door lock DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 602 of 2627

DRIVER DOOR MODULE

DESCRIPTION

A Driver Door Module (DDM) is used on all models

equipped with power locks, power windows, and

power mirrors. The DDM houses the following

switches:

²Power Lock Switch- The DDM includes a

two-way, momentary, resistor multiplexed switch to

control the power lock system.

²Power Mirror Selector Switch- A three-posi-

tion rocker switch in the DDM selects the right or

left power mirror for adjustment, or turns the power

mirror system Off.

²Power Mirror Adjustment Switches- Four

momentary, arrowhead shaped, directional switches

allow the driver to adjust the selected power mirror

in the Up, Down, Right, or Left directions.

²Power Window Lockout Switch- A two-way,

latching, push-button switch in the DDM allows the

vehicle operator to lock out the power window

switches on each passenger door so that the passen-

ger door power windows may be operated only from

the master switches in the DDM.

²Power Window Switches- The DDM houses a

two-way, momentary power window switch for the

driver side front door. This switch also has a second

detent in the Down direction and internal circuitry to

provide an Auto-Down feature for the driver side

front door power window. In addition to the power

window switch for its own door, the DDM houses

individual master switches for each passenger door

power window.

The DDM also incorporates several green Light-

Emitting Diodes (LEDs) that illuminate the power

lock and power window switch paddles, and the

power mirror switch directional buttons to improve

switch visibility in dark ambient lighting conditions.

The DDM cannot be adjusted or repaired and, if

faulty or damaged, the entire DDM unit must be

replaced.

OPERATION

The Driver Door Module (DDM) combines a power

lock switch, a driver power window switch with an

Auto-down feature, master switches for each passen-

ger door power window, a power window lockout

switch, a power mirror selector switch, and four

power mirror adjustment switches in a single unit.

The switches in the DDM can be diagnosed using

conventional diagnostic tools and methods.

Power Lock Switch

The DDM power lock switch circuitry is connected

in series between ground and the driver door switch

mux input of the instrument cluster. Each power lockswitch position (Lock, Unlock, and Neutral) provides

a different resistance value to the instrument cluster

input, which allows the instrument cluster to sense

the switch position. Based upon the power lock

switch input, the instrument cluster controls the bat-

tery and ground feed outputs to the individual power

lock motors to lock or unlock the door latches. The

Light-Emitting Diode (LED) in the DDM power lock

switch is connected to battery current through the

power window circuit breaker in the Integrated

Power Module (IPM) on a fused ignition switch out-

put (run-acc) circuit so that the switch will be illumi-

nated whenever the ignition switch is in the On or

Accessory positions.

Power Window Switches

The DDM power window switch circuitry is con-

nected to battery current through a circuit breaker in

the Integrated Power Module (IPM) on a fused igni-

tion switch output (run-acc) circuit so that the power

windows will operate whenever the ignition switch is

in the On or Accessory positions. Each two-way,

momentary master passenger power window switch

in the DDM provides battery current and ground to

the individual power window switches on each pas-

senger door so that the power window switch controls

the battery current and ground feeds to its respective

power window motor. The DDM switch for the driver

side front door power window is labeled ªAutoº and

includes an auto-down feature. When this switch is

depressed to a second momentary detent position and

released, the driver door power window is automati-

cally operated through an internal circuit and relay

to its fully lowered position. The Auto-down event is

cancelled if the switch paddle is depressed a second

time in either the Up or Down direction. When the

two position window lockout switch in the DDM is

depressed and latched in the lockout position, the

battery current feed to each of the individual passen-

ger power window switches is interrupted so that the

passenger door power windows can only be operated

from the master switches in the DDM. The window

lockout switch also controls the battery current feed

for the LED in each passenger power window switch

so that the switch will not be illuminated when it is

locked out.

Power Mirror Switches

The DDM power mirror switch circuitry is con-

nected to battery current through a fuse in the IPM

on a fused B(+) circuit so that the power mirrors

remain operational regardless of the ignition switch

position. A rocker type selector switch has three posi-

tions, one to select the right mirror, one to select the

left mirror, and a neutral Off position. After the right

or left mirror is selected, one of four directional but-

DRPOWER LOCKS 8N - 5

Page 603 of 2627

tons is depressed to move the selected mirror Up,

Down, Right or Left. The DDM power mirror switch

circuitry controls the battery current and ground

feeds to each of the four (two in each mirror head)

power mirror motors. The Light-Emitting Diode

(LED) in the DDM power mirror switch is connected

to battery current through the power window circuit

breaker in the IPM on a fused ignition switch output

(run-acc) circuit so that the switch directional but-

tons will be illuminated whenever the ignition switch

is in the On or Accessory positions.

DIAGNOSIS AND TESTING - DRIVER DOOR

MODULE

The Light-Emitting Diode (LED) illumination

lamps for all of the Driver Door Module (DDM)

power window, power lock, and power mirror

switches receive battery current through the power

window circuit breaker in the Integrated Power Mod-

ule (IPM). If all of the LEDs are inoperative in the

DDM, be certain to diagnose the power window sys-

tem before replacing the switch unit. (Refer to 8 -

ELECTRICAL/POWER WINDOWS - DIAGNOSIS

AND TESTING). If only one LED in the DDM is

inoperative, replace the faulty DDM. If the driver

side front door power window operates in a normal

manner, but the Auto-Down feature is inoperative,

replace the faulty DDM. Refer to the appropriate wir-

ing information.

(1) Disconnect and isolate the battery negative

cable. Remove the DDM from the door trim panel.

Disconnect the door wire harness connectors for the

DDM from the DDM connector receptacles.

