Removal DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 508 of 2627

(4) Install ignition coil(s). Refer to Ignition Coil

Removal/Installation.

5.7L V-8

(1) Special care should be taken when installing

spark plugs into the cylinder head spark plug wells.

Be sure the plugs do not drop into the plug wells as

electrodes can be damaged.

(2) Start the spark plug into cylinder head by

hand to avoid cross threading aluminum threads. To

aid in installation, attach a piece of rubber hose, or

an old spark plug boot to spark plug.

(3) The 5.7L V-8 is equipped with torque critical

design spark plugs. Do not exceed 15 ft. lbs. torque.

Tighten spark plugs. Refer to torque specifications.

(4) Before installing spark plug cables to either the

spark plugs or coils, apply dielectric grease to inside

of boots.

(5) To prevent ignition crossfire, spark plug cables

MUSTbe placed in cable tray (routing loom) into

their original position. Refer to Spark Plug Cable

Removal for a graphic.

(6) Install ignition coil(s) to necessary spark plugs.

Refer to Ignition Coil Installation.

(7) Install spark plug cables to remaining spark

plugs. Remember to apply dielectric grease to inside

of boots.

IGNITION COIL CAPACITOR

DESCRIPTION

One coil capacitor is used. It is located in the right-

rear section of the engine compartment.

OPERATION

The coil capacitor(s) help dampen the amount of

conducted electrical noise to the camshaft position

sensor, crankshaft position sensor, and throttle posi-

tion sensor. This noise is generated on the 12V sup-

ply wire to the ignition coils and fuel injectors.

REMOVAL

The coil capacitor is located in the right-rear sec-

tion of the engine compartment. It is attached with a

mounting stud and nut.

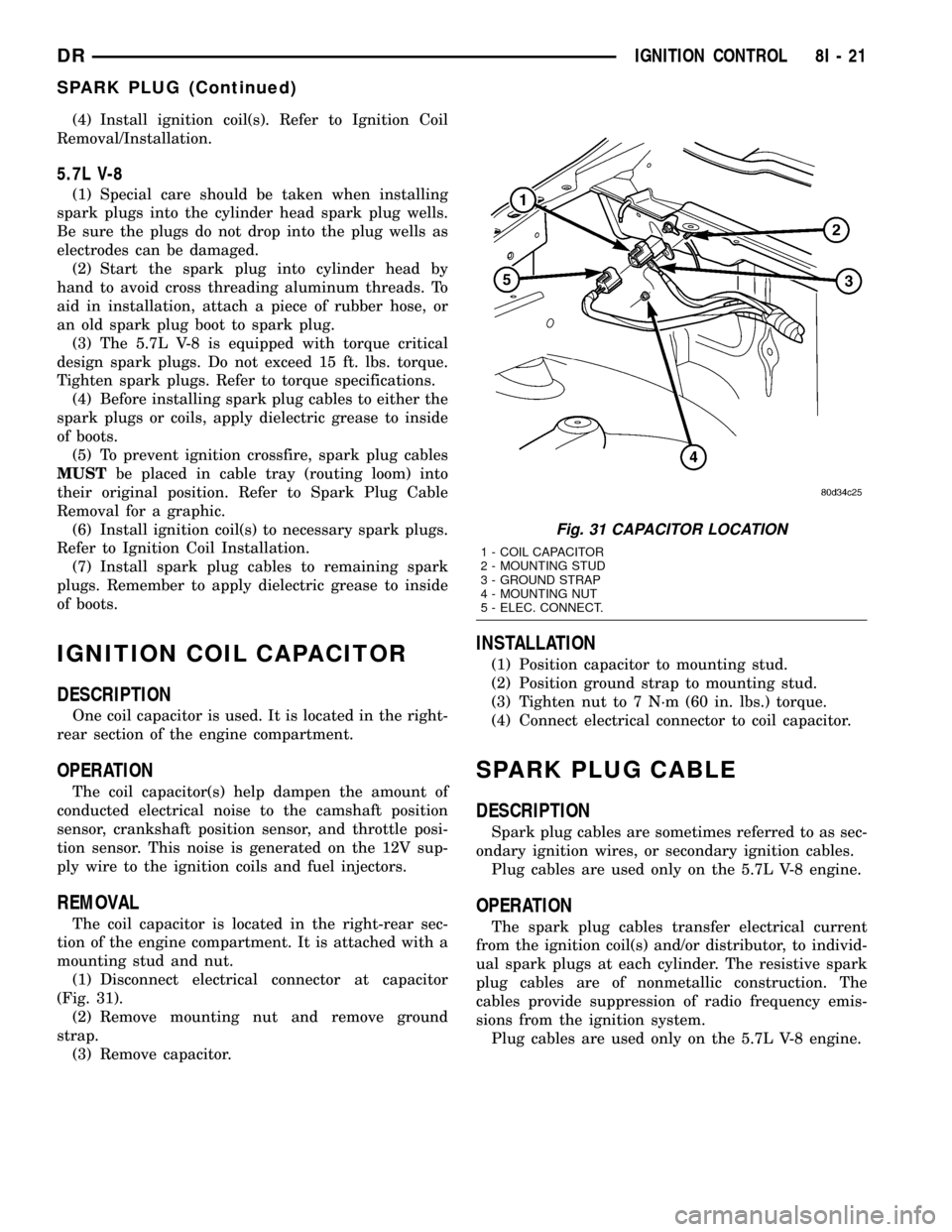

(1) Disconnect electrical connector at capacitor

(Fig. 31).

(2) Remove mounting nut and remove ground

strap.

(3) Remove capacitor.

INSTALLATION

(1) Position capacitor to mounting stud.

(2) Position ground strap to mounting stud.

(3) Tighten nut to 7 N´m (60 in. lbs.) torque.

(4) Connect electrical connector to coil capacitor.

SPARK PLUG CABLE

DESCRIPTION

Spark plug cables are sometimes referred to as sec-

ondary ignition wires, or secondary ignition cables.

Plug cables are used only on the 5.7L V-8 engine.

OPERATION

The spark plug cables transfer electrical current

from the ignition coil(s) and/or distributor, to individ-

ual spark plugs at each cylinder. The resistive spark

plug cables are of nonmetallic construction. The

cables provide suppression of radio frequency emis-

sions from the ignition system.

Plug cables are used only on the 5.7L V-8 engine.

Fig. 31 CAPACITOR LOCATION

1 - COIL CAPACITOR

2 - MOUNTING STUD

3 - GROUND STRAP

4 - MOUNTING NUT

5 - ELEC. CONNECT.

