Camshaft position sensor DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1156 of 2627

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

C315 DK GY At Driver Seat N/S

C316 BK At Passenger Seat N/S

C317 BK At Passenger Seat N/S

C319 BK Bottom Left of Left Door N/S

C320 Right Rear Door 43

C322 DK GY Left Rear of Frame 44, 46

C323 BK Left Side of Instrument Panel N/S

C327 BK Right Rear Fender 50, 51

C328 BK Left Rear Fender 50, 51, 52

Camshaft Position Sensor GY Right Front Side of Engine 3, 9

Capacitor Left Rear of Engine Compartment 4

Center High Mounted Stop

Lamp/Cargo LampBK Rear of Cab 49

Cigar Lighter Outlet NAT Rear of Cigar Lighter 32, 35, 36

Clearance Lamp No. 1 BK Left Roof 48

Clearance Lamp No. 2 BK Left-Center Roof 48

Clearance Lamp No. 3 BK Center Roof 48

Clearance Lamp No. 4 BK Right-Center Roof 48

Clearance Lamp No. 5 BK Right Roof 48

Clockspring C1 BK Steering Column 31

Clockspring C2 YL Steering Column 31

Clockspring C3 BK Steering Column N/S

Clockspring C4 BK Steering Column N/S

Clutch Interlock Brake Switch BK At Clutch Pedal 22, 24

Coil On Plug No.1 BK Left Top Side of Intake Manifold 6

Coil On Plug No.2 BK Right Top Side of Intake Manifold 3

Coil On Plug No.3 BK Left Top Side of Intake Manifold 6

Coil On Plug No.4 BK Right Top Side of Intake Manifold 3

Coil On Plug No.5 BK Left Top Side of Intake Manifold 5, 6

Coil On Plug No.6 BK Right Top Side of Intake Manifold 3

Coil On Plug No.7 BK Left Top Side of Intake Manifold 6

Coil On Plug No.8 BK Right Top Side of Intake Manifold 3

Compass/Mini-Trip Computer BK In Overhead Console N/S

Condenser Fan BK Near Condenser 23, 24

Controller Anti-Lock Brake C1 BK Left Fender Side Shield 22, 24, 25

Controller Anti-Lock Brake C2

(ABS)BK Left Fender Side Shield 22, 25

Crankshaft Position Sensor BK Right Rear of Engine Block 3, 9

Cylinder Lock Switch-Driver

(Premium)BK In Left Front Door 41

Cylinder Lock Switch-Passenger

(Premium)LT GY In Right Front Door N/S

Data Link Connector BK Left Bottom of Instrument Panel 35, 38

DR8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 3

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1163 of 2627

SPLICE

NUMBERLOCATION FIG.

S122 Left Front Fender 22

S123 Left Front Fender 22, 23

S124 Center Rear of Engine Compartment N/S

S125 Right Rear of Engine Compartment 4, 8

S130 Top Front of Transmission 3, 9

S132 Left Rear of Engine Compartment 3, 9

S133 Left Rear of Engine 4, 9

S134 Left Rear of Engine Compartment 3, 9

S135 Headlamp and Dash, Left Side N/S

S136 Left Front Fender 23

S137 Left Rear of Engine Compartment 21

S138 Left Rear of Engine N/S

S139 Right Front of Transmission N/S

S140 Right Rear Engine Compartment 22

S142 Left Side of Engine 3

S143 Left Side of Engine Compartment N/S

S144 Top Front of Transmission N/S

S145 Left Front Fender 23

S148 Top Front of Transmission 3

S149 Left Rear of Engine 6

S150 Top Center of Engine 3, 9

S153 Rear Engine Compartment N/S

S154 Left Top Engine N/S

S155 Left Rear Engine Compartment near T/O for Fuel Control Actuator 9

S157 Near T/O for Camshaft Position Sensor N/S

S158 Near T/O for C114 10

S159 Near T/O for Engine Control Module N/S

S160 Top Left Engine 10

S162 Left Side Engine N/S

S163 Right Side Engine N/S

S164 Near Engine Control Module C2 10

S165 Near Engine Control Module C2 10

S166 In Battery Positive Harness N/S

S168 Right Rear of Engine 3

S169 Right Rear of Engine 3, 7

S170 Left Engine 10

S171 Top Left Engine 10

S172 In T/O for Fuel Control Actuator N/S

S173 Near T/O for Engine Control Module N/S

S174 Near T/O for C114 N/S

S175 Near T/O for Engine Control Module N/S

8W - 91 - 10 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1234 of 2627

(12) Disconnect heater hoses from heater core and

remove hose assembly.

(13) Disconnect throttle and speed control cables.

(14) Remove upper radiator hose from engine.

(15) Remove lower radiator hose from engine.

(16) Remove radiator/cooling module assembly.

(17) Disconnect the engine to body ground straps

at the left side of cowl.

(18) Disconnect the engine wiring harness at the

following points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(19) Remove coil over plugs.

(20) Release fuel rail pressure.

(21) Remove fuel rail and secure away from

engine.