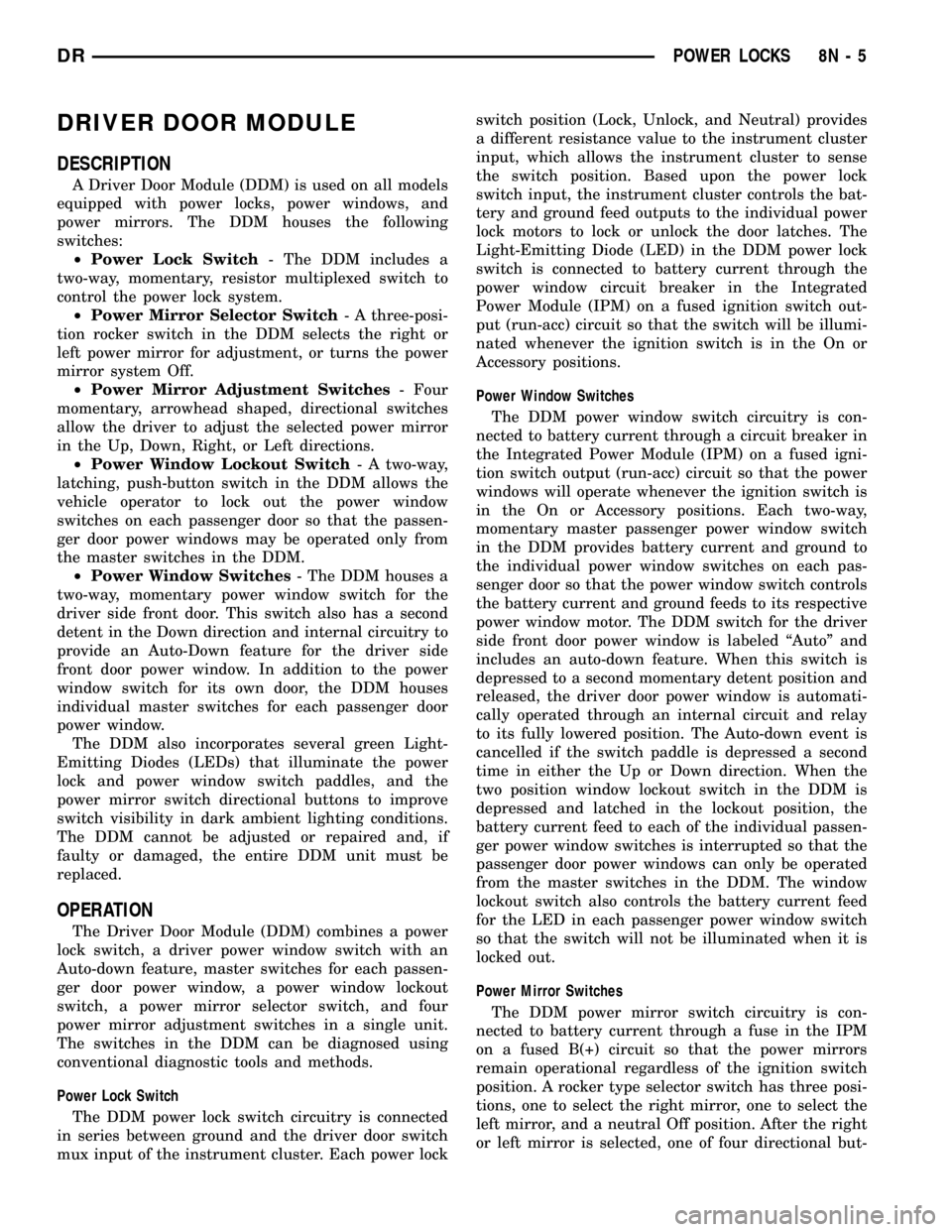

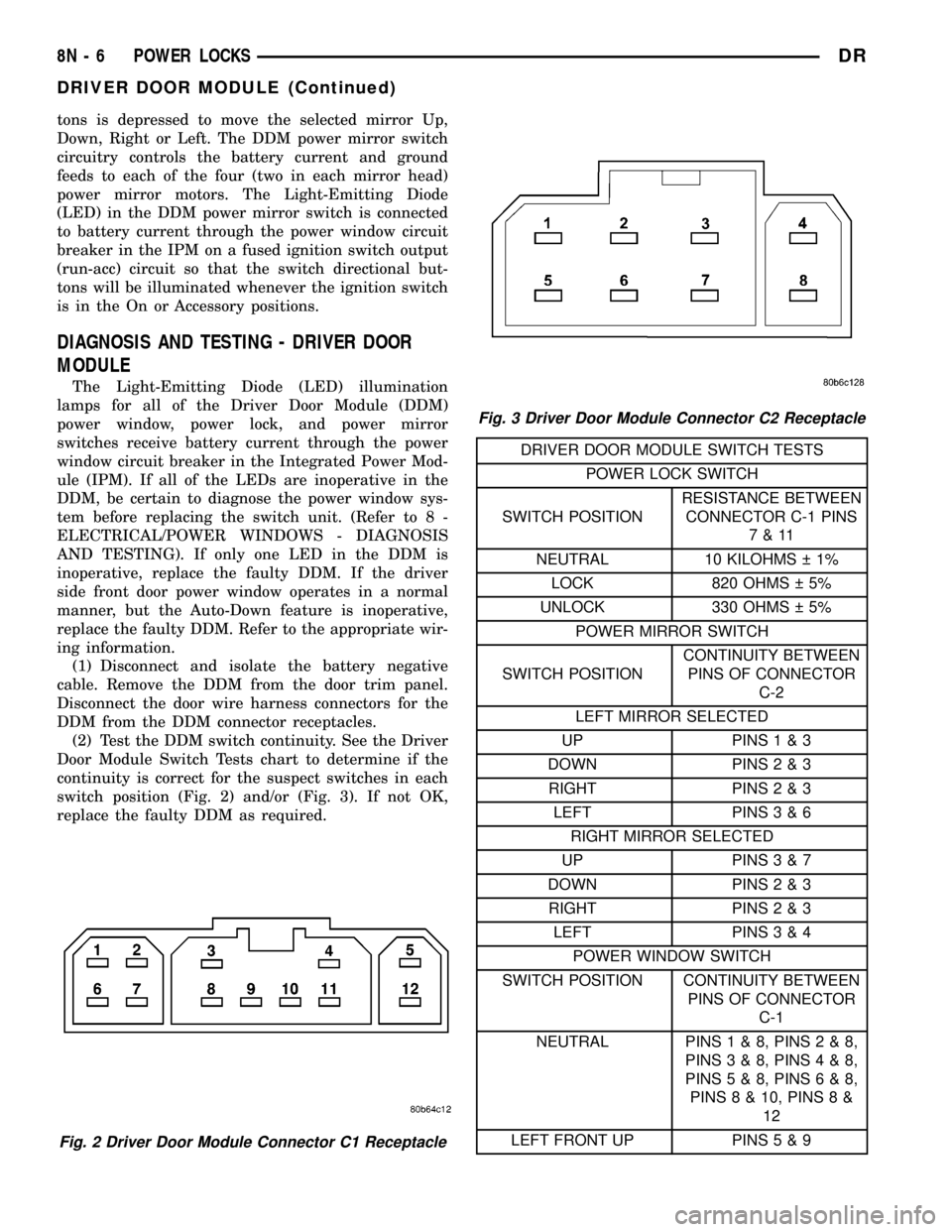

(2) Test the DDM switch continuity. See the Driver

Door Module Switch Tests chart to determine if the

continuity is correct for the suspect switches in each

switch position (Fig. 2) and/or (Fig. 3). If not OK,

replace the faulty DDM as required.

