tow DODGE RAM 1500 1998 2.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 54 of 2627

(8) Remove the hub/bearing from the steering

knuckle (Refer to 2 - SUSPENSION/FRONT/HUB /

BEARING - REMOVAL).

INSTALLATION

CAUTION: The ball joint stud tapers must be

CLEAN and DRY before installing the knuckle.

Clean the stud tapers with mineral spirits to remove

dirt and grease.

NOTE: When installing hub/bearing with ABS

brakes, position the speed sensor opening towards

the front of the vehicle.

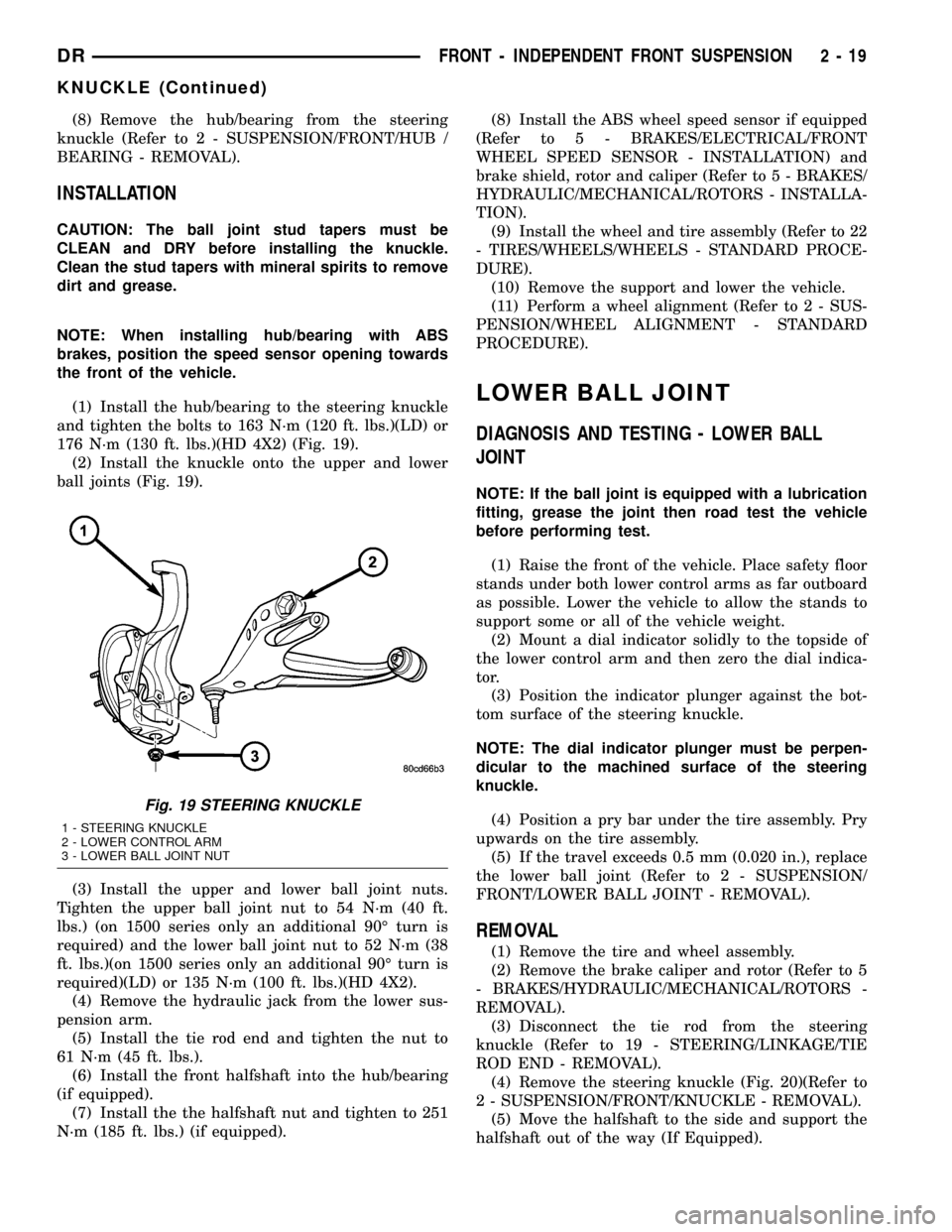

(1) Install the hub/bearing to the steering knuckle

and tighten the bolts to 163 N´m (120 ft. lbs.)(LD) or

176 N´m (130 ft. lbs.)(HD 4X2) (Fig. 19).

(2) Install the knuckle onto the upper and lower

ball joints (Fig. 19).

(3) Install the upper and lower ball joint nuts.

Tighten the upper ball joint nut to 54 N´m (40 ft.

lbs.) (on 1500 series only an additional 90É turn is

required) and the lower ball joint nut to 52 N´m (38

ft. lbs.)(on 1500 series only an additional 90É turn is

required)(LD) or 135 N´m (100 ft. lbs.)(HD 4X2).

(4) Remove the hydraulic jack from the lower sus-

pension arm.

(5) Install the tie rod end and tighten the nut to

61 N´m (45 ft. lbs.).

(6) Install the front halfshaft into the hub/bearing

(if equipped).

(7) Install the the halfshaft nut and tighten to 251

N´m (185 ft. lbs.) (if equipped).(8) Install the ABS wheel speed sensor if equipped

(Refer to 5 - BRAKES/ELECTRICAL/FRONT

WHEEL SPEED SENSOR - INSTALLATION) and

brake shield, rotor and caliper (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS - INSTALLA-

TION).

(9) Install the wheel and tire assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(10) Remove the support and lower the vehicle.

(11) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

LOWER BALL JOINT

DIAGNOSIS AND TESTING - LOWER BALL

JOINT

NOTE: If the ball joint is equipped with a lubrication

fitting, grease the joint then road test the vehicle

before performing test.

(1) Raise the front of the vehicle. Place safety floor

stands under both lower control arms as far outboard

as possible. Lower the vehicle to allow the stands to

support some or all of the vehicle weight.

(2) Mount a dial indicator solidly to the topside of

the lower control arm and then zero the dial indica-

tor.

(3) Position the indicator plunger against the bot-

tom surface of the steering knuckle.

NOTE: The dial indicator plunger must be perpen-

dicular to the machined surface of the steering

knuckle.

(4) Position a pry bar under the tire assembly. Pry

upwards on the tire assembly.

(5) If the travel exceeds 0.5 mm (0.020 in.), replace

the lower ball joint (Refer to 2 - SUSPENSION/

FRONT/LOWER BALL JOINT - REMOVAL).

REMOVAL

(1) Remove the tire and wheel assembly.

(2) Remove the brake caliper and rotor (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(3) Disconnect the tie rod from the steering

knuckle (Refer to 19 - STEERING/LINKAGE/TIE

ROD END - REMOVAL).

