTE: The bearing rotating torque should be con-

stant during a complete revolution of the pinion. If

the rotating torque varies, this indicates a binding

condition.

NOTE: The seal replacement is unacceptable if the

final pinion nut torque is less than 285 N´m (210 ft.

lbs.).

(11) Install propeller shaft with the installation

reference marks aligned.

(12) Tighten the companion flange bolts to 108

N´m (80 ft. lbs.).

(13) Install brake rotors.

(14) Check the differential lubricant level.

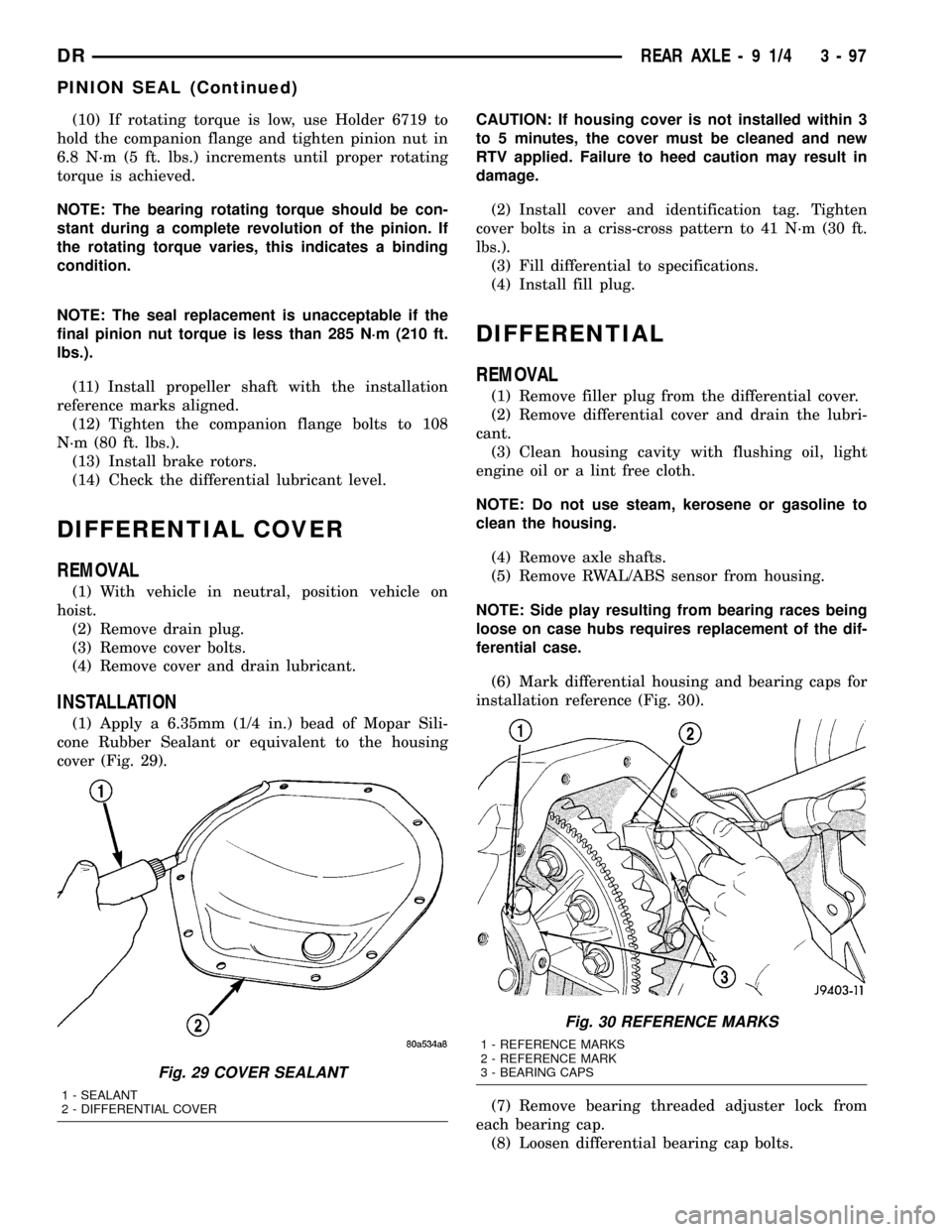

DIFFERENTIAL COVER

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove drain plug.

(3) Remove cover bolts.

(4) Remove cover and drain lubricant.

INSTALLATION

(1) Apply a 6.35mm (1/4 in.) bead of Mopar Sili-

cone Rubber Sealant or equivalent to the housing

cover (Fig. 29).CAUTION: If housing cover is not installed within 3

to 5 minutes, the cover must be cleaned and new

RTV applied. Failure to heed caution may result in

damage.

(2) Install cover and identification tag. Tighten

cover bolts in a criss-cross pattern to 41 N´m (30 ft.

lbs.).

(3) Fill differential to specifications.

(4) Install fill plug.

DIFFERENTIAL

REMOVAL

(1) Remove filler plug from the differential cover.

(2) Remove differential cover and drain the lubri-

cant.

(3) Clean housing cavity with flushing oil, light

engine oil or a lint free cloth.

NOTE: Do not use steam, kerosene or gasoline to

clean the housing.

(4) Remove axle shafts.

(5) Remove RWAL/ABS sensor from housing.

NOTE: Side play resulting from bearing races being

loose on case hubs requires replacement of the dif-

ferential case.

(6) Mark differential housing and bearing caps for

installation reference (Fig. 30).

