ECU DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2551 of 2627

HEATER INLET HOSE

REMOVAL

The heater inlet hose is constructed from rubber

hoses and plastic hose connectors. The ends are

secured to the heater core, engine and engine coolant

reservoir (depending on engine application) by spring

tension clamps.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(2) Remove the heater hose retaining brackets as

required (depending on engine application).

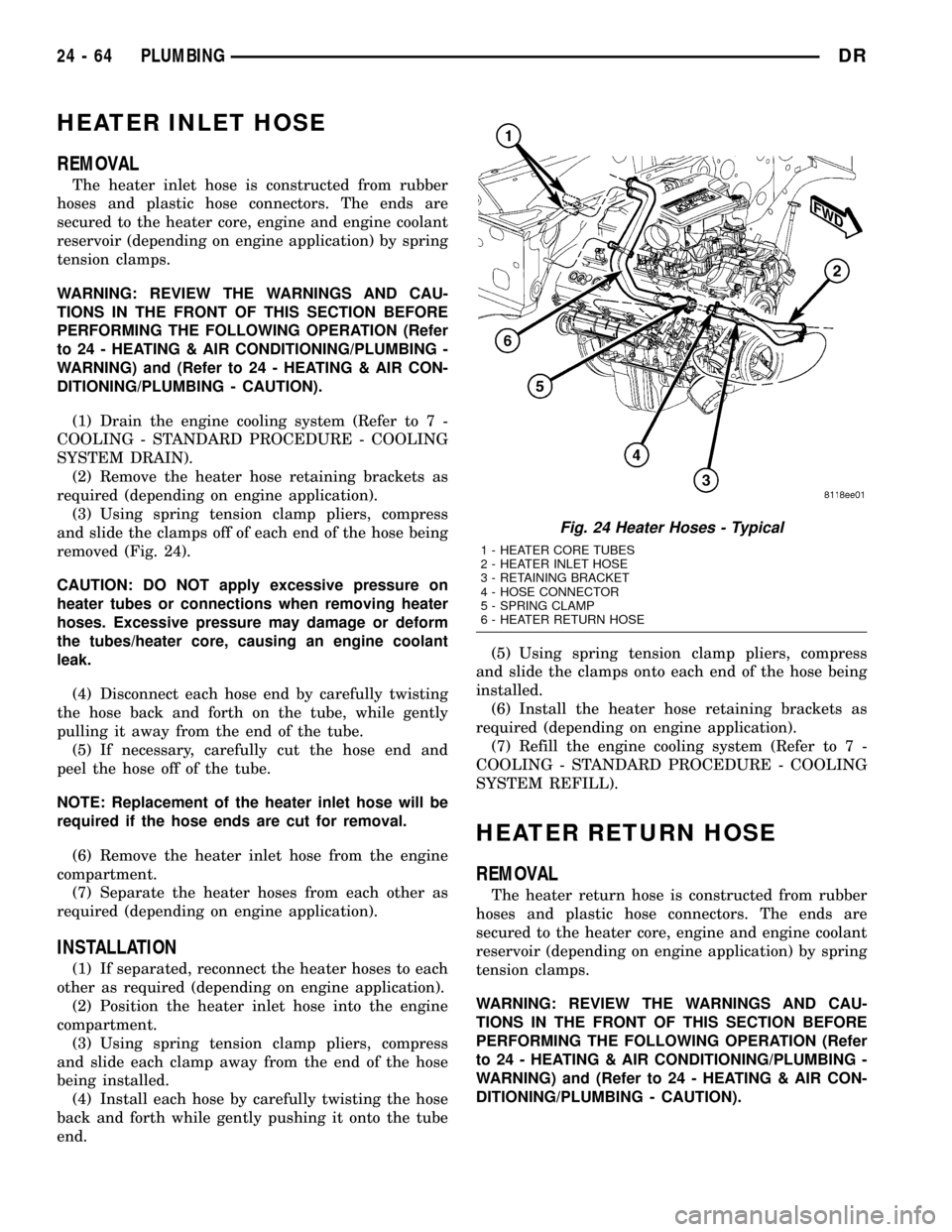

(3) Using spring tension clamp pliers, compress

and slide the clamps off of each end of the hose being

removed (Fig. 24).

CAUTION: DO NOT apply excessive pressure on

heater tubes or connections when removing heater

hoses. Excessive pressure may damage or deform

the tubes/heater core, causing an engine coolant

leak.

(4) Disconnect each hose end by carefully twisting

the hose back and forth on the tube, while gently

pulling it away from the end of the tube.

(5) If necessary, carefully cut the hose end and

peel the hose off of the tube.

NOTE: Replacement of the heater inlet hose will be

required if the hose ends are cut for removal.

(6) Remove the heater inlet hose from the engine

compartment.

(7) Separate the heater hoses from each other as

required (depending on engine application).

INSTALLATION

(1) If separated, reconnect the heater hoses to each

other as required (depending on engine application).

(2) Position the heater inlet hose into the engine

compartment.

(3) Using spring tension clamp pliers, compress

and slide each clamp away from the end of the hose

being installed.

(4) Install each hose by carefully twisting the hose

back and forth while gently pushing it onto the tube

end.(5) Using spring tension clamp pliers, compress

and slide the clamps onto each end of the hose being

installed.

(6) Install the heater hose retaining brackets as

required (depending on engine application).

(7) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

HEATER RETURN HOSE

REMOVAL

The heater return hose is constructed from rubber

hoses and plastic hose connectors. The ends are

secured to the heater core, engine and engine coolant

reservoir (depending on engine application) by spring

tension clamps.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

Fig. 24 Heater Hoses - Typical

1 - HEATER CORE TUBES

2 - HEATER INLET HOSE

3 - RETAINING BRACKET

4 - HOSE CONNECTOR

5 - SPRING CLAMP

6 - HEATER RETURN HOSE

24 - 64 PLUMBINGDR

Page 2553 of 2627

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(5) Remove the plastic cover from the condenser

outlet stud.

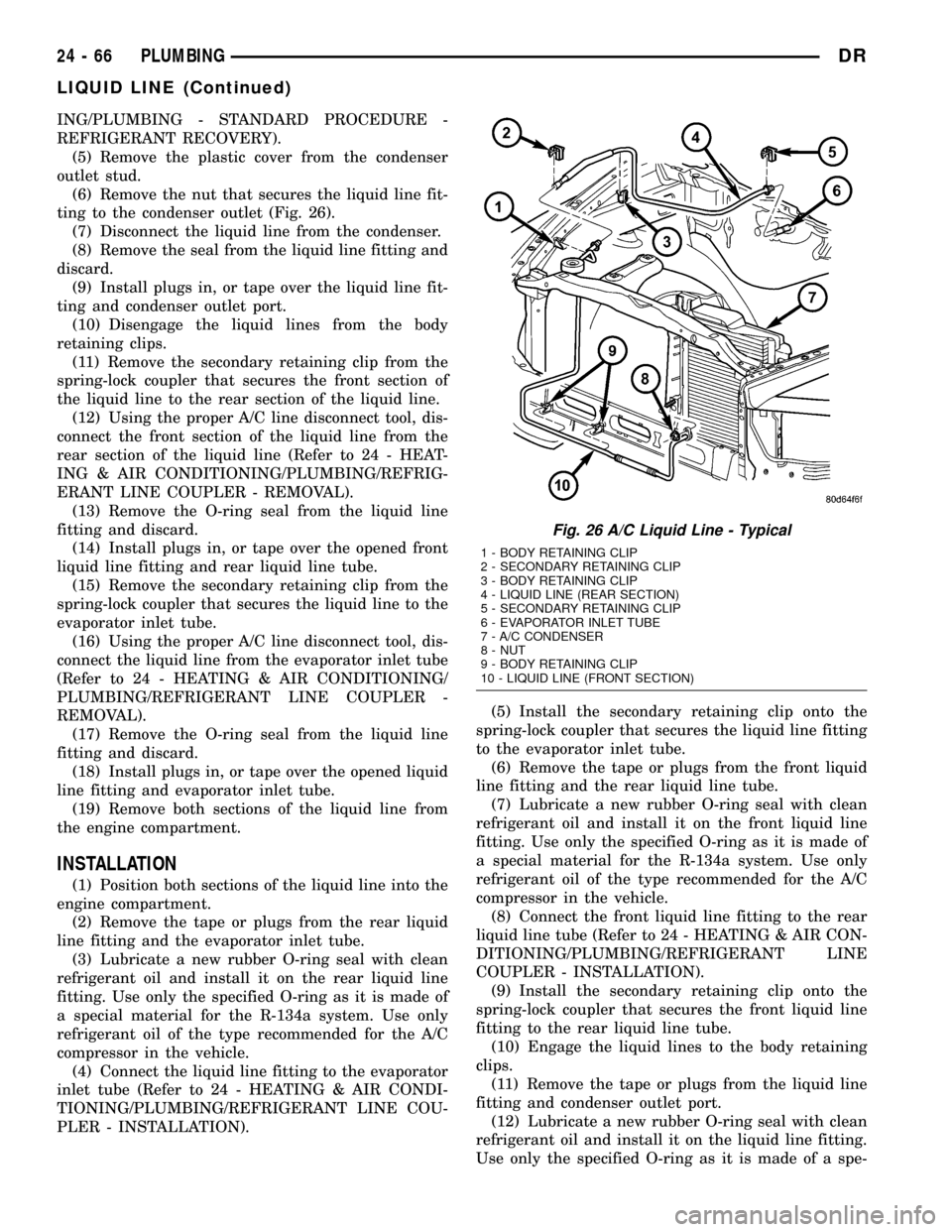

(6) Remove the nut that secures the liquid line fit-

ting to the condenser outlet (Fig. 26).