(4) Remove the steering knuckle (Fig. 20)(Refer to

2 - SUSPENSION/FRONT/KNUCKLE - REMOVAL).

(5) Move the halfshaft to the side and support the

halfshaft out of the way (If Equipped).

Fig. 19 STEERING KNUCKLE

1 - STEERING KNUCKLE

2 - LOWER CONTROL ARM

3 - LOWER BALL JOINT NUT

DRFRONT - INDEPENDENT FRONT SUSPENSION 2 - 19

KNUCKLE (Continued)

Page 80 of 2627

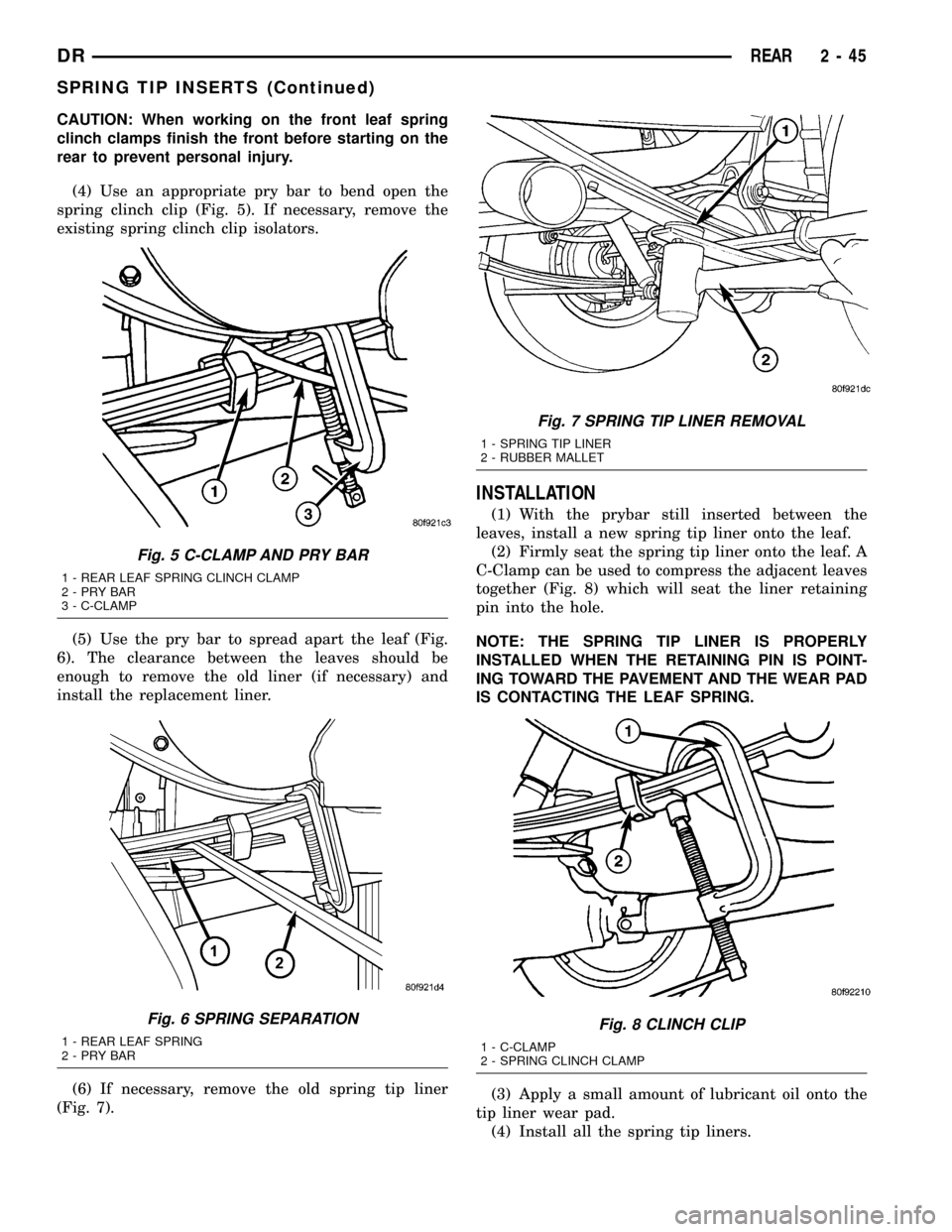

CAUTION: When working on the front leaf spring

clinch clamps finish the front before starting on the

rear to prevent personal injury.

(4) Use an appropriate pry bar to bend open the

spring clinch clip (Fig. 5). If necessary, remove the

existing spring clinch clip isolators.

(5) Use the pry bar to spread apart the leaf (Fig.

6). The clearance between the leaves should be

enough to remove the old liner (if necessary) and

install the replacement liner.

(6) If necessary, remove the old spring tip liner

(Fig. 7).

INSTALLATION

(1) With the prybar still inserted between the

leaves, install a new spring tip liner onto the leaf.

(2) Firmly seat the spring tip liner onto the leaf. A

C-Clamp can be used to compress the adjacent leaves

together (Fig. 8) which will seat the liner retaining

pin into the hole.

NOTE: THE SPRING TIP LINER IS PROPERLY

INSTALLED WHEN THE RETAINING PIN IS POINT-

ING TOWARD THE PAVEMENT AND THE WEAR PAD

IS CONTACTING THE LEAF SPRING.

(3) Apply a small amount of lubricant oil onto the

tip liner wear pad.

(4) Install all the spring tip liners.

Fig. 5 C-CLAMP AND PRY BAR

1 - REAR LEAF SPRING CLINCH CLAMP

2-PRYBAR

3 - C-CLAMP

Fig. 6 SPRING SEPARATION

1 - REAR LEAF SPRING

2-PRYBAR

Fig. 7 SPRING TIP LINER REMOVAL

1 - SPRING TIP LINER

2 - RUBBER MALLET

Fig. 8 CLINCH CLIP

1 - C-CLAMP

2 - SPRING CLINCH CLAMP

DRREAR 2 - 45

SPRING TIP INSERTS (Continued)

