Transmission shaft DODGE RAM 1500 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 548 of 2627

tioned at the relative engine speed position on the

gauge scale until the engine stops running, or until

the ignition switch is turned to the Off position,

whichever occurs first.

²Communication Error- If the cluster fails to

receive an engine speed message, it will hold the

gauge needle at the last indication for about three

seconds, or until the ignition switch is turned to the

Off position, whichever occurs first. After three sec-

onds, the gauge needle will return to the left end of

the gauge scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the tachometer needle will

be swept to several calibration points on the gauge

scale in a prescribed sequence in order to confirm the

functionality of the gauge and the cluster control cir-

cuitry.

On vehicles with a gasoline engine, the PCM con-

tinually monitors the crankshaft position sensor to

determine the engine speed. On vehicles with a die-

sel engine, the ECM continually monitors the engine

speed sensor to determine the engine speed. The

PCM or ECM then sends the proper engine speed

messages to the instrument cluster. For further diag-

nosis of the tachometer or the instrument cluster cir-

cuitry that controls the gauge, (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - DIAGNO-

SIS AND TESTING). For proper diagnosis of the

crankshaft position sensor, the engine speed sensor,

the PCM, the ECM, the PCI data bus, or the elec-

tronic message inputs to the instrument cluster that

control the tachometer, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

TOW/HAUL INDICATOR

DESCRIPTION

A tow/haul indicator is standard equipment on all

instrument clusters (Fig. 30). However, on vehicles

not equipped with the optional overdrive automatic

transmission, this indicator is electronically disabled.

The tow/haul indicator consists of the text ªTOW/

HAULº, which appears in the lower portion of the

odometer/trip odometer indicator Vacuum Fluores-

cent Display (VFD) unit. The VFD is soldered onto

the cluster electronic circuit board and is visible

through a window with a smoked clear lens located

on the lower edge of the tachometer gauge dial face

of the cluster overlay. The dark lens over the VFDprevents the indicator from being clearly visible

when it is not illuminated. The text ªTOW/HAULº

appear in an amber color and at the same lighting

level as the odometer/trip odometer information

when they are illuminated by the instrument cluster

electronic circuit board. The tow/haul indicator is ser-

viced as a unit with the VFD in the instrument clus-

ter.

OPERATION

The tow/haul indicator gives an indication to the

vehicle operator when the Off position of the tow/

haul switch has been selected, disabling the electron-

ically controlled overdrive feature of the automatic

transmission. This indicator is controlled by the

instrument cluster circuit board based upon cluster

programming and electronic messages received by

the cluster from the Powertrain Control Module

(PCM) over the Programmable Communications

Interface (PCI) data bus. The tow/haul indicator is

completely controlled by the instrument cluster logic

circuit, and that logic will only allow this indicator to

operate when the instrument cluster receives a bat-

tery current input on the fused ignition switch out-

put (run-start) circuit. Therefore, the indicator will

always be off when the ignition switch is in any posi-

tion except On or Start. The indicator only illumi-

nates when it is switched to ground by the

instrument cluster circuitry. The instrument cluster

will turn on the tow/haul off indicator for the follow-

ing reasons:

²Tow/Haul Lamp-On Message- Each time the

cluster receives a tow/haul lamp-on message from the

PCM indicating that the Off position of the tow/haul

switch has been selected, the tow/haul indicator will

be illuminated. The indicator remains illuminated

until the cluster receives a tow/haul lamp-off mes-

sage from the PCM, or until the ignition switch is

turned to the Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the tow/haul indicator will

be turned on, then off again during the VFD portion

of the test to confirm the functionality of the VFD

and the cluster control circuitry.

The PCM continually monitors the tow/haul switch

to determine the proper outputs to the automatic

transmission. The PCM then sends the proper tow/

haul lamp-on and lamp-off messages to the instru-

ment cluster. For further diagnosis of the tow/haul

indicator or the instrument cluster circuitry that con-

trols the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the overdrive con-

trol system, the PCM, the PCI data bus, or the elec-

tronic message inputs to the instrument cluster that

control the tow/haul indicator, a DRBIIItscan tool is

Fig. 30 Tow/Haul Indicator

DRINSTRUMENT CLUSTER 8J - 39

TACHOMETER (Continued)

Page 641 of 2627

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

NOTE: Before starting this procedure, be certain

that the front wheels are still in the straight-ahead

position.

(1) While holding the centered clockspring rotor

and case stationary in relation to each other, care-

fully slide the clockspring down over the steering col-

umn upper shaft.

(2) Align and seat the hole in the locating tab at

the eleven o'clock position on the clockspring case

over the locating pin on the multi-function switch

mounting housing (Fig. 20).

(3) Install and tighten the two screws that secure

the clockspring to the multi-function switch mount-

ing housing. Tighten the screws to 2 N´m (20 in.

lbs.).

(4) Reconnect the two instrument panel wire har-

ness connectors for the clockspring to the two connec-

tor receptacles below the steering column on the back

of the clockspring housing.

(5) Position the lower shroud onto the steering col-

umn.

(6) From below the steering column, install and

tighten the one center screw that secures the lower

shroud to the steering column lock housing. Tighten

the screw to 2 N´m (20 in. lbs.).(7) Position the upper shroud onto the steering col-

umn. If the vehicle is equipped with an automatic

transmission, be certain to engage the gearshift lever

gap hider into the openings in the right side of the

upper and lower shrouds.

(8) Align the snap features on the upper shroud

with the receptacles on the lower shroud and apply

hand pressure to snap them together.

(9) From below the steering column, install and

tighten the two screws that secure the upper shroud

to the lower shroud. Tighten the screws to 2 N´m (20

in. lbs.).

(10) If the vehicle is equipped with the optional tilt

steering column, align the steering column tilt knob

with the tilt adjuster mechanism lever located on the

left side of the column just below the multi-function

switch control stalk and, using hand pressure, push

the knob firmly onto the lever.

(11) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(12) If a new clockspring has been installed,

remove the plastic locking pin that is securing the

clockspring rotor to the clockspring case to maintain

clockspring centering.

NOTE: When reinstalling the steering wheel, be cer-

tain to index the yellow rubber booted engagement

dowel on the upper surface of the clockspring rotor

between the two fins cast into the lower surface of

the steering wheel armature hub.

(13) Reinstall the steering wheel onto the steering

column. (Refer to 19 - STEERING/COLUMN/STEER-

ING WHEEL - INSTALLATION).

(14) Reconnect the steering wheel wire harness

connectors to the upper clockspring connector recep-

tacles. Be certain that the steering wheel wire har-

ness is routed between the steering wheel back trim

cover and the steering wheel armature.

(15) Reinstall the driver airbag onto the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

8O - 22 RESTRAINTSDR

CLOCKSPRING (Continued)

Page 719 of 2627

INSTALLATION

(1) Position the wiper high/low relay to the proper

receptacle in the Integrated Power Module (IPM)

(Fig. 24).

(2) Align the wiper high/low relay terminals with

the terminal cavities in the IPM receptacle.

(3) Push firmly and evenly on the top of the wiper

high/low relay until the terminals are fully seated in

the terminal cavities in the IPM receptacle.

(4) Reinstall the cover onto the IPM.

(5) Reconnect the battery negative cable.

