coolant DODGE RAM 1500 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 345 of 2627

ENGINE

TABLE OF CONTENTS

page page

COOLANT

DESCRIPTION

DESCRIPTION - ENGINE COOLANT.......31

DESCRIPTION - HOAT COOLANT.........32

OPERATION...........................33

COOLANT RECOVERY CONTAINER- GAS

ENGINES

DESCRIPTION.........................33

OPERATION...........................33

REMOVAL.............................33

INSTALLATION.........................33

RADIATOR FAN - GAS ENGINES

REMOVAL.............................33

CLEANING............................34

INSPECTION..........................34

INSTALLATION.........................34

RADIATOR FAN - 5.9L DIESEL

REMOVAL.............................35

CLEANING............................35

INSPECTION..........................35

INSTALLATION.........................36

ENGINE BLOCK HEATER

DESCRIPTION.........................36

OPERATION...........................36

DIAGNOSIS AND TESTING - ENGINE BLOCK

HEATER ............................36

REMOVAL.............................37

INSTALLATION.........................37

ENGINE BLOCK HEATER - 5.9L DIESEL

DESCRIPTION.........................37

OPERATION...........................38

REMOVAL.............................38

INSTALLATION.........................38

ENGINE COOLANT TEMPERATURE SENSOR

DESCRIPTION.........................38

OPERATION...........................38

REMOVAL.............................39

INSTALLATION.........................41

ENGINE COOLANT THERMOSTAT- 5.7L

DESCRIPTION.........................41

OPERATION...........................41

DIAGNOSIS AND TESTINGÐTHERMOSTAT . . . 42

REMOVAL.............................42

INSTALLATION.........................43

ENGINE COOLANT THERMOSTAT - 3.7L/4.7L

DESCRIPTION.........................44

OPERATION...........................44

DIAGNOSIS AND TESTINGÐTHERMOSTAT . . . 44

REMOVAL.............................45INSTALLATION.........................45

ENGINE COOLANT THERMOSTAT - 5.9L

DIESEL

DESCRIPTION.........................46

OPERATION...........................46

DIAGNOSIS AND TESTING - THERMOSTAT . . . 47

REMOVAL.............................47

INSTALLATION.........................47

ENGINE COOLANT THERMOSTAT - 8.0L

DESCRIPTION.........................48

OPERATION...........................48

DIAGNOSIS AND TESTING - THERMOSTAT . . . 48

REMOVAL.............................49

INSTALLATION.........................49

FAN DRIVE VISCOUS CLUTCH-GAS ENGINES

DESCRIPTION.........................50

OPERATION...........................50

DIAGNOSIS AND TESTING - VISCOUS FAN

DRIVE..............................50

FAN DRIVE VISCOUS CLUTCH - 5.9L DIESEL

DESCRIPTION.........................52

OPERATION...........................52

DIAGNOSIS AND TESTING -

ELECTRONICALLY CONTROLLED VISCOUS

FAN DRIVE..........................52

RADIATOR-3.7L/4.7L/5.7L

DESCRIPTION.........................54

OPERATION...........................54

DIAGNOSIS AND TESTING - RADIATOR

COOLANT FLOW......................54

REMOVAL.............................54

CLEANING............................55

INSPECTION..........................55

INSTALLATION.........................55

RADIATOR - 5.9L DIESEL

DESCRIPTION.........................56

OPERATION...........................56

DIAGNOSIS AND TESTING - RADIATOR

COOLANT FLOW......................56

REMOVAL.............................56

CLEANING............................56

INSPECTION..........................56

INSTALLATION.........................57

RADIATOR PRESSURE CAP

DESCRIPTION.........................57

OPERATION...........................58

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - RADIATOR

CAP-TO-FILLER NECK SEAL.............58

7 - 30 ENGINEDR

Page 346 of 2627

DIAGNOSIS AND TESTING - RADIATOR

CAP................................58

CLEANING............................59

INSPECTION..........................59

WATER PUMP - 3.7L/4.7L

DESCRIPTION

DESCRIPTION - WATER PUMP...........59

DESCRIPTION - WATER PUMP BYPASS....59

OPERATION

OPERATIONÐWATER PUMP............60

OPERATION - WATER PUMP BYPASS.....60

REMOVAL.............................60

CLEANING............................61

INSPECTION..........................61

INSTALLATION.........................61

WATER PUMP - 5.9L DIESEL

DESCRIPTION.........................62OPERATION...........................62

DIAGNOSIS AND TESTINGÐWATER PUMP . . . 62

REMOVAL.............................62

CLEANING............................62

INSPECTION..........................62

INSTALLATION.........................62

WATER PUMP - 5.7L

REMOVAL.............................63

INSTALLATION.........................63

WATER PUMP - 8.0L

DIAGNOSIS AND TESTING - WATER PUMP . . . 63

REMOVAL.............................64

CLEANING............................66

INSPECTION..........................66

INSTALLATION.........................66

COOLANT

DESCRIPTION

DESCRIPTION - ENGINE COOLANT

ETHYLENE-GLYCOL MIXTURES

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only MopartAntifreeze/Coolant, 5

year/100,000 Mile Formula (ethylene-glycol base cool-

ant with corrosion inhibitors called HOAT, for Hybrid

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% distilled water to obtain a freeze

point of -37ÉC (-35ÉF).

The required ethylene-glycol (antifreeze) and water

mixture depends upon the climate and vehicle oper-

ating conditions. The antifreeze concentrationmust

alwaysbe a minimum of 44 percent, year-round in

all climates.If percentage is lower than 44 per-

cent, engine parts may be eroded by cavitation,

and cooling system components may be

severely damaged by corrosion.Maximum protec-

tion against freezing is provided with a 68% anti-

freeze concentration, which prevents freezing down to

-67.7É C (-90É F). A higher percentage will freeze at a

warmer temperature. Also, a higher percentage of

antifreeze can cause the engine to overheat becausethe specific heat of antifreeze is lower than that of

water.

Use of 100 percent ethylene-glycol will cause for-

mation of additive deposits in the system, as the cor-

rosion inhibitive additives in ethylene-glycol require

the presence of water to dissolve. The deposits act as

insulation, causing temperatures to rise to as high as

149É C (300É F). This temperature is hot enough to

melt plastic and soften solder. The increased temper-

ature can result in engine detonation. In addition,

100 percent ethylene-glycol freezes at 22É C (-8É F ).

PROPYLENE-GLYCOL MIXTURES

It's overall effective temperature range is smaller

than that of ethylene-glycol. The freeze point of 50/50

propylene-glycol and water is -32É C (-26É F). 5É C

higher than ethylene-glycol's freeze point. The boiling

point (protection against summer boil-over) of propy-

lene-glycol is 125É C (257ÉF)at96.5 kPa (14 psi),

compared to 128É C (263É F) for ethylene-glycol. Use

of propylene-glycol can result in boil-over or freeze-up

on a cooling system designed for ethylene-glycol. Pro-

pylene glycol also has poorer heat transfer character-

istics than ethylene glycol. This can increase cylinder

head temperatures under certain conditions.

