Valve body DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1423 of 2627

þ Loss of engine power

þ Engine misfiring

þ Poor fuel economy

²Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

þ Engine overheating

þ Loss of coolant

þ Excessive steam (white smoke) emitting from

exhaust

þ Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test in this

section. An engine cylinder head gasket leaking

between adjacent cylinders will result in approxi-

mately a 50±70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system.

(3) Remove the air cleaner resonator and duct

work.

(4) Remove the generator.

(5) Remove closed crankcase ventilation system.

(6) Disconnect the evaporation control system.

(7) Perform the Fuel System Pressure Release pro-

cedure (Refer to 14 - FUEL SYSTEM/FUEL DELIV-

ERY - STANDARD PROCEDURE). Disconnect the

fuel supply line (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE).

(8) Disconnect heater hoses.

(9) Remove cylinder head covers and gaskets.

(10) Remove intake manifold and throttle body as

an assembly.

(11) Remove rocker arm assemblies and push rods.

Identify to ensure installation in original locations.

(12) Remove the head bolts from each cylinder

head and remove cylinder heads. Discard the cylin-

der head gasket.

CLEANING

Clean all surfaces of cylinder block and cylinder

heads.

Clean cylinder block front and rear gasket surfaces

using a suitable solvent.

INSPECTION

(1) Inspect the cylinder head for out-of-flatness,

using a straightedge and a feeler gauge. If tolerances

exceed 0.0508 mm (0.002 in.) replace the cylinder

head.

(2) Inspect the valve seats for damage. Service the

valve seats as necessary.

(3) Inspect the valve guides for wear, cracks or

looseness. If either condition exist, replace the cylin-

der head.

(4) Inspect pushrods. Replace worn or bent push-

rods.

INSTALLATION

(1) Clean all surfaces of cylinder block and cylin-

der heads.

(2) Clean cylinder block front and rear gasket sur-

faces using a suitable solvent.

CAUTION: The head gaskets are not interchange-

able between left and right sides. They are marked

ªLº and ªRº to indicate left and right sides.

(3) Position new cylinder head gaskets onto the

cylinder block.

9 - 200 ENGINE - 5.7LDR

CYLINDER HEAD (Continued)

Page 1433 of 2627

INSTALLATION

(1) Throughly clean all gasket resdue from the

engine block.

(2) Use extream care and clean all gasket resdue

from the retainer.

(3) Position the gasket onto the retainer.

(4) Position the retainer onto the engine block.

(5) Install the retainer mounting bolts. Tighten the

bolts to 15 N´m (132 in. lbs.) using a crisscross pat-

tern, starting with the bolt on the lower right.

(6) Install a new rear seal(Refer to 9 - ENGINE/

ENGINE BLOCK/CRANKSHAFT OIL SEAL - REAR

- INSTALLATION).

(7) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(8) Install the drive plate / flywheel.

(9) Install the transmission.

(10) Check and verify engine oil level.

(11) Start engine and check for leaks.

FLEX PLATE

REMOVAL

(1) Remove the transmission.

(2) Remove the bolts and flexplate.

INSTALLATION

(1) Position the flexplate or flywheel onto the

crankshaft and install the bolts hand tight.

(2)For automatic transmissions:Tighten the

flexplate retaining bolts to 95 N´m (70 ft. lbs.).

(3)For manual transmissions:Tighten the fly-

wheel retaining bolts to 75 N´m (55 ft. lbs.).

(4) Install the transmission.

HYDRAULIC TAPPETS

DIAGNOSIS AND TESTING - HYDRAULIC

TAPPETS

Before disassembling any part of the engine to cor-

rect tappet noise, check the oil pressure. If vehicle

has no oil pressure gauge, install a reliable gauge at

the pressure sending-unit. The pressure should be

between 207-552 kPa (30-70 psi) at 3,000 RPM.

Check the oil level after the engine reaches normal

operating temperature. Allow 5 minutes to stabilize

oil level, check dipstick. The oil level in the pan

should never be above the FULL mark or below the

ADD OIL mark on dipstick. Either of these two con-

ditions could be responsible for noisy tappets.

OIL LEVEL

HIGH

If oil level is above the FULL mark, it is possible

for the connecting rods to dip into the oil. With the

engine running, this condition could create foam in

the oil pan. Foam in oil pan would be fed to the

hydraulic tappets by the oil pump causing them to

lose length and allow valves to seat noisily.

LOW

Low oil level may allow oil pump to take in air. When

air is fed to the tappets, they lose length, which allows

valves to seat noisily. Any leaks on intake side of oil

pump through which air can be drawn will create the

same tappet action. Check the lubrication system from

the intake strainer to the pump cover, including the

relief valve retainer cap. When tappet noise is due to

aeration, it may be intermittent or constant, and usu-

ally more than one tappet will be noisy. When oil level

and leaks have been corrected, operate the engine at

fast idle. Run engine for a sufficient time to allow all of

the air inside the tappets to be bled out.

TAPPET NOISE DIAGNOSIS

(1) To determine source of tappet noise, operate

engine at idle with cylinder head covers removed.

(2) Feel each valve spring or rocker arm to detect

noisy tappet. The noisy tappet will cause the affected

spring and/or rocker arm to vibrate or feel rough in

operation.

NOTE: Worn valve guides or cocked springs are

sometimes mistaken for noisy tappets. If such is

the case, noise may be dampened by applying side

thrust on the valve spring. If noise is not apprecia-

bly reduced, it can be assumed the noise is in the

tappet. Inspect the rocker arm push rod sockets

and push rod ends for wear.

(3)

Valve tappet noise ranges from light noise to a

heavy click. A light noise is usually caused by excessive

leak-down around the unit plunger, or by the plunger

partially sticking in the tappet body cylinder. The tap-

pet should be replaced. A heavy click is caused by a tap-

pet check valve not seating, or by foreign particles

wedged between the plunger and the tappet body. This

will cause the plunger to stick in the down position.

This heavy click will be accompanied by excessive clear-

ance between the valve stem and rocker arm as valve

closes. In either case, tappet assembly should be

removed for inspection and cleaning.

(4) The valve train generates a noise very much

like a light tappet noise during normal operation.

Care must be taken to ensure that tappets are mak-

ing the noise. If more than one tappet seems to be

noisy, it's probably not the tappets.