NOTE: It is not necessary to release the quick con-

nect fitting from the fuel supply line for engine

removal.

(22) Remove the PCV hose.

(23) Remove the breather hoses.

(24) Remove the vacuum hose for the power brake

booster.

(25) Disconnect knock sensors.

(26) Remove engine oil dipstick tube.

(27) Remove intake manifold.

(28) Install engine lifting fixture,special tool#8247,

using original fasteners from the removed intake

manifold, and fuel rail. Torque to factory specifica-

tions.

NOTE: Recheck bolt torque for engine lift plate

before removing engine.

(29) Secure the left and right engine wiring har-

nesses away from engine.

(30) Raise vehicle.

(31) Disconnect oxygen sensor wiring.

(32) Disconnect crankshaft postion sensor.

(33) Disconnect the engine block heater power

cable, if equipped.

(34) Disconnect the front propshaft at the front

differential and secure out of way.

NOTE: It is necessary to disconnect the front prop-

shaft for access to the starter and left side exhaust

flange.(35) Remove the starter.

(36) Remove the ground straps from the left and

right side of the block.

(37) Disconnect the right and left exhaust pipes at

the manifolds and from the crossover, and remove

from the vehicle.

NOTE: The exhaust clamps at the manifolds cannot

be reused. New clamps must be used or leaks may

occur.

(38) Remove the structural cover.

(39) Remove torque convertor bolts, and mark

location for reassembly.

(40) Remove transmission bellhousing to engine

bolts.

(41) Remove left and right engine mount thru

bolts.

(42) Lower the vehicle.

(43) Support the transmission with a suitable jack.

(44) Connect a suitable engine hoist to the engine

lift plate.

(45) Remove engine from vehicle.

INSTALLATION

(1) Position the engine in the vehicle.

(2) Install both left and right side engine mounts

onto engine.

(3) Raise the vehicle.

(4) Install the transmission bellhousing to engine

mounting bolts. Tighten the bolts to 41 N´m (30ft.

lbs.).

(5) Tighten the engine mount thru bolts.

(6) Install the torque convertor bolts.

(7) Connect the ground straps on the left and right

side of the engine.

(8) Install the starter.

(9) Connect the crankshaft position sensor.

(10) Install the engine block heater power cable, if

equipped.

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

(11) Install the structural cover.

NOTE: New clamps must be used on exhaust man-

ifold flanges. Failure to use new clamps may result

in exhaust leaks.

(12) Install the left and right exhaust pipes.

(13) Connect the left and right oxygen sensors.

(14) Lower vehicle.

(15) Remove the engine lift plate.

(16) Connect the knock sensors.

DRENGINE - 3.7L 9 - 11

ENGINE - 3.7L (Continued)

Page 1235 of 2627

(17) Connect the engine to body ground straps at

the left side of the cowl.

(18) Install the intake manifold.

(19) Install the engine oil dipstick tube.

(20) Install the power brake booster vacuum hose.

(21) Install the breather hoses.

(22) Install the PCV hose.

(23) Install the fuel rail.

(24) Install the coil over plugs.

(25) Connect the engine wiring harness at the fol-

lowing points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(26) Reinstall the radiator/cooling module assem-

bly.

(27) Connect lower radiator hose.

(28) Connect upper radiator hose.

(29) Connect throttle and speed control cables.

(30) Install the heater hose assembly.

(31) Install coolant recovery bottle.

(32) Install the power steering pump.

(33) Install the generator.

(34) Install the A/C compressor.

(35) Install the drive belt.

(36) Install the fan shroud with the viscous fan

assembly.

(37) Install the radiator core support bracket.

(38) Install the air cleaner assembly.

(39) Refill the engine cooling system.

(40) Recharge the air conditioning.

(41) Install the hood.

(42) Check and fill engine oil.

(43) Connect the battery negative cable.

(44) Start the engine and check for leaks.SPECIFICATIONS

SPECIFICATIONS - 3.7L ENGINE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Type 90É SOHC V6 12 Valve

Number of

Cylinders4

Firing Order 1-6-5-4-3-2

Lead Cylinder No. 1 Left Bank

Compression

Ratio9.1:1

Max. Variation

Between

Cylinders25%

Metric Standard

Displacement 3.7 Liters 226 Cubic

Inches

Bore 93.0 mm 3.66 in.

Stroke 90.8 mm 3.40 in.

Horsepower 210@5200 RPM

Torque 225ft. lbs.@4200 PRM

Compression

Pressure1172-1551 kPa 170-225 psi

CYLINDER BLOCK

DESCRIPTION SPECIFICATION

Metric Standard

Bore Diameter 93.0 .0075

mm3.6619 0.0003

in.

Out of Round

(MAX)0.076 mm 0.003 in.

Taper (MAX) 0.051 mm 0.002 in.

9 - 12 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1256 of 2627

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Oil leak or excessive cam bore wear in cylin-

der head.

(11) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head and cam on camshaft at

base circle. Depress part of rocker arm over adjuster.