Page 117 of 2627

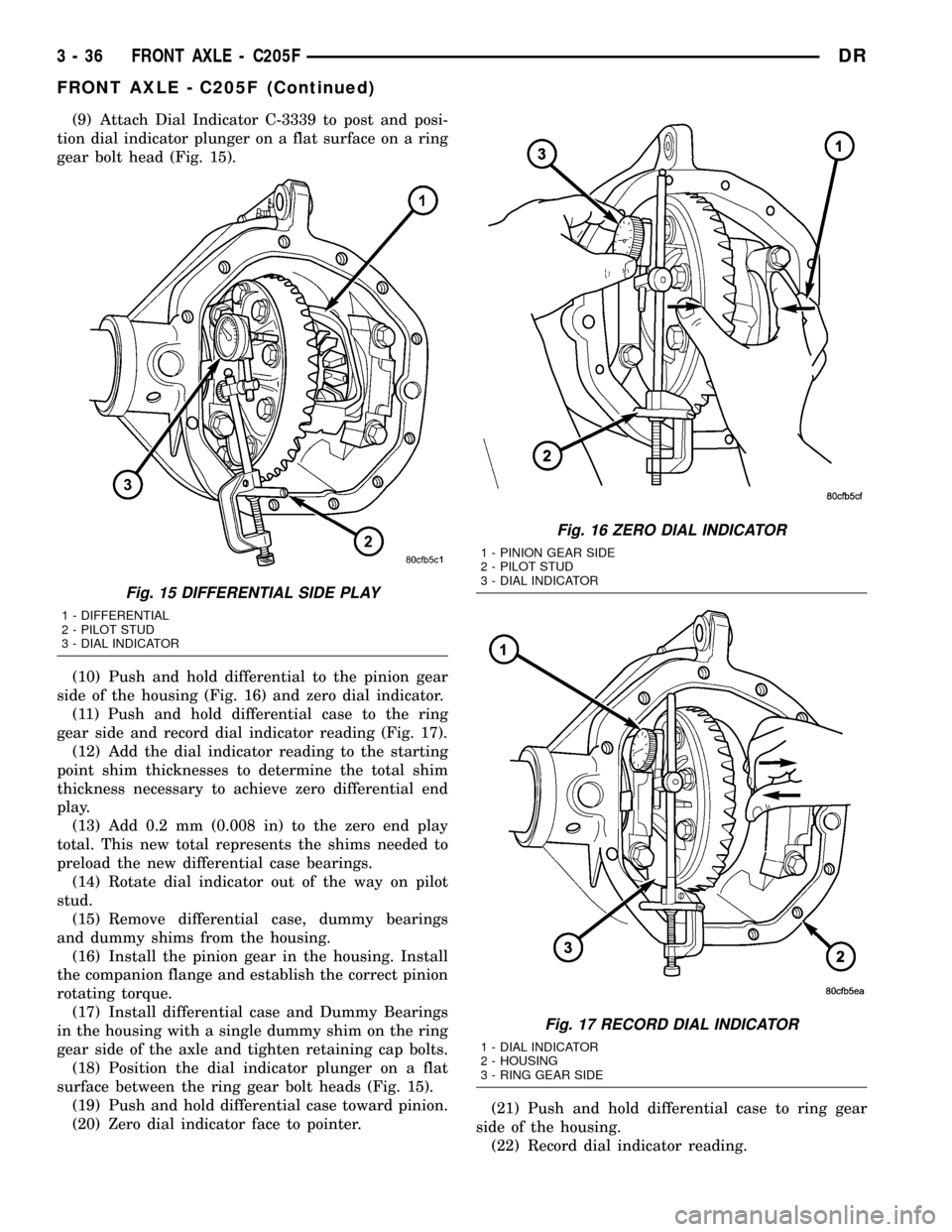

(9) Attach Dial Indicator C-3339 to post and posi-

tion dial indicator plunger on a flat surface on a ring

gear bolt head (Fig. 15).

(10) Push and hold differential to the pinion gear

side of the housing (Fig. 16) and zero dial indicator.

(11) Push and hold differential case to the ring

gear side and record dial indicator reading (Fig. 17).

(12) Add the dial indicator reading to the starting

point shim thicknesses to determine the total shim

thickness necessary to achieve zero differential end

play.

(13) Add 0.2 mm (0.008 in) to the zero end play

total. This new total represents the shims needed to

preload the new differential case bearings.

(14) Rotate dial indicator out of the way on pilot

stud.

(15) Remove differential case, dummy bearings

and dummy shims from the housing.

(16) Install the pinion gear in the housing. Install

the companion flange and establish the correct pinion

rotating torque.

(17) Install differential case and Dummy Bearings

in the housing with a single dummy shim on the ring

gear side of the axle and tighten retaining cap bolts.

(18) Position the dial indicator plunger on a flat

surface between the ring gear bolt heads (Fig. 15).

(19) Push and hold differential case toward pinion.

(20) Zero dial indicator face to pointer.(21) Push and hold differential case to ring gear

side of the housing.

(22) Record dial indicator reading.

Fig. 15 DIFFERENTIAL SIDE PLAY

1 - DIFFERENTIAL

2 - PILOT STUD

3 - DIAL INDICATOR

Fig. 16 ZERO DIAL INDICATOR

1 - PINION GEAR SIDE

2 - PILOT STUD

3 - DIAL INDICATOR

Fig. 17 RECORD DIAL INDICATOR

1 - DIAL INDICATOR

2 - HOUSING

3 - RING GEAR SIDE

3 - 36 FRONT AXLE - C205FDR

FRONT AXLE - C205F (Continued)