WIPER MODULE

DESCRIPTION

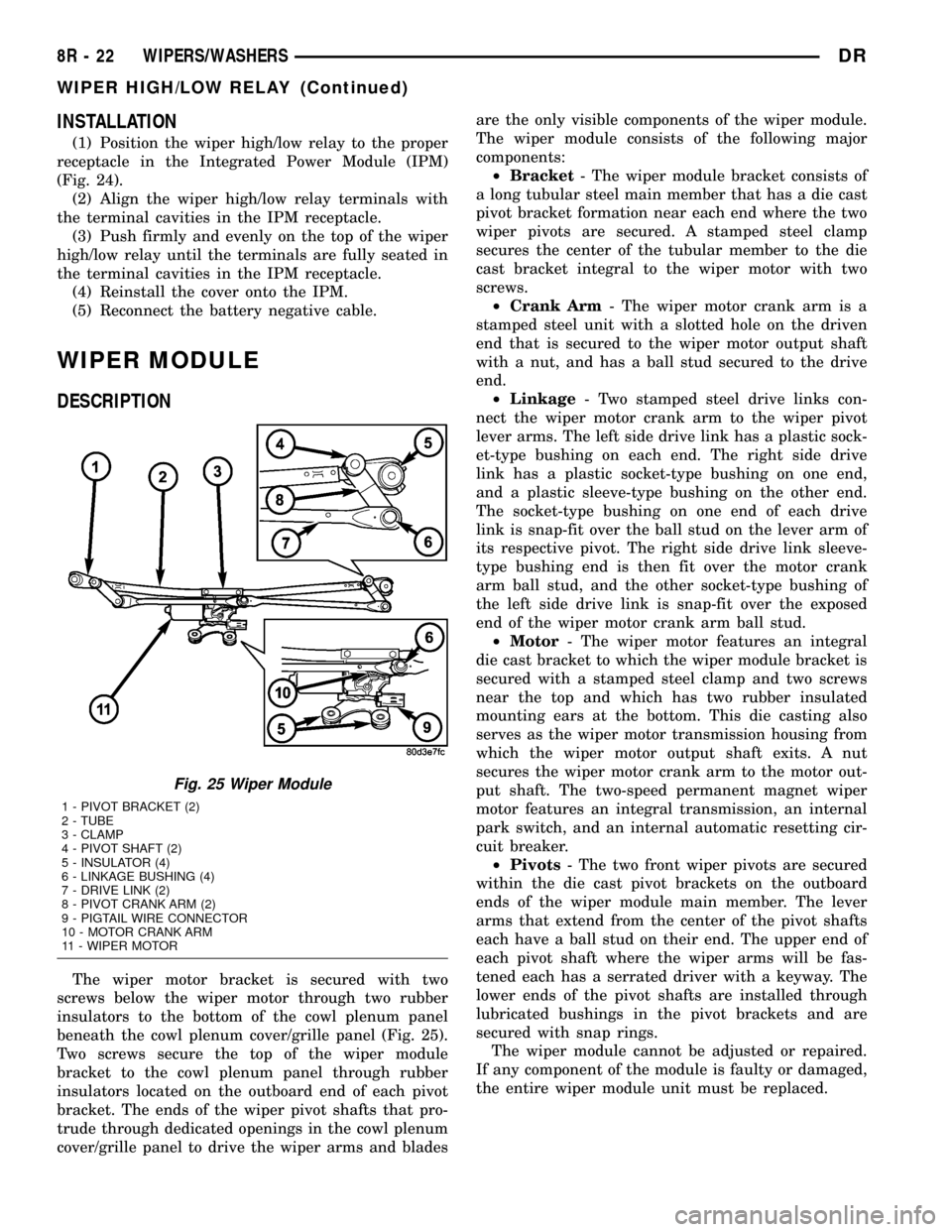

The wiper motor bracket is secured with two

screws below the wiper motor through two rubber

insulators to the bottom of the cowl plenum panel

beneath the cowl plenum cover/grille panel (Fig. 25).

Two screws secure the top of the wiper module

bracket to the cowl plenum panel through rubber

insulators located on the outboard end of each pivot

bracket. The ends of the wiper pivot shafts that pro-

trude through dedicated openings in the cowl plenum

cover/grille panel to drive the wiper arms and bladesare the only visible components of the wiper module.

The wiper module consists of the following major

components:

²Bracket- The wiper module bracket consists of

a long tubular steel main member that has a die cast

pivot bracket formation near each end where the two

wiper pivots are secured. A stamped steel clamp

secures the center of the tubular member to the die

cast bracket integral to the wiper motor with two

screws.

²Crank Arm- The wiper motor crank arm is a

stamped steel unit with a slotted hole on the driven

end that is secured to the wiper motor output shaft

with a nut, and has a ball stud secured to the drive

end.

²Linkage- Two stamped steel drive links con-

nect the wiper motor crank arm to the wiper pivot

lever arms. The left side drive link has a plastic sock-

et-type bushing on each end. The right side drive

link has a plastic socket-type bushing on one end,

and a plastic sleeve-type bushing on the other end.

The socket-type bushing on one end of each drive

link is snap-fit over the ball stud on the lever arm of

its respective pivot. The right side drive link sleeve-

type bushing end is then fit over the motor crank

arm ball stud, and the other socket-type bushing of

the left side drive link is snap-fit over the exposed

end of the wiper motor crank arm ball stud.

²Motor- The wiper motor features an integral

die cast bracket to which the wiper module bracket is

secured with a stamped steel clamp and two screws

near the top and which has two rubber insulated

mounting ears at the bottom. This die casting also

serves as the wiper motor transmission housing from

which the wiper motor output shaft exits. A nut

secures the wiper motor crank arm to the motor out-

put shaft. The two-speed permanent magnet wiper

motor features an integral transmission, an internal

park switch, and an internal automatic resetting cir-

cuit breaker.

²Pivots- The two front wiper pivots are secured

within the die cast pivot brackets on the outboard

ends of the wiper module main member. The lever

arms that extend from the center of the pivot shafts

each have a ball stud on their end. The upper end of

each pivot shaft where the wiper arms will be fas-

tened each has a serrated driver with a keyway. The

lower ends of the pivot shafts are installed through

lubricated bushings in the pivot brackets and are

secured with snap rings.

The wiper module cannot be adjusted or repaired.

If any component of the module is faulty or damaged,

the entire wiper module unit must be replaced.

Fig. 25 Wiper Module

1 - PIVOT BRACKET (2)

2 - TUBE

3 - CLAMP

4 - PIVOT SHAFT (2)

5 - INSULATOR (4)

6 - LINKAGE BUSHING (4)

7 - DRIVE LINK (2)

8 - PIVOT CRANK ARM (2)

9 - PIGTAIL WIRE CONNECTOR

10 - MOTOR CRANK ARM

11 - WIPER MOTOR

8R - 22 WIPERS/WASHERSDR

WIPER HIGH/LOW RELAY (Continued)

