Over drive DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1989 of 2627

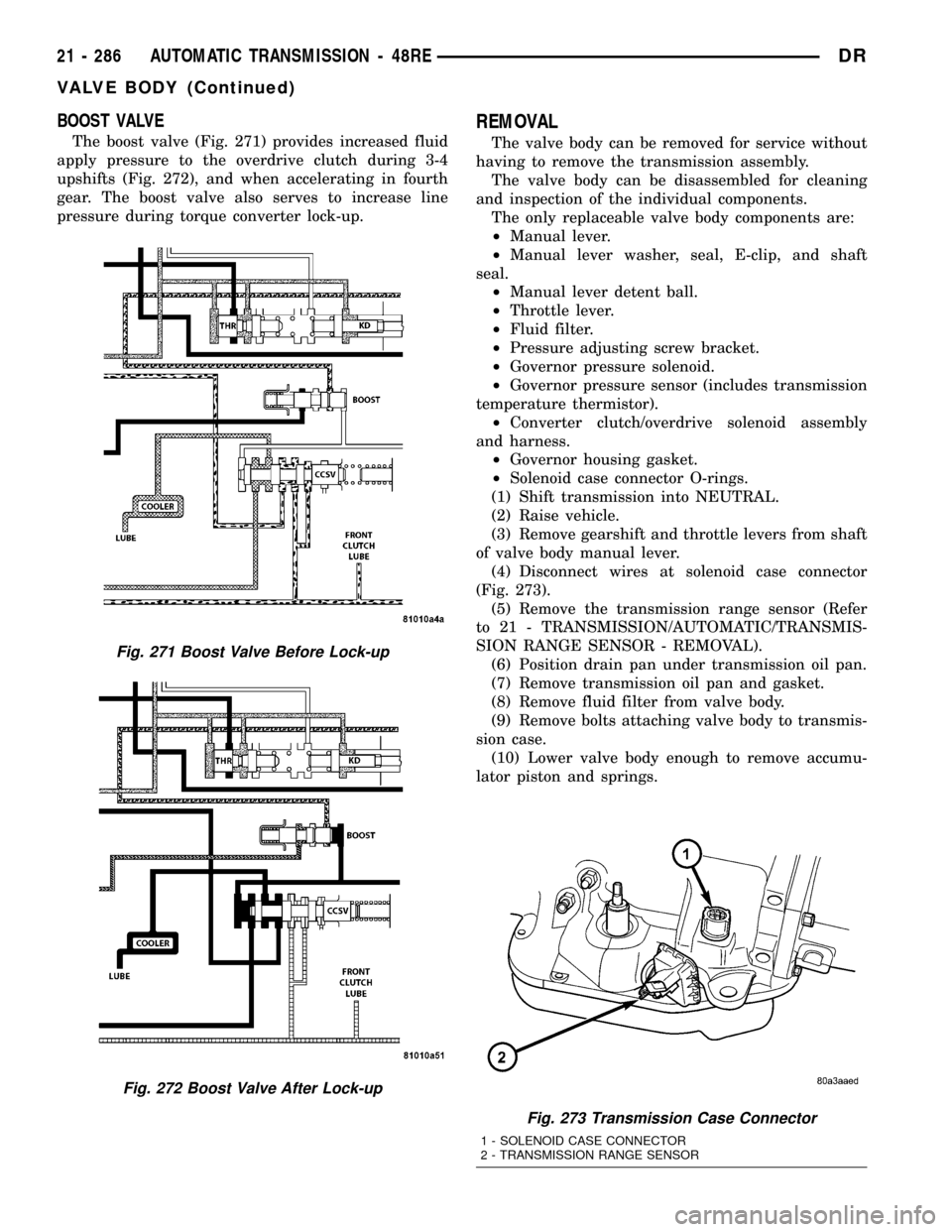

BOOST VALVE

The boost valve (Fig. 271) provides increased fluid

apply pressure to the overdrive clutch during 3-4

upshifts (Fig. 272), and when accelerating in fourth

gear. The boost valve also serves to increase line

pressure during torque converter lock-up.

REMOVAL

The valve body can be removed for service without

having to remove the transmission assembly.

The valve body can be disassembled for cleaning

and inspection of the individual components.

The only replaceable valve body components are:

²Manual lever.

²Manual lever washer, seal, E-clip, and shaft

seal.

²Manual lever detent ball.

²Throttle lever.

²Fluid filter.

²Pressure adjusting screw bracket.

²Governor pressure solenoid.

²Governor pressure sensor (includes transmission

temperature thermistor).

²Converter clutch/overdrive solenoid assembly

and harness.

²Governor housing gasket.

²Solenoid case connector O-rings.

(1) Shift transmission into NEUTRAL.

(2) Raise vehicle.

(3) Remove gearshift and throttle levers from shaft

of valve body manual lever.

(4) Disconnect wires at solenoid case connector

(Fig. 273).

(5) Remove the transmission range sensor (Refer

to 21 - TRANSMISSION/AUTOMATIC/TRANSMIS-

SION RANGE SENSOR - REMOVAL).

(6) Position drain pan under transmission oil pan.

(7) Remove transmission oil pan and gasket.

(8) Remove fluid filter from valve body.

(9) Remove bolts attaching valve body to transmis-

sion case.

(10) Lower valve body enough to remove accumu-

lator piston and springs.