DRIGNITION CONTROL 8I - 21

SPARK PLUG (Continued)

Page 509 of 2627

REMOVAL

5.7L V-8

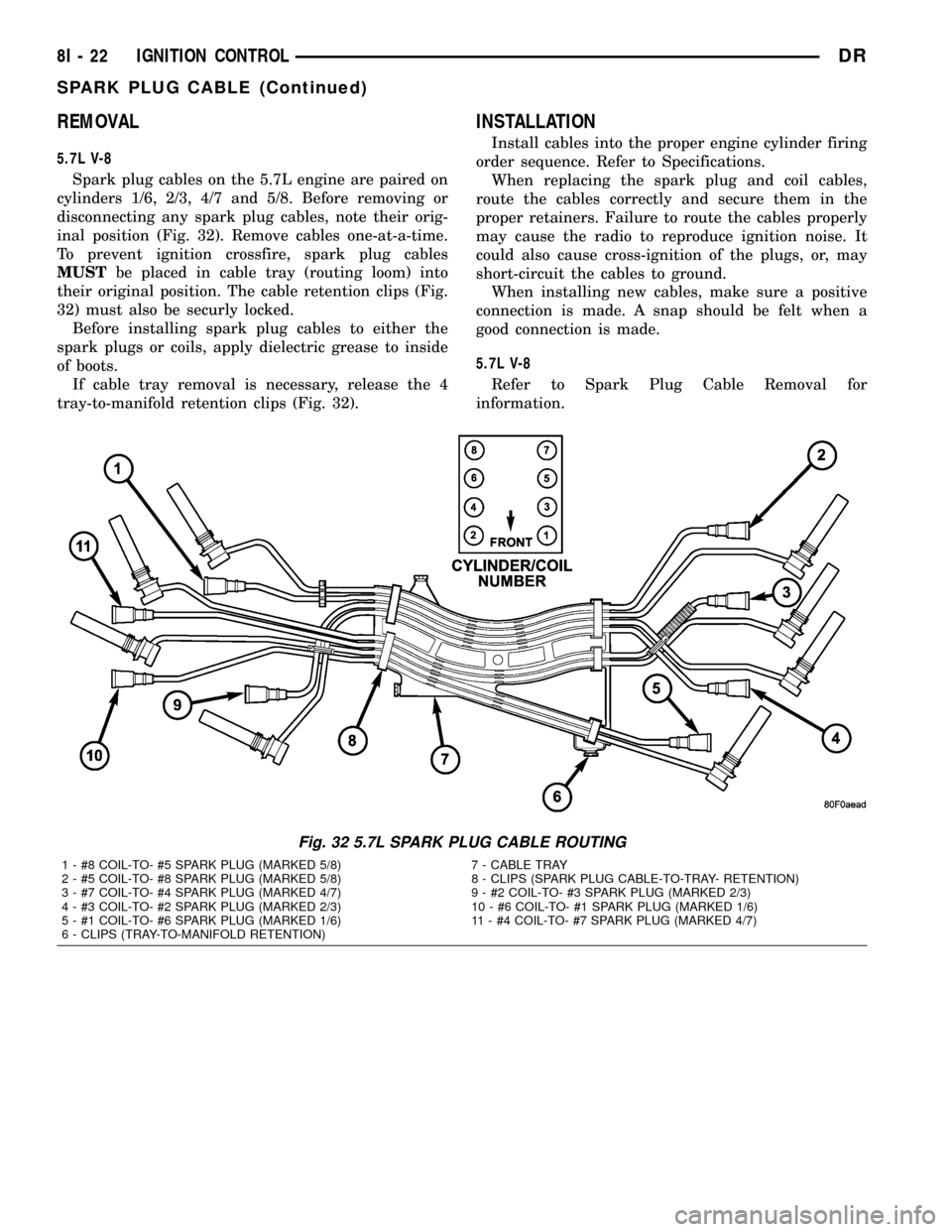

Spark plug cables on the 5.7L engine are paired on

cylinders 1/6, 2/3, 4/7 and 5/8. Before removing or

disconnecting any spark plug cables, note their orig-

inal position (Fig. 32). Remove cables one-at-a-time.

To prevent ignition crossfire, spark plug cables

MUSTbe placed in cable tray (routing loom) into

their original position. The cable retention clips (Fig.

32) must also be securly locked.

Before installing spark plug cables to either the

spark plugs or coils, apply dielectric grease to inside

of boots.

If cable tray removal is necessary, release the 4

tray-to-manifold retention clips (Fig. 32).

INSTALLATION

Install cables into the proper engine cylinder firing

order sequence. Refer to Specifications.

When replacing the spark plug and coil cables,

route the cables correctly and secure them in the

proper retainers. Failure to route the cables properly

may cause the radio to reproduce ignition noise. It

could also cause cross-ignition of the plugs, or, may

short-circuit the cables to ground.

When installing new cables, make sure a positive

connection is made. A snap should be felt when a

good connection is made.

5.7L V-8

Refer to Spark Plug Cable Removal for

information.

Fig. 32 5.7L SPARK PLUG CABLE ROUTING

1 - #8 COIL-TO- #5 SPARK PLUG (MARKED 5/8) 7 - CABLE TRAY

2 - #5 COIL-TO- #8 SPARK PLUG (MARKED 5/8) 8 - CLIPS (SPARK PLUG CABLE-TO-TRAY- RETENTION)

3 - #7 COIL-TO- #4 SPARK PLUG (MARKED 4/7) 9 - #2 COIL-TO- #3 SPARK PLUG (MARKED 2/3)

4 - #3 COIL-TO- #2 SPARK PLUG (MARKED 2/3) 10 - #6 COIL-TO- #1 SPARK PLUG (MARKED 1/6)

5 - #1 COIL-TO- #6 SPARK PLUG (MARKED 1/6) 11 - #4 COIL-TO- #7 SPARK PLUG (MARKED 4/7)

6 - CLIPS (TRAY-TO-MANIFOLD RETENTION)

8I - 22 IGNITION CONTROLDR

SPARK PLUG CABLE (Continued)

Page 510 of 2627

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION..........................2

OPERATION............................6

DIAGNOSIS AND TESTING - INSTRUMENT

CLUSTER...........................10

REMOVAL.............................14

DISASSEMBLY.........................14

ASSEMBLY............................15

INSTALLATION.........................16

ABS INDICATOR

DESCRIPTION.........................17

OPERATION...........................17

AIRBAG INDICATOR

DESCRIPTION.........................18

OPERATION...........................18

BRAKE/PARK BRAKE INDICATOR

DESCRIPTION.........................19

OPERATION...........................19

DIAGNOSIS AND TESTING - BRAKE

INDICATOR..........................20

CARGO LAMP INDICATOR

DESCRIPTION.........................20

OPERATION...........................20

CHECK GAUGES INDICATOR

DESCRIPTION.........................21

OPERATION...........................21

CRUISE INDICATOR

DESCRIPTION.........................22

OPERATION...........................22

DOOR AJAR INDICATOR

DESCRIPTION.........................23

OPERATION...........................23

ENGINE TEMPERATURE GAUGE

DESCRIPTION.........................24

OPERATION...........................24

ETC INDICATOR

DESCRIPTION.........................25

OPERATION...........................25

FUEL GAUGE

DESCRIPTION.........................26

OPERATION...........................26

GEAR SELECTOR INDICATOR

DESCRIPTION.........................27

OPERATION...........................27

HIGH BEAM INDICATOR

DESCRIPTION.........................28

OPERATION...........................28

LAMP OUT INDICATOR

DESCRIPTION.........................29OPERATION...........................29

LOW FUEL INDICATOR

DESCRIPTION.........................30

OPERATION...........................30

MALFUNCTION INDICATOR LAMP (MIL)

