height DODGE RAM 1500 1998 2.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 655 of 2627

(4) Reconnect the yellow seat belt tensioner pigtail

wire connector to the body wire harness take out and

connector for the tensioner.

(5) Engage the seat belt tensioner pigtail wire

retainer into the hole in the inner B-pillar sheet

metal.

(6) On the driver side only, reconnect the body

wire harness take out and white connector to the

seat belt tension reducer connector receptacle near

the bottom of the retractor.

(7) Position the seat belt web guide to its mount-

ing location on the inner B-pillar near the belt line.

(8) Install and tighten the screw that secures the

seat belt web guide to the inner B-pillar. Tighten the

screw to 2 N´m (20 in. lbs.).

(9) Reinstall the upper and lower trim onto the

inner B-pillar. (Refer to 23 - BODY/INTERIOR/B-

PILLAR UPPER TRIM - INSTALLATION) and

(Refer to 23 - BODY/INTERIOR/B-PILLAR LOWER

TRIM - INSTALLATION).

(10) Position the seat belt turning loop onto the

height adjuster on the upper inner B-pillar.

(11) Install and tighten the screw that secures the

seat belt turning loop to the height adjuster. Tighten

the screw to 40 N´m (29 ft. lbs.).

(12) Engage the lower snap features of the new

trim cover over the front outboard seat belt turning

loop and, using hand pressure, press firmly and

evenly on the top of the trim cover until it snaps into

place.

(13) Position the lower seat belt anchor to the

lower inner B-pillar.

(14) Install and tighten the screw that secures the

lower seat belt anchor to the B-pillar. Tighten the

screw to 40 N´m (29 ft. lbs.).

(15) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

(16) Move the front seat back to its rearward posi-

tion.INSTALLATION - QUAD CAB

The following procedure is for replacement of a

faulty or damaged front outboard seat belt and

retractor unit, which includes a seat belt tensioner

for this model. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/SEAT BELT TENSIONER - DESCRIP-

TION). The only component of this seat belt and

retractor unit that is available for individual service

replacement is the plastic web stop button that pre-

vents the latch plate from falling to the floor while in

the stored position. Refer to the instructions supplied

with the service kit for the proper web stop button

replacement procedures.

The seat belt retractor on the passenger's side of

all models includes a switchable automatic locking

mechanism. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/AUTOMATIC LOCKING RETRACTOR -

DESCRIPTION).

If the seat belt or retractor is faulty or damaged,

but the seat belt tensioner is not deployed, review

the recommended procedures for handling non-de-

ployed supplemental restraints. (Refer to 8 - ELEC-

TRICAL/RESTRAINTS - STANDARD PROCEDURE

- HANDLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the seat belt tensioner has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the front outboard seat belt and

retractor from the vehicle. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - STANDARD PROCEDURE -

SERVICE AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

8O - 36 RESTRAINTSDR

FRONT OUTBOARD SEAT BELT & RETRACTOR (Continued)

Page 656 of 2627

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

(1) Position the front outboard seat belt and

retractor to the retractor mounting hole in the lower

inner B-pillar (Fig. 32).

(2) Engage the hooks on the upper retractor

bracket into the slots in the lower inner B-pillar

above the retractor mounting hole.

(3) Install and tighten the screw that secures the

lower retractor bracket to the lower inner B-pillar

below the retractor mounting hole. Tighten the screw

to 40 N´m (29 ft. lbs.).

(4) Reconnect the yellow seat belt tensioner pigtail

wire connector to the body wire harness take out and

connector for the tensioner.

(5) Engage the seat belt tensioner pigtail wire

retainer into the hole in the inner B-pillar sheet

metal.

(6) Position the seat belt web guide to its mount-

ing location on the inner B-pillar near the belt line.

(7) Install and tighten the screw that secures the

seat belt web guide to the inner B-pillar. Tighten the

screw to 2 N´m (20 in. lbs.).

(8) Reinstall the upper and lower trim onto the

inner B-pillar. (Refer to 23 - BODY/INTERIOR/B-

PILLAR UPPER TRIM - INSTALLATION) and

(Refer to 23 - BODY/INTERIOR/B-PILLAR LOWER

TRIM - INSTALLATION).

(9) Position the seat belt turning loop onto the

height adjuster on the upper inner B-pillar.