Propylene-glycol/ethylene-glycol Mixtures can

cause the destabilization of various corrosion inhibi-

tors, causing damage to the various cooling system

components. Also, once ethylene-glycol and propy-

lene-glycol based coolants are mixed in the vehicle,

conventional methods of determining freeze point will

not be accurate. Both the refractive index and spe-

cific gravity differ between ethylene glycol and propy-

lene glycol.

DRENGINE 7 - 31

Page 347 of 2627

DESCRIPTION - HOAT COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE-GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE-GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene-Glycol based coolants

is not recommended, as they provide less freeze

protection and less corrosion protection.

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene-glycol base coolant with organic corro-

sion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% ethylene-glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Mixing of

coolants other than specified (non-HOAT or other

HOAT), may result in engine damage that may not

be covered under the new vehicle warranty, and

decreased corrosion protection.

COOLANT PERFORMANCE

The required ethylene-glycol (antifreeze) and water

mixture depends upon climate and vehicle operating

conditions. The coolant performance of various mix-

tures follows:

Pure Water-Water can absorb more heat than a

mixture of water and ethylene-glycol. This is for pur-

pose of heat transfer only. Water also freezes at a

higher temperature and allows corrosion.

100 percent Ethylene-Glycol-The corrosion

inhibiting additives in ethylene-glycol need the pres-

ence of water to dissolve. Without water, additives

form deposits in system. These act as insulation

causing temperature to rise to as high as 149ÉC

(300ÉF). This temperature is hot enough to melt plas-

tic and soften solder. The increased temperature can

result in engine detonation. In addition, 100 percent

ethylene-glycol freezes at -22ÉC (-8ÉF).

50/50 Ethylene-Glycol and Water-Is the recom-

mended mixture, it provides protection against freez-

ing to -37ÉC (-34ÉF). The antifreeze concentration

must alwaysbe a minimum of 44 percent, year-

round in all climates. If percentage is lower, engine

parts may be eroded by cavitation. Maximum protec-

tion against freezing is provided with a 68 percent

antifreeze concentration, which prevents freezing

down to -67.7ÉC (-90ÉF). A higher percentage will

freeze at a warmer temperature. Also, a higher per-

centage of antifreeze can cause the engine to over-

heat because specific heat of antifreeze is lower than

that of water.

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethyl-

ene-glycol.

COOLANT SELECTION AND ADDITIVES

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (glycol base coolant with

corrosion inhibitors called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% distilled water to obtain to obtain a

freeze point of -37ÉC (-35ÉF). If it loses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed coolant solution.

CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

7 - 32 ENGINEDR

COOLANT (Continued)

Page 348 of 2627

OPERATION

Coolant flows through the engine block absorbing

the heat from the engine, then flows to the radiator

where the cooling fins in the radiator transfers the

heat from the coolant to the atmosphere. During cold

weather the ethylene-glycol or propylene-glycol cool-

ant prevents water present in the cooling system

from freezing within temperatures indicated by mix-

ture ratio of coolant to water.

COOLANT RECOVERY

CONTAINER- GAS ENGINES

DESCRIPTION

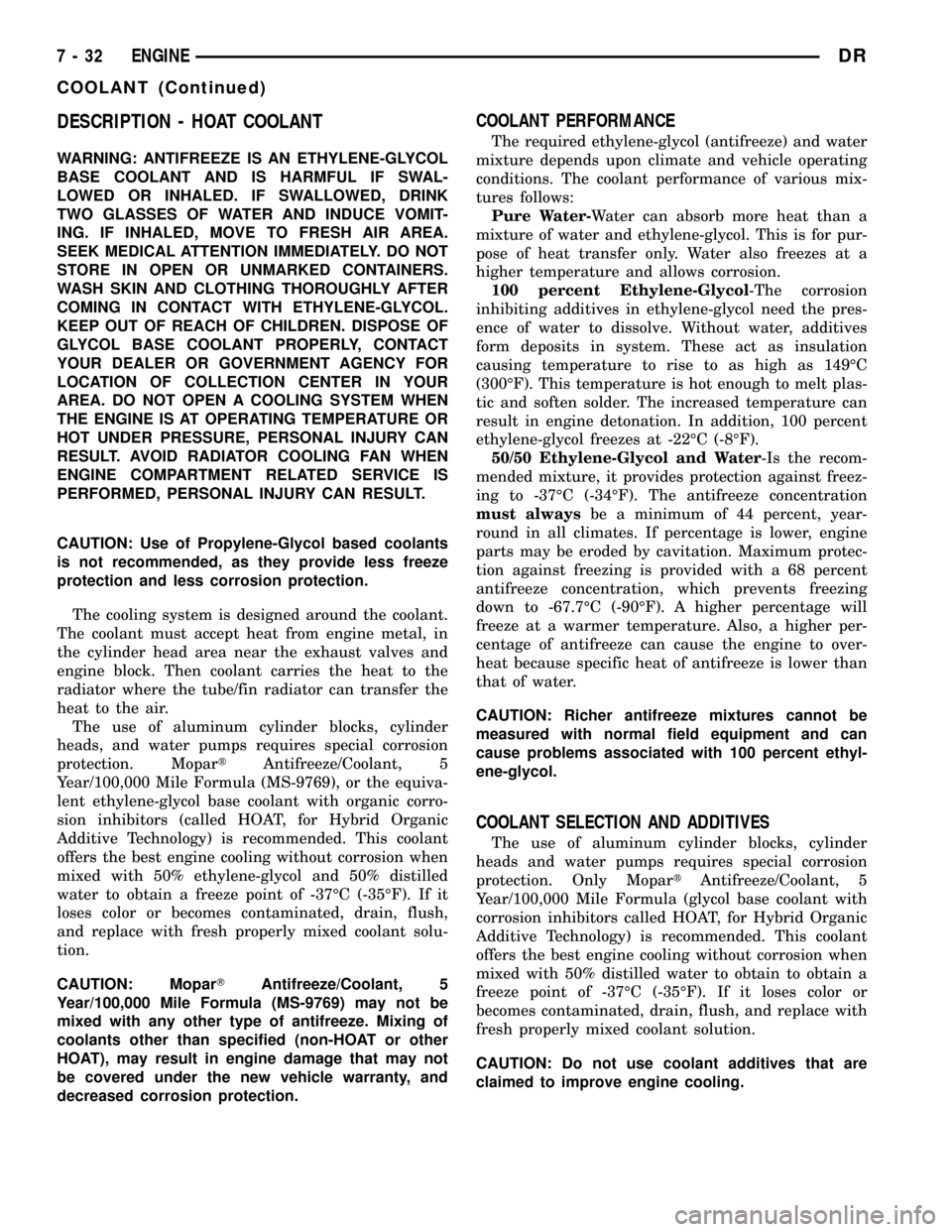

The coolant reserve/overflow tank is mounted on

top of the fan shroud, and is made of high tempera-

ture plastic (Fig. 1).