(7) Remove bearing threaded adjuster lock from

each bearing cap.

(8) Loosen differential bearing cap bolts.

Fig. 29 COVER SEALANT

1 - SEALANT

2 - DIFFERENTIAL COVER

Fig. 30 REFERENCE MARKS

1 - REFERENCE MARKS

2 - REFERENCE MARK

3 - BEARING CAPS

DRREAR AXLE - 9 1/4 3 - 97

PINION SEAL (Continued)

Page 272 of 2627

(3) Install parking brake cable in the brake lever.

(4) Install the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - INSTALLA-

TION). (Fig. 66).

(5) Install axle shaft, (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - INSTALLATION).

(6) Adjust brake shoes to drum with brake gauge

(Refer to 5 - BRAKES/PARKING BRAKE/SHOES -

ADJUSTMENTS).

(7) Install the rotor (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - INSTALLA-

TION).

(8) Install the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION).

(9) Install the caliper (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- INSTALLATION).

(10) Install wheel and tire assembly.

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts.

Swollen rubber parts indicate the presence of

petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If brake fluid is contaminated, drain and thor-

oughly flush system. Replace master cylinder, propor-

tioning valve, caliper seals, wheel cylinder seals,

Antilock Brakes hydraulic unit and all hydraulic

fluid hoses.

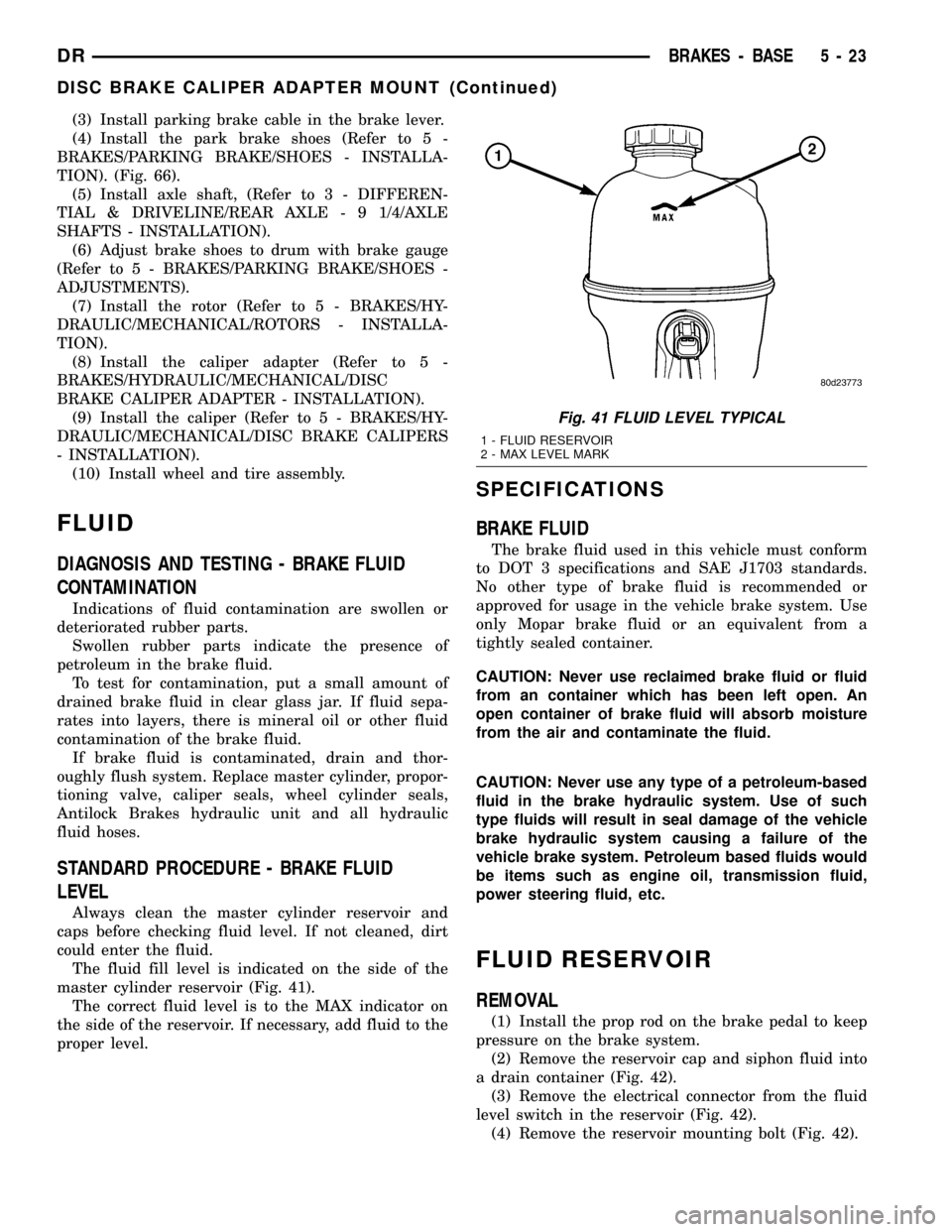

STANDARD PROCEDURE - BRAKE FLUID

LEVEL

Always clean the master cylinder reservoir and

caps before checking fluid level. If not cleaned, dirt

could enter the fluid.

The fluid fill level is indicated on the side of the

master cylinder reservoir (Fig. 41).

The correct fluid level is to the MAX indicator on

the side of the reservoir. If necessary, add fluid to the

proper level.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications and SAE J1703 standards.