Fig. 273 Transmission Case Connector

1 - SOLENOID CASE CONNECTOR

2 - TRANSMISSION RANGE SENSOR

Fig. 271 Boost Valve Before Lock-up

Fig. 272 Boost Valve After Lock-up

21 - 286 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 1990 of 2627

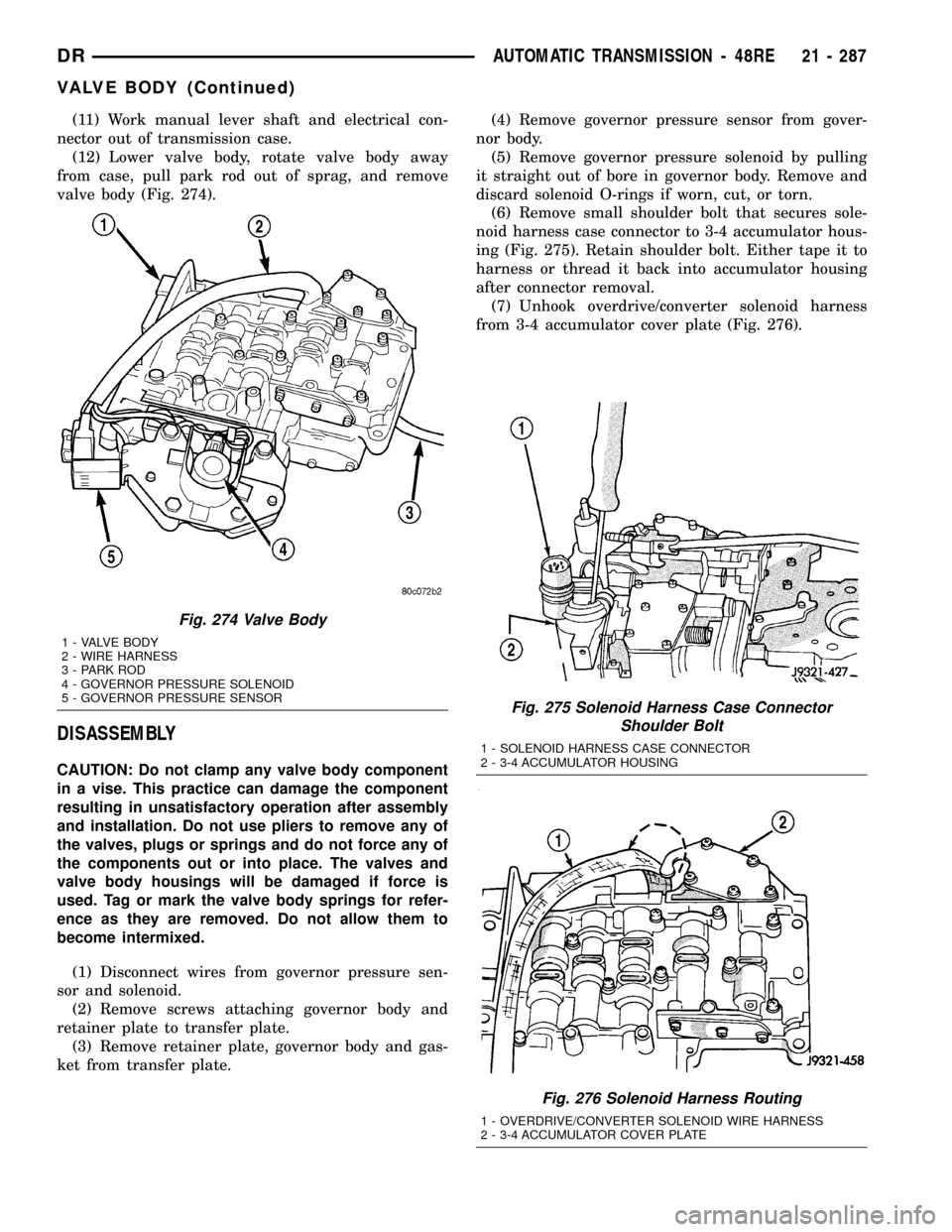

(11) Work manual lever shaft and electrical con-

nector out of transmission case.

(12) Lower valve body, rotate valve body away

from case, pull park rod out of sprag, and remove

valve body (Fig. 274).

DISASSEMBLY

CAUTION: Do not clamp any valve body component

in a vise. This practice can damage the component

resulting in unsatisfactory operation after assembly

and installation. Do not use pliers to remove any of

the valves, plugs or springs and do not force any of

the components out or into place. The valves and

valve body housings will be damaged if force is

used. Tag or mark the valve body springs for refer-

ence as they are removed. Do not allow them to

become intermixed.

(1) Disconnect wires from governor pressure sen-

sor and solenoid.

(2) Remove screws attaching governor body and

retainer plate to transfer plate.

(3) Remove retainer plate, governor body and gas-

ket from transfer plate.(4) Remove governor pressure sensor from gover-

nor body.

(5) Remove governor pressure solenoid by pulling

it straight out of bore in governor body. Remove and

discard solenoid O-rings if worn, cut, or torn.

(6) Remove small shoulder bolt that secures sole-

noid harness case connector to 3-4 accumulator hous-

ing (Fig. 275). Retain shoulder bolt. Either tape it to

harness or thread it back into accumulator housing

after connector removal.

(7) Unhook overdrive/converter solenoid harness

from 3-4 accumulator cover plate (Fig. 276).

Fig. 275 Solenoid Harness Case Connector

Shoulder Bolt

1 - SOLENOID HARNESS CASE CONNECTOR

2 - 3-4 ACCUMULATOR HOUSING

Fig. 276 Solenoid Harness Routing

1 - OVERDRIVE/CONVERTER SOLENOID WIRE HARNESS

2 - 3-4 ACCUMULATOR COVER PLATE

Fig. 274 Valve Body

1 - VALVE BODY

2 - WIRE HARNESS

3 - PARK ROD

4 - GOVERNOR PRESSURE SOLENOID

5 - GOVERNOR PRESSURE SENSOR

DRAUTOMATIC TRANSMISSION - 48RE 21 - 287

VALVE BODY (Continued)