Page 744 of 2627

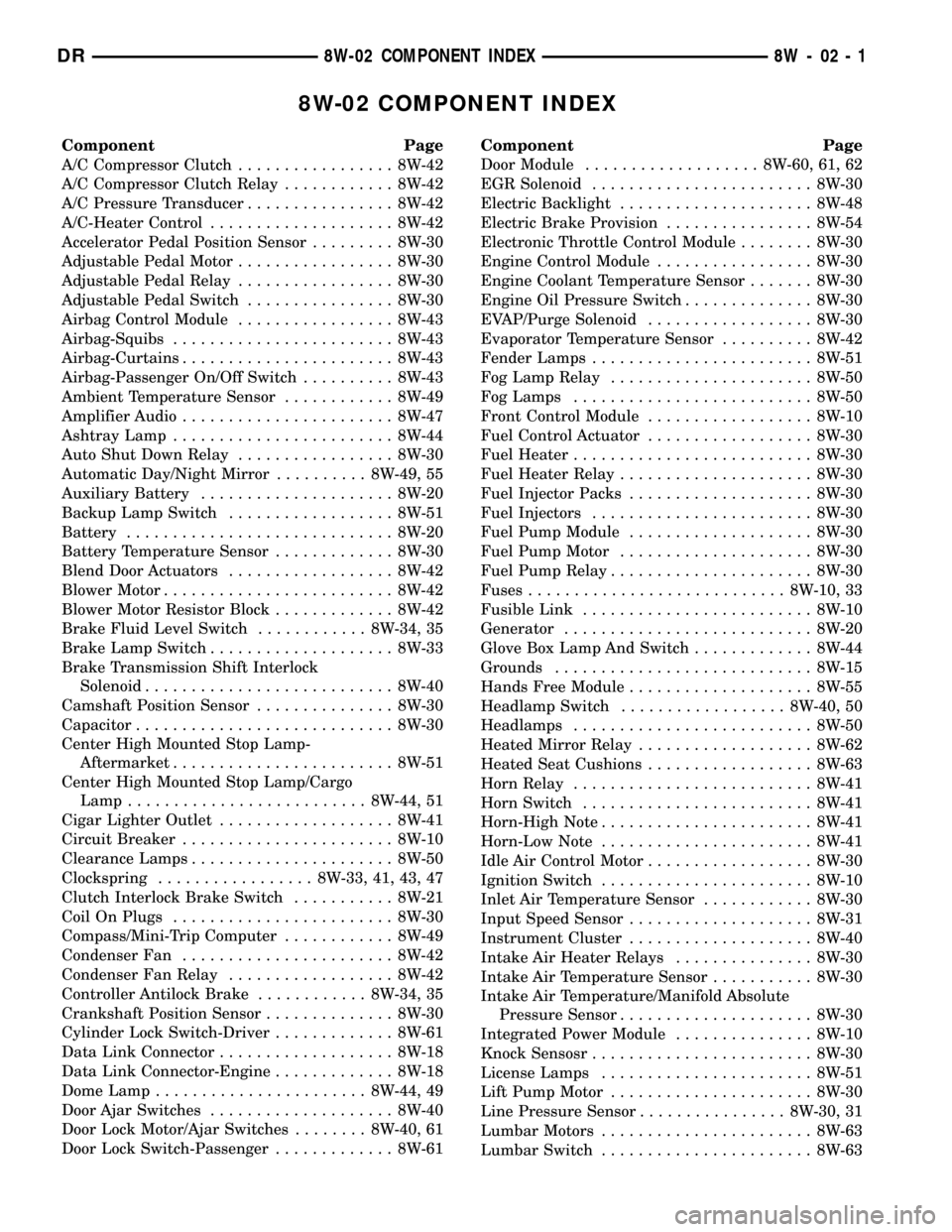

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch................. 8W-42

A/C Compressor Clutch Relay............ 8W-42

A/C Pressure Transducer................ 8W-42

A/C-Heater Control.................... 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Adjustable Pedal Motor................. 8W-30

Adjustable Pedal Relay................. 8W-30

Adjustable Pedal Switch................ 8W-30

Airbag Control Module................. 8W-43

Airbag-Squibs........................ 8W-43

Airbag-Curtains....................... 8W-43

Airbag-Passenger On/Off Switch.......... 8W-43

Ambient Temperature Sensor............ 8W-49

Amplifier Audio....................... 8W-47

Ashtray Lamp........................ 8W-44

Auto Shut Down Relay................. 8W-30

Automatic Day/Night Mirror.......... 8W-49, 55

Auxiliary Battery..................... 8W-20

Backup Lamp Switch.................. 8W-51

Battery............................. 8W-20

Battery Temperature Sensor............. 8W-30

Blend Door Actuators.................. 8W-42

Blower Motor......................... 8W-42

Blower Motor Resistor Block............. 8W-42

Brake Fluid Level Switch............ 8W-34, 35

Brake Lamp Switch.................... 8W-33

Brake Transmission Shift Interlock

Solenoid........................... 8W-40

Camshaft Position Sensor............... 8W-30

Capacitor............................ 8W-30

Center High Mounted Stop Lamp-

Aftermarket........................ 8W-51

Center High Mounted Stop Lamp/Cargo

Lamp.......................... 8W-44, 51

Cigar Lighter Outlet................... 8W-41

Circuit Breaker....................... 8W-10

Clearance Lamps...................... 8W-50

Clockspring................. 8W-33, 41, 43, 47

Clutch Interlock Brake Switch........... 8W-21

Coil On Plugs........................ 8W-30

Compass/Mini-Trip Computer............ 8W-49

Condenser Fan....................... 8W-42

Condenser Fan Relay.................. 8W-42

Controller Antilock Brake............ 8W-34, 35

Crankshaft Position Sensor.............. 8W-30

Cylinder Lock Switch-Driver............. 8W-61

Data Link Connector................... 8W-18

Data Link Connector-Engine............. 8W-18

Dome Lamp....................... 8W-44, 49

Door Ajar Switches.................... 8W-40

Door Lock Motor/Ajar Switches........ 8W-40, 61

Door Lock Switch-Passenger............. 8W-61Component Page

Door Module................... 8W-60, 61, 62

EGR Solenoid........................ 8W-30

Electric Backlight..................... 8W-48

Electric Brake Provision................ 8W-54

Electronic Throttle Control Module........ 8W-30

Engine Control Module................. 8W-30

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Pressure Switch.............. 8W-30