No other type of brake fluid is recommended or

approved for usage in the vehicle brake system. Use

only Mopar brake fluid or an equivalent from a

tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

FLUID RESERVOIR

REMOVAL

(1) Install the prop rod on the brake pedal to keep

pressure on the brake system.

(2) Remove the reservoir cap and siphon fluid into

a drain container (Fig. 42).

(3) Remove the electrical connector from the fluid

level switch in the reservoir (Fig. 42).

(4) Remove the reservoir mounting bolt (Fig. 42).

Fig. 41 FLUID LEVEL TYPICAL

1 - FLUID RESERVOIR

2 - MAX LEVEL MARK

DRBRAKES - BASE 5 - 23

DISC BRAKE CALIPER ADAPTER MOUNT (Continued)

Page 321 of 2627

PRESSURE TESTER METHOD

The engine should be at normal operating temper-

ature. Recheck the system cold if the cause of coolant

loss is not located during the warm engine examina-

tion.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING.

Carefully remove the radiator pressure cap from

the filler neck and check the coolant level. Push

down on the cap to disengage it from the stop tabs.

Wipe the inside of the filler neck and examine the

lower inside sealing seat for nicks, cracks, paint, dirt

and solder residue. Inspect the radiator-to- reserve/

overflow tank hose for internal obstructions. Insert a

wire through the hose to be sure it is not obstructed.

Inspect the cams on the outside of the filler neck.

If the cams are damaged, seating of the pressure cap

valve and tester seal will be affected.

Attach pressure tester (7700 or an equivalent) to

radiator filler neck.

Operate the tester pump to apply 103.4 kPa (15

psi) pressure to the system. If the hoses enlarge

excessively or bulges while testing, replace as neces-

sary. Observe the gauge pointer and determine the

condition of the cooling system according to following

criteria:

Holds Steady:If the pointer remains steady for

two minutes, serious coolant leaks are not present in

system. However, there could be an internal leakthat does not appear with normal system test pres-

sure. If it is certain that coolant is being lost and

leaks cannot be detected, inspect for interior leakage

or perform Internal Leakage Test. Refer to INTER-

NAL LEAKAGE INSPECTION.

Drops Slowly:Indicates a small leak or seepage

is occurring. Examine all of the connections for seep-

age or slight leakage with a flashlight. Inspect the

radiator, hoses, gasket edges and heater. Seal the

small leak holes with a Sealer Lubricant (or equiva-

lent). Repair the leak holes and inspect the system

again with pressure applied.

Drops Quickly:Indicates that serious leakage is

occurring. Examine the system for external leakage.

If leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.

INTERNAL LEAKAGE INSPECTION

Remove the engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil. An alternative method is to operate engine for a

short period to churn the oil. After this is done,

remove the engine dipstick and inspect for water

globules. Also inspect the transmission dipstick for

water globules and transmission fluid cooler for leak-

age.

WARNING: WITH RADIATOR PRESSURE TESTER

TOOL INSTALLED ON RADIATOR, DO NOT ALLOW

PRESSURE TO EXCEED 145 kPa (21 PSI). PRES-

SURE WILL BUILD UP QUICKLY IF A COMBUSTION

LEAK IS PRESENT. TO RELEASE PRESSURE,

ROCK TESTER FROM SIDE TO SIDE. WHEN

REMOVING TESTER, DO NOT TURN TESTER MORE

THAN 1/2 TURN IF SYSTEM IS UNDER PRESSURE.

Operate the engine without the pressure cap on

the radiator until the thermostat opens. Attach a

Pressure Tester to the filler neck. If pressure builds

up quickly it indicates a combustion leak exists. This

is usually the result of a cylinder head gasket leak or

crack in engine. Repair as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi).

Fluctuation of the gauge pointer indicates compres-

sion or combustion leakage into cooling system.

Because the vehicle is equipped with a catalytic

converter,do notshort out cylinders to isolate com-

pression leak.