Page 141 of 2627

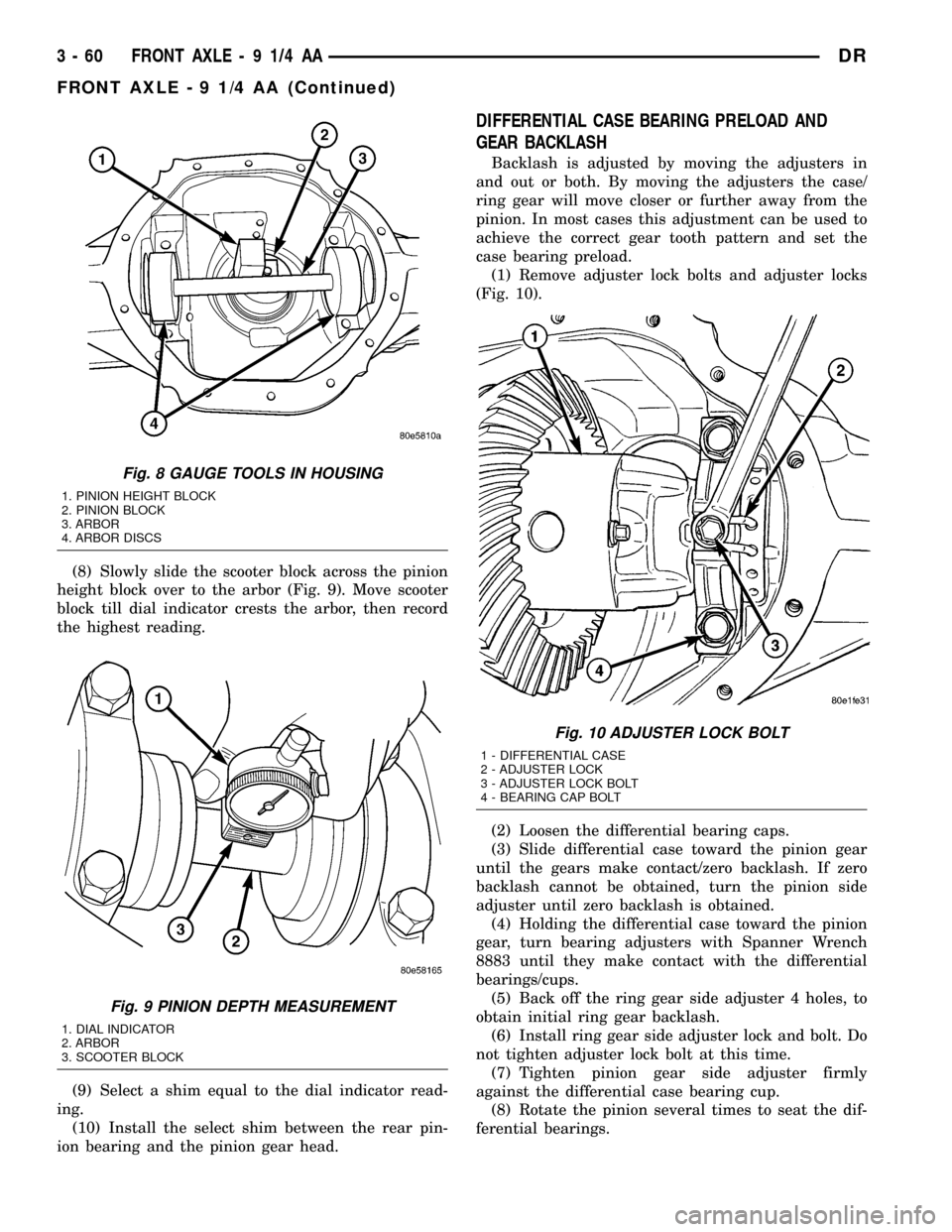

(8) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 9). Move scooter

block till dial indicator crests the arbor, then record

the highest reading.

(9) Select a shim equal to the dial indicator read-

ing.

(10) Install the select shim between the rear pin-

ion bearing and the pinion gear head.

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 10).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(6) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(7) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(8) Rotate the pinion several times to seat the dif-

ferential bearings.

Fig. 8 GAUGE TOOLS IN HOUSING

1. PINION HEIGHT BLOCK

2. PINION BLOCK

3. ARBOR

4. ARBOR DISCS

Fig. 9 PINION DEPTH MEASUREMENT

1. DIAL INDICATOR

2. ARBOR

3. SCOOTER BLOCK

Fig. 10 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

3 - 60 FRONT AXLE - 9 1/4 AADR

FRONT AXLE - 9 1/4 AA (Continued)

Page 155 of 2627

(4) Align hole in the pinion gears with hole in the

differential case.

(5) Install pinion shaft.

(6) Installnewpinion shaft lock bolt and tighten

to 52 N´m (38 ft. lbs.).

INSTALLATION

(1) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.

CAUTION: Do not use water, steam, kerosene or

gasoline for cleaning.

(2) Lubricate differential case bearing.

(3) Install differential case with bearings cups into

the housing.

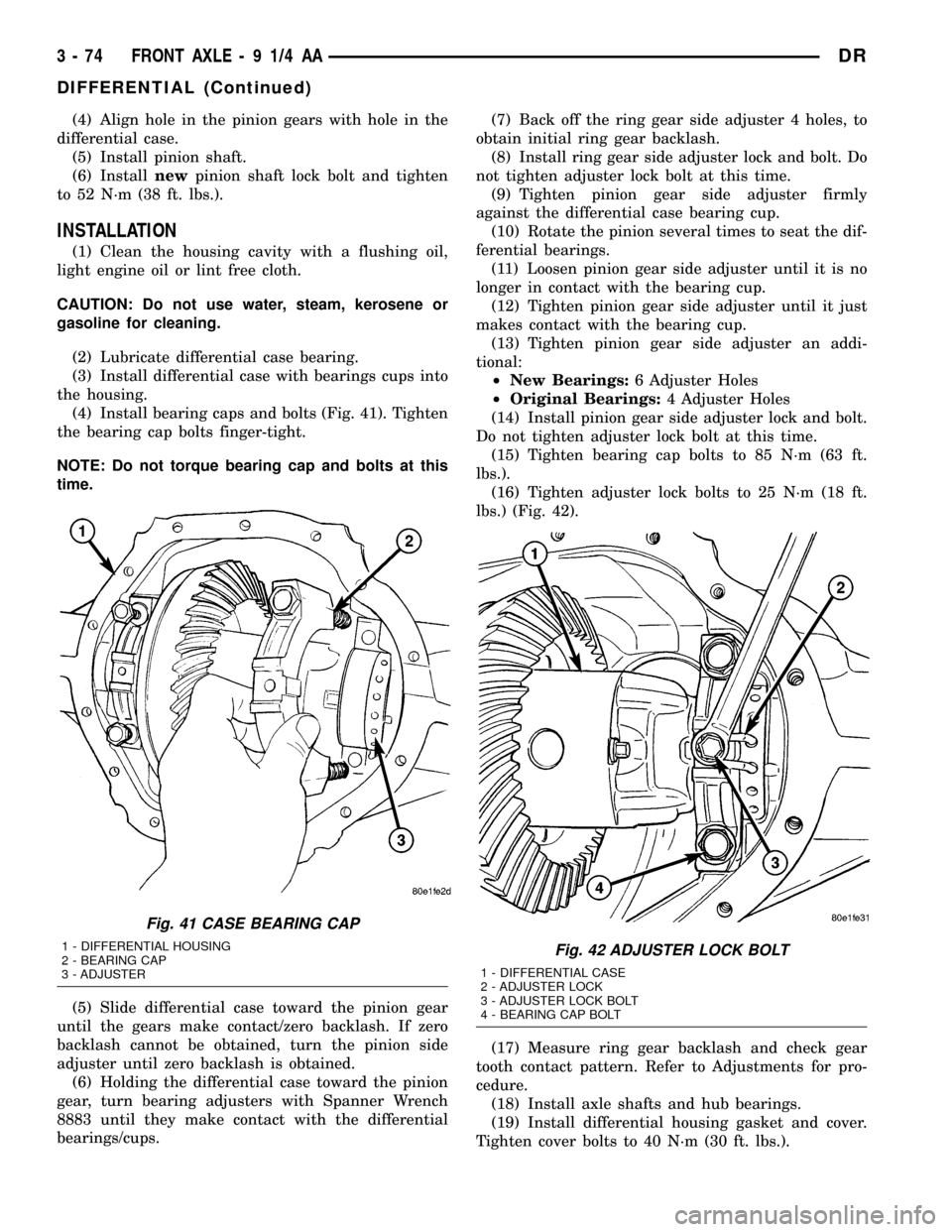

(4) Install bearing caps and bolts (Fig. 41). Tighten

the bearing cap bolts finger-tight.