Page 1991 of 2627

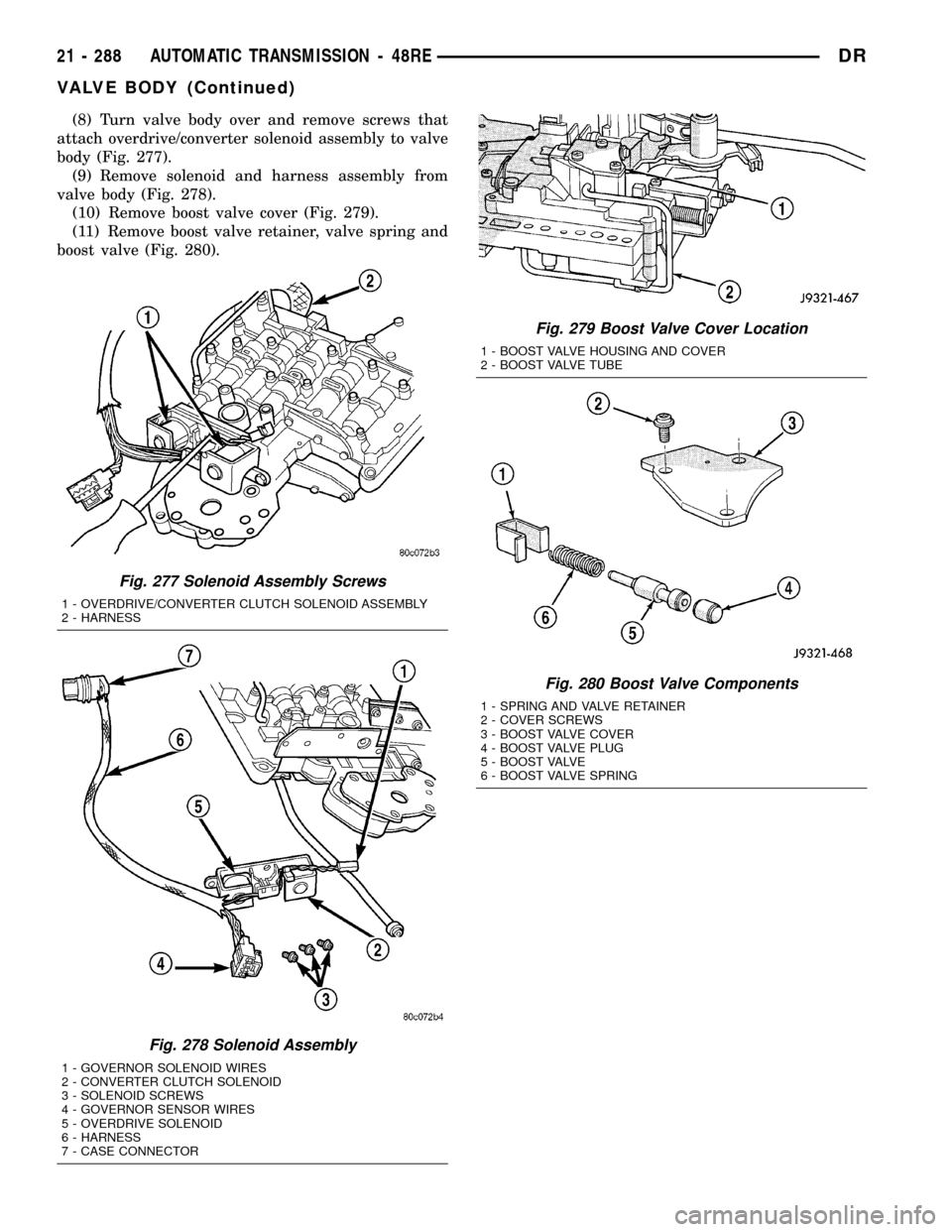

(8) Turn valve body over and remove screws that

attach overdrive/converter solenoid assembly to valve

body (Fig. 277).

(9) Remove solenoid and harness assembly from

valve body (Fig. 278).

(10) Remove boost valve cover (Fig. 279).

(11) Remove boost valve retainer, valve spring and

boost valve (Fig. 280).

Fig. 277 Solenoid Assembly Screws

1 - OVERDRIVE/CONVERTER CLUTCH SOLENOID ASSEMBLY

2 - HARNESS

Fig. 278 Solenoid Assembly

1 - GOVERNOR SOLENOID WIRES

2 - CONVERTER CLUTCH SOLENOID

3 - SOLENOID SCREWS

4 - GOVERNOR SENSOR WIRES

5 - OVERDRIVE SOLENOID

6 - HARNESS

7 - CASE CONNECTOR

Fig. 279 Boost Valve Cover Location

1 - BOOST VALVE HOUSING AND COVER

2 - BOOST VALVE TUBE

Fig. 280 Boost Valve Components

1 - SPRING AND VALVE RETAINER

2 - COVER SCREWS

3 - BOOST VALVE COVER

4 - BOOST VALVE PLUG

5 - BOOST VALVE

6 - BOOST VALVE SPRING

21 - 288 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 1995 of 2627

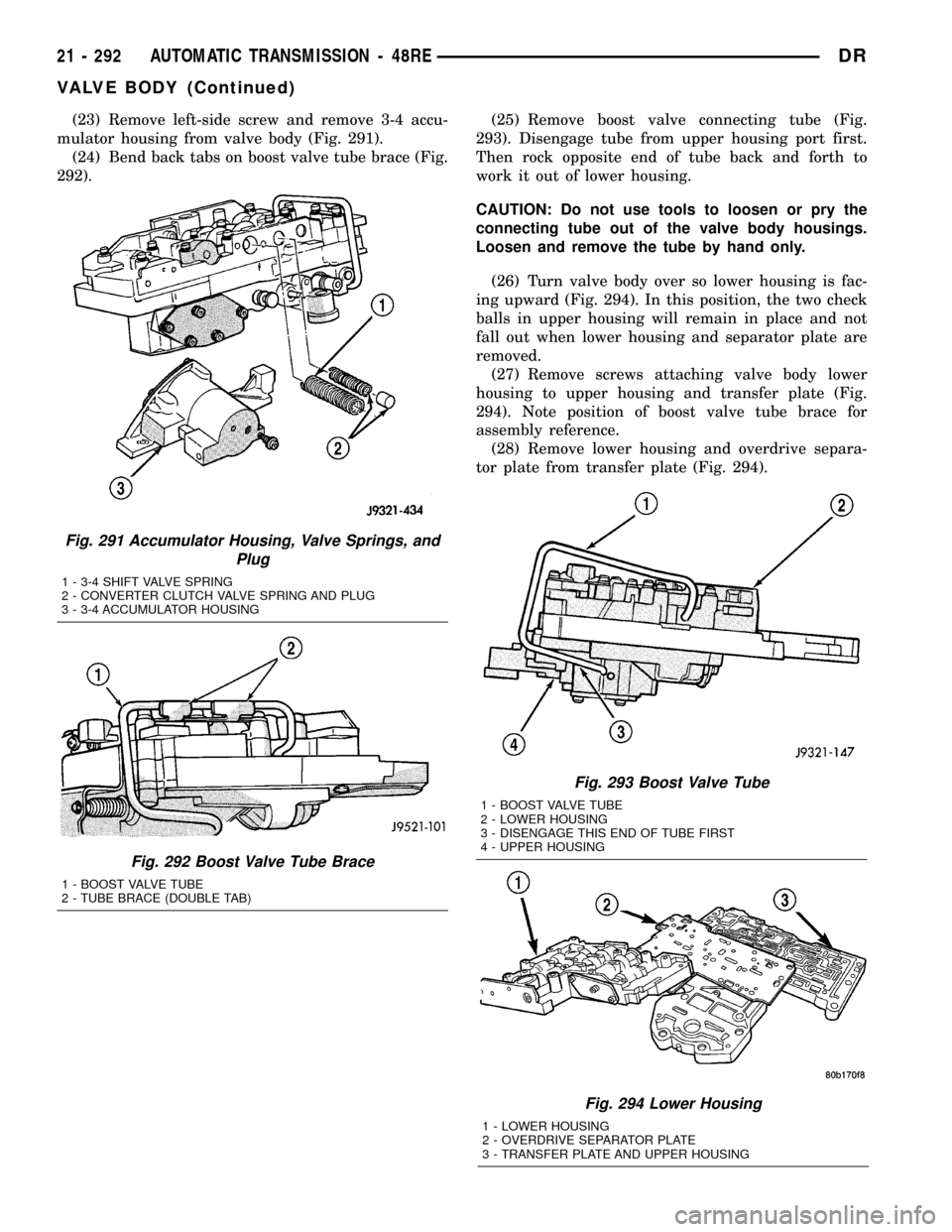

(23) Remove left-side screw and remove 3-4 accu-

mulator housing from valve body (Fig. 291).

