Engine control 2 DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1575 of 2627

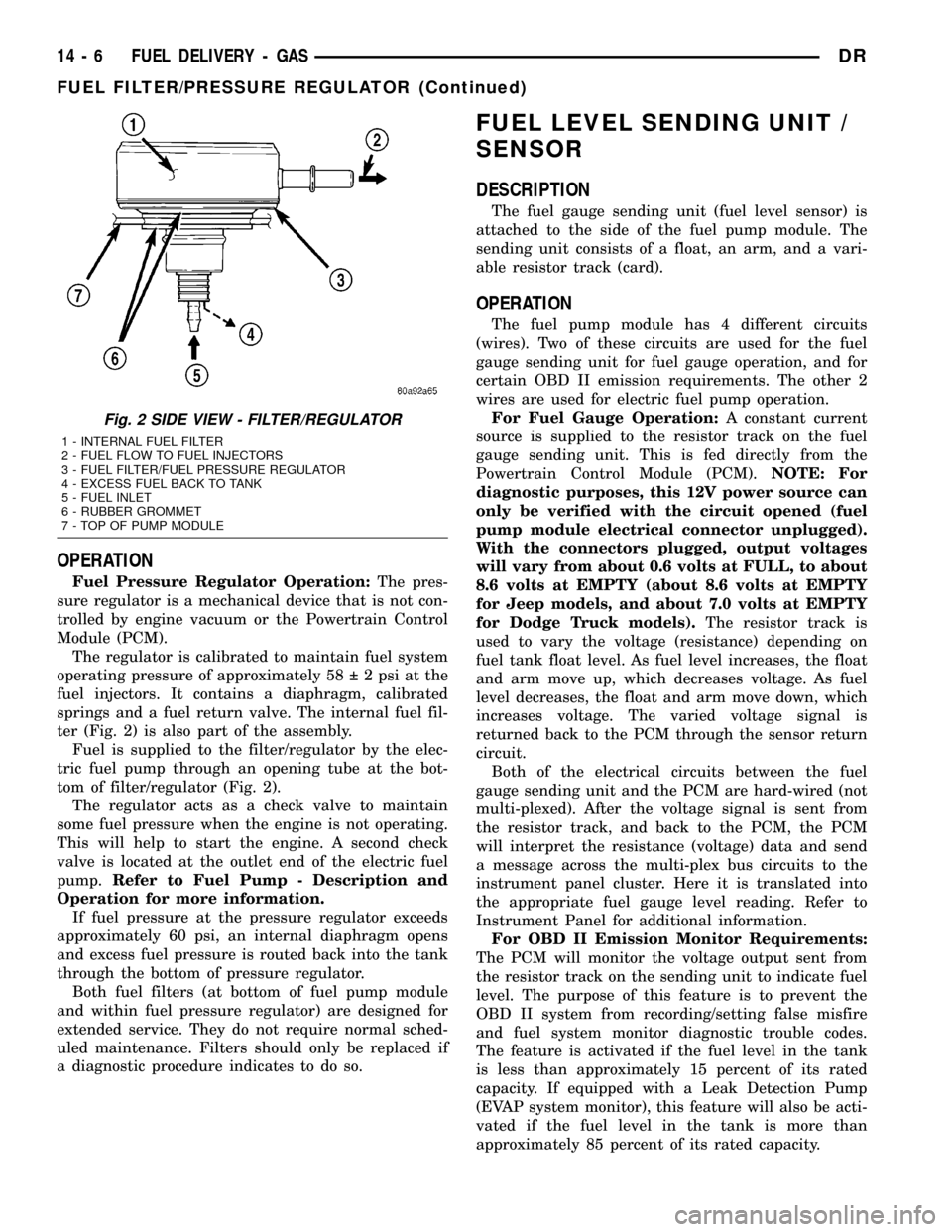

OPERATION

Fuel Pressure Regulator Operation:The pres-

sure regulator is a mechanical device that is not con-

trolled by engine vacuum or the Powertrain Control

Module (PCM).

The regulator is calibrated to maintain fuel system

operating pressure of approximately 58 2 psi at the

fuel injectors. It contains a diaphragm, calibrated

springs and a fuel return valve. The internal fuel fil-

ter (Fig. 2) is also part of the assembly.

Fuel is supplied to the filter/regulator by the elec-

tric fuel pump through an opening tube at the bot-

tom of filter/regulator (Fig. 2).

The regulator acts as a check valve to maintain

some fuel pressure when the engine is not operating.

This will help to start the engine. A second check

valve is located at the outlet end of the electric fuel

pump.Refer to Fuel Pump - Description and

Operation for more information.

If fuel pressure at the pressure regulator exceeds

approximately 60 psi, an internal diaphragm opens

and excess fuel pressure is routed back into the tank

through the bottom of pressure regulator.

Both fuel filters (at bottom of fuel pump module

and within fuel pressure regulator) are designed for

extended service. They do not require normal sched-

uled maintenance. Filters should only be replaced if

a diagnostic procedure indicates to do so.

FUEL LEVEL SENDING UNIT /

SENSOR

DESCRIPTION

The fuel gauge sending unit (fuel level sensor) is

attached to the side of the fuel pump module. The

sending unit consists of a float, an arm, and a vari-

able resistor track (card).

OPERATION

The fuel pump module has 4 different circuits

(wires). Two of these circuits are used for the fuel

gauge sending unit for fuel gauge operation, and for

certain OBD II emission requirements. The other 2

wires are used for electric fuel pump operation.

For Fuel Gauge Operation:A constant current

source is supplied to the resistor track on the fuel

gauge sending unit. This is fed directly from the

Powertrain Control Module (PCM).NOTE: For

diagnostic purposes, this 12V power source can

only be verified with the circuit opened (fuel

pump module electrical connector unplugged).

With the connectors plugged, output voltages

will vary from about 0.6 volts at FULL, to about

8.6 volts at EMPTY (about 8.6 volts at EMPTY

for Jeep models, and about 7.0 volts at EMPTY

for Dodge Truck models).The resistor track is

used to vary the voltage (resistance) depending on

fuel tank float level. As fuel level increases, the float

and arm move up, which decreases voltage. As fuel

level decreases, the float and arm move down, which

increases voltage. The varied voltage signal is

returned back to the PCM through the sensor return

circuit.

Both of the electrical circuits between the fuel

gauge sending unit and the PCM are hard-wired (not

multi-plexed). After the voltage signal is sent from

the resistor track, and back to the PCM, the PCM

will interpret the resistance (voltage) data and send

a message across the multi-plex bus circuits to the

instrument panel cluster. Here it is translated into

the appropriate fuel gauge level reading. Refer to

Instrument Panel for additional information.

