Temperature wiring DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 600 of 2627

AUTOMATIC DOOR LOCKS

When the automatic door locks are ENABLED the

door locks will lock when the vehicle is moving at

about 25.7 Km/h (15 mph), all doors are closed and

the accelerator pedal is depressed. This feature can

be switched ON or OFF as desired. When the system

is DISABLED the door locks will operate normally,

but will not lock automatically when the vehicle is

rolling. Once the automatic door locks have been

actuated, they will not try to lock the doors again

until a door is opened.

DOOR LOCK INHIBIT

If the key is in the ignition, in any position, and

either front door is ajar, the doors can not be locked,

but the unlock function still operates. Pressing the

RKE lock/unlock button under these conditions will

result in a normal lock/unlock activation.

After the key is removed from the ignition switch,

or the doors are closed, the power door locks will

operate normally.

DOOR LOCK CIRCUIT PROTECTION

If the door lock switch is actuated continuously for

more than five seconds the instrument cluster will

turn the output driver OFF (the instrument cluster

would consider the switch stuck). Each lock motor is

protected with a Positive Temperature Coefficient

device that prevents motor burn out.

REMOTE KEYLESS ENTRY

²LOCK: Pressing the LOCK button locks all

doors, sounds horn (chirp) once if enabled, flashes the

park lamps once if enabled, and arms the Vehicle

Theft Security System (VTSS), if enabled. The chirp

verifies that the RKE module has sent a message to

the instrument cluster for door lock operation. If a

door has not been closed before pressing the LOCK

button, the vehicle may not be secured and the VTSS

(if equipped) will not arm until the door is closed.

²UNLOCK: Pressing the UNLOCK button once

will unlock the driver's door first if enabled, flashes

the park lamps twice if enabled, activates the illumi-

nated entry system, and disarms the Vehicle Theft

Security System (VTSS), if equipped. Pressing the

UNLOCK button twice within five seconds will

unlock all doors, if driver's door first is enabled.

²PANIC:

Pressing the PANIC button sounds the

horns at half second intervals, flashes the exterior

lamps, and turns ON the interior lamps. The panic

alarm will remain on for three minutes, or until the

PANIC button is actuated again or the vehicle speed

exceeds 25.7 Km/h (15 mph) will cancel the panic event.

The Remote Keyless Entry Module is capable of

retaining the transmitter Vehicle Access Code(s) in its

memory even after vehicle power has been interrupted.

DIAGNOSIS AND TESTING - POWER LOCKS

The most reliable, efficient, and accurate

means to diagnose the power lock system

requires the use of a DRBIIItscan tool and the

proper Diagnostic Procedures manual.

Following are tests that will help to diagnose the

hard wired components and circuits of the power lock

system. However, these tests may not prove conclu-

sive in the diagnosis of this system. In order to

obtain conclusive testing of the power lock system,

the Programmable Communications Interface (PCI)

data bus network and all of the electronic modules

that provide inputs to, or receive outputs from the

power lock system components must be checked.

The instrument cluster will set Diagnostic Trouble

Codes (DTC) for the power lock system.

Refer to the appropriate wiring information.

PRELIMINARY DIAGNOSIS

As a preliminary diagnosis for the power lock sys-

tem, note the system operation while you actuate

both the Lock and Unlock functions with the power

lock switches and with the Remote Keyless Entry

(RKE) transmitter. Then, proceed as follows:

²If the entire power lock system fails to function

with either the power lock switches or the RKE

transmitter, check the fused B(+) fuse in the Inte-

grated Power Module (IPM).

²If the power lock system functions with both

power lock switches, but not with the RKE transmit-

ter, proceed to diagnosis of the Remote Keyless Entry

(RKE) system. (Refer to 8 - ELECTRICAL/POWER

LOCKS/KEYLESS ENTRY TRANSMITTER - DIAG-

NOSIS AND TESTING) or (Refer to 8 - ELECTRI-

CAL/POWER LOCKS/REMOTE KEYLESS ENTRY

MODULE - DIAGNOSIS AND TESTING).

²If the power lock system functions with the RKE

transmitter, but not with one or both power lock

switches, proceed to diagnosis of the door lock

switches. (Refer to 8 - ELECTRICAL/POWER

LOCKS/POWER LOCK SWITCH - DIAGNOSIS AND

TESTING).

²If the driver side power lock switch operates

only the driver side front door power lock motor, but

all other power lock motors operate with the passen-

ger side power lock switch or the RKE transmitter,

use a DRBIIItscan tool and the appropriate diagnos-

tic information to diagnose the Programmable Com-

munications Interface (PCI) data bus.

²If only one power lock motor fails to operate

with both power lock switches and the RKE trans-

mitter, proceed to diagnosis of the power lock motor.

(Refer to 8 - ELECTRICAL/POWER LOCKS/POWER

LOCK MOTOR - DIAGNOSIS AND TESTING).

DRPOWER LOCKS 8N - 3

POWER LOCKS (Continued)