(7) Disconnect the liquid line from the condenser.

(8) Remove the seal from the liquid line fitting and

discard.

(9) Install plugs in, or tape over the liquid line fit-

ting and condenser outlet port.

(10) Disengage the liquid lines from the body

retaining clips.

(11) Remove the secondary retaining clip from the

spring-lock coupler that secures the front section of

the liquid line to the rear section of the liquid line.

(12) Using the proper A/C line disconnect tool, dis-

connect the front section of the liquid line from the

rear section of the liquid line (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/REFRIG-

ERANT LINE COUPLER - REMOVAL).

(13) Remove the O-ring seal from the liquid line

fitting and discard.

(14) Install plugs in, or tape over the opened front

liquid line fitting and rear liquid line tube.

(15) Remove the secondary retaining clip from the

spring-lock coupler that secures the liquid line to the

evaporator inlet tube.

(16) Using the proper A/C line disconnect tool, dis-

connect the liquid line from the evaporator inlet tube

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/REFRIGERANT LINE COUPLER -

REMOVAL).

(17) Remove the O-ring seal from the liquid line

fitting and discard.

(18) Install plugs in, or tape over the opened liquid

line fitting and evaporator inlet tube.

(19) Remove both sections of the liquid line from

the engine compartment.

INSTALLATION

(1) Position both sections of the liquid line into the

engine compartment.

(2) Remove the tape or plugs from the rear liquid

line fitting and the evaporator inlet tube.

(3) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the rear liquid line

fitting. Use only the specified O-ring as it is made of

a special material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

(4) Connect the liquid line fitting to the evaporator

inlet tube (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/REFRIGERANT LINE COU-

PLER - INSTALLATION).(5) Install the secondary retaining clip onto the

spring-lock coupler that secures the liquid line fitting

to the evaporator inlet tube.

(6) Remove the tape or plugs from the front liquid

line fitting and the rear liquid line tube.

(7) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the front liquid line

fitting. Use only the specified O-ring as it is made of

a special material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

(8) Connect the front liquid line fitting to the rear

liquid line tube (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING/REFRIGERANT LINE

COUPLER - INSTALLATION).

(9) Install the secondary retaining clip onto the

spring-lock coupler that secures the front liquid line

fitting to the rear liquid line tube.

(10) Engage the liquid lines to the body retaining

clips.

(11) Remove the tape or plugs from the liquid line

fitting and condenser outlet port.

(12) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

Use only the specified O-ring as it is made of a spe-

Fig. 26 A/C Liquid Line - Typical

1 - BODY RETAINING CLIP

2 - SECONDARY RETAINING CLIP

3 - BODY RETAINING CLIP

4 - LIQUID LINE (REAR SECTION)

5 - SECONDARY RETAINING CLIP

6 - EVAPORATOR INLET TUBE

7 - A/C CONDENSER

8 - NUT

9 - BODY RETAINING CLIP

10 - LIQUID LINE (FRONT SECTION)

24 - 66 PLUMBINGDR

LIQUID LINE (Continued)

Page 2554 of 2627

cial material for the R-134a system. Use only refrig-

erant oil of the type recommended for the A/C

compressor in the vehicle.

(13) Connect the liquid line to the condenser outlet

port.

(14) Install and tighten the nut that secures the

liquid line fitting to the condenser. Tighten the nut to

20 N´m (180 in. lbs.).

(15) Install the plastic cover onto the condenser

outlet stud.

(16) If equipped with the diesel engine, install the

passenger side battery tray (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - INSTALLATION).

(17) If equipped with the diesel engine, install the

passenger side battery (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM/BATTERY - INSTALLATION).

(18) Reconnect the battery negative cables.

(19) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(20) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

REFRIGERANT

DESCRIPTION

The refrigerant used in this air conditioning sys-

tem is a HydroFluoroCarbon (HFC), type R-134a.

Unlike R-12, which is a ChloroFluoroCarbon (CFC),

R-134a refrigerant does not contain ozone-depleting

chlorine. R-134a refrigerant is a non-toxic, non-flam-

mable, clear, and colorless liquefied gas.

Even though R-134a does not contain chlorine, it

must be reclaimed and recycled just like CFC-type

refrigerants. This is because R-134a is a greenhouse

gas and can contribute to global warming.

OPERATION

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

small amount of R-12 added to an R-134a refrigerant

system will cause compressor failure, refrigerant oil

sludge or poor air conditioning system performance.

In addition, the PolyAlkylene Glycol (PAG) synthetic

refrigerant oils used in an R-134a refrigerant system

are not compatible with the mineral-based refriger-

ant oils used in an R-12 refrigerant system.

R-134a refrigerant system service ports, service

tool couplers and refrigerant dispensing bottles have

all been designed with unique fittings to ensure that

an R-134a system is not accidentally contaminated

with the wrong refrigerant (R-12). There are alsolabels posted in the engine compartment of the vehi-

cle and on the compressor identifying to service tech-

nicians that the air conditioning system is equipped

with R-134a.

REFRIGERANT LINE COUPLER

DESCRIPTION

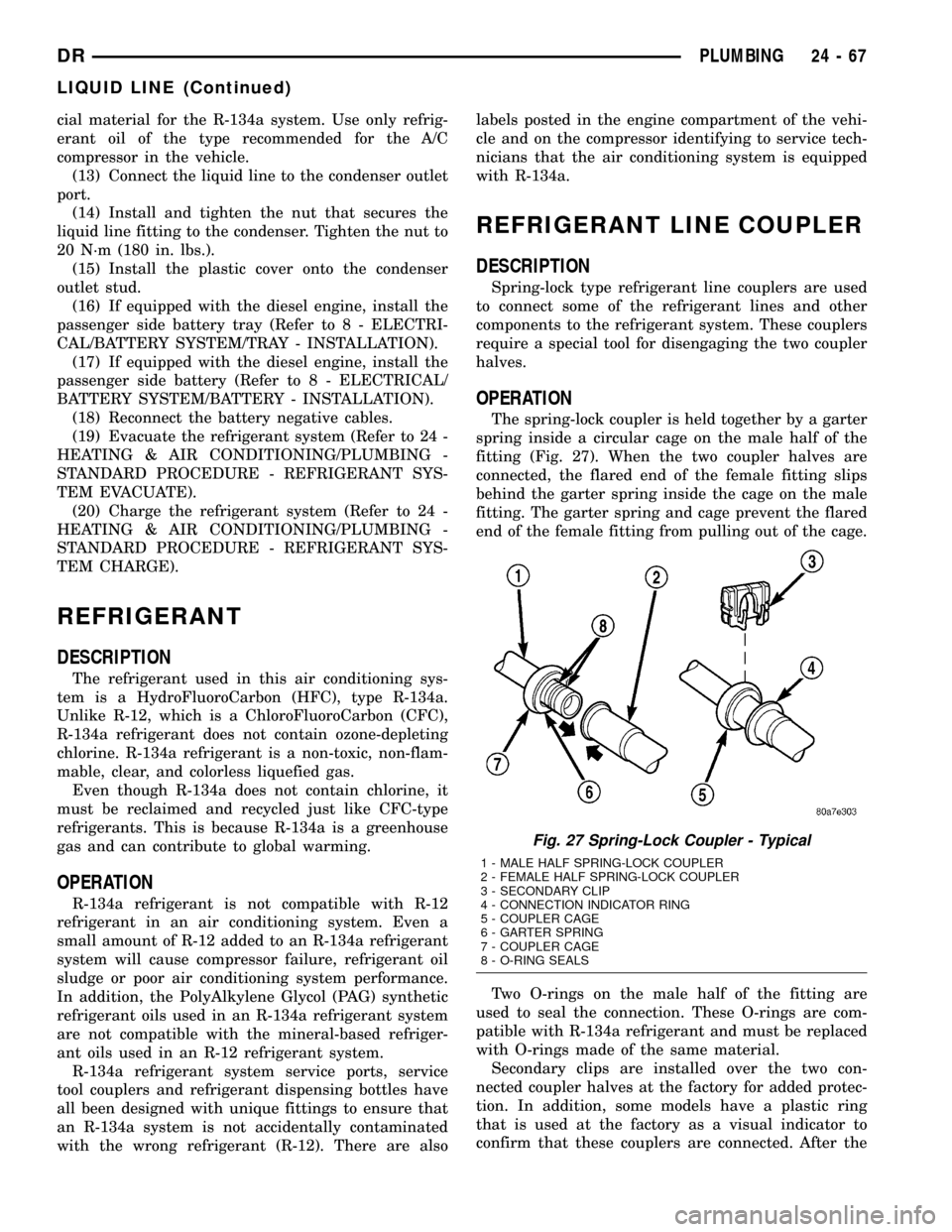

Spring-lock type refrigerant line couplers are used

to connect some of the refrigerant lines and other

components to the refrigerant system. These couplers

require a special tool for disengaging the two coupler

halves.