Normal adjusters should feel very firm. Spongy

adjusters can be bottomed out easily.

b. Remove suspected lash adjusters, and replace.

c. Before installation, make sure adjusters are at

least partially full of oil. This can be verified by little

or no plunger travel when lash adjuster is depressed.

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the right side

exhaust manifold.

(4) Drain the engine coolant(Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(5) Lower the vehicle.

(6) Remove the intake manifold(Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(7) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(8) Remove the fan shroud(Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL).

(9) Remove oil fill housing from cylinder head.

(10) Remove accessory drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(11) Rotate the crankshaft until the damper timing

mark is aligned with TDC indicator mark.

(12) Verify the V6 mark on the camshaft sprocket

is at the 12 o'clock position. Rotate the crankshaft

one turn if necessary.

(13) Remove the crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(14) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(15) Lock the secondary timing chains to the idler

sprocket using Special Tool 8429 Timing Chain Hold-

ing Fixture.NOTE: Mark the secondary timing chain prior to

removal to aid in installation.

(16) Mark the secondary timing chain, one link on

each side of the V6 mark on the camshaft drive gear.

(17) Remove the right side secondary chain ten-

sioner(Refer to 9 - ENGINE/VALVE TIMING/TIM-

ING BELT/CHAIN AND SPROCKETS - REMOVAL).

(18) Remove the cylinder head access plug.

(19) Remove the right side secondary chain

guide(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL).

CAUTION: The nut on the right side camshaft

sprocket should not be removed for any reason, as

the sprocket and camshaft sensor target wheel is

serviced as an assembly. If the nut was removed,

torque nut to 5 N´m (44 in. lbs.).

(20) Remove the retaining bolt and the camshaft

drive gear.

CAUTION: Do not allow the engine to rotate. severe

damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts at

the front of the cylinder head. Do not attempt to

remove the cylinder head without removing these

four bolts.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason. A damaged target wheel

can result in a vehicle no start condition.

NOTE: The cylinder head is attached to the cylinder

block with twelve bolts.

(21) Remove the cylinder head retaining bolts.

(22) Remove the cylinder head and gasket. Discard

the gasket.

CAUTION: Do not lay the cylinder head on its gas-

ket sealing surface, do to the design of the cylinder

head gasket any distortion to the cylinder head

sealing surface may prevent the gasket from prop-

erly sealing resulting in leaks.

DRENGINE - 3.7L 9 - 33

CYLINDER HEAD - RIGHT (Continued)

Page 1258 of 2627

CAUTION: The nut on the right side camshaft

sprocket should not be removed for any reason, as

the sprocket and camshaft sensor target wheel is

serviced as an assembly. If the nut was removed,

torque nut to 5 NM ( 60 in. lbs.).

(7) Position the secondary chain onto the camshaft

drive gear, making sure one marked chain link is on

either side of the V6 mark on the gear then using

Special Tool 8428 Camshaft Wrench, position the

gear onto the camshaft.

CAUTION: Remove excess oil from camshaft

sprocket retaining bolt before reinstalling bolt. Fail-

ure to do so may cause over-torquing of bolt result-

ing in bolt failure.

(8) Install the camshaft drive gear retaining bolt.

(9) Install the right side secondary chain guide(Re-

fer to 9 - ENGINE/VALVE TIMING/TIMING BELT/

CHAIN AND SPROCKETS - INSTALLATION).

(10) Install the cylinder head access plug.

(11) Re-set and install the right side secondary

chain tensioner(Refer to 9 - ENGINE/VALVE TIM-

ING/TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION).

(12) Remove Special Tool 8429.

(13) Install the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(14) Install the crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION). Tighten damper bolt 175 N´m (130

Ft. Lbs.).

(15) Install accessory drive belt(Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(16) Install the fan shroud(Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION).

(17) Install the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(18) Install the intake manifold(Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(19) Install oil fill housing onto cylinder head.

(20) Refill the cooling system(Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(21) Raise the vehicle.

(22) Install the exhaust pipe onto the right

exhaust manifold.

(23) Lower the vehicle.

(24) Reconnect battery negative cable.

(25) Start the engine and check for leaks.CAMSHAFT(S)

DESCRIPTION

The camshafts consist of powdered metal steel

lobes which are sinter-bonded to a steel tube. Four

bearing journals are machined into the camshaft.

Camshaft end play is controlled by two thrust walls

that border the nose piece journal. Engine oil enters

the hollow camshafts at the third journal and lubri-

cates every intake lobe rocker through a drilled pas-

sage in the intake lobe.

REMOVAL

CAUTION: When the timing chain is removed and

the cylinder heads are still installed, DO NOT force-

fully rotate the camshafts or crankshaft indepen-

dently of each other. Severe valve and/or piston

damage can occur.

CAUTION: When removing the cam sprocket, timing

chains or camshaft, Failure to use special tool 8379

will result in hydraulic tensioner ratchet over exten-

sion, Requiring timing chain cover removal to re-set

the tensioner ratchet.

(1) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) Set engine to TDC cylinder No. 1, camshaft

sprocket V6 marks at the 12 o'clock position.