For OBD II Emission Monitor Requirements:

The PCM will monitor the voltage output sent from

the resistor track on the sending unit to indicate fuel

level. The purpose of this feature is to prevent the

OBD II system from recording/setting false misfire

and fuel system monitor diagnostic trouble codes.

The feature is activated if the fuel level in the tank

is less than approximately 15 percent of its rated

capacity. If equipped with a Leak Detection Pump

(EVAP system monitor), this feature will also be acti-

vated if the fuel level in the tank is more than

approximately 85 percent of its rated capacity.

Fig. 2 SIDE VIEW - FILTER/REGULATOR

1 - INTERNAL FUEL FILTER

2 - FUEL FLOW TO FUEL INJECTORS

3 - FUEL FILTER/FUEL PRESSURE REGULATOR

4 - EXCESS FUEL BACK TO TANK

5 - FUEL INLET

6 - RUBBER GROMMET

7 - TOP OF PUMP MODULE

14 - 6 FUEL DELIVERY - GASDR

FUEL FILTER/PRESSURE REGULATOR (Continued)

Page 1586 of 2627

(15) Install air duct to air box.

(16) Connect battery cable to battery.

(17) Start engine and check for leaks.

5.7L V-8

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in intake manifold.

(5) Guide each injector into intake manifold. Be

careful not to tear injector o-rings.

(6) Pushrightside of fuel rail down until fuel

injectors have bottomed on shoulders. Pushleftfuel

rail down until injectors have bottomed on shoulders.

(7) Install 4 fuel rail holdown clamps and 4 mount-

ing bolts. Refer to Torque Specifications.

(8) Position spark plug cable tray and cable assem-

bly to intake manifold. Snap 4 cable tray retaining

clips into intake manifold.

(9) Install all cables to spark plugs and ignition

coils.

(10) Connect electrical connector to throttle body.

(11) Install electrical connectors to all 8 ignition

coils. Refer to Ignition Coil Removal/Installation.

(12) Connect electrical connector to throttle body.

(13) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 17). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

(14) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(15) Install air resonator to throttle body (2 bolts).

(16) Install flexible air duct to air box.

(17) Connect battery cable to battery.

(18) Start engine and check for leaks.

FUEL TANK

DESCRIPTION

The fuel tank is constructed of a plastic material.

Its main functions are for fuel storage and for place-

ment of the fuel pump module, and (if equipped) cer-

tain ORVR components.

OPERATION

All models pass a full 360 degree rollover test

without fuel leakage. To accomplish this, fuel and

vapor flow controls are required for all fuel tank con-

nections.Two check (control) valves are mounted into the

top of the fuel tank. Refer to Fuel Tank Check Valve

for additional information.

An evaporation control system is connected to the

fuel tank to reduce emissions of fuel vapors into the

atmosphere. When fuel evaporates from the fuel

tank, vapors pass through vent hoses or tubes to a

charcoal canister where they are temporarily held.

When the engine is running, the vapors are drawn

into the intake manifold. Certain models are also

equipped with a self-diagnosing system using a Leak

Detection Pump (LDP) and/or an On-Board Refueling

Vapor Recovery (ORVR) system. Refer to Emission

Control System for additional information.

REMOVAL- EXCEPT DIESEL

Fuel Tank Draining

WARNING: THE FUEL SYSTEM MAY BE UNDER

CONSTANT FUEL PRESSURE EVEN WITH THE

ENGINE OFF. THIS PRESSURE MUST BE

RELEASED BEFORE SERVICING FUEL TANK.

Two different procedures may be used to drain fuel

tank: through the fuel fill fitting on tank, or using

the DRBtscan tool. Due to a one-way check valve

installed into the fuel fill opening fitting at the tank,

the tank cannot be drained conventionally at the fill

cap.

The quickest draining procedure involves removing

the rubber fuel fill hose.

As an alternative procedure, the electric fuel pump

may be activated allowing tank to be drained at fuel

rail connection. Refer to DRB scan tool for fuel pump

activation procedures. Before disconnecting fuel line

at fuel rail, release fuel pressure. Refer to the Fuel

System Pressure Release Procedure for procedures.

Attach end of special test hose tool number 6541,

6539, 6631 or 6923 at fuel rail disconnection (tool

number will depend on model and/or engine applica-

tion). Position opposite end of this hose tool to an

approved gasoline draining station. Activate fuel

pump and drain tank until empty.

If electric fuel pump is not operating, fuel must be

drained through fuel fill fitting at tank. Refer to fol-

lowing procedures.

(1) Release fuel system pressure.

(2) Raise vehicle.

(3) Thoroughly clean area around fuel fill fitting

and rubber fuel fill hose at tank.

(4) If vehicle is equipped with 4 doors and a 6 foot

(short) box, remove left-rear tire/wheel.

(5) Loosen clamp (Fig. 23) and disconnect rubber

fuel fill hose at tank fitting. Using an approved gas

holding tank, drain fuel tank through this fitting.

DRFUEL DELIVERY - GAS 14 - 17

FUEL RAIL (Continued)

Page 1590 of 2627

FUEL INJECTION - GAS

TABLE OF CONTENTS

page page

ACCELERATOR PEDAL

REMOVAL.............................21

INSTALLATION.........................21

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................22

CRANKSHAFT POSITION SENSOR

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL.............................24

INSTALLATION.........................25

FUEL INJECTOR

DESCRIPTION.........................26

OPERATION

OPERATION - FUEL INJECTOR..........26

OPERATION - PCM OUTPUT............27

REMOVAL.............................27

INSTALLATION.........................27

FUEL PUMP RELAY

DESCRIPTION.........................27

OPERATION...........................27

REMOVAL.............................28

INSTALLATION.........................28

IDLE AIR CONTROL MOTOR

DESCRIPTION.........................28

OPERATION...........................28

REMOVAL.............................29

INSTALLATION.........................29INTAKE AIR TEMPERATURE SENSOR

DESCRIPTION.........................30

OPERATION...........................30

REMOVAL.............................30

INSTALLATION.........................31

MAP SENSOR

DESCRIPTION.........................32

OPERATION...........................32

REMOVAL.............................33

INSTALLATION.........................34

OXYGEN SENSOR

DESCRIPTION.........................35

REMOVAL.............................35

INSTALLATION.........................36

PTO SWITCH

DESCRIPTION.........................36

OPERATION...........................36

THROTTLE BODY

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL.............................36

INSTALLATION.........................37

THROTTLE CONTROL CABLE

REMOVAL.............................38

INSTALLATION.........................40

THROTTLE POSITION SENSOR

DESCRIPTION.........................41

OPERATION...........................41

REMOVAL.............................41

INSTALLATION.........................43

ACCELERATOR PEDAL

REMOVAL

The following procedure applies only to vehicles

without the Adjustable Pedal Package (code XAP).

The accelerator pedal is serviced as a complete

assembly including the bracket.