OPERATION

The spring-lock coupler is held together by a garter

spring inside a circular cage on the male half of the

fitting (Fig. 27). When the two coupler halves are

connected, the flared end of the female fitting slips

behind the garter spring inside the cage on the male

fitting. The garter spring and cage prevent the flared

end of the female fitting from pulling out of the cage.

Two O-rings on the male half of the fitting are

used to seal the connection. These O-rings are com-

patible with R-134a refrigerant and must be replaced

with O-rings made of the same material.

Secondary clips are installed over the two con-

nected coupler halves at the factory for added protec-

tion. In addition, some models have a plastic ring

that is used at the factory as a visual indicator to

confirm that these couplers are connected. After the

Fig. 27 Spring-Lock Coupler - Typical

1 - MALE HALF SPRING-LOCK COUPLER

2 - FEMALE HALF SPRING-LOCK COUPLER

3 - SECONDARY CLIP

4 - CONNECTION INDICATOR RING

5 - COUPLER CAGE

6 - GARTER SPRING

7 - COUPLER CAGE

8 - O-RING SEALS

DRPLUMBING 24 - 67

LIQUID LINE (Continued)

Page 2558 of 2627

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(3) Disconnect the wire harness connector from the

A/C pressure transducer.

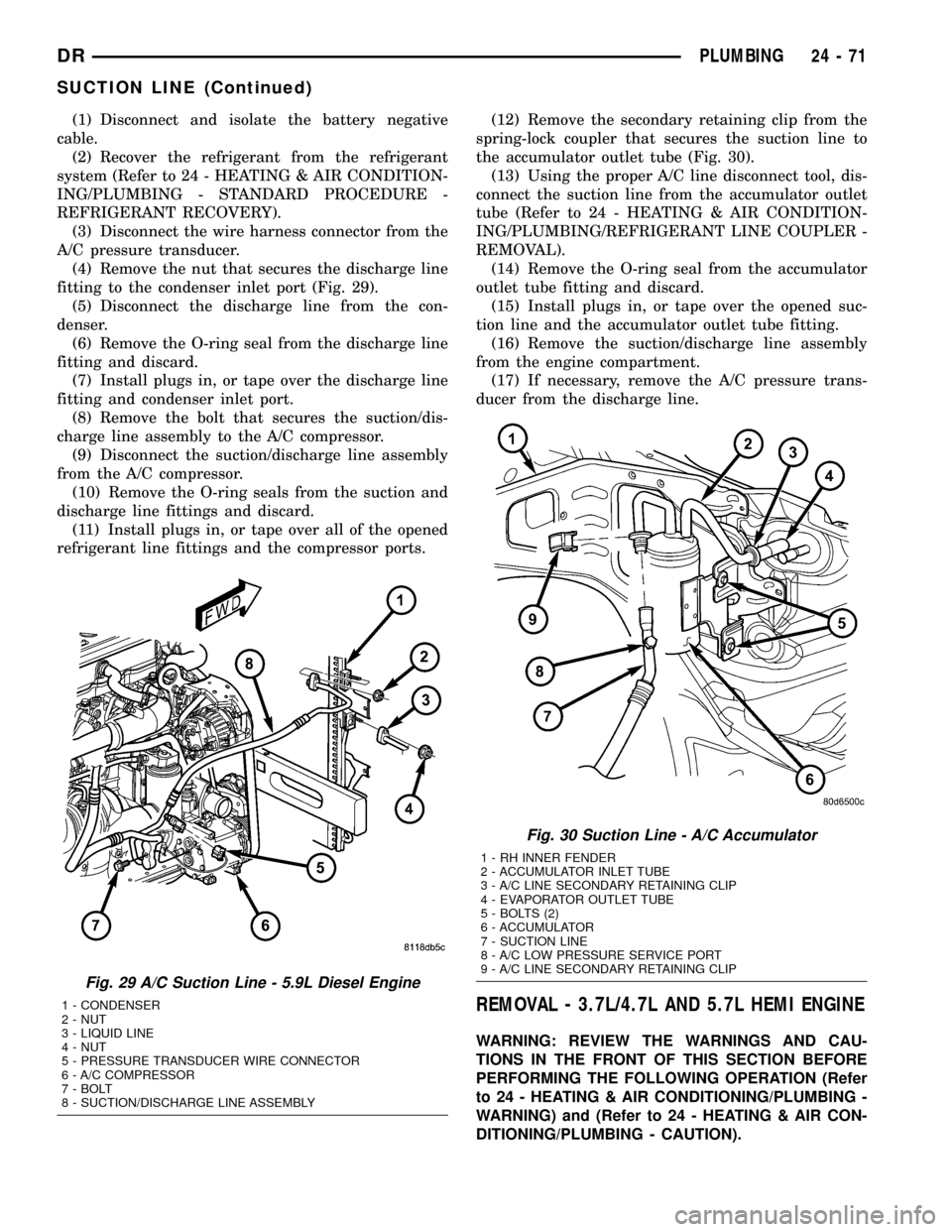

(4) Remove the nut that secures the discharge line

fitting to the condenser inlet port (Fig. 29).

(5) Disconnect the discharge line from the con-

denser.

(6) Remove the O-ring seal from the discharge line

fitting and discard.

(7) Install plugs in, or tape over the discharge line

fitting and condenser inlet port.

(8) Remove the bolt that secures the suction/dis-

charge line assembly to the A/C compressor.

(9) Disconnect the suction/discharge line assembly

from the A/C compressor.

(10) Remove the O-ring seals from the suction and

discharge line fittings and discard.

(11) Install plugs in, or tape over all of the opened

refrigerant line fittings and the compressor ports.(12) Remove the secondary retaining clip from the

spring-lock coupler that secures the suction line to

the accumulator outlet tube (Fig. 30).

(13) Using the proper A/C line disconnect tool, dis-

connect the suction line from the accumulator outlet

tube (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING/REFRIGERANT LINE COUPLER -

REMOVAL).

(14) Remove the O-ring seal from the accumulator

outlet tube fitting and discard.

(15) Install plugs in, or tape over the opened suc-

tion line and the accumulator outlet tube fitting.

(16) Remove the suction/discharge line assembly

from the engine compartment.

(17) If necessary, remove the A/C pressure trans-

ducer from the discharge line.

REMOVAL - 3.7L/4.7L AND 5.7L HEMI ENGINE

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

Fig. 29 A/C Suction Line - 5.9L Diesel Engine

1 - CONDENSER

2 - NUT

3 - LIQUID LINE

4 - NUT

5 - PRESSURE TRANSDUCER WIRE CONNECTOR

6 - A/C COMPRESSOR

7 - BOLT

8 - SUCTION/DISCHARGE LINE ASSEMBLY

Fig. 30 Suction Line - A/C Accumulator

1 - RH INNER FENDER

2 - ACCUMULATOR INLET TUBE

3 - A/C LINE SECONDARY RETAINING CLIP

4 - EVAPORATOR OUTLET TUBE

5 - BOLTS (2)

6 - ACCUMULATOR

7 - SUCTION LINE

8 - A/C LOW PRESSURE SERVICE PORT

9 - A/C LINE SECONDARY RETAINING CLIP

DRPLUMBING 24 - 71

SUCTION LINE (Continued)

