Power steering DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 341 of 2627

CONDITION POSSIBLE CAUSES CORRECTION

CORD EDGE FAILURE

(Tensile member exposed at edges

of belt or separated from belt body)1. Incorrect belt tension 1. Inspect/Replace tensioner if

necessary

2. Belt contacting stationary object 2. Replace belt

3. Pulley(s) out of tolerance 3. Replace pulley

4. Insufficient adhesion between

tensile member and rubber matrix4. Replace belt

REMOVAL

CAUTION: DO NOT LET TENSIONER ARM SNAP

BACK TO THE FREEARM POSITION, SEVER DAM-

AGE MAY OCCUR TO THE TENSIONER.

Belt tension is not adjustable. Belt adjustment is

maintained by an automatic (spring load) belt ten-

sioner.

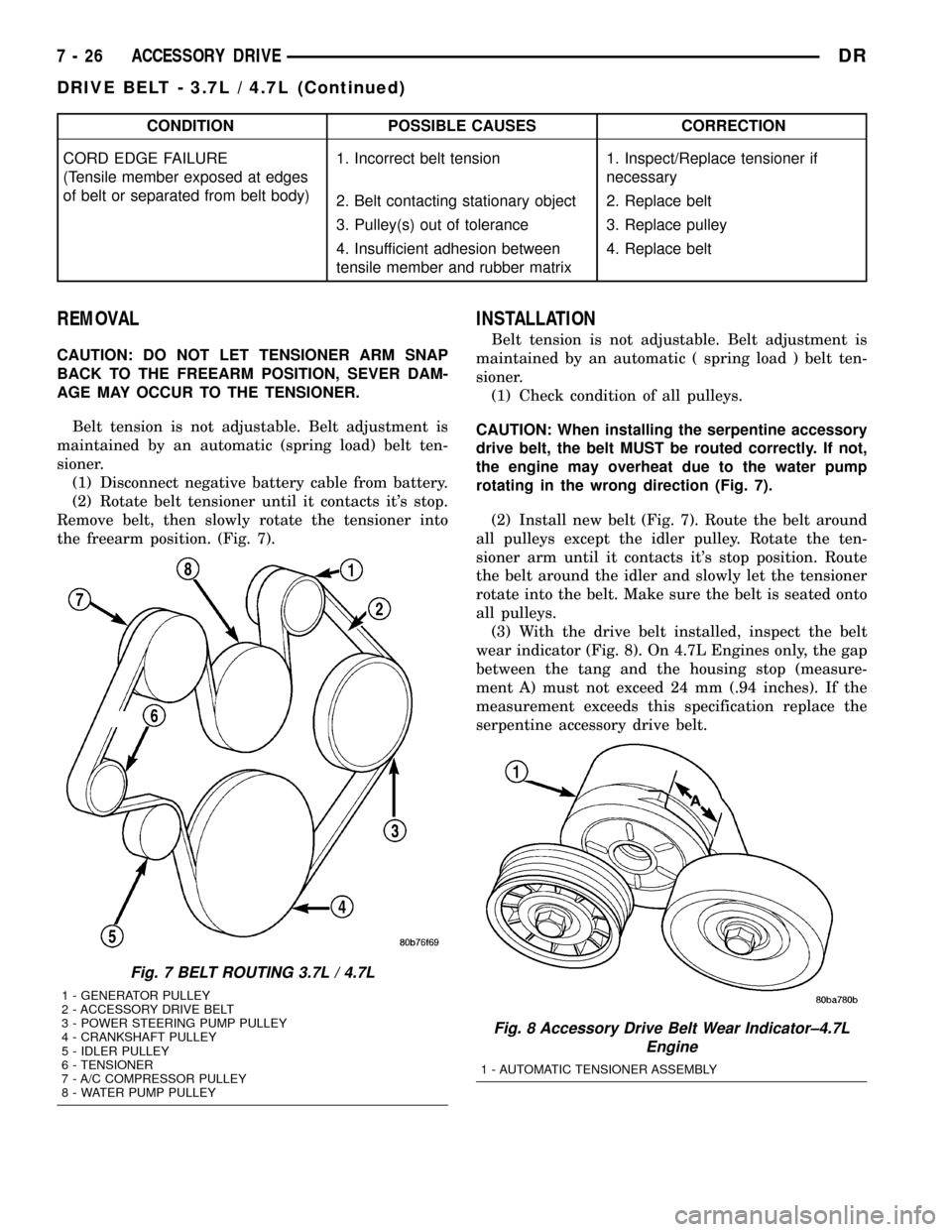

(1) Disconnect negative battery cable from battery.

(2) Rotate belt tensioner until it contacts it's stop.

Remove belt, then slowly rotate the tensioner into

the freearm position. (Fig. 7).

INSTALLATION

Belt tension is not adjustable. Belt adjustment is

maintained by an automatic ( spring load ) belt ten-

sioner.

(1) Check condition of all pulleys.

CAUTION: When installing the serpentine accessory

drive belt, the belt MUST be routed correctly. If not,

the engine may overheat due to the water pump

rotating in the wrong direction (Fig. 7).

(2) Install new belt (Fig. 7). Route the belt around

all pulleys except the idler pulley. Rotate the ten-

sioner arm until it contacts it's stop position. Route

the belt around the idler and slowly let the tensioner

rotate into the belt. Make sure the belt is seated onto

all pulleys.

(3) With the drive belt installed, inspect the belt

wear indicator (Fig. 8). On 4.7L Engines only, the gap

between the tang and the housing stop (measure-

ment A) must not exceed 24 mm (.94 inches). If the

measurement exceeds this specification replace the

serpentine accessory drive belt.

Fig. 7 BELT ROUTING 3.7L / 4.7L

1 - GENERATOR PULLEY

2 - ACCESSORY DRIVE BELT

3 - POWER STEERING PUMP PULLEY

4 - CRANKSHAFT PULLEY

5 - IDLER PULLEY

6 - TENSIONER

7 - A/C COMPRESSOR PULLEY

8 - WATER PUMP PULLEY

Fig. 8 Accessory Drive Belt Wear Indicator±4.7L

Engine

1 - AUTOMATIC TENSIONER ASSEMBLY

7 - 26 ACCESSORY DRIVEDR

DRIVE BELT - 3.7L / 4.7L (Continued)