OPERATION

The coolant reserve/overflow system works in con-

junction with the radiator pressure cap. It utilizes

thermal expansion and contraction of coolant to keep

coolant free of trapped air. It provides a volume for

expansion and contraction of coolant. It also provides

a convenient and safe method for checking coolant

level and adjusting level at atmospheric pressure.

This is done without removing the radiator pressure

cap. The system also provides some reserve coolantto the radiator to cover minor leaks and evaporation

or boiling losses.

As the engine cools, a vacuum is formed in the

cooling system of both the radiator and engine. Cool-

ant will then be drawn from the coolant tank and

returned to a proper level in the radiator.

REMOVAL

(1) Remove recovery hose from radiator.

(2) Remove the coolant container to fan shroud

mounting bolt.

(3) Tilt the container backward towards the engine

to disengage the mounting pin locking features and

lift the container away from the fan shroud (Fig. 1).

INSTALLATION

(1) Align the coolant container mounting pins into

the slots on the fan shroud and push the container

onto the fan shroud.

(2) Secure the container to the fan shroud with the

bolt. Tighten to 8.5N´m (75 in-lbs).

NOTE: Ensure that the locking feature on the

mounting pins has engaged.

(3) Connect the recovery hose to the radiator (Fig.

1).

RADIATOR FAN - GAS

ENGINES

REMOVAL

CAUTION: If the viscous fan drive is replaced

because of mechanical damage, the cooling fan

blades should also be inspected. Inspect for fatigue

cracks, loose blades, or loose rivets that could

have resulted from excessive vibration. Replace fan

blade assembly if any of these conditions are

found. Also inspect water pump bearing and shaft

assembly for any related damage due to a viscous

fan drive malfunction.

(1) Disconnect negative battery cable from battery.

(2) Remove coolant reserve/overflow container from

fan shroud and lay aside.Do Notdisconnect the

hoses or drain coolant from the container.

(3) The thermal viscous fan drive/fan blade assem-

bly is attached (threaded) to the water pump hub

shaft (Fig. 3). Remove the fan blade/viscous fan drive

assembly from the water pump by turning the

mounting nut counterclockwise as viewed from the

front. Threads on the viscous fan drive areRIGHT-

HAND.A 36 MM Fan Wrench should be used to pre-

vent pulley from rotating (Fig. 2).

Fig. 1 Coolant Recovery Bottle - Gas Engine

1 - SCREW

2 - COOLANT RECOVERY CONTAINER

3 - RADIATOR/RADIATOR CAP

4 - FAN SHROUD

DRENGINE 7 - 33

COOLANT (Continued)

Page 350 of 2627

(4) Install the fan blade/viscous fan drive assembly

to the water pump shaft (Fig. 3). Tighten mounting

nut to 50 N´m (37 ft. lbs.).

(5) Install the coolant reserve/overflow container

to the fan shroud.

(6) Connect the negative battery cable.

NOTE:

Viscous Fan Drive Fluid Pump Out Requirement:

After installing a new viscous fan drive, bring the

engine speed up to approximately 2000 rpm and

hold for approximately two minutes. This will

ensure proper fluid distribution within the drive.

RADIATOR FAN - 5.9L DIESEL

REMOVAL

CAUTION: If the electronically controlled viscous

fan drive is replaced because of mechanical dam-

age, the cooling fan blades should also be

inspected. Inspect for fatigue cracks, or chipped

blades that could have resulted from excessive

vibration. Replace fan blade assembly if any of

these conditions are found. Also inspect wiring har-

ness and connectors for damage.

(1) Disconnect the battery negative cables.

(2) Remove coolant recovery container (Refer to 7 -

COOLING/ENGINE/COOLANT RECOVERY CON-

TAINER - REMOVAL).

(3) Using a fastener removal tool, remove the two

push pin fasteners from the fan shroud lower half.

(4) Unseat the four fastening tabs and remove the

lower radiator shroud.

(5) Disconnect electrical connector.

(6) Remove the electronically controlled viscous fan

drive electrical wire from the upper radiator shroud.

(7) Using a fastener removal tool, remove the wir-

ing harness bracket from the upper radiator shroud.

CAUTION: Do not remove the fan pulley bolts. This

pulley is under spring tension.

