lug pattern DODGE RAM 1500 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1938 of 2627

INSTALLATION

(1) Be sure overdrive unit Alignment Tool 6227-2

is fully seated before moving unit. If tool is not

seated and gear splines rotate out of alignment, over-

drive unit will have to be disassembled in order to

realign splines.

(2) If overdrive piston retainer was not removed

during service and original case gasket is no longer

reusable, prepare new gasket by trimming it.

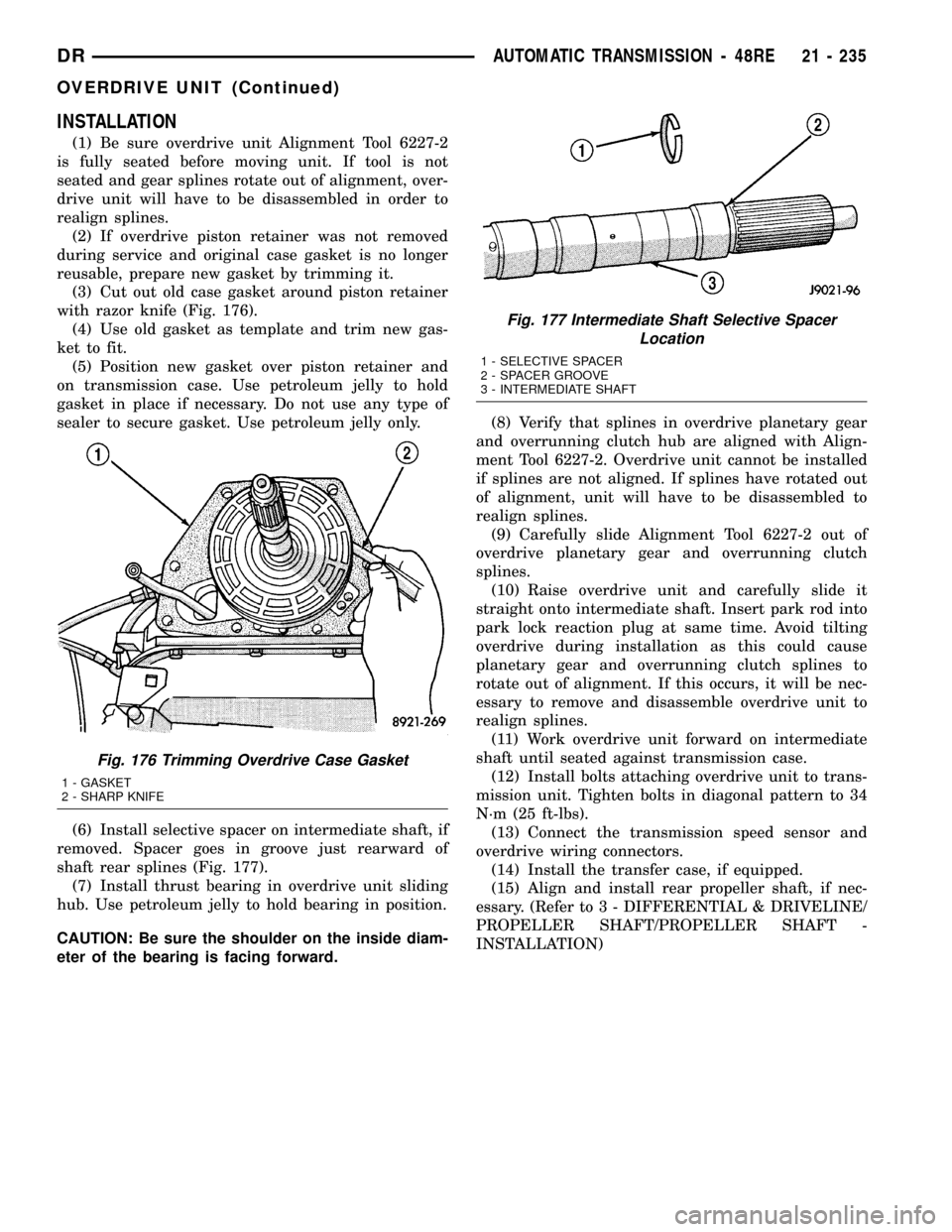

(3) Cut out old case gasket around piston retainer

with razor knife (Fig. 176).