Page 344 of 2627

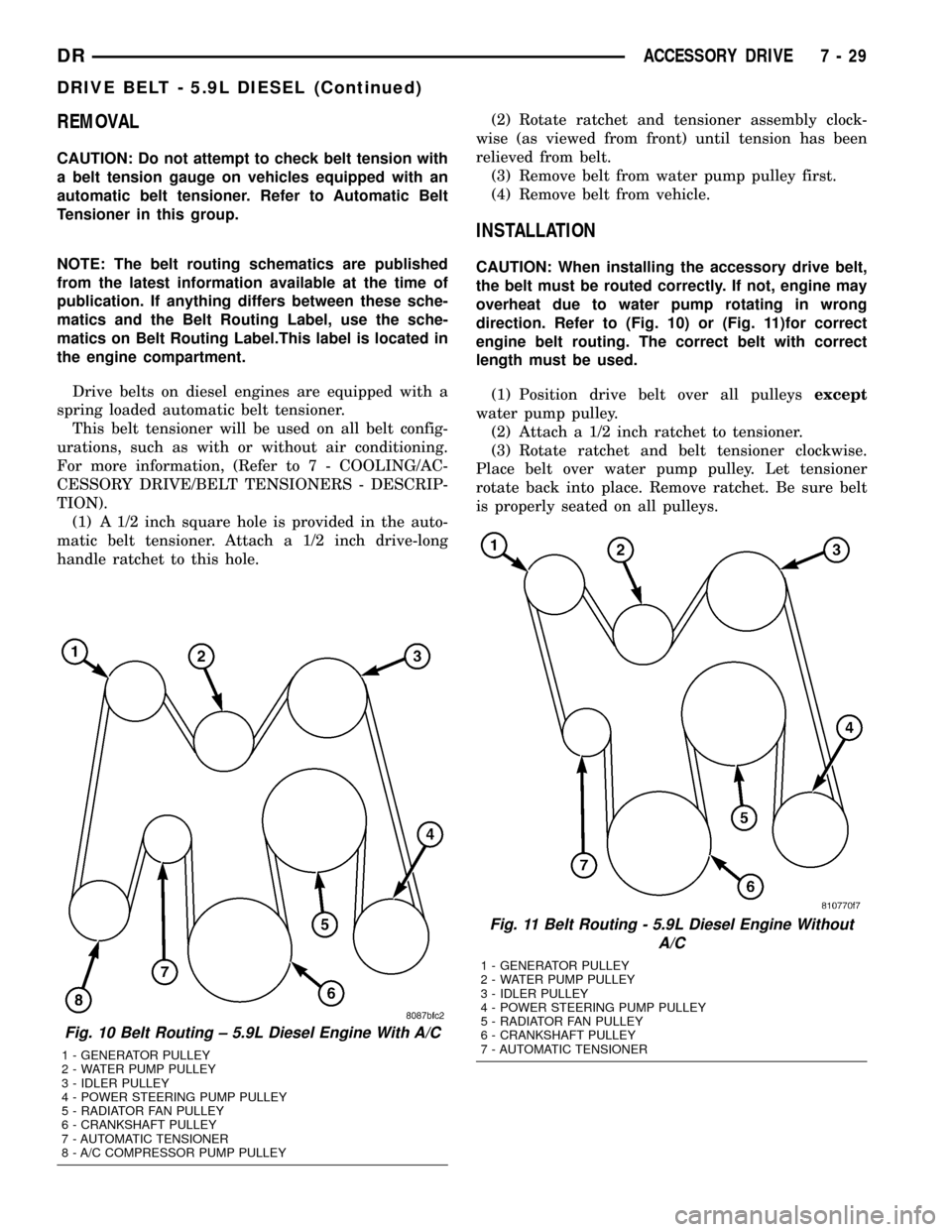

REMOVAL

CAUTION: Do not attempt to check belt tension with

a belt tension gauge on vehicles equipped with an

automatic belt tensioner. Refer to Automatic Belt

Tensioner in this group.

NOTE: The belt routing schematics are published

from the latest information available at the time of

publication. If anything differs between these sche-

matics and the Belt Routing Label, use the sche-

matics on Belt Routing Label.This label is located in

the engine compartment.

Drive belts on diesel engines are equipped with a

spring loaded automatic belt tensioner.

This belt tensioner will be used on all belt config-

urations, such as with or without air conditioning.

For more information, (Refer to 7 - COOLING/AC-

CESSORY DRIVE/BELT TENSIONERS - DESCRIP-

TION).

(1) A 1/2 inch square hole is provided in the auto-

matic belt tensioner. Attach a 1/2 inch drive-long

handle ratchet to this hole.(2) Rotate ratchet and tensioner assembly clock-

wise (as viewed from front) until tension has been

relieved from belt.

(3) Remove belt from water pump pulley first.

(4) Remove belt from vehicle.

INSTALLATION

CAUTION: When installing the accessory drive belt,

the belt must be routed correctly. If not, engine may

overheat due to water pump rotating in wrong

direction. Refer to (Fig. 10) or (Fig. 11)for correct

engine belt routing. The correct belt with correct

length must be used.

(1) Position drive belt over all pulleysexcept

water pump pulley.

(2) Attach a 1/2 inch ratchet to tensioner.

(3) Rotate ratchet and belt tensioner clockwise.

Place belt over water pump pulley. Let tensioner

rotate back into place. Remove ratchet. Be sure belt

is properly seated on all pulleys.

Fig. 10 Belt Routing ± 5.9L Diesel Engine With A/C

1 - GENERATOR PULLEY

2 - WATER PUMP PULLEY

3 - IDLER PULLEY

4 - POWER STEERING PUMP PULLEY

5 - RADIATOR FAN PULLEY

6 - CRANKSHAFT PULLEY

7 - AUTOMATIC TENSIONER

8 - A/C COMPRESSOR PUMP PULLEY

Fig. 11 Belt Routing - 5.9L Diesel Engine Without

A/C

1 - GENERATOR PULLEY

2 - WATER PUMP PULLEY

3 - IDLER PULLEY

4 - POWER STEERING PUMP PULLEY

5 - RADIATOR FAN PULLEY

6 - CRANKSHAFT PULLEY

7 - AUTOMATIC TENSIONER

DRACCESSORY DRIVE 7 - 29

DRIVE BELT - 5.9L DIESEL (Continued)

Page 359 of 2627

(7) Air Conditioned vehicles; Install the generator.

Tighten the bolts to 41 N´m (30 ft. lbs.).

(8) Install the support bracket (generator mount-

ing bracket-to-intake manifold). (Fig. 17). Tighten the

bolts to 54 N´m (40 ft. lbs.).

(9) Install the accessory drive belt (Fig. 18)(Refer

to 7 - COOLING/ACCESSORY DRIVE/DRIVE

BELTS - INSTALLATION).

(10) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(11) Connect battery negative cable.

(12) Start and warm the engine. Check for leaks.

ENGINE COOLANT

THERMOSTAT - 3.7L/4.7L

DESCRIPTION

CAUTION: Do not operate the engine without a ther-

mostat, except for servicing or testing.

A pellet-type thermostat controls the operating

temperature of the engine by controlling the amount

of coolant flow to the radiator. On all engines the

thermostat is closed below 195ÉF (90ÉC). Above this

temperature, coolant is allowed to flow to the radia-

tor. This provides quick engine warm up and overall

temperature control. On the 3.7L4.7L engine the

thermostat is designed to block the flow of the cool-

ant bypass journal by 50% instead of completely

blocking the flow. This design controls coolant tem-

perature more accurately (Fig. 23).The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes other prob-

lems. These are: longer engine warmup time, unreli-

able warmup performance, increased exhaust

emissions and crankcase condensation. This conden-

sation can result in sludge formation.

OPERATION

The wax pellet is located in a sealed container at

the spring end of the thermostat. When heated, the

pellet expands, overcoming closing spring tension

and water pump pressure to force the valve to open.

DIAGNOSIS AND TESTINGÐTHERMOSTAT

ON-BOARD DIAGNOSTICS

Allgasoline powered modelsare equipped with

On-Board Diagnostics for certain cooling system com-

ponents. Refer to On-Board Diagnostics (OBD) in the

Diagnosis section of this group for additional infor-

mation. If the powertrain control module (PCM)