(10) Install and tighten the screw that secures the

seat belt turning loop to the height adjuster. Tighten

the screw to 40 N´m (29 ft. lbs.).

(11) Engage the lower snap features of the new

trim cover over the front outboard seat belt turningloop and, using hand pressure, press firmly and

evenly on the top of the trim cover until it snaps into

place.

(12) Position the lower seat belt anchor to the floor

panel near the base of the inner B-pillar.

(13) Install and tighten the screw that secures the

lower seat belt anchor to the floor panel near the

base of the inner B-pillar. Tighten the screw to 40

N´m (29 ft. lbs.).

(14) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

(15) Move the front seat back to its rearward posi-

tion.

FRONT OUTBOARD SEAT

BELT BUCKLE

REMOVAL

A traveling front outboard seat belt buckle is

located on the inboard side of each front outboard

seat section (40 percent) used on all models. The seat

belt buckle on the driver's side front seat for all mod-

els also includes a seat belt switch. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT SWITCH -

DESCRIPTION).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

DRRESTRAINTS 8O - 37

FRONT OUTBOARD SEAT BELT & RETRACTOR (Continued)

Page 674 of 2627

SEAT BELT TURNING LOOP

ADJUSTER

REMOVAL

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

(1) Unsnap and remove the trim cover from the

front outboard seat belt turning loop to access the

screw that secures the turning loop to the height

adjuster on the upper inner B-pillar. Discard the

removed turning loop trim cover as it is not intended

for reuse.

(2) Remove the screw that secures the seat belt

turning loop to the height adjuster.

(3) Remove the front seat belt turning loop from

the height adjuster.

(4) Remove the upper trim from the inner B-pillar.

(Refer to 23 - BODY/INTERIOR/B-PILLAR UPPER

TRIM - REMOVAL).

(5) Loosen the two screws that secure the seat belt

turning loop height adjuster far enough to remove

the adjuster from the upper B-pillar (Fig. 50).

(6) Disengage the tab near the lower end of the

seat belt turning loop height adjuster from the slot in

the sheet metal and remove the adjuster from the

inner B-pillar.

INSTALLATION

WARNING: TO AVOID PERSONAL INJURY OR DEATH,

DURING AND FOLLOWING ANY SEAT BELT OR

CHILD RESTRAINT ANCHOR SERVICE, CAREFULLY

INSPECT ALL SEAT BELTS, BUCKLES, MOUNTING

HARDWARE, RETRACTORS, TETHER STRAPS, AND

ANCHORS FOR PROPER INSTALLATION, OPERA-

TION, OR DAMAGE. REPLACE ANY BELT THAT IS

CUT, FRAYED, OR TORN. STRAIGHTEN ANY BELT

THAT IS TWISTED. TIGHTEN ANY LOOSE FASTEN-

ERS. REPLACE ANY BELT THAT HAS A DAMAGED

OR INOPERATIVE BUCKLE OR RETRACTOR.