If the needle on dial of the pressure tester does not

fluctuate, race engine a few times to check for an

abnormal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

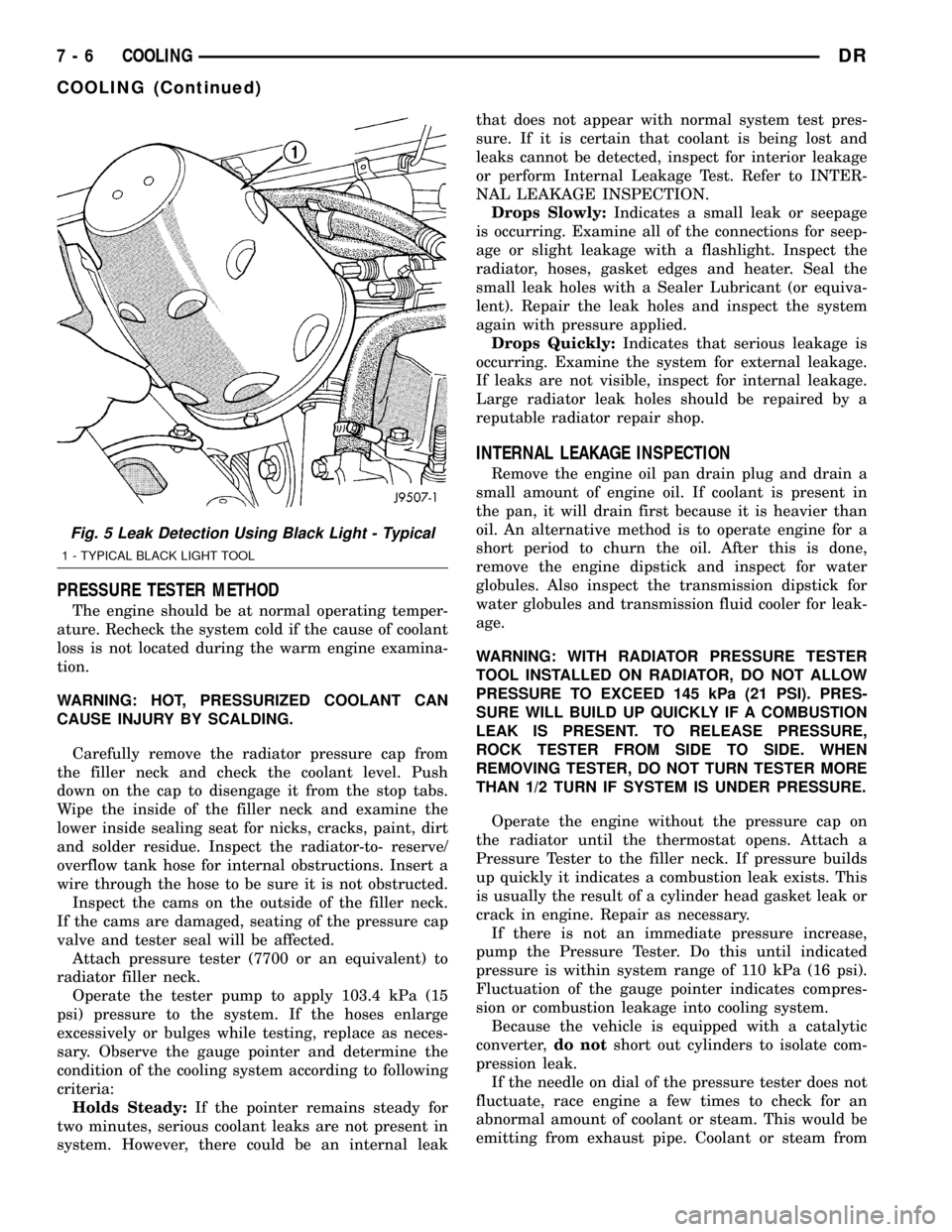

Fig. 5 Leak Detection Using Black Light - Typical

1 - TYPICAL BLACK LIGHT TOOL

7 - 6 COOLINGDR

COOLING (Continued)

Page 322 of 2627

exhaust pipe may indicate a faulty cylinder head gas-

ket, cracked engine cylinder block or cylinder head.

A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail-

able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST - WITHOUT

PRESSURE TESTER

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

Drain sufficient coolant to allow thermostat

removal. (Refer to 7 - COOLING/ENGINE/ENGINECOOLANT THERMOSTAT - REMOVAL). Remove

accessory drive belt (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - REMOVAL).

Add coolant to radiator to bring level to within 6.3

mm (1/4 in) of the top of the thermostat housing.

CAUTION: Avoid overheating. Do not operate

engine for an excessive period of time. Open drain-

cock immediately after test to eliminate boil over.

Start engine and accelerate rapidly three times, to

approximately 3000 rpm while observing coolant. If

internal engine combustion gases are leaking into

cooling system, bubbles will appear in coolant. If bub-

bles do not appear, internal combustion gas leakage

is not present.