detects low engine coolant temperature, it will record

a Diagnostic Trouble Code (DTC) in the PCM mem-

ory. Do not change a thermostat for lack of heat as

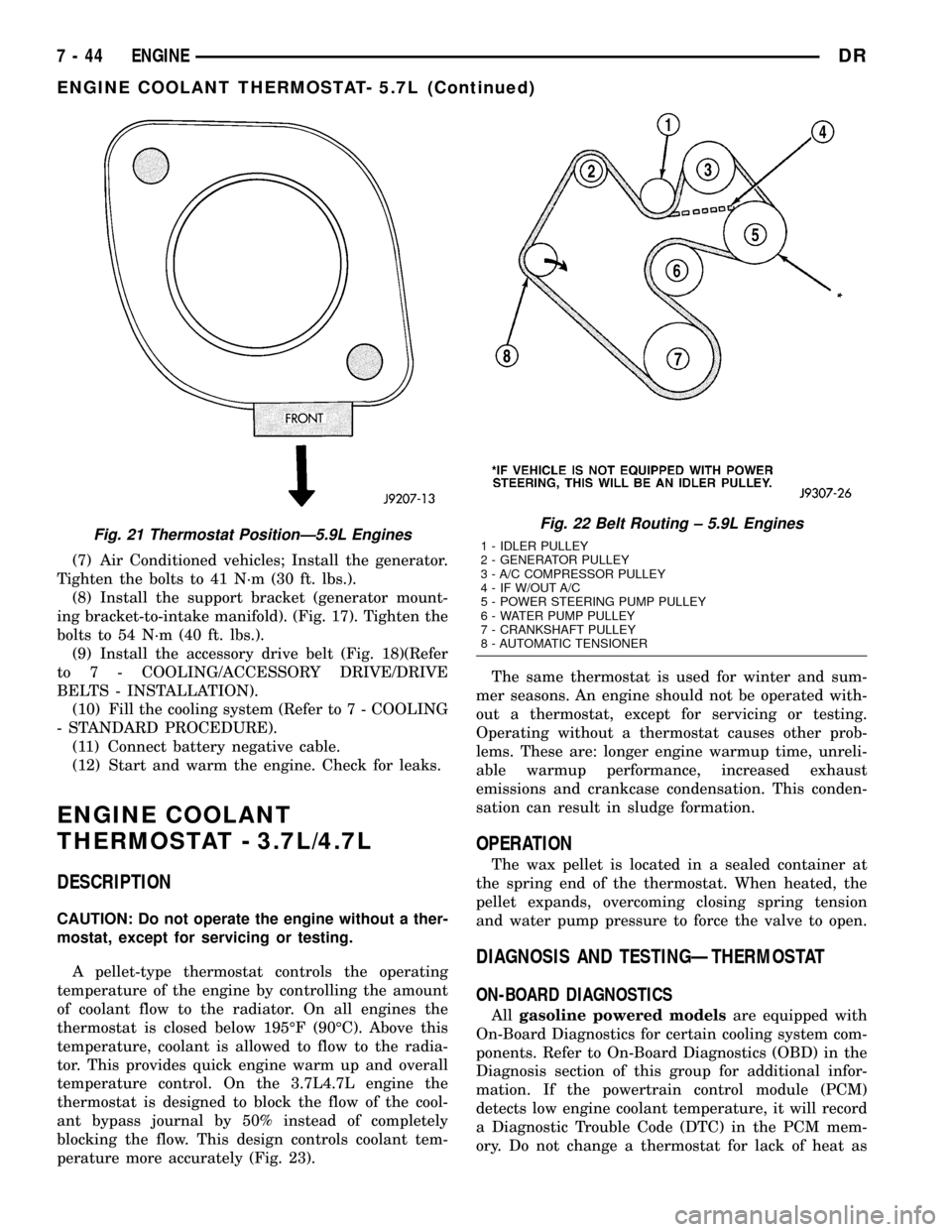

Fig. 21 Thermostat PositionÐ5.9L EnginesFig. 22 Belt Routing ± 5.9L Engines

1 - IDLER PULLEY

2 - GENERATOR PULLEY

3 - A/C COMPRESSOR PULLEY

4 - IF W/OUT A/C

5 - POWER STEERING PUMP PULLEY

6 - WATER PUMP PULLEY

7 - CRANKSHAFT PULLEY

8 - AUTOMATIC TENSIONER

7 - 44 ENGINEDR

ENGINE COOLANT THERMOSTAT- 5.7L (Continued)

Page 369 of 2627

RADIATOR-3.7L/4.7L/5.7L

DESCRIPTION

The radiator is a aluminum cross-flow design with

horizontal tubes through the radiator core and verti-

cal plastic side tanks (Fig. 38).

This radiator does not contain an internal trans-

mission oil cooler.

OPERATION

The radiator supplies sufficient heat transfer using

the cooling fins interlaced between the horizontal

tubes in the radiator core to cool the engine.

DIAGNOSIS AND TESTING - RADIATOR

COOLANT FLOW

Use the following procedure to determine if coolant

is flowing through the cooling system.

(1) Idle engine until operating temperature is

reached. If the upper radiator hose is warm to the

touch, the thermostat is opening and coolant is flow-

ing to the radiator.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. USING A RAG TO

COVER THE RADIATOR PRESSURE CAP, OPEN

RADIATOR CAP SLOWLY TO THE FIRST STOP. THIS

WILL ALLOW ANY BUILT-UP PRESSURE TO VENT

TO THE RESERVE/OVERFLOW TANK. AFTER PRES-

SURE BUILD-UP HAS BEEN RELEASED, REMOVE

CAP FROM FILLER NECK.

(2) Drain a small amount of coolant from the radi-

ator until the ends of the radiator tubes are visible

through the filler neck. Idle the engine at normal

operating temperature. If coolant is flowing past the

exposed tubes, the coolant is circulating.

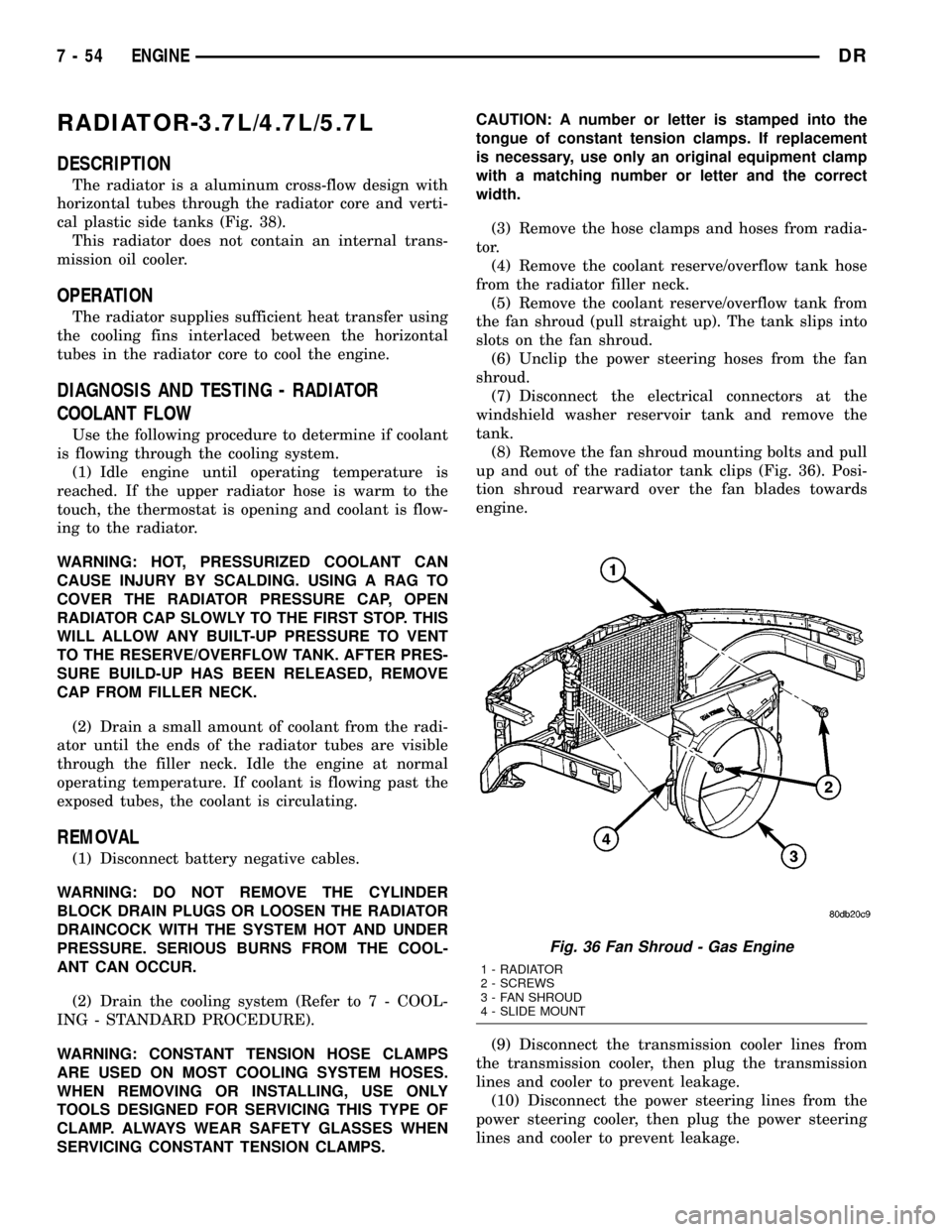

REMOVAL

(1) Disconnect battery negative cables.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM THE COOL-

ANT CAN OCCUR.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter and the correct

width.