9 - 210 ENGINE - 5.7LDR

CRANKSHAFT REAR OIL SEAL RETAINER (Continued)

Page 1447 of 2627

OIL PAN

REMOVAL

(1) Disconnect the negative battery cable.

(2) Install engine support fixture special tool #

8534.Do not raise engine at this time.

(3) Loosen both left and right side engine mount

through bolts. Do not remove bolts.

(4) Remove the structural dust cover, if equipped.

(5) Drain engine oil.

(6) Remove the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - REMOVAL).

CAUTION: Only raise the engine enough to provide

clearance for oil pan removal. Check for proper

clearance at fan shroud to fan and cowl to intake

manifold.

(7) Raise engine using special tool # 8534 to pro-

vide clearance to remove oil pan.

NOTE: Do not pry on oil pan or oil pan gasket. Gas-

ket is integral to engine windage tray and does not

come out with oil pan.

(8) Remove the oil pan mounting bolts and oil pan.

NOTE: The double ended oil pan studs must be

installed in the same location that they were

removed from.

(9) Unbolt oil pump pickup tube and remove tube.

(10) Inspect the integral windage tray and gasket

and replace as needed.

INSTALLATION

(1) Clean the oil pan gasket mating surface of the

block and oil pan.

(2) Inspect the integral windage tray and gasket

and replace as needed.

(3) Reinstall the oil pump pickup tube with new

o-ring. Tighten tube to pump fasteners to 28 N´m

(250 in. lbs.).

NOTE: The double ended oil pan studs must be

installed in the same location that they were

removed from.

(4) Position the oil pan and install the mounting

bolts and studs.. Tighten the mounting bolts to 12

N´m (105 in.lbs.).

(5) Lower the engine into mounts using special

tool # 8534.

(6) Install both the left and right side engine

mount through bolts. Tighten the nuts to 68 N´m (50

ft. lbs.).(7) Remove special tool # 8534.

(8) Install structural dust cover, if equipped.

(9) Install the front crossmember(Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT CROSS-

MEMBER - INSTALLATION).

(10) Fill engine oil.

(11) Reconnect the negative battery cable.

(12) Start engine and check for leaks.

OIL PUMP

REMOVAL

(1) Remove the oil pan and pick-up tube(Refer to 9

- ENGINE/LUBRICATION/OIL PAN - REMOVAL).

(2) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(3) Remove the four bolts, and the oil pump.

CLEANING

(1) Wash all parts in a suitable solvent.

INSPECTION

CAUTION: Oil pump pressure relief valve and

spring should not be removed from the oil pump. If

these components are disassembled and or

removed from the pump the entire oil pump assem-

bly must be replaced.

(1) Remove the pump cover.

(2) Clean all parts thoroughly. Mating surface of

the oil pump housing should be smooth. If the pump

cover is scratched or grooved the oil pump assembly

should be replaced.

(3) Slide outer rotor into the body of the oil pump.

Press the outer rotor to one side of the oil pump body

and measure clearance between the outer rotor and

the body (Fig. 30). If the measurement is 0.235mm

(0.009 in.) or more the oil pump assembly must be

replaced.

(4) Install the inner rotor in the into the oil pump

body. Measure the clearance between the inner and

outer rotors (Fig. 31). If the clearance between the

rotors is .150 mm (0.006 in.) or more the oil pump

assembly must be replaced.

(5) Place a straight edge across the body of the oil

pump (between the bolt holes), if a feeler gauge of

.095 mm (0.0038 in.) or greater can be inserted

between the straightedge and the rotors, the pump

must be replaced (Fig. 32).