EVAP/Purge Solenoid.................. 8W-30

Evaporator Temperature Sensor.......... 8W-42

Fender Lamps........................ 8W-51

Fog Lamp Relay...................... 8W-50

Fog Lamps.......................... 8W-50

Front Control Module.................. 8W-10

Fuel Control Actuator.................. 8W-30

Fuel Heater.......................... 8W-30

Fuel Heater Relay..................... 8W-30

Fuel Injector Packs.................... 8W-30

Fuel Injectors........................ 8W-30

Fuel Pump Module.................... 8W-30

Fuel Pump Motor..................... 8W-30

Fuel Pump Relay...................... 8W-30

Fuses............................ 8W-10, 33

Fusible Link......................... 8W-10

Generator........................... 8W-20

Glove Box Lamp And Switch............. 8W-44

Grounds............................ 8W-15

Hands Free Module.................... 8W-55

Headlamp Switch.................. 8W-40, 50

Headlamps.......................... 8W-50

Heated Mirror Relay................... 8W-62

Heated Seat Cushions.................. 8W-63

Horn Relay.......................... 8W-41

Horn Switch......................... 8W-41

Horn-High Note....................... 8W-41

Horn-Low Note....................... 8W-41

Idle Air Control Motor.................. 8W-30

Ignition Switch....................... 8W-10

Inlet Air Temperature Sensor............ 8W-30

Input Speed Sensor.................... 8W-31

Instrument Cluster.................... 8W-40

Intake Air Heater Relays............... 8W-30

Intake Air Temperature Sensor........... 8W-30

Intake Air Temperature/Manifold Absolute

Pressure Sensor..................... 8W-30

Integrated Power Module............... 8W-10

Knock Sensosr........................ 8W-30

License Lamps....................... 8W-51

Lift Pump Motor...................... 8W-30

Line Pressure Sensor................ 8W-30, 31

Lumbar Motors....................... 8W-63

Lumbar Switch....................... 8W-63

DR8W-02 COMPONENT INDEX 8W - 02 - 1

Page 832 of 2627

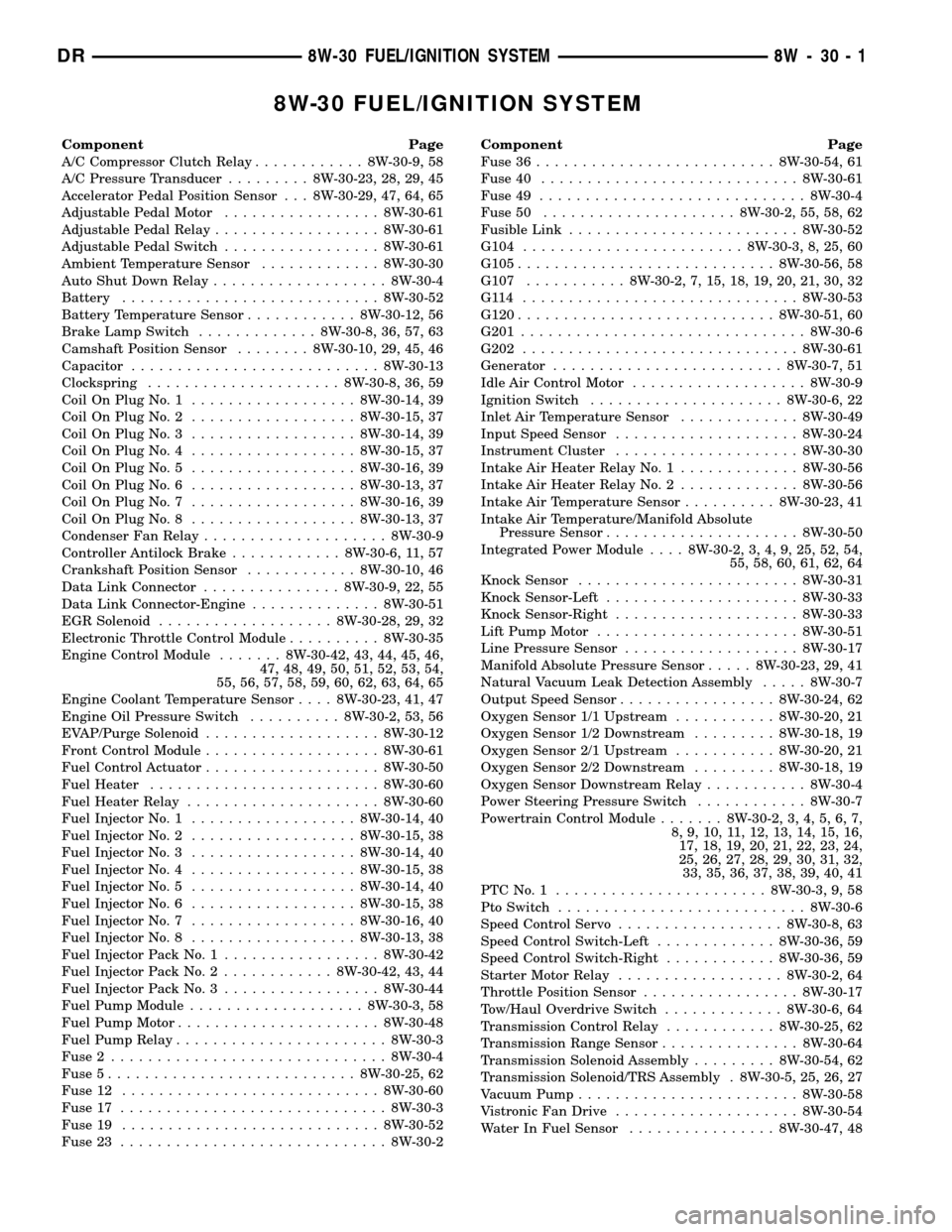

8W-30 FUEL/IGNITION SYSTEM

Component Page

A/C Compressor Clutch Relay............ 8W-30-9, 58

A/C Pressure Transducer......... 8W-30-23, 28, 29, 45

Accelerator Pedal Position Sensor . . . 8W-30-29, 47, 64, 65

Adjustable Pedal Motor................. 8W-30-61

Adjustable Pedal Relay.................. 8W-30-61

Adjustable Pedal Switch................. 8W-30-61

Ambient Temperature Sensor............. 8W-30-30

Auto Shut Down Relay................... 8W-30-4

Battery............................ 8W-30-52

Battery Temperature Sensor............ 8W-30-12, 56

Brake Lamp Switch............. 8W-30-8, 36, 57, 63

Camshaft Position Sensor........ 8W-30-10, 29, 45, 46

Capacitor........................... 8W-30-13

Clockspring..................... 8W-30-8, 36, 59

Coil On Plug No. 1.................. 8W-30-14, 39

Coil On Plug No. 2.................. 8W-30-15, 37

Coil On Plug No. 3.................. 8W-30-14, 39

Coil On Plug No. 4.................. 8W-30-15, 37

Coil On Plug No. 5.................. 8W-30-16, 39

Coil On Plug No. 6.................. 8W-30-13, 37

Coil On Plug No. 7.................. 8W-30-16, 39

Coil On Plug No. 8.................. 8W-30-13, 37

Condenser Fan Relay.................... 8W-30-9