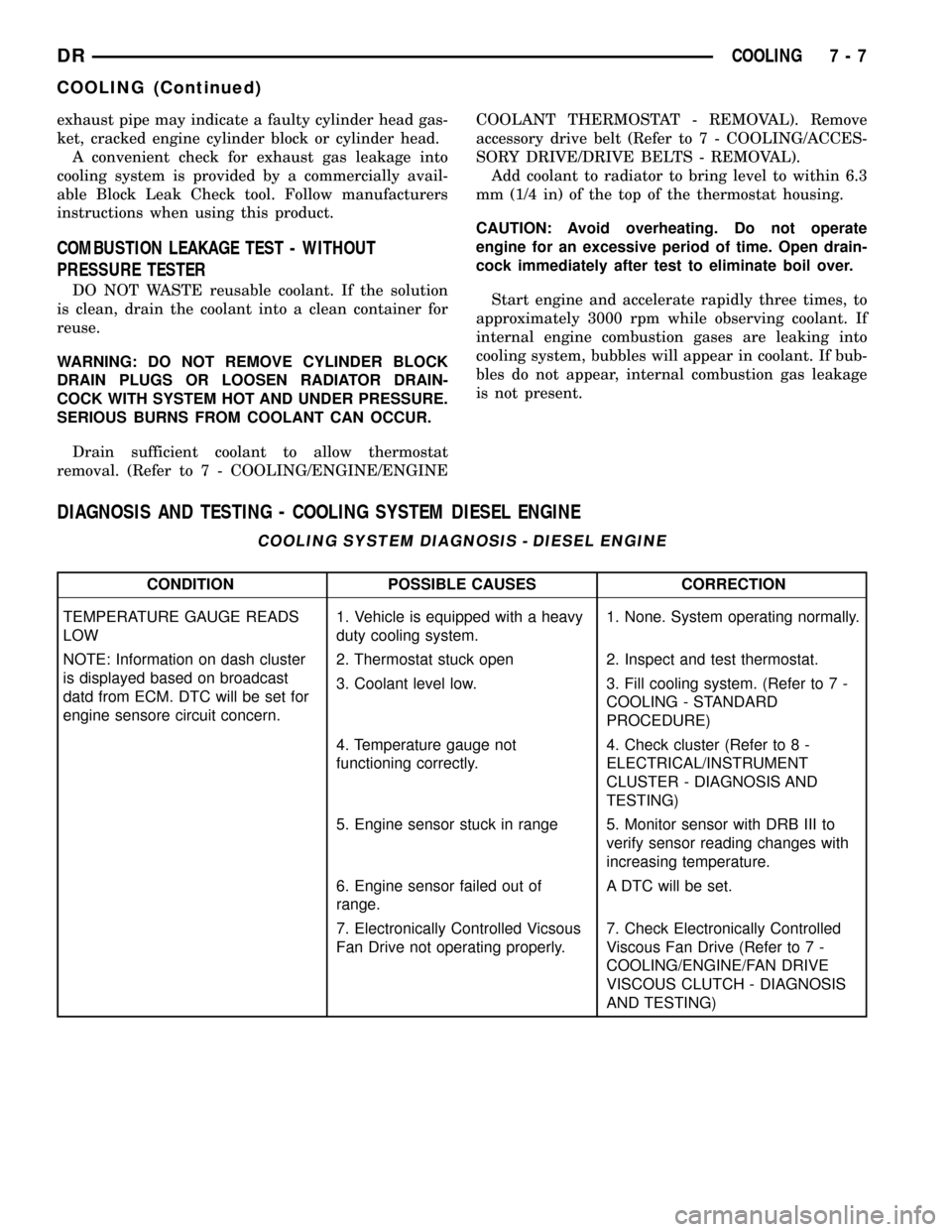

DIAGNOSIS AND TESTING - COOLING SYSTEM DIESEL ENGINE

COOLING SYSTEM DIAGNOSIS - DIESEL ENGINE

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE READS

LOW1. Vehicle is equipped with a heavy

duty cooling system.1. None. System operating normally.

NOTE: Information on dash cluster

is displayed based on broadcast

datd from ECM. DTC will be set for

engine sensore circuit concern.2. Thermostat stuck open 2. Inspect and test thermostat.

3. Coolant level low. 3. Fill cooling system. (Refer to 7 -

COOLING - STANDARD

PROCEDURE)

4. Temperature gauge not

functioning correctly.4. Check cluster (Refer to 8 -

ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND

TESTING)

5. Engine sensor stuck in range 5. Monitor sensor with DRB III to

verify sensor reading changes with

increasing temperature.

6. Engine sensor failed out of

range.A DTC will be set.

7. Electronically Controlled Vicsous

Fan Drive not operating properly.7. Check Electronically Controlled

Viscous Fan Drive (Refer to 7 -

COOLING/ENGINE/FAN DRIVE

VISCOUS CLUTCH - DIAGNOSIS

AND TESTING)

DRCOOLING 7 - 7

COOLING (Continued)