The accelerator cable is connected to the upper

part of the accelerator pedal arm by a plastic

retainer (clip) (Fig. 1). This plastic retainer snaps

into the top of the accelerator pedal arm.

(1) From inside the vehicle, hold up accelerator

pedal. Remove plastic cable retainer (clip) and throt-

tle cable core wire from upper end of accelerator

pedal arm (Fig. 1). Plastic cable retainer (clip) snaps

into pedal arm.(2) Remove 2 accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.INSTALLATION

(1) Place accelerator pedal assembly over 2 studs.

(2) Install and tighten 2 mounting nuts. Refer to

Torque Specifications.

(3) Slide throttle cable into opening slot in top of

pedal arm.

(4) Push plastic cable retainer (clip) into accelera-

tor pedal arm opening until it snaps into place.

(5) Before starting engine, operate accelerator

pedal to check for any binding.

DRFUEL INJECTION - GAS 14 - 21

Page 1592 of 2627

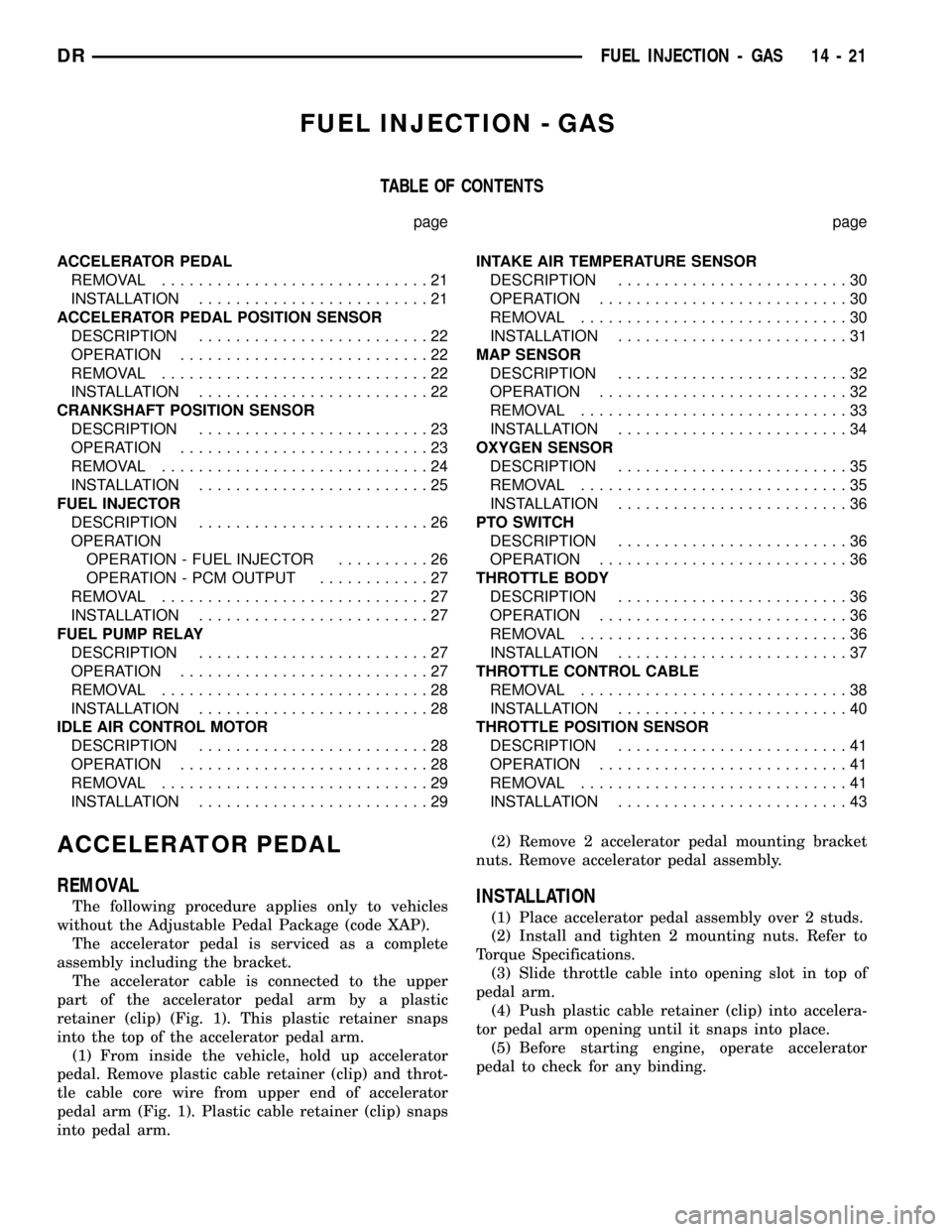

(5) Position APPS assembly to bottom of battery

tray and install 3 bolts. Refer to Torque Specifica-

tions.

(6) Install wheelhouse liner. Refer to Body.

(7)The 5.7L V-8 engine is equipped with a

fully electronic accelerator pedal position sen-

sor. If equipped with a 5.7L, also perform the

following 3 steps:

(a) Connect negative battery cable to battery.

(b) Turn ignition switch ON, but do not crank

engine.

(c) Leave ignition switch ON for a minimum of

10 seconds. This will allow PCM to learn electrical

parameters.

(d) The DRB IIItScan Tool may also be used to

learn electrical parameters. Go to the Miscella-

neous menu, and then select ETC Learn.

(8) If the previous step is not performed, a Diag-

nostic Trouble Code (DTC) will be set.

(9) If necessary, use DRB IIItScan Tool to erase

any Diagnostic Trouble Codes (DTC's) from PCM.

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

4.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

5.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

OPERATION

3.7L V-6

Engine speed and crankshaft position are provided

through the CKP (Crankshaft Position) sensor. The

sensor generates pulses that are the input sent to the

Powertrain Control Module (PCM). The PCM inter-

prets the sensor input to determine the crankshaft

position. The PCM then uses this position, along with

other inputs, to determine injector sequence and igni-

tion timing.