(3) Remove the hose clamps and hoses from radia-

tor.

(4) Remove the coolant reserve/overflow tank hose

from the radiator filler neck.

(5) Remove the coolant reserve/overflow tank from

the fan shroud (pull straight up). The tank slips into

slots on the fan shroud.

(6) Unclip the power steering hoses from the fan

shroud.

(7) Disconnect the electrical connectors at the

windshield washer reservoir tank and remove the

tank.

(8) Remove the fan shroud mounting bolts and pull

up and out of the radiator tank clips (Fig. 36). Posi-

tion shroud rearward over the fan blades towards

engine.

(9) Disconnect the transmission cooler lines from

the transmission cooler, then plug the transmission

lines and cooler to prevent leakage.

(10) Disconnect the power steering lines from the

power steering cooler, then plug the power steering

lines and cooler to prevent leakage.

Fig. 36 Fan Shroud - Gas Engine

1 - RADIATOR

2 - SCREWS

3 - FAN SHROUD

4 - SLIDE MOUNT

7 - 54 ENGINEDR

Page 370 of 2627

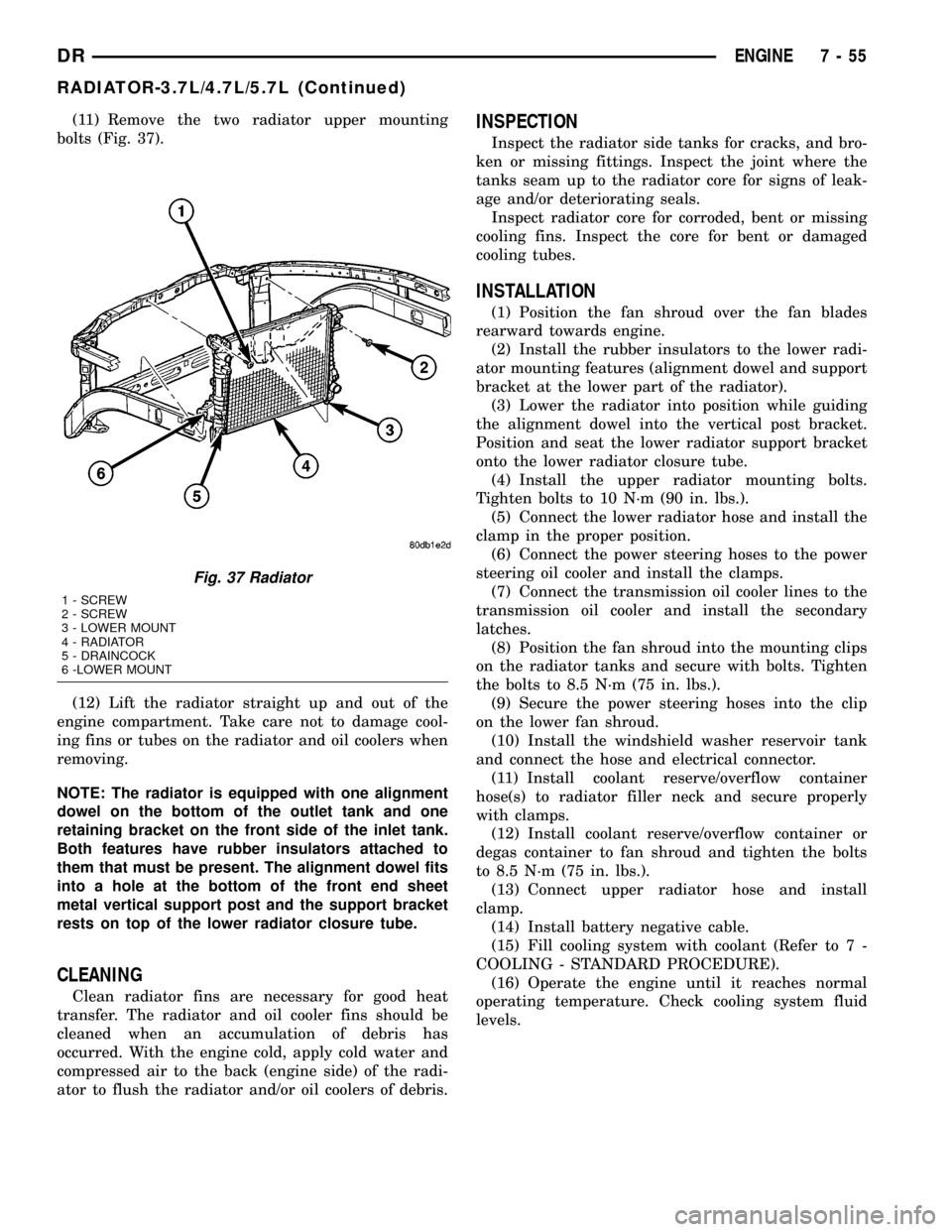

(11) Remove the two radiator upper mounting

bolts (Fig. 37).

(12) Lift the radiator straight up and out of the

engine compartment. Take care not to damage cool-

ing fins or tubes on the radiator and oil coolers when

removing.

NOTE: The radiator is equipped with one alignment

dowel on the bottom of the outlet tank and one

retaining bracket on the front side of the inlet tank.

Both features have rubber insulators attached to

them that must be present. The alignment dowel fits

into a hole at the bottom of the front end sheet

metal vertical support post and the support bracket

rests on top of the lower radiator closure tube.

CLEANING

Clean radiator fins are necessary for good heat

transfer. The radiator and oil cooler fins should be

cleaned when an accumulation of debris has

occurred. With the engine cold, apply cold water and

compressed air to the back (engine side) of the radi-

ator to flush the radiator and/or oil coolers of debris.

INSPECTION

Inspect the radiator side tanks for cracks, and bro-

ken or missing fittings. Inspect the joint where the

tanks seam up to the radiator core for signs of leak-

age and/or deteriorating seals.

Inspect radiator core for corroded, bent or missing

cooling fins. Inspect the core for bent or damaged

cooling tubes.

INSTALLATION

(1) Position the fan shroud over the fan blades

rearward towards engine.

(2) Install the rubber insulators to the lower radi-

ator mounting features (alignment dowel and support

bracket at the lower part of the radiator).

(3) Lower the radiator into position while guiding

the alignment dowel into the vertical post bracket.

Position and seat the lower radiator support bracket

onto the lower radiator closure tube.

(4) Install the upper radiator mounting bolts.

Tighten bolts to 10 N´m (90 in. lbs.).

(5) Connect the lower radiator hose and install the

clamp in the proper position.

(6) Connect the power steering hoses to the power

steering oil cooler and install the clamps.

(7) Connect the transmission oil cooler lines to the

transmission oil cooler and install the secondary

latches.

(8) Position the fan shroud into the mounting clips

on the radiator tanks and secure with bolts. Tighten

the bolts to 8.5 N´m (75 in. lbs.).

(9) Secure the power steering hoses into the clip

on the lower fan shroud.

(10) Install the windshield washer reservoir tank

and connect the hose and electrical connector.

(11) Install coolant reserve/overflow container

hose(s) to radiator filler neck and secure properly

with clamps.

(12) Install coolant reserve/overflow container or

degas container to fan shroud and tighten the bolts

to 8.5 N´m (75 in. lbs.).

(13) Connect upper radiator hose and install

clamp.

(14) Install battery negative cable.

(15) Fill cooling system with coolant (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(16) Operate the engine until it reaches normal

operating temperature. Check cooling system fluid

levels.

Fig. 37 Radiator

1 - SCREW

2 - SCREW

3 - LOWER MOUNT

4 - RADIATOR

5 - DRAINCOCK

6 -LOWER MOUNT

DRENGINE 7 - 55

RADIATOR-3.7L/4.7L/5.7L (Continued)

Page 371 of 2627

RADIATOR - 5.9L DIESEL

DESCRIPTION

The radiator is a aluminum cross-flow design with

horizontal tubes through the radiator core and verti-

cal plastic side tanks (Fig. 38).