REPLACE ANY BELT THAT HAS A BENT OR DAM-

AGED LATCH PLATE OR ANCHOR PLATE. REPLACE

ANY CHILD RESTRAINT ANCHOR OR THE UNIT TO

WHICH THE ANCHOR IS INTEGRAL THAT HAS BEEN

BENT OR DAMAGED. NEVER ATTEMPT TO REPAIR A

SEAT BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

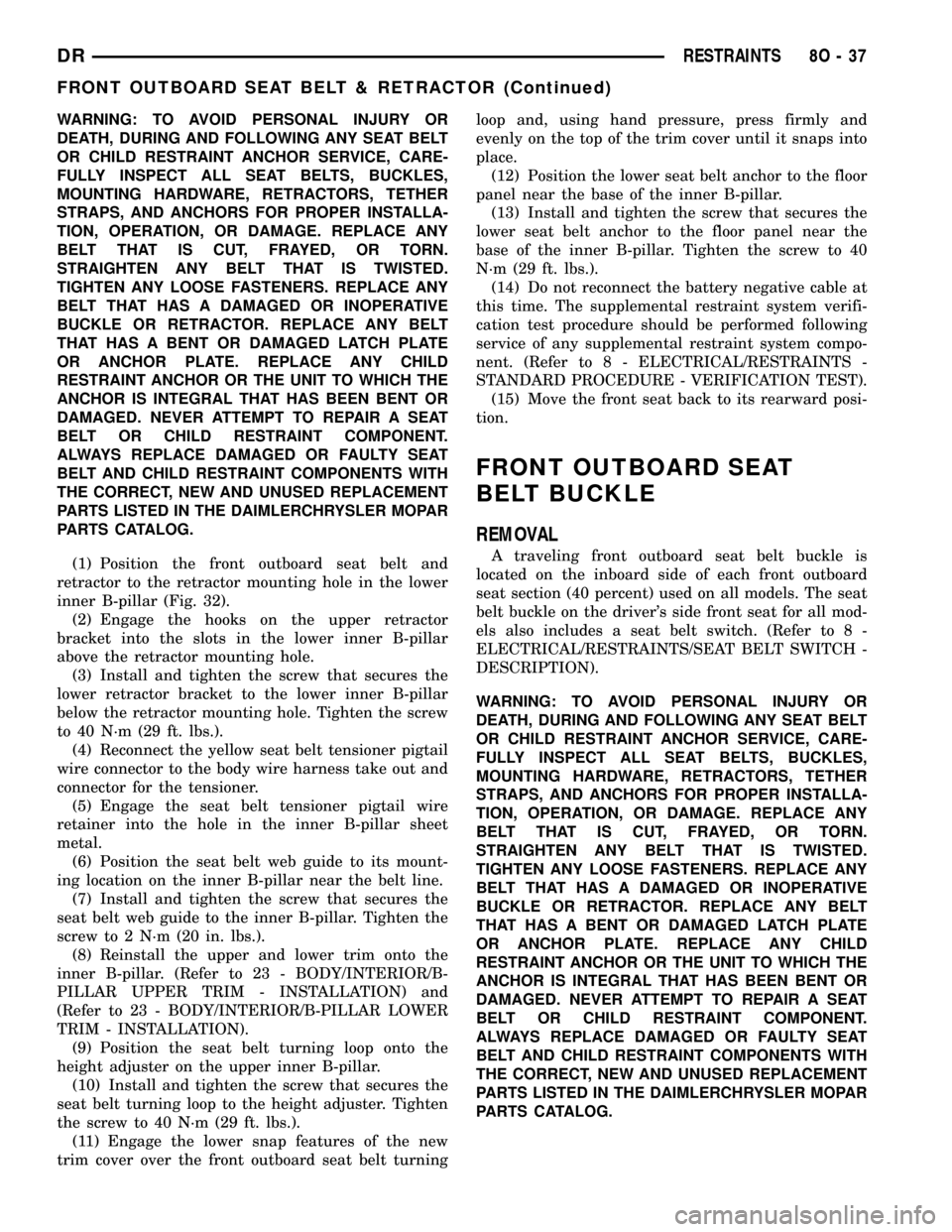

(1) Position the front seat belt turning loop

adjuster to the inner B-pillar (Fig. 50).

(2) Engage the tab near the lower end of the seat

belt turning loop height adjuster into the slot in the

sheet metal of the inner B-pillar.

(3) Hand tighten the lower of the two screws that

secure the seat belt turning loop height adjuster to

the upper B-pillar far enough to keep the tab on the

lower end of the adjuster engaged in the B-pillar slot.

Fig. 50 Seat Belt Turning Loop Adjuster Remove/

Install

1 - B-PILLAR

2 - ADJUSTER

3 - SCREW (2)

4 - GRAB HANDLE BRACKET (QUAD CAB ONLY)

DRRESTRAINTS 8O - 55

Page 675 of 2627

(4) Install the upper screw that secures the seat

belt turning loop height adjuster to the upper B-pil-

lar, then tighten both the upper and lower screws to

40 N´m (29 ft. lbs.).

(5) Reinstall the upper trim onto the inside of the

B-pillar. (Refer to 23 - BODY/INTERIOR/B-PILLAR

UPPER TRIM - INSTALLATION).

(6) Position the seat belt turning loop onto the

height adjuster on the upper inner B-pillar.

(7) Install and tighten the screw that secures the

seat belt turning loop to the height adjuster. Tighten

the screw to 40 N´m (29 ft. lbs.).

(8) Engage the lower snap features of the new trim

cover over the front outboard seat belt turning loop

and, using hand pressure, press firmly and evenly on

the top of the trim cover until it snaps into place.