(4) Use old gasket as template and trim new gas-

ket to fit.

(5) Position new gasket over piston retainer and

on transmission case. Use petroleum jelly to hold

gasket in place if necessary. Do not use any type of

sealer to secure gasket. Use petroleum jelly only.

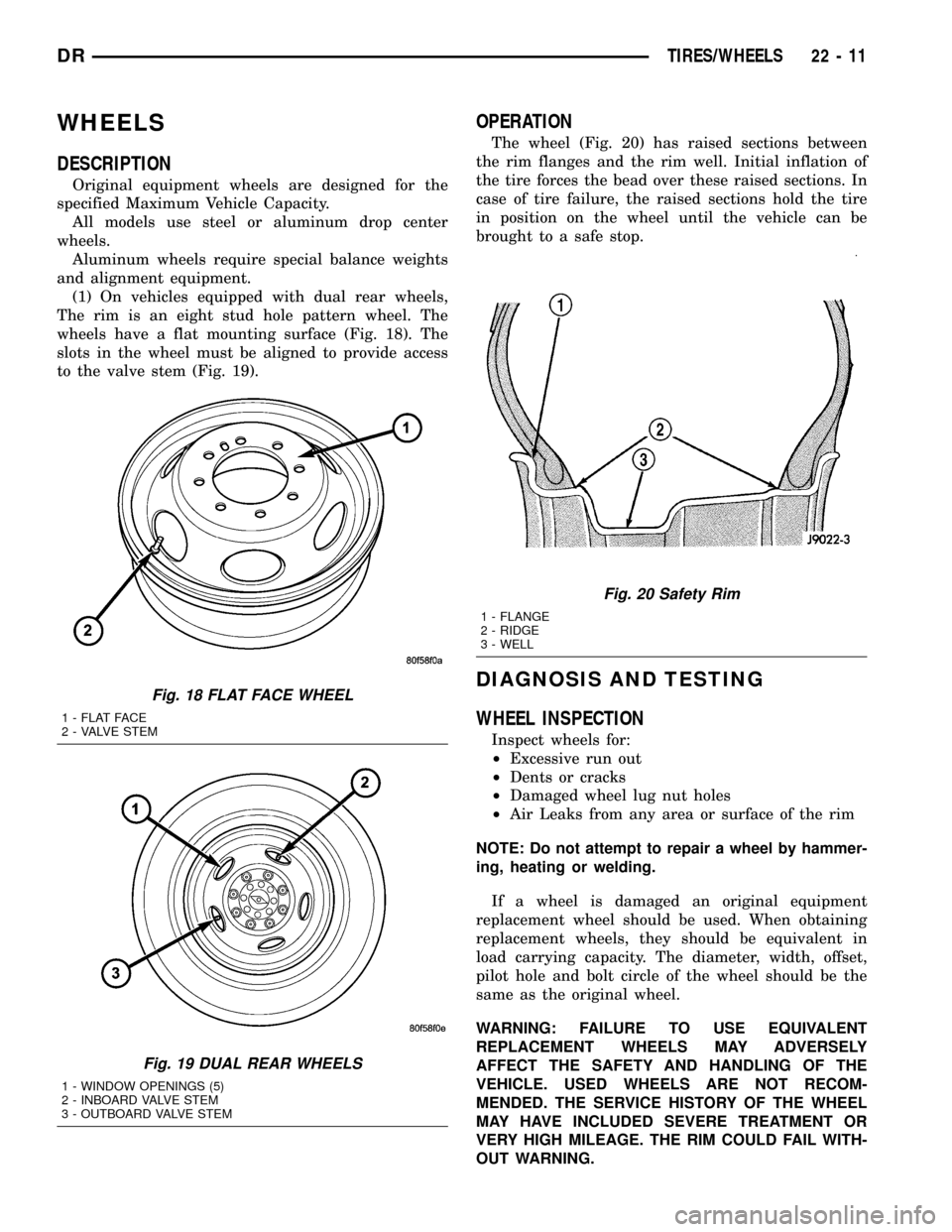

(6) Install selective spacer on intermediate shaft, if

removed. Spacer goes in groove just rearward of

shaft rear splines (Fig. 177).

(7) Install thrust bearing in overdrive unit sliding

hub. Use petroleum jelly to hold bearing in position.

CAUTION: Be sure the shoulder on the inside diam-

eter of the bearing is facing forward.(8) Verify that splines in overdrive planetary gear

and overrunning clutch hub are aligned with Align-

ment Tool 6227-2. Overdrive unit cannot be installed

if splines are not aligned. If splines have rotated out

of alignment, unit will have to be disassembled to

realign splines.

(9) Carefully slide Alignment Tool 6227-2 out of

overdrive planetary gear and overrunning clutch

splines.

(10) Raise overdrive unit and carefully slide it

straight onto intermediate shaft. Insert park rod into

park lock reaction plug at same time. Avoid tilting