DESCRIPTION.........................31

OPERATION...........................31

ODOMETER

DESCRIPTION.........................32

OPERATION...........................32

OIL PRESSURE GAUGE

DESCRIPTION.........................33

OPERATION...........................33

SEATBELT INDICATOR

DESCRIPTION.........................34

OPERATION...........................34

STANDARD PROCEDURE - ENHANCED

SEATBELT REMINDER PROGRAMMING....35

SECURITY INDICATOR

DESCRIPTION.........................35

OPERATION...........................36

SERVICE 4WD INDICATOR

DESCRIPTION.........................36

OPERATION...........................37

SPEEDOMETER

DESCRIPTION.........................37

OPERATION...........................37

TACHOMETER

DESCRIPTION.........................38

OPERATION...........................38

TOW/HAUL INDICATOR

DESCRIPTION.........................39

OPERATION...........................39

TRANS TEMP INDICATOR

DESCRIPTION.........................40

OPERATION...........................40

TURN SIGNAL INDICATOR

DESCRIPTION.........................40

OPERATION...........................41

UPSHIFT INDICATOR

DESCRIPTION.........................41

OPERATION...........................42

VOLTAGE GAUGE

DESCRIPTION.........................42

OPERATION...........................43

WAIT-TO-START INDICATOR

DESCRIPTION.........................44

OPERATION...........................44

DRINSTRUMENT CLUSTER 8J - 1

Page 523 of 2627

INSTRUMENT CLUSTER FAILURE MESSAGE

Fault Code Description Correction

AC ABS messages not received. Refer to the appropriate diagnostic information.

AD FCM messages not received. Refer to the appropriate diagnostic information.

AE ACM messages not received. Refer to the appropriate diagnostic information.

AF SKIM messages not received. Refer to the appropriate diagnostic information.

B0 RKE fob batteries low. Refer to the appropriate diagnostic information.

B1 RKE module communication link. Refer to the appropriate diagnostic information.

00 Done All Diagnostic Trouble Codes (DTC) have been

displayed.

(7) The actuator test is now completed. The instru-

ment cluster will automatically exit the self-diagnos-

tic mode and return to normal operation at the

completion of the test, if the ignition switch is turned

to the Off position during the test, or if a vehicle

speed message indicating that the vehicle is moving

is received from the PCM over the PCI data bus dur-

ing the test.

(8) Go back to Step 1 to repeat the test, if neces-

sary.

REMOVAL

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

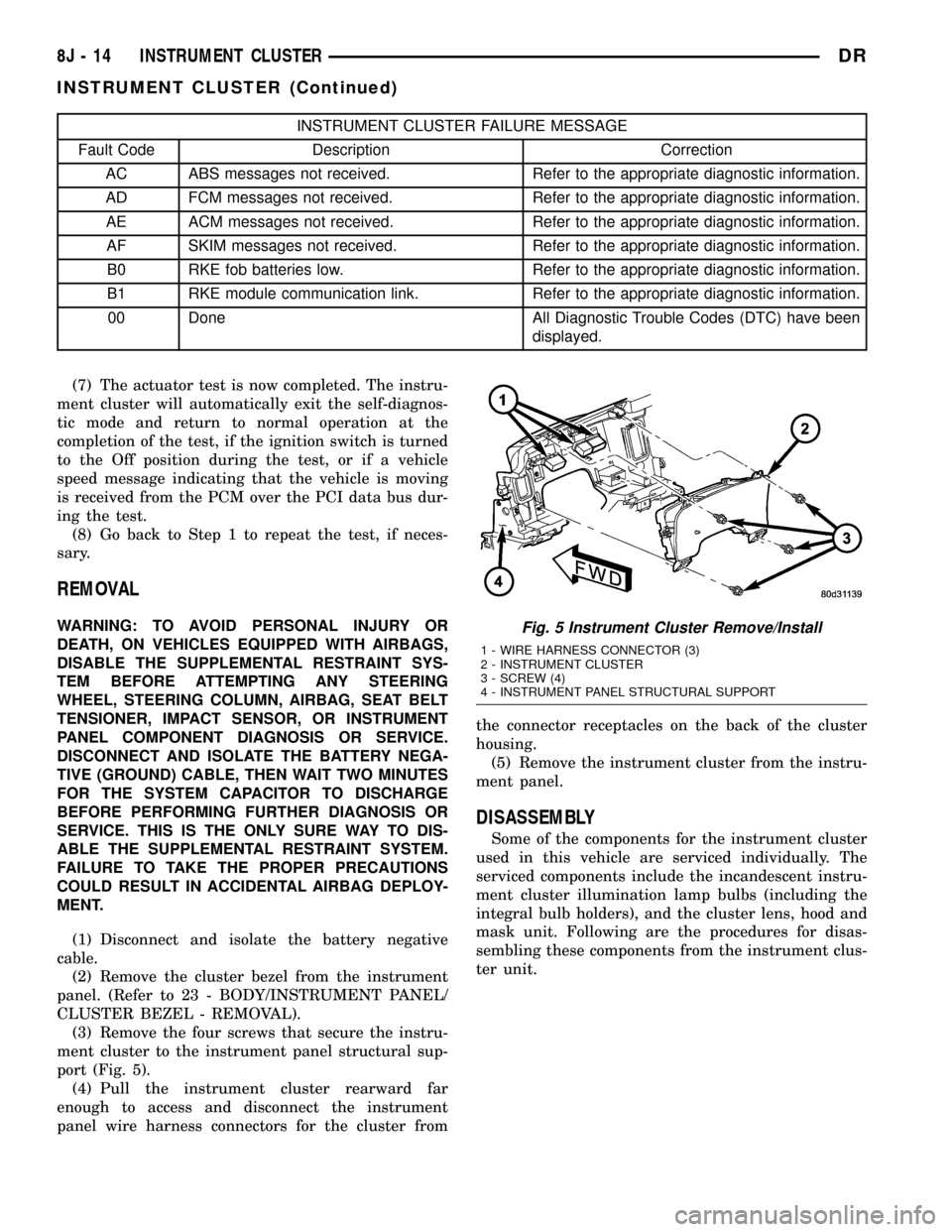

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cluster bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - REMOVAL).

(3) Remove the four screws that secure the instru-

ment cluster to the instrument panel structural sup-

port (Fig. 5).

(4) Pull the instrument cluster rearward far

enough to access and disconnect the instrument

panel wire harness connectors for the cluster fromthe connector receptacles on the back of the cluster

housing.

(5) Remove the instrument cluster from the instru-

ment panel.

DISASSEMBLY

Some of the components for the instrument cluster

used in this vehicle are serviced individually. The

serviced components include the incandescent instru-

ment cluster illumination lamp bulbs (including the

integral bulb holders), and the cluster lens, hood and

mask unit. Following are the procedures for disas-

sembling these components from the instrument clus-

ter unit.