(3) Mark one link on the secondary timing chain

on both sides of the V6 mark on the camshaft

sprocket to aid in installation.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason, Severe damage will occur

to the target wheel. A damaged target wheel could

cause a vehicle no start condition.

(4) Loosen butDO NOTremove the camshaft

sprocket retaining bolt. Leave bolt snug against

sprocket.

NOTE: The timing chain tensioners must be

secured prior to removing the camshaft sprockets.

Failure to secure tensioners will allow the tension-

ers to extend, requiring timing chain cover removal

in order to reset tensioners.

CAUTION: Do not force wedge past the narrowest

point between the chain strands. Damage to the

tensioners may occur.

DRENGINE - 3.7L 9 - 35

CYLINDER HEAD - RIGHT (Continued)

Page 1259 of 2627

(5) Position Special Tool 8379 timing chain wedge

between the timing chain strands. Tap the tool to

securely wedge the timing chain against the ten-

sioner arm and guide.

(6) Remove the camshaft position sensor.

(7) Hold the camshaft with Special Tool 8428 Cam-

shaft Wrench, while removing the camshaft sprocket

bolt and sprocket.

(8) Starting at the outside working inward, loosen

the camshaft bearing cap retaining bolts 1/2 turn at

a time. Repeat until all load is off the bearing caps.

CAUTION: DO NOT STAMP OR STRIKE THE CAM-

SHAFT BEARING CAPS. SEVERE DAMAGE WILL

OCCUR TO THE BEARING CAPS.

NOTE: When the camshaft is removed the rocker

arms may slide downward, mark the rocker arms

before removing camshaft.

(9) Remove the camshaft bearing caps and the

camshaft.

INSTALLATION

(1) Lubricate camshaft journals with clean engine

oil.

NOTE: Position the right side camshaft so that the

camshaft sprocket dowel is near the 10 o'clock

position, This will place the camshaft at the neutral

position easing the installation of the camshaft

bearing caps.

(2) Position the camshaft into the cylinder head.

(3) Install the camshaft bearing caps, hand tighten

the retaining bolts.

NOTE: Caps should be installed so that the

stamped numbers on the caps are in numerical

order, ( 1 thru 4 ) from the front to the rear of the

engine. All caps should be installed so that the

stamped arrows on the caps point toward the front

of the engine.