Page 327 of 2627

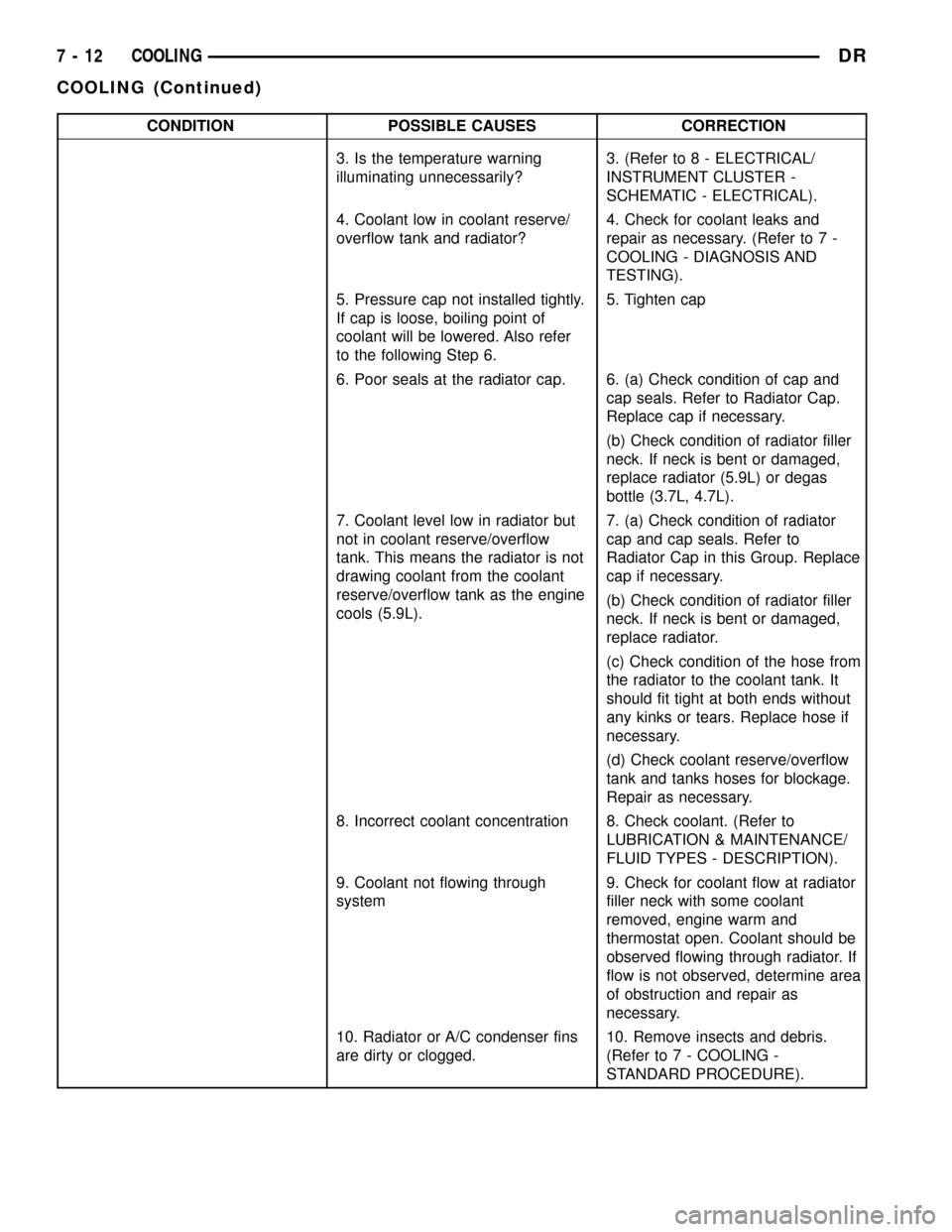

CONDITION POSSIBLE CAUSES CORRECTION

3. Is the temperature warning

illuminating unnecessarily?3. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER -

SCHEMATIC - ELECTRICAL).

4. Coolant low in coolant reserve/

overflow tank and radiator?4. Check for coolant leaks and

repair as necessary. (Refer to 7 -

COOLING - DIAGNOSIS AND

TESTING).

5. Pressure cap not installed tightly.

If cap is loose, boiling point of

coolant will be lowered. Also refer

to the following Step 6.5. Tighten cap

6. Poor seals at the radiator cap. 6. (a) Check condition of cap and

cap seals. Refer to Radiator Cap.

Replace cap if necessary.

(b) Check condition of radiator filler

neck. If neck is bent or damaged,

replace radiator (5.9L) or degas

bottle (3.7L, 4.7L).

7. Coolant level low in radiator but

not in coolant reserve/overflow

tank. This means the radiator is not

drawing coolant from the coolant

reserve/overflow tank as the engine

cools (5.9L).7. (a) Check condition of radiator

cap and cap seals. Refer to

Radiator Cap in this Group. Replace

cap if necessary.

(b) Check condition of radiator filler

neck. If neck is bent or damaged,

replace radiator.

(c) Check condition of the hose from

the radiator to the coolant tank. It

should fit tight at both ends without

any kinks or tears. Replace hose if

necessary.

(d) Check coolant reserve/overflow

tank and tanks hoses for blockage.

Repair as necessary.

8. Incorrect coolant concentration 8. Check coolant. (Refer to

LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION).

9. Coolant not flowing through

system9. Check for coolant flow at radiator

filler neck with some coolant

removed, engine warm and

thermostat open. Coolant should be

observed flowing through radiator. If

flow is not observed, determine area

of obstruction and repair as

necessary.

10. Radiator or A/C condenser fins

are dirty or clogged.10. Remove insects and debris.

(Refer to 7 - COOLING -

STANDARD PROCEDURE).

7 - 12 COOLINGDR

COOLING (Continued)