Page 2559 of 2627

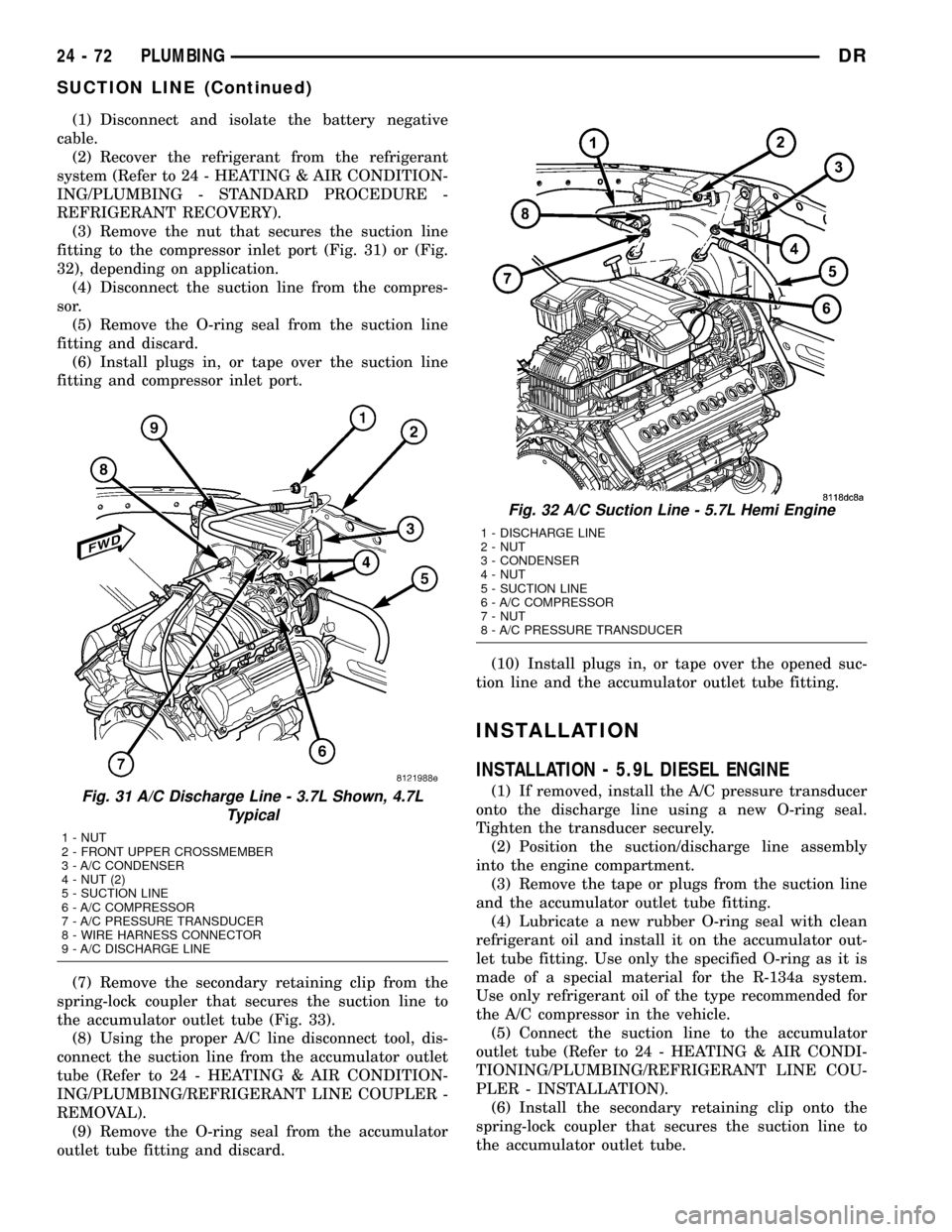

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY).

(3) Remove the nut that secures the suction line

fitting to the compressor inlet port (Fig. 31) or (Fig.

32), depending on application.

(4) Disconnect the suction line from the compres-

sor.

(5) Remove the O-ring seal from the suction line

fitting and discard.

(6) Install plugs in, or tape over the suction line

fitting and compressor inlet port.

