tire type DODGE RAM 1500 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2501 of 2627

spikes and electromagnetic interference that can be

generated as the electromagnetic field of the relay

coil collapses.

The A/C compressor clutch relay terminals are con-

nected to the vehicle electrical system through a

receptacle in the integrated power module (IPM). The

inputs and outputs of the A/C compressor clutch

relay include:

²The common feed terminal (30) receives a bat-

tery current input from a fuse in the IPM through a

fused B(+) circuit at all times.

²The coil ground terminal (86) receives a ground

input from the PCM/ECM through the A/C compres-

sor clutch relay control circuit only when the PCM/

ECM electronically pulls the control circuit to

ground.

²The coil battery terminal (85) receives a battery

current input from PTC 1 in the IPM through a

fused ignition switch output (run) circuit only when

the ignition switch is in the On position.

²The normally open terminal (87) provides a bat-

tery current output to the compressor clutch coil

through the A/C compressor clutch relay output cir-

cuit only when the A/C compressor clutch relay coil is

energized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the A/C compres-

sor clutch relay coil is de-energized.

Refer to the appropriate wiring information for

diagnosis and testing of the micro-relay and for com-

plete HVAC wiring diagrams.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

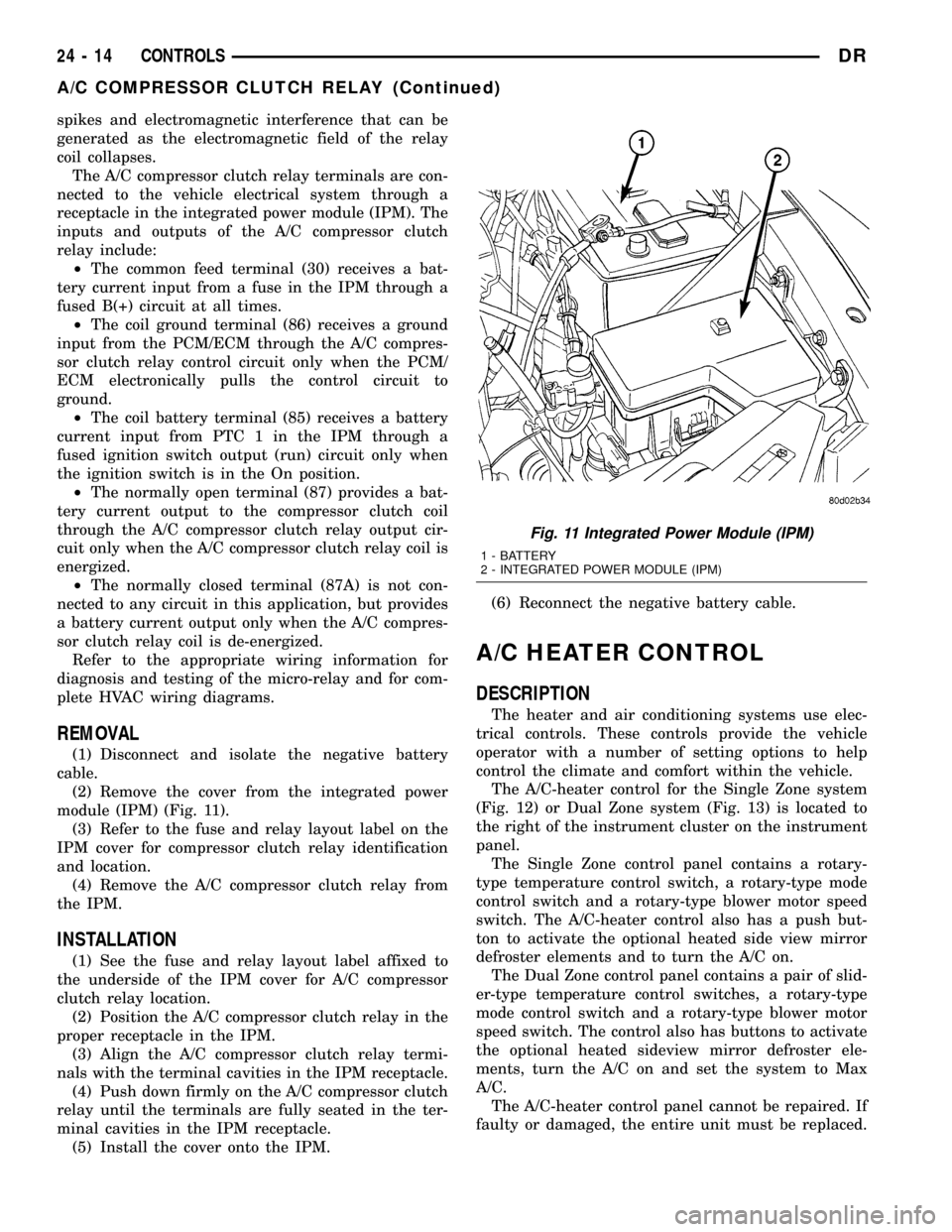

(2) Remove the cover from the integrated power

module (IPM) (Fig. 11).

(3) Refer to the fuse and relay layout label on the

IPM cover for compressor clutch relay identification

and location.

(4) Remove the A/C compressor clutch relay from

the IPM.

INSTALLATION

(1) See the fuse and relay layout label affixed to

the underside of the IPM cover for A/C compressor

clutch relay location.

(2) Position the A/C compressor clutch relay in the

proper receptacle in the IPM.

(3) Align the A/C compressor clutch relay termi-

nals with the terminal cavities in the IPM receptacle.

(4) Push down firmly on the A/C compressor clutch

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install the cover onto the IPM.(6) Reconnect the negative battery cable.

A/C HEATER CONTROL

DESCRIPTION

The heater and air conditioning systems use elec-

trical controls. These controls provide the vehicle

operator with a number of setting options to help

control the climate and comfort within the vehicle.