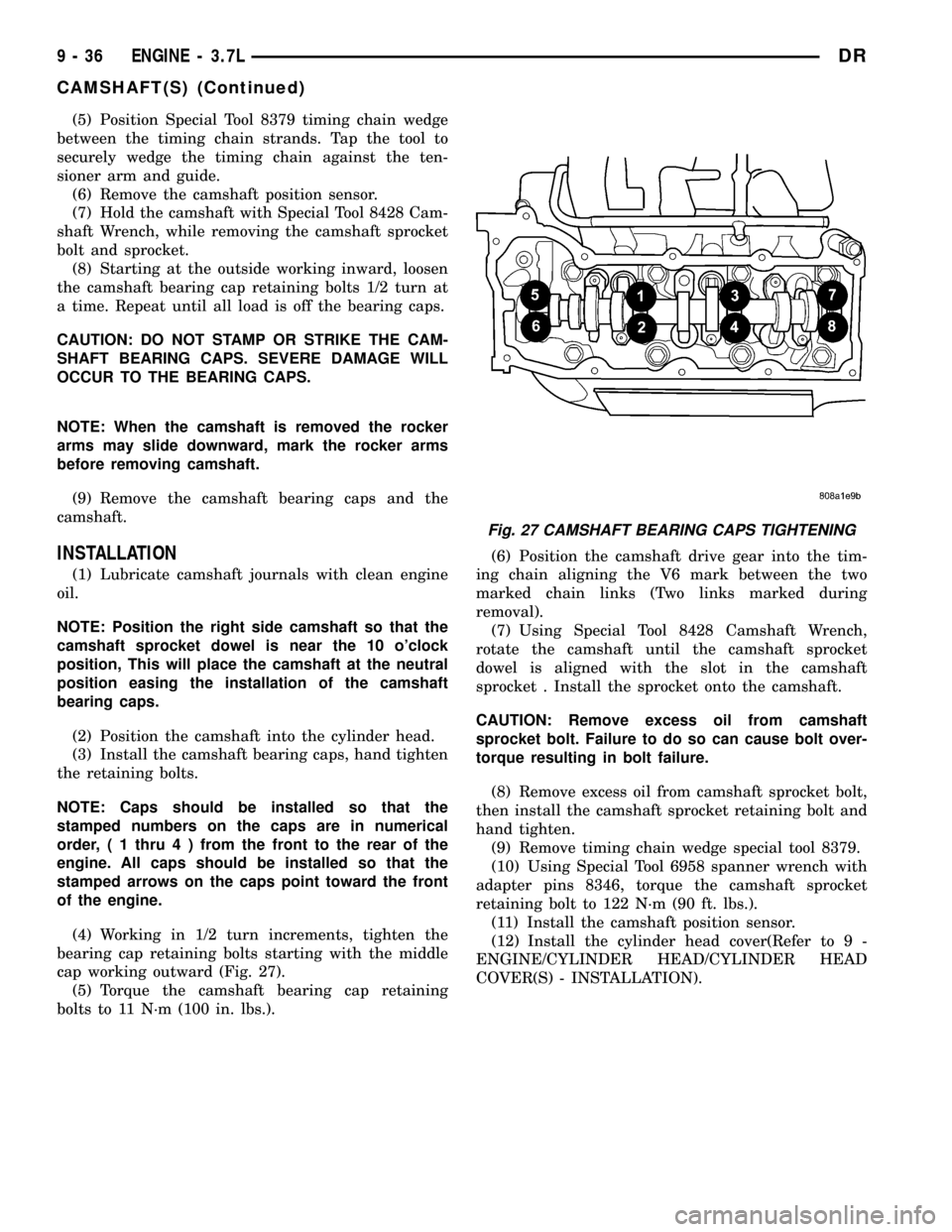

(4) Working in 1/2 turn increments, tighten the

bearing cap retaining bolts starting with the middle

cap working outward (Fig. 27).

(5) Torque the camshaft bearing cap retaining

bolts to 11 N´m (100 in. lbs.).(6) Position the camshaft drive gear into the tim-

ing chain aligning the V6 mark between the two

marked chain links (Two links marked during

removal).

(7) Using Special Tool 8428 Camshaft Wrench,

rotate the camshaft until the camshaft sprocket

dowel is aligned with the slot in the camshaft

sprocket . Install the sprocket onto the camshaft.

CAUTION: Remove excess oil from camshaft

sprocket bolt. Failure to do so can cause bolt over-

torque resulting in bolt failure.

(8) Remove excess oil from camshaft sprocket bolt,

then install the camshaft sprocket retaining bolt and

hand tighten.

(9) Remove timing chain wedge special tool 8379.

(10) Using Special Tool 6958 spanner wrench with

adapter pins 8346, torque the camshaft sprocket

retaining bolt to 122 N´m (90 ft. lbs.).

(11) Install the camshaft position sensor.

(12) Install the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

Fig. 27 CAMSHAFT BEARING CAPS TIGHTENING

9 - 36 ENGINE - 3.7LDR

CAMSHAFT(S) (Continued)