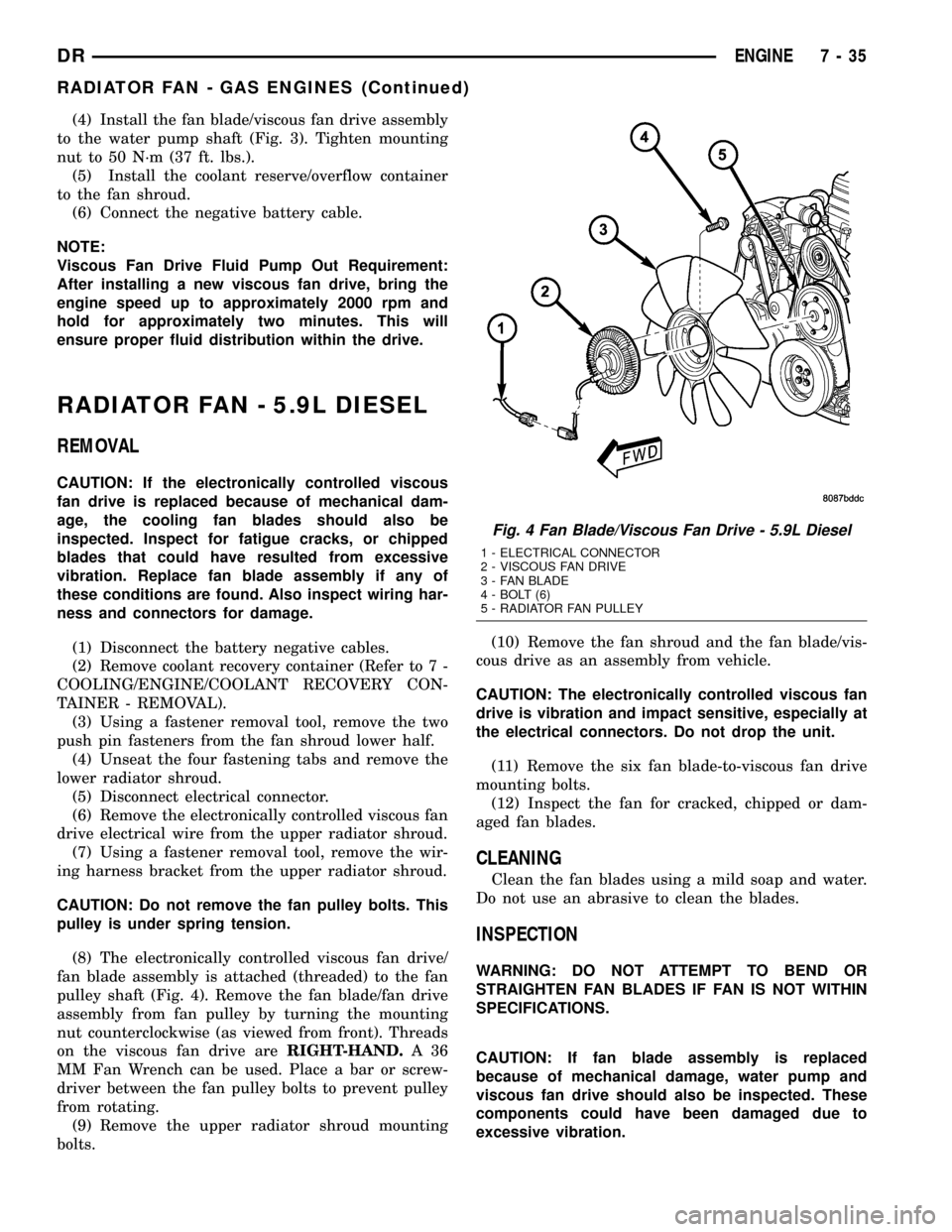

(8) The electronically controlled viscous fan drive/

fan blade assembly is attached (threaded) to the fan

pulley shaft (Fig. 4). Remove the fan blade/fan drive

assembly from fan pulley by turning the mounting

nut counterclockwise (as viewed from front). Threads

on the viscous fan drive areRIGHT-HAND.A36

MM Fan Wrench can be used. Place a bar or screw-

driver between the fan pulley bolts to prevent pulley

from rotating.

(9) Remove the upper radiator shroud mounting

bolts.(10) Remove the fan shroud and the fan blade/vis-

cous drive as an assembly from vehicle.

CAUTION: The electronically controlled viscous fan

drive is vibration and impact sensitive, especially at

the electrical connectors. Do not drop the unit.

(11) Remove the six fan blade-to-viscous fan drive

mounting bolts.

(12) Inspect the fan for cracked, chipped or dam-

aged fan blades.

CLEANING

Clean the fan blades using a mild soap and water.

Do not use an abrasive to clean the blades.

INSPECTION

WARNING: DO NOT ATTEMPT TO BEND OR

STRAIGHTEN FAN BLADES IF FAN IS NOT WITHIN

SPECIFICATIONS.

CAUTION: If fan blade assembly is replaced

because of mechanical damage, water pump and

viscous fan drive should also be inspected. These

components could have been damaged due to

excessive vibration.

Fig. 4 Fan Blade/Viscous Fan Drive - 5.9L Diesel

1 - ELECTRICAL CONNECTOR

2 - VISCOUS FAN DRIVE

3 - FAN BLADE

4 - BOLT (6)

5 - RADIATOR FAN PULLEY

DRENGINE 7 - 35

RADIATOR FAN - GAS ENGINES (Continued)

Page 351 of 2627

INSTALLATION

(1) Install fan blade assembly to electrically con-

trolled viscous fan drive. Tighten mounting bolts to

24 N´m (18 ft. lbs.) torque.

(2) Position the fan blade/viscous fan drive to the

vehicle as an assembly.

(3) Install the viscous fan drive assembly onto fan

pulley hub shaft (Fig. 4). Tighten mounting nut to

115 N´m (85 ft. lbs.) torque.

(4) Install upper fan shroud. Make sure the upper

shroud locks into the tabs on the lower radiator.

(5) Install two upper shroud mounting bolts.

Tighten to 11.8 N´m (105 in. lbs.) torque.