This radiator does not contain an internal trans-

mission oil cooler.

OPERATION

The radiator supplies sufficient heat transfer using

the cooling fins interlaced between the horizontal

tubes in the radiator core to cool the engine.

DIAGNOSIS AND TESTING - RADIATOR

COOLANT FLOW

Use the following procedure to determine if coolant

is flowing through the cooling system.

(1) Idle engine until operating temperature is

reached. If the upper radiator hose is warm to the

touch, the thermostat is opening and coolant is flow-

ing to the radiator.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. USING A RAG TO

COVER THE RADIATOR PRESSURE CAP, OPEN

RADIATOR CAP SLOWLY TO THE FIRST STOP. THIS

WILL ALLOW ANY BUILT-UP PRESSURE TO VENT

TO THE RESERVE/OVERFLOW TANK. AFTER PRES-

SURE BUILD-UP HAS BEEN RELEASED, REMOVE

CAP FROM FILLER NECK.

(2) Drain a small amount of coolant from the radi-

ator until the ends of the radiator tubes are visible

through the filler neck. Idle the engine at normal

operating temperature. If coolant is flowing past the

exposed tubes, the coolant is circulating.

REMOVAL

(1) Disconnect both battery negative cables.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER6094). ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only an original equipment clamp

with a matching number or letter.

(3) Remove air box and turbocharger inlet tube.

(4) Remove coolant tank hose, washer bottle hose

and the positive battery cable from the fastening

clips located on top of the radiator.

(5) Remove hose clamps and hoses from radiator.

(6) Remove the power steering cooler mounting

bolts and position the power steering cooler out of

the way.

(7) Disconnect the transmission cooler lines at the

transmission cooler. The transmission cooler will

remain on the radiator and can be removed as an

assembly.

(8) Disconnect the electronic viscous fan drive elec-

trical connector.

(9) Using a fastener removal tool, remove the two

push pins and the lower shroud assembly and elec-

tronic viscous fan drive wiring from the upper shroud

assembly. Position wiring out of the way. Do not

impact or damage the electronic viscous fan drive or

pull it's wiring.

(10) Using a fastener tool, remove the wiring har-

ness bracket from the upper fan shroud.

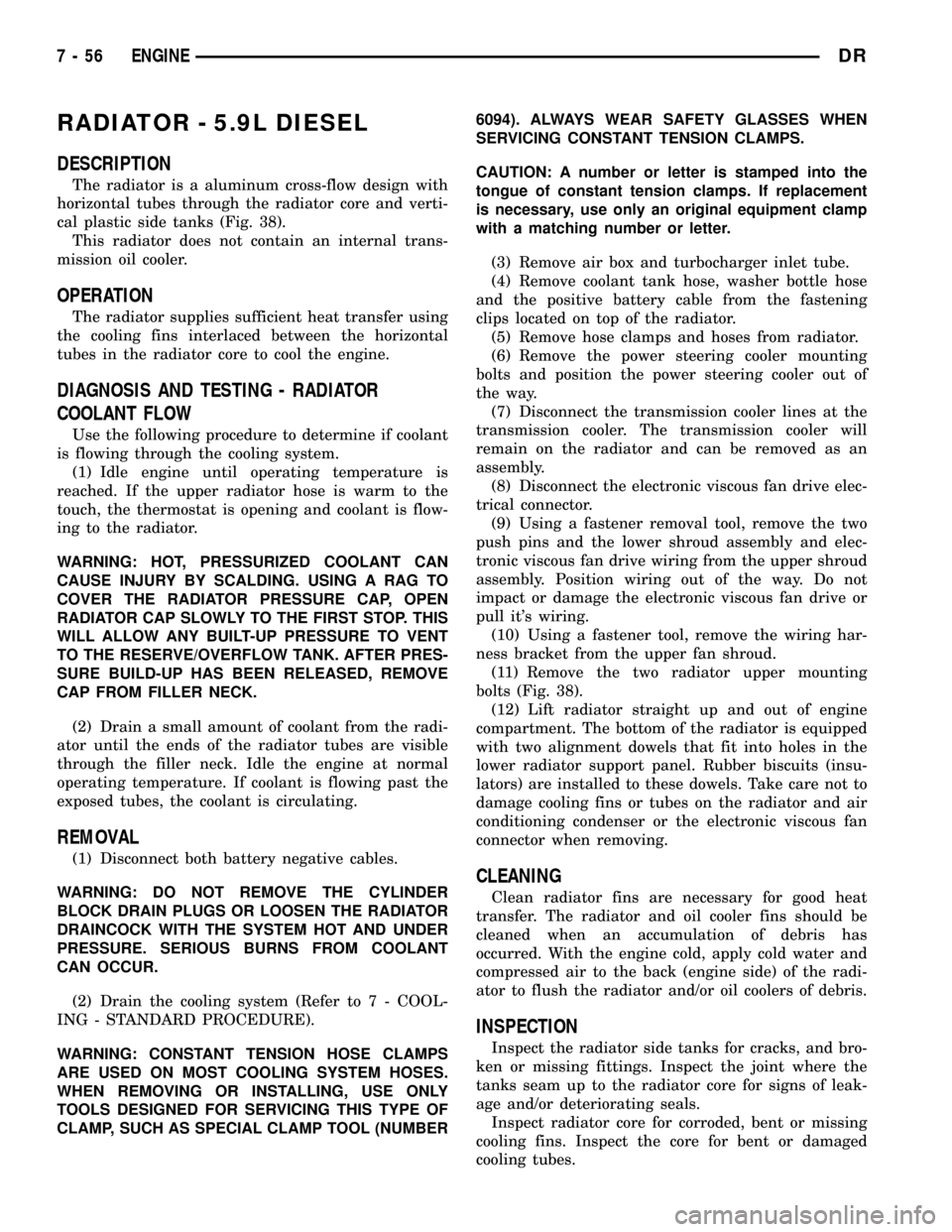

(11) Remove the two radiator upper mounting

bolts (Fig. 38).

(12) Lift radiator straight up and out of engine

compartment. The bottom of the radiator is equipped

with two alignment dowels that fit into holes in the

lower radiator support panel. Rubber biscuits (insu-

lators) are installed to these dowels. Take care not to

damage cooling fins or tubes on the radiator and air

conditioning condenser or the electronic viscous fan

connector when removing.

CLEANING

Clean radiator fins are necessary for good heat

transfer. The radiator and oil cooler fins should be

cleaned when an accumulation of debris has

occurred. With the engine cold, apply cold water and

compressed air to the back (engine side) of the radi-

ator to flush the radiator and/or oil coolers of debris.

INSPECTION

Inspect the radiator side tanks for cracks, and bro-

ken or missing fittings. Inspect the joint where the

tanks seam up to the radiator core for signs of leak-

age and/or deteriorating seals.

Inspect radiator core for corroded, bent or missing

cooling fins. Inspect the core for bent or damaged

cooling tubes.

7 - 56 ENGINEDR

Page 372 of 2627

INSTALLATION

(1) Install rubber insulators to alignment dowels

at lower part of radiator.

(2) Lower the radiator into position while guiding

the two alignment dowels into lower radiator sup-

port. Different alignment holes are provided in the

lower radiator support for each engine application.

(3) Install two upper radiator mounting bolts.

Tighten bolts to 11.8 N´m (105 in. lbs.) torque.

(4) Connect both radiator hoses and install hose

clamps.

(5) Connect transmission cooler lines to transmis-

sion cooler. Inspect quick connect fittings for debris

and install until an audible ªclickº is heard. Pull

apart to verify connection.

(6) Position power steering cooler on the radiator

and tighten nuts to 10 N´m (90 in. lbs.)