SIDE CURTAIN AIRBAG

DESCRIPTION

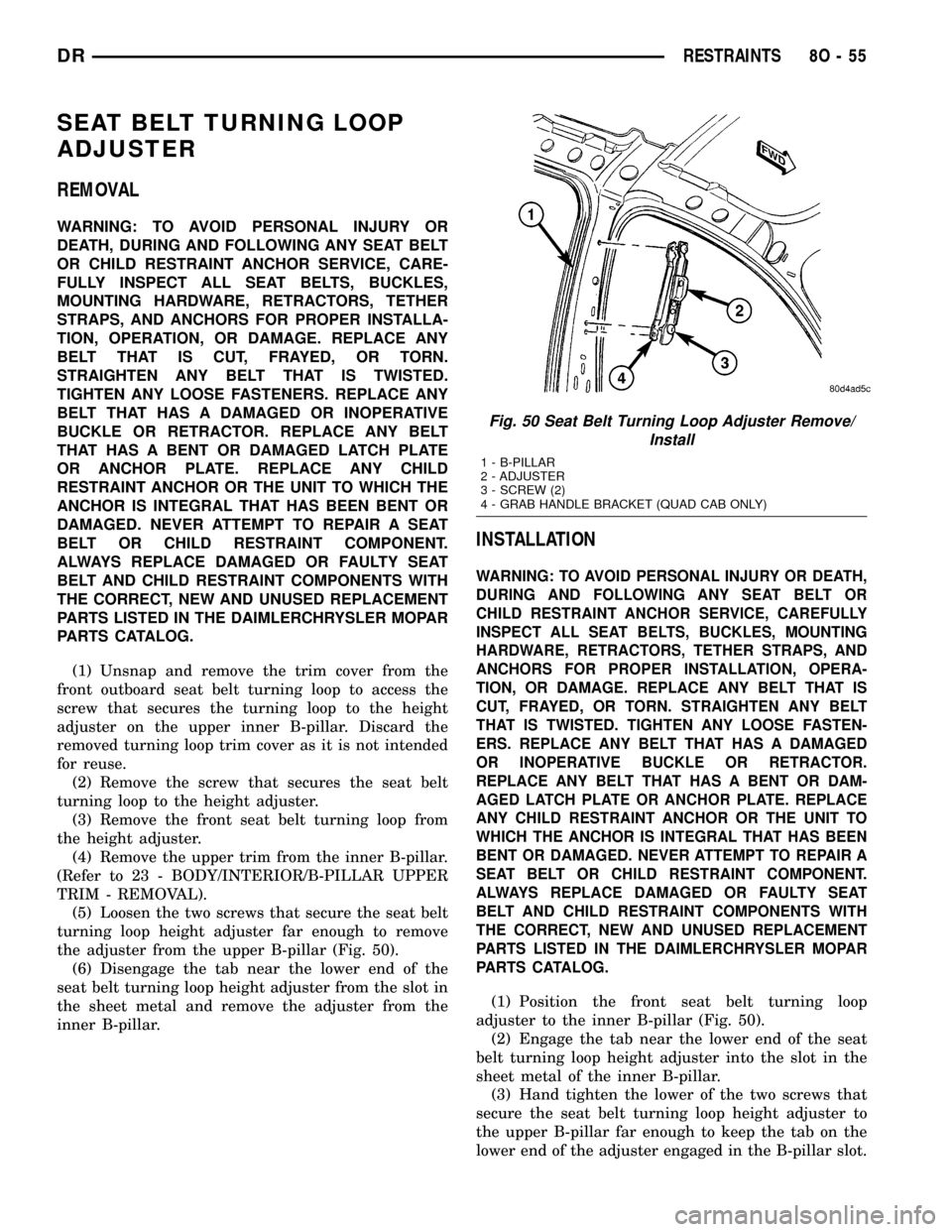

Optional side curtain airbags are available for this

model when it is also equipped with dual front air-

bags. These airbags are passive, inflatable, Supple-

mental Restraint System (SRS) components, and

vehicles with this equipment can be readily identified

by a molded identification trim button with the ªSRS

- AIRBAGº logo located on the headliner above each

A-pillar, and above each B-pillar on quad cab models

(Fig. 51). This system is designed to reduce injuries

to the vehicle occupants in the event of a side impact

collision.

Vehicles equipped with side curtain airbags have

two individually controlled curtain airbag units.