(6) Reinstall the pump cover. Torque fasteners to

15 N´m (132 in. lbs.).

9 - 224 ENGINE - 5.7LDR

Page 1519 of 2627

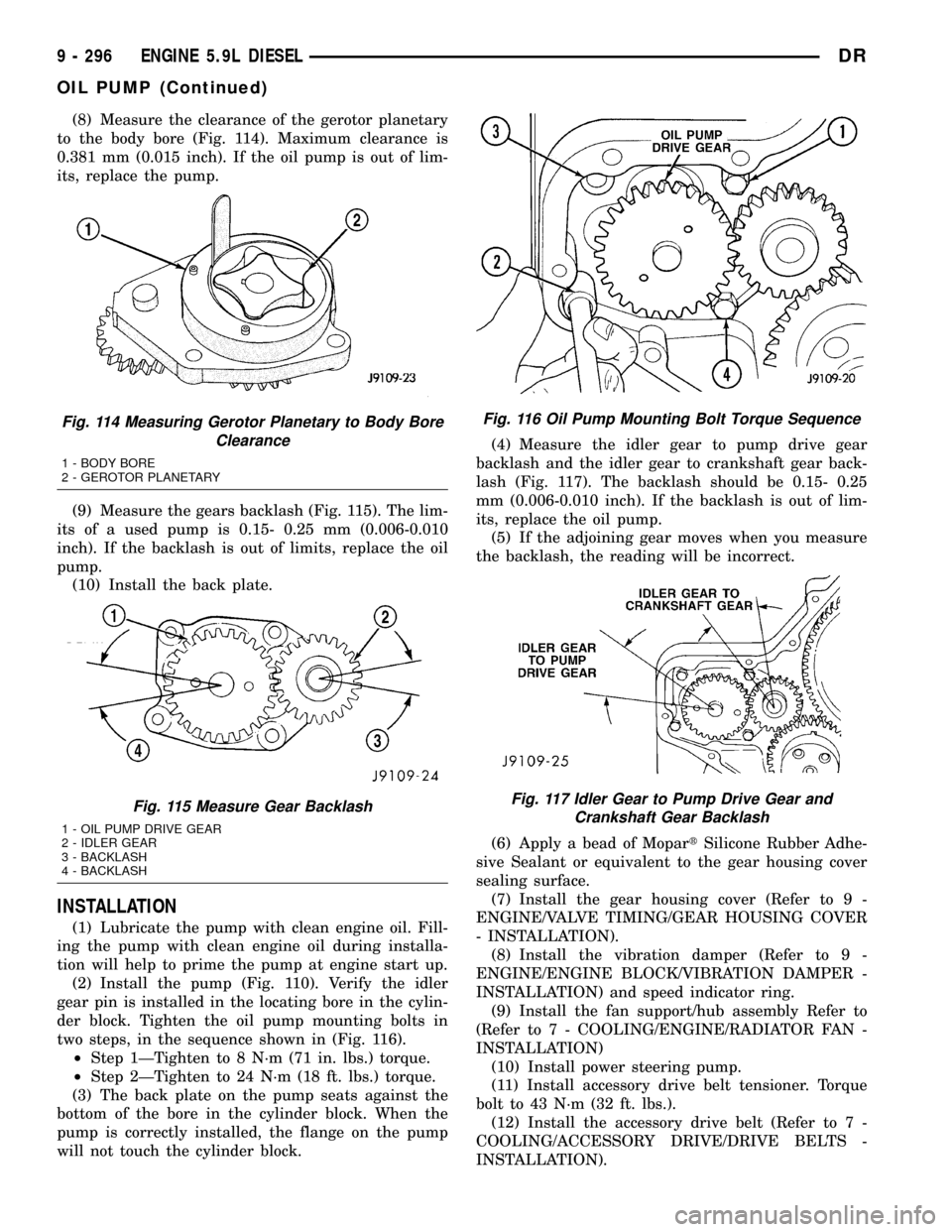

(8) Measure the clearance of the gerotor planetary

to the body bore (Fig. 114). Maximum clearance is

0.381 mm (0.015 inch). If the oil pump is out of lim-

its, replace the pump.

(9) Measure the gears backlash (Fig. 115). The lim-

its of a used pump is 0.15- 0.25 mm (0.006-0.010

inch). If the backlash is out of limits, replace the oil

pump.

(10) Install the back plate.

INSTALLATION

(1) Lubricate the pump with clean engine oil. Fill-

ing the pump with clean engine oil during installa-

tion will help to prime the pump at engine start up.

(2) Install the pump (Fig. 110). Verify the idler

gear pin is installed in the locating bore in the cylin-

der block. Tighten the oil pump mounting bolts in

two steps, in the sequence shown in (Fig. 116).

²Step 1ÐTighten to 8 N´m (71 in. lbs.) torque.

²Step 2ÐTighten to 24 N´m (18 ft. lbs.) torque.

(3) The back plate on the pump seats against the

bottom of the bore in the cylinder block. When the

pump is correctly installed, the flange on the pump

will not touch the cylinder block.(4) Measure the idler gear to pump drive gear

backlash and the idler gear to crankshaft gear back-

lash (Fig. 117). The backlash should be 0.15- 0.25

mm (0.006-0.010 inch). If the backlash is out of lim-

its, replace the oil pump.

(5) If the adjoining gear moves when you measure

the backlash, the reading will be incorrect.

(6) Apply a bead of MopartSilicone Rubber Adhe-

sive Sealant or equivalent to the gear housing cover

sealing surface.

(7) Install the gear housing cover (Refer to 9 -

ENGINE/VALVE TIMING/GEAR HOUSING COVER

- INSTALLATION).

(8) Install the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION) and speed indicator ring.

(9) Install the fan support/hub assembly Refer to

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION)

(10) Install power steering pump.

(11) Install accessory drive belt tensioner. Torque

bolt to 43 N´m (32 ft. lbs.).

(12) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

Fig. 114 Measuring Gerotor Planetary to Body Bore

Clearance

1 - BODY BORE

2 - GEROTOR PLANETARY

Fig. 115 Measure Gear Backlash

1 - OIL PUMP DRIVE GEAR

2 - IDLER GEAR

3 - BACKLASH

4 - BACKLASH

Fig. 116 Oil Pump Mounting Bolt Torque Sequence

Fig. 117 Idler Gear to Pump Drive Gear and

Crankshaft Gear Backlash

9 - 296 ENGINE 5.9L DIESELDR

OIL PUMP (Continued)

Page 1531 of 2627

SPECIAL TOOLS

CATALYTIC CONVERTER

DESCRIPTION - CATALYTIC CONVERTER

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

CAUTION: DO NOT remove spark plug wires from

plugs or by any other means short out cylinders.

Failure of the catalytic converter can occur due to a

temperature increase caused by unburned fuel

passing through the converter.

The stainless steel catalytic converter body is

designed to last the life of the vehicle. Excessive heat

can result in bulging or other distortion, but exces-

sive heat will not be the fault of the converter. If

unburned fuel enters the converter, overheating may

occur. If a converter is heat-damaged, correct the

cause of the damage at the same time the converter

is replaced. Also, inspect all other components of the

exhaust system for heat damage.

Unleaded gasoline must be used to avoid con-

taminating the catalyst core.

50 State emission vehicles incorporate two mini

catalytic converters located after the exhaust mani-

folds and before the inline catalytic converter.

OPERATION

The catalytic converter captures and burns any

unburned fuel mixture exiting the combustion cham-

bers during the exhaust stroke of the engine. This

process aids in reducing emissions output.

REMOVAL

REMOVAL

WARNING: IF TORCHES ARE USED WHEN WORK-

ING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove the bolts from the crossover pipe to the

catalytic converter connection.

(4) Disconnect oxygen sensor wiring.

(5) Loosen the nuts from the clamp that hold the

catalytic converter to the exhaust pipe flange connec-

tion.

NOTE: Do not remove nut from T-Bolt. Only remove

nut far enough, so that the T end can be removed

from the clamp.

(6) Remove the T bolt end of the fastener, from the

clamp.

(7) Spread the clamp, and remove the catalytic

converter from the vehicle.

(8) Discard the clamp.

NOTE: The catalytic converter to exhaust manifold

clamp is not reusable. Always use a new clamp

when reinstalling the catalytic converter.

REMOVAL

(1) Raise and support vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove clamps and nuts.

(4) Remove the catalytic converter.

INSPECTION

Look at the stainless steel body of the converter,

inspect for bulging or other distortion that could be a

result of overheating. If the converter has a heat

shield attached make sure it is not bent or loose.

If you suspect internal damage to the catalyst, tap-

ping the bottom of the catalyst with a rubber mallet

may indicate a damaged core.

INSTALLATION

INSTALLATION

NOTE: The catalytic converter to exhaust manifold

clamp is not reusable. Always use a new clamp

when reinstalling the catalytic converter.