(24) Bend back tabs on boost valve tube brace (Fig.

292).(25) Remove boost valve connecting tube (Fig.

293). Disengage tube from upper housing port first.

Then rock opposite end of tube back and forth to

work it out of lower housing.

CAUTION: Do not use tools to loosen or pry the

connecting tube out of the valve body housings.

Loosen and remove the tube by hand only.

(26) Turn valve body over so lower housing is fac-

ing upward (Fig. 294). In this position, the two check

balls in upper housing will remain in place and not

fall out when lower housing and separator plate are

removed.

(27) Remove screws attaching valve body lower

housing to upper housing and transfer plate (Fig.

294). Note position of boost valve tube brace for

assembly reference.

(28) Remove lower housing and overdrive separa-

tor plate from transfer plate (Fig. 294).

Fig. 293 Boost Valve Tube

1 - BOOST VALVE TUBE

2 - LOWER HOUSING

3 - DISENGAGE THIS END OF TUBE FIRST

4 - UPPER HOUSING

Fig. 294 Lower Housing

1 - LOWER HOUSING

2 - OVERDRIVE SEPARATOR PLATE

3 - TRANSFER PLATE AND UPPER HOUSING

Fig. 291 Accumulator Housing, Valve Springs, and

Plug

1 - 3-4 SHIFT VALVE SPRING

2 - CONVERTER CLUTCH VALVE SPRING AND PLUG

3 - 3-4 ACCUMULATOR HOUSING

Fig. 292 Boost Valve Tube Brace

1 - BOOST VALVE TUBE

2 - TUBE BRACE (DOUBLE TAB)

21 - 292 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2000 of 2627

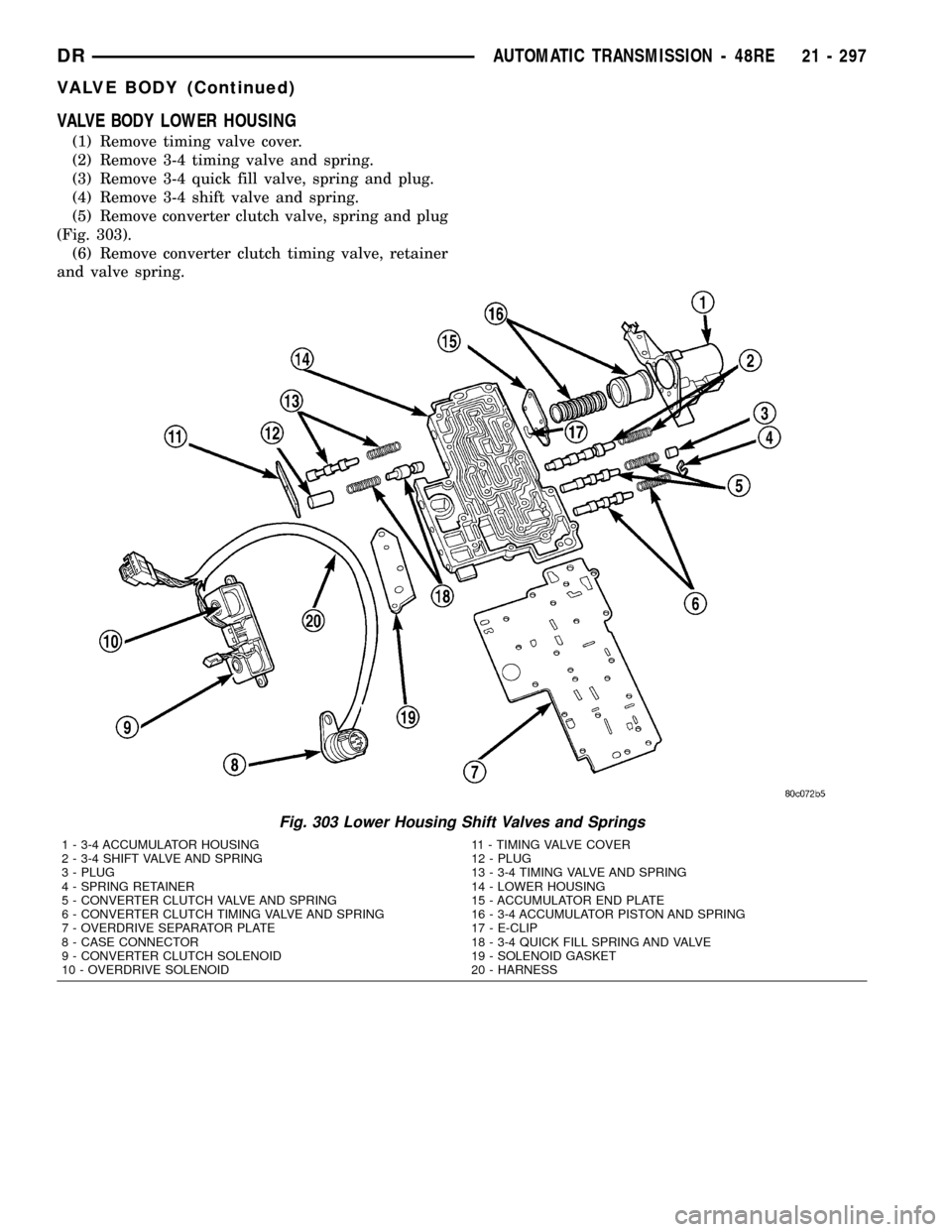

VALVE BODY LOWER HOUSING

(1) Remove timing valve cover.

(2) Remove 3-4 timing valve and spring.

(3) Remove 3-4 quick fill valve, spring and plug.

(4) Remove 3-4 shift valve and spring.

(5) Remove converter clutch valve, spring and plug

(Fig. 303).

(6) Remove converter clutch timing valve, retainer

and valve spring.