DRIVER DOOR MODULE SWITCH TESTS

POWER LOCK SWITCH

SWITCH POSITIONRESISTANCE BETWEEN

CONNECTOR C-1 PINS

7&11

NEUTRAL 10 KILOHMS 1%

LOCK 820 OHMS 5%

UNLOCK 330 OHMS 5%

POWER MIRROR SWITCH

SWITCH POSITIONCONTINUITY BETWEEN

PINS OF CONNECTOR

C-2

LEFT MIRROR SELECTED

UP PINS1&3

DOWN PINS2&3

RIGHT PINS2&3

LEFT PINS3&6

RIGHT MIRROR SELECTED

UP PINS3&7

DOWN PINS2&3

RIGHT PINS2&3

LEFT PINS3&4

POWER WINDOW SWITCH

SWITCH POSITION CONTINUITY BETWEEN

PINS OF CONNECTOR

C-1

NEUTRAL PINS1&8,PINS2&8,

PINS3&8,PINS4&8,

PINS5&8,PINS6&8,

PINS 8 & 10, PINS 8 &

12

LEFT FRONT UP PINS5&9

Fig. 2 Driver Door Module Connector C1 Receptacle

Fig. 3 Driver Door Module Connector C2 Receptacle

8N - 6 POWER LOCKSDR

DRIVER DOOR MODULE (Continued)

Page 604 of 2627

DRIVER DOOR MODULE SWITCH TESTS

LEFT FRONT DOWN PINS9&12

RIGHT FRONT UP PINS3&9

RIGHT FRONT DOWN PINS6&9

LEFT REAR UP PINS4&9

LEFT REAR DOWN PINS9&10

RIGHT REAR UP PINS2&9

RIGHT REAR DOWN PINS1&9

POWER WINDOW LOCKOUT SWITCH

SWITCH POSITION CONTINUITY BETWEEN

OFF (SWITCH BUTTON

RAISED - NOT

DEPRESSED)PIN 9 OF CONNECTOR

C-1&PIN8OF

CONNECTOR C-2

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door trim panel (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(3) Remove the driver door module from the trim

panel bezel.

INSTALLATION

(1) Install driver door module to trim panel bezel.

(2) Install door trim panel (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION).

(3) Connect battery negative cable.

REMOTE KEYLESS ENTRY

MODULE

DESCRIPTION

When an RKE lock message is sent to the instru-

ment cluster, the instrument cluster actuates the

door locks, the interior lighting is turned off, the

horn chirps (if this feature is enabled), the park

lamps flash (if this feature is enabled) and, if the

vehicle is so equipped, the Vehicle Theft Security

System (VTSS) is armed. When an RKE unlock mes-

sage is sent to the instrument cluster, the instrument

cluster actuates the driver side front door (or all

doors if this feature is enabled) unlock, the interior

lighting is turned on and, if the vehicle is so

equipped, the VTSS is disarmed.

When an RKE panic message is sent to the instru-

ment cluster, the instrument cluster actuates the

driver side front door (or all doors if this feature is

enabled) unlock, the interior lighting is turned on

and, if the vehicle is so equipped, the VTSS is dis-

armed. The panic message will also cause the exte-

rior lamps (including the headlights) to flash, andthe horn to sound for about three minutes, or until a

second panic message is sent to the instrument clus-

ter. A vehicle speed of about 25.7 kilometers-per-hour

(15 miles-per-hour) will also cancel the panic event.

Refer to the owner's manual for more information

on the features, use and operation of the RKE sys-

tem.

OPERATION

Whenever the vehicle battery power is interrupted,

the Remote Keyless Module (RKE) Module will retain

all vehicle access codes in its memory. When replac-

ing or adding a key fob transmitter (maximum of 4) a

DRB IIItscan tool is required to program the RKE

Module to accept the new Vehicle Access Code if a

customer owned transmitter is not available.

If a functioning transmitter is available, (Refer to 8

- ELECTRICAL/POWER LOCKS/KEYLESS ENTRY

TRANSMITTER - STANDARD PROCEDURE)

DIAGNOSIS AND TESTING - REMOTE KEYLESS

ENTRY MODULE

The most reliable, efficient, and accurate means to

diagnose the power lock system requires the use of a

DRBIIItscan tool and the proper Diagnostic Proce-

dures manual.

Refer to the appropriate wiring information.

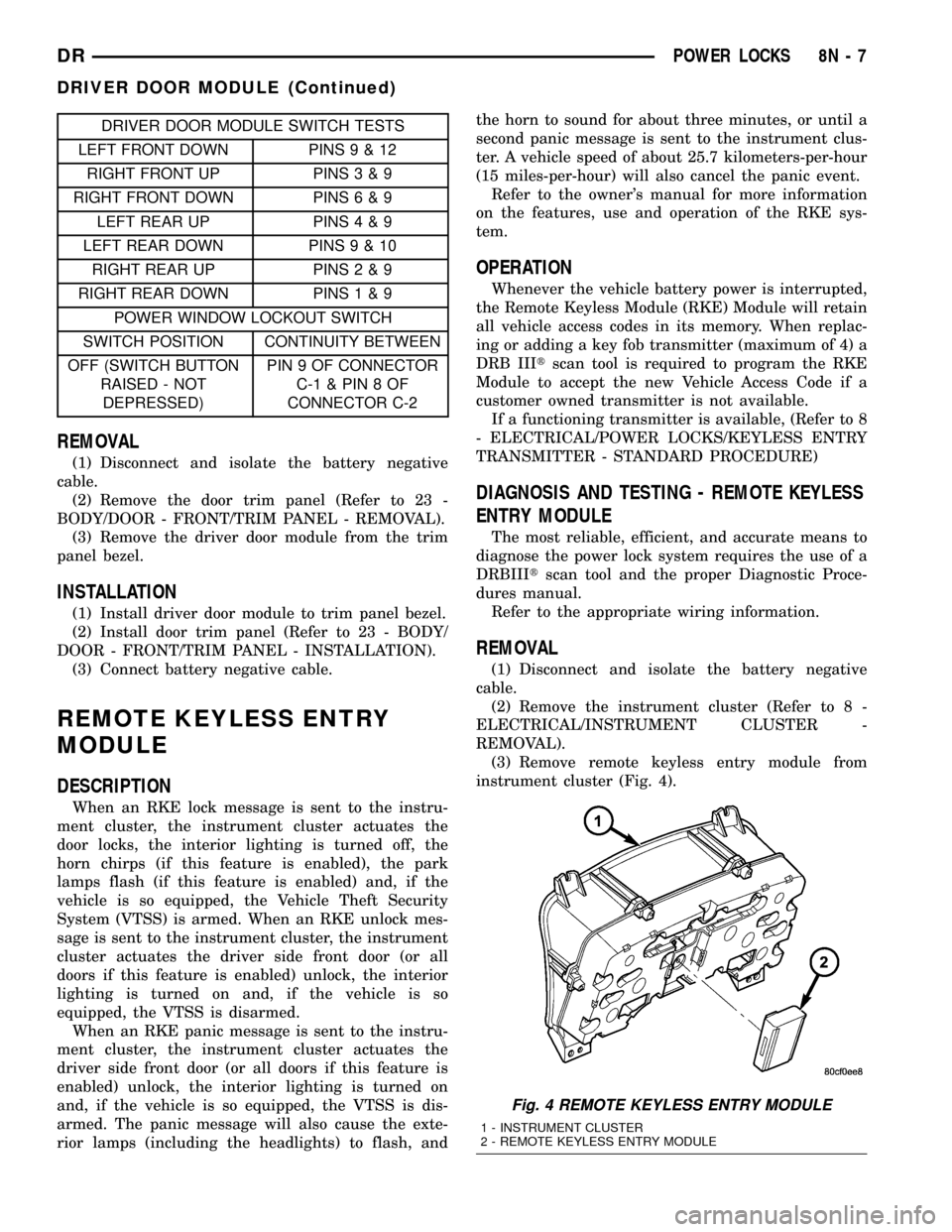

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument cluster (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER -

REMOVAL).