Page 1307 of 2627

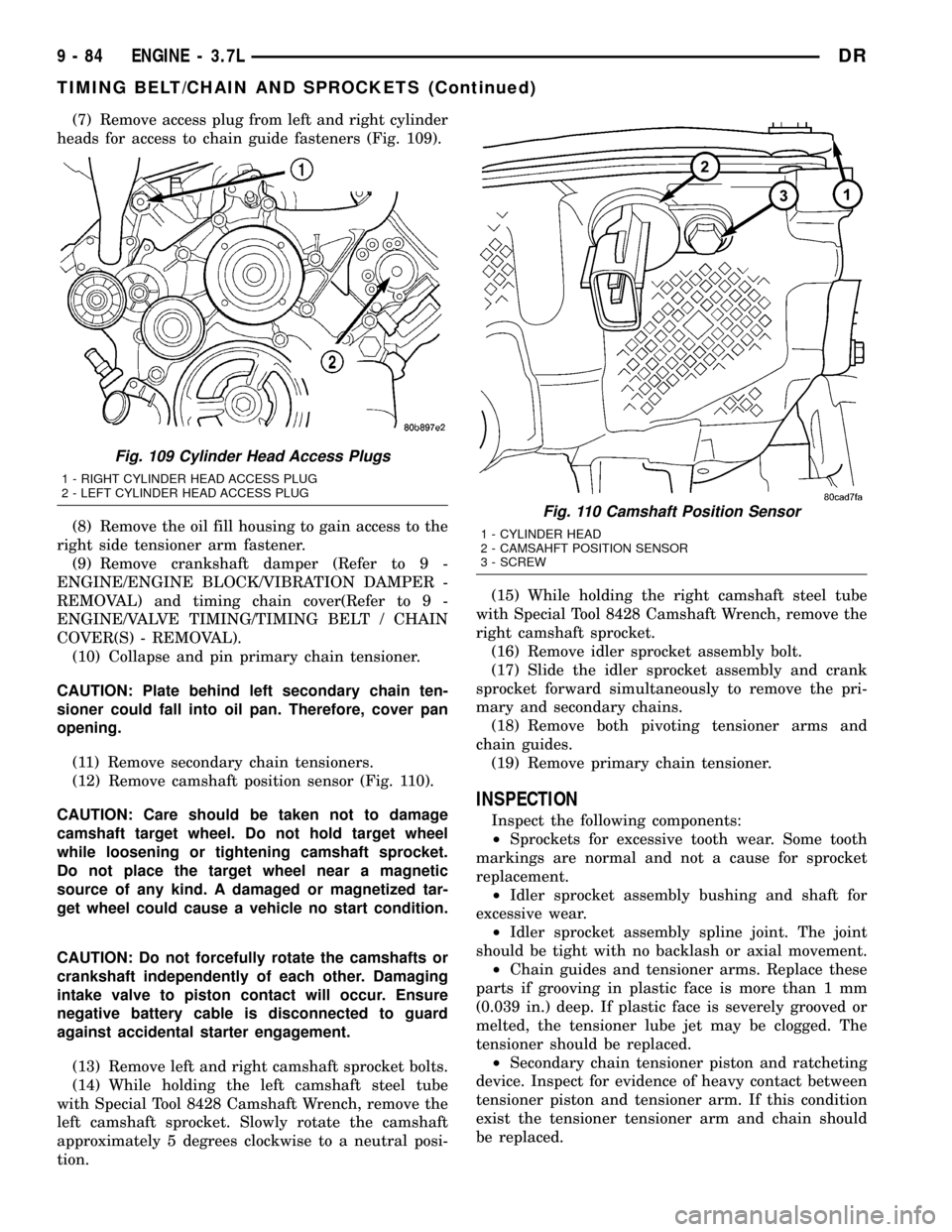

(7) Remove access plug from left and right cylinder

heads for access to chain guide fasteners (Fig. 109).

(8) Remove the oil fill housing to gain access to the

right side tensioner arm fastener.

(9) Remove crankshaft damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL) and timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(10) Collapse and pin primary chain tensioner.

CAUTION: Plate behind left secondary chain ten-

sioner could fall into oil pan. Therefore, cover pan

opening.

(11) Remove secondary chain tensioners.

(12) Remove camshaft position sensor (Fig. 110).

CAUTION: Care should be taken not to damage

camshaft target wheel. Do not hold target wheel

while loosening or tightening camshaft sprocket.

Do not place the target wheel near a magnetic

source of any kind. A damaged or magnetized tar-

get wheel could cause a vehicle no start condition.

CAUTION: Do not forcefully rotate the camshafts or

crankshaft independently of each other. Damaging

intake valve to piston contact will occur. Ensure

negative battery cable is disconnected to guard

against accidental starter engagement.

(13) Remove left and right camshaft sprocket bolts.

(14) While holding the left camshaft steel tube

with Special Tool 8428 Camshaft Wrench, remove the

left camshaft sprocket. Slowly rotate the camshaft

approximately 5 degrees clockwise to a neutral posi-

tion.(15) While holding the right camshaft steel tube

with Special Tool 8428 Camshaft Wrench, remove the

right camshaft sprocket.

(16) Remove idler sprocket assembly bolt.

(17) Slide the idler sprocket assembly and crank

sprocket forward simultaneously to remove the pri-

mary and secondary chains.

(18) Remove both pivoting tensioner arms and

chain guides.

(19) Remove primary chain tensioner.

INSPECTION

Inspect the following components:

²Sprockets for excessive tooth wear. Some tooth

markings are normal and not a cause for sprocket

replacement.

²Idler sprocket assembly bushing and shaft for

excessive wear.

²Idler sprocket assembly spline joint. The joint

should be tight with no backlash or axial movement.

²Chain guides and tensioner arms. Replace these

parts if grooving in plastic face is more than 1 mm

(0.039 in.) deep. If plastic face is severely grooved or

melted, the tensioner lube jet may be clogged. The

tensioner should be replaced.

²Secondary chain tensioner piston and ratcheting

device. Inspect for evidence of heavy contact between

tensioner piston and tensioner arm. If this condition

exist the tensioner tensioner arm and chain should

be replaced.

Fig. 109 Cylinder Head Access Plugs

1 - RIGHT CYLINDER HEAD ACCESS PLUG

2 - LEFT CYLINDER HEAD ACCESS PLUG

Fig. 110 Camshaft Position Sensor

1 - CYLINDER HEAD

2 - CAMSAHFT POSITION SENSOR

3 - SCREW

9 - 84 ENGINE - 3.7LDR

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 1318 of 2627

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

REMOVAL

NOTE: This procedure applies to both the 4X2 and

4X4 vehicles, steps that apply to the 4X4 vehicle

only, are identified.

(1) Disconnect the battery negative and positive

cables.

(2) Remove the battery and the battery tray.

(3) Raise vehicle on hoist.

(4) Remove exhaust crossover pipe from exhaust

manifolds.

(5)4X4 vehiclesDisconnect axle vent tube from

left side engine mount.

(6) Remove the through bolt retaining nut and bolt

from both the left and right side engine mounts.

(7)4X4 vehiclesRemove locknut from left and

right side engine mount brackets.

(8) Disconnect two ground straps from the lower

left hand side and one ground strap from the lower

right hand side of the engine.