NOTE: Do not torque bearing cap and bolts at this

time.

(5) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(6) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.(7) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(8) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(9) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(10) Rotate the pinion several times to seat the dif-

ferential bearings.

(11) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup.

(12) Tighten pinion gear side adjuster until it just

makes contact with the bearing cup.

(13) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings:6 Adjuster Holes

²Original Bearings:4 Adjuster Holes

(14) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(15) Tighten bearing cap bolts to 85 N´m (63 ft.

lbs.).

(16) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.) (Fig. 42).

(17) Measure ring gear backlash and check gear

tooth contact pattern. Refer to Adjustments for pro-

cedure.

(18) Install axle shafts and hub bearings.

(19) Install differential housing gasket and cover.

Tighten cover bolts to 40 N´m (30 ft. lbs.).

Fig. 41 CASE BEARING CAP

1 - DIFFERENTIAL HOUSING

2 - BEARING CAP

3 - ADJUSTERFig. 42 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

3 - 74 FRONT AXLE - 9 1/4 AADR

DIFFERENTIAL (Continued)

Page 198 of 2627

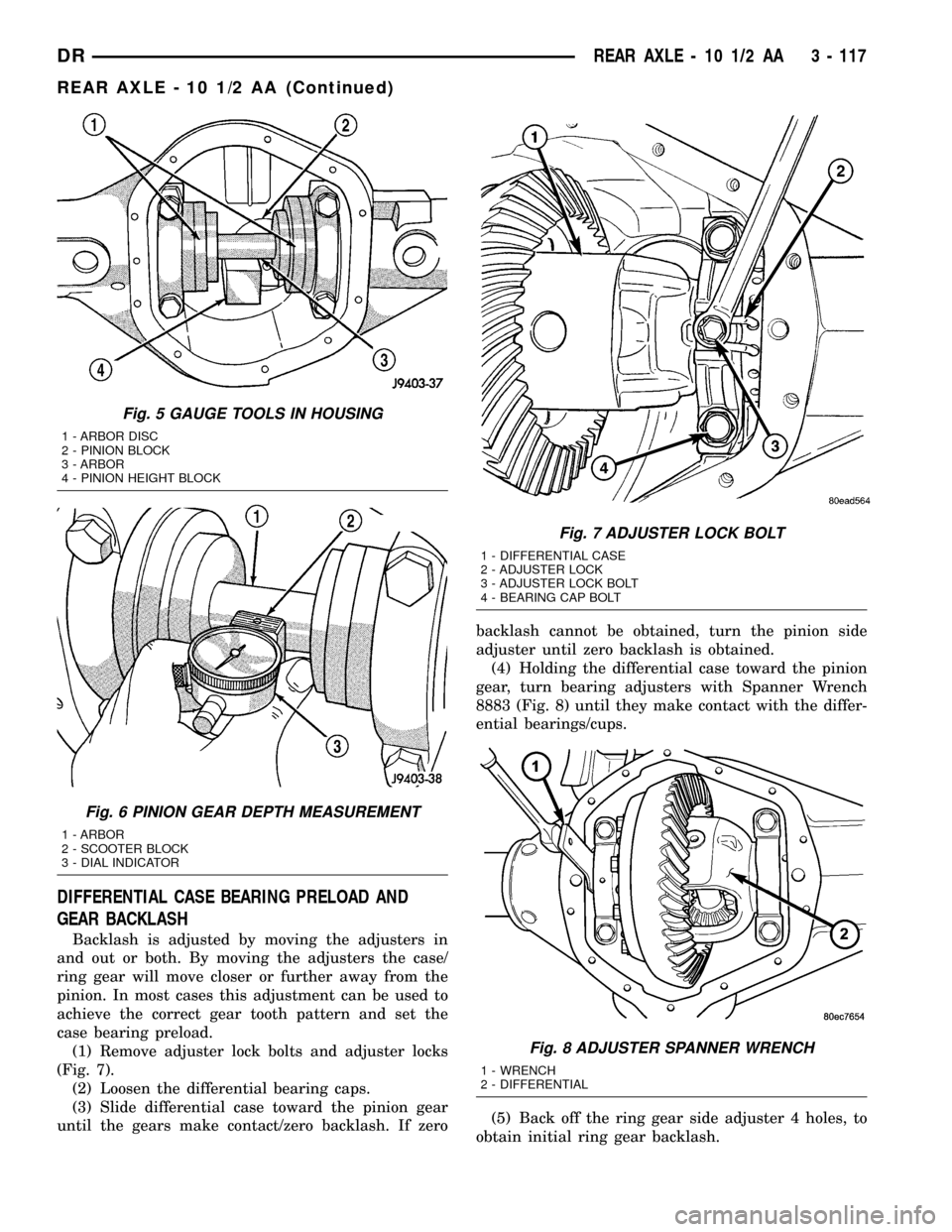

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 7).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zerobacklash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 (Fig. 8) until they make contact with the differ-