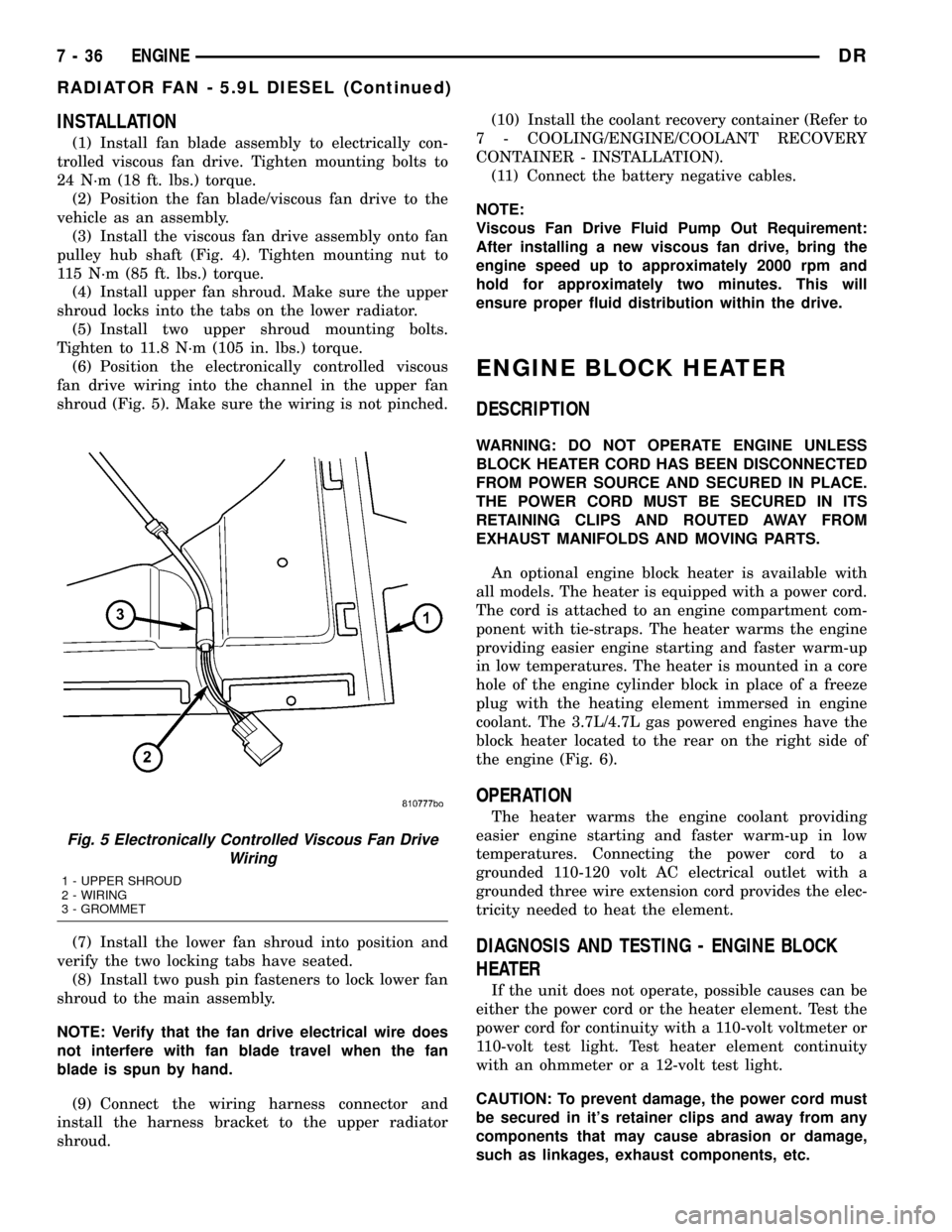

(6) Position the electronically controlled viscous

fan drive wiring into the channel in the upper fan

shroud (Fig. 5). Make sure the wiring is not pinched.

(7) Install the lower fan shroud into position and

verify the two locking tabs have seated.

(8) Install two push pin fasteners to lock lower fan

shroud to the main assembly.

NOTE: Verify that the fan drive electrical wire does

not interfere with fan blade travel when the fan

blade is spun by hand.

(9) Connect the wiring harness connector and

install the harness bracket to the upper radiator

shroud.(10) Install the coolant recovery container (Refer to

7 - COOLING/ENGINE/COOLANT RECOVERY

CONTAINER - INSTALLATION).

(11) Connect the battery negative cables.

NOTE:

Viscous Fan Drive Fluid Pump Out Requirement:

After installing a new viscous fan drive, bring the

engine speed up to approximately 2000 rpm and

hold for approximately two minutes. This will

ensure proper fluid distribution within the drive.

ENGINE BLOCK HEATER

DESCRIPTION

WARNING: DO NOT OPERATE ENGINE UNLESS

BLOCK HEATER CORD HAS BEEN DISCONNECTED

FROM POWER SOURCE AND SECURED IN PLACE.

THE POWER CORD MUST BE SECURED IN ITS

RETAINING CLIPS AND ROUTED AWAY FROM

EXHAUST MANIFOLDS AND MOVING PARTS.

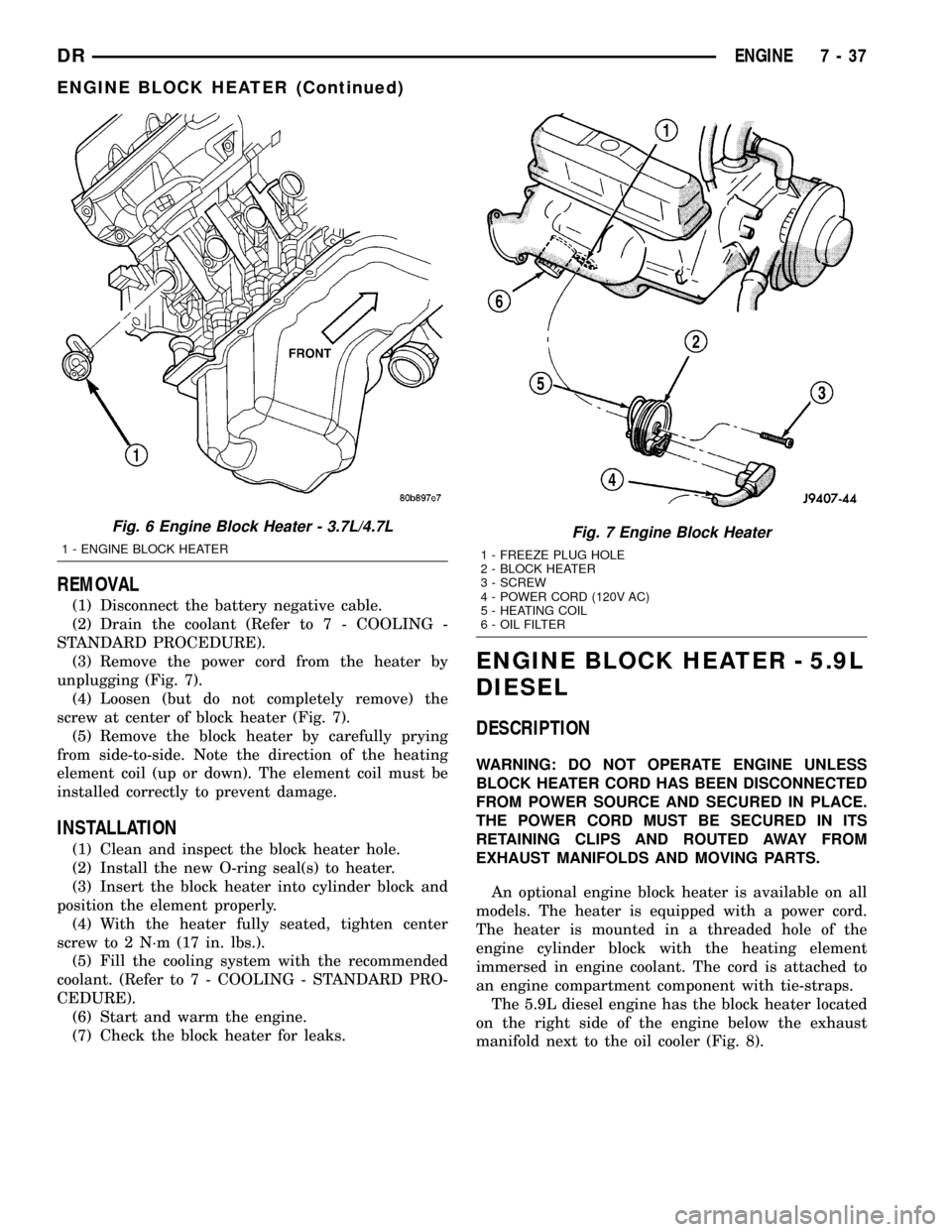

An optional engine block heater is available with

all models. The heater is equipped with a power cord.

The cord is attached to an engine compartment com-

ponent with tie-straps. The heater warms the engine

providing easier engine starting and faster warm-up

in low temperatures. The heater is mounted in a core

hole of the engine cylinder block in place of a freeze

plug with the heating element immersed in engine

coolant. The 3.7L/4.7L gas powered engines have the

block heater located to the rear on the right side of

the engine (Fig. 6).

OPERATION

The heater warms the engine coolant providing

easier engine starting and faster warm-up in low

temperatures. Connecting the power cord to a

grounded 110-120 volt AC electrical outlet with a

grounded three wire extension cord provides the elec-

tricity needed to heat the element.