Fig. 3 APPS REMOVE / INSTALL

1 - BOTTOM OF BATTERY TRAY

2 - ELECTRICAL CONNECTOR

3 - APPS

4 - SWING-DOWN DOOR

5 - CABLE (TO PEDAL)

6 - CABLE RELEASE TAB

Fig. 4 APPS CABLE

1 - APPS LEVER

2 - BALL SOCKET

3 - SWING-DOWN DOOR

4 - CABLE CLIP

5 - CABLE

DRFUEL INJECTION - GAS 14 - 23

ACCELERATOR PEDAL POSITION SENSOR (Continued)

Page 1593 of 2627

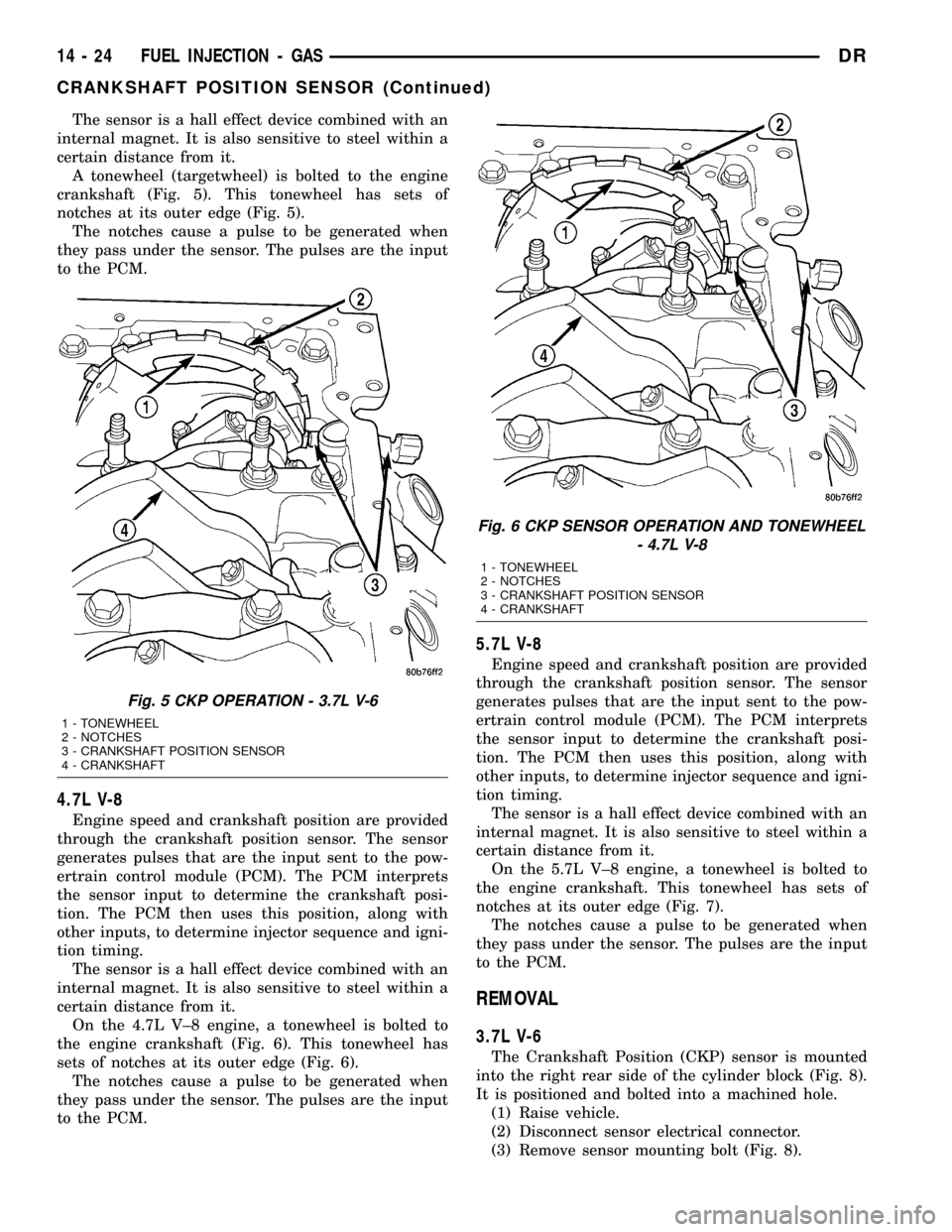

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

A tonewheel (targetwheel) is bolted to the engine

crankshaft (Fig. 5). This tonewheel has sets of

notches at its outer edge (Fig. 5).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