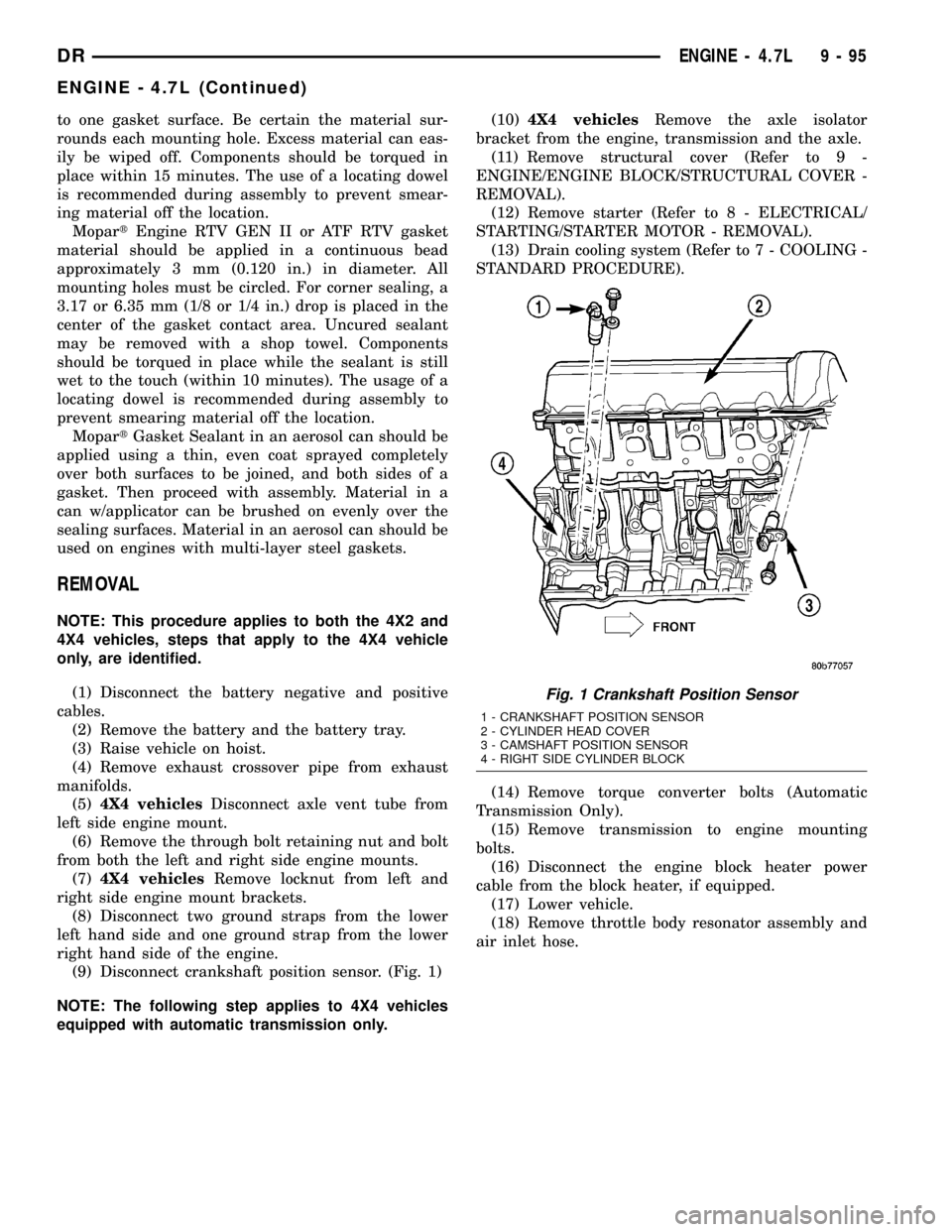

(9) Disconnect crankshaft position sensor. (Fig. 1)

NOTE: The following step applies to 4X4 vehicles

equipped with automatic transmission only.(10)4X4 vehiclesRemove the axle isolator

bracket from the engine, transmission and the axle.

(11) Remove structural cover (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL).

(12) Remove starter (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - REMOVAL).

(13) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(14) Remove torque converter bolts (Automatic

Transmission Only).

(15) Remove transmission to engine mounting

bolts.

(16) Disconnect the engine block heater power

cable from the block heater, if equipped.

(17) Lower vehicle.

(18) Remove throttle body resonator assembly and

air inlet hose.

Fig. 1 Crankshaft Position Sensor

1 - CRANKSHAFT POSITION SENSOR

2 - CYLINDER HEAD COVER

3 - CAMSHAFT POSITION SENSOR

4 - RIGHT SIDE CYLINDER BLOCK

DRENGINE - 4.7L 9 - 95

ENGINE - 4.7L (Continued)

Page 1319 of 2627

(19) Disconnect throttle and speed control cables.

(20) Disconnect tube from both the left and right

side crankcase breathers (Fig. 2). Remove breathers

(21) Discharge A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/REFRIG-

ERANT - STANDARD PROCEDURE).

(22) Remove A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - REMOVAL).

(23) Remove shroud, fan assembly (Refer to 7 -

COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL) and accessory drive belt

(Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - REMOVAL).

(24) Disconnect transmission oil cooler lines at the

radiator.

(25) Disconnect radiator upper and lower hoses.

(26) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL), A/C condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL) and

transmission oil cooler.

(27) Remove generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).

(28) Disconnect the two heater hoses from the tim-

ing chain cover and heater core.

(29) Unclip and remove heater hoses and tubes

from the intake manifold.