DIAGNOSIS AND TESTING - ENGINE BLOCK

HEATER

If the unit does not operate, possible causes can be

either the power cord or the heater element. Test the

power cord for continuity with a 110-volt voltmeter or

110-volt test light. Test heater element continuity

with an ohmmeter or a 12-volt test light.

CAUTION: To prevent damage, the power cord must

be secured in it's retainer clips and away from any

components that may cause abrasion or damage,

such as linkages, exhaust components, etc.

Fig. 5 Electronically Controlled Viscous Fan Drive

Wiring

1 - UPPER SHROUD

2 - WIRING

3 - GROMMET

7 - 36 ENGINEDR

RADIATOR FAN - 5.9L DIESEL (Continued)

Page 352 of 2627

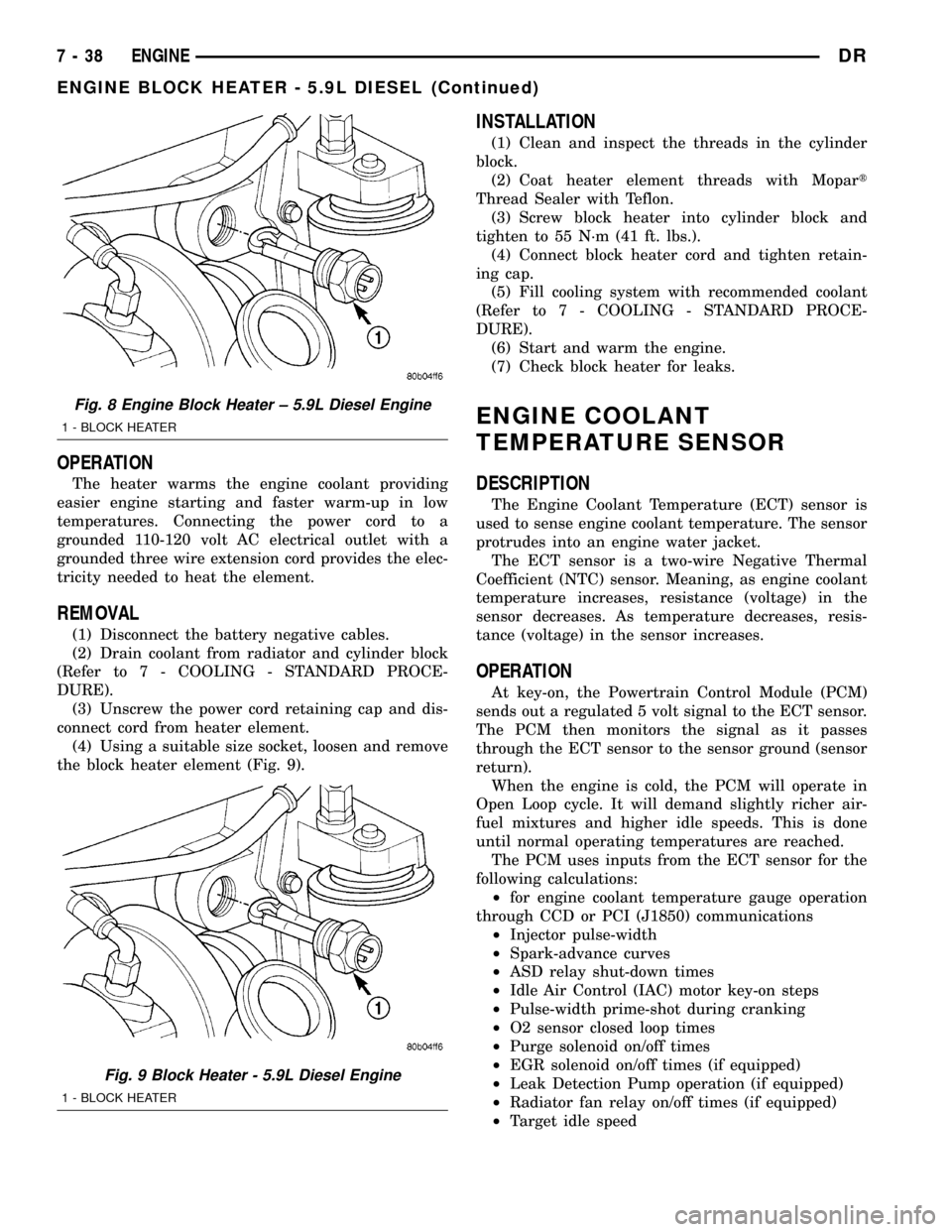

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain the coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove the power cord from the heater by

unplugging (Fig. 7).

(4) Loosen (but do not completely remove) the

screw at center of block heater (Fig. 7).

(5) Remove the block heater by carefully prying

from side-to-side. Note the direction of the heating

element coil (up or down). The element coil must be

installed correctly to prevent damage.

INSTALLATION

(1) Clean and inspect the block heater hole.

(2) Install the new O-ring seal(s) to heater.

(3) Insert the block heater into cylinder block and

position the element properly.

(4) With the heater fully seated, tighten center

screw to 2 N´m (17 in. lbs.).

(5) Fill the cooling system with the recommended

coolant. (Refer to 7 - COOLING - STANDARD PRO-

CEDURE).

(6) Start and warm the engine.

(7) Check the block heater for leaks.

ENGINE BLOCK HEATER - 5.9L

DIESEL

DESCRIPTION

WARNING: DO NOT OPERATE ENGINE UNLESS

BLOCK HEATER CORD HAS BEEN DISCONNECTED

FROM POWER SOURCE AND SECURED IN PLACE.

THE POWER CORD MUST BE SECURED IN ITS

RETAINING CLIPS AND ROUTED AWAY FROM

EXHAUST MANIFOLDS AND MOVING PARTS.

An optional engine block heater is available on all

models. The heater is equipped with a power cord.

The heater is mounted in a threaded hole of the

engine cylinder block with the heating element

immersed in engine coolant. The cord is attached to

an engine compartment component with tie-straps.

The 5.9L diesel engine has the block heater located

on the right side of the engine below the exhaust

manifold next to the oil cooler (Fig. 8).

Fig. 6 Engine Block Heater - 3.7L/4.7L

1 - ENGINE BLOCK HEATER

Fig. 7 Engine Block Heater

1 - FREEZE PLUG HOLE

2 - BLOCK HEATER

3 - SCREW

4 - POWER CORD (120V AC)

5 - HEATING COIL

6 - OIL FILTER

DRENGINE 7 - 37

ENGINE BLOCK HEATER (Continued)

Page 353 of 2627

OPERATION

The heater warms the engine coolant providing

easier engine starting and faster warm-up in low

temperatures. Connecting the power cord to a

grounded 110-120 volt AC electrical outlet with a

grounded three wire extension cord provides the elec-

tricity needed to heat the element.