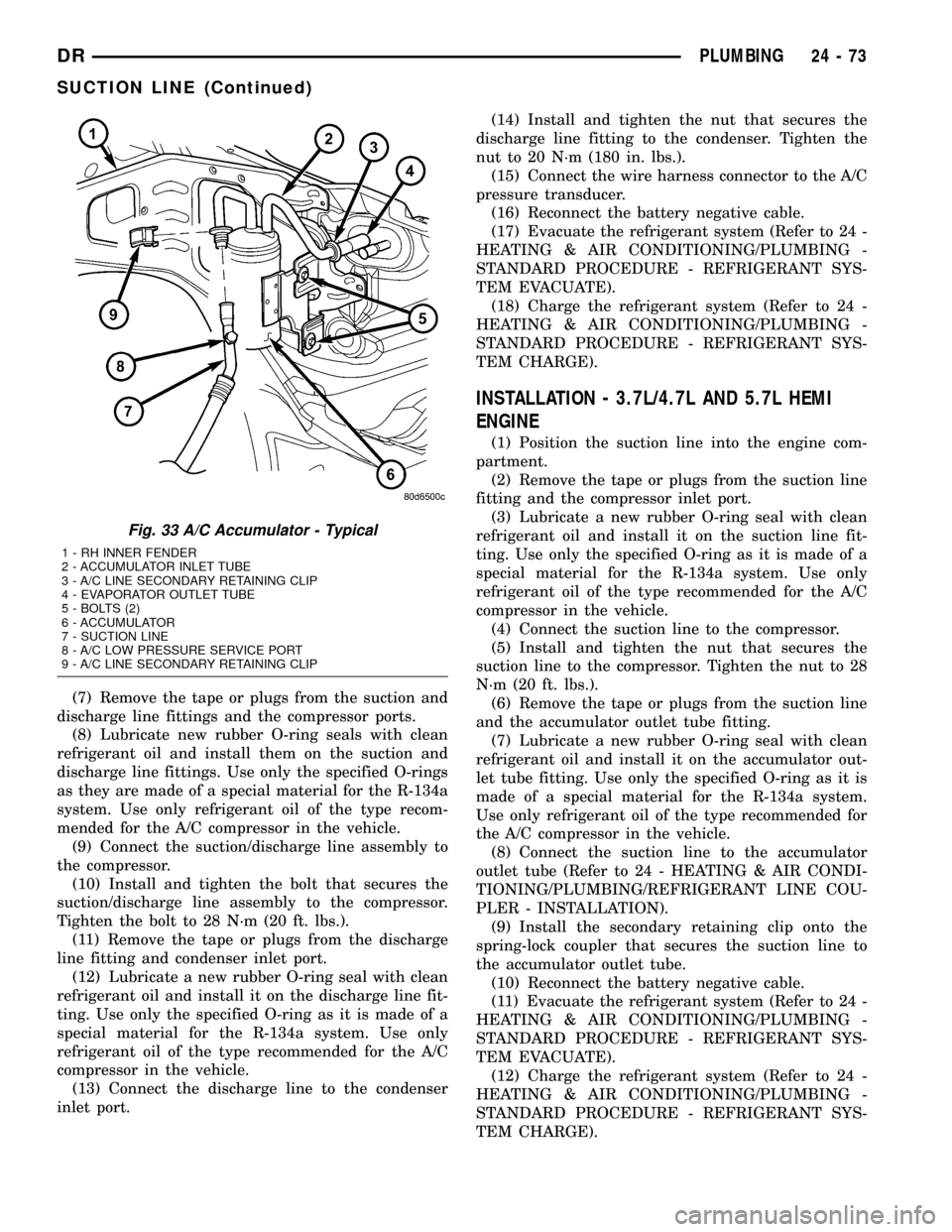

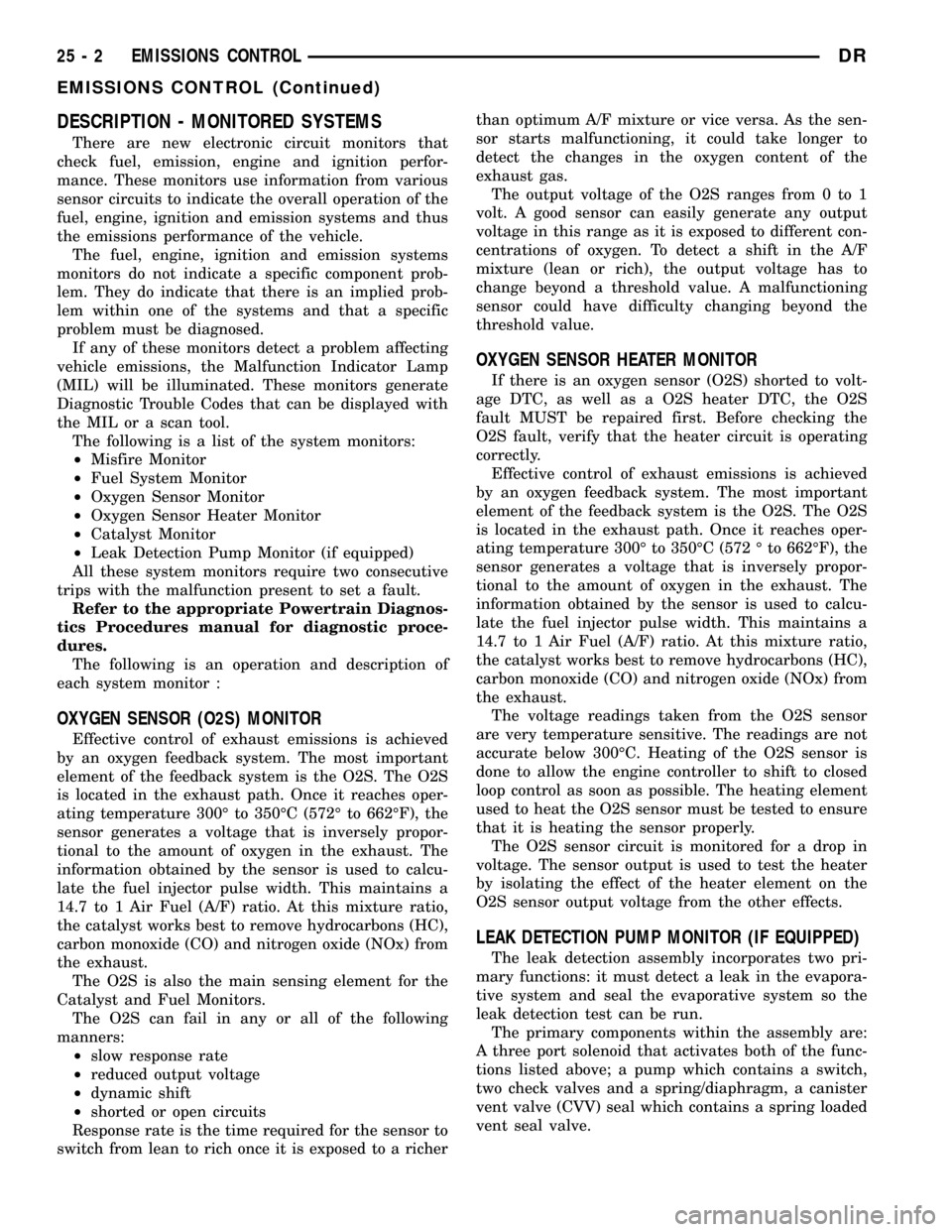

(7) Remove the secondary retaining clip from the

spring-lock coupler that secures the suction line to

the accumulator outlet tube (Fig. 33).

(8) Using the proper A/C line disconnect tool, dis-

connect the suction line from the accumulator outlet

tube (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING/REFRIGERANT LINE COUPLER -

REMOVAL).

(9) Remove the O-ring seal from the accumulator

outlet tube fitting and discard.(10) Install plugs in, or tape over the opened suc-

tion line and the accumulator outlet tube fitting.

INSTALLATION

INSTALLATION - 5.9L DIESEL ENGINE

(1) If removed, install the A/C pressure transducer

onto the discharge line using a new O-ring seal.

Tighten the transducer securely.

(2) Position the suction/discharge line assembly

into the engine compartment.

(3) Remove the tape or plugs from the suction line

and the accumulator outlet tube fitting.

(4) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the accumulator out-

let tube fitting. Use only the specified O-ring as it is

made of a special material for the R-134a system.

Use only refrigerant oil of the type recommended for

the A/C compressor in the vehicle.

(5) Connect the suction line to the accumulator

outlet tube (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/REFRIGERANT LINE COU-

PLER - INSTALLATION).

(6) Install the secondary retaining clip onto the

spring-lock coupler that secures the suction line to

the accumulator outlet tube.Fig. 31 A/C Discharge Line - 3.7L Shown, 4.7L

Typical

1 - NUT

2 - FRONT UPPER CROSSMEMBER

3 - A/C CONDENSER

4 - NUT (2)

5 - SUCTION LINE

6 - A/C COMPRESSOR

7 - A/C PRESSURE TRANSDUCER

8 - WIRE HARNESS CONNECTOR

9 - A/C DISCHARGE LINE

Fig. 32 A/C Suction Line - 5.7L Hemi Engine

1 - DISCHARGE LINE

2 - NUT

3 - CONDENSER

4 - NUT

5 - SUCTION LINE

6 - A/C COMPRESSOR

7 - NUT

8 - A/C PRESSURE TRANSDUCER

24 - 72 PLUMBINGDR

SUCTION LINE (Continued)

Page 2560 of 2627

(7) Remove the tape or plugs from the suction and

discharge line fittings and the compressor ports.

(8) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the suction and

discharge line fittings. Use only the specified O-rings

as they are made of a special material for the R-134a

system. Use only refrigerant oil of the type recom-

mended for the A/C compressor in the vehicle.

(9) Connect the suction/discharge line assembly to

the compressor.

(10) Install and tighten the bolt that secures the

suction/discharge line assembly to the compressor.

Tighten the bolt to 28 N´m (20 ft. lbs.).

(11) Remove the tape or plugs from the discharge

line fitting and condenser inlet port.

(12) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the discharge line fit-

ting. Use only the specified O-ring as it is made of a

special material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

(13) Connect the discharge line to the condenser

inlet port.(14) Install and tighten the nut that secures the

discharge line fitting to the condenser. Tighten the

nut to 20 N´m (180 in. lbs.).

(15) Connect the wire harness connector to the A/C

pressure transducer.

(16) Reconnect the battery negative cable.

(17) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(18) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

INSTALLATION - 3.7L/4.7L AND 5.7L HEMI

ENGINE

(1) Position the suction line into the engine com-

partment.

(2) Remove the tape or plugs from the suction line

fitting and the compressor inlet port.

(3) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the suction line fit-

ting. Use only the specified O-ring as it is made of a

special material for the R-134a system. Use only

refrigerant oil of the type recommended for the A/C

compressor in the vehicle.

(4) Connect the suction line to the compressor.

(5) Install and tighten the nut that secures the

suction line to the compressor. Tighten the nut to 28

N´m (20 ft. lbs.).

(6) Remove the tape or plugs from the suction line

and the accumulator outlet tube fitting.

(7) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the accumulator out-

let tube fitting. Use only the specified O-ring as it is

made of a special material for the R-134a system.

Use only refrigerant oil of the type recommended for

the A/C compressor in the vehicle.

(8) Connect the suction line to the accumulator

outlet tube (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/REFRIGERANT LINE COU-

PLER - INSTALLATION).

(9) Install the secondary retaining clip onto the

spring-lock coupler that secures the suction line to

the accumulator outlet tube.

(10) Reconnect the battery negative cable.

(11) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(12) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

Fig. 33 A/C Accumulator - Typical

1 - RH INNER FENDER

2 - ACCUMULATOR INLET TUBE

3 - A/C LINE SECONDARY RETAINING CLIP

4 - EVAPORATOR OUTLET TUBE

5 - BOLTS (2)

6 - ACCUMULATOR

7 - SUCTION LINE

8 - A/C LOW PRESSURE SERVICE PORT

9 - A/C LINE SECONDARY RETAINING CLIP

DRPLUMBING 24 - 73

SUCTION LINE (Continued)

Page 2563 of 2627

DESCRIPTION - MONITORED SYSTEMS

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator Lamp

(MIL) will be illuminated. These monitors generate

Diagnostic Trouble Codes that can be displayed with

the MIL or a scan tool.

The following is a list of the system monitors:

²Misfire Monitor

²Fuel System Monitor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

²Leak Detection Pump Monitor (if equipped)

All these system monitors require two consecutive

trips with the malfunction present to set a fault.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

The following is an operation and description of

each system monitor :

OXYGEN SENSOR (O2S) MONITOR

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572É to 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from

the exhaust.

The O2S is also the main sensing element for the

Catalyst and Fuel Monitors.

The O2S can fail in any or all of the following

manners:

²slow response rate

²reduced output voltage

²dynamic shift

²shorted or open circuits

Response rate is the time required for the sensor to

switch from lean to rich once it is exposed to a richerthan optimum A/F mixture or vice versa. As the sen-

sor starts malfunctioning, it could take longer to

detect the changes in the oxygen content of the

exhaust gas.

The output voltage of the O2S ranges from 0 to 1

volt. A good sensor can easily generate any output

voltage in this range as it is exposed to different con-

centrations of oxygen. To detect a shift in the A/F

mixture (lean or rich), the output voltage has to

change beyond a threshold value. A malfunctioning

sensor could have difficulty changing beyond the

threshold value.

OXYGEN SENSOR HEATER MONITOR

If there is an oxygen sensor (O2S) shorted to volt-

age DTC, as well as a O2S heater DTC, the O2S

fault MUST be repaired first. Before checking the

O2S fault, verify that the heater circuit is operating

correctly.

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572 É to 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from

the exhaust.