ential bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

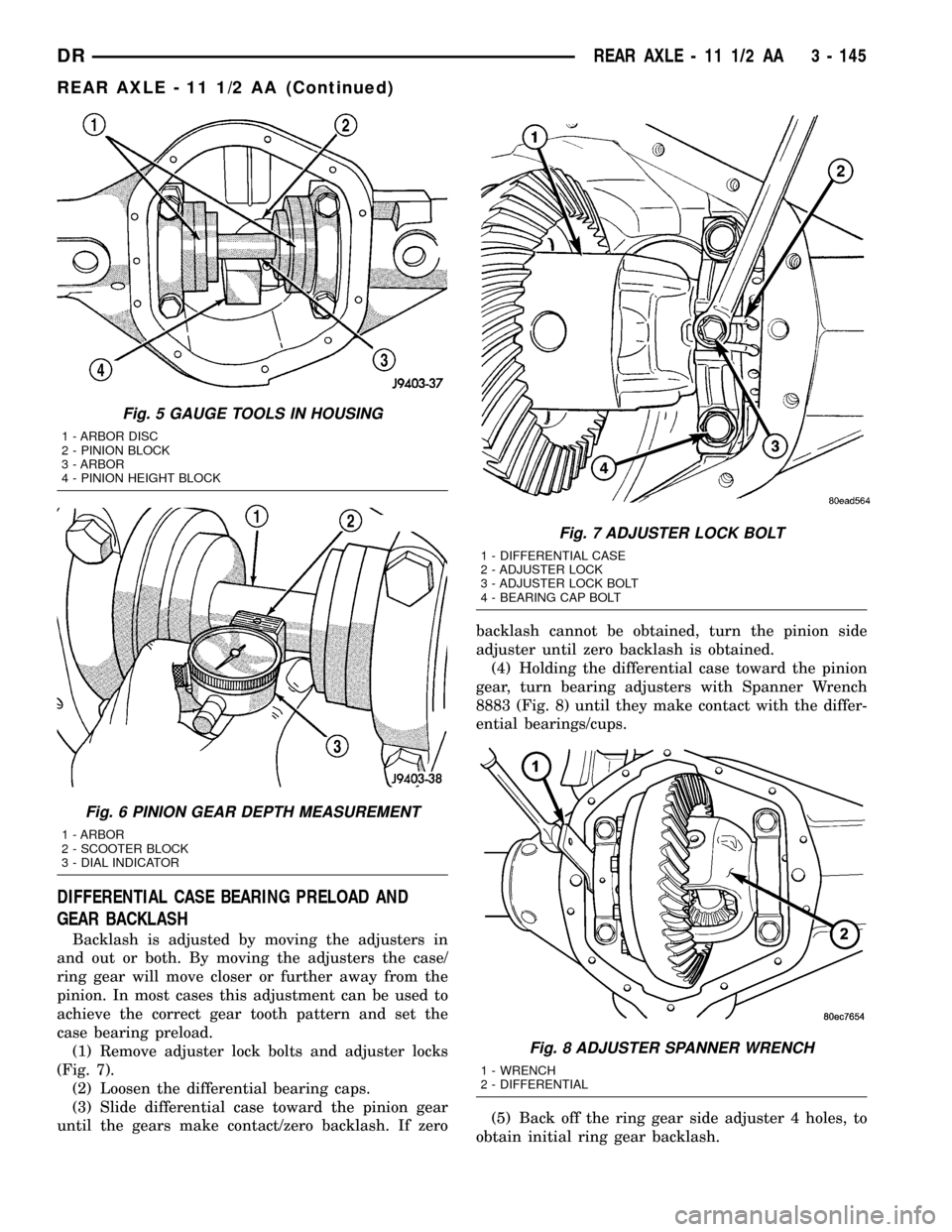

Fig. 5 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 6 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 7 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 8 ADJUSTER SPANNER WRENCH

1 - WRENCH

2 - DIFFERENTIAL

DRREAR AXLE - 10 1/2 AA 3 - 117

REAR AXLE - 10 1/2 AA (Continued)

Page 211 of 2627

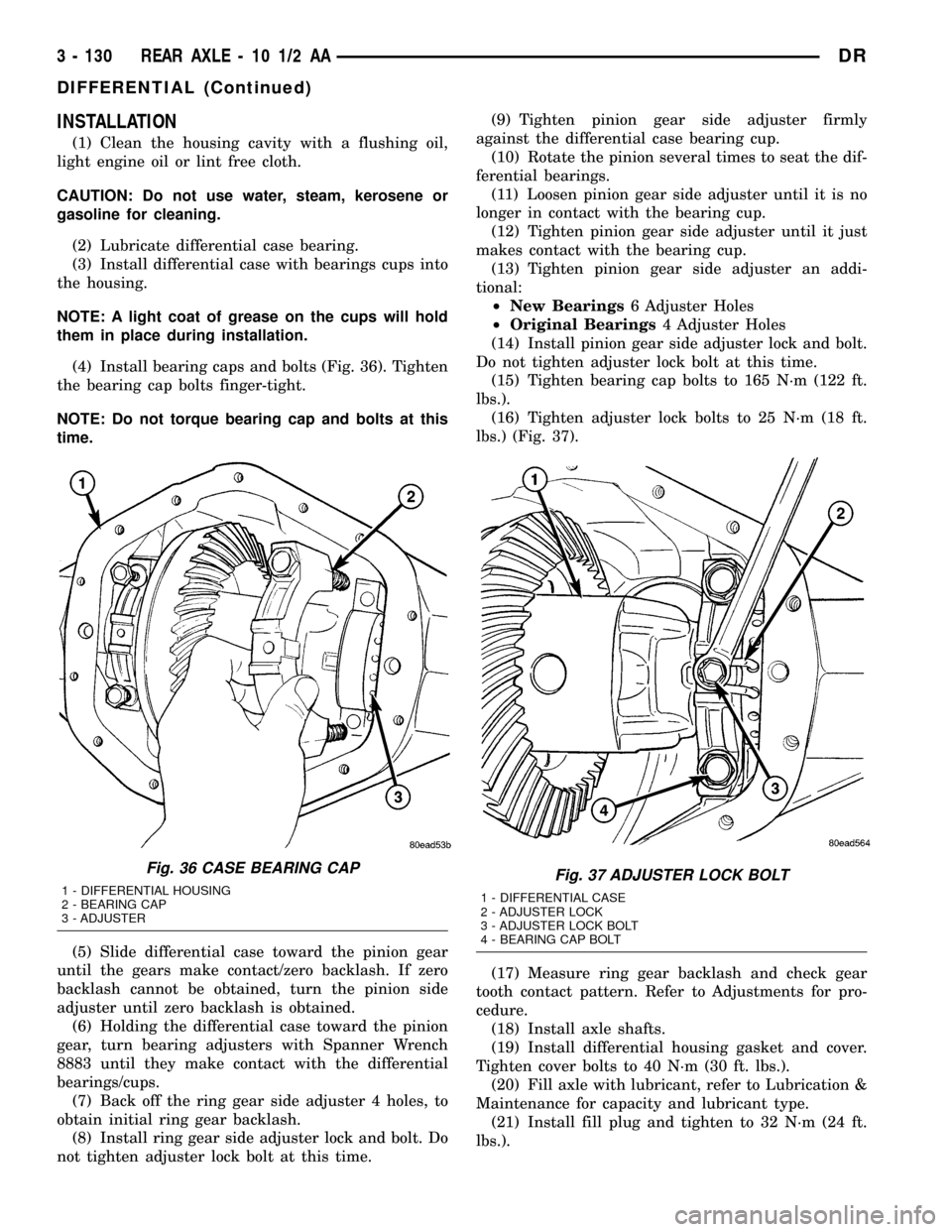

INSTALLATION

(1) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.

CAUTION: Do not use water, steam, kerosene or

gasoline for cleaning.

(2) Lubricate differential case bearing.

(3) Install differential case with bearings cups into

the housing.

NOTE: A light coat of grease on the cups will hold

them in place during installation.

(4) Install bearing caps and bolts (Fig. 36). Tighten

the bearing cap bolts finger-tight.

NOTE: Do not torque bearing cap and bolts at this

time.

(5) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(6) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.

(7) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(8) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.(9) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(10) Rotate the pinion several times to seat the dif-

ferential bearings.

(11) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup.

(12) Tighten pinion gear side adjuster until it just

makes contact with the bearing cup.

(13) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings6 Adjuster Holes

²Original Bearings4 Adjuster Holes

(14) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

(15) Tighten bearing cap bolts to 165 N´m (122 ft.

lbs.).

(16) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.) (Fig. 37).

(17) Measure ring gear backlash and check gear

tooth contact pattern. Refer to Adjustments for pro-

cedure.