REMOVAL

(1) Disconnect the battery negative cables.

(2) Drain coolant from radiator and cylinder block

(Refer to 7 - COOLING - STANDARD PROCE-

DURE).

(3) Unscrew the power cord retaining cap and dis-

connect cord from heater element.

(4) Using a suitable size socket, loosen and remove

the block heater element (Fig. 9).

INSTALLATION

(1) Clean and inspect the threads in the cylinder

block.

(2) Coat heater element threads with Mopart

Thread Sealer with Teflon.

(3) Screw block heater into cylinder block and

tighten to 55 N´m (41 ft. lbs.).

(4) Connect block heater cord and tighten retain-

ing cap.

(5) Fill cooling system with recommended coolant

(Refer to 7 - COOLING - STANDARD PROCE-

DURE).

(6) Start and warm the engine.

(7) Check block heater for leaks.

ENGINE COOLANT

TEMPERATURE SENSOR

DESCRIPTION

The Engine Coolant Temperature (ECT) sensor is

used to sense engine coolant temperature. The sensor

protrudes into an engine water jacket.

The ECT sensor is a two-wire Negative Thermal

Coefficient (NTC) sensor. Meaning, as engine coolant

temperature increases, resistance (voltage) in the

sensor decreases. As temperature decreases, resis-

tance (voltage) in the sensor increases.

OPERATION

At key-on, the Powertrain Control Module (PCM)

sends out a regulated 5 volt signal to the ECT sensor.

The PCM then monitors the signal as it passes

through the ECT sensor to the sensor ground (sensor

return).

When the engine is cold, the PCM will operate in

Open Loop cycle. It will demand slightly richer air-

fuel mixtures and higher idle speeds. This is done

until normal operating temperatures are reached.

The PCM uses inputs from the ECT sensor for the

following calculations:

²for engine coolant temperature gauge operation

through CCD or PCI (J1850) communications

²Injector pulse-width

²Spark-advance curves

²ASD relay shut-down times

²Idle Air Control (IAC) motor key-on steps

²Pulse-width prime-shot during cranking

²O2 sensor closed loop times

²Purge solenoid on/off times

²EGR solenoid on/off times (if equipped)

²Leak Detection Pump operation (if equipped)

²Radiator fan relay on/off times (if equipped)

²Target idle speed

Fig. 8 Engine Block Heater ± 5.9L Diesel Engine

1 - BLOCK HEATER

Fig. 9 Block Heater - 5.9L Diesel Engine

1 - BLOCK HEATER

7 - 38 ENGINEDR

ENGINE BLOCK HEATER - 5.9L DIESEL (Continued)

Page 354 of 2627

REMOVAL

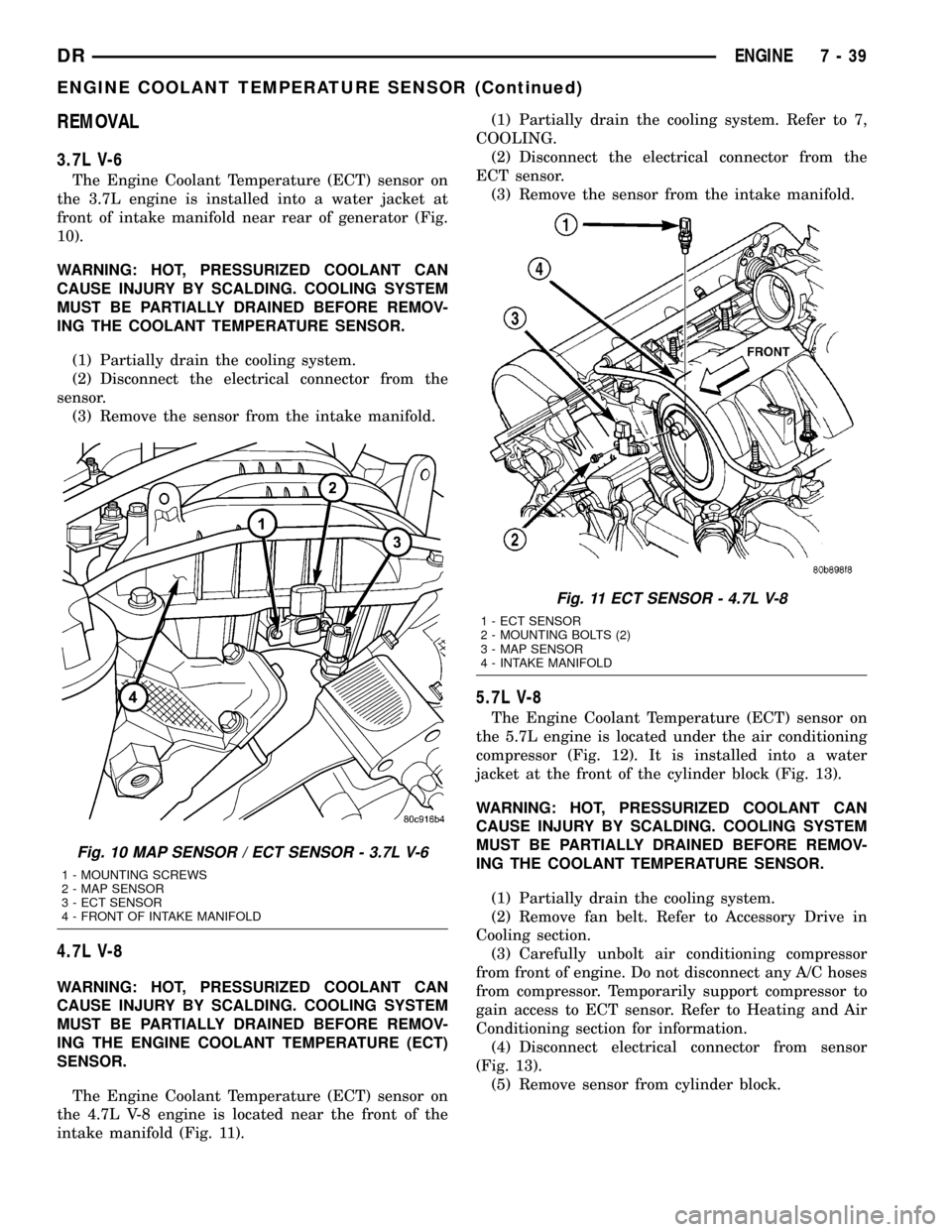

3.7L V-6

The Engine Coolant Temperature (ECT) sensor on

the 3.7L engine is installed into a water jacket at

front of intake manifold near rear of generator (Fig.

10).

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE COOLANT TEMPERATURE SENSOR.

(1) Partially drain the cooling system.

(2) Disconnect the electrical connector from the

sensor.

(3) Remove the sensor from the intake manifold.