The voltage readings taken from the O2S sensor

are very temperature sensitive. The readings are not

accurate below 300ÉC. Heating of the O2S sensor is

done to allow the engine controller to shift to closed

loop control as soon as possible. The heating element

used to heat the O2S sensor must be tested to ensure

that it is heating the sensor properly.

The O2S sensor circuit is monitored for a drop in

voltage. The sensor output is used to test the heater

by isolating the effect of the heater element on the

O2S sensor output voltage from the other effects.

LEAK DETECTION PUMP MONITOR (IF EQUIPPED)

The leak detection assembly incorporates two pri-

mary functions: it must detect a leak in the evapora-

tive system and seal the evaporative system so the

leak detection test can be run.

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

25 - 2 EMISSIONS CONTROLDR

EMISSIONS CONTROL (Continued)

Page 2567 of 2627

For example, when the MIL is illuminated for an

Oxygen Sensor fault, the Task Manager does not run

the Catalyst Monitor until the Oxygen Sensor fault is

remedied. Since the Catalyst Monitor is based on sig-

nals from the Oxygen Sensor, running the test would

produce inaccurate results.

²Conflict

There are situations when the Task Manager does

not run a test if another monitor is in progress. In

these situations, the effects of another monitor run-

ning could result in an erroneous failure. If thiscon-

flictis present, the monitor is not run until the

conflicting condition passes. Most likely the monitor

will run later after the conflicting monitor has

passed.

For example, if the Fuel System Monitor is in

progress, the Task Manager does not run the EGR

Monitor. Since both tests monitor changes in air/fuel

ratio and adaptive fuel compensation, the monitors

will conflict with each other.

²Suspend

Occasionally the Task Manager may not allow a two

trip fault to mature. The Task Manager willsus-

pendthe maturing of a fault if a condition exists

that may induce an erroneous failure. This prevents

illuminating the MIL for the wrong fault and allows

more precis diagnosis.

For example, if the PCM is storing a one trip fault

for the Oxygen Sensor and the EGR monitor, the

Task Manager may still run the EGR Monitor but

will suspend the results until the Oxygen Sensor

Monitor either passes or fails. At that point the Task

Manager can determine if the EGR system is actu-

ally failing or if an Oxygen Sensor is failing.

MIL Illumination

The PCM Task Manager carries out the illumina-

tion of the MIL. The Task Manager triggers MIL illu-

mination upon test failure, depending on monitor

failure criteria.

The Task Manager Screen shows both a Requested

MIL state and an Actual MIL state. When the MIL is

illuminated upon completion of a test for a third trip,

the Requested MIL state changes to OFF. However,

the MIL remains illuminated until the next key

cycle. (On some vehicles, the MIL will actually turn

OFF during the third key cycle) During the key cycle

for the third good trip, the Requested MIL state is

OFF, while the Actual MILL state is ON. After the

next key cycle, the MIL is not illuminated and both

MIL states read OFF.

Diagnostic Trouble Codes (DTCs)

With OBD II, different DTC faults have different

priorities according to regulations. As a result, the

priorities determine MIL illumination and DTC era-sure. DTCs are entered according to individual prior-

ity. DTCs with a higher priority overwrite lower

priority DTCs.

Priorities

²Priority 0 ÐNon-emissions related trouble codes

²Priority 1 Ð One trip failure of a two trip fault

for non-fuel system and non-misfire.

²Priority 2 Ð One trip failure of a two trip fault

for fuel system (rich/lean) or misfire.

²Priority3ÐTwotrip failure for a non-fuel sys-

tem and non-misfire or matured one trip comprehen-

sive component fault.

²Priority4ÐTwotrip failure or matured fault

for fuel system (rich/lean) and misfire or one trip cat-

alyst damaging misfire.

Non-emissions related failures have no priority.

One trip failures of two trip faults have low priority.

Two trip failures or matured faults have higher pri-

ority. One and two trip failures of fuel system and

misfire monitor take precedence over non-fuel system

and non-misfire failures.

DTC Self Erasure

With one trip components or systems, the MIL is

illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure

in two consecutive trips for MIL illumination. Upon

failure of the first test, the Task Manager enters a

maturing code. If the component fails the test for a

second time the code matures and a DTC is set.

After three good trips the MIL is extinguished and

the Task Manager automatically switches the trip

counter to a warm-up cycle counter. DTCs are auto-

matically erased following 40 warm-up cycles if the

component does not fail again.

For misfire and fuel system monitors, the compo-

nent must pass the test under a Similar Conditions

Window in order to record a good trip. A Similar Con-

ditions Window is when engine RPM is within 375

RPM and load is within 10% of when the fault

occurred.

NOTE: It is important to understand that a compo-

nent does not have to fail under a similar window of

operation to mature. It must pass the test under a

Similar Conditions Window when it failed to record

a Good Trip for DTC erasure for misfire and fuel

system monitors.

DTCs can be erased anytime with a DRB III. Eras-

ing the DTC with the DRB III erases all OBD II

information. The DRB III automatically displays a

warning that erasing the DTC will also erase all

OBD II monitor data. This includes all counter infor-

mation for warm-up cycles, trips and Freeze Frame.

25 - 6 EMISSIONS CONTROLDR

EMISSIONS CONTROL (Continued)

Page 2574 of 2627

FUEL FILLER CAP

DESCRIPTION

The plastic fuel tank filler tube cap is threaded

onto the end of the fuel fill tube. Certain models are

equipped with a 1/4 turn cap.

OPERATION

The loss of any fuel or vapor out of fuel filler tube

is prevented by the use of a pressure-vacuum fuel fill

cap. Relief valves inside the cap will release fuel tank

pressure at predetermined pressures. Fuel tank vac-

uum will also be released at predetermined values.

This cap must be replaced by a similar unit if

replacement is necessary. This is in order for the sys-

tem to remain effective.

CAUTION: Remove fill cap before servicing any fuel

system component to relieve tank pressure. If

equipped with a Leak Detection Pump (LDP), or

NVLD system, the cap must be tightened securely.

If cap is left loose, a Diagnostic Trouble Code (DTC)

may be set.

REMOVAL

REMOVAL/INSTALLATION

If replacement of the 1/4 turn fuel tank filler tube

cap is necessary, it must be replaced with an identi-

cal cap to be sure of correct system operation.

CAUTION: Remove the fuel tank filler tube cap to

relieve fuel tank pressure. The cap must be

removed prior to disconnecting any fuel system

component or before draining the fuel tank.

LEAK DETECTION PUMP

DESCRIPTION

Vehicles equipped with JTEC engine control mod-

ules use a leak detection pump. Vehicles equipped

with NGC engine control modules use an NVLD

pump. Refer to Natural Vacuum - Leak Detection

(NVLD) for additional information.

The evaporative emission system is designed to

prevent the escape of fuel vapors from the fuel sys-

tem (Fig. 4). Leaks in the system, even small ones,

can allow fuel vapors to escape into the atmosphere.

Government regulations require onboard testing to

make sure that the evaporative (EVAP) system is

functioning properly. The leak detection system tests

for EVAP system leaks and blockage. It also performs

self-diagnostics. During self-diagnostics, the Power-

train Control Module (PCM) first checks the Leak

Detection Pump (LDP) for electrical and mechanical

faults. If the first checks pass, the PCM then uses

the LDP to seal the vent valve and pump air into the

system to pressurize it. If a leak is present, the PCM

will continue pumping the LDP to replace the air

that leaks out. The PCM determines the size of the

leak based on how fast/long it must pump the LDP

as it tries to maintain pressure in the system.

EVAP LEAK DETECTION SYSTEM COMPONENTS

Service Port: Used with special tools like the Miller

Evaporative Emissions Leak Detector (EELD) to test

for leaks in the system.