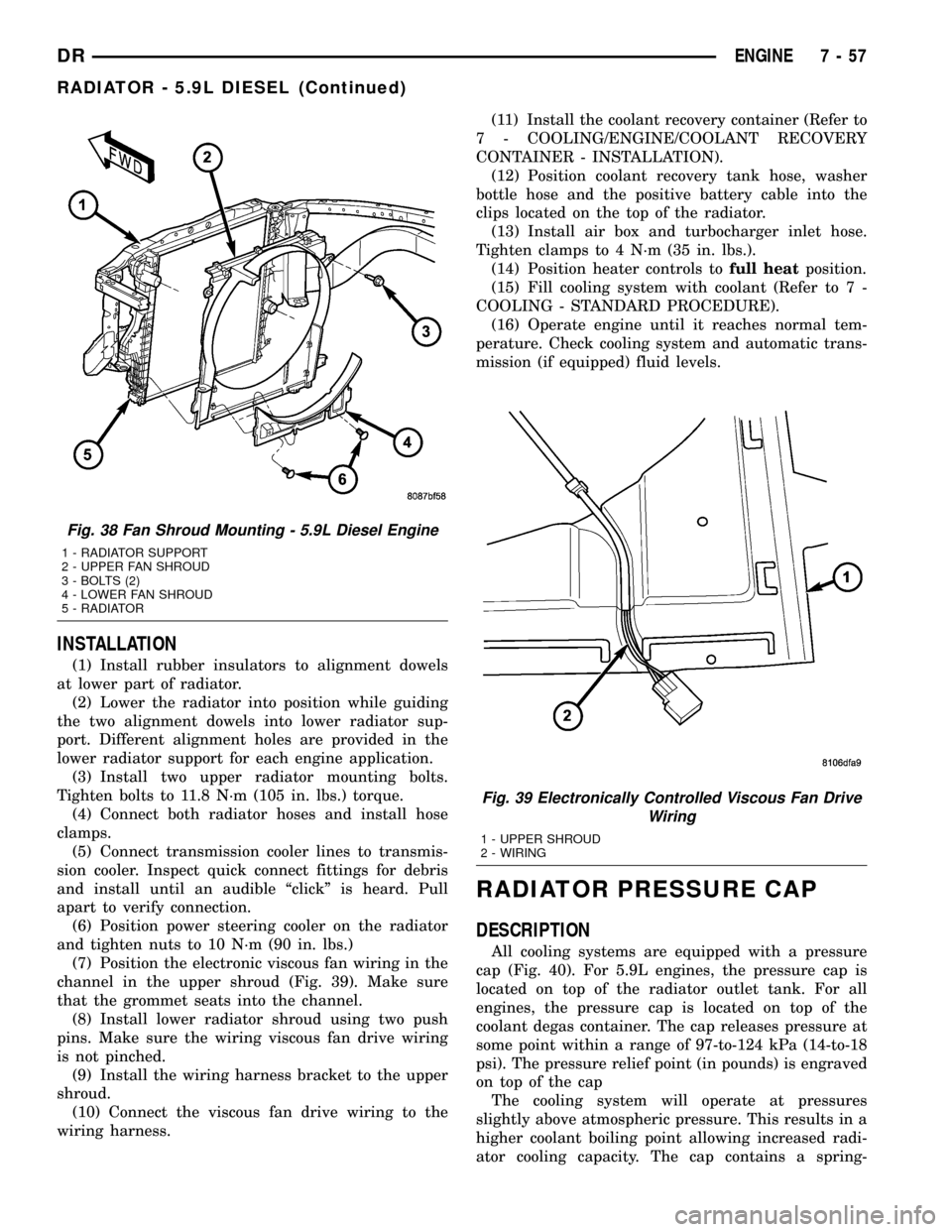

(7) Position the electronic viscous fan wiring in the

channel in the upper shroud (Fig. 39). Make sure

that the grommet seats into the channel.

(8) Install lower radiator shroud using two push

pins. Make sure the wiring viscous fan drive wiring

is not pinched.

(9) Install the wiring harness bracket to the upper

shroud.

(10) Connect the viscous fan drive wiring to the

wiring harness.(11) Install the coolant recovery container (Refer to

7 - COOLING/ENGINE/COOLANT RECOVERY

CONTAINER - INSTALLATION).

(12) Position coolant recovery tank hose, washer

bottle hose and the positive battery cable into the

clips located on the top of the radiator.

(13) Install air box and turbocharger inlet hose.

Tighten clamps to 4 N´m (35 in. lbs.).

(14) Position heater controls tofull heatposition.

(15) Fill cooling system with coolant (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(16) Operate engine until it reaches normal tem-

perature. Check cooling system and automatic trans-

mission (if equipped) fluid levels.

RADIATOR PRESSURE CAP

DESCRIPTION

All cooling systems are equipped with a pressure

cap (Fig. 40). For 5.9L engines, the pressure cap is

located on top of the radiator outlet tank. For all

engines, the pressure cap is located on top of the

coolant degas container. The cap releases pressure at

some point within a range of 97-to-124 kPa (14-to-18

psi). The pressure relief point (in pounds) is engraved

on top of the cap

The cooling system will operate at pressures

slightly above atmospheric pressure. This results in a

higher coolant boiling point allowing increased radi-

ator cooling capacity. The cap contains a spring-

Fig. 38 Fan Shroud Mounting - 5.9L Diesel Engine

1 - RADIATOR SUPPORT

2 - UPPER FAN SHROUD

3 - BOLTS (2)

4 - LOWER FAN SHROUD

5 - RADIATOR

Fig. 39 Electronically Controlled Viscous Fan Drive

Wiring

1 - UPPER SHROUD

2 - WIRING

DRENGINE 7 - 57

RADIATOR - 5.9L DIESEL (Continued)

Page 377 of 2627

(3) Spin the water pump to be sure that the pump

impeller does not rub against the timing chain case/

cover.

(4) Connect the radiator lower hose to the water

pump.

(5) Relax the tension from the belt tensioner (Fig.

46). Install the drive belt (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