(3) Remove remote keyless entry module from

instrument cluster (Fig. 4).

Fig. 4 REMOTE KEYLESS ENTRY MODULE

1 - INSTRUMENT CLUSTER

2 - REMOTE KEYLESS ENTRY MODULE

DRPOWER LOCKS 8N - 7

DRIVER DOOR MODULE (Continued)

Page 605 of 2627

INSTALLATION

(1) Install remote keyless entry module to instru-

ment cluster.

(2) Install instrument cluster (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - INSTALLA-

TION).

(3) Connect the battery negative cable.

REMOTE KEYLESS ENTRY

TRANSMITTER

DIAGNOSIS AND TESTING - REMOTE KEYLESS

ENTRY TRANSMITTER

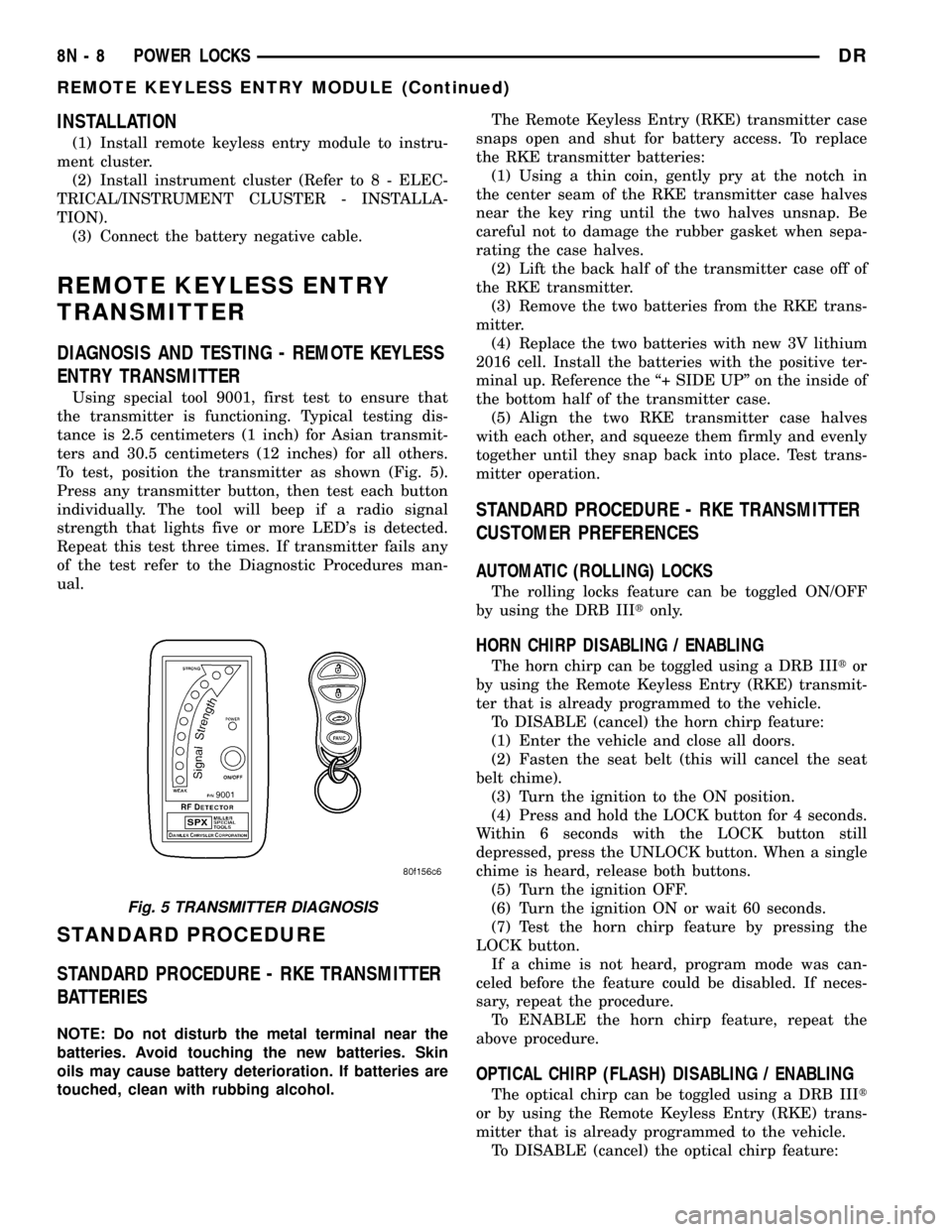

Using special tool 9001, first test to ensure that

the transmitter is functioning. Typical testing dis-

tance is 2.5 centimeters (1 inch) for Asian transmit-

ters and 30.5 centimeters (12 inches) for all others.

To test, position the transmitter as shown (Fig. 5).

Press any transmitter button, then test each button

individually. The tool will beep if a radio signal

strength that lights five or more LED's is detected.

Repeat this test three times. If transmitter fails any

of the test refer to the Diagnostic Procedures man-

ual.

STANDARD PROCEDURE

STANDARD PROCEDURE - RKE TRANSMITTER

BATTERIES

NOTE: Do not disturb the metal terminal near the

batteries. Avoid touching the new batteries. Skin

oils may cause battery deterioration. If batteries are

touched, clean with rubbing alcohol.The Remote Keyless Entry (RKE) transmitter case

snaps open and shut for battery access. To replace

the RKE transmitter batteries:

(1) Using a thin coin, gently pry at the notch in

the center seam of the RKE transmitter case halves

near the key ring until the two halves unsnap. Be

careful not to damage the rubber gasket when sepa-

rating the case halves.

(2) Lift the back half of the transmitter case off of

the RKE transmitter.

(3) Remove the two batteries from the RKE trans-

mitter.

(4) Replace the two batteries with new 3V lithium

2016 cell. Install the batteries with the positive ter-

minal up. Reference the ª+ SIDE UPº on the inside of

the bottom half of the transmitter case.

(5) Align the two RKE transmitter case halves

with each other, and squeeze them firmly and evenly

together until they snap back into place. Test trans-

mitter operation.

STANDARD PROCEDURE - RKE TRANSMITTER

CUSTOMER PREFERENCES

AUTOMATIC (ROLLING) LOCKS

The rolling locks feature can be toggled ON/OFF

by using the DRB IIItonly.