overdrive during installation as this could cause

planetary gear and overrunning clutch splines to

rotate out of alignment. If this occurs, it will be nec-

essary to remove and disassemble overdrive unit to

realign splines.

(11) Work overdrive unit forward on intermediate

shaft until seated against transmission case.

(12) Install bolts attaching overdrive unit to trans-

mission unit. Tighten bolts in diagonal pattern to 34

N´m (25 ft-lbs).

(13) Connect the transmission speed sensor and

overdrive wiring connectors.

(14) Install the transfer case, if equipped.

(15) Align and install rear propeller shaft, if nec-

essary. (Refer to 3 - DIFFERENTIAL & DRIVELINE/

PROPELLER SHAFT/PROPELLER SHAFT -

INSTALLATION)

Fig. 176 Trimming Overdrive Case Gasket

1 - GASKET

2 - SHARP KNIFE

Fig. 177 Intermediate Shaft Selective Spacer

Location

1 - SELECTIVE SPACER

2 - SPACER GROOVE

3 - INTERMEDIATE SHAFT

DRAUTOMATIC TRANSMISSION - 48RE 21 - 235

OVERDRIVE UNIT (Continued)

Page 2290 of 2627

WHEELS

DESCRIPTION

Original equipment wheels are designed for the

specified Maximum Vehicle Capacity.

All models use steel or aluminum drop center

wheels.

Aluminum wheels require special balance weights

and alignment equipment.