Fig. 5 Instrument Cluster Remove/Install

1 - WIRE HARNESS CONNECTOR (3)

2 - INSTRUMENT CLUSTER

3 - SCREW (4)

4 - INSTRUMENT PANEL STRUCTURAL SUPPORT

8J - 14 INSTRUMENT CLUSTERDR

INSTRUMENT CLUSTER (Continued)

Page 524 of 2627

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

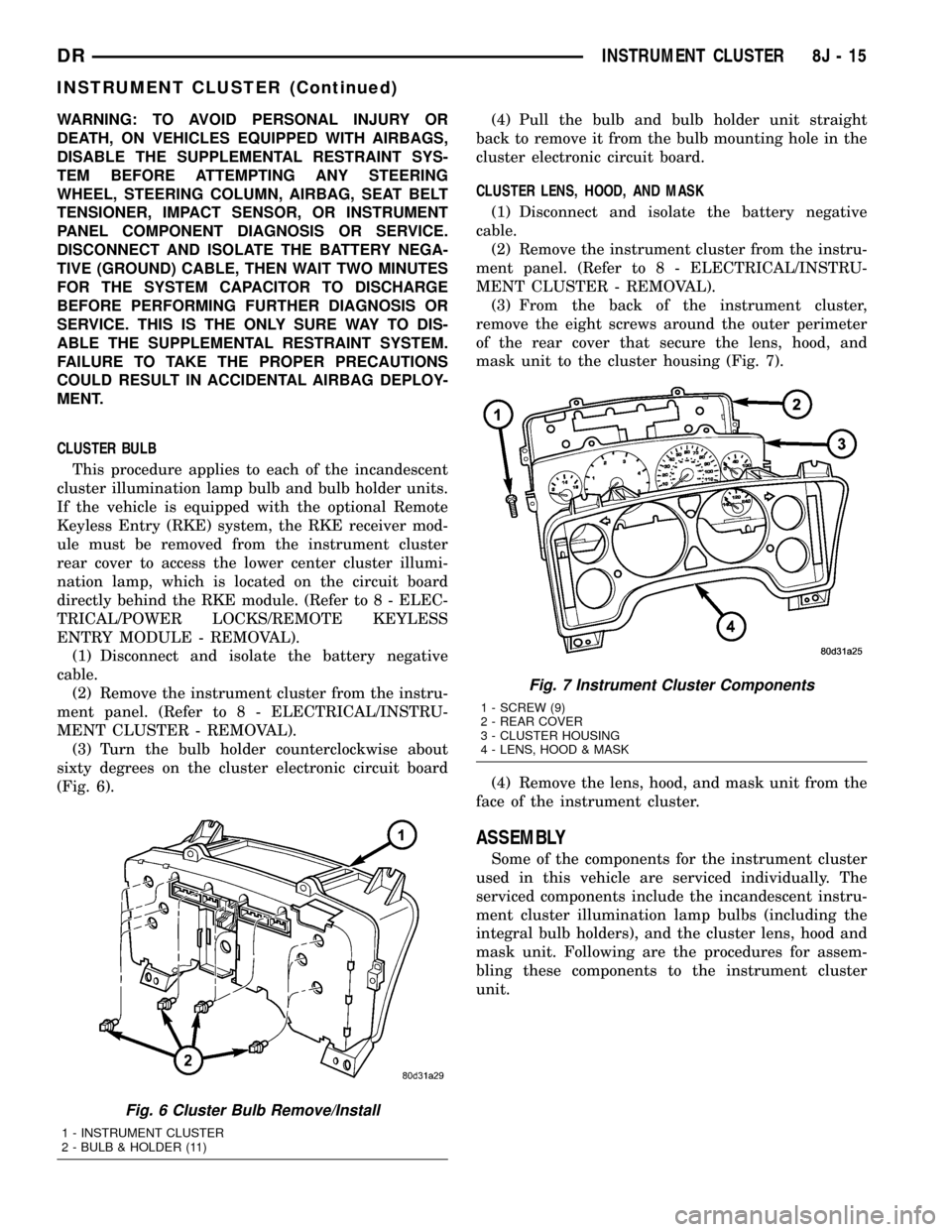

CLUSTER BULB

This procedure applies to each of the incandescent

cluster illumination lamp bulb and bulb holder units.

If the vehicle is equipped with the optional Remote

Keyless Entry (RKE) system, the RKE receiver mod-

ule must be removed from the instrument cluster

rear cover to access the lower center cluster illumi-

nation lamp, which is located on the circuit board

directly behind the RKE module. (Refer to 8 - ELEC-

TRICAL/POWER LOCKS/REMOTE KEYLESS

ENTRY MODULE - REMOVAL).

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster from the instru-

ment panel. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - REMOVAL).

(3) Turn the bulb holder counterclockwise about

sixty degrees on the cluster electronic circuit board

(Fig. 6).(4) Pull the bulb and bulb holder unit straight

back to remove it from the bulb mounting hole in the

cluster electronic circuit board.