(18) Install axle shafts.

(19) Install differential housing gasket and cover.

Tighten cover bolts to 40 N´m (30 ft. lbs.).

(20) Fill axle with lubricant, refer to Lubrication &

Maintenance for capacity and lubricant type.

(21) Install fill plug and tighten to 32 N´m (24 ft.

lbs.).

Fig. 36 CASE BEARING CAP

1 - DIFFERENTIAL HOUSING

2 - BEARING CAP

3 - ADJUSTERFig. 37 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

3 - 130 REAR AXLE - 10 1/2 AADR

DIFFERENTIAL (Continued)

Page 212 of 2627

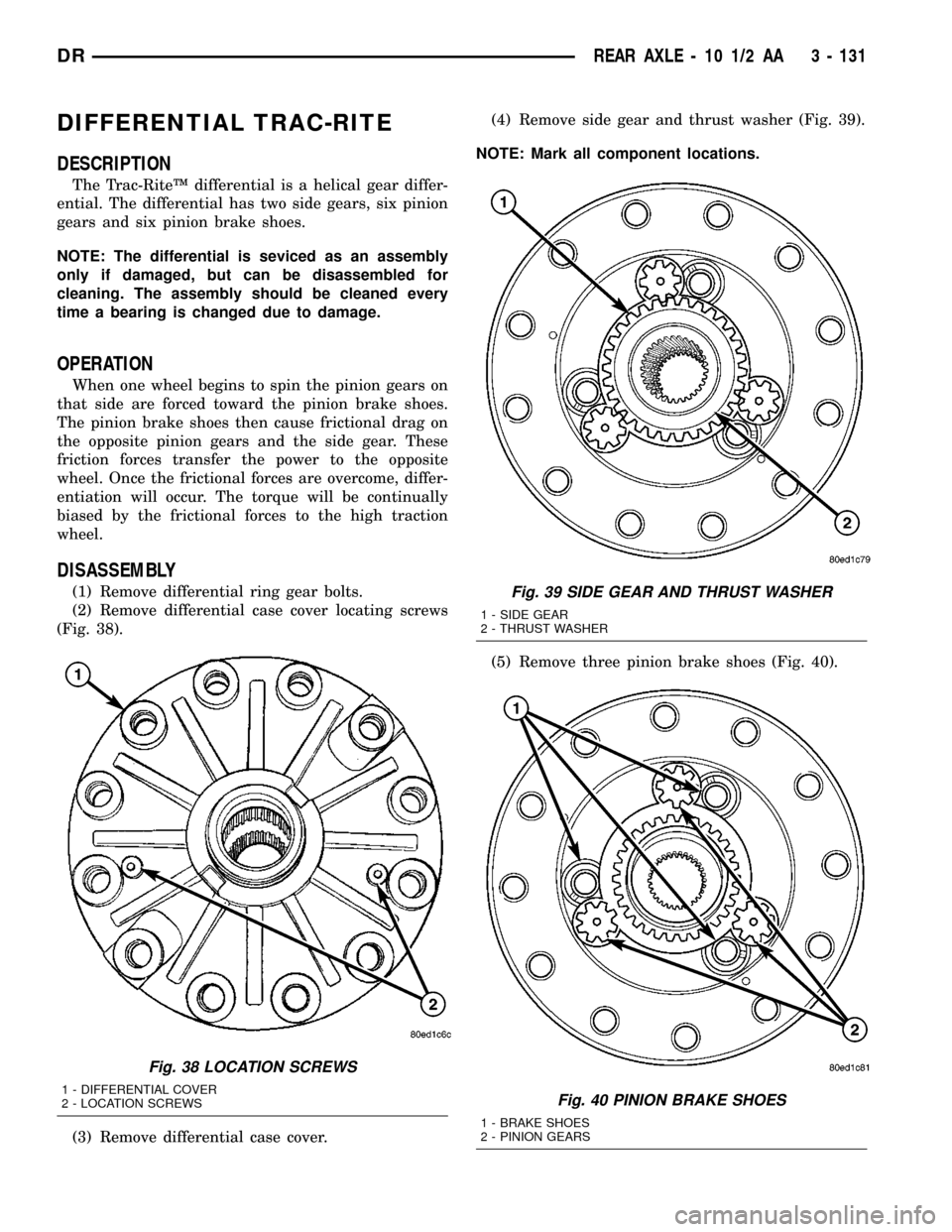

DIFFERENTIAL TRAC-RITE

DESCRIPTION

The Trac-RiteŸ differential is a helical gear differ-

ential. The differential has two side gears, six pinion

gears and six pinion brake shoes.

NOTE: The differential is seviced as an assembly

only if damaged, but can be disassembled for

cleaning. The assembly should be cleaned every

time a bearing is changed due to damage.

OPERATION

When one wheel begins to spin the pinion gears on

that side are forced toward the pinion brake shoes.

The pinion brake shoes then cause frictional drag on

the opposite pinion gears and the side gear. These

friction forces transfer the power to the opposite

wheel. Once the frictional forces are overcome, differ-

entiation will occur. The torque will be continually

biased by the frictional forces to the high traction

wheel.

DISASSEMBLY

(1) Remove differential ring gear bolts.

(2) Remove differential case cover locating screws

(Fig. 38).

(3) Remove differential case cover.(4) Remove side gear and thrust washer (Fig. 39).

NOTE: Mark all component locations.

(5) Remove three pinion brake shoes (Fig. 40).

Fig. 38 LOCATION SCREWS

1 - DIFFERENTIAL COVER

2 - LOCATION SCREWS

Fig. 39 SIDE GEAR AND THRUST WASHER

1 - SIDE GEAR

2 - THRUST WASHER

Fig. 40 PINION BRAKE SHOES

1 - BRAKE SHOES

2 - PINION GEARS

DRREAR AXLE - 10 1/2 AA 3 - 131

Page 226 of 2627

DIFFERENTIAL CASE BEARING PRELOAD AND

GEAR BACKLASH

Backlash is adjusted by moving the adjusters in

and out or both. By moving the adjusters the case/

ring gear will move closer or further away from the

pinion. In most cases this adjustment can be used to

achieve the correct gear tooth pattern and set the

case bearing preload.

(1) Remove adjuster lock bolts and adjuster locks

(Fig. 7).

(2) Loosen the differential bearing caps.

(3) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zerobacklash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(4) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 (Fig. 8) until they make contact with the differ-

ential bearings/cups.

(5) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

Fig. 5 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCK

Fig. 6 PINION GEAR DEPTH MEASUREMENT

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 7 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

Fig. 8 ADJUSTER SPANNER WRENCH

1 - WRENCH

2 - DIFFERENTIAL

DRREAR AXLE - 11 1/2 AA 3 - 145

REAR AXLE - 11 1/2 AA (Continued)

Page 239 of 2627

(5) Slide differential case toward the pinion gear

until the gears make contact/zero backlash. If zero

backlash cannot be obtained, turn the pinion side

adjuster until zero backlash is obtained.