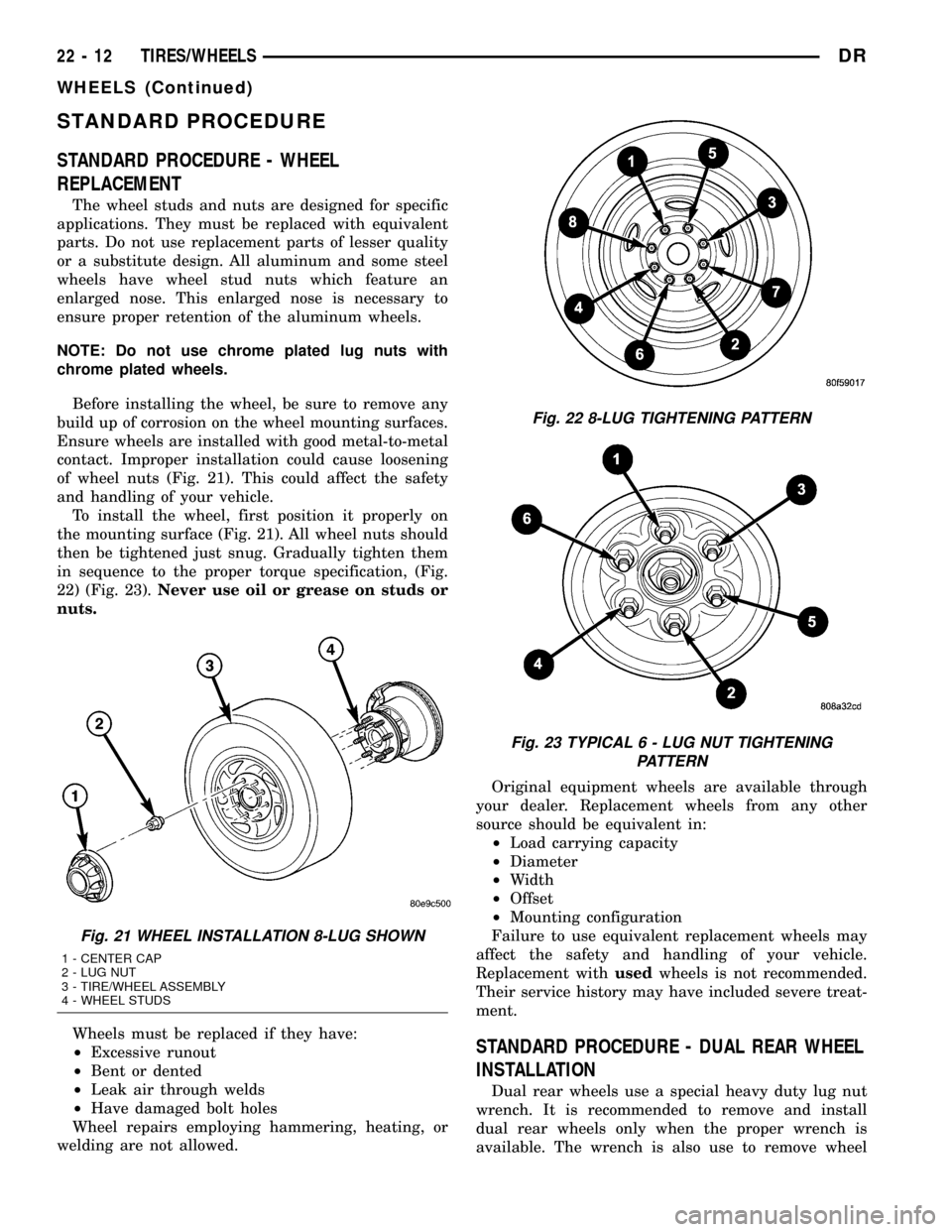

(1) On vehicles equipped with dual rear wheels,

The rim is an eight stud hole pattern wheel. The

wheels have a flat mounting surface (Fig. 18). The

slots in the wheel must be aligned to provide access

to the valve stem (Fig. 19).

OPERATION

The wheel (Fig. 20) has raised sections between

the rim flanges and the rim well. Initial inflation of

the tire forces the bead over these raised sections. In

case of tire failure, the raised sections hold the tire

in position on the wheel until the vehicle can be

brought to a safe stop.

DIAGNOSIS AND TESTING

WHEEL INSPECTION

Inspect wheels for:

²Excessive run out

²Dents or cracks

²Damaged wheel lug nut holes

²Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by hammer-

ing, heating or welding.

If a wheel is damaged an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they should be equivalent in

load carrying capacity. The diameter, width, offset,

pilot hole and bolt circle of the wheel should be the

same as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF THE

VEHICLE. USED WHEELS ARE NOT RECOM-

MENDED. THE SERVICE HISTORY OF THE WHEEL

MAY HAVE INCLUDED SEVERE TREATMENT OR

VERY HIGH MILEAGE. THE RIM COULD FAIL WITH-

OUT WARNING.