Page 329 of 2627

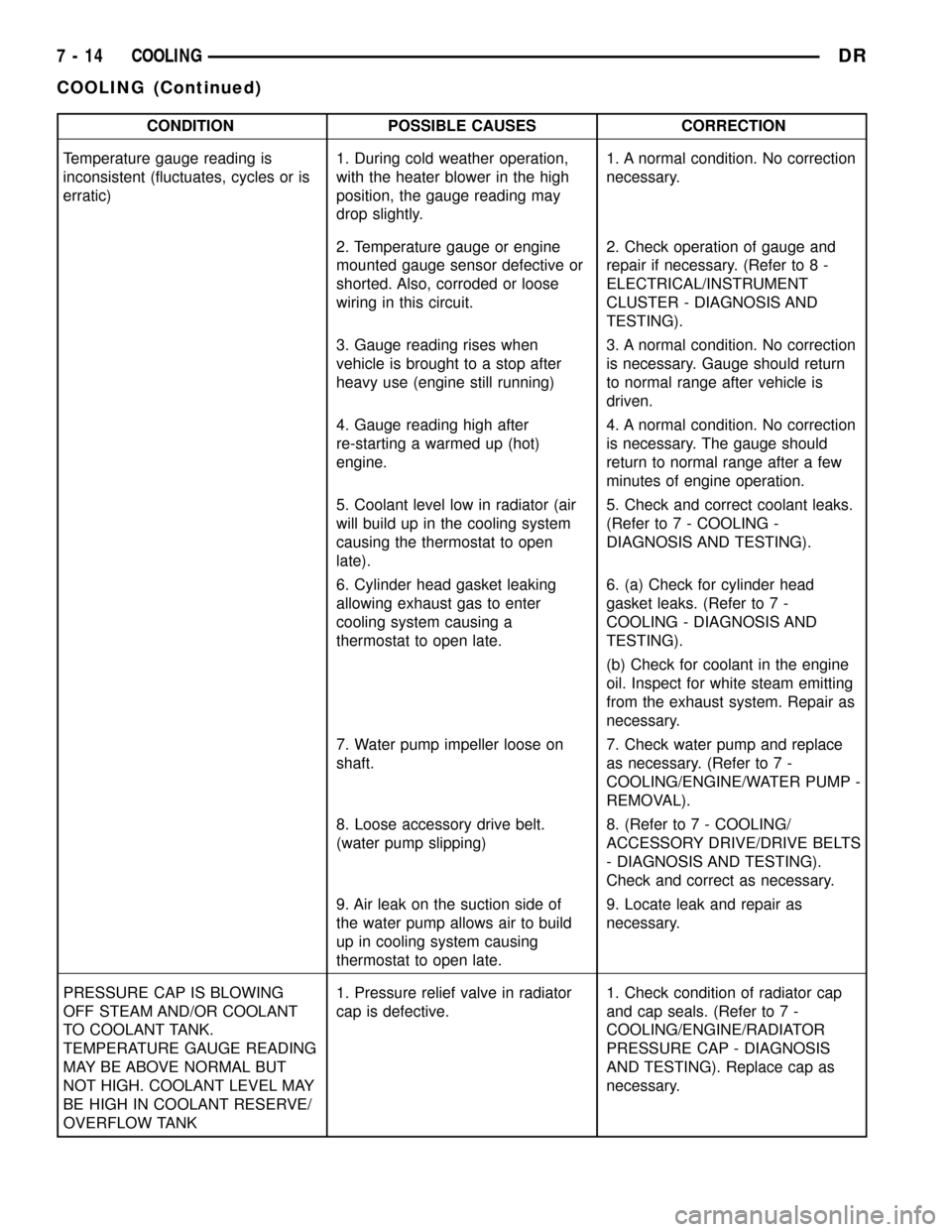

CONDITION POSSIBLE CAUSES CORRECTION

Temperature gauge reading is

inconsistent (fluctuates, cycles or is

erratic)1. During cold weather operation,

with the heater blower in the high

position, the gauge reading may

drop slightly.1. A normal condition. No correction

necessary.

2. Temperature gauge or engine

mounted gauge sensor defective or

shorted. Also, corroded or loose

wiring in this circuit.2. Check operation of gauge and

repair if necessary. (Refer to 8 -

ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND

TESTING).

3. Gauge reading rises when

vehicle is brought to a stop after

heavy use (engine still running)3. A normal condition. No correction

is necessary. Gauge should return

to normal range after vehicle is

driven.

4. Gauge reading high after

re-starting a warmed up (hot)

engine.4. A normal condition. No correction

is necessary. The gauge should

return to normal range after a few

minutes of engine operation.

5. Coolant level low in radiator (air

will build up in the cooling system

causing the thermostat to open

late).5. Check and correct coolant leaks.

(Refer to 7 - COOLING -

DIAGNOSIS AND TESTING).

6. Cylinder head gasket leaking

allowing exhaust gas to enter

cooling system causing a

thermostat to open late.6. (a) Check for cylinder head

gasket leaks. (Refer to 7 -

COOLING - DIAGNOSIS AND

TESTING).

(b) Check for coolant in the engine

oil. Inspect for white steam emitting

from the exhaust system. Repair as

necessary.

7. Water pump impeller loose on

shaft.7. Check water pump and replace

as necessary. (Refer to 7 -

COOLING/ENGINE/WATER PUMP -

REMOVAL).

8. Loose accessory drive belt.

(water pump slipping)8. (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS

- DIAGNOSIS AND TESTING).

Check and correct as necessary.

9. Air leak on the suction side of

the water pump allows air to build

up in cooling system causing

thermostat to open late.9. Locate leak and repair as

necessary.

PRESSURE CAP IS BLOWING

OFF STEAM AND/OR COOLANT

TO COOLANT TANK.

TEMPERATURE GAUGE READING

MAY BE ABOVE NORMAL BUT

NOT HIGH. COOLANT LEVEL MAY

BE HIGH IN COOLANT RESERVE/

OVERFLOW TANK1. Pressure relief valve in radiator

cap is defective.1. Check condition of radiator cap

and cap seals. (Refer to 7 -

COOLING/ENGINE/RADIATOR

PRESSURE CAP - DIAGNOSIS

AND TESTING). Replace cap as

necessary.

7 - 14 COOLINGDR

COOLING (Continued)