Fig. 303 Lower Housing Shift Valves and Springs

1 - 3-4 ACCUMULATOR HOUSING 11 - TIMING VALVE COVER

2 - 3-4 SHIFT VALVE AND SPRING 12 - PLUG

3 - PLUG 13 - 3-4 TIMING VALVE AND SPRING

4 - SPRING RETAINER 14 - LOWER HOUSING

5 - CONVERTER CLUTCH VALVE AND SPRING 15 - ACCUMULATOR END PLATE

6 - CONVERTER CLUTCH TIMING VALVE AND SPRING 16 - 3-4 ACCUMULATOR PISTON AND SPRING

7 - OVERDRIVE SEPARATOR PLATE 17 - E-CLIP

8 - CASE CONNECTOR 18 - 3-4 QUICK FILL SPRING AND VALVE

9 - CONVERTER CLUTCH SOLENOID 19 - SOLENOID GASKET

10 - OVERDRIVE SOLENOID 20 - HARNESS

DRAUTOMATIC TRANSMISSION - 48RE 21 - 297

VALVE BODY (Continued)

Page 2003 of 2627

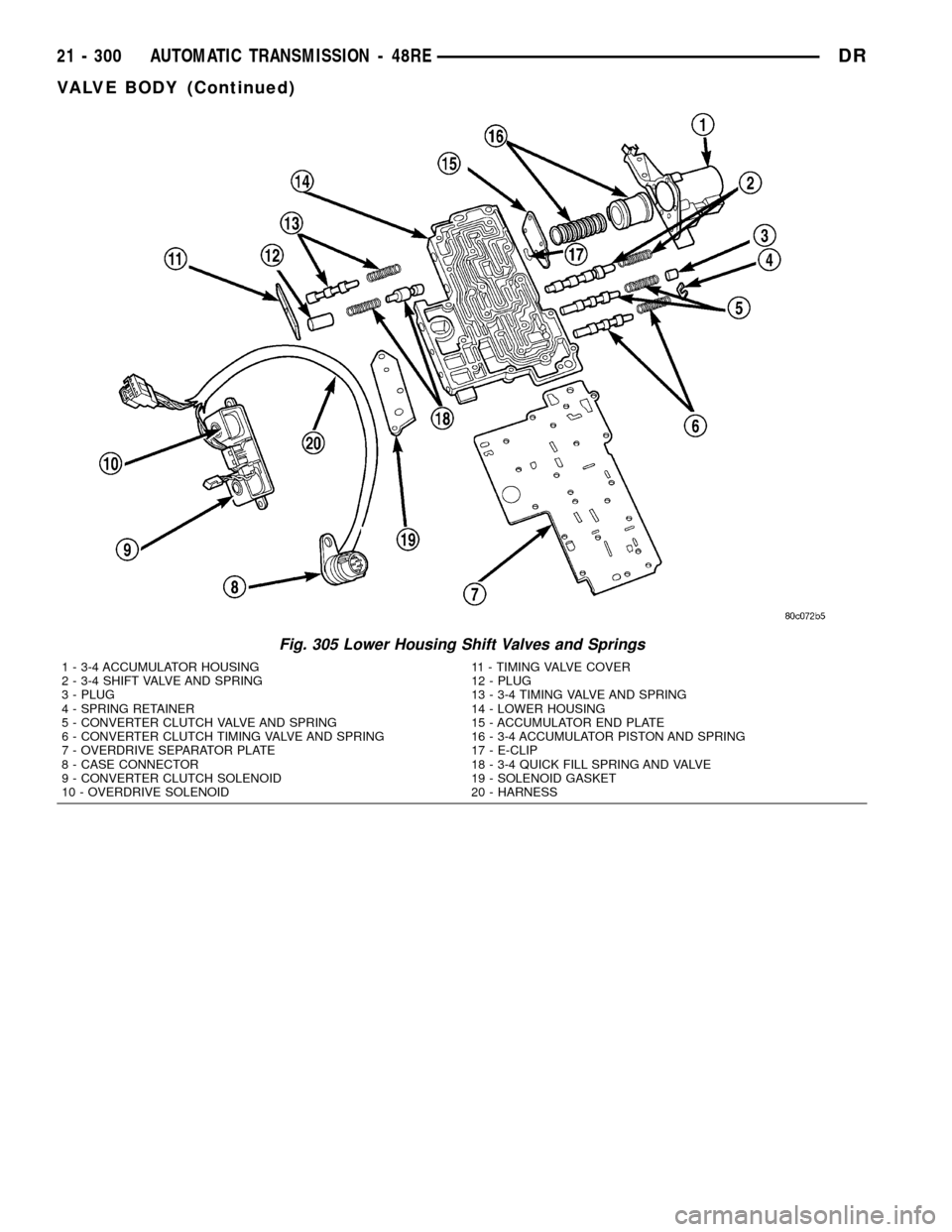

Fig. 305 Lower Housing Shift Valves and Springs

1 - 3-4 ACCUMULATOR HOUSING 11 - TIMING VALVE COVER

2 - 3-4 SHIFT VALVE AND SPRING 12 - PLUG

3 - PLUG 13 - 3-4 TIMING VALVE AND SPRING

4 - SPRING RETAINER 14 - LOWER HOUSING

5 - CONVERTER CLUTCH VALVE AND SPRING 15 - ACCUMULATOR END PLATE

6 - CONVERTER CLUTCH TIMING VALVE AND SPRING 16 - 3-4 ACCUMULATOR PISTON AND SPRING

7 - OVERDRIVE SEPARATOR PLATE 17 - E-CLIP

8 - CASE CONNECTOR 18 - 3-4 QUICK FILL SPRING AND VALVE

9 - CONVERTER CLUTCH SOLENOID 19 - SOLENOID GASKET

10 - OVERDRIVE SOLENOID 20 - HARNESS