Controller Antilock Brake............ 8W-30-6, 11, 57

Crankshaft Position Sensor............ 8W-30-10, 46

Data Link Connector............... 8W-30-9, 22, 55

Data Link Connector-Engine.............. 8W-30-51

EGR Solenoid................... 8W-30-28, 29, 32

Electronic Throttle Control Module.......... 8W-30-35

Engine Control Module....... 8W-30-42, 43, 44, 45, 46,

47, 48, 49, 50, 51, 52, 53, 54,

55, 56, 57, 58, 59, 60, 62, 63, 64, 65

Engine Coolant Temperature Sensor.... 8W-30-23, 41, 47

Engine Oil Pressure Switch.......... 8W-30-2, 53, 56

EVAP/Purge Solenoid................... 8W-30-12

Front Control Module................... 8W-30-61

Fuel Control Actuator................... 8W-30-50

Fuel Heater......................... 8W-30-60

Fuel Heater Relay..................... 8W-30-60

Fuel Injector No. 1.................. 8W-30-14, 40

Fuel Injector No. 2.................. 8W-30-15, 38

Fuel Injector No. 3.................. 8W-30-14, 40

Fuel Injector No. 4.................. 8W-30-15, 38

Fuel Injector No. 5.................. 8W-30-14, 40

Fuel Injector No. 6.................. 8W-30-15, 38

Fuel Injector No. 7.................. 8W-30-16, 40

Fuel Injector No. 8.................. 8W-30-13, 38

Fuel Injector Pack No. 1................. 8W-30-42

Fuel Injector Pack No. 2............ 8W-30-42, 43, 44

Fuel Injector Pack No. 3................. 8W-30-44

Fuel Pump Module................... 8W-30-3, 58

Fuel Pump Motor...................... 8W-30-48

Fuel Pump Relay....................... 8W-30-3

Fuse 2.............................. 8W-30-4

Fuse 5........................... 8W-30-25, 62

Fuse 12............................ 8W-30-60

Fuse 17............................. 8W-30-3

Fuse 19............................ 8W-30-52

Fuse 23............................. 8W-30-2Component Page

Fuse 36.......................... 8W-30-54, 61

Fuse 40............................ 8W-30-61

Fuse 49............................. 8W-30-4

Fuse 50..................... 8W-30-2, 55, 58, 62

Fusible Link......................... 8W-30-52

G104........................ 8W-30-3, 8, 25, 60

G105............................ 8W-30-56, 58

G107........... 8W-30-2, 7, 15, 18, 19, 20, 21, 30, 32

G114 .............................. 8W-30-53

G120............................ 8W-30-51, 60

G201............................... 8W-30-6

G202.............................. 8W-30-61

Generator......................... 8W-30-7, 51

Idle Air Control Motor................... 8W-30-9

Ignition Switch..................... 8W-30-6, 22

Inlet Air Temperature Sensor............. 8W-30-49

Input Speed Sensor.................... 8W-30-24

Instrument Cluster.................... 8W-30-30

Intake Air Heater Relay No. 1............. 8W-30-56

Intake Air Heater Relay No. 2............. 8W-30-56

Intake Air Temperature Sensor.......... 8W-30-23, 41

Intake Air Temperature/Manifold Absolute

Pressure Sensor..................... 8W-30-50

Integrated Power Module.... 8W-30-2, 3, 4, 9, 25, 52, 54,

55, 58, 60, 61, 62, 64

Knock Sensor........................ 8W-30-31

Knock Sensor-Left..................... 8W-30-33

Knock Sensor-Right.................... 8W-30-33

Lift Pump Motor...................... 8W-30-51

Line Pressure Sensor................... 8W-30-17

Manifold Absolute Pressure Sensor..... 8W-30-23, 29, 41