TURBOCHARGER TESTER 9022

11 - 6 EXHAUST SYSTEMDR

EXHAUST SYSTEM (Continued)

Page 1532 of 2627

(1) Position the catalytic converter onto the

exhaust pipe flange connection. Tighten the nuts to

28 N´m (250 in. lbs.) torque.

(2) Install the muffler onto the catalytic converter

until the alignment tab is inserted into the align-

ment slot.

(3) Install the exhaust clamp at the muffler and

catalytic converter connection. Tighten the clamp

nuts to 54.2 N´m (40 ft. lbs.) torque.

(4) Connect oxygen sensor wiring.

(5) Lower the vehicle.

(6) Start the engine and inspect for exhaust leaks.

Reair exhaust leaks as necessary.

(7) Check the exhaust system for contact with the

body panels. A minimum of 25.4 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed..

INSTALLATION

(1) Assemble converter and clamps loosely in

place.

(2) Install the exhaust pipe onto exhaust mani-

folds, tighten 31 N´m (23 ft. lbs.).

(3) Tighten all clamp nuts to 52.2 N´m (40 ft. lbs.)

torque.

(4) Lower the vehicle.

(5) Start the engine and inspect for exhaust leaks.

Reair exhaust leaks as necessary.

(6) Check the exhaust system for contact with the

body panels. A minimum of 25.4 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed..

EXHAUST PIPE

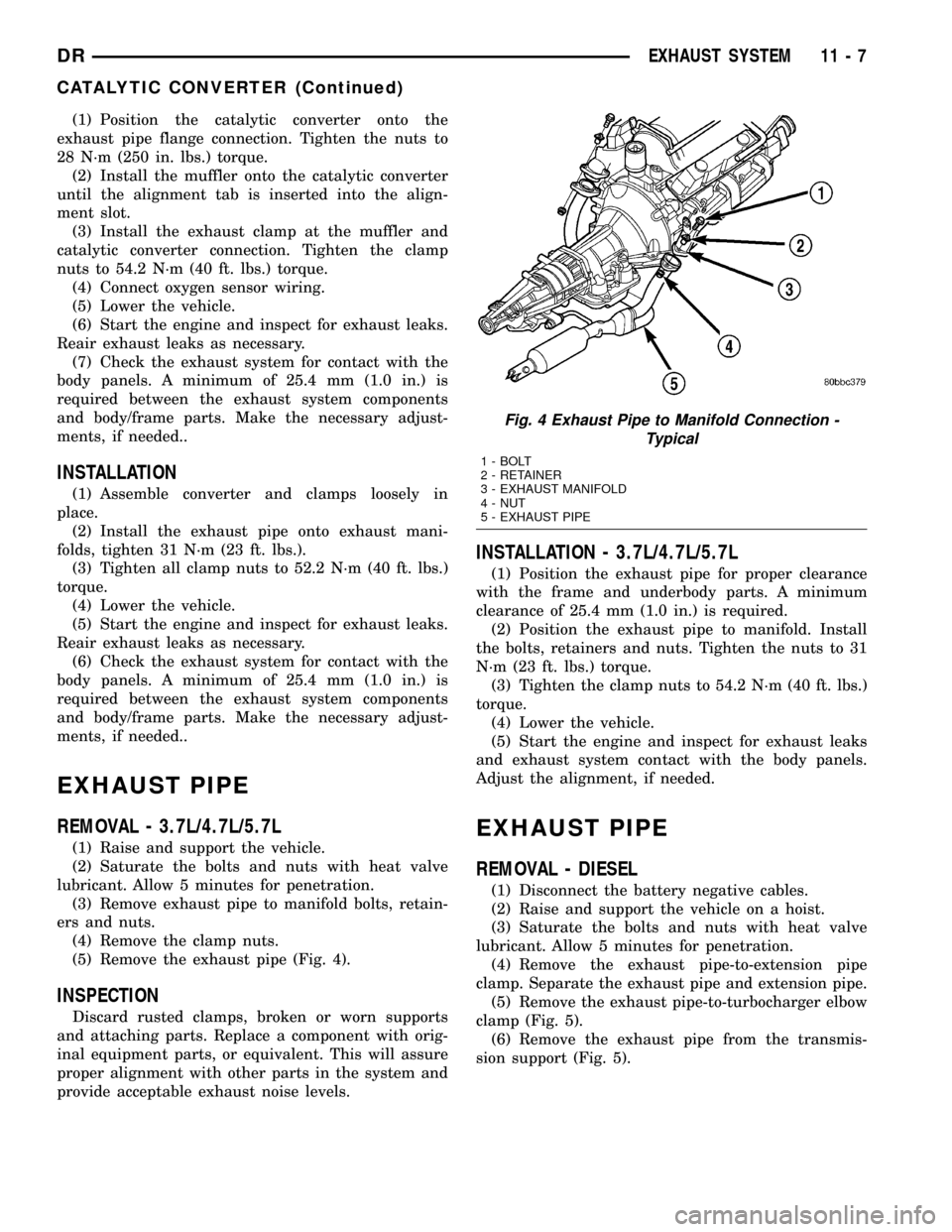

REMOVAL - 3.7L/4.7L/5.7L

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove exhaust pipe to manifold bolts, retain-

ers and nuts.

(4) Remove the clamp nuts.

(5) Remove the exhaust pipe (Fig. 4).

INSPECTION

Discard rusted clamps, broken or worn supports

and attaching parts. Replace a component with orig-

inal equipment parts, or equivalent. This will assure

proper alignment with other parts in the system and

provide acceptable exhaust noise levels.

INSTALLATION - 3.7L/4.7L/5.7L

(1) Position the exhaust pipe for proper clearance

with the frame and underbody parts. A minimum

clearance of 25.4 mm (1.0 in.) is required.

(2) Position the exhaust pipe to manifold. Install

the bolts, retainers and nuts. Tighten the nuts to 31

N´m (23 ft. lbs.) torque.

(3) Tighten the clamp nuts to 54.2 N´m (40 ft. lbs.)

torque.

(4) Lower the vehicle.

(5) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

EXHAUST PIPE

REMOVAL - DIESEL

(1) Disconnect the battery negative cables.

(2) Raise and support the vehicle on a hoist.

(3) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(4) Remove the exhaust pipe-to-extension pipe

clamp. Separate the exhaust pipe and extension pipe.