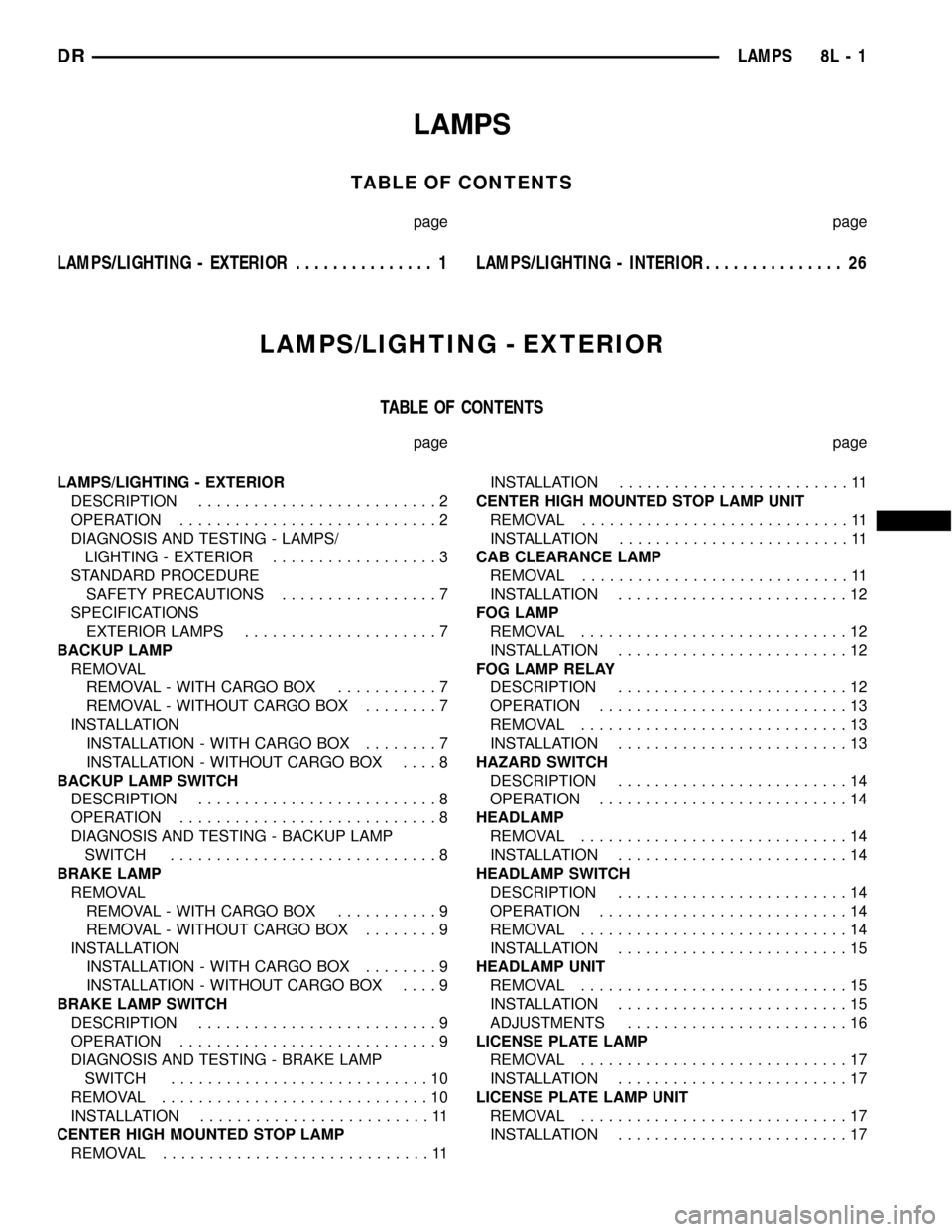

CLUSTER LENS, HOOD, AND MASK

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster from the instru-

ment panel. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - REMOVAL).

(3) From the back of the instrument cluster,

remove the eight screws around the outer perimeter

of the rear cover that secure the lens, hood, and

mask unit to the cluster housing (Fig. 7).

(4) Remove the lens, hood, and mask unit from the

face of the instrument cluster.

ASSEMBLY

Some of the components for the instrument cluster

used in this vehicle are serviced individually. The

serviced components include the incandescent instru-

ment cluster illumination lamp bulbs (including the

integral bulb holders), and the cluster lens, hood and

mask unit. Following are the procedures for assem-

bling these components to the instrument cluster

unit.

Fig. 6 Cluster Bulb Remove/Install

1 - INSTRUMENT CLUSTER

2 - BULB & HOLDER (11)

Fig. 7 Instrument Cluster Components

1 - SCREW (9)

2 - REAR COVER

3 - CLUSTER HOUSING

4 - LENS, HOOD & MASK

DRINSTRUMENT CLUSTER 8J - 15

INSTRUMENT CLUSTER (Continued)

Page 556 of 2627

LAMPS

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - EXTERIOR............... 1LAMPS/LIGHTING - INTERIOR............... 26

LAMPS/LIGHTING - EXTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION..........................2

OPERATION............................2

DIAGNOSIS AND TESTING - LAMPS/

LIGHTING - EXTERIOR..................3

STANDARD PROCEDURE

SAFETY PRECAUTIONS.................7

SPECIFICATIONS

EXTERIOR LAMPS.....................7

BACKUP LAMP

REMOVAL

REMOVAL - WITH CARGO BOX...........7

REMOVAL - WITHOUT CARGO BOX........7

INSTALLATION

INSTALLATION - WITH CARGO BOX........7

INSTALLATION - WITHOUT CARGO BOX....8

BACKUP LAMP SWITCH

DESCRIPTION..........................8

OPERATION............................8

DIAGNOSIS AND TESTING - BACKUP LAMP

SWITCH.............................8

BRAKE LAMP

REMOVAL

REMOVAL - WITH CARGO BOX...........9

REMOVAL - WITHOUT CARGO BOX........9

INSTALLATION

INSTALLATION - WITH CARGO BOX........9

INSTALLATION - WITHOUT CARGO BOX....9

BRAKE LAMP SWITCH

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - BRAKE LAMP

SWITCH............................10

REMOVAL.............................10

INSTALLATION.........................11

CENTER HIGH MOUNTED STOP LAMP

REMOVAL.............................11INSTALLATION.........................11

CENTER HIGH MOUNTED STOP LAMP UNIT

REMOVAL.............................11

INSTALLATION.........................11

CAB CLEARANCE LAMP

REMOVAL.............................11

INSTALLATION.........................12

FOG LAMP

REMOVAL.............................12

INSTALLATION.........................12

FOG LAMP RELAY

DESCRIPTION.........................12

OPERATION...........................13

REMOVAL.............................13

INSTALLATION.........................13

HAZARD SWITCH

DESCRIPTION.........................14

OPERATION...........................14

HEADLAMP

REMOVAL.............................14

INSTALLATION.........................14

HEADLAMP SWITCH

DESCRIPTION.........................14

OPERATION...........................14

REMOVAL.............................14

INSTALLATION.........................15

HEADLAMP UNIT

REMOVAL.............................15

INSTALLATION.........................15

ADJUSTMENTS........................16

LICENSE PLATE LAMP

REMOVAL.............................17

INSTALLATION.........................17

LICENSE PLATE LAMP UNIT

REMOVAL.............................17

INSTALLATION.........................17

DRLAMPS 8L - 1

Page 557 of 2627

MARKER LAMP UNIT

REMOVAL

REMOVAL - FENDER MARKER LAMP......17

REMOVAL - TAILGATE MARKER LAMP.....18

INSTALLATION

INSTALLATION - FENDER MARKER LAMP . . 18

INSTALLATION - TAILGATE MARKER LAMP . 18

MULTI-FUNCTION SWITCH

DESCRIPTION - TURN SIGNAL SYSTEM.....18

OPERATION - TURN SIGNAL SYSTEM.......18

DIAGNOSIS AND TESTING - MULTI-

FUNCTION SWITCH...................18

REMOVAL.............................19

INSTALLATION.........................19

PARK LAMP RELAY

DESCRIPTION.........................20

OPERATION...........................20

DIAGNOSIS AND TESTING - PARK LAMP

RELAY..............................20

REMOVAL.............................21

INSTALLATION.........................21

PARK/TURN SIGNAL LAMP

REMOVAL.............................21

INSTALLATION.........................21

TAIL LAMP

REMOVAL

REMOVAL - WITH CARGO BOX..........22REMOVAL - WITHOUT CARGO BOX.......22

INSTALLATION

INSTALLATION - WITH CARGO BOX.......22

INSTALLATION - WITHOUT CARGO BOX . . . 22

TAIL LAMP UNIT

REMOVAL

REMOVAL - WITH CARGO BOX..........22

REMOVAL - WITHOUT CARGO BOX.......23

INSTALLATION

INSTALLATION - WITH CARGO BOX.......23

INSTALLATION - WITHOUT CARGO BOX . . . 23

TRAILER TOW WIRING

DESCRIPTION.........................24

TURN LAMP

REMOVAL

REMOVAL - WITH CARGO BOX..........24

REMOVAL - WITHOUT CARGO BOX.......24

INSTALLATION

INSTALLATION - WITH CARGO BOX.......24

INSTALLATION - WITHOUT CARGO BOX . . . 24

UNDERHOOD LAMP

REMOVAL.............................25

INSTALLATION.........................25

UNDERHOOD LAMP UNIT

REMOVAL.............................25

INSTALLATION.........................25

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION

The exterior lighting system for this model include

the following components:

²Backup Lamps

²Brake Lamps

²Daytime Running Lamps

²Front Fog Lamps

²Hazard Warning Lamps

²Headlamps

²Park Lamps

²Turn Signal Lamps

Other components of the exterior lighting system

for this model include:

²Backup Lamp Switch

²Brake Lamp Switch

²Front Control Module

²Front Fog Lamp Relay

²Hazard Switch

²Multi-Function Switch

²Park Lamp Relay

²Trailer Tow Connectors

Some of the interior and exterior lighting functions

are governed by the front control module. The head-

lamp, dome, and door ajar switchs provide signals to

the instrument cluster. The instrument cluster sends

a J1850 message to the front control module to

enable the necessary components for illumination.Hard wired circuitry connects the exterior lighting

system components to the electrical system of the

vehicle. Refer to the appropriate wiring information.OPERATION

DAYTIME RUNNING LAMPS

Power is reduced using pulse-width modulation to

the high beams, where by the power is switched on

and off rapidly instead of remaining on continuously.

The duration and interval of the power pulses is pro-

grammed into the Front Control Module (FCM).

HEADLAMP SYSTEM

The instrument cluster monitors both the multi-

plexed headlamp and multifunction switches. The

instrument cluster transmits a J1850 bus message to

the front control module (FCM) to activate the head-

lamps. The headlamp system will default to head-

lamps ON position when ignition switch is ON and

when an open or short circuit failure occurs on the

headlamp switch input to the instrument cluster. The

system will return to normal operation when the

open or short is repaired. A fault will be reported by

the Instrument Cluster when a failure occurs on the

dimmer or headlamp switch input.

If the exterior lamps are ON, and the headlamp

switch is in any position other than OFF, with the

ignition switch OFF (LOCK) after 5 minutes, the

8L - 2 LAMPS/LIGHTING - EXTERIORDR

Page 562 of 2627

STANDARD PROCEDURE

SAFETY PRECAUTIONS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result.Do not use bulbs with higher

candle power than indicated in the Bulb Application

table . Damage to lamp and/or Daytime Running

Lamp Module can result.Do not use fuses, circuit

breakers or relays having greater amperage value

than indicated on the fuse panel or in the Owners

Manual.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges are not holding the com-

ponent in place.

SPECIFICATIONS

EXTERIOR LAMPS

CAUTION: Do not use bulbs that have a higher can-

dle power than the bulb listed in the Bulb Applica-

tion Table. Damage to lamp can result. Do not touch

halogen bulbs with fingers or other oily surfaces.

Bulb life will be reduced.

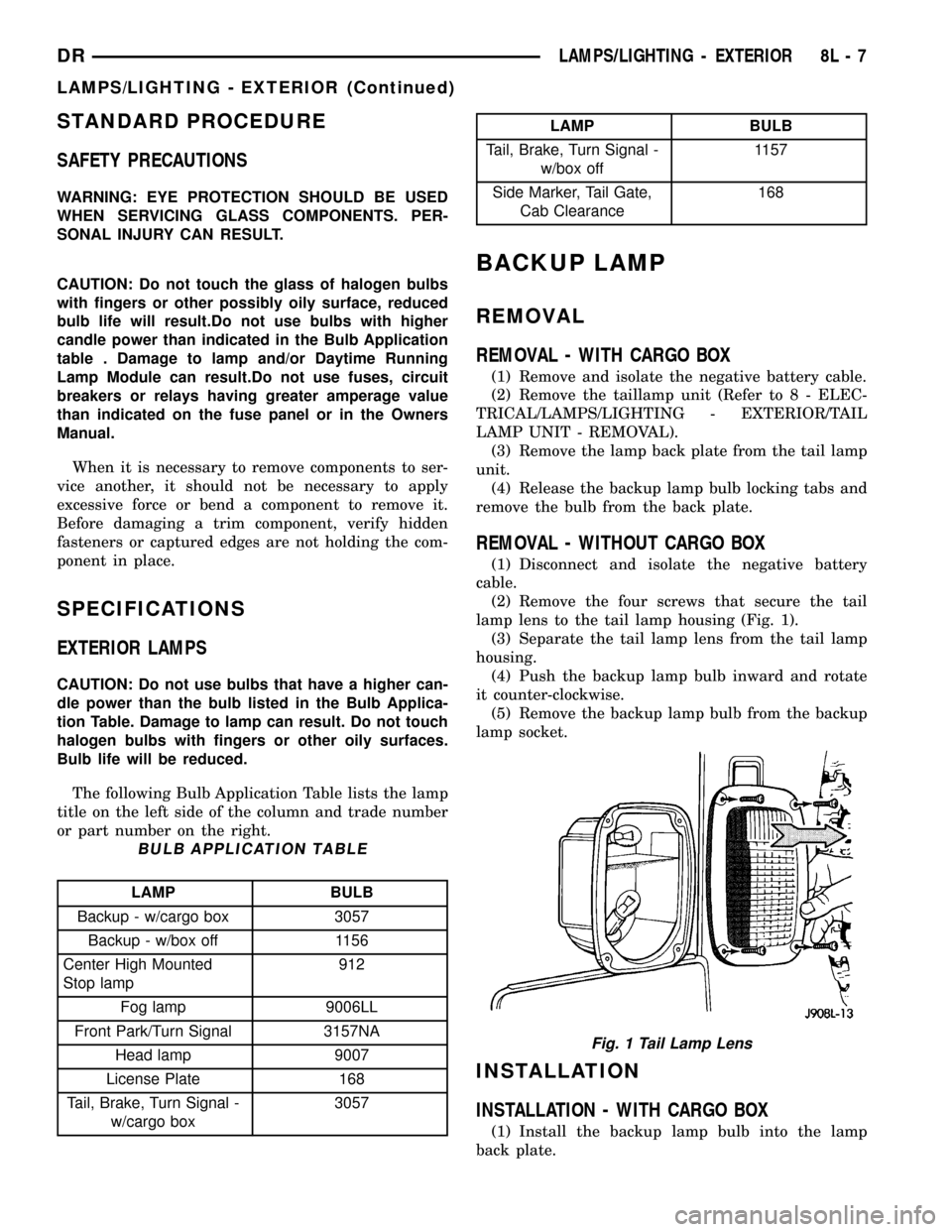

The following Bulb Application Table lists the lamp

title on the left side of the column and trade number

or part number on the right.

BULB APPLICATION TABLE

LAMP BULB

Backup - w/cargo box 3057

Backup - w/box off 1156

Center High Mounted

Stop lamp912

Fog lamp 9006LL

Front Park/Turn Signal 3157NA

Head lamp 9007

License Plate 168

Tail, Brake, Turn Signal -

w/cargo box3057

LAMP BULB

Tail, Brake, Turn Signal -

w/box off1157

Side Marker, Tail Gate,

Cab Clearance168

BACKUP LAMP

REMOVAL

REMOVAL - WITH CARGO BOX

(1) Remove and isolate the negative battery cable.

(2) Remove the taillamp unit (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP UNIT - REMOVAL).