These airbag units are concealed and mounted above

the headliner where they are each secured to one of

the roof side rails (Fig. 52). Each folded airbag cush-

ion is contained within a long extruded plastic chan-

nel that extends along the roof rail from the A-pillarat the front of the vehicle to just behind the B-pillar

on standard cab models, and to just behind the C-pil-

lar on quad cab models. A tether extends down the

A-pillar from the front of the airbag cushion, where it

is retained to the pillar with plastic push-in routing

clips and it is secured to the base of the A-pillar near

the belt line with a screw.

The hybrid-type inflator for each airbag is secured

to the roof rail at the rear of the airbag unit behind

the B-pillar (standard cab) or C-pillar (quad cab), and

is connected to the airbag cushion by a long tubular

manifold. The inflator bracket and the extruded air-

bag cushion channel are located with plastic push-in

fasteners to the roof rail, then secured with screws to

spring nuts located in the roof rail. A two-wire take

out of the body wire harness with a keyed and

latched connector insulator connects directly to an

integral receptacle on the inflator initiator.

The side curtain airbag unit cannot be adjusted or

repaired and must be replaced if deployed, faulty, or

in any way damaged. Once a side curtain airbag has

been deployed, the complete airbag unit, the head-

liner, the upper A, B, and C-pillar trim, and all other

visibly damaged components must be replaced.

OPERATION

Each side curtain airbag is deployed individually

by an electrical signal generated by the Airbag Con-

trol Module (ACM) to which it is connected through

left or right curtain airbag line 1 and line 2 (or

squib) circuits. The hybrid-type inflator assembly for

each airbag contains a small canister of highly com-

Fig. 51 SRS Logo

Fig. 52 Side Curtain Airbag

1 - WIRE HARNESS CONNECTOR

2 - B-PILLAR (STD CAB) OR C-PILLAR (QUAD CAB)

3 - INFLATOR

4 - MANIFOLD

5 - ROOF SIDE RAIL

6 - A-PILLAR

7 - TETHER

8 - CHANNEL

8O - 56 RESTRAINTSDR

SEAT BELT TURNING LOOP ADJUSTER (Continued)