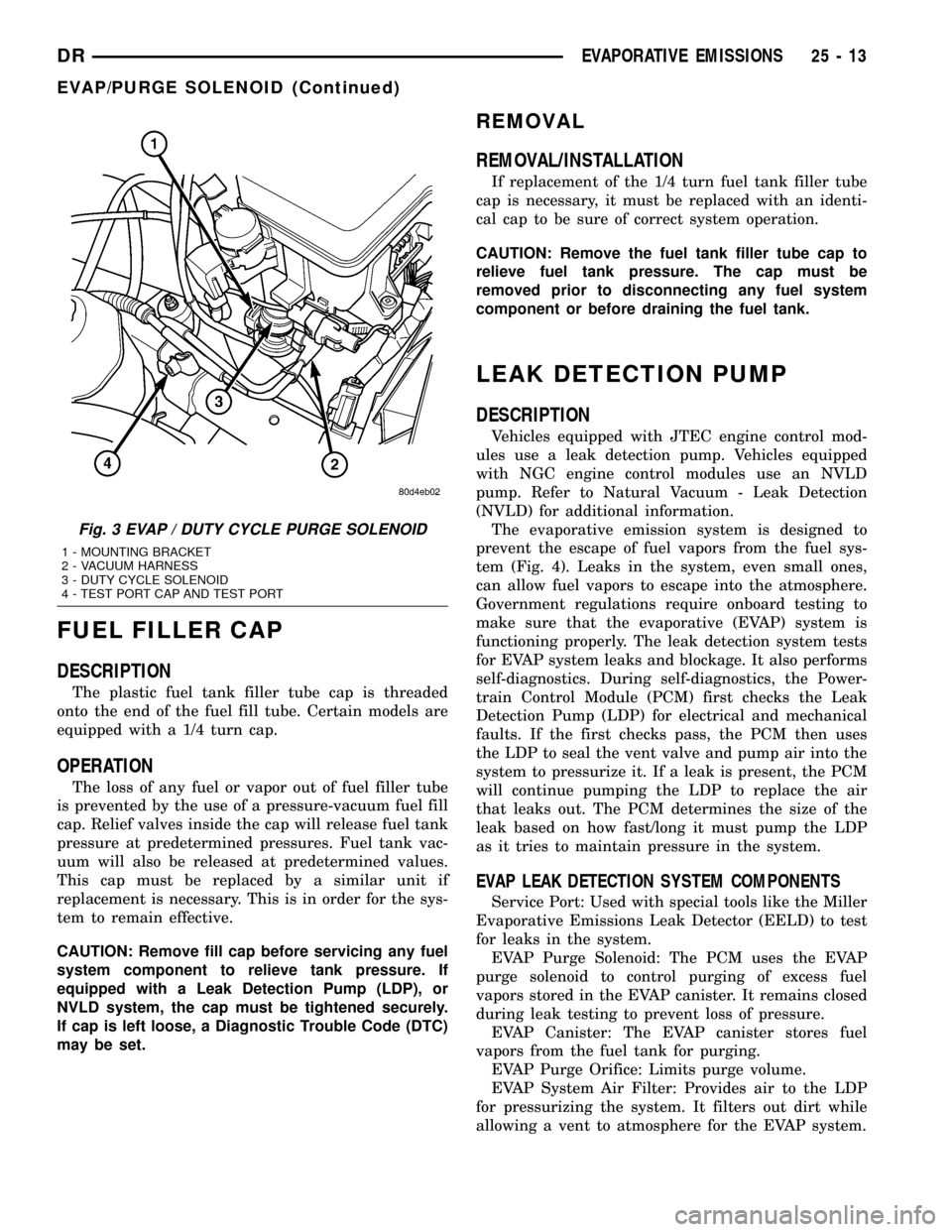

EVAP Purge Solenoid: The PCM uses the EVAP

purge solenoid to control purging of excess fuel

vapors stored in the EVAP canister. It remains closed

during leak testing to prevent loss of pressure.

EVAP Canister: The EVAP canister stores fuel

vapors from the fuel tank for purging.

EVAP Purge Orifice: Limits purge volume.

EVAP System Air Filter: Provides air to the LDP

for pressurizing the system. It filters out dirt while

allowing a vent to atmosphere for the EVAP system.

Fig. 3 EVAP / DUTY CYCLE PURGE SOLENOID

1 - MOUNTING BRACKET

2 - VACUUM HARNESS

3 - DUTY CYCLE SOLENOID

4 - TEST PORT CAP AND TEST PORT

DREVAPORATIVE EMISSIONS 25 - 13

EVAP/PURGE SOLENOID (Continued)

Page 2604 of 2627

IGNITION CIRCUIT SENSE -

DESCRIPTION.......................8E-10

IGNITION CIRCUIT SENSE - OPERATION . . 8E-11

IGNITION COIL - DESCRIPTION..........8I-11

IGNITION COIL - INSTALLATION.........8I-14

IGNITION COIL - OPERATION............8I-12

IGNITION COIL - REMOVAL.............8I-13

IGNITION COIL CAPACITOR -

DESCRIPTION........................8I-21

IGNITION COIL CAPACITOR -

INSTALLATION.......................8I-21

IGNITION COIL CAPACITOR - OPERATION . . 8I-21

IGNITION COIL CAPACITOR - REMOVAL . . . 8I-21

IGNITION COIL RESISTANCE, 3.7L V-6.....8I-5

IGNITION COIL RESISTANCE, 4.7L V-8.....8I-5

IGNITION COIL RESISTANCE, 5.7L V-8.....8I-5

IGNITION CONTROL - DESCRIPTION.......8I-1

IGNITION SWITCH - DESCRIPTION........19-9

IGNITION SWITCH - DESCRIPTION,

KEY-IN.............................19-11

IGNITION SWITCH - DIAGNOSIS AND

TESTING............................19-9

IGNITION SWITCH - INSTALLATION......19-11

IGNITION SWITCH - OPERATION.........19-9

IGNITION SWITCH - REMOVAL..........19-10

IGNITION SWITCH AND KEY LOCK

CYLINDER - DIAGNOSIS AND TESTING . . . 19-11

IGNITION TIMING, SPECIFICATIONS.......8I-5

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE........................8F-11