Natural Vacuum Leak Detection Assembly..... 8W-30-7

Output Speed Sensor................. 8W-30-24, 62

Oxygen Sensor 1/1 Upstream........... 8W-30-20, 21

Oxygen Sensor 1/2 Downstream......... 8W-30-18, 19

Oxygen Sensor 2/1 Upstream........... 8W-30-20, 21

Oxygen Sensor 2/2 Downstream......... 8W-30-18, 19

Oxygen Sensor Downstream Relay........... 8W-30-4

Power Steering Pressure Switch............ 8W-30-7

Powertrain Control Module....... 8W-30-2, 3, 4, 5, 6, 7,

8, 9, 10, 11, 12, 13, 14, 15, 16,

17, 18, 19, 20, 21, 22, 23, 24,

25, 26, 27, 28, 29, 30, 31, 32,

33, 35, 36, 37, 38, 39, 40, 41

PTCNo.1 ....................... 8W-30-3, 9, 58

Pto Switch........................... 8W-30-6

Speed Control Servo.................. 8W-30-8, 63

Speed Control Switch-Left............. 8W-30-36, 59

Speed Control Switch-Right............ 8W-30-36, 59

Starter Motor Relay.................. 8W-30-2, 64

Throttle Position Sensor................. 8W-30-17

Tow/Haul Overdrive Switch............. 8W-30-6, 64

Transmission Control Relay............ 8W-30-25, 62

Transmission Range Sensor............... 8W-30-64

Transmission Solenoid Assembly......... 8W-30-54, 62

Transmission Solenoid/TRS Assembly . 8W-30-5, 25, 26, 27

Vacuum Pump........................ 8W-30-58

Vistronic Fan Drive.................... 8W-30-54

Water In Fuel Sensor................ 8W-30-47, 48

DR8W-30 FUEL/IGNITION SYSTEM 8W - 30 - 1

Page 898 of 2627

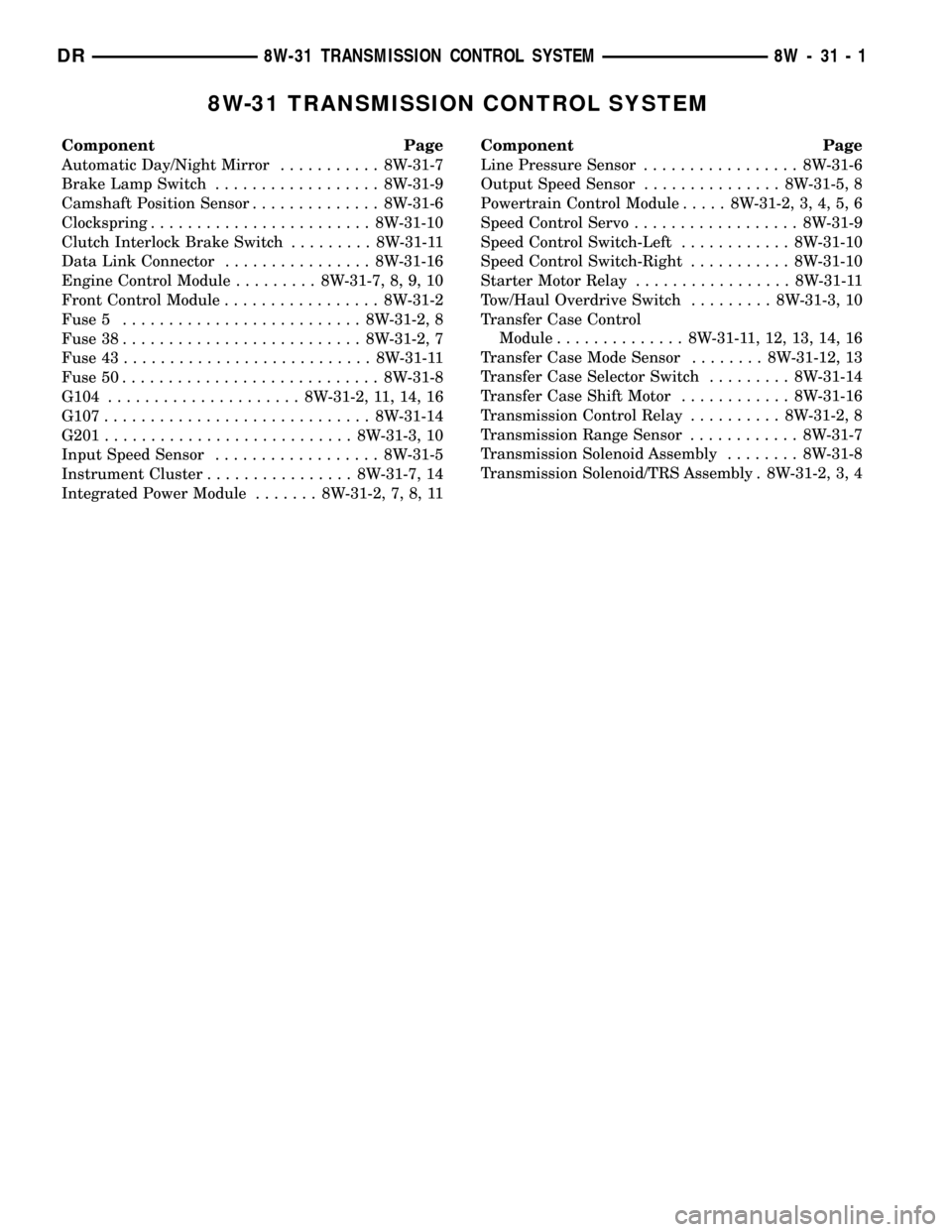

8W-31 TRANSMISSION CONTROL SYSTEM

Component Page

Automatic Day/Night Mirror........... 8W-31-7

Brake Lamp Switch.................. 8W-31-9

Camshaft Position Sensor.............. 8W-31-6

Clockspring........................ 8W-31-10

Clutch Interlock Brake Switch......... 8W-31-11

Data Link Connector................ 8W-31-16

Engine Control Module......... 8W-31-7, 8, 9, 10

Front Control Module................. 8W-31-2

Fuse 5.......................... 8W-31-2, 8

Fuse 38.......................... 8W-31-2, 7

Fuse 43........................... 8W-31-11

Fuse 50............................ 8W-31-8

G104..................... 8W-31-2, 11, 14, 16

G107............................. 8W-31-14

G201........................... 8W-31-3, 10

Input Speed Sensor.................. 8W-31-5

Instrument Cluster................ 8W-31-7, 14

Integrated Power Module....... 8W-31-2, 7, 8, 11Component Page

Line Pressure Sensor................. 8W-31-6

Output Speed Sensor............... 8W-31-5, 8

Powertrain Control Module..... 8W-31-2, 3, 4, 5, 6

Speed Control Servo.................. 8W-31-9

Speed Control Switch-Left............ 8W-31-10

Speed Control Switch-Right........... 8W-31-10

Starter Motor Relay................. 8W-31-11

Tow/Haul Overdrive Switch......... 8W-31-3, 10

Transfer Case Control

Module.............. 8W-31-11, 12, 13, 14, 16

Transfer Case Mode Sensor........ 8W-31-12, 13

Transfer Case Selector Switch......... 8W-31-14

Transfer Case Shift Motor............ 8W-31-16

Transmission Control Relay.......... 8W-31-2, 8

Transmission Range Sensor............ 8W-31-7

Transmission Solenoid Assembly........ 8W-31-8

Transmission Solenoid/TRS Assembly . 8W-31-2, 3, 4

DR8W-31 TRANSMISSION CONTROL SYSTEM 8W - 31 - 1

Page 1163 of 2627

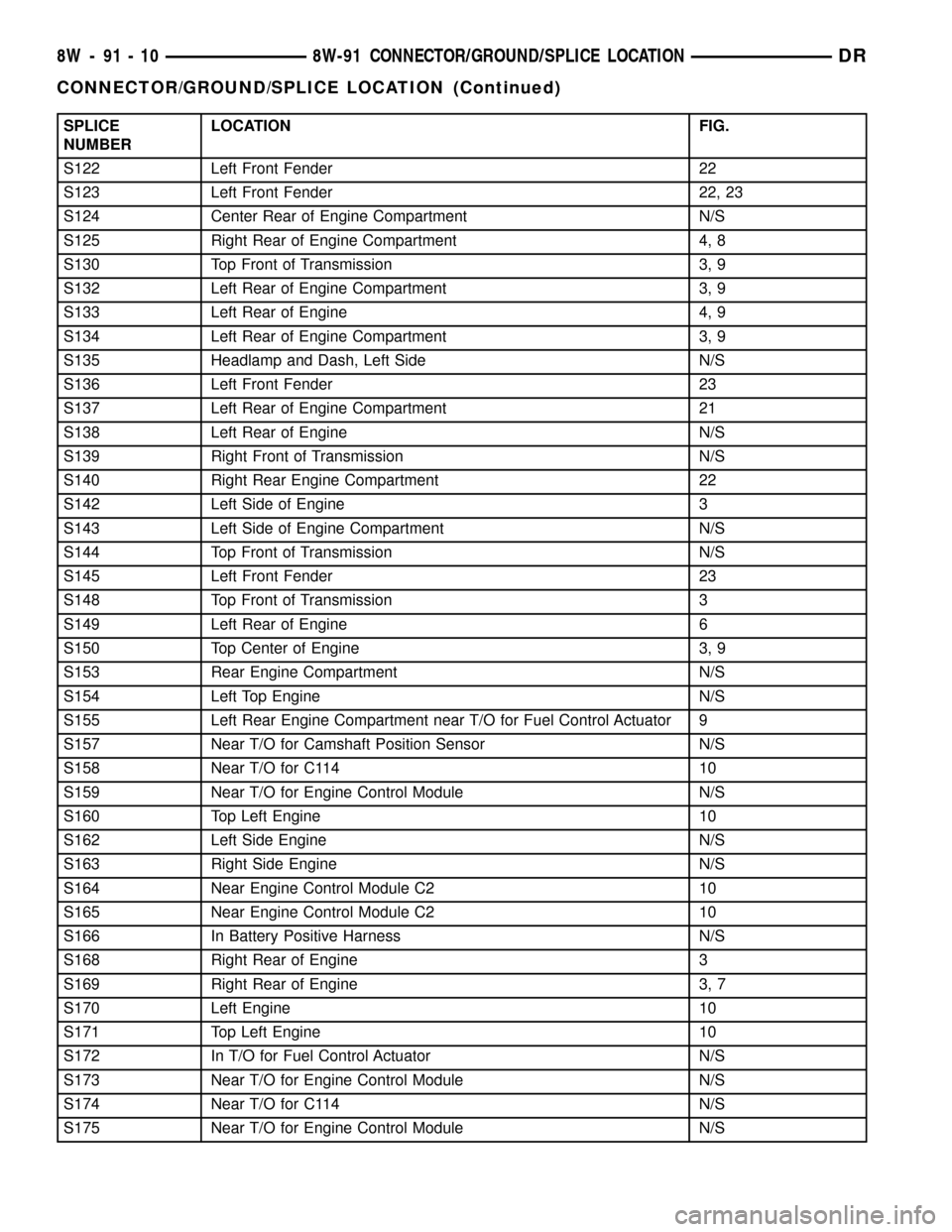

SPLICE

NUMBERLOCATION FIG.