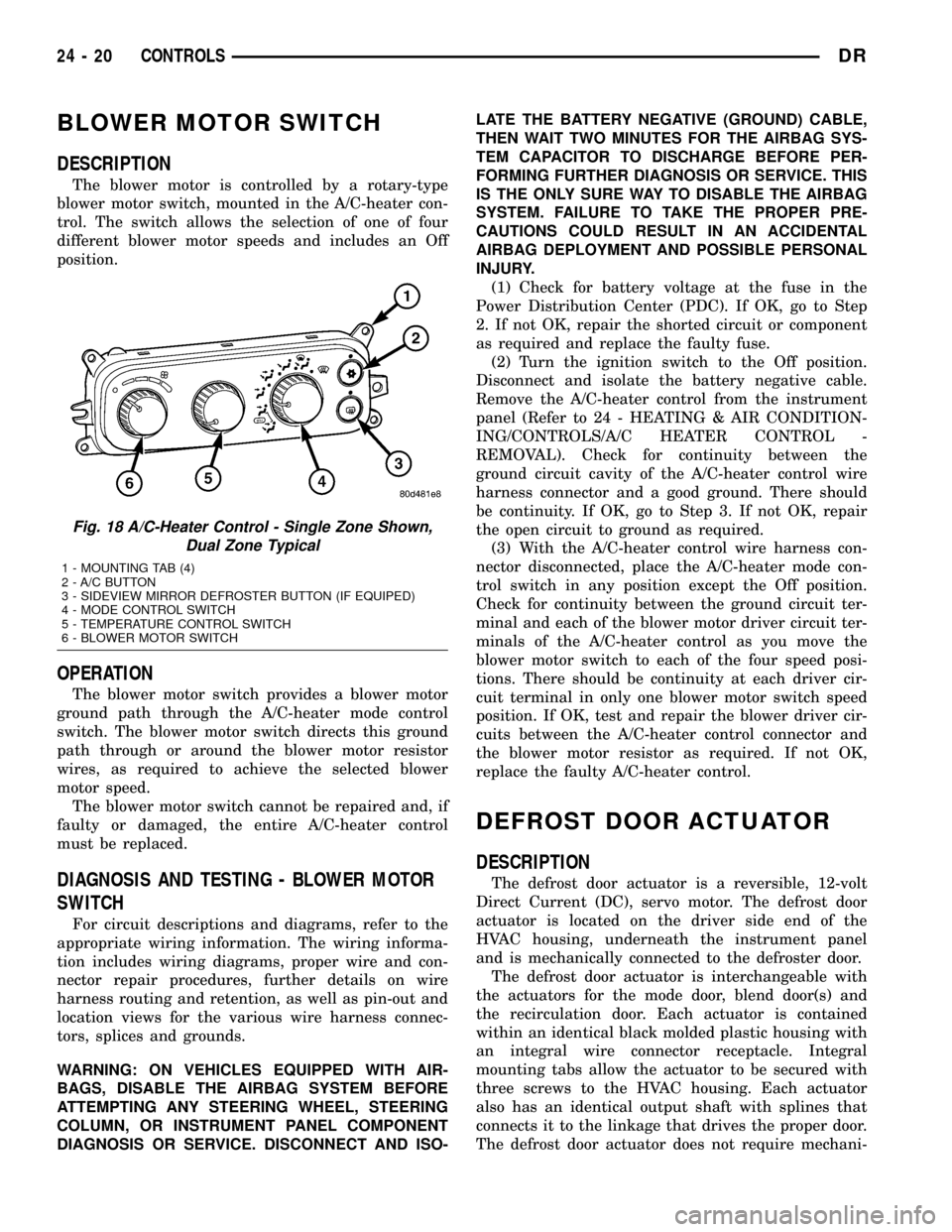

The A/C-heater control for the Single Zone system

(Fig. 12) or Dual Zone system (Fig. 13) is located to

the right of the instrument cluster on the instrument

panel.

The Single Zone control panel contains a rotary-

type temperature control switch, a rotary-type mode

control switch and a rotary-type blower motor speed

switch. The A/C-heater control also has a push but-

ton to activate the optional heated side view mirror

defroster elements and to turn the A/C on.

The Dual Zone control panel contains a pair of slid-

er-type temperature control switches, a rotary-type

mode control switch and a rotary-type blower motor

speed switch. The control also has buttons to activate

the optional heated sideview mirror defroster ele-

ments, turn the A/C on and set the system to Max

A/C.

The A/C-heater control panel cannot be repaired. If

faulty or damaged, the entire unit must be replaced.

Fig. 11 Integrated Power Module (IPM)

1 - BATTERY

2 - INTEGRATED POWER MODULE (IPM)

24 - 14 CONTROLSDR

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 2507 of 2627

BLOWER MOTOR SWITCH

DESCRIPTION

The blower motor is controlled by a rotary-type

blower motor switch, mounted in the A/C-heater con-

trol. The switch allows the selection of one of four

different blower motor speeds and includes an Off

position.

OPERATION

The blower motor switch provides a blower motor

ground path through the A/C-heater mode control

switch. The blower motor switch directs this ground

path through or around the blower motor resistor

wires, as required to achieve the selected blower

motor speed.

The blower motor switch cannot be repaired and, if

faulty or damaged, the entire A/C-heater control

must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

SWITCH

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check for battery voltage at the fuse in the

Power Distribution Center (PDC). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the A/C-heater control from the instrument

panel (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS/A/C HEATER CONTROL -

REMOVAL). Check for continuity between the

ground circuit cavity of the A/C-heater control wire

harness connector and a good ground. There should

be continuity. If OK, go to Step 3. If not OK, repair

the open circuit to ground as required.