Page 334 of 2627

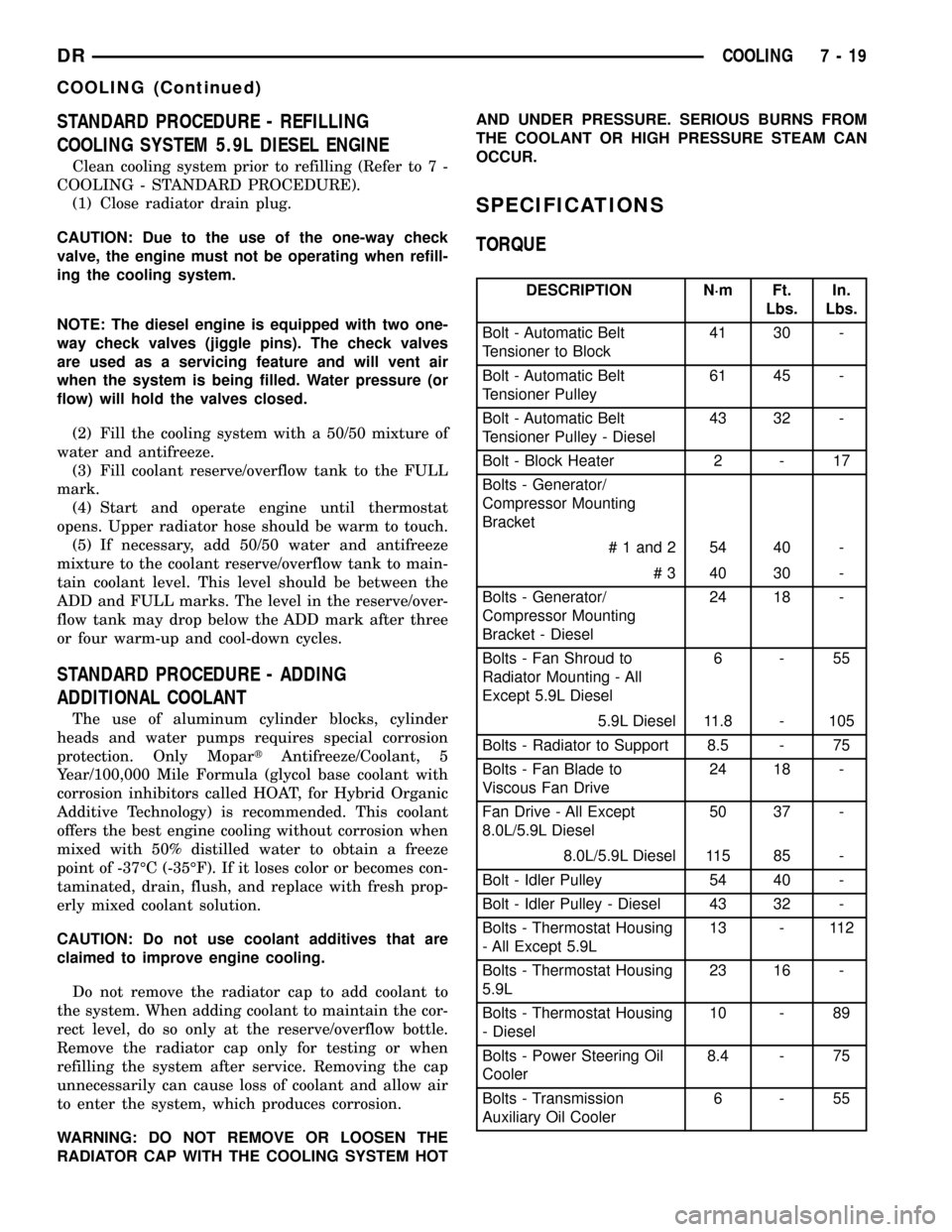

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 5.9L DIESEL ENGINE

Clean cooling system prior to refilling (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(1) Close radiator drain plug.

CAUTION: Due to the use of the one-way check

valve, the engine must not be operating when refill-

ing the cooling system.

NOTE: The diesel engine is equipped with two one-

way check valves (jiggle pins). The check valves

are used as a servicing feature and will vent air

when the system is being filled. Water pressure (or

flow) will hold the valves closed.

(2) Fill the cooling system with a 50/50 mixture of

water and antifreeze.

(3) Fill coolant reserve/overflow tank to the FULL

mark.

(4) Start and operate engine until thermostat

opens. Upper radiator hose should be warm to touch.

(5) If necessary, add 50/50 water and antifreeze

mixture to the coolant reserve/overflow tank to main-

tain coolant level. This level should be between the

ADD and FULL marks. The level in the reserve/over-

flow tank may drop below the ADD mark after three

or four warm-up and cool-down cycles.

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (glycol base coolant with

corrosion inhibitors called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% distilled water to obtain a freeze

point of -37ÉC (-35ÉF). If it loses color or becomes con-

taminated, drain, flush, and replace with fresh prop-

erly mixed coolant solution.

CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

Do not remove the radiator cap to add coolant to

the system. When adding coolant to maintain the cor-

rect level, do so only at the reserve/overflow bottle.

Remove the radiator cap only for testing or when

refilling the system after service. Removing the cap

unnecessarily can cause loss of coolant and allow air

to enter the system, which produces corrosion.

WARNING: DO NOT REMOVE OR LOOSEN THE

RADIATOR CAP WITH THE COOLING SYSTEM HOTAND UNDER PRESSURE. SERIOUS BURNS FROM

THE COOLANT OR HIGH PRESSURE STEAM CAN

OCCUR.

SPECIFICATIONS

TORQUE

DESCRIPTION N´m Ft.

Lbs.In.

Lbs.

Bolt - Automatic Belt

Tensioner to Block41 30 -

Bolt - Automatic Belt

Tensioner Pulley61 45 -

Bolt - Automatic Belt

Tensioner Pulley - Diesel43 32 -

Bolt - Block Heater 2 - 17

Bolts - Generator/

Compressor Mounting

Bracket

# 1 and 2 54 40 -

# 3 40 30 -

Bolts - Generator/

Compressor Mounting

Bracket - Diesel24 18 -

Bolts - Fan Shroud to

Radiator Mounting - All

Except 5.9L Diesel6-55

5.9L Diesel 11.8 - 105

Bolts - Radiator to Support 8.5 - 75

Bolts - Fan Blade to

Viscous Fan Drive24 18 -

Fan Drive - All Except

8.0L/5.9L Diesel50 37 -

8.0L/5.9L Diesel 115 85 -

Bolt - Idler Pulley 54 40 -

Bolt - Idler Pulley - Diesel 43 32 -

Bolts - Thermostat Housing

- All Except 5.9L13 - 112

Bolts - Thermostat Housing

5.9L23 16 -

Bolts - Thermostat Housing

- Diesel10 - 89

Bolts - Power Steering Oil

Cooler8.4 - 75

Bolts - Transmission

Auxiliary Oil Cooler6-55

DRCOOLING 7 - 19

COOLING (Continued)