S122 Left Front Fender 22

S123 Left Front Fender 22, 23

S124 Center Rear of Engine Compartment N/S

S125 Right Rear of Engine Compartment 4, 8

S130 Top Front of Transmission 3, 9

S132 Left Rear of Engine Compartment 3, 9

S133 Left Rear of Engine 4, 9

S134 Left Rear of Engine Compartment 3, 9

S135 Headlamp and Dash, Left Side N/S

S136 Left Front Fender 23

S137 Left Rear of Engine Compartment 21

S138 Left Rear of Engine N/S

S139 Right Front of Transmission N/S

S140 Right Rear Engine Compartment 22

S142 Left Side of Engine 3

S143 Left Side of Engine Compartment N/S

S144 Top Front of Transmission N/S

S145 Left Front Fender 23

S148 Top Front of Transmission 3

S149 Left Rear of Engine 6

S150 Top Center of Engine 3, 9

S153 Rear Engine Compartment N/S

S154 Left Top Engine N/S

S155 Left Rear Engine Compartment near T/O for Fuel Control Actuator 9

S157 Near T/O for Camshaft Position Sensor N/S

S158 Near T/O for C114 10

S159 Near T/O for Engine Control Module N/S

S160 Top Left Engine 10

S162 Left Side Engine N/S

S163 Right Side Engine N/S

S164 Near Engine Control Module C2 10

S165 Near Engine Control Module C2 10

S166 In Battery Positive Harness N/S

S168 Right Rear of Engine 3

S169 Right Rear of Engine 3, 7

S170 Left Engine 10

S171 Top Left Engine 10

S172 In T/O for Fuel Control Actuator N/S

S173 Near T/O for Engine Control Module N/S

S174 Near T/O for C114 N/S

S175 Near T/O for Engine Control Module N/S

8W - 91 - 10 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1234 of 2627

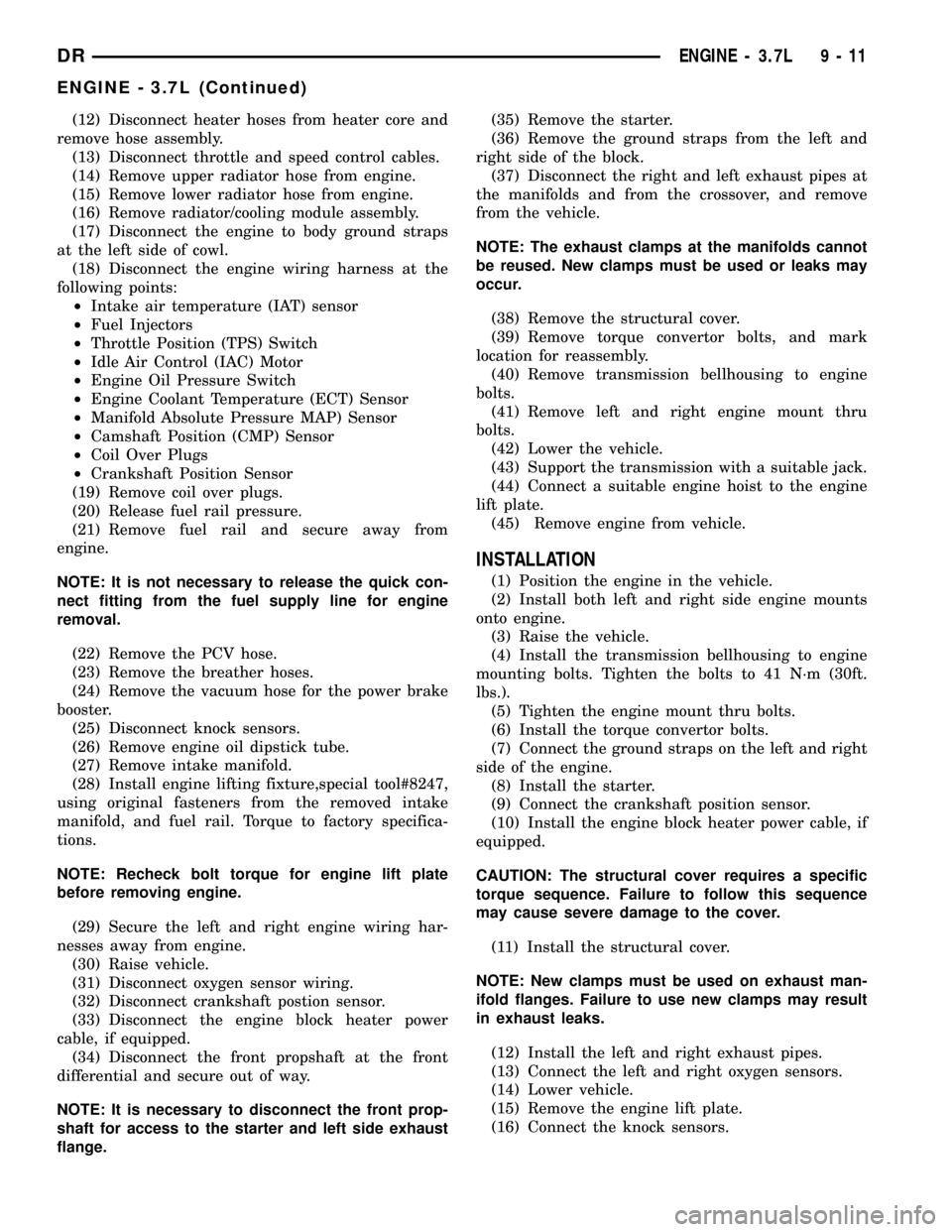

(12) Disconnect heater hoses from heater core and

remove hose assembly.

(13) Disconnect throttle and speed control cables.

(14) Remove upper radiator hose from engine.

(15) Remove lower radiator hose from engine.

(16) Remove radiator/cooling module assembly.

(17) Disconnect the engine to body ground straps

at the left side of cowl.

(18) Disconnect the engine wiring harness at the

following points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(19) Remove coil over plugs.

(20) Release fuel rail pressure.

(21) Remove fuel rail and secure away from

engine.

NOTE: It is not necessary to release the quick con-

nect fitting from the fuel supply line for engine

removal.

(22) Remove the PCV hose.

(23) Remove the breather hoses.

(24) Remove the vacuum hose for the power brake

booster.

(25) Disconnect knock sensors.

(26) Remove engine oil dipstick tube.

(27) Remove intake manifold.

(28) Install engine lifting fixture,special tool#8247,

using original fasteners from the removed intake

manifold, and fuel rail. Torque to factory specifica-

tions.

NOTE: Recheck bolt torque for engine lift plate

before removing engine.

(29) Secure the left and right engine wiring har-

nesses away from engine.

(30) Raise vehicle.

(31) Disconnect oxygen sensor wiring.

(32) Disconnect crankshaft postion sensor.

(33) Disconnect the engine block heater power

cable, if equipped.

(34) Disconnect the front propshaft at the front

differential and secure out of way.

NOTE: It is necessary to disconnect the front prop-

shaft for access to the starter and left side exhaust

flange.(35) Remove the starter.

(36) Remove the ground straps from the left and

right side of the block.

(37) Disconnect the right and left exhaust pipes at

the manifolds and from the crossover, and remove

from the vehicle.

NOTE: The exhaust clamps at the manifolds cannot

be reused. New clamps must be used or leaks may

occur.

(38) Remove the structural cover.

(39) Remove torque convertor bolts, and mark

location for reassembly.

(40) Remove transmission bellhousing to engine

bolts.

(41) Remove left and right engine mount thru

bolts.

(42) Lower the vehicle.

(43) Support the transmission with a suitable jack.

(44) Connect a suitable engine hoist to the engine

lift plate.

(45) Remove engine from vehicle.

INSTALLATION

(1) Position the engine in the vehicle.

(2) Install both left and right side engine mounts

onto engine.

(3) Raise the vehicle.

(4) Install the transmission bellhousing to engine

mounting bolts. Tighten the bolts to 41 N´m (30ft.

lbs.).

(5) Tighten the engine mount thru bolts.

(6) Install the torque convertor bolts.

(7) Connect the ground straps on the left and right

side of the engine.

(8) Install the starter.

(9) Connect the crankshaft position sensor.

(10) Install the engine block heater power cable, if

equipped.

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

(11) Install the structural cover.

NOTE: New clamps must be used on exhaust man-

ifold flanges. Failure to use new clamps may result

in exhaust leaks.

(12) Install the left and right exhaust pipes.

(13) Connect the left and right oxygen sensors.

(14) Lower vehicle.

(15) Remove the engine lift plate.

(16) Connect the knock sensors.