21 - 300 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2005 of 2627

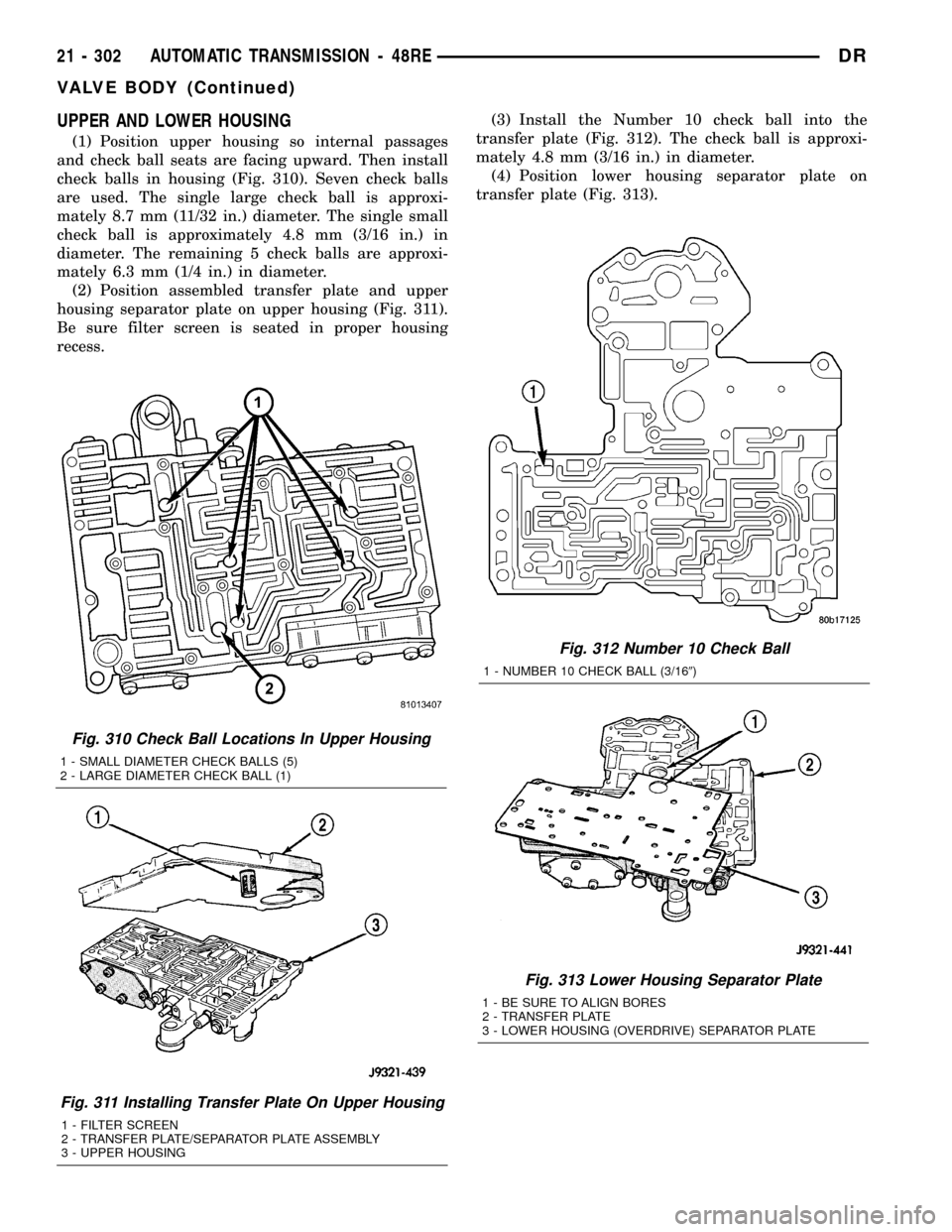

UPPER AND LOWER HOUSING

(1) Position upper housing so internal passages

and check ball seats are facing upward. Then install

check balls in housing (Fig. 310). Seven check balls

are used. The single large check ball is approxi-

mately 8.7 mm (11/32 in.) diameter. The single small

check ball is approximately 4.8 mm (3/16 in.) in

diameter. The remaining 5 check balls are approxi-

mately 6.3 mm (1/4 in.) in diameter.

(2) Position assembled transfer plate and upper

housing separator plate on upper housing (Fig. 311).

Be sure filter screen is seated in proper housing

recess.(3) Install the Number 10 check ball into the

transfer plate (Fig. 312). The check ball is approxi-

mately 4.8 mm (3/16 in.) in diameter.

(4) Position lower housing separator plate on

transfer plate (Fig. 313).

Fig. 310 Check Ball Locations In Upper Housing

1 - SMALL DIAMETER CHECK BALLS (5)

2 - LARGE DIAMETER CHECK BALL (1)

Fig. 311 Installing Transfer Plate On Upper Housing

1 - FILTER SCREEN

2 - TRANSFER PLATE/SEPARATOR PLATE ASSEMBLY

3 - UPPER HOUSING

Fig. 312 Number 10 Check Ball

1 - NUMBER 10 CHECK BALL (3/169)