(5) Remove the exhaust pipe-to-turbocharger elbow

clamp (Fig. 5).

(6) Remove the exhaust pipe from the transmis-

sion support (Fig. 5).

Fig. 4 Exhaust Pipe to Manifold Connection -

Typical

1 - BOLT

2 - RETAINER

3 - EXHAUST MANIFOLD

4 - NUT

5 - EXHAUST PIPE

DREXHAUST SYSTEM 11 - 7

CATALYTIC CONVERTER (Continued)

Page 1534 of 2627

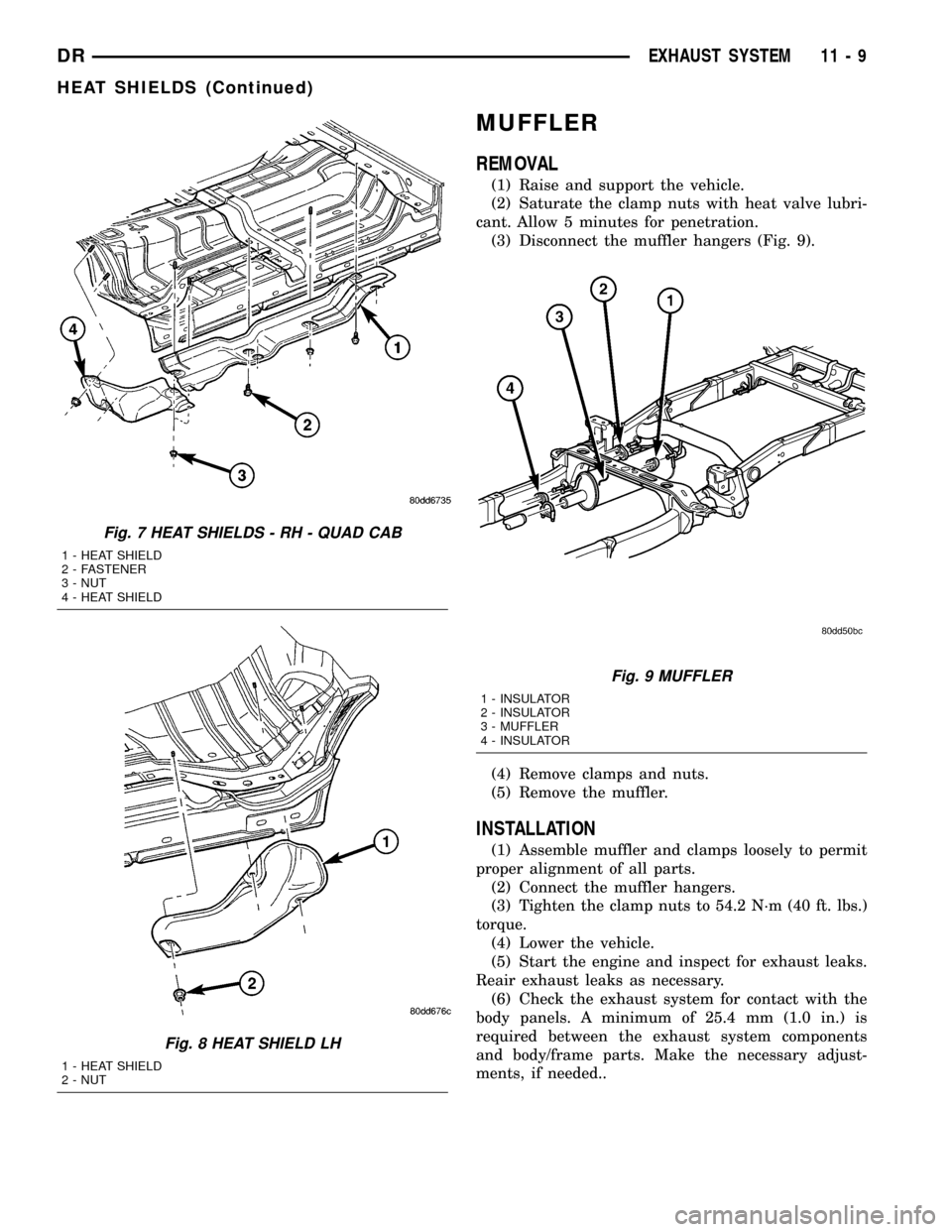

MUFFLER

REMOVAL

(1) Raise and support the vehicle.

(2) Saturate the clamp nuts with heat valve lubri-

cant. Allow 5 minutes for penetration.

(3) Disconnect the muffler hangers (Fig. 9).

(4) Remove clamps and nuts.

(5) Remove the muffler.

INSTALLATION

(1) Assemble muffler and clamps loosely to permit

proper alignment of all parts.

(2) Connect the muffler hangers.

(3) Tighten the clamp nuts to 54.2 N´m (40 ft. lbs.)

torque.

(4) Lower the vehicle.

(5) Start the engine and inspect for exhaust leaks.

Reair exhaust leaks as necessary.

(6) Check the exhaust system for contact with the

body panels. A minimum of 25.4 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed..

Fig. 7 HEAT SHIELDS - RH - QUAD CAB

1 - HEAT SHIELD

2 - FASTENER

3 - NUT

4 - HEAT SHIELD

Fig. 8 HEAT SHIELD LH

1 - HEAT SHIELD

2 - NUT

Fig. 9 MUFFLER

1 - INSULATOR

2 - INSULATOR

3 - MUFFLER

4 - INSULATOR

DREXHAUST SYSTEM 11 - 9

HEAT SHIELDS (Continued)