IMMOBILIZER MODULE - DESCRIPTION,

SENTRY KEY........................8E-13

IMMOBILIZER MODULE - INSTALLATION,

SENTRY KEY........................8E-15

IMMOBILIZER MODULE - OPERATION,

SENTRY KEY........................8E-13

IMMOBILIZER MODULE - REMOVAL,

SENTRY KEY........................8E-15

IMMOBILIZER MODULE (SKIM) -

DESCRIPTION, SENTRY KEY.............8Q-1

IMMOBILIZER MODULE (SKIM) -

OPERATION, SENTRY KEY..............8Q-2

IMMOBILIZER SYSTEM INDICATOR

LAMP - DESCRIPTION, SENTRY KEY......8Q-5

IMMOBILIZER SYSTEM INDICATOR

LAMP - OPERATION, SENTRY KEY........8Q-5

IMMOBILIZER SYSTEM INITIALIZATION,

STANDARD PROCEDURE - SENTRY

KEY................................8Q-3

IMMOBILIZER SYSTEM (SKIS) -

DESCRIPTION, SENTRY KEY.............8Q-1

IMMOBILIZER SYSTEM (SKIS) -

OPERATION, SENTRY KEY..............8Q-2

IMMOBILIZER SYSTEM TRANSPONDER

PROGRAMMING, STANDARD

PROCEDURE - SENTRY KEY.............8Q-4

IMPACT SENSOR - DESCRIPTION, SIDE . . 8O-59

IMPACT SENSOR - OPERATION, SIDE....8O-59

INCORRECT FLUID LEVEL - DIAGNOSIS

AND TESTING, EFFECTS OF......21-201,21-366

INDEPENDENT FRONT SUSPENSION -

DESCRIPTION, GEAR..................19-17

INDEPENDENT FRONT SUSPENSION -

INSTALLATION, GEAR.................19-18

INDEPENDENT FRONT SUSPENSION -

REMOVAL, GEAR.....................19-17

INDICATOR - DESCRIPTION, ABS........8J-17

INDICATOR - DESCRIPTION, AIRBAG.....8J-18

INDICATOR - DESCRIPTION, BRAKE/

PARK BRAKE........................8J-19

INDICATOR - DESCRIPTION, CARGO

LAMP

..............................8J-20

INDICATOR - DESCRIPTION, CHECK

GAUGES

............................8J-21

INDICATOR - DESCRIPTION, CRUISE

.....8J-22

INDICATOR - DESCRIPTION, DOOR AJAR

. . 8J-23

INDICATOR - DESCRIPTION, ETC

........8J-25

INDICATOR - DESCRIPTION, GEAR

SELECTOR

..........................8J-27

INDICATOR - DESCRIPTION, HIGH BEAM

. . 8J-28

INDICATOR - DESCRIPTION, LAMP OUT

. . . 8J-29

INDICATOR - DESCRIPTION, LOW FUEL

. . . 8J-30

INDICATOR - DESCRIPTION, SEATBELT

. . . 8J-34

INDICATOR - DESCRIPTION, SECURITY

. . . 8J-35

INDICATOR - DESCRIPTION, SERVICE

4WD

...............................8J-36

INDICATOR - DESCRIPTION, TOW/HAUL

. . . 8J-39INDICATOR - DESCRIPTION, TRANS

TEMP..............................8J-40

INDICATOR - DESCRIPTION, TURN

SIGNAL............................8J-40

INDICATOR - DESCRIPTION, UPSHIFT....8J-41

INDICATOR - DESCRIPTION, WAIT-TO-

START .............................8J-44

INDICATOR - DESCRIPTION, WASHER

FLUID..............................8J-44

INDICATOR - DESCRIPTION, WATER-IN-

FUEL..............................8J-45

INDICATOR - DIAGNOSIS AND TESTING,

BRAKE.............................8J-20

INDICATOR - OPERATION, ABS..........8J-17

INDICATOR - OPERATION, AIRBAG.......8J-18

INDICATOR - OPERATION, BRAKE/PARK

BRAKE.............................8J-19

INDICATOR - OPERATION, CARGO LAMP . . 8J-20

INDICATOR - OPERATION, CHECK

GAUGES............................8J-21

INDICATOR - OPERATION, CRUISE.......8J-22

INDICATOR - OPERATION, DOOR AJAR . . . 8J-23

INDICATOR - OPERATION, ETC..........8J-25

INDICATOR - OPERATION, GEAR

SELECTOR..........................8J-27

INDICATOR - OPERATION, HIGH BEAM....8J-28

INDICATOR - OPERATION, LAMP OUT....8J-29

INDICATOR - OPERATION, LOW FUEL.....8J-30

INDICATOR - OPERATION, SEATBELT.....8J-34

INDICATOR - OPERATION, SECURITY......8J-36

INDICATOR - OPERATION, SERVICE 4WD . . 8J-37

INDICATOR - OPERATION, TOW/HAUL....8J-39

INDICATOR - OPERATION, TRANS TEMP . . 8J-40

INDICATOR - OPERATION, TURN SIGNAL . . 8J-41

INDICATOR - OPERATION, UPSHIFT......8J-42

INDICATOR - OPERATION, WAIT-TO-

START .............................8J-44

INDICATOR - OPERATION, WASHER

FLUID..............................8J-44

INDICATOR - OPERATION, WATER-IN-

FUEL..............................8J-45

INDICATOR LAMP - DESCRIPTION,

SENTRY KEY IMMOBILIZER SYSTEM......8Q-5

INDICATOR LAMP - OPERATION,

SENTRY KEY IMMOBILIZER SYSTEM......8Q-5

INDICATOR LAMP (MIL) - DESCRIPTION,

MALFUNCTION.......................8J-31

INDICATOR LAMP (MIL) - OPERATION,

MALFUNCTION.......................8J-31

INDICATOR TEST - STANDARD

PROCEDURE, BUILT-IN................8F-10

INDICATORS - DIAGNOSIS AND

TESTING, TREAD WEAR................22-8

INERTIA HINGE COVER - INSTALLATION,

CENTER SEAT BACK..................23-77

INERTIA HINGE COVER - REMOVAL,

CENTER SEAT BACK..................23-77

INFLATION PRESSURES - DESCRIPTION,

TIRE................................22-7

INFO CENTER - DESCRIPTION,

ELECTRONIC VEHICLE.................8M-7

INFO CENTER - INSTALLATION,

ELECTRONIC VEHICLE.................8M-9

INFO CENTER - OPERATION,

ELECTRONIC VEHICLE.................8M-7

INFO CENTER - REMOVAL, ELECTRONIC

VEHICLE............................8M-9

INITIAL OPERATION - STANDARD

PROCEDURE, POWER STEERING

PUMP.............................19-40

INITIALIZATION, STANDARD PROCEDURE

- SENTRY KEY IMMOBILIZER SYSTEM....8Q-3

INJECTED RINGS - ASSEMBLY, WITH......3-13

INJECTED RINGS - DISASSEMBLY, WITH . . . 3-11

INJECTION PUMP - DESCRIPTION, FUEL . . 14-53

INJECTION PUMP - INSTALLATION, FUEL . 14-55

INJECTION PUMP - OPERATION, FUEL....14-53

INJECTION PUMP - REMOVAL, FUEL.....14-54

INJECTION PUMP TIMING - DIAGNOSIS

AND TESTING, FUEL..................14-53

INJECTOR - DESCRIPTION, FUEL . . . 14-26,14-74

INJECTOR - INSTALLATION, FUEL........14-77

INJECTOR - OPERATION, FUEL

.....14-26,14-74

INJECTOR - REMOVAL, FUEL

...........14-75

INJECTOR FIRING ORDER, DIESEL -

FUEL

..............................14-48

INJECTOR RAIL - DESCRIPTION, FUEL

....14-78

INJECTOR RAIL - INSTALLATION, FUEL

. . . 14-78INJECTOR RAIL - OPERATION, FUEL.....14-78

INJECTOR RAIL - REMOVAL, FUEL.......14-78

INLET AIR TEMPERATURE SENSOR/

PRESSURE SENSOR - DESCRIPTION.....14-79

INLET AIR TEMPERATURE SENSOR/

PRESSURE SENSOR - INSTALLATION.....14-79

INLET AIR TEMPERATURE SENSOR/

PRESSURE SENSOR - OPERATION.......14-79

INLET AIR TEMPERATURE SENSOR/

PRESSURE SENSOR - REMOVAL........14-79

INLET FILTER - INSTALLATION..........14-20

INLET FILTER - REMOVAL..............14-20

INLET HOSE - INSTALLATION, HEATER....24-64

INLET HOSE - REMOVAL, HEATER.......24-64

INNER BELT MOLDING - INSTALLATION,

FRONT DOOR.......................23-93

INNER BELT MOLDING - INSTALLATION,

REAR DOOR........................23-94

INNER BELT MOLDING - REMOVAL,

FRONT DOOR.......................23-93

INNER BELT MOLDING - REMOVAL,

REAR DOOR........................23-94

INPUT - OPERATION, ASD SENSE - PCM . . . 8I-5

INPUT CLUTCH ASSEMBLY - ASSEMBLY . 21-378

INPUT CLUTCH ASSEMBLY -

DESCRIPTION......................21-373

INPUT CLUTCH ASSEMBLY -

DISASSEMBLY......................21-374

INPUT CLUTCH ASSEMBLY - OPERATION . 21-373

INPUT SHAFT SEAL - INSTALLATION,

STEERING GEAR.......................19-29

INPUT SHAFT SEAL - REMOVAL,

STEERING GEAR.....................19-27

INPUT SPEED SENSOR - DESCRIPTION . . 21-382

INPUT SPEED SENSOR - INSTALLATION . 21-382

INPUT SPEED SENSOR - OPERATION....21-382

INPUT SPEED SENSOR - REMOVAL.....21-382

INSERTS - INSTALLATION, SPRING TIP....2-45

INSERTS - REMOVAL, SPRING TIP........2-44

INSIDE HANDLE ACTUATOR -

INSTALLATION..................23-22,23-32

INSIDE HANDLE ACTUATOR - REMOVAL . . 23-22,

23-31

INSTRUMENT CLUSTER - ASSEMBLY.....8J-15

INSTRUMENT CLUSTER - DESCRIPTION . . . 8J-2

INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING.......................8J-10

INSTRUMENT CLUSTER - DISASSEMBLY . . 8J-14

INSTRUMENT CLUSTER - INSTALLATION . . 8J-16

INSTRUMENT CLUSTER - OPERATION.....8J-6

INSTRUMENT CLUSTER - REMOVAL.....8J-14

INSTRUMENT PANEL ANTENNA CABLE -

INSTALLATION.......................8A-7

INSTRUMENT PANEL ANTENNA CABLE -

REMOVAL...........................8A-7

INSTRUMENT PANEL ASSEMBLY -

INSTALLATION.......................23-55

INSTRUMENT PANEL ASSEMBLY -

REMOVAL..........................23-52

INSTRUMENT PANEL CENTER BEZEL -

INSTALLATION.......................23-57

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL..........................23-57

INSTRUMENT PANEL DEMISTER DUCTS

- INSTALLATION.....................24-37

INSTRUMENT PANEL DEMISTER DUCTS

- REMOVAL.........................24-36

INSTRUMENT PANEL DRIVER SIDE

BEZEL - INSTALLATION................23-58

INSTRUMENT PANEL DRIVER SIDE

BEZEL - REMOVAL...................23-58

INSTRUMENT PANEL DUCTS -

INSTALLATION.......................24-37

INSTRUMENT PANEL DUCTS - REMOVAL . 24-37

INSTRUMENT PANEL HEADLAMP

SWITCH BEZEL - INSTALLATION.........23-56

INSTRUMENT PANEL HEADLAMP

SWITCH BEZEL - REMOVAL............23-56

INSTRUMENT PANEL LOWER

SURROUND - INSTALLATION...........23-59

INSTRUMENT PANEL LOWER

SURROUND - REMOVAL

...............23-59

INSTRUMENT PANEL TOP COVER -

INSTALLATION

.......................23-59

INSTRUMENT PANEL TOP COVER -

REMOVAL

..........................23-58

INTAKE AIR HEATER - DESCRIPTION

.....14-80

INTAKE AIR HEATER - INSTALLATION

.....14-80

DRINDEX 17

Description Group-Page Description Group-Page Description Group-Page