Fig. 313 Lower Housing Separator Plate

1 - BE SURE TO ALIGN BORES

2 - TRANSFER PLATE

3 - LOWER HOUSING (OVERDRIVE) SEPARATOR PLATE

21 - 302 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2011 of 2627

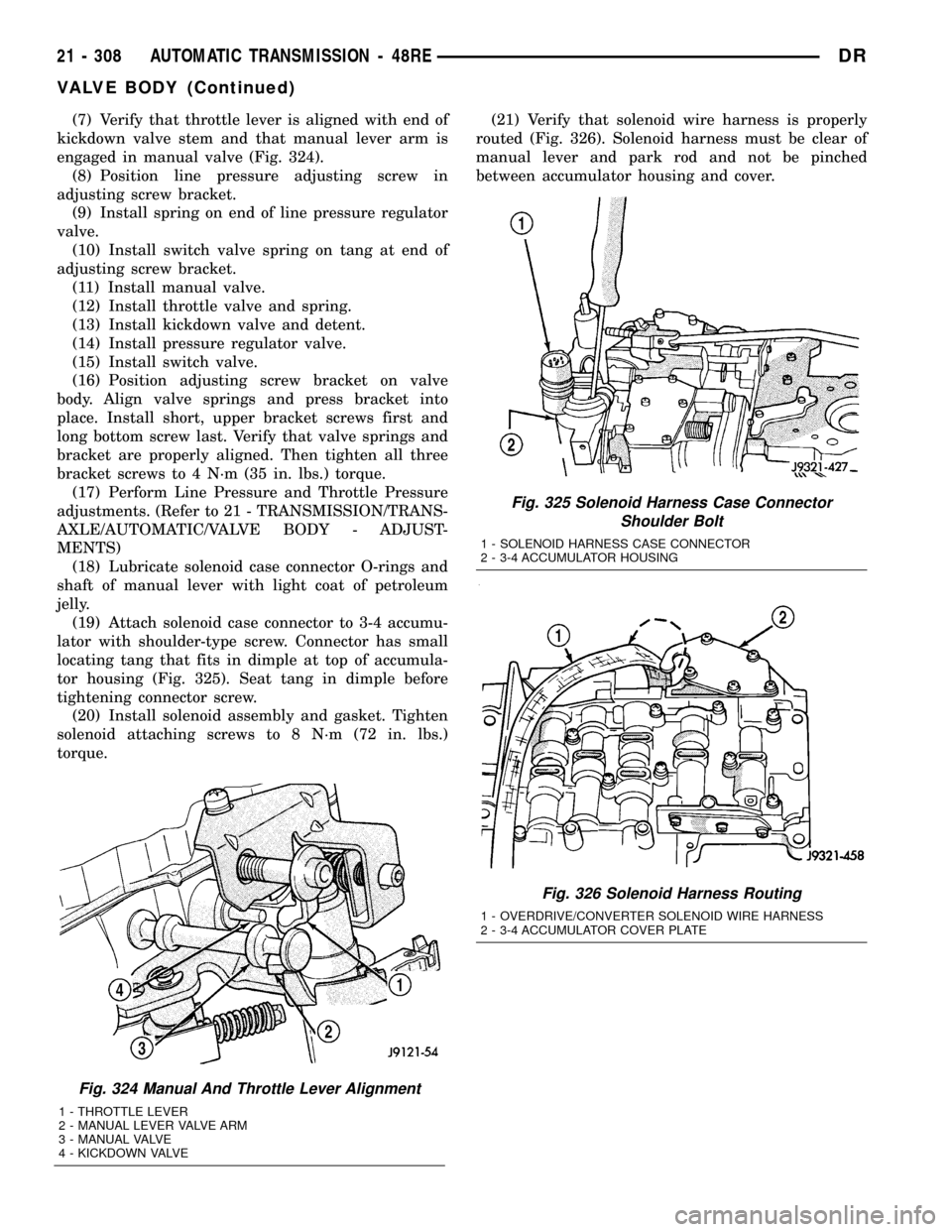

(7) Verify that throttle lever is aligned with end of

kickdown valve stem and that manual lever arm is

engaged in manual valve (Fig. 324).

(8) Position line pressure adjusting screw in

adjusting screw bracket.

(9) Install spring on end of line pressure regulator

valve.

(10) Install switch valve spring on tang at end of

adjusting screw bracket.

(11) Install manual valve.

(12) Install throttle valve and spring.

(13) Install kickdown valve and detent.

(14) Install pressure regulator valve.

(15) Install switch valve.

(16) Position adjusting screw bracket on valve

body. Align valve springs and press bracket into

place. Install short, upper bracket screws first and

long bottom screw last. Verify that valve springs and

bracket are properly aligned. Then tighten all three

bracket screws to 4 N´m (35 in. lbs.) torque.

(17) Perform Line Pressure and Throttle Pressure

adjustments. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC/VALVE BODY - ADJUST-

MENTS)

(18) Lubricate solenoid case connector O-rings and

shaft of manual lever with light coat of petroleum

jelly.

(19) Attach solenoid case connector to 3-4 accumu-

lator with shoulder-type screw. Connector has small

locating tang that fits in dimple at top of accumula-

tor housing (Fig. 325). Seat tang in dimple before

tightening connector screw.

(20) Install solenoid assembly and gasket. Tighten

solenoid attaching screws to 8 N´m (72 in. lbs.)

torque.(21) Verify that solenoid wire harness is properly

routed (Fig. 326). Solenoid harness must be clear of

manual lever and park rod and not be pinched

between accumulator housing and cover.

Fig. 324 Manual And Throttle Lever Alignment

1 - THROTTLE LEVER

2 - MANUAL LEVER VALVE ARM

3 - MANUAL VALVE

4 - KICKDOWN VALVE

Fig. 325 Solenoid Harness Case Connector

Shoulder Bolt

1 - SOLENOID HARNESS CASE CONNECTOR

2 - 3-4 ACCUMULATOR HOUSING

Fig. 326 Solenoid Harness Routing

1 - OVERDRIVE/CONVERTER SOLENOID WIRE HARNESS

2 - 3-4 ACCUMULATOR COVER PLATE

21 - 308 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2015 of 2627

INSTALLATION........................391

OUTPUT SPEED SENSOR

DESCRIPTION........................391

OPERATION..........................391

REMOVAL............................391

INSTALLATION........................392

TOW/HAUL OVERDRIVE SWITCH

DESCRIPTION........................392

OPERATION..........................392

REMOVAL............................392

INSTALLATION........................393

PISTONS

DESCRIPTION........................393

OPERATION..........................393

PLANETARY GEARTRAIN

DESCRIPTION........................395

OPERATION..........................396

DISASSEMBLY........................396

CLEANING...........................396

INSPECTION.........................397

ASSEMBLY...........................397

SHIFT MECHANISM

DESCRIPTION........................398

OPERATION..........................398

SOLENOID SWITCH VALVE

DESCRIPTION........................398

OPERATION..........................398

SOLENOIDS

DESCRIPTION........................398OPERATION..........................399

TORQUE CONVERTER

DESCRIPTION........................399

OPERATION..........................403

REMOVAL............................404

INSTALLATION........................404

TRANSMISSION CONTROL RELAY

DESCRIPTION........................405

OPERATION..........................405

TRANSMISSION RANGE SENSOR

DESCRIPTION........................405

OPERATION..........................405

TRANSMISSION SOLENOID/TRS ASSEMBLY

DESCRIPTION........................406

OPERATION..........................406

REMOVAL............................407

INSTALLATION........................408

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION........................408

OPERATION..........................408

VALVE BODY

DESCRIPTION........................408

OPERATION..........................408

REMOVAL............................410

DISASSEMBLY........................410

CLEANING...........................412

INSPECTION.........................413

ASSEMBLY...........................414

INSTALLATION........................414

AUTOMATIC TRANSMISSION -

45RFE/545RFE

DESCRIPTION

The 45RFE/545RFE automatic transmissions is a

sophisticated, multi-range, electronically controlled

transmission which combines optimized gear ratios

for responsive performance, state of the art efficiency

features and low NVH. Other features include driver

adaptive shifting and three planetary gear sets to

provide wide ratio capability with precise ratio steps

for optimum driveability. The three planetary gear

sets also make available a unique alternate second

gear ratio. The primary 2nd gear ratio fits between

1st and 3rd gears for normal through-gear accelera-

tions. The alternate second gear ratio (2prime) allows

smoother 4-2 kickdowns at high speeds to provide

2nd gear passing performance over a wider highway

cruising range.

The hydraulic portion of the transmission consists

of the transmission fluid, fluid passages, hydraulic

valves, and various line pressure control components.The primary mechanical components of the trans-

mission consist of the following:

²Three multiple disc input clutches

²Three multiple disc holding clutches

²Five hydraulic accumulators

²Three planetary gear sets

²Dual Stage Hydraulic oil pump

²Valve body

²Solenoid pack

The TCM is the ªheartº or ªbrainº of the electronic

control system and relies on information from vari-

ous direct and indirect inputs (sensors, switches, etc.)

to determine driver demand and vehicle operating

conditions. With this information, the TCM can cal-

culate and perform timely and quality shifts through

various output or control devices (solenoid pack,

transmission control relay, etc.).