Page 1535 of 2627

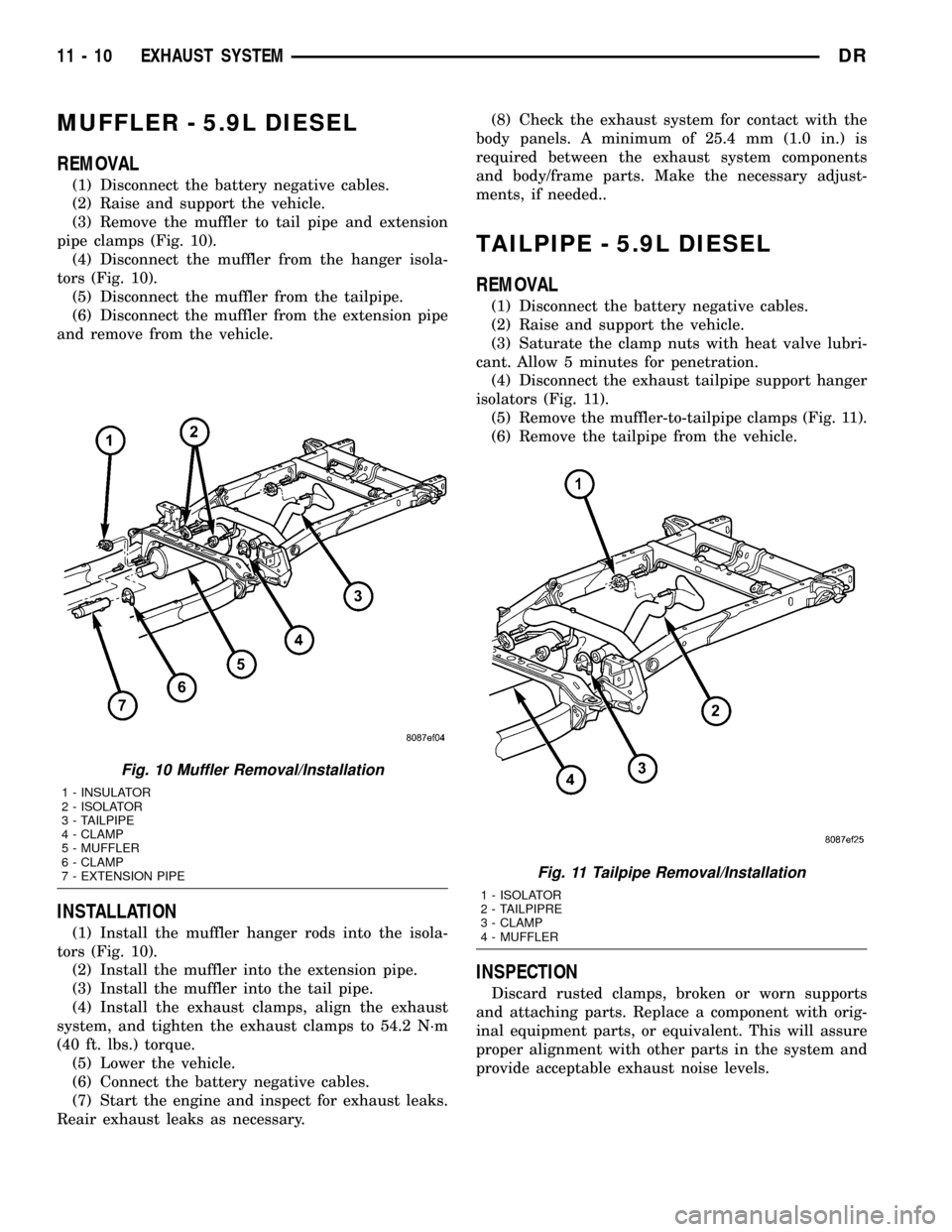

MUFFLER - 5.9L DIESEL

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise and support the vehicle.

(3) Remove the muffler to tail pipe and extension

pipe clamps (Fig. 10).

(4) Disconnect the muffler from the hanger isola-

tors (Fig. 10).

(5) Disconnect the muffler from the tailpipe.

(6) Disconnect the muffler from the extension pipe

and remove from the vehicle.

INSTALLATION

(1) Install the muffler hanger rods into the isola-

tors (Fig. 10).

(2) Install the muffler into the extension pipe.

(3) Install the muffler into the tail pipe.

(4) Install the exhaust clamps, align the exhaust

system, and tighten the exhaust clamps to 54.2 N´m

(40 ft. lbs.) torque.

(5) Lower the vehicle.

(6) Connect the battery negative cables.

(7) Start the engine and inspect for exhaust leaks.

Reair exhaust leaks as necessary.(8) Check the exhaust system for contact with the

body panels. A minimum of 25.4 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed..

TAILPIPE - 5.9L DIESEL

REMOVAL

(1) Disconnect the battery negative cables.

(2) Raise and support the vehicle.

(3) Saturate the clamp nuts with heat valve lubri-

cant. Allow 5 minutes for penetration.

(4) Disconnect the exhaust tailpipe support hanger

isolators (Fig. 11).

(5) Remove the muffler-to-tailpipe clamps (Fig. 11).

(6) Remove the tailpipe from the vehicle.

INSPECTION

Discard rusted clamps, broken or worn supports

and attaching parts. Replace a component with orig-

inal equipment parts, or equivalent. This will assure

proper alignment with other parts in the system and

provide acceptable exhaust noise levels.

Fig. 10 Muffler Removal/Installation

1 - INSULATOR

2 - ISOLATOR

3 - TAILPIPE

4 - CLAMP

5 - MUFFLER

6 - CLAMP

7 - EXTENSION PIPE

Fig. 11 Tailpipe Removal/Installation

1 - ISOLATOR

2 - TAILPIPRE

3 - CLAMP

4 - MUFFLER

11 - 10 EXHAUST SYSTEMDR

Page 1536 of 2627

INSTALLATION

(1) Install the tailpipe into the muffler.

(2) Install the tailpipe hanger rods into the isola-

tors (Fig. 11)

(3) Install the exhaust clamp, align the exhaust

system, and tighten the clamp 48 N´m (35 ft. lbs.)

torque.

(4) Lower the vehicle.

(5) Connect the battery negative cables.

(6) Start the engine and inspect for exhaust leaks.

Reair exhaust leaks as necessary.

(7) Check the exhaust system for contact with the

body panels. A minimum of 25.4 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed..