Fig. 18 FLAT FACE WHEEL

1 - FLAT FACE

2 - VALVE STEM

Fig. 19 DUAL REAR WHEELS

1 - WINDOW OPENINGS (5)

2 - INBOARD VALVE STEM

3 - OUTBOARD VALVE STEM

Fig. 20 Safety Rim

1 - FLANGE

2 - RIDGE

3 - WELL

DRTIRES/WHEELS 22 - 11

Page 2291 of 2627

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL

REPLACEMENT

The wheel studs and nuts are designed for specific

applications. They must be replaced with equivalent

parts. Do not use replacement parts of lesser quality

or a substitute design. All aluminum and some steel

wheels have wheel stud nuts which feature an

enlarged nose. This enlarged nose is necessary to

ensure proper retention of the aluminum wheels.

NOTE: Do not use chrome plated lug nuts with

chrome plated wheels.

Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces.

Ensure wheels are installed with good metal-to-metal

contact. Improper installation could cause loosening

of wheel nuts (Fig. 21). This could affect the safety

and handling of your vehicle.

To install the wheel, first position it properly on

the mounting surface (Fig. 21). All wheel nuts should

then be tightened just snug. Gradually tighten them

in sequence to the proper torque specification, (Fig.

22) (Fig. 23).Never use oil or grease on studs or

nuts.

Wheels must be replaced if they have:

²Excessive runout

²Bent or dented

²Leak air through welds

²Have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed.Original equipment wheels are available through

your dealer. Replacement wheels from any other

source should be equivalent in:

²Load carrying capacity

²Diameter

²Width

²Offset

²Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle.

Replacement withusedwheels is not recommended.

Their service history may have included severe treat-

ment.

STANDARD PROCEDURE - DUAL REAR WHEEL

INSTALLATION

Dual rear wheels use a special heavy duty lug nut

wrench. It is recommended to remove and install

dual rear wheels only when the proper wrench is

available. The wrench is also use to remove wheel

Fig. 21 WHEEL INSTALLATION 8-LUG SHOWN

1 - CENTER CAP

2 - LUG NUT

3 - TIRE/WHEEL ASSEMBLY

4 - WHEEL STUDS

Fig. 22 8-LUG TIGHTENING PATTERN

Fig. 23 TYPICAL 6 - LUG NUT TIGHTENING

PATTERN

22 - 12 TIRES/WHEELSDR

WHEELS (Continued)

Page 2292 of 2627

center caps for more information refer to Owner's

Manual.

The tires on both wheels must be completely raised

off the ground when tightening the lug nuts. This

will ensure correct wheel centering and maximum

wheel clamping.