Page 1238 of 2627

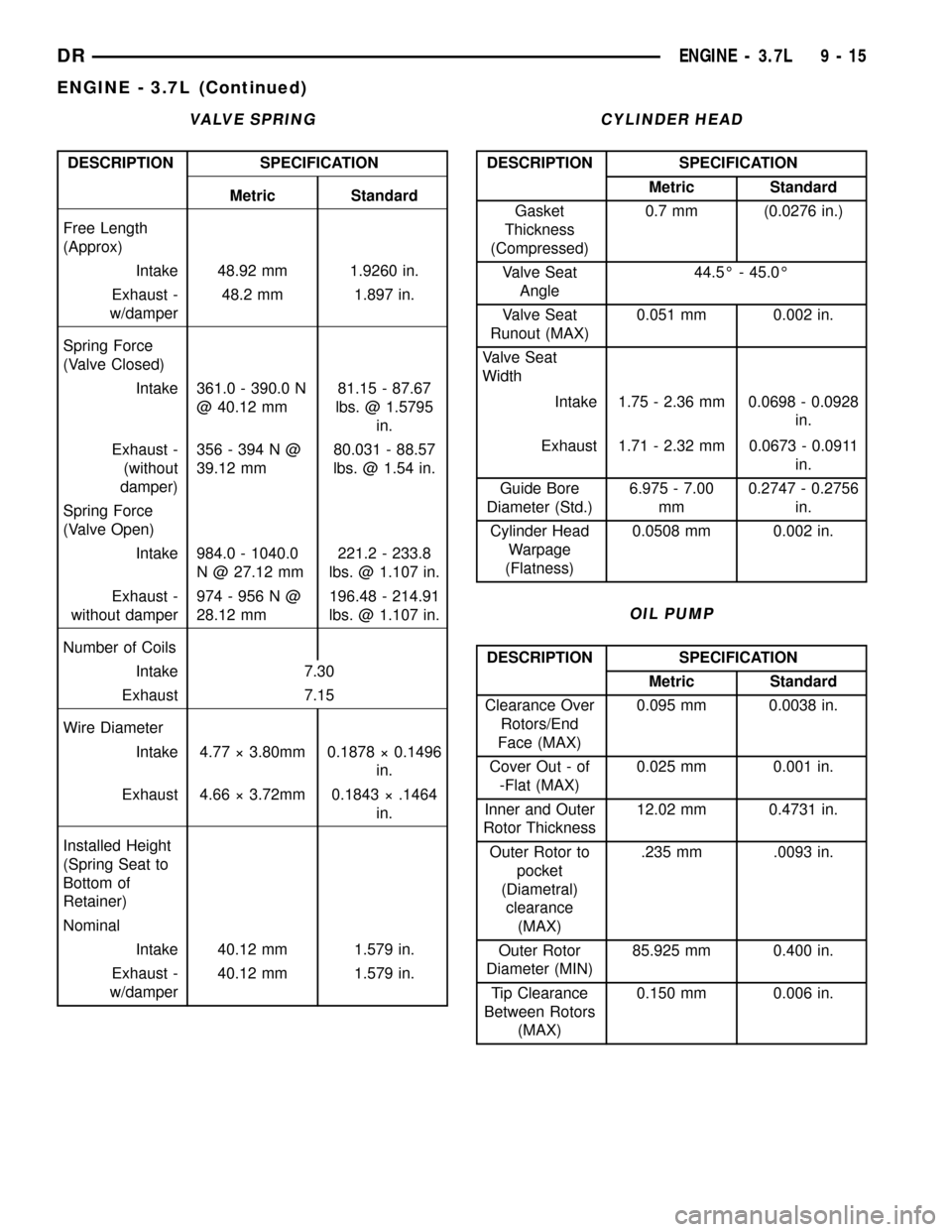

VALVE SPRING

DESCRIPTION SPECIFICATION

Metric Standard

Free Length

(Approx)

Intake 48.92 mm 1.9260 in.

Exhaust -

w/damper48.2 mm 1.897 in.

Spring Force

(Valve Closed)

Intake 361.0 - 390.0 N

@ 40.12 mm81.15 - 87.67

lbs. @ 1.5795

in.

Exhaust -

(without

damper)356-394N@

39.12 mm80.031 - 88.57

lbs. @ 1.54 in.

Spring Force

(Valve Open)

Intake 984.0 - 1040.0

N @ 27.12 mm221.2 - 233.8

lbs. @ 1.107 in.

Exhaust -

without damper974-956N@

28.12 mm196.48 - 214.91

lbs. @ 1.107 in.

Number of Coils

Intake 7.30

Exhaust 7.15

Wire Diameter

Intake 4.77 ý 3.80mm 0.1878 ý 0.1496

in.

Exhaust 4.66 ý 3.72mm 0.1843 ý .1464

in.

Installed Height

(Spring Seat to

Bottom of

Retainer)

Nominal

Intake 40.12 mm 1.579 in.

Exhaust -

w/damper40.12 mm 1.579 in.

CYLINDER HEAD

DESCRIPTION SPECIFICATION

Metric Standard

Gasket

Thickness

(Compressed)0.7 mm (0.0276 in.)

Valve Seat

Angle44.5É - 45.0É

Valve Seat

Runout (MAX)0.051 mm 0.002 in.

Valve Seat

Width

Intake 1.75 - 2.36 mm 0.0698 - 0.0928

in.

Exhaust 1.71 - 2.32 mm 0.0673 - 0.0911

in.

Guide Bore

Diameter (Std.)6.975 - 7.00

mm0.2747 - 0.2756

in.

Cylinder Head

Warpage

(Flatness)0.0508 mm 0.002 in.

OIL PUMP

DESCRIPTION SPECIFICATION

Metric Standard

Clearance Over

Rotors/End

Face (MAX)0.095 mm 0.0038 in.

Cover Out - of

-Flat (MAX)0.025 mm 0.001 in.

Inner and Outer

Rotor Thickness12.02 mm 0.4731 in.

Outer Rotor to

pocket

(Diametral)

clearance

(MAX).235 mm .0093 in.

Outer Rotor

Diameter (MIN)85.925 mm 0.400 in.

Tip Clearance

Between Rotors

(MAX)0.150 mm 0.006 in.