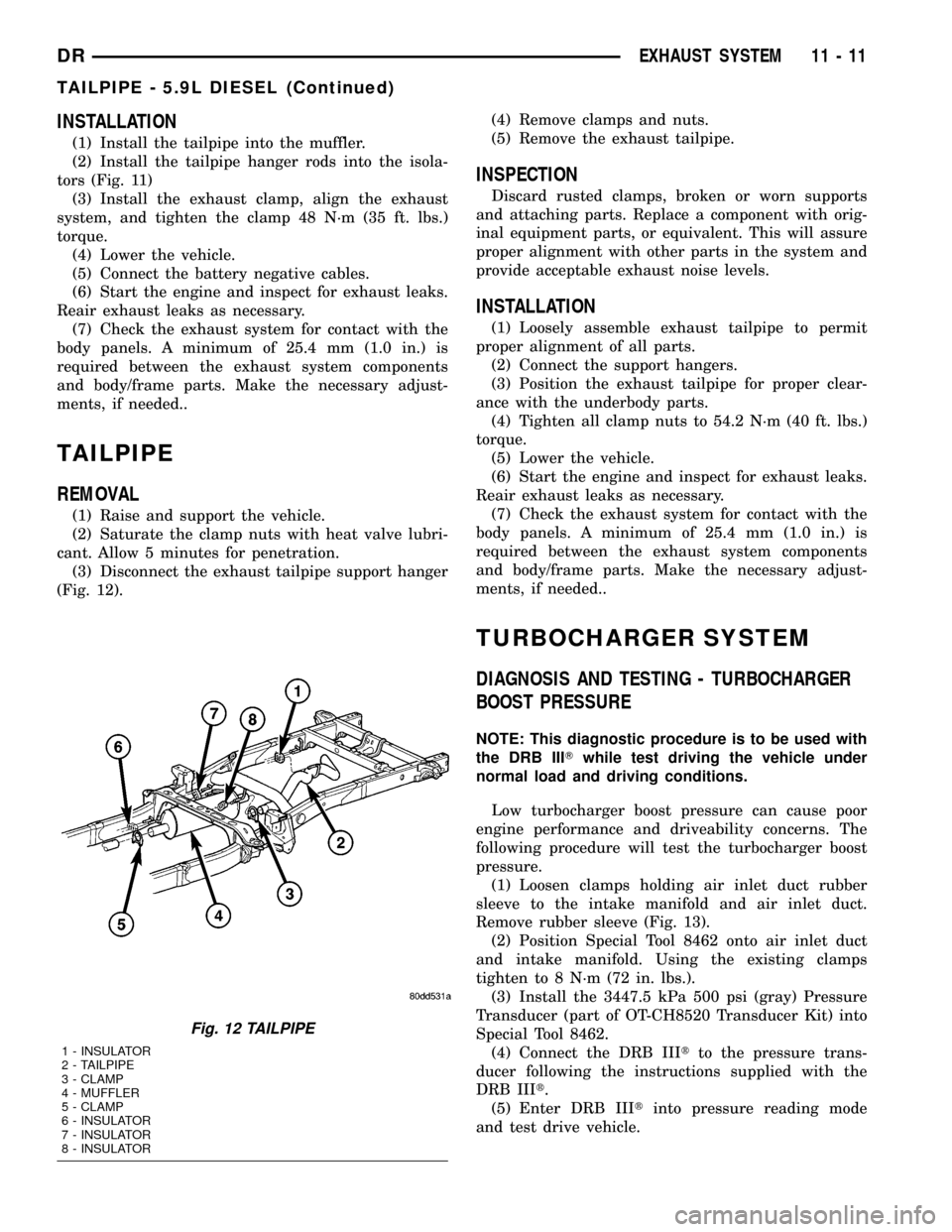

TAILPIPE

REMOVAL

(1) Raise and support the vehicle.

(2) Saturate the clamp nuts with heat valve lubri-

cant. Allow 5 minutes for penetration.

(3) Disconnect the exhaust tailpipe support hanger

(Fig. 12).(4) Remove clamps and nuts.

(5) Remove the exhaust tailpipe.

INSPECTION

Discard rusted clamps, broken or worn supports

and attaching parts. Replace a component with orig-

inal equipment parts, or equivalent. This will assure

proper alignment with other parts in the system and

provide acceptable exhaust noise levels.

INSTALLATION

(1) Loosely assemble exhaust tailpipe to permit

proper alignment of all parts.

(2) Connect the support hangers.

(3) Position the exhaust tailpipe for proper clear-

ance with the underbody parts.

(4) Tighten all clamp nuts to 54.2 N´m (40 ft. lbs.)

torque.

(5) Lower the vehicle.

(6) Start the engine and inspect for exhaust leaks.

Reair exhaust leaks as necessary.

(7) Check the exhaust system for contact with the

body panels. A minimum of 25.4 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed..

TURBOCHARGER SYSTEM

DIAGNOSIS AND TESTING - TURBOCHARGER

BOOST PRESSURE

NOTE: This diagnostic procedure is to be used with

the DRB IIITwhile test driving the vehicle under

normal load and driving conditions.

Low turbocharger boost pressure can cause poor

engine performance and driveability concerns. The

following procedure will test the turbocharger boost

pressure.

(1) Loosen clamps holding air inlet duct rubber

sleeve to the intake manifold and air inlet duct.

Remove rubber sleeve (Fig. 13).

(2) Position Special Tool 8462 onto air inlet duct

and intake manifold. Using the existing clamps

tighten to 8 N´m (72 in. lbs.).

(3) Install the 3447.5 kPa 500 psi (gray) Pressure

Transducer (part of OT-CH8520 Transducer Kit) into

Special Tool 8462.

(4) Connect the DRB IIItto the pressure trans-

ducer following the instructions supplied with the

DRB IIIt.

(5) Enter DRB IIItinto pressure reading mode

and test drive vehicle.

Fig. 12 TAILPIPE

1 - INSULATOR

2 - TAILPIPE

3 - CLAMP

4 - MUFFLER

5 - CLAMP

6 - INSULATOR

7 - INSULATOR

8 - INSULATOR

DREXHAUST SYSTEM 11 - 11

TAILPIPE - 5.9L DIESEL (Continued)