Page 1154 of 2627

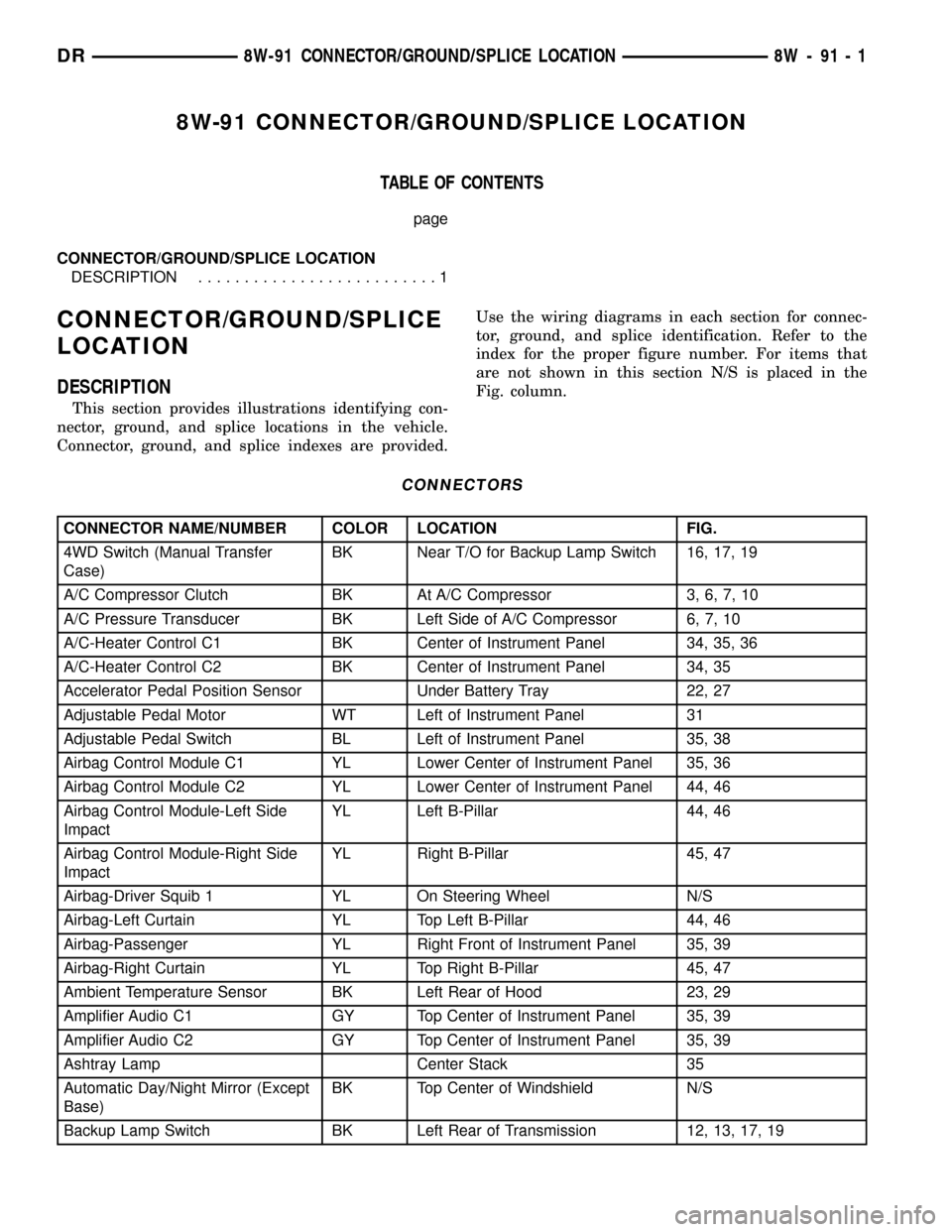

8W-91 CONNECTOR/GROUND/SPLICE LOCATION

TABLE OF CONTENTS

page

CONNECTOR/GROUND/SPLICE LOCATION

DESCRIPTION..........................1

CONNECTOR/GROUND/SPLICE

LOCATION

DESCRIPTION

This section provides illustrations identifying con-

nector, ground, and splice locations in the vehicle.

Connector, ground, and splice indexes are provided.Use the wiring diagrams in each section for connec-

tor, ground, and splice identification. Refer to the

index for the proper figure number. For items that

are not shown in this section N/S is placed in the

Fig. column.

CONNECTORS

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

4WD Switch (Manual Transfer

Case)BK Near T/O for Backup Lamp Switch 16, 17, 19

A/C Compressor Clutch BK At A/C Compressor 3, 6, 7, 10

A/C Pressure Transducer BK Left Side of A/C Compressor 6, 7, 10

A/C-Heater Control C1 BK Center of Instrument Panel 34, 35, 36

A/C-Heater Control C2 BK Center of Instrument Panel 34, 35

Accelerator Pedal Position Sensor Under Battery Tray 22, 27

Adjustable Pedal Motor WT Left of Instrument Panel 31

Adjustable Pedal Switch BL Left of Instrument Panel 35, 38

Airbag Control Module C1 YL Lower Center of Instrument Panel 35, 36

Airbag Control Module C2 YL Lower Center of Instrument Panel 44, 46

Airbag Control Module-Left Side

ImpactYL Left B-Pillar 44, 46

Airbag Control Module-Right Side

ImpactYL Right B-Pillar 45, 47

Airbag-Driver Squib 1 YL On Steering Wheel N/S

Airbag-Left Curtain YL Top Left B-Pillar 44, 46

Airbag-Passenger YL Right Front of Instrument Panel 35, 39

Airbag-Right Curtain YL Top Right B-Pillar 45, 47

Ambient Temperature Sensor BK Left Rear of Hood 23, 29

Amplifier Audio C1 GY Top Center of Instrument Panel 35, 39

Amplifier Audio C2 GY Top Center of Instrument Panel 35, 39

Ashtray Lamp Center Stack 35

Automatic Day/Night Mirror (Except

Base)BK Top Center of Windshield N/S

Backup Lamp Switch BK Left Rear of Transmission 12, 13, 17, 19

DR8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 1

Page 1234 of 2627

(12) Disconnect heater hoses from heater core and

remove hose assembly.

(13) Disconnect throttle and speed control cables.

(14) Remove upper radiator hose from engine.

(15) Remove lower radiator hose from engine.

(16) Remove radiator/cooling module assembly.

(17) Disconnect the engine to body ground straps

at the left side of cowl.

(18) Disconnect the engine wiring harness at the

following points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(19) Remove coil over plugs.

(20) Release fuel rail pressure.

(21) Remove fuel rail and secure away from

engine.

NOTE: It is not necessary to release the quick con-

nect fitting from the fuel supply line for engine

removal.

(22) Remove the PCV hose.

(23) Remove the breather hoses.

(24) Remove the vacuum hose for the power brake

booster.

(25) Disconnect knock sensors.

(26) Remove engine oil dipstick tube.

(27) Remove intake manifold.

(28) Install engine lifting fixture,special tool#8247,

using original fasteners from the removed intake

manifold, and fuel rail. Torque to factory specifica-

tions.

NOTE: Recheck bolt torque for engine lift plate

before removing engine.

(29) Secure the left and right engine wiring har-

nesses away from engine.

(30) Raise vehicle.

(31) Disconnect oxygen sensor wiring.

(32) Disconnect crankshaft postion sensor.

(33) Disconnect the engine block heater power

cable, if equipped.

(34) Disconnect the front propshaft at the front

differential and secure out of way.

NOTE: It is necessary to disconnect the front prop-

shaft for access to the starter and left side exhaust

flange.(35) Remove the starter.

(36) Remove the ground straps from the left and

right side of the block.

(37) Disconnect the right and left exhaust pipes at

the manifolds and from the crossover, and remove

from the vehicle.

NOTE: The exhaust clamps at the manifolds cannot

be reused. New clamps must be used or leaks may

occur.

(38) Remove the structural cover.

(39) Remove torque convertor bolts, and mark

location for reassembly.

(40) Remove transmission bellhousing to engine

bolts.

(41) Remove left and right engine mount thru

bolts.

(42) Lower the vehicle.

(43) Support the transmission with a suitable jack.

(44) Connect a suitable engine hoist to the engine

lift plate.

(45) Remove engine from vehicle.

INSTALLATION

(1) Position the engine in the vehicle.

(2) Install both left and right side engine mounts

onto engine.

(3) Raise the vehicle.

(4) Install the transmission bellhousing to engine

mounting bolts. Tighten the bolts to 41 N´m (30ft.

lbs.).

(5) Tighten the engine mount thru bolts.

(6) Install the torque convertor bolts.

(7) Connect the ground straps on the left and right

side of the engine.

(8) Install the starter.

(9) Connect the crankshaft position sensor.

(10) Install the engine block heater power cable, if

equipped.

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

(11) Install the structural cover.

NOTE: New clamps must be used on exhaust man-

ifold flanges. Failure to use new clamps may result

in exhaust leaks.

(12) Install the left and right exhaust pipes.

(13) Connect the left and right oxygen sensors.

(14) Lower vehicle.

(15) Remove the engine lift plate.

(16) Connect the knock sensors.

DRENGINE - 3.7L 9 - 11

ENGINE - 3.7L (Continued)

Page 1235 of 2627

(17) Connect the engine to body ground straps at

the left side of the cowl.

(18) Install the intake manifold.

(19) Install the engine oil dipstick tube.

(20) Install the power brake booster vacuum hose.

(21) Install the breather hoses.

(22) Install the PCV hose.

(23) Install the fuel rail.

(24) Install the coil over plugs.

(25) Connect the engine wiring harness at the fol-

lowing points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(26) Reinstall the radiator/cooling module assem-

bly.

(27) Connect lower radiator hose.

(28) Connect upper radiator hose.

(29) Connect throttle and speed control cables.