(3) Remove the lamp back plate from the tail lamp

unit.

(4) Release the backup lamp bulb locking tabs and

remove the bulb from the back plate.

REMOVAL - WITHOUT CARGO BOX

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the four screws that secure the tail

lamp lens to the tail lamp housing (Fig. 1).

(3) Separate the tail lamp lens from the tail lamp

housing.

(4) Push the backup lamp bulb inward and rotate

it counter-clockwise.

(5) Remove the backup lamp bulb from the backup

lamp socket.

INSTALLATION

INSTALLATION - WITH CARGO BOX

(1) Install the backup lamp bulb into the lamp

back plate.

Fig. 1 Tail Lamp Lens

DRLAMPS/LIGHTING - EXTERIOR 8L - 7

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 564 of 2627

BRAKE LAMP

REMOVAL

REMOVAL - WITH CARGO BOX

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the tail lamp unit (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP UNIT - REMOVAL).

(3) Remove the lamp back plate from the tail lamp

unit.

(4) Release the brake lamp bulb locking tabs and

remove the bulb from the back plate.

REMOVAL - WITHOUT CARGO BOX

(1) Disconnect and isolate the negative battery

cable.

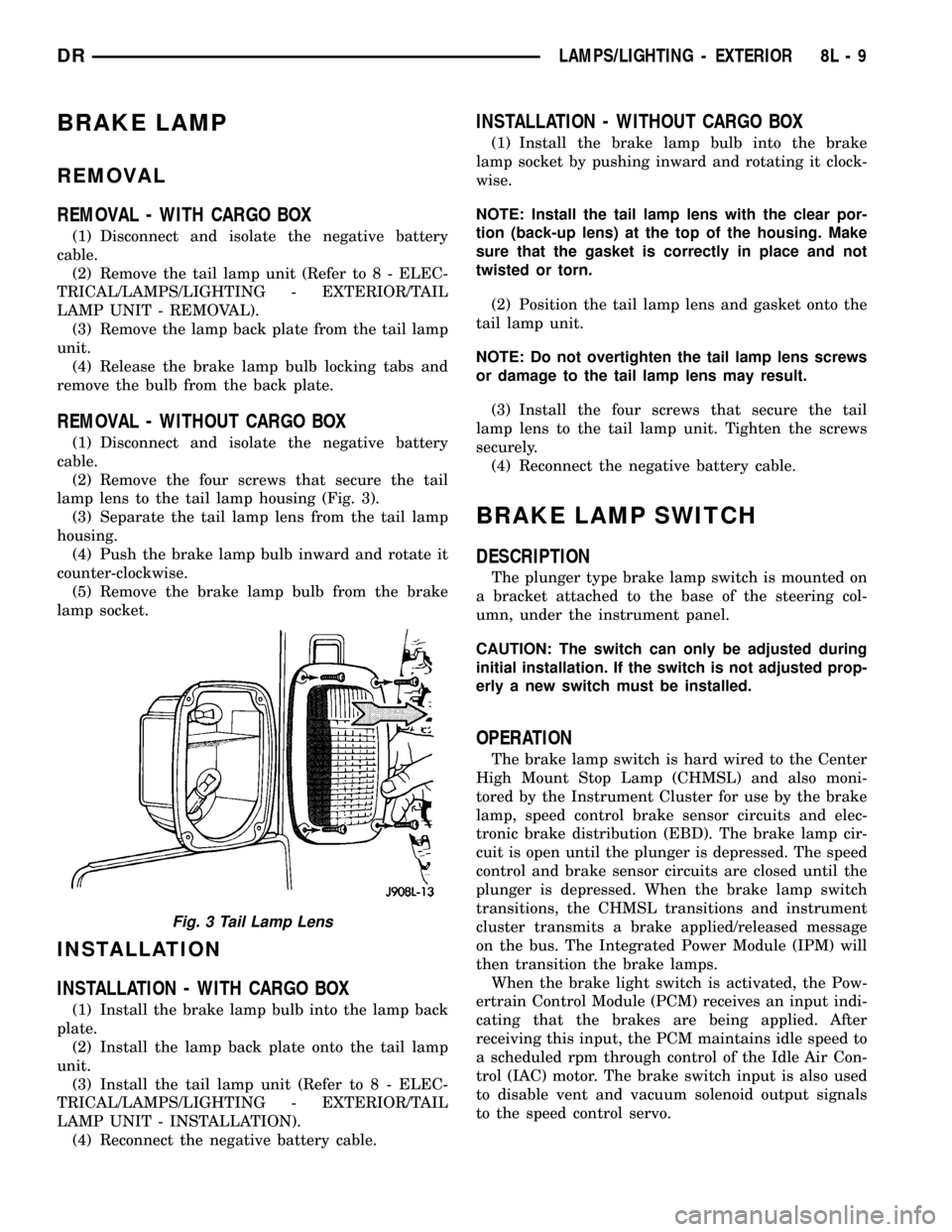

(2) Remove the four screws that secure the tail

lamp lens to the tail lamp housing (Fig. 3).

(3) Separate the tail lamp lens from the tail lamp

housing.

(4) Push the brake lamp bulb inward and rotate it

counter-clockwise.

(5) Remove the brake lamp bulb from the brake

lamp socket.

INSTALLATION

INSTALLATION - WITH CARGO BOX

(1) Install the brake lamp bulb into the lamp back

plate.

(2) Install the lamp back plate onto the tail lamp

unit.

(3) Install the tail lamp unit (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP UNIT - INSTALLATION).

(4) Reconnect the negative battery cable.

INSTALLATION - WITHOUT CARGO BOX

(1) Install the brake lamp bulb into the brake

lamp socket by pushing inward and rotating it clock-

wise.

NOTE: Install the tail lamp lens with the clear por-

tion (back-up lens) at the top of the housing. Make

sure that the gasket is correctly in place and not

twisted or torn.

(2) Position the tail lamp lens and gasket onto the

tail lamp unit.

NOTE: Do not overtighten the tail lamp lens screws

or damage to the tail lamp lens may result.

(3) Install the four screws that secure the tail

lamp lens to the tail lamp unit. Tighten the screws

securely.

(4) Reconnect the negative battery cable.

BRAKE LAMP SWITCH

DESCRIPTION

The plunger type brake lamp switch is mounted on

a bracket attached to the base of the steering col-

umn, under the instrument panel.

CAUTION: The switch can only be adjusted during

initial installation. If the switch is not adjusted prop-

erly a new switch must be installed.

OPERATION

The brake lamp switch is hard wired to the Center

High Mount Stop Lamp (CHMSL) and also moni-

tored by the Instrument Cluster for use by the brake

lamp, speed control brake sensor circuits and elec-

tronic brake distribution (EBD). The brake lamp cir-

cuit is open until the plunger is depressed. The speed

control and brake sensor circuits are closed until the

plunger is depressed. When the brake lamp switch

transitions, the CHMSL transitions and instrument

cluster transmits a brake applied/released message

on the bus. The Integrated Power Module (IPM) will

then transition the brake lamps.