DRENGINE - 3.7L 9 - 11

ENGINE - 3.7L (Continued)

Page 1239 of 2627

OIL PRESSURE

SPECIFICATION SPECIFICATION

Metric Standard

At Curb Idle

Speed (MIN)*25 kPa 4 psi

@ 3000 rpm 170 - 758 kPa 25 - 110 psi

* CAUTION: If pressure is zero at curb idle, DO

NOT run engine at 3000 rpm.

TORQUE

DESCRIPTION N´m Ft.

Lbs.In.

Lbs.

Camshaft

Non - Oiled Sprocket Bolt 122 90 -

Bearing Cap Bolts 11 - 100

Counterbalance shaft

retaining bolt28 - 250

Timing Chain Cover-Bolts 58 43 -

Connecting Rod Cap-Bolts 27 20 -

PLUS 90É TURN

Bed Plate-Bolts Refer to Procedure

Crankshaft Damper-Bolt 175 130 -

Cylinder Head-Bolts

M11 Bolts Refer To Procedure

M8 Bolts Refer To Procedure

Cylinder Head Cover-Bolts 12 - 105

Exhaust Manifold-Bolts 25 18 -

Exhaust Manifold Heat

Shield-Nuts8-72

Then loosen 45É

DESCRIPTION N´m Ft.

Lbs.In.

Lbs.

Flexplate-Bolts 95 70 -

Engine Mount Bracket to

Block-Bolts61 45 -

Rear Mount to Transmission-

Bolts46 34 -

Generator Mounting-Bolts

M10 Bolts 54 40 -

M8 Bolts 28 - 250

Intake Manifold-Bolts 12 - 105

Refer to Procedure

for Tightening

Sequence

Oil Pan-Bolts 15 - 130

Oil Pan-Drain Plug 34 25 -

Oil Pump-Bolts 28 - 250

Oil Pump Cover-Bolts 12 - 105

Oil Pickup Tube-Bolt and Nut 28 - 250

Oil Dipstick Tube to Engine

Block-Bolt15 - 130

Oil Fill Tube-Bolts 12 - 105

Timing Chain Guide-Bolts 28 - 250

Timing Chain Tensioner Arm 28 - 250

Hydraulic Tensioner-Bolts 28 - 250

Timing Chain Primary

Tensioner-Bolts28 - 250

Timing Drive Idler Sprocket-

Bolt34 25 -

Thermostat Housing-Bolts 12 - 105

Water Pump-Bolts 58 43 -

9 - 16 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1262 of 2627

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

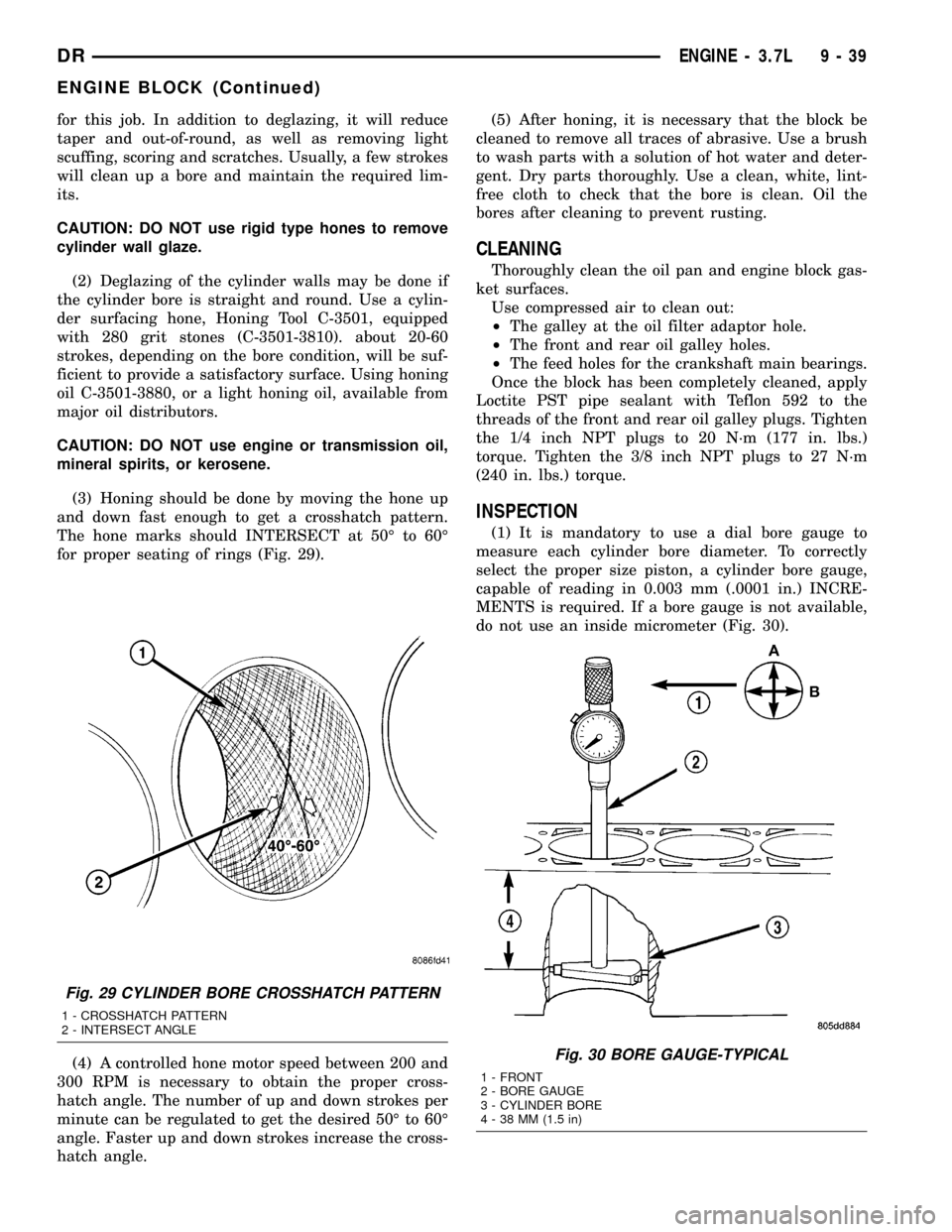

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 50É to 60É

for proper seating of rings (Fig. 29).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

CLEANING

Thoroughly clean the oil pan and engine block gas-

ket surfaces.

Use compressed air to clean out:

²The galley at the oil filter adaptor hole.

²The front and rear oil galley holes.

²The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply

Loctite PST pipe sealant with Teflon 592 to the

threads of the front and rear oil galley plugs. Tighten

the 1/4 inch NPT plugs to 20 N´m (177 in. lbs.)

torque. Tighten the 3/8 inch NPT plugs to 27 N´m

(240 in. lbs.) torque.

INSPECTION

(1) It is mandatory to use a dial bore gauge to

measure each cylinder bore diameter. To correctly

select the proper size piston, a cylinder bore gauge,

capable of reading in 0.003 mm (.0001 in.) INCRE-

MENTS is required. If a bore gauge is not available,

do not use an inside micrometer (Fig. 30).

Fig. 29 CYLINDER BORE CROSSHATCH PATTERN

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

Fig. 30 BORE GAUGE-TYPICAL

1 - FRONT

2 - BORE GAUGE

3 - CYLINDER BORE

4 - 38 MM (1.5 in)

DRENGINE - 3.7L 9 - 39

ENGINE BLOCK (Continued)