(30) Install the heater hose assembly.

(31) Install coolant recovery bottle.

(32) Install the power steering pump.

(33) Install the generator.

(34) Install the A/C compressor.

(35) Install the drive belt.

(36) Install the fan shroud with the viscous fan

assembly.

(37) Install the radiator core support bracket.

(38) Install the air cleaner assembly.

(39) Refill the engine cooling system.

(40) Recharge the air conditioning.

(41) Install the hood.

(42) Check and fill engine oil.

(43) Connect the battery negative cable.

(44) Start the engine and check for leaks.SPECIFICATIONS

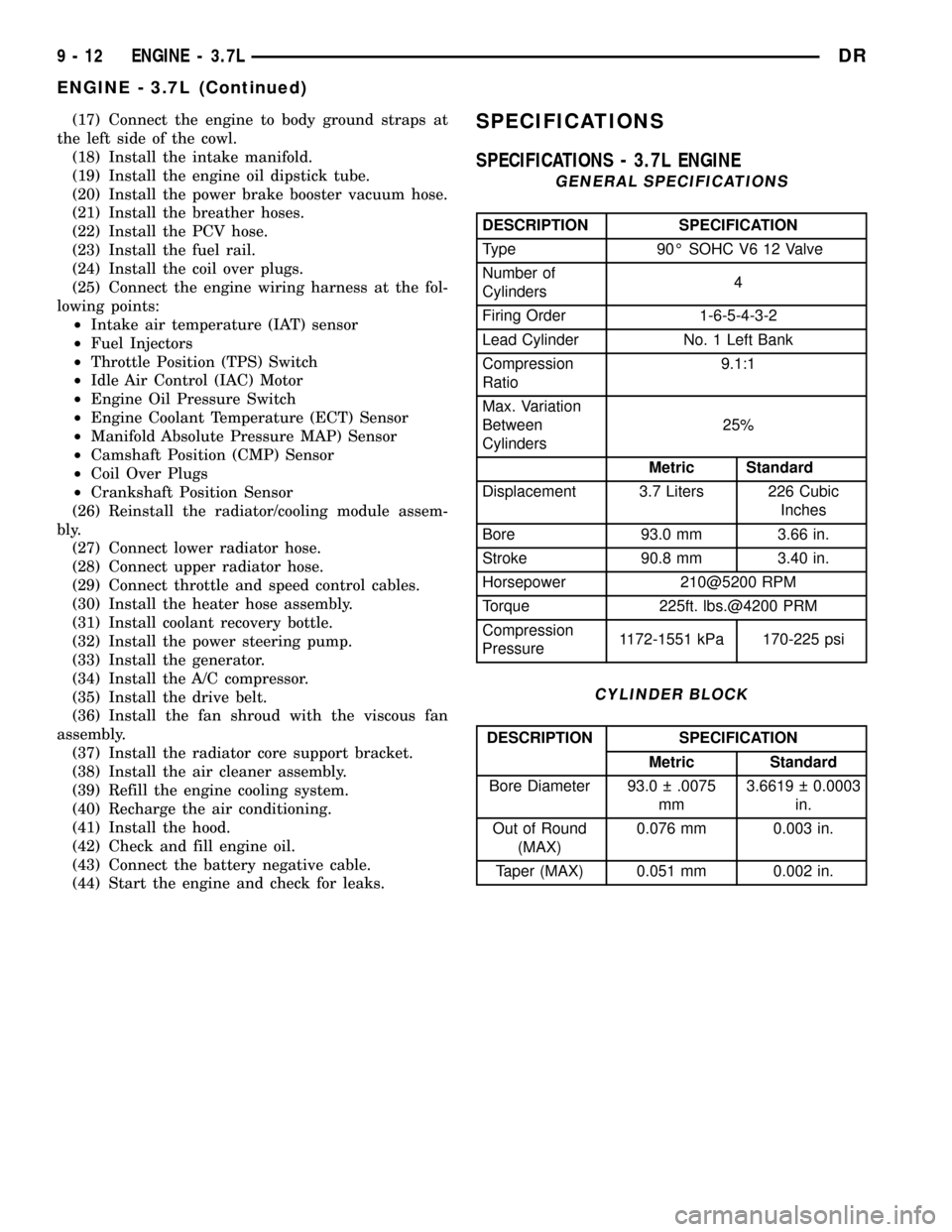

SPECIFICATIONS - 3.7L ENGINE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Type 90É SOHC V6 12 Valve

Number of

Cylinders4

Firing Order 1-6-5-4-3-2

Lead Cylinder No. 1 Left Bank

Compression

Ratio9.1:1

Max. Variation

Between

Cylinders25%

Metric Standard

Displacement 3.7 Liters 226 Cubic

Inches

Bore 93.0 mm 3.66 in.

Stroke 90.8 mm 3.40 in.

Horsepower 210@5200 RPM

Torque 225ft. lbs.@4200 PRM

Compression

Pressure1172-1551 kPa 170-225 psi

CYLINDER BLOCK

DESCRIPTION SPECIFICATION

Metric Standard

Bore Diameter 93.0 .0075

mm3.6619 0.0003

in.

Out of Round

(MAX)0.076 mm 0.003 in.

Taper (MAX) 0.051 mm 0.002 in.