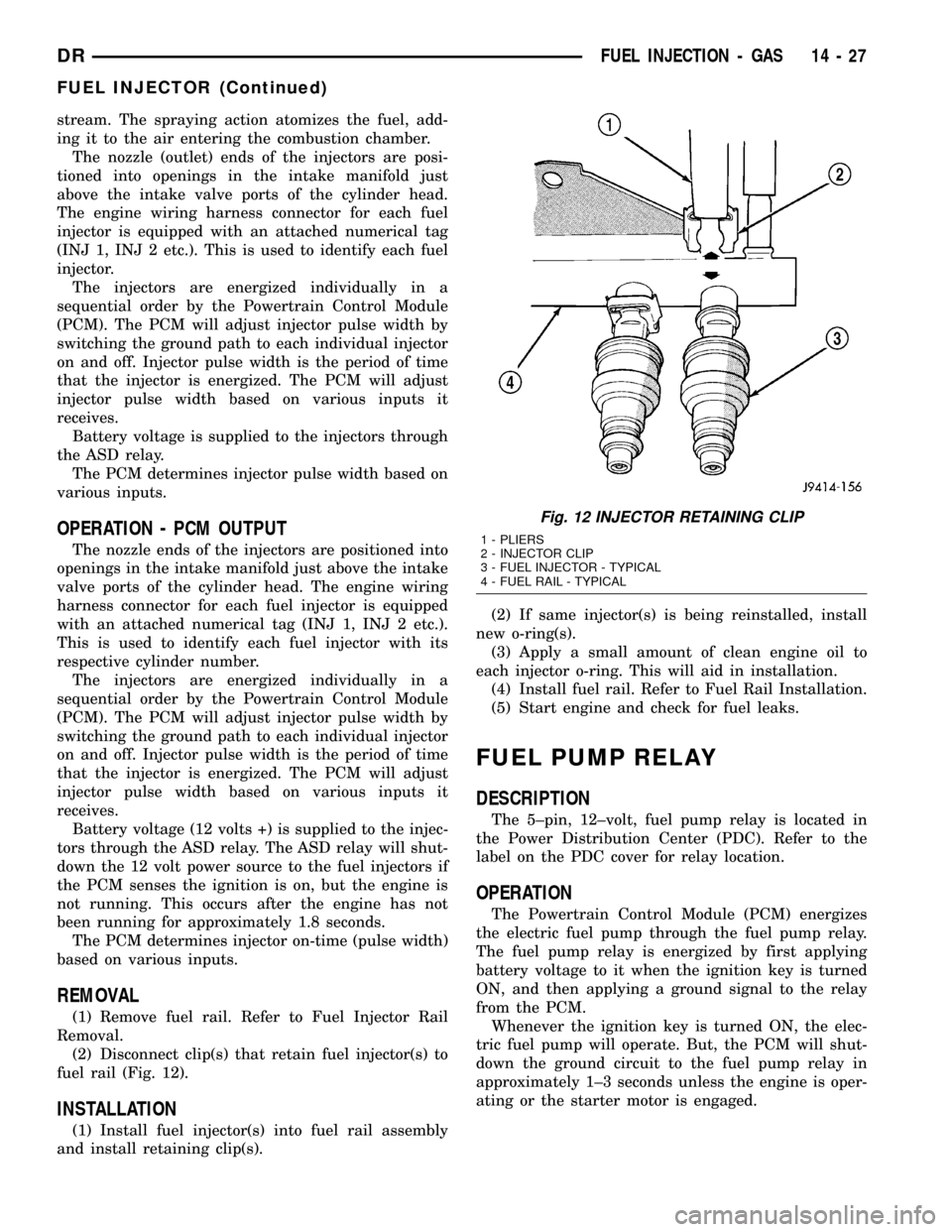

4.7L V-8

Engine speed and crankshaft position are provided

through the crankshaft position sensor. The sensor

generates pulses that are the input sent to the pow-

ertrain control module (PCM). The PCM interprets

the sensor input to determine the crankshaft posi-

tion. The PCM then uses this position, along with

other inputs, to determine injector sequence and igni-

tion timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

On the 4.7L V±8 engine, a tonewheel is bolted to

the engine crankshaft (Fig. 6). This tonewheel has

sets of notches at its outer edge (Fig. 6).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

5.7L V-8

Engine speed and crankshaft position are provided

through the crankshaft position sensor. The sensor

generates pulses that are the input sent to the pow-

ertrain control module (PCM). The PCM interprets

the sensor input to determine the crankshaft posi-

tion. The PCM then uses this position, along with

other inputs, to determine injector sequence and igni-

tion timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

On the 5.7L V±8 engine, a tonewheel is bolted to

the engine crankshaft. This tonewheel has sets of

notches at its outer edge (Fig. 7).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

REMOVAL

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block (Fig. 8).

It is positioned and bolted into a machined hole.

(1) Raise vehicle.

(2) Disconnect sensor electrical connector.

(3) Remove sensor mounting bolt (Fig. 8).

Fig. 5 CKP OPERATION - 3.7L V-6

1 - TONEWHEEL

2 - NOTCHES

3 - CRANKSHAFT POSITION SENSOR

4 - CRANKSHAFT

Fig. 6 CKP SENSOR OPERATION AND TONEWHEEL

- 4.7L V-8

1 - TONEWHEEL

2 - NOTCHES

3 - CRANKSHAFT POSITION SENSOR

4 - CRANKSHAFT

14 - 24 FUEL INJECTION - GASDR

CRANKSHAFT POSITION SENSOR (Continued)

Page 1596 of 2627

stream. The spraying action atomizes the fuel, add-

ing it to the air entering the combustion chamber.

The nozzle (outlet) ends of the injectors are posi-

tioned into openings in the intake manifold just

above the intake valve ports of the cylinder head.

The engine wiring harness connector for each fuel

injector is equipped with an attached numerical tag

(INJ 1, INJ 2 etc.). This is used to identify each fuel

injector.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage is supplied to the injectors through

the ASD relay.

The PCM determines injector pulse width based on

various inputs.

OPERATION - PCM OUTPUT

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the intake

valve ports of the cylinder head. The engine wiring

harness connector for each fuel injector is equipped

with an attached numerical tag (INJ 1, INJ 2 etc.).

This is used to identify each fuel injector with its

respective cylinder number.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage (12 volts +) is supplied to the injec-

tors through the ASD relay. The ASD relay will shut-

down the 12 volt power source to the fuel injectors if

the PCM senses the ignition is on, but the engine is

not running. This occurs after the engine has not

been running for approximately 1.8 seconds.

The PCM determines injector on-time (pulse width)

based on various inputs.

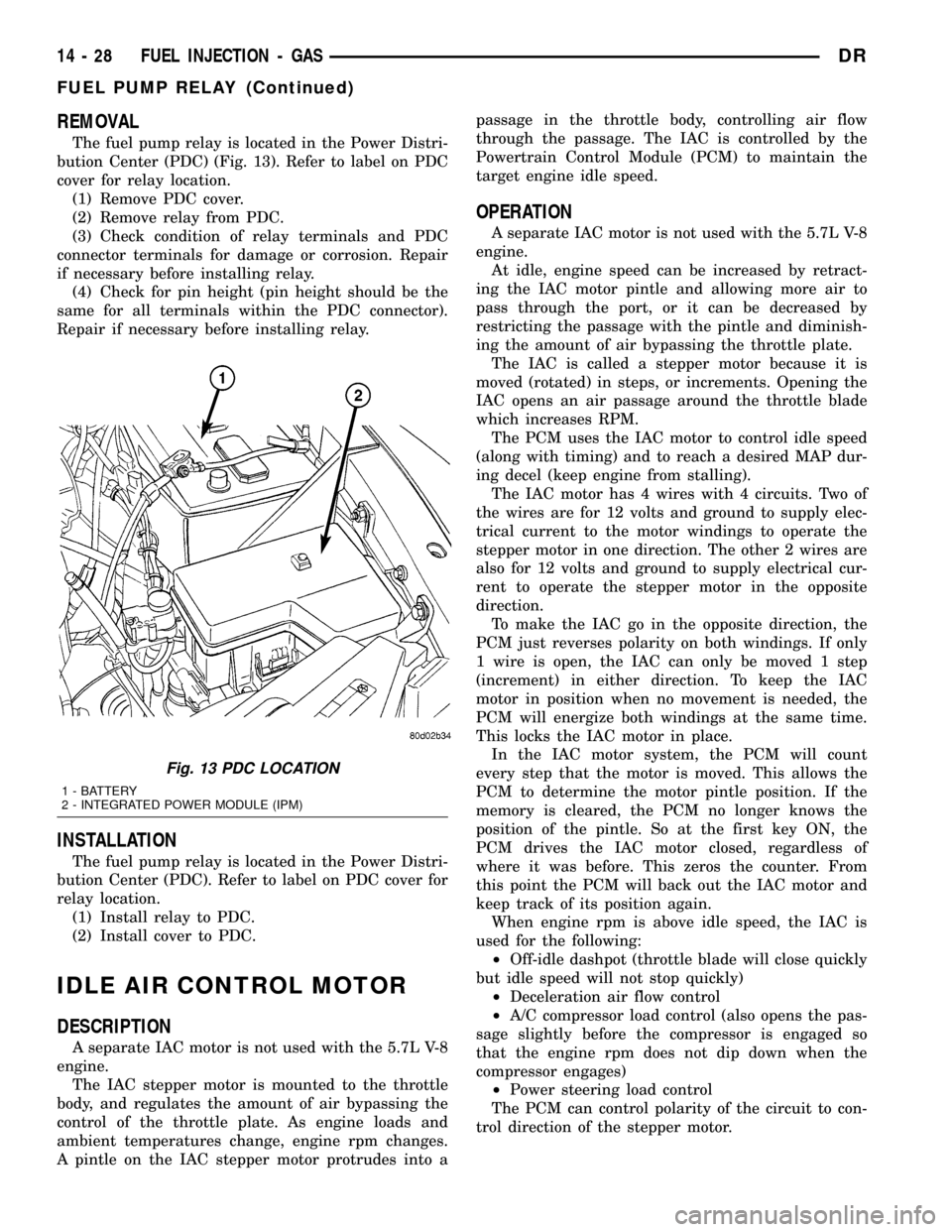

REMOVAL

(1) Remove fuel rail. Refer to Fuel Injector Rail

Removal.