21 - 312 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

Page 2016 of 2627

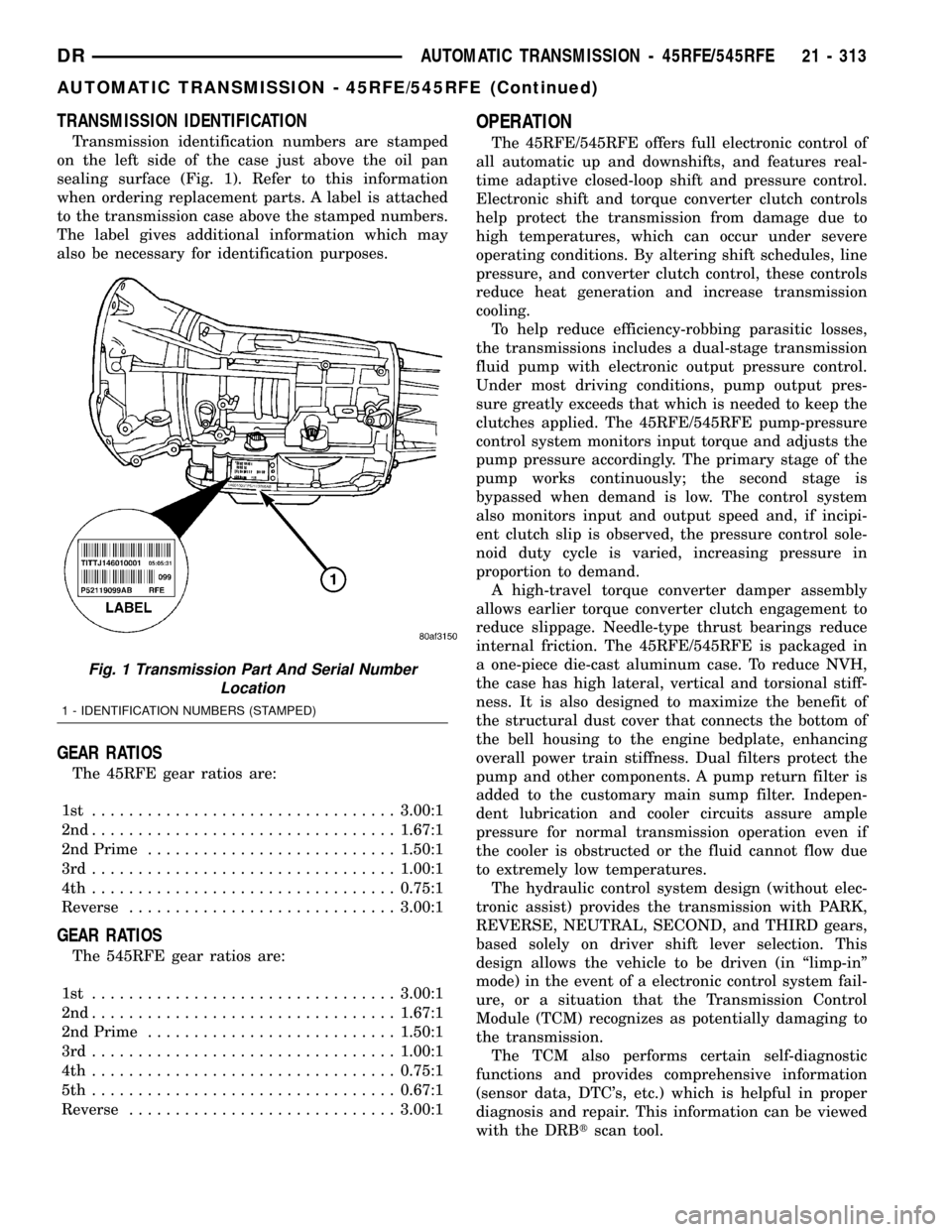

TRANSMISSION IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan

sealing surface (Fig. 1). Refer to this information

when ordering replacement parts. A label is attached

to the transmission case above the stamped numbers.

The label gives additional information which may

also be necessary for identification purposes.

GEAR RATIOS

The 45RFE gear ratios are:

1st .................................3.00:1

2nd.................................1.67:1

2nd Prime...........................1.50:1

3rd.................................1.00:1

4th .................................0.75:1

Reverse.............................3.00:1

GEAR RATIOS

The 545RFE gear ratios are:

1st .................................3.00:1

2nd.................................1.67:1

2nd Prime...........................1.50:1

3rd.................................1.00:1

4th .................................0.75:1

5th .................................0.67:1

Reverse.............................3.00:1

OPERATION

The 45RFE/545RFE offers full electronic control of

all automatic up and downshifts, and features real-

time adaptive closed-loop shift and pressure control.

Electronic shift and torque converter clutch controls

help protect the transmission from damage due to

high temperatures, which can occur under severe

operating conditions. By altering shift schedules, line

pressure, and converter clutch control, these controls

reduce heat generation and increase transmission

cooling.

To help reduce efficiency-robbing parasitic losses,

the transmissions includes a dual-stage transmission

fluid pump with electronic output pressure control.

Under most driving conditions, pump output pres-

sure greatly exceeds that which is needed to keep the

clutches applied. The 45RFE/545RFE pump-pressure

control system monitors input torque and adjusts the

pump pressure accordingly. The primary stage of the

pump works continuously; the second stage is

bypassed when demand is low. The control system

also monitors input and output speed and, if incipi-

ent clutch slip is observed, the pressure control sole-

noid duty cycle is varied, increasing pressure in

proportion to demand.

A high-travel torque converter damper assembly

allows earlier torque converter clutch engagement to

reduce slippage. Needle-type thrust bearings reduce

internal friction. The 45RFE/545RFE is packaged in

a one-piece die-cast aluminum case. To reduce NVH,

the case has high lateral, vertical and torsional stiff-

ness. It is also designed to maximize the benefit of

the structural dust cover that connects the bottom of

the bell housing to the engine bedplate, enhancing

overall power train stiffness. Dual filters protect the

pump and other components. A pump return filter is

added to the customary main sump filter. Indepen-

dent lubrication and cooler circuits assure ample

pressure for normal transmission operation even if

the cooler is obstructed or the fluid cannot flow due

to extremely low temperatures.

The hydraulic control system design (without elec-

tronic assist) provides the transmission with PARK,

REVERSE, NEUTRAL, SECOND, and THIRD gears,

based solely on driver shift lever selection. This

design allows the vehicle to be driven (in ªlimp-inº

mode) in the event of a electronic control system fail-

ure, or a situation that the Transmission Control

Module (TCM) recognizes as potentially damaging to

the transmission.

The TCM also performs certain self-diagnostic

functions and provides comprehensive information

(sensor data, DTC's, etc.) which is helpful in proper

diagnosis and repair. This information can be viewed

with the DRBtscan tool.

Fig. 1 Transmission Part And Serial Number

Location

1 - IDENTIFICATION NUMBERS (STAMPED)

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 313

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)