9 - 12 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1321 of 2627

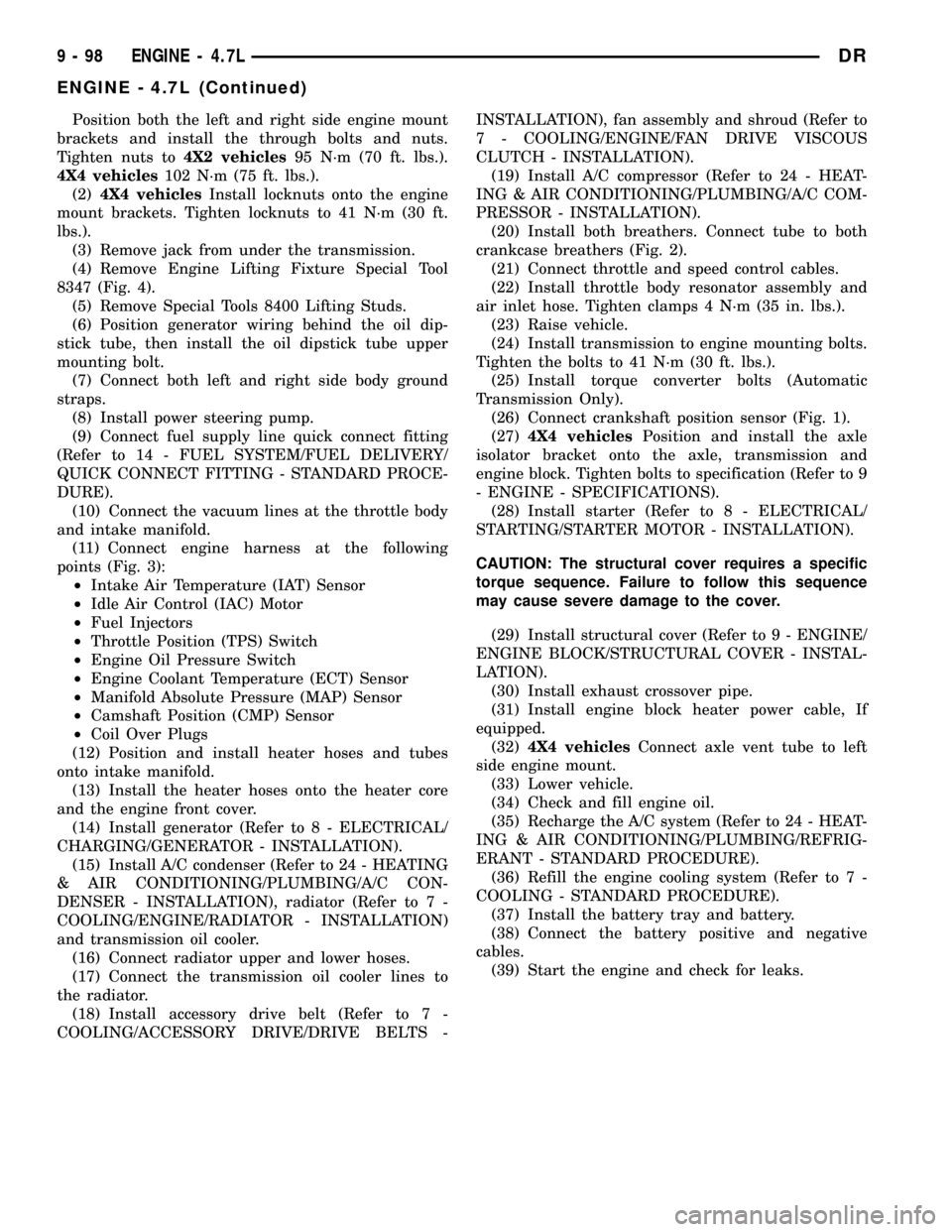

Position both the left and right side engine mount

brackets and install the through bolts and nuts.

Tighten nuts to4X2 vehicles95 N´m (70 ft. lbs.).

4X4 vehicles102 N´m (75 ft. lbs.).

(2)4X4 vehiclesInstall locknuts onto the engine

mount brackets. Tighten locknuts to 41 N´m (30 ft.

lbs.).

(3) Remove jack from under the transmission.

(4) Remove Engine Lifting Fixture Special Tool

8347 (Fig. 4).

(5) Remove Special Tools 8400 Lifting Studs.

(6) Position generator wiring behind the oil dip-

stick tube, then install the oil dipstick tube upper

mounting bolt.

(7) Connect both left and right side body ground

straps.

(8) Install power steering pump.

(9) Connect fuel supply line quick connect fitting

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

QUICK CONNECT FITTING - STANDARD PROCE-

DURE).

(10) Connect the vacuum lines at the throttle body

and intake manifold.

(11) Connect engine harness at the following

points (Fig. 3):

²Intake Air Temperature (IAT) Sensor

²Idle Air Control (IAC) Motor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

(12) Position and install heater hoses and tubes

onto intake manifold.

(13) Install the heater hoses onto the heater core

and the engine front cover.

(14) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

(15) Install A/C condenser (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/A/C CON-

DENSER - INSTALLATION), radiator (Refer to 7 -

COOLING/ENGINE/RADIATOR - INSTALLATION)

and transmission oil cooler.

(16) Connect radiator upper and lower hoses.

(17) Connect the transmission oil cooler lines to

the radiator.

(18) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -INSTALLATION), fan assembly and shroud (Refer to

7 - COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - INSTALLATION).

(19) Install A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - INSTALLATION).

(20) Install both breathers. Connect tube to both

crankcase breathers (Fig. 2).

(21) Connect throttle and speed control cables.

(22) Install throttle body resonator assembly and

air inlet hose. Tighten clamps 4 N´m (35 in. lbs.).

(23) Raise vehicle.

(24) Install transmission to engine mounting bolts.

Tighten the bolts to 41 N´m (30 ft. lbs.).

(25) Install torque converter bolts (Automatic

Transmission Only).

(26) Connect crankshaft position sensor (Fig. 1).

(27)4X4 vehiclesPosition and install the axle

isolator bracket onto the axle, transmission and

engine block. Tighten bolts to specification (Refer to 9

- ENGINE - SPECIFICATIONS).

(28) Install starter (Refer to 8 - ELECTRICAL/

STARTING/STARTER MOTOR - INSTALLATION).

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

(29) Install structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION).

(30) Install exhaust crossover pipe.

(31) Install engine block heater power cable, If

equipped.

(32)4X4 vehiclesConnect axle vent tube to left

side engine mount.

(33) Lower vehicle.

(34) Check and fill engine oil.

(35) Recharge the A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/REFRIG-

ERANT - STANDARD PROCEDURE).

(36) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(37) Install the battery tray and battery.

(38) Connect the battery positive and negative

cables.

(39) Start the engine and check for leaks.

9 - 98 ENGINE - 4.7LDR

ENGINE - 4.7L (Continued)

Page 1520 of 2627

(13) Install the cooling fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION).

(14) Connect battery negative cables.

(15) Start engine and check for oil leaks.