(2) Disconnect clip(s) that retain fuel injector(s) to

fuel rail (Fig. 12).

INSTALLATION

(1) Install fuel injector(s) into fuel rail assembly

and install retaining clip(s).(2) If same injector(s) is being reinstalled, install

new o-ring(s).

(3) Apply a small amount of clean engine oil to

each injector o-ring. This will aid in installation.

(4) Install fuel rail. Refer to Fuel Rail Installation.

(5) Start engine and check for fuel leaks.

FUEL PUMP RELAY

DESCRIPTION

The 5±pin, 12±volt, fuel pump relay is located in

the Power Distribution Center (PDC). Refer to the

label on the PDC cover for relay location.

OPERATION

The Powertrain Control Module (PCM) energizes

the electric fuel pump through the fuel pump relay.

The fuel pump relay is energized by first applying

battery voltage to it when the ignition key is turned

ON, and then applying a ground signal to the relay

from the PCM.

Whenever the ignition key is turned ON, the elec-

tric fuel pump will operate. But, the PCM will shut-

down the ground circuit to the fuel pump relay in

approximately 1±3 seconds unless the engine is oper-

ating or the starter motor is engaged.

Fig. 12 INJECTOR RETAINING CLIP

1 - PLIERS

2 - INJECTOR CLIP

3 - FUEL INJECTOR - TYPICAL

4 - FUEL RAIL - TYPICAL

DRFUEL INJECTION - GAS 14 - 27

FUEL INJECTOR (Continued)

Page 1597 of 2627

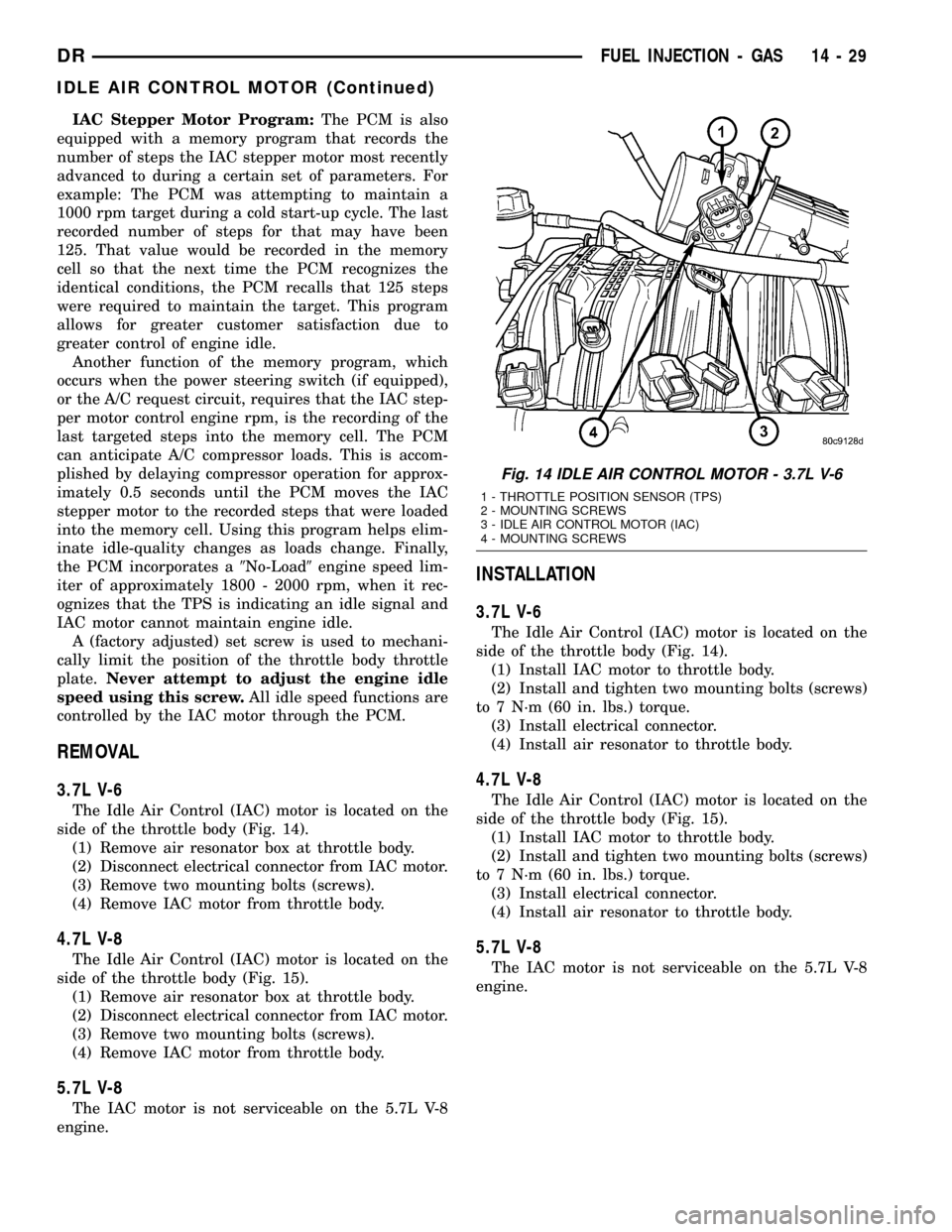

REMOVAL

The fuel pump relay is located in the Power Distri-

bution Center (PDC) (Fig. 13). Refer to label on PDC

cover for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The fuel pump relay is located in the Power Distri-

bution Center (PDC). Refer to label on PDC cover for

relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

IDLE AIR CONTROL MOTOR

DESCRIPTION

A separate IAC motor is not used with the 5.7L V-8

engine.

The IAC stepper motor is mounted to the throttle

body, and regulates the amount of air bypassing the

control of the throttle plate. As engine loads and

ambient temperatures change, engine rpm changes.

A pintle on the IAC stepper motor protrudes into apassage in the throttle body, controlling air flow

through the passage. The IAC is controlled by the

Powertrain Control Module (PCM) to maintain the

target engine idle speed.

OPERATION

A separate IAC motor is not used with the 5.7L V-8

engine.

At idle, engine speed can be increased by retract-

ing the IAC motor pintle and allowing more air to

pass through the port, or it can be decreased by

restricting the passage with the pintle and diminish-

ing the amount of air bypassing the throttle plate.