4.7L V-8

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE ENGINE COOLANT TEMPERATURE (ECT)

SENSOR.

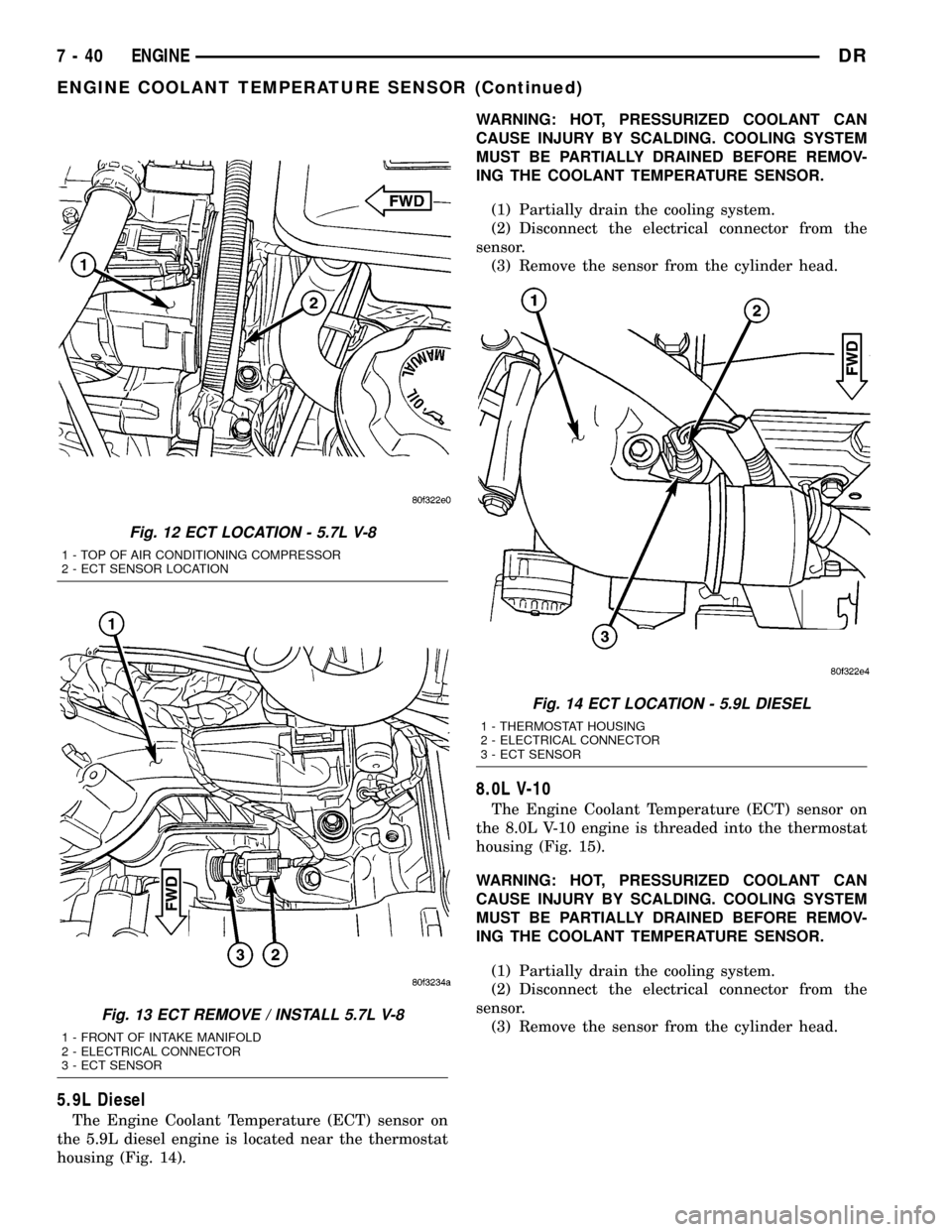

The Engine Coolant Temperature (ECT) sensor on

the 4.7L V-8 engine is located near the front of the

intake manifold (Fig. 11).(1) Partially drain the cooling system. Refer to 7,

COOLING.

(2) Disconnect the electrical connector from the

ECT sensor.

(3) Remove the sensor from the intake manifold.

5.7L V-8

The Engine Coolant Temperature (ECT) sensor on

the 5.7L engine is located under the air conditioning

compressor (Fig. 12). It is installed into a water

jacket at the front of the cylinder block (Fig. 13).

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE COOLANT TEMPERATURE SENSOR.

(1) Partially drain the cooling system.

(2) Remove fan belt. Refer to Accessory Drive in

Cooling section.

(3) Carefully unbolt air conditioning compressor

from front of engine. Do not disconnect any A/C hoses

from compressor. Temporarily support compressor to

gain access to ECT sensor. Refer to Heating and Air

Conditioning section for information.

(4) Disconnect electrical connector from sensor

(Fig. 13).

(5) Remove sensor from cylinder block.

Fig. 10 MAP SENSOR / ECT SENSOR - 3.7L V-6

1 - MOUNTING SCREWS

2 - MAP SENSOR

3 - ECT SENSOR

4 - FRONT OF INTAKE MANIFOLD

Fig. 11 ECT SENSOR - 4.7L V-8

1 - ECT SENSOR

2 - MOUNTING BOLTS (2)

3 - MAP SENSOR

4 - INTAKE MANIFOLD

DRENGINE 7 - 39

ENGINE COOLANT TEMPERATURE SENSOR (Continued)

Page 355 of 2627

5.9L Diesel

The Engine Coolant Temperature (ECT) sensor on

the 5.9L diesel engine is located near the thermostat

housing (Fig. 14).WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE COOLANT TEMPERATURE SENSOR.

(1) Partially drain the cooling system.

(2) Disconnect the electrical connector from the

sensor.

(3) Remove the sensor from the cylinder head.

8.0L V-10

The Engine Coolant Temperature (ECT) sensor on

the 8.0L V-10 engine is threaded into the thermostat

housing (Fig. 15).

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE COOLANT TEMPERATURE SENSOR.

(1) Partially drain the cooling system.

(2) Disconnect the electrical connector from the

sensor.

(3) Remove the sensor from the cylinder head.

Fig. 12 ECT LOCATION - 5.7L V-8

1 - TOP OF AIR CONDITIONING COMPRESSOR

2 - ECT SENSOR LOCATION

Fig. 13 ECT REMOVE / INSTALL 5.7L V-8

1 - FRONT OF INTAKE MANIFOLD

2 - ELECTRICAL CONNECTOR

3 - ECT SENSOR

Fig. 14 ECT LOCATION - 5.9L DIESEL

1 - THERMOSTAT HOUSING

2 - ELECTRICAL CONNECTOR

3 - ECT SENSOR

7 - 40 ENGINEDR

ENGINE COOLANT TEMPERATURE SENSOR (Continued)