(3) With the A/C-heater control wire harness con-

nector disconnected, place the A/C-heater mode con-

trol switch in any position except the Off position.

Check for continuity between the ground circuit ter-

minal and each of the blower motor driver circuit ter-

minals of the A/C-heater control as you move the

blower motor switch to each of the four speed posi-

tions. There should be continuity at each driver cir-

cuit terminal in only one blower motor switch speed

position. If OK, test and repair the blower driver cir-

cuits between the A/C-heater control connector and

the blower motor resistor as required. If not OK,

replace the faulty A/C-heater control.

DEFROST DOOR ACTUATOR

DESCRIPTION

The defrost door actuator is a reversible, 12-volt

Direct Current (DC), servo motor. The defrost door

actuator is located on the driver side end of the

HVAC housing, underneath the instrument panel

and is mechanically connected to the defroster door.

The defrost door actuator is interchangeable with

the actuators for the mode door, blend door(s) and

the recirculation door. Each actuator is contained

within an identical black molded plastic housing with

an integral wire connector receptacle. Integral

mounting tabs allow the actuator to be secured with

three screws to the HVAC housing. Each actuator

also has an identical output shaft with splines that

connects it to the linkage that drives the proper door.

The defrost door actuator does not require mechani-

Fig. 18 A/C-Heater Control - Single Zone Shown,

Dual Zone Typical

1 - MOUNTING TAB (4)

2 - A/C BUTTON

3 - SIDEVIEW MIRROR DEFROSTER BUTTON (IF EQUIPED)

4 - MODE CONTROL SWITCH

5 - TEMPERATURE CONTROL SWITCH

6 - BLOWER MOTOR SWITCH

24 - 20 CONTROLSDR

Page 2532 of 2627

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING TUBING

AND FITTINGS

CAUTION: The system must be completely empty

before opening any fitting or connection in the

refrigeration system. Open fittings with caution

even after the system has been emptied. If any

pressure is noticed as a fitting is loosened,

retighten fitting and evacuate the system again.

A good rule for the flexible hose lines is to keep the

radius of all bends at least 10 times the diameter of

the hose. Sharper bends will reduce the flow of

refrigerant. The flexible hose lines should be routed

so they are at least 3 inches (80 mm) from the

exhaust manifold. Inspect all flexible hose lines to

make sure they are in good condition and properly

routed.

The use of correct wrenches when making connec-

tions is very important. Improper wrenches or

improper use of wrenches can damage the fittings.

The internal parts of the A/C system will remain sta-

ble as long as moisture-free refrigerant and refrig-

erant oil is used. Abnormal amounts of dirt,

moisture or air can upset the chemical stability.

This may cause operational troubles or even seri-

ous damage if present in more than very small

quantities. Before disconnecting a component,

clean the outside of the fittings thoroughly to pre-

vent contamination from entering the refrigerant

system.

When opening a refrigeration system, have every-

thing you will need to repair the system ready. This

will minimize the amount of time the system must

be opened. Cap or plug all lines and fittings as

soon as they are opened. This will help prevent the

entrance of dirt and moisture. All new lines and

components should be capped or sealed until they

are ready to be used. Before connecting a compo-

nent, clean the outside of the fittings thoroughly to

prevent contamination from entering the refrigerant

system.

All tools, including the refrigerant dispensing mani-

fold, the manifold gauge set, and test hoses should

be kept clean and dry.

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the

capacity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all connec-

tions are pressure tight. Dirt and moisture can enter

the system when it is opened for repair or replace-

ment of lines or components. The refrigerant oil willabsorb moisture readily out of the air. This moisture

will convert into acids within a closed system.