The IAC is called a stepper motor because it is

moved (rotated) in steps, or increments. Opening the

IAC opens an air passage around the throttle blade

which increases RPM.

The PCM uses the IAC motor to control idle speed

(along with timing) and to reach a desired MAP dur-

ing decel (keep engine from stalling).

The IAC motor has 4 wires with 4 circuits. Two of

the wires are for 12 volts and ground to supply elec-

trical current to the motor windings to operate the

stepper motor in one direction. The other 2 wires are

also for 12 volts and ground to supply electrical cur-

rent to operate the stepper motor in the opposite

direction.

To make the IAC go in the opposite direction, the

PCM just reverses polarity on both windings. If only

1 wire is open, the IAC can only be moved 1 step

(increment) in either direction. To keep the IAC

motor in position when no movement is needed, the

PCM will energize both windings at the same time.

This locks the IAC motor in place.

In the IAC motor system, the PCM will count

every step that the motor is moved. This allows the

PCM to determine the motor pintle position. If the

memory is cleared, the PCM no longer knows the

position of the pintle. So at the first key ON, the

PCM drives the IAC motor closed, regardless of

where it was before. This zeros the counter. From

this point the PCM will back out the IAC motor and

keep track of its position again.

When engine rpm is above idle speed, the IAC is

used for the following:

²Off-idle dashpot (throttle blade will close quickly

but idle speed will not stop quickly)

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

²Power steering load control

The PCM can control polarity of the circuit to con-

trol direction of the stepper motor.

Fig. 13 PDC LOCATION

1 - BATTERY

2 - INTEGRATED POWER MODULE (IPM)

14 - 28 FUEL INJECTION - GASDR

FUEL PUMP RELAY (Continued)

Page 1598 of 2627

IAC Stepper Motor Program:The PCM is also

equipped with a memory program that records the

number of steps the IAC stepper motor most recently

advanced to during a certain set of parameters. For

example: The PCM was attempting to maintain a

1000 rpm target during a cold start-up cycle. The last

recorded number of steps for that may have been

125. That value would be recorded in the memory

cell so that the next time the PCM recognizes the

identical conditions, the PCM recalls that 125 steps

were required to maintain the target. This program

allows for greater customer satisfaction due to

greater control of engine idle.

Another function of the memory program, which

occurs when the power steering switch (if equipped),

or the A/C request circuit, requires that the IAC step-

per motor control engine rpm, is the recording of the

last targeted steps into the memory cell. The PCM

can anticipate A/C compressor loads. This is accom-

plished by delaying compressor operation for approx-

imately 0.5 seconds until the PCM moves the IAC

stepper motor to the recorded steps that were loaded

into the memory cell. Using this program helps elim-

inate idle-quality changes as loads change. Finally,

the PCM incorporates a9No-Load9engine speed lim-

iter of approximately 1800 - 2000 rpm, when it rec-

ognizes that the TPS is indicating an idle signal and

IAC motor cannot maintain engine idle.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the IAC motor through the PCM.

REMOVAL

3.7L V-6

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 14).

(1) Remove air resonator box at throttle body.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws).

(4) Remove IAC motor from throttle body.

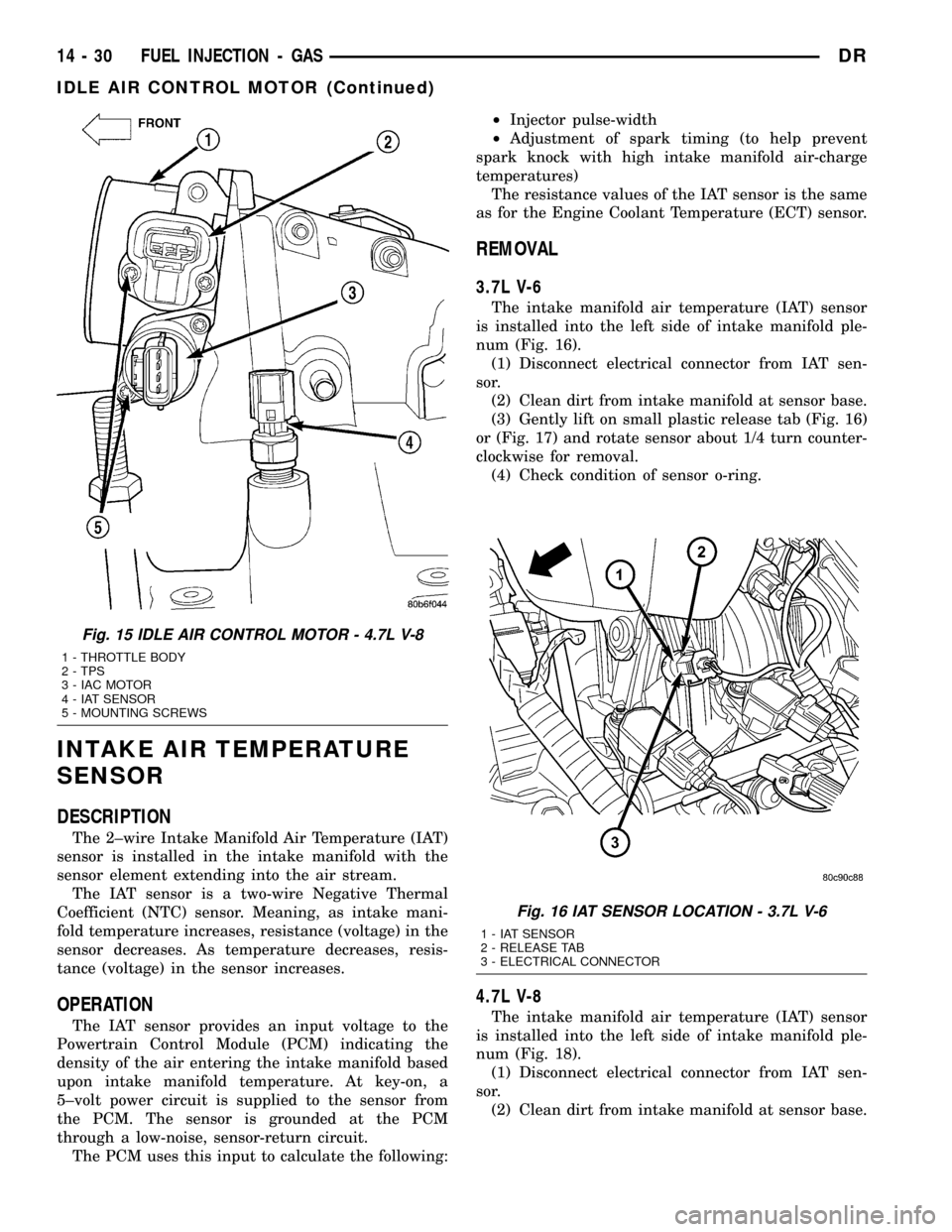

4.7L V-8

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 15).