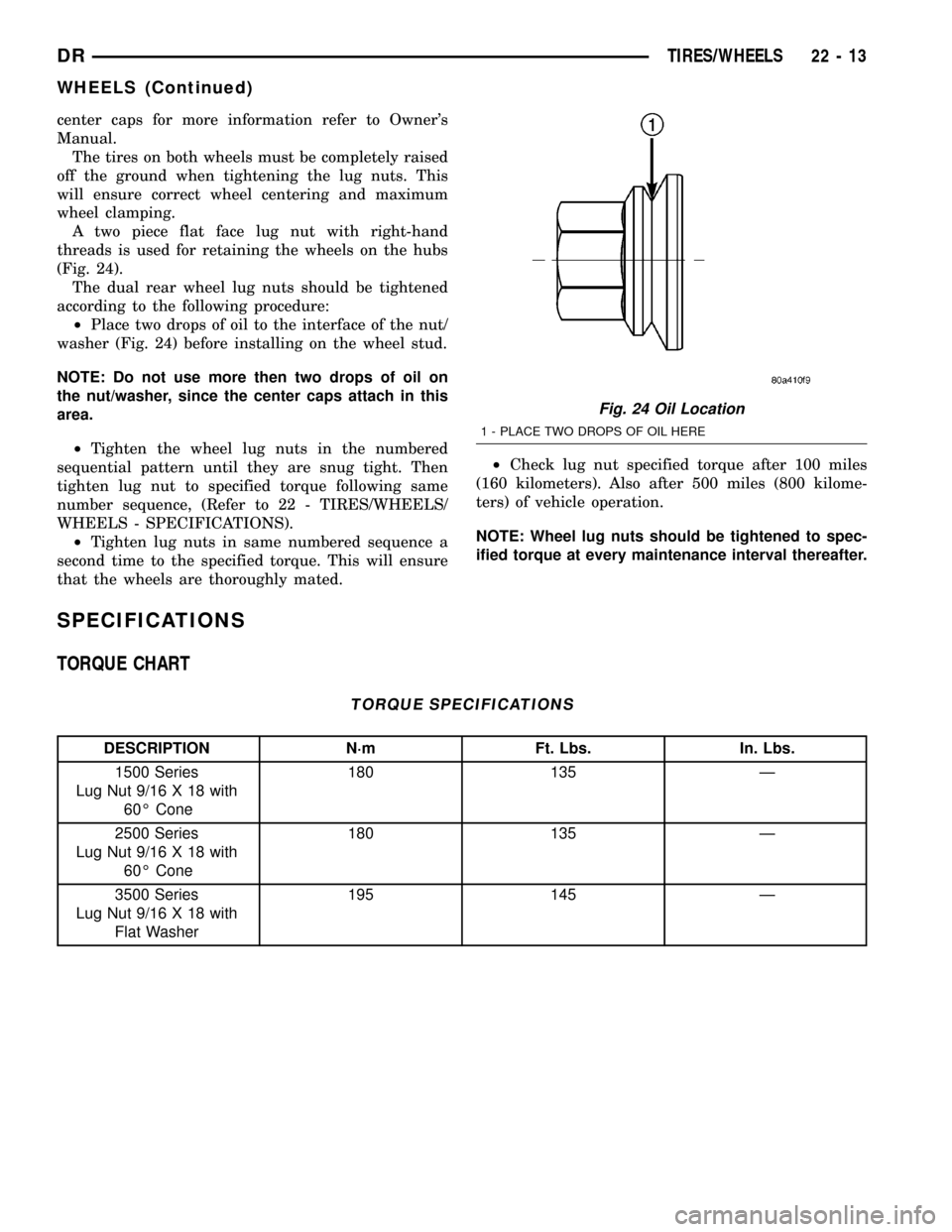

A two piece flat face lug nut with right-hand

threads is used for retaining the wheels on the hubs

(Fig. 24).

The dual rear wheel lug nuts should be tightened

according to the following procedure:

²Place two drops of oil to the interface of the nut/

washer (Fig. 24) before installing on the wheel stud.

NOTE: Do not use more then two drops of oil on

the nut/washer, since the center caps attach in this

area.

²Tighten the wheel lug nuts in the numbered

sequential pattern until they are snug tight. Then

tighten lug nut to specified torque following same

number sequence, (Refer to 22 - TIRES/WHEELS/

WHEELS - SPECIFICATIONS).

²Tighten lug nuts in same numbered sequence a

second time to the specified torque. This will ensure

that the wheels are thoroughly mated.²Check lug nut specified torque after 100 miles

(160 kilometers). Also after 500 miles (800 kilome-

ters) of vehicle operation.

NOTE: Wheel lug nuts should be tightened to spec-

ified torque at every maintenance interval thereafter.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

1500 Series

Lug Nut 9/16 X 18 with

60É Cone180 135 Ð

2500 Series

Lug Nut 9/16 X 18 with

60É Cone180 135 Ð

3500 Series

Lug Nut 9/16 X 18 with

Flat Washer195 145 Ð

Fig. 24 Oil Location

1 - PLACE TWO DROPS OF OIL HERE

DRTIRES/WHEELS 22 - 13

WHEELS (Continued)