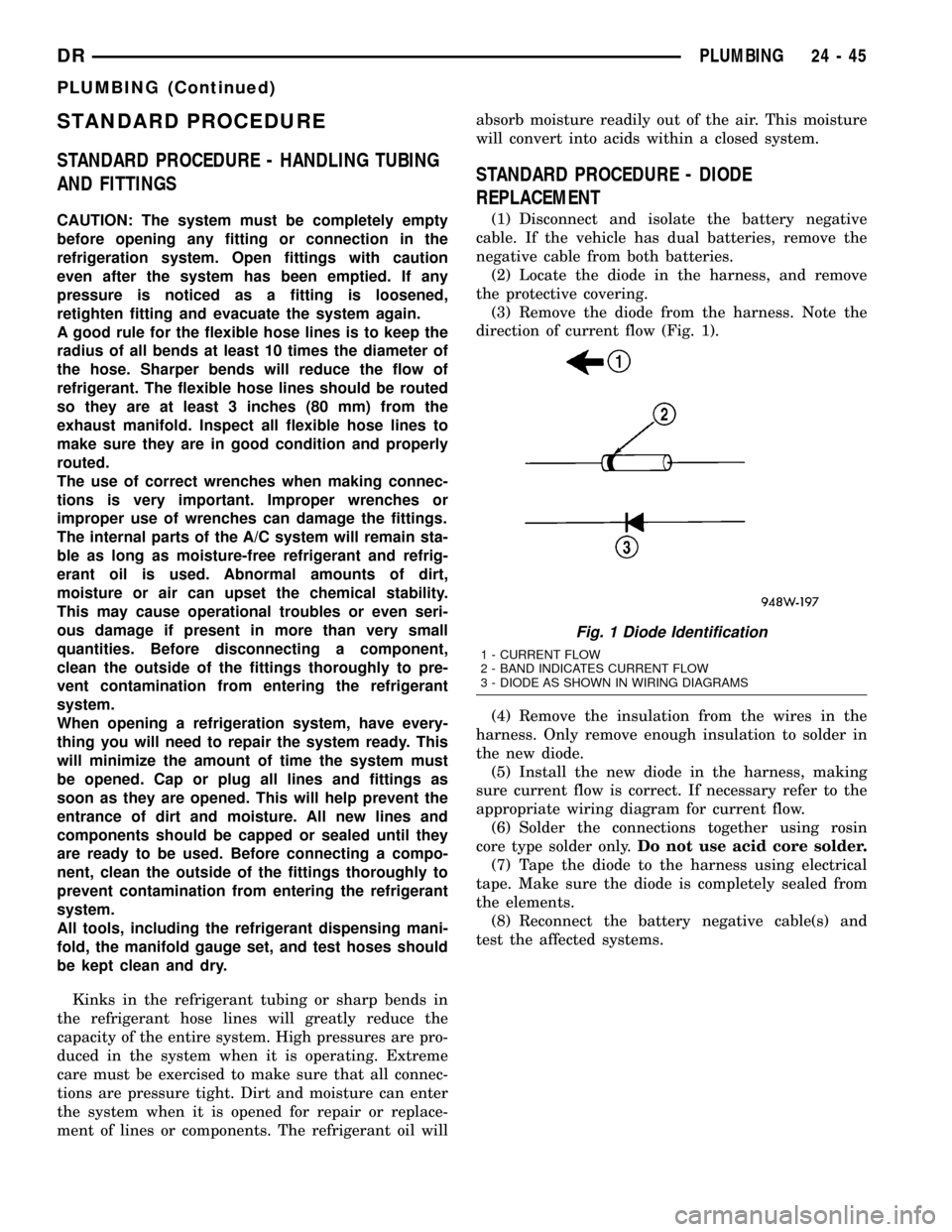

STANDARD PROCEDURE - DIODE

REPLACEMENT

(1) Disconnect and isolate the battery negative

cable. If the vehicle has dual batteries, remove the

negative cable from both batteries.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness. Note the

direction of current flow (Fig. 1).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connections together using rosin

core type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape. Make sure the diode is completely sealed from

the elements.

(8) Reconnect the battery negative cable(s) and

test the affected systems.