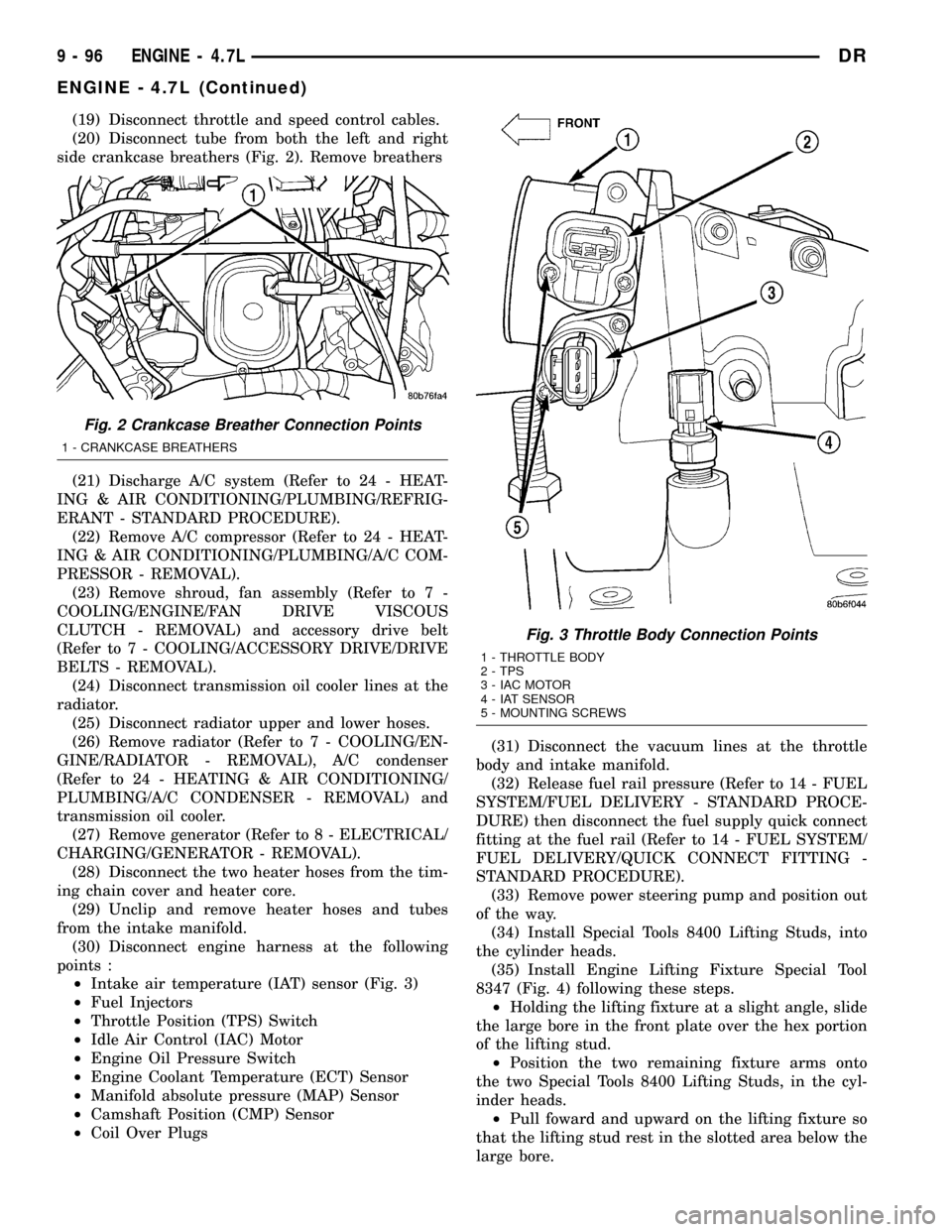

(30) Disconnect engine harness at the following

points :

²Intake air temperature (IAT) sensor (Fig. 3)

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold absolute pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs(31) Disconnect the vacuum lines at the throttle

body and intake manifold.

(32) Release fuel rail pressure (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - STANDARD PROCE-

DURE) then disconnect the fuel supply quick connect

fitting at the fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/QUICK CONNECT FITTING -

STANDARD PROCEDURE).

(33) Remove power steering pump and position out

of the way.

(34) Install Special Tools 8400 Lifting Studs, into

the cylinder heads.

(35) Install Engine Lifting Fixture Special Tool

8347 (Fig. 4) following these steps.

²Holding the lifting fixture at a slight angle, slide

the large bore in the front plate over the hex portion

of the lifting stud.

²Position the two remaining fixture arms onto

the two Special Tools 8400 Lifting Studs, in the cyl-

inder heads.

²Pull foward and upward on the lifting fixture so

that the lifting stud rest in the slotted area below the

large bore.

Fig. 2 Crankcase Breather Connection Points

1 - CRANKCASE BREATHERS

Fig. 3 Throttle Body Connection Points

1 - THROTTLE BODY

2 - TPS

3 - IAC MOTOR

4 - IAT SENSOR

5 - MOUNTING SCREWS

9 - 96 ENGINE - 4.7LDR

ENGINE - 4.7L (Continued)