INTAKE MANIFOLD

REMOVAL

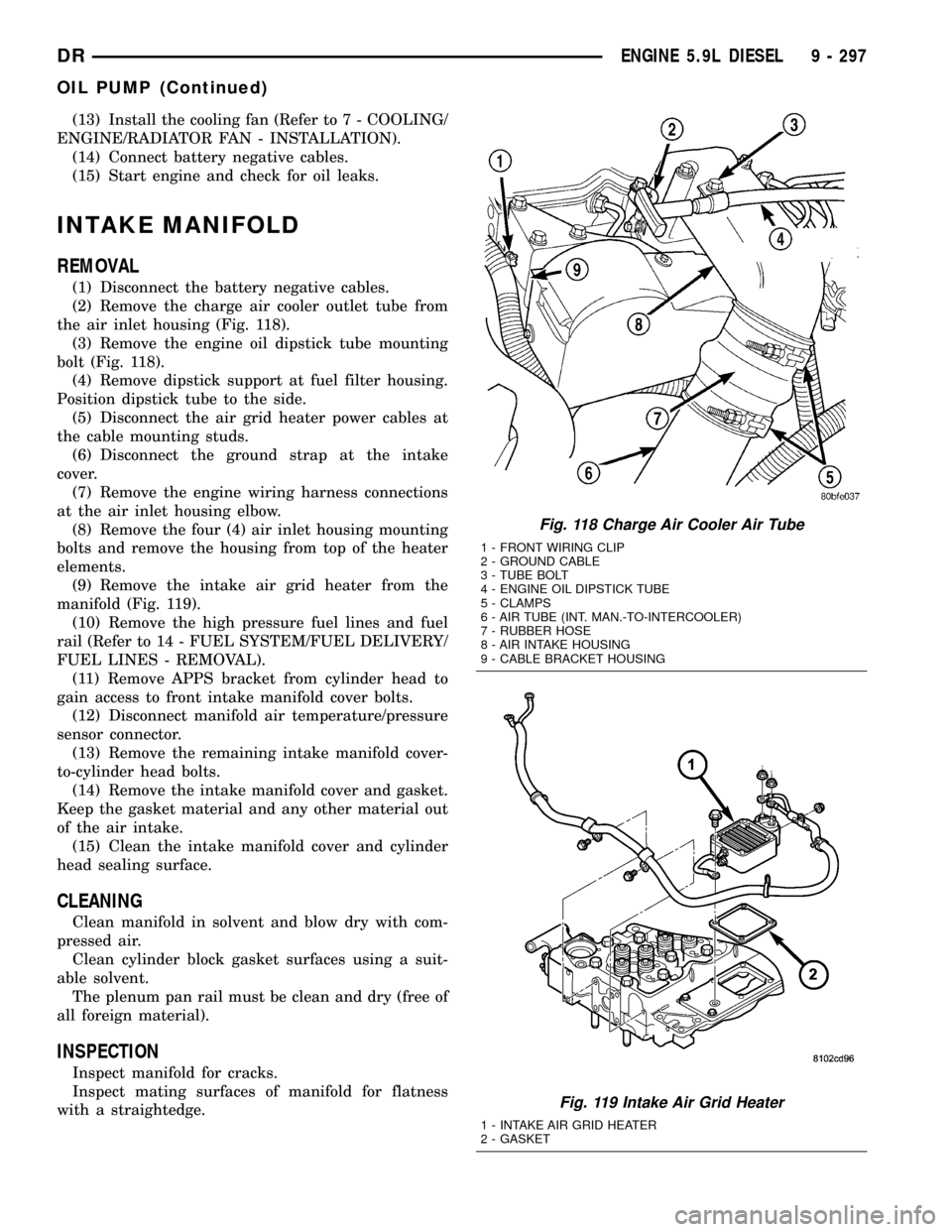

(1) Disconnect the battery negative cables.

(2) Remove the charge air cooler outlet tube from

the air inlet housing (Fig. 118).

(3) Remove the engine oil dipstick tube mounting

bolt (Fig. 118).

(4) Remove dipstick support at fuel filter housing.

Position dipstick tube to the side.

(5) Disconnect the air grid heater power cables at

the cable mounting studs.

(6) Disconnect the ground strap at the intake

cover.

(7) Remove the engine wiring harness connections

at the air inlet housing elbow.

(8) Remove the four (4) air inlet housing mounting

bolts and remove the housing from top of the heater

elements.

(9) Remove the intake air grid heater from the

manifold (Fig. 119).

(10) Remove the high pressure fuel lines and fuel

rail (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL LINES - REMOVAL).

(11) Remove APPS bracket from cylinder head to

gain access to front intake manifold cover bolts.

(12) Disconnect manifold air temperature/pressure

sensor connector.

(13) Remove the remaining intake manifold cover-

to-cylinder head bolts.

(14) Remove the intake manifold cover and gasket.

Keep the gasket material and any other material out

of the air intake.

(15) Clean the intake manifold cover and cylinder

head sealing surface.

CLEANING

Clean manifold in solvent and blow dry with com-

pressed air.

Clean cylinder block gasket surfaces using a suit-

able solvent.

The plenum pan rail must be clean and dry (free of

all foreign material).

INSPECTION

Inspect manifold for cracks.

Inspect mating surfaces of manifold for flatness

with a straightedge.

Fig. 118 Charge Air Cooler Air Tube

1 - FRONT WIRING CLIP

2 - GROUND CABLE

3 - TUBE BOLT

4 - ENGINE OIL DIPSTICK TUBE

5 - CLAMPS

6 - AIR TUBE (INT. MAN.-TO-INTERCOOLER)

7 - RUBBER HOSE

8 - AIR INTAKE HOUSING

9 - CABLE BRACKET HOUSING

Fig. 119 Intake Air Grid Heater

1 - INTAKE AIR GRID HEATER

2 - GASKET

DRENGINE 5.9L DIESEL 9 - 297

OIL PUMP (Continued)

Page 1531 of 2627

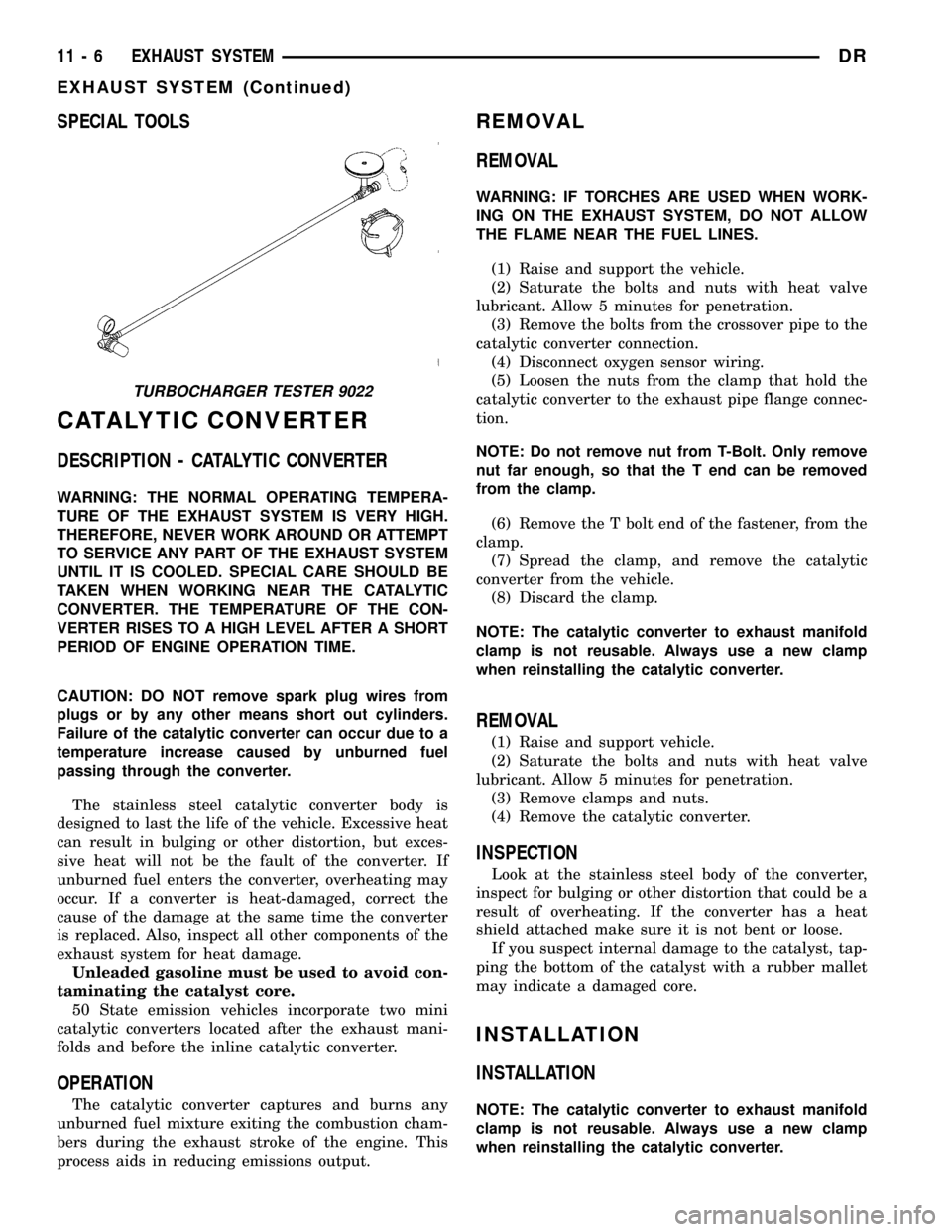

SPECIAL TOOLS

CATALYTIC CONVERTER

DESCRIPTION - CATALYTIC CONVERTER

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

CAUTION: DO NOT remove spark plug wires from

plugs or by any other means short out cylinders.