HORN CHIRP DISABLING / ENABLING

The horn chirp can be toggled using a DRB IIItor

by using the Remote Keyless Entry (RKE) transmit-

ter that is already programmed to the vehicle.

To DISABLE (cancel) the horn chirp feature:

(1) Enter the vehicle and close all doors.

(2) Fasten the seat belt (this will cancel the seat

belt chime).

(3) Turn the ignition to the ON position.

(4) Press and hold the LOCK button for 4 seconds.

Within 6 seconds with the LOCK button still

depressed, press the UNLOCK button. When a single

chime is heard, release both buttons.

(5) Turn the ignition OFF.

(6) Turn the ignition ON or wait 60 seconds.

(7) Test the horn chirp feature by pressing the

LOCK button.

If a chime is not heard, program mode was can-

celed before the feature could be disabled. If neces-

sary, repeat the procedure.

To ENABLE the horn chirp feature, repeat the

above procedure.

OPTICAL CHIRP (FLASH) DISABLING / ENABLING

The optical chirp can be toggled using a DRB IIIt

or by using the Remote Keyless Entry (RKE) trans-

mitter that is already programmed to the vehicle.

To DISABLE (cancel) the optical chirp feature:

Fig. 5 TRANSMITTER DIAGNOSIS

8N - 8 POWER LOCKSDR

REMOTE KEYLESS ENTRY MODULE (Continued)

Page 606 of 2627

(1) Enter the vehicle and close all doors.

(2) Fasten the seat belt (this will cancel the seat

belt chime).

(3) Turn the ignition to the ON position.

(4) Press and hold the LOCK button for 4 seconds.

Within 6 seconds with the LOCK button still

depressed, press the PANIC button. When a single

chime is heard, release both buttons.

(5) Turn the ignition OFF.

(6) Turn the ignition ON or wait 60 seconds.

(7) Test the optical chirp feature by pressing the

LOCK button.

If a chime is not heard, program mode was can-

celed before the feature could be disabled. If neces-

sary, repeat the procedure.

To ENABLE the optical chirp feature, repeat the

above procedure.

UNLOCK SEQUENCE

The unlock sequence can be toggled using a DRB

IIItor by using the Remote Keyless Entry (RKE)

transmitter that is already programmed to the vehi-

cle.

To toggle between Driver door first and Unlock all

doors function:

(1) Enter the vehicle and close all doors.

(2) Fasten the seat belt (this will cancel the seat

belt chime).

(3) Turn the ignition to the ON position.

(4) Press and hold the UNLOCK button for 4 sec-

onds. Within 6 seconds with the UNLOCK button

still depressed, press the LOCK button. When a sin-

gle chime is heard, release both buttons.

(5) Turn the ignition OFF.

(6) Turn the ignition ON or wait 60 seconds.

If a chime is not heard, program mode was can-

celed before the feature could be disabled. If neces-

sary, repeat the procedure.

To toggle this feature, repeat the above procedure.

STANDARD PROCEDURE - RKE TRANSMITTER

PROGRAMING

New Remote Keyless Entry (RKE) transmitters can

be programed using the DRB IIItscan tool and the

proper Diagnostic Procedures manual. The DRB IIIt

scan tool can provide confirmation that the PCI data

bus is functional, and that all of the electronic mod-

ules are sending and receiving the proper messages

on the PCI data bus.The following procedure can be used as long as one

programmed transmitter is available:

NOTE: When entering program mode using that

programmed fob, ALL currently programmed fobs

will be erased and they will have to be repro-

grammed for the vehicle. If program mode is

entered and no action is performed, the previously

programmed fobs will continue to function.

(1) Enter the vehicle and close all doors.

(2) Fasten the seat belt (this will cancel the seat

belt chime). Turn the ignition to the RUN position.

(3) Press and hold the UNLOCK button on a pro-

grammed transmitter for 4 to 10 seconds. Within the

4 to 10 seconds with the UNLOCK button still

depressed, press the PANIC button for one second.

When a single chime is heard, release both button-

s.The chime indicates the system is in program

mode.

(4) Press and release both the LOCK and

UNLOCK buttons simultaneously on a fob to be pro-

grammed. A single chime will be heard, this indicates

the fob has been recognized.

(5) Press and release any button on the same fob.

A single chime will be heard, this indicates the fob

has been programmed.

(6) Repeat steps 4 and 5 for up to a total of 4 fobs.

(7) Turn the ignition OFF.

(8) Turn the ignition ON or wait 60 seconds.

The vehicle will remain in program mode for up to

60 seconds from when the original chime (step 3) was

heard. After 60 seconds, all programmed transmitters

will function normally.

SPECIFICATIONS - REMOTE KEYLESS ENTRY

TRANSMITTER

RANGE

Normal operation range is up to a distance of 3 to

7 meters (10 to 23 ft.) of the vehicle. Range may be

better or worse depending on the environment

around the vehicle.

DRPOWER LOCKS 8N - 9

REMOTE KEYLESS ENTRY TRANSMITTER (Continued)

Page 607 of 2627

POWER MIRRORS

TABLE OF CONTENTS

page page

POWER MIRRORS

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - POWER

MIRRORS...........................10

AUTOMATIC DAY / NIGHT MIRROR

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING - AUTOMATIC DAY

/ NIGHT MIRROR......................11REMOVAL.............................12

POWER MIRROR SWITCH

DIAGNOSIS AND TESTING - POWER MIRROR

SWITCH............................12

REMOVAL.............................12

SIDEVIEW MIRROR

REMOVAL.............................12

POWER MIRRORS

DESCRIPTION

AUTOMATIC DAY/NIGHT MIRROR

The automatic day/night mirror system is able to

automatically change the reflectance of the inside

rear view mirror in order to reduce the glare of head-

lamps approaching the vehicle from the rear. The

automatic day/night rear view mirror receives bat-

tery current through a fuse in the Integrated Power

Module (IPM) only when the ignition switch is in the

On position.

OUTSIDE REAR VIEW MIRROR

The power operated outside rear view mirrors

allow the driver to adjust both outside mirrors elec-

trically from the driver side front seat position by

operating a switch on the driver side front door trim

panel. The power mirrors receive a non-switched bat-

tery feed through a fuse in the Integrated Power

Module (IPM) so that the system will remain opera-

tional, regardless of the ignition switch position.

OPERATION

AUTOMATIC DAY/NIGHT MIRROR

A switch located on the bottom of the automatic

day/night mirror housing allows the vehicle operator

to select whether the automatic dimming feature is

operational. When the automatic day/night mirror is

turned on, the mirror switch is lighted by an integral

Light-Emitting Diode (LED). The mirror will auto-

matically disable its self-dimming feature whenever

the vehicle is being driven in reverse.