When the brake light switch is activated, the Pow-

ertrain Control Module (PCM) receives an input indi-

cating that the brakes are being applied. After

receiving this input, the PCM maintains idle speed to

a scheduled rpm through control of the Idle Air Con-

trol (IAC) motor. The brake switch input is also used

to disable vent and vacuum solenoid output signals

to the speed control servo.

Fig. 3 Tail Lamp Lens

DRLAMPS/LIGHTING - EXTERIOR 8L - 9

Page 565 of 2627

Vehicles equipped with the speed control option use

a dual function brake lamp switch. The PCM moni-

tors the state of the dual function brake lamp switch.

The brake switch is equipped with three sets of

contacts, one normally open and the other two nor-

mally closed (brakes disengaged). The PCM sends a

12 volt signal to one of the normally closed contacts

in the brake switch, which is returned to the PCM as

a brake switch state signal. With the contacts closed,

the 12 volt signal is pulled to ground causing the sig-

nal to go low. The low voltage signal, monitored by

the PCM, indicates that the brakes are not applied.

When the brakes are applied, the contacts open,

causing the PCM's output brake signal to go high,

disengaging the speed control, cutting off PCM power

to the speed control solenoids.

The second set of normally closed contacts supplies

12 volts from the PCM any time speed control is

turned on. Through the brake switch, voltage is

routed to the speed control servo solenoids. The

speed control solenoids (vacuum, vent and dump) are

provided this voltage any time the speed control is

ON and the brakes are disengaged.

When the driver applies the brakes, the contacts

open and voltage is interrupted to the solenoids. The

normally open contacts are fed battery voltage. When

the brakes are applied, battery voltage is supplied to

the brake lamps.

The brake lamp switch can only be adjusted once.

That is at the initial installation of the switch. If the

switch is not adjusted properly or has been removed,

a new switch must be installed and adjusted.

DIAGNOSIS AND TESTING - BRAKE LAMP

SWITCH

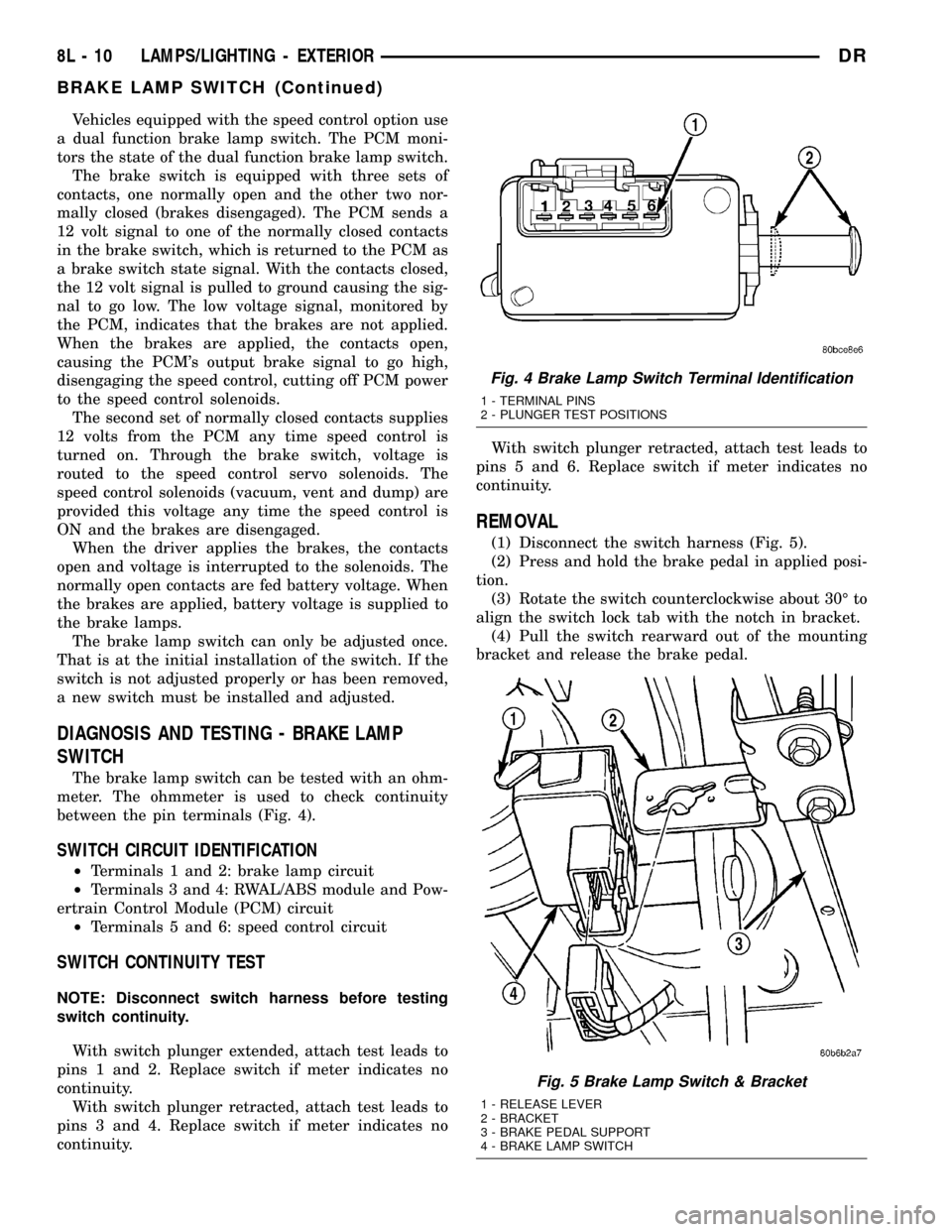

The brake lamp switch can be tested with an ohm-

meter. The ohmmeter is used to check continuity

between the pin terminals (Fig. 4).

SWITCH CIRCUIT IDENTIFICATION

²Terminals 1 and 2: brake lamp circuit

²Terminals 3 and 4: RWAL/ABS module and Pow-

ertrain Control Module (PCM) circuit

²Terminals 5 and 6: speed control circuit

SWITCH CONTINUITY TEST

NOTE: Disconnect switch harness before testing

switch continuity.

With switch plunger extended, attach test leads to

pins 1 and 2. Replace switch if meter indicates no

continuity.

With switch plunger retracted, attach test leads to

pins 3 and 4. Replace switch if meter indicates no

continuity.With switch plunger retracted, attach test leads to

pins 5 and 6. Replace switch if meter indicates no

continuity.

REMOVAL

(1) Disconnect the switch harness (Fig. 5).

(2) Press and hold the brake pedal in applied posi-

tion.

(3) Rotate the switch counterclockwise about 30É to

align the switch lock tab with the notch in bracket.

(4) Pull the switch rearward out of the mounting

bracket and release the brake pedal.

Fig. 4 Brake Lamp Switch Terminal Identification

1 - TERMINAL PINS

2 - PLUNGER TEST POSITIONS

Fig. 5 Brake Lamp Switch & Bracket

1 - RELEASE LEVER

2 - BRACKET

3 - BRAKE PEDAL SUPPORT

4 - BRAKE LAMP SWITCH

8L - 10 LAMPS/LIGHTING - EXTERIORDR

BRAKE LAMP SWITCH (Continued)