Failure of the catalytic converter can occur due to a

temperature increase caused by unburned fuel

passing through the converter.

The stainless steel catalytic converter body is

designed to last the life of the vehicle. Excessive heat

can result in bulging or other distortion, but exces-

sive heat will not be the fault of the converter. If

unburned fuel enters the converter, overheating may

occur. If a converter is heat-damaged, correct the

cause of the damage at the same time the converter

is replaced. Also, inspect all other components of the

exhaust system for heat damage.

Unleaded gasoline must be used to avoid con-

taminating the catalyst core.

50 State emission vehicles incorporate two mini

catalytic converters located after the exhaust mani-

folds and before the inline catalytic converter.

OPERATION

The catalytic converter captures and burns any

unburned fuel mixture exiting the combustion cham-

bers during the exhaust stroke of the engine. This

process aids in reducing emissions output.

REMOVAL

REMOVAL

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove the bolts from the crossover pipe to the

catalytic converter connection.

(4) Disconnect oxygen sensor wiring.

(5) Loosen the nuts from the clamp that hold the

catalytic converter to the exhaust pipe flange connec-

tion.

NOTE: Do not remove nut from T-Bolt. Only remove

nut far enough, so that the T end can be removed

from the clamp.

(6) Remove the T bolt end of the fastener, from the

clamp.

(7) Spread the clamp, and remove the catalytic

converter from the vehicle.

(8) Discard the clamp.

NOTE: The catalytic converter to exhaust manifold

clamp is not reusable. Always use a new clamp

when reinstalling the catalytic converter.

REMOVAL

(1) Raise and support vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove clamps and nuts.

(4) Remove the catalytic converter.

INSPECTION

Look at the stainless steel body of the converter,

inspect for bulging or other distortion that could be a

result of overheating. If the converter has a heat

shield attached make sure it is not bent or loose.

If you suspect internal damage to the catalyst, tap-

ping the bottom of the catalyst with a rubber mallet

may indicate a damaged core.

INSTALLATION

INSTALLATION

NOTE: The catalytic converter to exhaust manifold

clamp is not reusable. Always use a new clamp

when reinstalling the catalytic converter.

TURBOCHARGER TESTER 9022

11 - 6 EXHAUST SYSTEMDR

EXHAUST SYSTEM (Continued)

Page 1557 of 2627

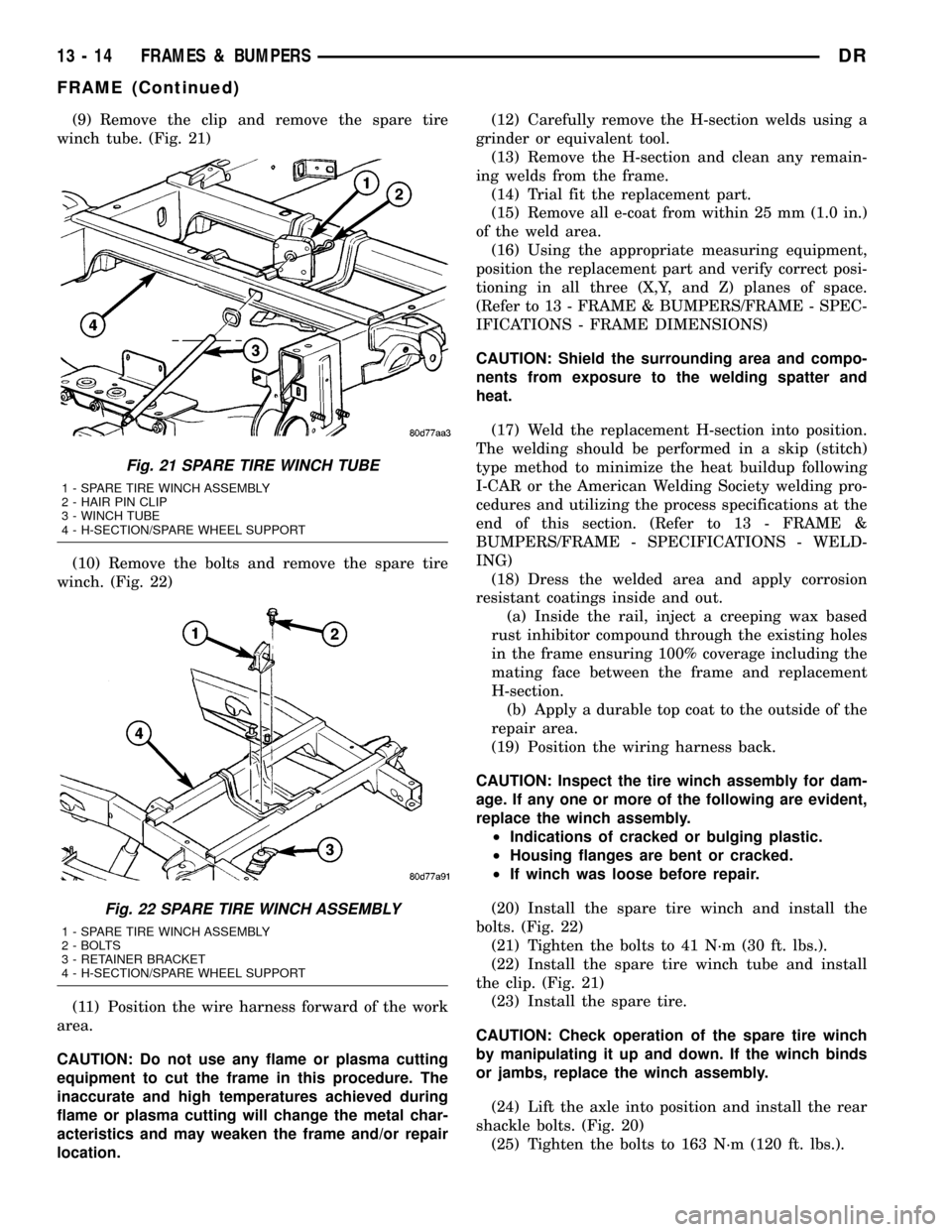

(9) Remove the clip and remove the spare tire

winch tube. (Fig. 21)

(10) Remove the bolts and remove the spare tire

winch. (Fig. 22)

(11) Position the wire harness forward of the work

area.

CAUTION: Do not use any flame or plasma cutting

equipment to cut the frame in this procedure. The

inaccurate and high temperatures achieved during

flame or plasma cutting will change the metal char-

acteristics and may weaken the frame and/or repair

location.(12) Carefully remove the H-section welds using a

grinder or equivalent tool.

(13) Remove the H-section and clean any remain-

ing welds from the frame.

(14) Trial fit the replacement part.

(15) Remove all e-coat from within 25 mm (1.0 in.)

of the weld area.

(16) Using the appropriate measuring equipment,

position the replacement part and verify correct posi-

tioning in all three (X,Y, and Z) planes of space.

(Refer to 13 - FRAME & BUMPERS/FRAME - SPEC-

IFICATIONS - FRAME DIMENSIONS)

CAUTION: Shield the surrounding area and compo-

nents from exposure to the welding spatter and

heat.

(17) Weld the replacement H-section into position.

The welding should be performed in a skip (stitch)

type method to minimize the heat buildup following

I-CAR or the American Welding Society welding pro-

cedures and utilizing the process specifications at the

end of this section. (Refer to 13 - FRAME &

BUMPERS/FRAME - SPECIFICATIONS - WELD-

ING)

(18) Dress the welded area and apply corrosion

resistant coatings inside and out.