OUTSIDE REAR VIEW MIRROR

The heated mirrors include an electric heating grid

behind the mirror glass in each outside mirror, which

can clear the mirror glass of ice, snow, or fog. (Refer

to 8 - ELECTRICAL/HEATED MIRRORS -

DESCRIPTION) for more information.

DIAGNOSIS AND TESTING - POWER MIRRORS

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to switch.

(1) Remove the power mirror switch (Refer to 8 -

ELECTRICAL/POWER LOCKS/DOOR MODULE -

REMOVAL).

(2) Disconnect wire harness connector from back of

power mirror switch.

(3) Connect the clip end of a 12 volt test light to

Pin 5 in the mirror switch harness connector. Touch

the test light probe to Pin 3.

If the test light illuminates, the wiring circuit

between the battery and switch is OK.

If the lamp does not illuminate, first check fuse in

the Integrated Power Module (IPM). If fuse is OK,

then check for a broken wire.

Refer to the appropriate wiring information.

POWER MIRROR MOTOR TEST

If the power mirror switch is receiving proper cur-

rent and ground and mirrors do not operate, proceed

with power mirror motor test. Refer to the appropri-

ate wiring information.

(1) Remove the power mirror switch (Refer to 8 -

ELECTRICAL/POWER LOCKS/DOOR MODULE -

REMOVAL).

8N - 10 POWER MIRRORSDR

Page 609 of 2627

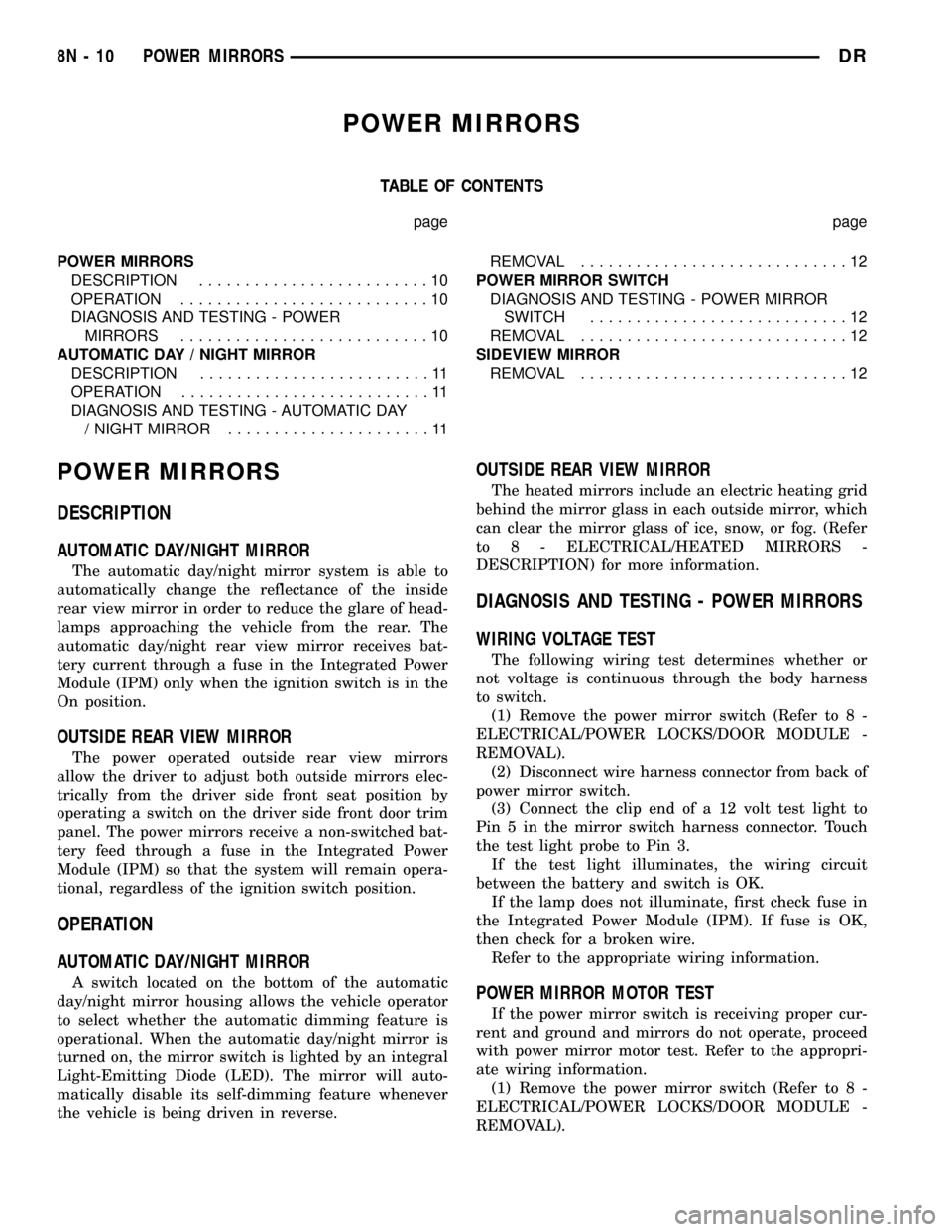

(5) Connect the battery negative cable. Turn the

ignition switch to the On position. Set the parking

brake. Place the transmission gear selector lever in

the Reverse position. Check for battery voltage at the

backup lamp switch output circuit cavity of the auto-

matic day/night mirror wire harness connector. If

OK, go to Step 6. If not OK, repair the open circuit

as required.

(6) Turn the ignition switch to the Off position.

Disconnect the battery negative cable. Plug in the

automatic day/night mirror wire harness connector.

Connect the battery negative cable. Turn the ignition

switch to the On position. Place the transmission

gear selector lever in the Neutral position. Place the

mirror switch in the On (the LED in the mirror

switch is lighted) position. Cover the forward facing

ambient photocell sensor to keep out any ambient

light.NOTE: The ambient photocell sensor must be cov-

ered completely, so that no light reaches the sen-

sor. Use a finger pressed tightly against the sensor,

or cover the sensor completely with electrical tape.

(7) Shine a light into the rearward facing head-

lamp photocell sensor. The mirror glass should

darken. If OK, go to Step 8. If not OK, replace the

faulty automatic day/night mirror unit.

(8) With the mirror glass darkened, place the

transmission gear selector lever in the Reverse posi-

tion. The mirror should return to its normal reflec-

tance. If not OK, replace the faulty automatic day/

night mirror unit.

REMOVAL

For removal procedures, (Refer to 23 - BODY/IN-

TERIOR/REAR VIEW MIRROR - REMOVAL).

POWER MIRROR SWITCH

DIAGNOSIS AND TESTING - POWER MIRROR

SWITCH

The power mirror switch is included with the

Driver Door Module. (Refer to 8 - ELECTRICAL/

POWER LOCKS/DOOR MODULE - DIAGNOSIS

AND TESTING).

REMOVAL

The power mirror switch is included with the

Driver Door Module. (Refer to 8 - ELECTRICAL/

POWER LOCKS/DOOR MODULE - REMOVAL).