Fig. 1 Diode Identification

1 - CURRENT FLOW

2 - BAND INDICATES CURRENT FLOW

3 - DIODE AS SHOWN IN WIRING DIAGRAMS

DRPLUMBING 24 - 45

PLUMBING (Continued)

Page 2535 of 2627

After the system has been tested for leaks and

evacuated, a refrigerant (R-134a) charge can be

injected into the system.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) If using a separate vacuum pump close all

valves before disconnecting pump. Connect manifold

gauge set to the A/C service ports.

NOTE: Always refer to the underhood HVAC Speci-

fication label for the refrigerant fill level of the vehi-

cle being serviced.

(2) Measure refrigerant (refer to capacities). Refer

to the instructions provided with the equipment

being used.

(3) Verify engine is shut off. Open the suction and

discharge valves. Open the charge valve to allow the

refrigerant to flow into the system. When the trans-

fer of refrigerant has stopped, close the suction and

discharge valve.

(4) If all of the charge did not transfer from the

dispensing device, put vehicle controls into the fol-

lowing mode:

²Automatic transmission in park or manual

transmission in neutral

²Engine at idle

²A/C mode control set to outside air

²A/C mode control set to panel mode

²A/C temperature control set to full cool

²Blower motor control set on highest speed

²Vehicle windows closed

If the A/C compressor does not engage, test the

compressor clutch control circuit and correct any fail-

ure (Refer to 8 - ELECTRICAL/WIRING DIAGRAM

INFORMATION - DIAGNOSIS AND TESTING).

(5) Open the suction valve to allow the remaining

refrigerant to transfer to the system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH-PRESSURE) VALVE AT THIS TIME.

(6) Close all valves and test the A/C system perfor-

mance.

(7) Disconnect the charging station or manifold

gauge set. Install the service port caps.

REFRIGERANT CHARGE CAPACITY

The R-134a refrigerant system charge capacity for

this vehicle can be found on the underhood HVAC

specfication tag.

A/C COMPRESSOR

DESCRIPTION

DESCRIPTION - A/C COMPRESSOR

The A/C system on models equipped with the 5.9L

engine use a Sanden SD-7 reciprocating swash plate-

type compressor. This compressor has a fixed dis-

placement of 165 cubic centimeter (10.068 cubic

inches) and has both the suction and discharge ports

located on the cylinder head.

The A/C system on models equipped with the 3.7L,

4.7L and 5.7L engines use a Denso 10S17 reciprocat-

ing swash plate-type compressor. This compressor

has a fixed displacement of 170 cubic centimeter and

has both the suction and discharge ports located on

the cylinder head.

A label identifying the use of R-134a refrigerant is

located on both A/C compressors.

DESCRIPTION - HIGH PRESSURE RELIEF

VALVE

A high pressure relief valve is located on the com-

pressor cylinder head, which is on the rear of the

compressor. This mechanical valve is designed to

vent refrigerant from the system to protect against

damage to the compressor and other system compo-

nents, caused by condenser air flow restriction or an

overcharge of refrigerant.

OPERATION

OPERATION - A/C COMPRESSOR

The A/C compressor is driven by the engine

through an electric clutch, drive pulley and belt

arrangement. The compressor is lubricated by refrig-

erant oil that is circulated throughout the refrigerant

system with the refrigerant.

The compressor draws in low-pressure refrigerant

vapor from the evaporator through its suction port. It

then compresses the refrigerant into a high-pressure,

high-temperature refrigerant vapor, which is then

pumped to the condenser through the compressor dis-

charge port.

The compressor cannot be repaired. If faulty or

damaged, the entire compressor assembly must be

replaced. The compressor clutch, pulley and clutch

coil are available for service.

OPERATION - HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents the system

when a discharge pressure of 3445 to 4135 kPa (500

to 600 psi) or above is reached. The valve closes

24 - 48 PLUMBINGDR

PLUMBING (Continued)