(a) Inside the rail, inject a creeping wax based

rust inhibitor compound through the existing holes

in the frame ensuring 100% coverage including the

mating face between the frame and replacement

H-section.

(b) Apply a durable top coat to the outside of the

repair area.

(19) Position the wiring harness back.

CAUTION: Inspect the tire winch assembly for dam-

age. If any one or more of the following are evident,

replace the winch assembly.

²Indications of cracked or bulging plastic.

²Housing flanges are bent or cracked.

²If winch was loose before repair.

(20) Install the spare tire winch and install the

bolts. (Fig. 22)

(21) Tighten the bolts to 41 N´m (30 ft. lbs.).

(22) Install the spare tire winch tube and install

the clip. (Fig. 21)

(23) Install the spare tire.

CAUTION: Check operation of the spare tire winch

by manipulating it up and down. If the winch binds

or jambs, replace the winch assembly.

(24) Lift the axle into position and install the rear

shackle bolts. (Fig. 20)

(25) Tighten the bolts to 163 N´m (120 ft. lbs.).

Fig. 21 SPARE TIRE WINCH TUBE

1 - SPARE TIRE WINCH ASSEMBLY

2 - HAIR PIN CLIP

3 - WINCH TUBE

4 - H-SECTION/SPARE WHEEL SUPPORT

Fig. 22 SPARE TIRE WINCH ASSEMBLY

1 - SPARE TIRE WINCH ASSEMBLY

2 - BOLTS

3 - RETAINER BRACKET

4 - H-SECTION/SPARE WHEEL SUPPORT

13 - 14 FRAMES & BUMPERSDR

FRAME (Continued)

Page 1649 of 2627

INTAKE AIR HEATER

DESCRIPTION

The intake manifold air heater element assembly

is located in the top of the intake manifold.

OPERATION

The air heater elements are used to heat incoming

air to the intake manifold. This is done to help

engine starting and improve driveability with cool or

cold outside temperatures.

Electrical supply for the 2 air heater elements is

controlled by the Engine Control Module (ECM)

through the 2 air heater relays. Refer to Intake Man-

ifold Air Heater Relays for more information.

Two heavy-duty cables connect the 2 air heater ele-

ments to the 2 air heater relays. Each of these cables

will supply approximately 95 amps at 12 volts to an

individual heating element within the heater block

assembly.

Refer to the Powertrain Diagnostic Procedures

manual for electrical operation and complete descrip-

tion of the intake heaters, including pre-heat and

post-heat cycles.

REMOVAL

If servicing either of the heater elements, the

entire block/element assembly must be replaced.

(1) Disconnect both negative battery cables at both

batteries. Cover and isolate ends of both cables.

(2) Remove both the intake manifold air intake

tube (above injection pump), and its rubber connector

hose (Fig. 26).

(3) Lift 2 rubber covers (Fig. 27) to gain access to 2

positive (+) cable nuts. Remove these 2 nuts (Fig. 28)

and remove 2 cables from studs.

(4) Disconnect ground strap (Fig. 27) at heater ele-

ment stud.

(5) Remove wiring harness clips.

(6) Remove engine oil dipstick tube bracket from

air inlet connection and fuel filter housing.

(7) Remove 4 housing mounting bolts (Fig. 27) and

remove heater element assembly.

INSTALLATION

If servicing either of the heater elements, the

entire block/element assembly must be replaced.

(1) Using 2 new gaskets, position element assem-

bly and air housing to intake manifold.

(2) Install ground cable to air housing.

(3) Install 4 housing bolts and tighten to 24 N´m

(18 ft. lbs.) torque.

(4) Connect 2 positive (+) heater cables at cable

mounting studs.Do not allow either of the cable

eyelets to contact any other metal source other

than the cable nuts/studs.

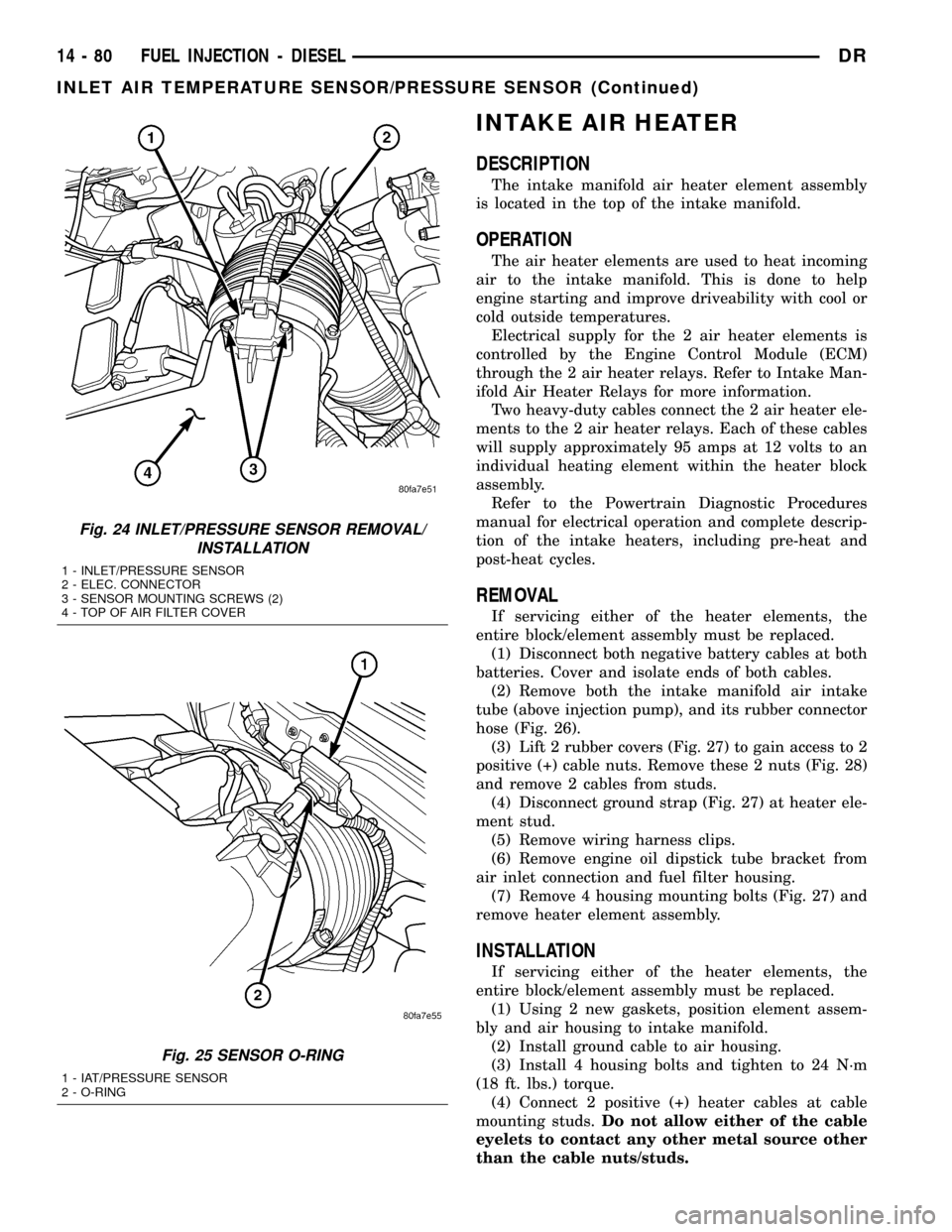

Fig. 24 INLET/PRESSURE SENSOR REMOVAL/

INSTALLATION

1 - INLET/PRESSURE SENSOR

2 - ELEC. CONNECTOR

3 - SENSOR MOUNTING SCREWS (2)