SIDEVIEW MIRROR

REMOVAL

(Refer to 23 - BODY/EXTERIOR/SIDE VIEW MIR-

ROR - REMOVAL).

Fig. 2 Automatic Day/Night Mirror

1 - REAR FACING SENSOR

2 - CONNECTOR

3 - FORWARD FACING SENSOR

4 - SWITCH

8N - 12 POWER MIRRORSDR

AUTOMATIC DAY / NIGHT MIRROR (Continued)

Page 616 of 2627

POWER WINDOWS

TABLE OF CONTENTS

page page

POWER WINDOWS

DESCRIPTION.........................19

OPERATION...........................19

DIAGNOSIS AND TESTING - POWER

WINDOWS...........................19

WINDOW MOTOR

REMOVAL.............................20WINDOW SWITCH

DIAGNOSIS AND TESTING - WINDOW

SWITCH............................20

REMOVAL.............................20

INSTALLATION.........................21

POWER WINDOWS

DESCRIPTION

The power window system allows each of the door

windows to be raised and lowered electrically by

actuating a switch on each door panel. A master

switch on the drivers door allows the driver to raise

or lower each of the passenger door windows and to

lock out the individual switches on the passenger

doors from operation. The power window system

receives battery feed through a fuse in the Integrated

Power Module (IPM) and a circuit breaker located in

the instrument panel wiring harness near the park

brake pedal, only when the ignition switch is in the

RUN or ACCESSORY position.

OPERATION

WINDOW SWITCH

The power window switches control the battery

and ground feeds to the power window motors. The

passenger door power window switches receive their

battery and ground feeds through the circuitry of the

drivers window switch. When the power window lock-

out switch is in the Lock position, the battery feed

for the passenger door window switches is inter-

rupted.

WINDOW MOTOR

Window motors use permanent type magnets. The

B+ and ground applied at the motor terminal pins

will cause the motor to rotate in one direction.

Reversing current through the motor terminals will

cause the motor to rotate in the opposite direction.

DIAGNOSIS AND TESTING - POWER

WINDOWS

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to the front switch.

(1) Remove the Driver Door Module (Refer to 8 -

ELECTRICAL/POWER LOCKS/DOOR MODULE -

REMOVAL).

(2) Disconnect wire connector from back of power

window switch.

(3) Switch ignition to the ON position.

(4) Connect the clip end of a 12 volt test light to

Pin 14 of the window switch harness connector.

Touch the test light probe to Pin 10.

²If the test light illuminates, the wiring circuit

between the battery and switch is OK.

²If the lamp does not illuminate, first check the

fuse in the Integrated Power Module (IPM). Check

the circuit breaker located near the park brake

pedal. If fuse and circuit breaker are OK, then check

for a broken wire.

Refer to the appropriate wiring information.

POWER WINDOW MOTOR TEST

If the power window motor is receiving proper cur-

rent and ground and does not operate, proceed with

motor test.

(1) Remove front door trim panel as necessary to

gain access to power window motor wire connector

(Refer to 23 - BODY/DOOR - FRONT/TRIM PANEL -

REMOVAL).

(2) Disconnect power window motor wire connector

from door harness.

(3) Using two jumper wires, connect one to a bat-

tery (+) source and the other to a good ground (-).

(4) Connect the Negative (-) jumper probe to one of

the motor connector terminals.

DRPOWER WINDOWS 8N - 19

Page 617 of 2627

(5) Momentarily touch the Positive (+) jumper

probe to the other motor connector terminal.

When positive probe is connected the motor should

rotate in one direction to either move window up or

down. If window is all the way up or down the motor

will grunt and the inner door panel will flex when

actuated in that one direction.

(6) Reverse jumper probes at the motor connector

terminals and window should now move in opposite

direction. If window does not move or grunt, replace

the motor.

If window moved completely up or down, reverse

the jumper probes and cycle window to the opposite

position to verify full operation.

If motor grunts and does not move, verify that reg-

ulator is not binding.

WINDOW MOTOR

REMOVAL

The window motor is serviced with the window

regulator (Refer to 23 - BODY/DOOR - FRONT/WIN-

DOW REGULATOR - REMOVAL) or (Refer to 23 -

BODY/DOORS - REAR/WINDOW REGULATOR -

REMOVAL).

WINDOW SWITCH

DIAGNOSIS AND TESTING - WINDOW SWITCH

The Light-Emitting Diode (LED) illumination

lamps for all of the power window and lock switch

and bezel unit switch paddles receive battery current

through the power window circuit breaker in the

junction block. If all of the LEDs are inoperative in

both the power window and lock switch units and the

power windows are inoperative, (Refer to 8 - ELEC-

TRICAL/POWER WINDOWS - DIAGNOSIS AND

TESTING). If the power windows operate, but any or

all of the LEDs are inoperative, the power window

and lock switch units with the inoperative LED(s) is

faulty and must be replaced. For complete circuit dia-

grams, refer to the appropriate wiring information.

(1) Check the fuse in the Integrated Power Module

(IPM) and the circuit breaker located near the park

brake pedal. If OK, go to Step 2. If not OK, replace

the faulty fuse or circuit breaker.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the Inte-

grated Power Module (IPM). If OK, turn the ignition

switch to the Off position and go to Step 3. If not OK,

check circuit breaker and repair the circuit to the

ignition switch as required.

(3) Disconnect and isolate the battery negative

cable. Remove the power window switch unit fromthe door trim panel (passenger doors). The drivers

door switch is included with the Driver Door Module

(Refer to 8 - ELECTRICAL/POWER LOCKS/DOOR

MODULE - DIAGNOSIS AND TESTING) for service

procedures. Unplug the wire harness connector from

the switch unit.