(1) Remove air resonator box at throttle body.

(2) Disconnect electrical connector from IAC motor.

(3) Remove two mounting bolts (screws).

(4) Remove IAC motor from throttle body.

5.7L V-8

The IAC motor is not serviceable on the 5.7L V-8

engine.

INSTALLATION

3.7L V-6

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 14).

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air resonator to throttle body.

4.7L V-8

The Idle Air Control (IAC) motor is located on the

side of the throttle body (Fig. 15).

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air resonator to throttle body.

5.7L V-8

The IAC motor is not serviceable on the 5.7L V-8

engine.

Fig. 14 IDLE AIR CONTROL MOTOR - 3.7L V-6

1 - THROTTLE POSITION SENSOR (TPS)

2 - MOUNTING SCREWS

3 - IDLE AIR CONTROL MOTOR (IAC)

4 - MOUNTING SCREWS

DRFUEL INJECTION - GAS 14 - 29

IDLE AIR CONTROL MOTOR (Continued)

Page 1599 of 2627

INTAKE AIR TEMPERATURE

SENSOR

DESCRIPTION

The 2±wire Intake Manifold Air Temperature (IAT)

sensor is installed in the intake manifold with the

sensor element extending into the air stream.

The IAT sensor is a two-wire Negative Thermal

Coefficient (NTC) sensor. Meaning, as intake mani-

fold temperature increases, resistance (voltage) in the

sensor decreases. As temperature decreases, resis-

tance (voltage) in the sensor increases.

OPERATION

The IAT sensor provides an input voltage to the

Powertrain Control Module (PCM) indicating the

density of the air entering the intake manifold based

upon intake manifold temperature. At key-on, a

5±volt power circuit is supplied to the sensor from

the PCM. The sensor is grounded at the PCM

through a low-noise, sensor-return circuit.

The PCM uses this input to calculate the following:²Injector pulse-width

²Adjustment of spark timing (to help prevent

spark knock with high intake manifold air-charge

temperatures)

The resistance values of the IAT sensor is the same

as for the Engine Coolant Temperature (ECT) sensor.

REMOVAL

3.7L V-6

The intake manifold air temperature (IAT) sensor

is installed into the left side of intake manifold ple-

num (Fig. 16).

(1) Disconnect electrical connector from IAT sen-

sor.

(2) Clean dirt from intake manifold at sensor base.

(3) Gently lift on small plastic release tab (Fig. 16)

or (Fig. 17) and rotate sensor about 1/4 turn counter-

clockwise for removal.

(4) Check condition of sensor o-ring.

4.7L V-8

The intake manifold air temperature (IAT) sensor

is installed into the left side of intake manifold ple-

num (Fig. 18).

(1) Disconnect electrical connector from IAT sen-

sor.

(2) Clean dirt from intake manifold at sensor base.

Fig. 15 IDLE AIR CONTROL MOTOR - 4.7L V-8

1 - THROTTLE BODY

2 - TPS

3 - IAC MOTOR

4 - IAT SENSOR

5 - MOUNTING SCREWS

Fig. 16 IAT SENSOR LOCATION - 3.7L V-6

1 - IAT SENSOR

2 - RELEASE TAB

3 - ELECTRICAL CONNECTOR

14 - 30 FUEL INJECTION - GASDR

IDLE AIR CONTROL MOTOR (Continued)

Page 1601 of 2627

(3) Position sensor into intake manifold and rotate

clockwise until past release tab.

(4) Install electrical connector.

5.7L V-8

The intake manifold air temperature (IAT) sensor

is installed into the front of the intake manifold air

box plenum (Fig. 19).

(1) Check condition of sensor o-ring.

(2) Clean sensor mounting hole in intake manifold.

(3) Position sensor into intake manifold and rotate

clockwise until past release tab.

(4) Install electrical connector.

MAP SENSOR

DESCRIPTION

3.7L V-6

The Manifold Absolute Pressure (MAP) sensor is

mounted into the front of the intake manifold with 2

screws.

4.7L V-8

The Manifold Absolute Pressure (MAP) sensor is

mounted into the front of the intake manifold with 2

screws.

5.7L V-8

The Manifold Absolute Pressure (MAP) sensor is

mounted to the front of the intake manifold air ple-

num box.

OPERATION

The MAP sensor is used as an input to the Power-

train Control Module (PCM). It contains a silicon

based sensing unit to provide data on the manifold

vacuum that draws the air/fuel mixture into the com-

bustion chamber. The PCM requires this information

to determine injector pulse width and spark advance.

When manifold absolute pressure (MAP) equals

Barometric pressure, the pulse width will be at max-

imum.

A 5 volt reference is supplied from the PCM and

returns a voltage signal to the PCM that reflects

manifold pressure. The zero pressure reading is 0.5V

and full scale is 4.5V. For a pressure swing of 0±15

psi, the voltage changes 4.0V. To operate the sensor,

it is supplied a regulated 4.8 to 5.1 volts. Ground is

provided through the low-noise, sensor return circuit

at the PCM.

The MAP sensor input is the number one contrib-

utor to fuel injector pulse width. The most important

function of the MAP sensor is to determine baromet-

ric pressure. The PCM needs to know if the vehicle is

at sea level or at a higher altitude, because the air

density changes with altitude. It will also help to cor-

rect for varying barometric pressure. Barometric

pressure and altitude have a direct inverse correla-

tion; as altitude goes up, barometric goes down. At

key-on, the PCM powers up and looks at MAP volt-

age, and based upon the voltage it sees, it knows the

current barometric pressure (relative to altitude).

Once the engine starts, the PCM looks at the voltage

again, continuously every 12 milliseconds, and com-

pares the current voltage to what it was at key-on.

The difference between current voltage and what it

was at key-on, is manifold vacuum.

During key-on (engine not running) the sensor

reads (updates) barometric pressure. A normal range

can be obtained by monitoring a known good sensor.

As the altitude increases, the air becomes thinner

(less oxygen). If a vehicle is started and driven to a

very different altitude than where it was at key-on,

the barometric pressure needs to be updated. Any

time the PCM sees Wide Open Throttle (WOT), based

upon Throttle Position Sensor (TPS) angle and RPM,

it will update barometric pressure in the MAP mem-

ory cell. With periodic updates, the PCM can make

its calculations more effectively.

The PCM uses the MAP sensor input to aid in cal-

culating the following:

²Manifold pressure

²Barometric pressure

Fig. 20 5.7L IAT SENSOR R/I

1 - FRONT OF INTAKE MANIFOLD PLENUM

2 - IAT SENSOR

3 - RELEASE TAB

14 - 32 FUEL INJECTION - GASDR

INTAKE AIR TEMPERATURE SENSOR (Continued)