4 - TOP OF AIR FILTER COVER

Fig. 25 SENSOR O-RING

1 - IAT/PRESSURE SENSOR

2 - O-RING

14 - 80 FUEL INJECTION - DIESELDR

INLET AIR TEMPERATURE SENSOR/PRESSURE SENSOR (Continued)

Page 1651 of 2627

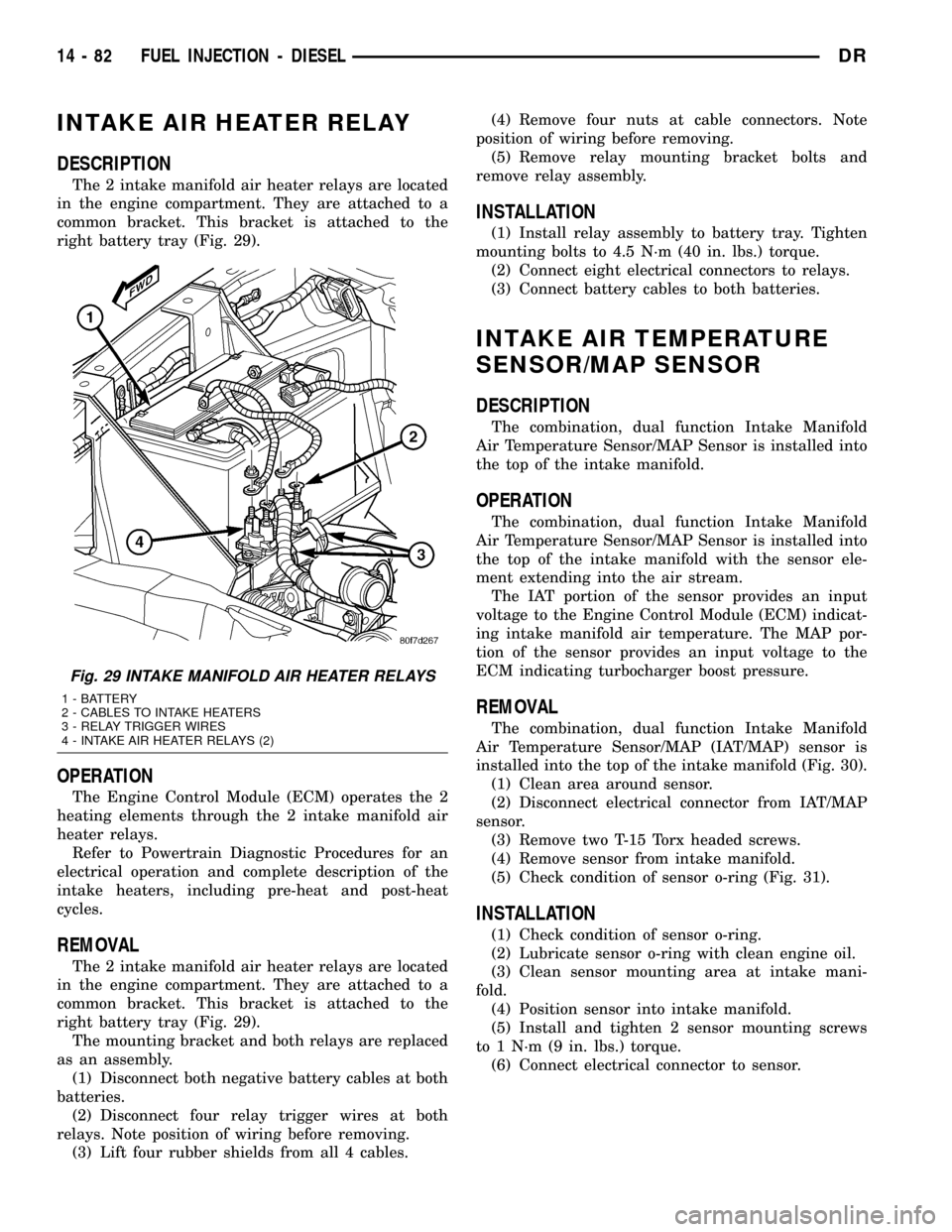

INTAKE AIR HEATER RELAY

DESCRIPTION

The 2 intake manifold air heater relays are located

in the engine compartment. They are attached to a

common bracket. This bracket is attached to the

right battery tray (Fig. 29).

OPERATION

The Engine Control Module (ECM) operates the 2

heating elements through the 2 intake manifold air

heater relays.

Refer to Powertrain Diagnostic Procedures for an

electrical operation and complete description of the

intake heaters, including pre-heat and post-heat

cycles.

REMOVAL

The 2 intake manifold air heater relays are located

in the engine compartment. They are attached to a

common bracket. This bracket is attached to the

right battery tray (Fig. 29).

The mounting bracket and both relays are replaced

as an assembly.

(1) Disconnect both negative battery cables at both

batteries.

(2) Disconnect four relay trigger wires at both

relays. Note position of wiring before removing.

(3) Lift four rubber shields from all 4 cables.(4) Remove four nuts at cable connectors. Note

position of wiring before removing.

(5) Remove relay mounting bracket bolts and

remove relay assembly.

INSTALLATION

(1) Install relay assembly to battery tray. Tighten

mounting bolts to 4.5 N´m (40 in. lbs.) torque.

(2) Connect eight electrical connectors to relays.

(3) Connect battery cables to both batteries.

INTAKE AIR TEMPERATURE

SENSOR/MAP SENSOR

DESCRIPTION

The combination, dual function Intake Manifold

Air Temperature Sensor/MAP Sensor is installed into

the top of the intake manifold.

OPERATION

The combination, dual function Intake Manifold

Air Temperature Sensor/MAP Sensor is installed into

the top of the intake manifold with the sensor ele-

ment extending into the air stream.

The IAT portion of the sensor provides an input

voltage to the Engine Control Module (ECM) indicat-

ing intake manifold air temperature. The MAP por-

tion of the sensor provides an input voltage to the

ECM indicating turbocharger boost pressure.

REMOVAL

The combination, dual function Intake Manifold

Air Temperature Sensor/MAP (IAT/MAP) sensor is

installed into the top of the intake manifold (Fig. 30).

(1) Clean area around sensor.

(2) Disconnect electrical connector from IAT/MAP

sensor.

(3) Remove two T-15 Torx headed screws.

(4) Remove sensor from intake manifold.

(5) Check condition of sensor o-ring (Fig. 31).

INSTALLATION

(1) Check condition of sensor o-ring.

(2) Lubricate sensor o-ring with clean engine oil.

(3) Clean sensor mounting area at intake mani-

fold.

(4) Position sensor into intake manifold.

(5) Install and tighten 2 sensor mounting screws

to 1 N´m (9 in. lbs.) torque.

(6) Connect electrical connector to sensor.

Fig. 29 INTAKE MANIFOLD AIR HEATER RELAYS

1 - BATTERY

2 - CABLES TO INTAKE HEATERS

3 - RELAY TRIGGER WIRES

4 - INTAKE AIR HEATER RELAYS (2)

14 - 82 FUEL INJECTION - DIESELDR