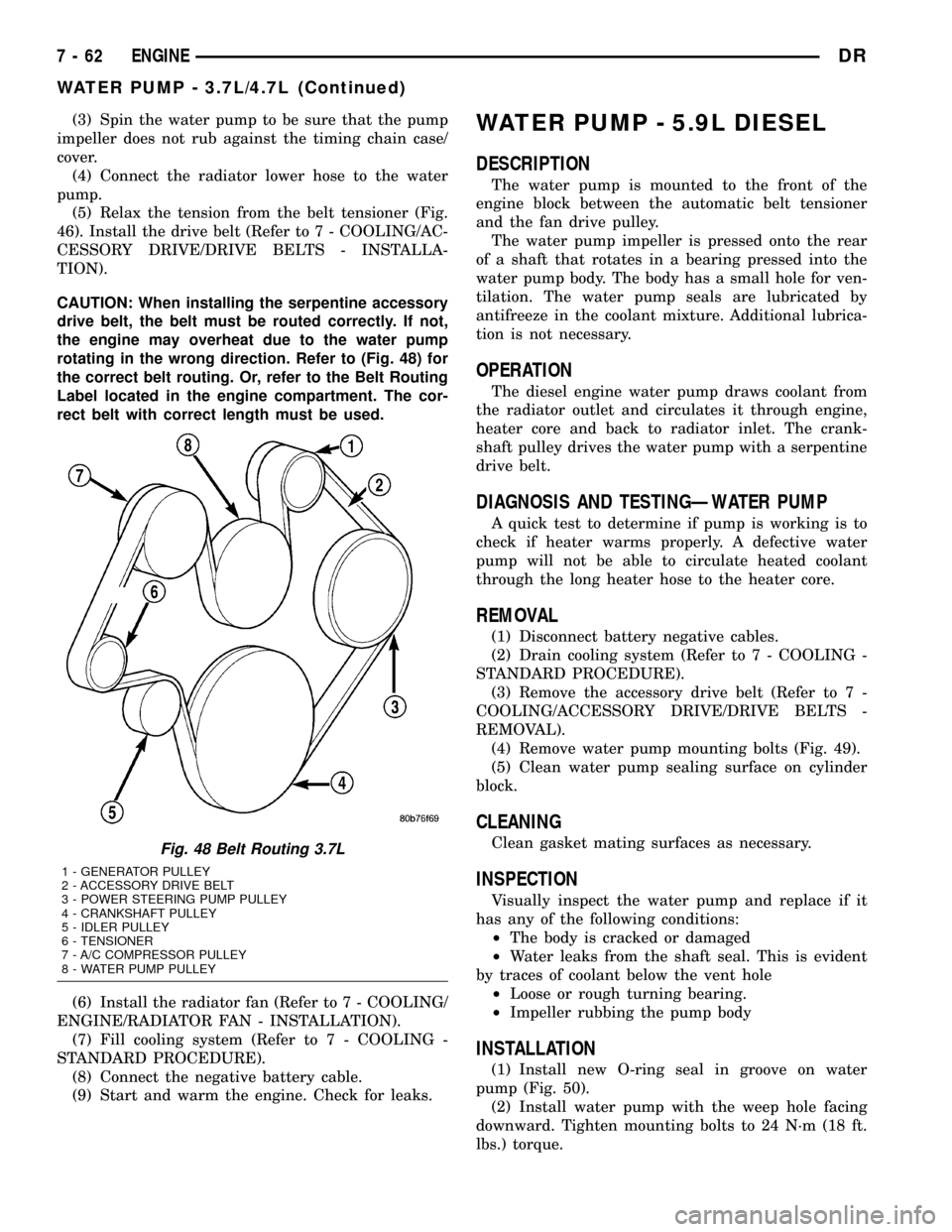

CAUTION: When installing the serpentine accessory

drive belt, the belt must be routed correctly. If not,

the engine may overheat due to the water pump

rotating in the wrong direction. Refer to (Fig. 48) for

the correct belt routing. Or, refer to the Belt Routing

Label located in the engine compartment. The cor-

rect belt with correct length must be used.

(6) Install the radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION).

(7) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(8) Connect the negative battery cable.

(9) Start and warm the engine. Check for leaks.WATER PUMP - 5.9L DIESEL

DESCRIPTION

The water pump is mounted to the front of the

engine block between the automatic belt tensioner

and the fan drive pulley.

The water pump impeller is pressed onto the rear

of a shaft that rotates in a bearing pressed into the

water pump body. The body has a small hole for ven-

tilation. The water pump seals are lubricated by

antifreeze in the coolant mixture. Additional lubrica-

tion is not necessary.

OPERATION

The diesel engine water pump draws coolant from

the radiator outlet and circulates it through engine,

heater core and back to radiator inlet. The crank-

shaft pulley drives the water pump with a serpentine

drive belt.

DIAGNOSIS AND TESTINGÐWATER PUMP

A quick test to determine if pump is working is to

check if heater warms properly. A defective water

pump will not be able to circulate heated coolant

through the long heater hose to the heater core.

REMOVAL

(1) Disconnect battery negative cables.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove water pump mounting bolts (Fig. 49).

(5) Clean water pump sealing surface on cylinder

block.

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Visually inspect the water pump and replace if it

has any of the following conditions:

²The body is cracked or damaged

²Water leaks from the shaft seal. This is evident

by traces of coolant below the vent hole

²Loose or rough turning bearing.

²Impeller rubbing the pump body

INSTALLATION

(1) Install new O-ring seal in groove on water

pump (Fig. 50).

(2) Install water pump with the weep hole facing

downward. Tighten mounting bolts to 24 N´m (18 ft.

lbs.) torque.

Fig. 48 Belt Routing 3.7L

1 - GENERATOR PULLEY

2 - ACCESSORY DRIVE BELT

3 - POWER STEERING PUMP PULLEY

4 - CRANKSHAFT PULLEY

5 - IDLER PULLEY

6 - TENSIONER

7 - A/C COMPRESSOR PULLEY

8 - WATER PUMP PULLEY

7 - 62 ENGINEDR

WATER PUMP - 3.7L/4.7L (Continued)

Page 382 of 2627

TRANSMISSION

TABLE OF CONTENTS

page page

TRANS COOLER

DESCRIPTION.........................67

OPERATION...........................67

REMOVAL.............................68

INSTALLATION.........................68

TRANS COOLER - 5.9L DIESEL

DESCRIPTION.........................68

OPERATION...........................69REMOVAL

REMOVAL - AIR TO OIL COOLER.........69

REMOVAL - WATER TO OIL COOLER......69

DISASSEMBLY - 5.9L DIESEL ONLY.........70

ASSEMBLY - 5.9L DIESEL ONLY...........70

INSTALLATION

INSTALLATION - AIR TO OIL COOLER.....70

INSTALLATION - WATER-TO-AIR COOLER . . 70

TRANS COOLER

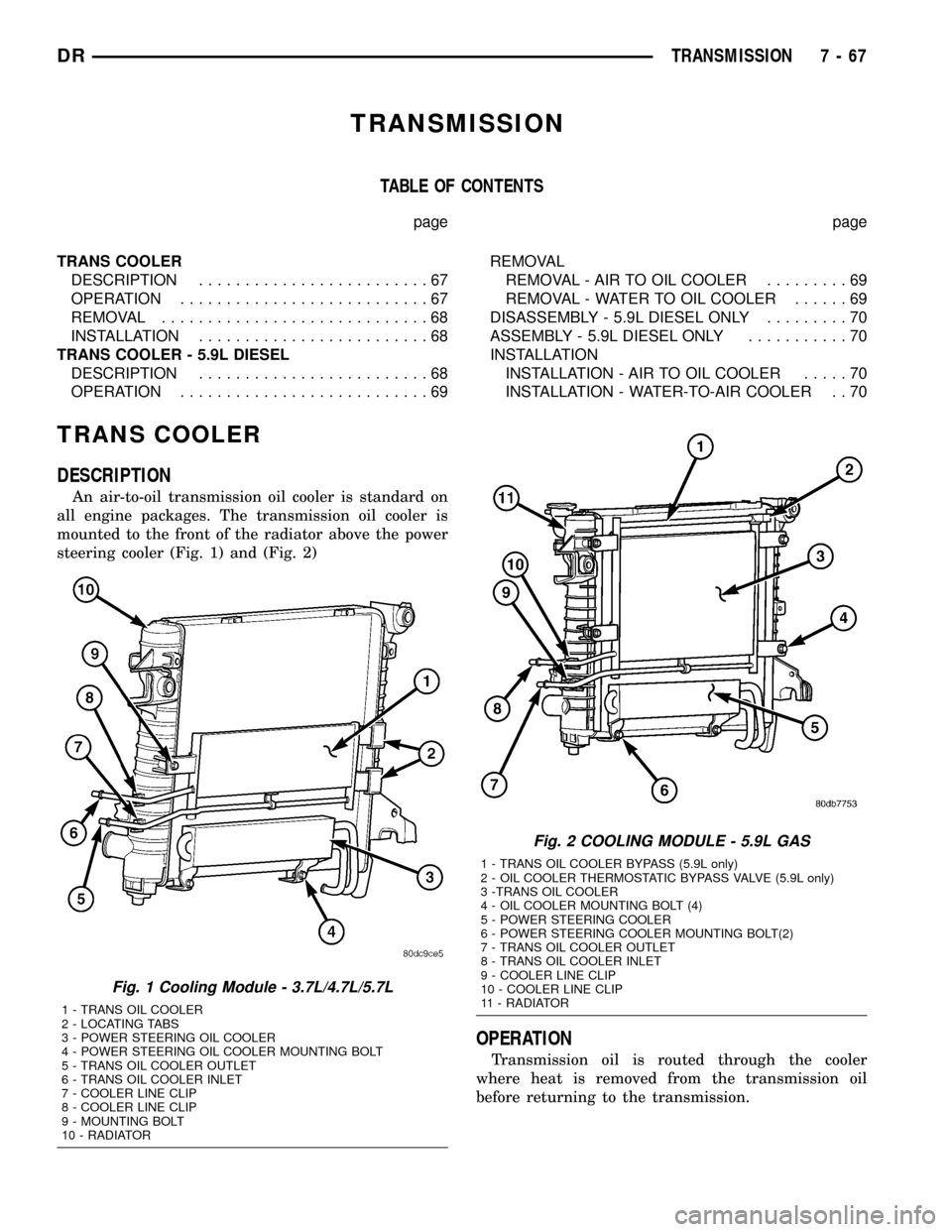

DESCRIPTION

An air-to-oil transmission oil cooler is standard on

all engine packages. The transmission oil cooler is

mounted to the front of the radiator above the power

steering cooler (Fig. 1) and (Fig. 2)

OPERATION

Transmission oil is routed through the cooler

where heat is removed from the transmission oil

before returning to the transmission.