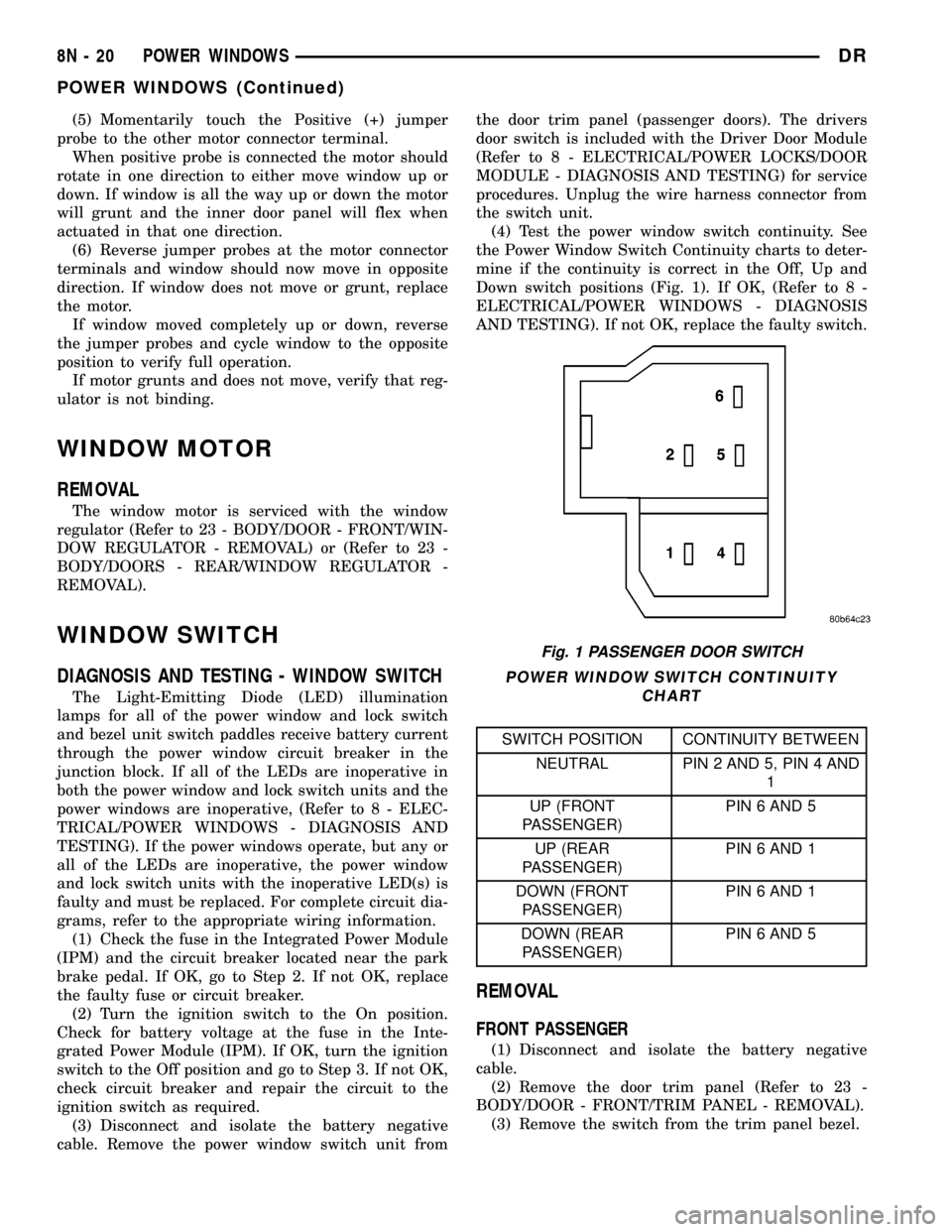

(4) Test the power window switch continuity. See

the Power Window Switch Continuity charts to deter-

mine if the continuity is correct in the Off, Up and

Down switch positions (Fig. 1). If OK, (Refer to 8 -

ELECTRICAL/POWER WINDOWS - DIAGNOSIS

AND TESTING). If not OK, replace the faulty switch.

POWER WINDOW SWITCH CONTINUITY

CHART

SWITCH POSITION CONTINUITY BETWEEN

NEUTRAL PIN 2 AND 5, PIN 4 AND

1

UP (FRONT

PASSENGER)PIN 6 AND 5

UP (REAR

PASSENGER)PIN 6 AND 1

DOWN (FRONT

PASSENGER)PIN 6 AND 1

DOWN (REAR

PASSENGER)PIN 6 AND 5

REMOVAL

FRONT PASSENGER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door trim panel (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(3) Remove the switch from the trim panel bezel.

Fig. 1 PASSENGER DOOR SWITCH

8N - 20 POWER WINDOWSDR

POWER WINDOWS (Continued)

Page 623 of 2627

²Airbag Indicator- The airbag indicator is inte-

gral to the ElectroMechanical Instrument Cluster

(EMIC), which is located on the instrument panel in

front of the driver.

²Clockspring- The clockspring is located near

the top of the steering column, directly beneath the

steering wheel.

²Driver Airbag- The driver airbag is located in

the center of the steering wheel, beneath the driver

airbag trim cover.

²Driver Knee Blocker- The driver knee blocker

is a structural unit secured to the back side of and

integral to the instrument panel steering column

opening cover.

²Passenger Airbag- The passenger airbag is

located on the instrument panel, beneath the passen-

ger airbag door on the instrument panel above the

glove box on the passenger side of the vehicle.

²Passenger Airbag On/Off Switch- Standard

cab models without a rear seat are equipped with a

passenger airbag on/off switch, which is located on

the right side of the instrument panel center bezel.

²Passenger Knee Blocker- The passenger knee

blocker is a structural reinforcement that is integral

to and concealed within the glove box door.

²Seat Belt Tensioner- The seat belt tensioner

is integral to the front outboard seat belt retractor

units on vehicles equipped with dual front airbags.

²Side Impact Sensor- Two side impact sensors

are used on vehicles equipped with the optional side

curtain airbags, one left side and one right side. One

sensor is located behind the B-pillar trim near the

base of each B-pillar.

²Side Curtain Airbag- In vehicles equipped

with this option, a side curtain airbag is located on

each inside roof side rail above the headliner, and

extends from the A-pillar to the B-pillar on standard

cab models, and from the A-pillar to the C-pillar on

quad cab models.The ACM and the EMIC each contain a central

processing unit and programming that allow them to

communicate with each other using the Programma-

ble Communications Interface (PCI) data bus net-

work. This method of communication is used by the

ACM for control of the airbag indicator on all models

equipped with dual front airbags. (Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/

COMMUNICATION - DESCRIPTION).

Hard wired circuitry connects the supplemental

restraint system components to each other through

the electrical system of the vehicle. These hard wired

circuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system,

and to the supplemental restraint system compo-

nents through the use of a combination of soldered

splices, splice block connectors, and many different

types of wire harness terminal connectors and insu-

lators. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

OPERATION

ACTIVE RESTRAINTS

The primary passenger restraints in this or any

other vehicle are the standard equipment factory-in-

stalled seat belts and child restraint anchors. Seat

belts and child restraint anchors are referred to as

an active restraint because the vehicle occupants are

required to physically fasten and properly adjust

these restraints in order to benefit from them. See

the owner's manual in the vehicle glove box for more

information on the features, use and operation of all

of the factory-installed active restraints.

PASSIVE RESTRAINTS

The passive restraints are referred to as a supple-

mental restraint system because they were designed

and are intended to enhance the protection for the

occupants of the vehicleonlywhen used in conjunc-

tion with the seat belts. They are referred to as pas-

sive restraints because the vehicle occupants are not

required to do anything to make them operate; how-

ever, the vehicle occupants must be wearing their

seat belts in order to obtain the maximum safety

benefit from the factory-installed supplemental

restraint system.

The supplemental restraint system electrical cir-

cuits are continuously monitored and controlled by a

microprocessor and software contained within the

Fig. 2 SRS Logo

8O - 4 RESTRAINTSDR

RESTRAINTS (Continued)