Page 1580 of 2627

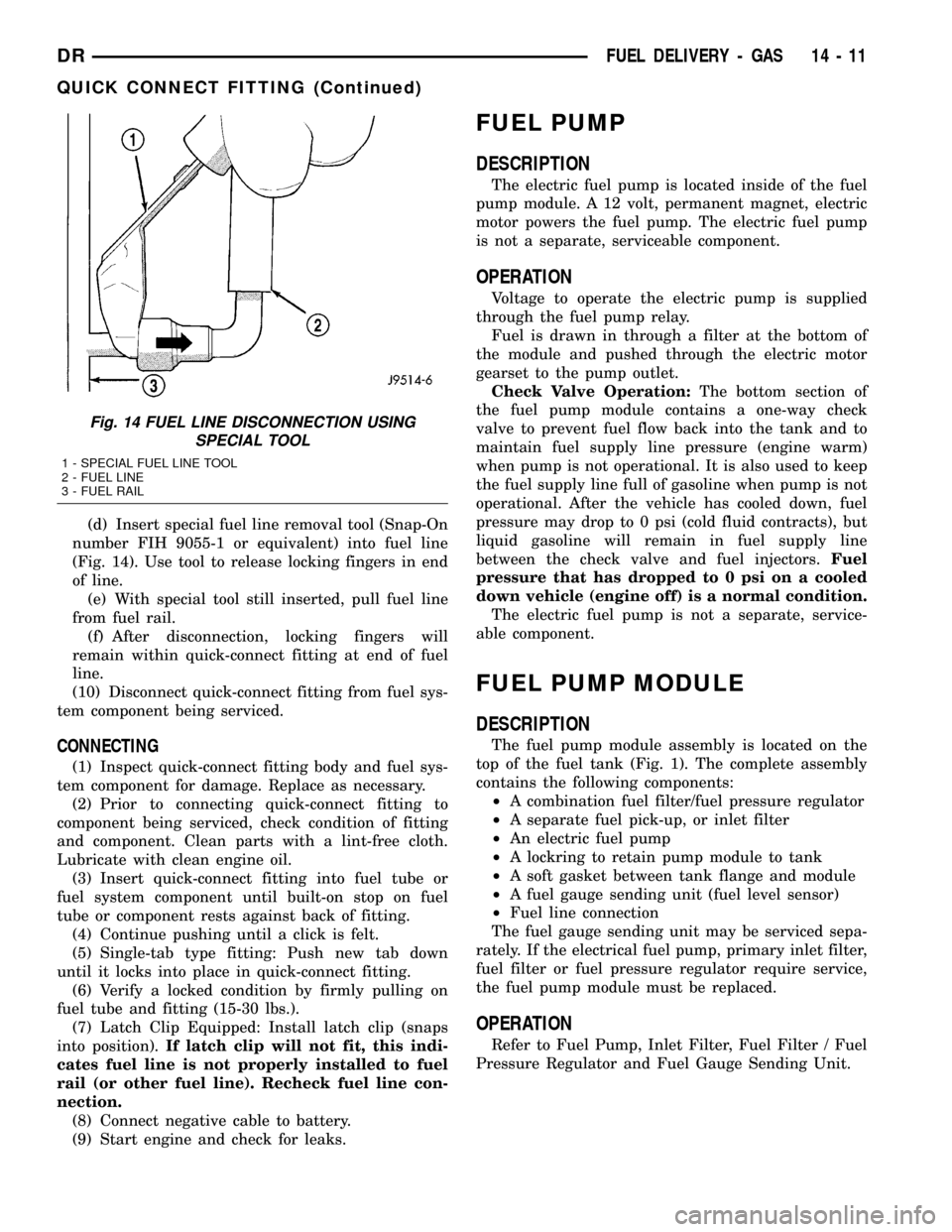

(d) Insert special fuel line removal tool (Snap-On

number FIH 9055-1 or equivalent) into fuel line

(Fig. 14). Use tool to release locking fingers in end

of line.

(e) With special tool still inserted, pull fuel line

from fuel rail.

(f) After disconnection, locking fingers will

remain within quick-connect fitting at end of fuel

line.

(10) Disconnect quick-connect fitting from fuel sys-

tem component being serviced.

CONNECTING

(1) Inspect quick-connect fitting body and fuel sys-

tem component for damage. Replace as necessary.

(2) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(3) Insert quick-connect fitting into fuel tube or

fuel system component until built-on stop on fuel

tube or component rests against back of fitting.

(4) Continue pushing until a click is felt.

(5) Single-tab type fitting: Push new tab down

until it locks into place in quick-connect fitting.

(6) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(7) Latch Clip Equipped: Install latch clip (snaps

into position).If latch clip will not fit, this indi-

cates fuel line is not properly installed to fuel

rail (or other fuel line). Recheck fuel line con-

nection.

(8) Connect negative cable to battery.

(9) Start engine and check for leaks.

FUEL PUMP

DESCRIPTION

The electric fuel pump is located inside of the fuel

pump module. A 12 volt, permanent magnet, electric

motor powers the fuel pump. The electric fuel pump

is not a separate, serviceable component.

OPERATION

Voltage to operate the electric pump is supplied

through the fuel pump relay.

Fuel is drawn in through a filter at the bottom of

the module and pushed through the electric motor

gearset to the pump outlet.

Check Valve Operation:The bottom section of

the fuel pump module contains a one-way check

valve to prevent fuel flow back into the tank and to

maintain fuel supply line pressure (engine warm)

when pump is not operational. It is also used to keep

the fuel supply line full of gasoline when pump is not

operational. After the vehicle has cooled down, fuel

pressure may drop to 0 psi (cold fluid contracts), but

liquid gasoline will remain in fuel supply line

between the check valve and fuel injectors.Fuel

pressure that has dropped to 0 psi on a cooled

down vehicle (engine off) is a normal condition.

The electric fuel pump is not a separate, service-

able component.

FUEL PUMP MODULE

DESCRIPTION

The fuel pump module assembly is located on the

top of the fuel tank (Fig. 1). The complete assembly

contains the following components:

²A combination fuel filter/fuel pressure regulator

²A separate fuel pick-up, or inlet filter

²An electric fuel pump

²A lockring to retain pump module to tank

²A soft gasket between tank flange and module

²A fuel gauge sending unit (fuel level sensor)

²Fuel line connection

The fuel gauge sending unit may be serviced sepa-

rately. If the electrical fuel pump, primary inlet filter,

fuel filter or fuel pressure regulator require service,

the fuel pump module must be replaced.

OPERATION

Refer to Fuel Pump, Inlet Filter, Fuel Filter / Fuel

Pressure Regulator and Fuel Gauge Sending Unit.

Fig. 14 FUEL LINE DISCONNECTION USING

SPECIAL TOOL

1 - SPECIAL FUEL LINE TOOL

2 - FUEL LINE

3 - FUEL RAIL

DRFUEL DELIVERY - GAS 14 - 11

QUICK CONNECT FITTING (Continued)