Fig. 1 Cooling Module - 3.7L/4.7L/5.7L

1 - TRANS OIL COOLER

2 - LOCATING TABS

3 - POWER STEERING OIL COOLER

4 - POWER STEERING OIL COOLER MOUNTING BOLT

5 - TRANS OIL COOLER OUTLET

6 - TRANS OIL COOLER INLET

7 - COOLER LINE CLIP

8 - COOLER LINE CLIP

9 - MOUNTING BOLT

10 - RADIATOR

Fig. 2 COOLING MODULE - 5.9L GAS

1 - TRANS OIL COOLER BYPASS (5.9L only)

2 - OIL COOLER THERMOSTATIC BYPASS VALVE (5.9L only)

3 -TRANS OIL COOLER

4 - OIL COOLER MOUNTING BOLT (4)

5 - POWER STEERING COOLER

6 - POWER STEERING COOLER MOUNTING BOLT(2)

7 - TRANS OIL COOLER OUTLET

8 - TRANS OIL COOLER INLET

9 - COOLER LINE CLIP

10 - COOLER LINE CLIP

11 - RADIATOR

DRTRANSMISSION 7 - 67

Page 387 of 2627

The optional navigation radio system receives GPS

signals from up to eight satellites to display the posi-

tion and direction of the vehicle. Map information is

supplied through a DVD-ROM. An electronic gyro-

sensor and the vehicle's speed sensor enable the sys-

tem to display the present vehicle position even in

locations where GPS signals may be blocked.

When a destination is selected, the navigation sys-

tem uses information from the map to quickly calcu-

late a route. As the vehicle is driven along the chosen

route, the operator is guided with pictorial displays

and voice prompts. For complete operating instruc-

tions, refer to the manual included with the vehicle.

On vehicles that are equipped with the optional

remote radio switches, the Instrument Cluster

receives hard wired resistor multiplexed inputs from

the remote radio switches. The programming in the

Instrument Cluster allows it to process those inputs

and send the proper messages to the radio receiver

over the Programmable Communication Interface

(PCI) bus network to control the radio volume up or

down, station seek up or down, preset station

advance, and mode advance functions.DIAGNOSIS AND TESTING - AUDIO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the

DRB IIIt, refer to the appropriate Diagnostic

Service Manual.

Refer to the appropriate wiring information.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

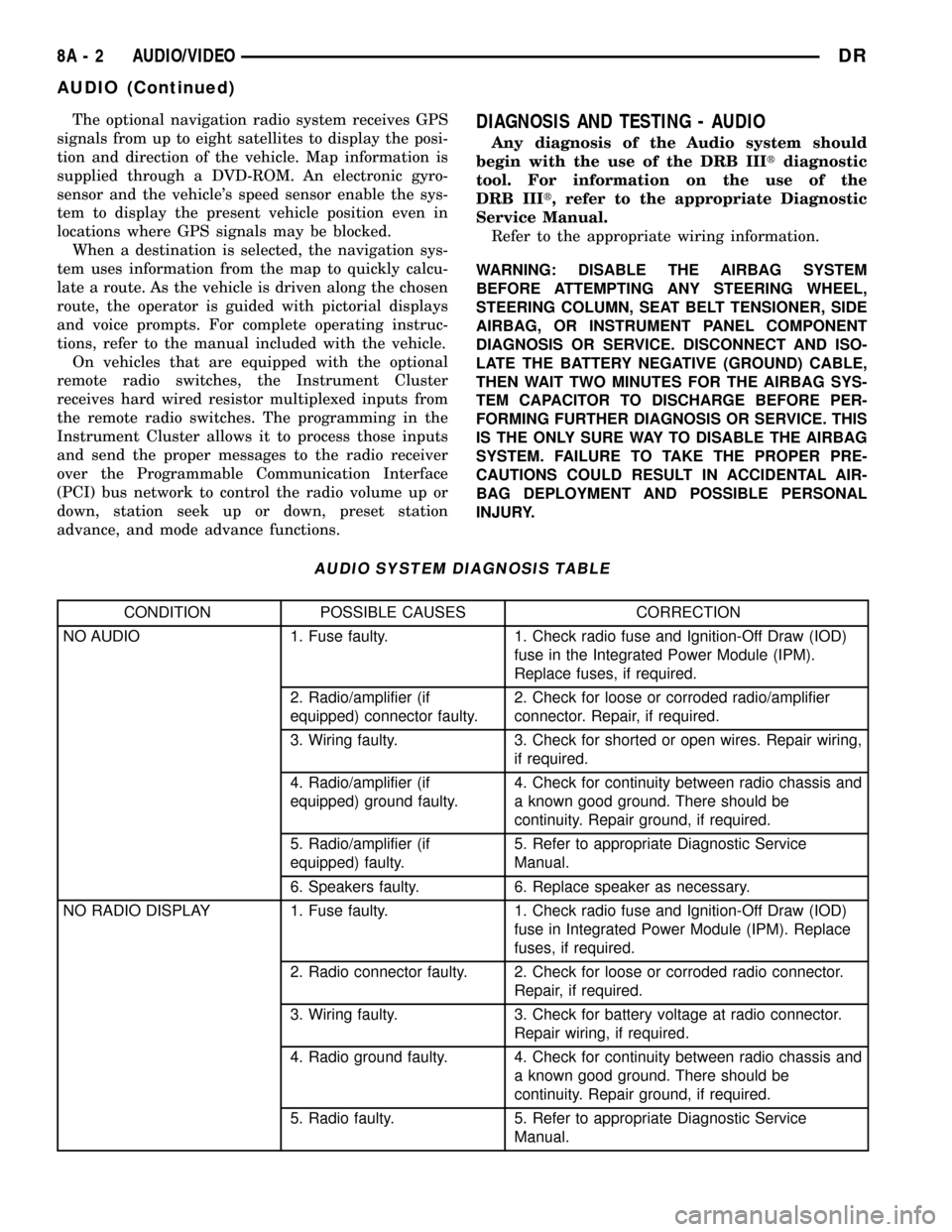

AUDIO SYSTEM DIAGNOSIS TABLE

CONDITION POSSIBLE CAUSES CORRECTION

NO AUDIO 1. Fuse faulty. 1. Check radio fuse and Ignition-Off Draw (IOD)

fuse in the Integrated Power Module (IPM).

Replace fuses, if required.

2. Radio/amplifier (if

equipped) connector faulty.2. Check for loose or corroded radio/amplifier

connector. Repair, if required.

3. Wiring faulty. 3. Check for shorted or open wires. Repair wiring,

if required.

4. Radio/amplifier (if

equipped) ground faulty.4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio/amplifier (if

equipped) faulty.5. Refer to appropriate Diagnostic Service

Manual.

6. Speakers faulty. 6. Replace speaker as necessary.

NO RADIO DISPLAY 1. Fuse faulty. 1. Check radio fuse and Ignition-Off Draw (IOD)

fuse in Integrated Power Module (IPM). Replace

fuses, if required.

2. Radio connector faulty. 2. Check for loose or corroded radio connector.

Repair, if required.

3. Wiring faulty. 3. Check for battery voltage at radio connector.

Repair wiring, if required.

4. Radio ground faulty. 4. Check for continuity between radio chassis and

a known good ground. There should be

continuity. Repair ground, if required.

5. Radio faulty. 5. Refer to appropriate Diagnostic Service

Manual.

8A - 2 AUDIO/VIDEODR

AUDIO (Continued)