(6) Holding the differential case toward the pinion

gear, turn bearing adjusters with Spanner Wrench

8883 until they make contact with the differential

bearings/cups.

(7) Back off the ring gear side adjuster 4 holes, to

obtain initial ring gear backlash.

(8) Install ring gear side adjuster lock and bolt. Do

not tighten adjuster lock bolt at this time.

(9) Tighten pinion gear side adjuster firmly

against the differential case bearing cup.

(10) Rotate the pinion several times to seat the dif-

ferential bearings.

(11) Loosen pinion gear side adjuster until it is no

longer in contact with the bearing cup.

(12) Tighten pinion gear side adjuster until it just

makes contact with the bearing cup.

(13) Tighten pinion gear side adjuster an addi-

tional:

²New Bearings6 Adjuster Holes

²Original Bearings4 Adjuster Holes

(14) Install pinion gear side adjuster lock and bolt.

Do not tighten adjuster lock bolt at this time.

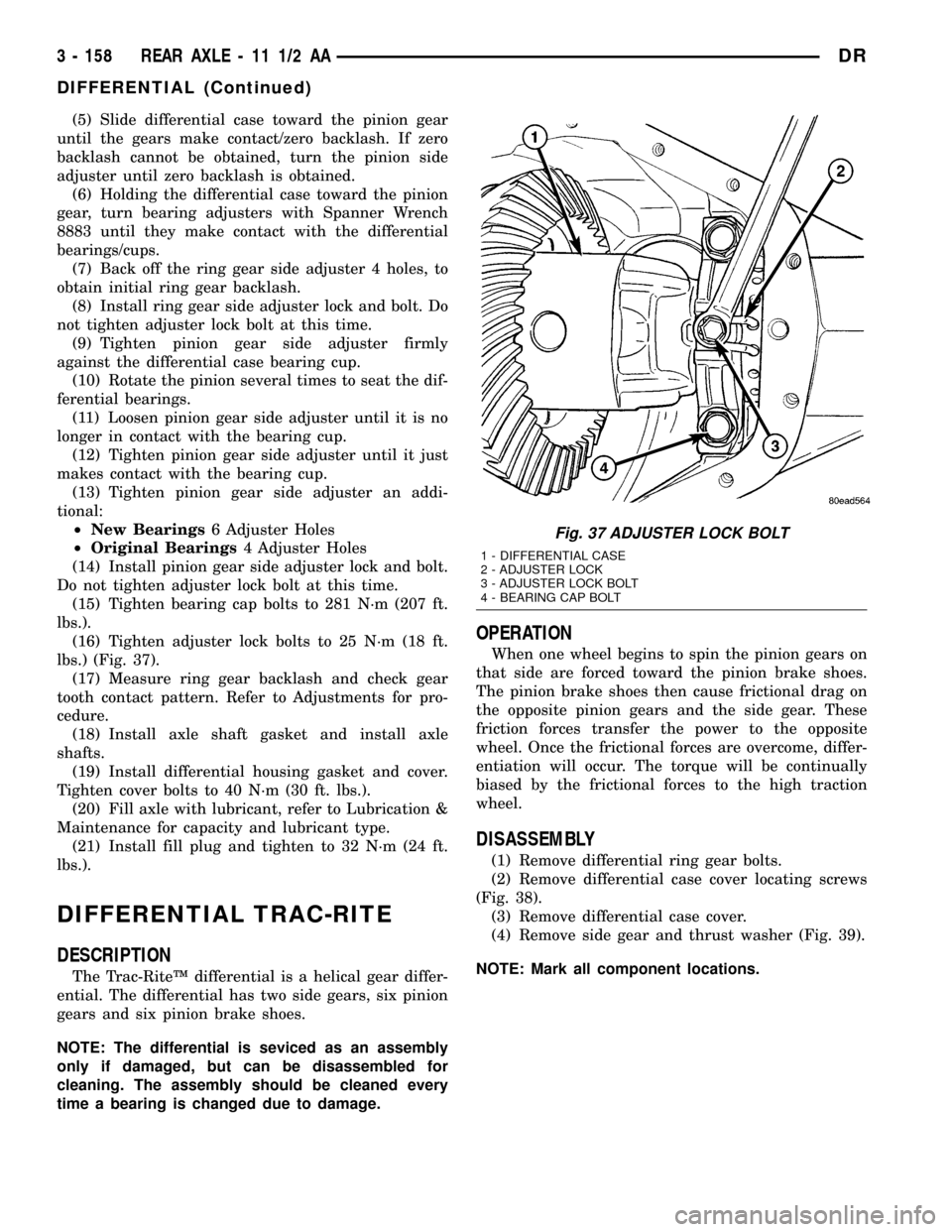

(15) Tighten bearing cap bolts to 281 N´m (207 ft.

lbs.).

(16) Tighten adjuster lock bolts to 25 N´m (18 ft.

lbs.) (Fig. 37).

(17) Measure ring gear backlash and check gear

tooth contact pattern. Refer to Adjustments for pro-

cedure.

(18) Install axle shaft gasket and install axle

shafts.

(19) Install differential housing gasket and cover.

Tighten cover bolts to 40 N´m (30 ft. lbs.).

(20) Fill axle with lubricant, refer to Lubrication &

Maintenance for capacity and lubricant type.

(21) Install fill plug and tighten to 32 N´m (24 ft.

lbs.).

DIFFERENTIAL TRAC-RITE

DESCRIPTION

The Trac-RiteŸ differential is a helical gear differ-

ential. The differential has two side gears, six pinion

gears and six pinion brake shoes.

NOTE: The differential is seviced as an assembly

only if damaged, but can be disassembled for

cleaning. The assembly should be cleaned every

time a bearing is changed due to damage.

OPERATION

When one wheel begins to spin the pinion gears on

that side are forced toward the pinion brake shoes.

The pinion brake shoes then cause frictional drag on

the opposite pinion gears and the side gear. These

friction forces transfer the power to the opposite

wheel. Once the frictional forces are overcome, differ-

entiation will occur. The torque will be continually

biased by the frictional forces to the high traction

wheel.

DISASSEMBLY

(1) Remove differential ring gear bolts.

(2) Remove differential case cover locating screws

(Fig. 38).

(3) Remove differential case cover.

(4) Remove side gear and thrust washer (Fig. 39).

NOTE: Mark all component locations.

Fig. 37 ADJUSTER LOCK BOLT

1 - DIFFERENTIAL CASE

2 - ADJUSTER LOCK

3 - ADJUSTER LOCK BOLT

4 - BEARING CAP BOLT

3 - 158 REAR AXLE - 11 1/2 AADR

DIFFERENTIAL (Continued)