DRENGINE - 3.7L 9 - 15

ENGINE - 3.7L (Continued)

Page 1251 of 2627

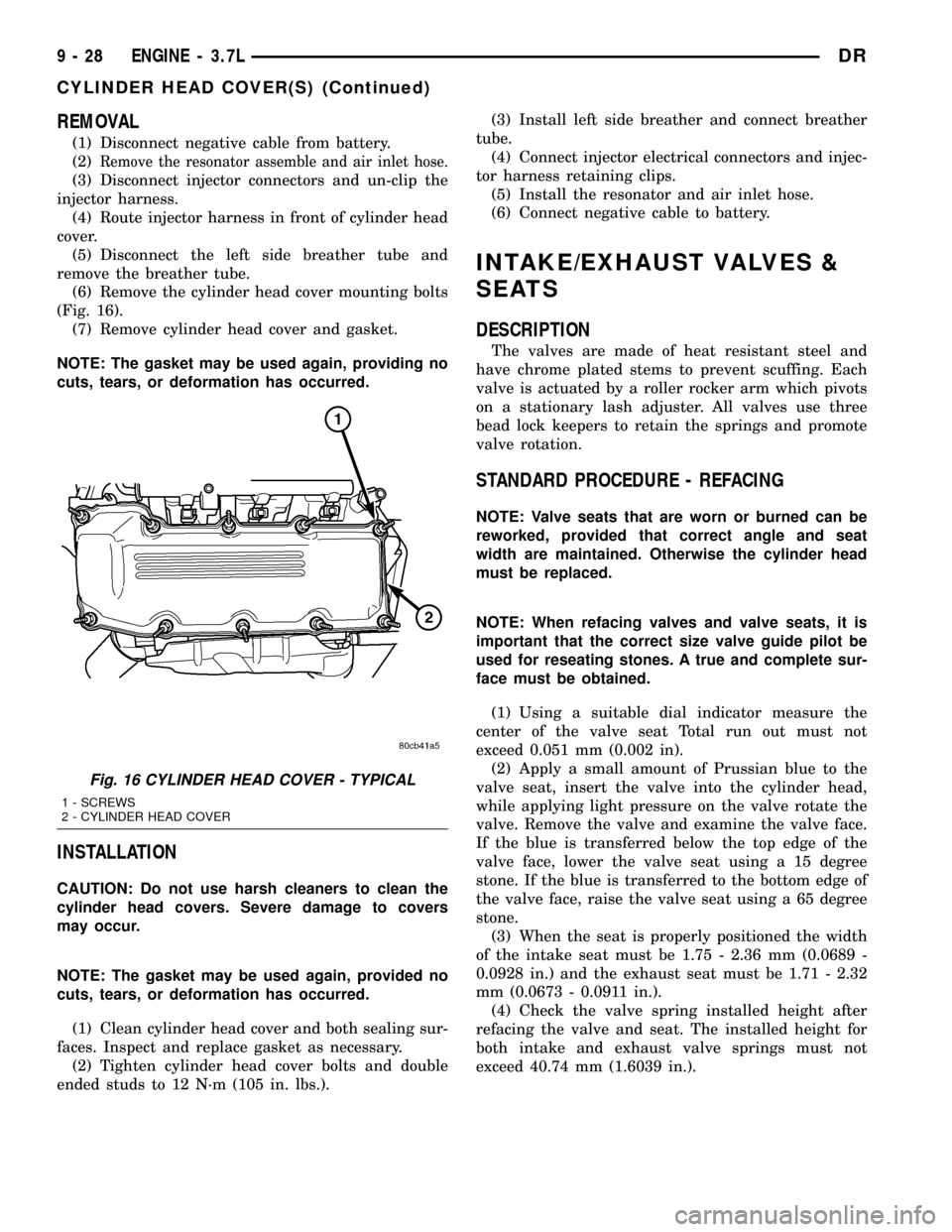

REMOVAL

(1) Disconnect negative cable from battery.

(2)

Remove the resonator assemble and air inlet hose.

(3) Disconnect injector connectors and un-clip the

injector harness.

(4) Route injector harness in front of cylinder head

cover.

(5) Disconnect the left side breather tube and

remove the breather tube.

(6) Remove the cylinder head cover mounting bolts

(Fig. 16).

(7) Remove cylinder head cover and gasket.

NOTE: The gasket may be used again, providing no

cuts, tears, or deformation has occurred.

INSTALLATION

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2) Tighten cylinder head cover bolts and double

ended studs to 12 N´m (105 in. lbs.).(3) Install left side breather and connect breather

tube.

(4) Connect injector electrical connectors and injec-

tor harness retaining clips.

(5) Install the resonator and air inlet hose.

(6) Connect negative cable to battery.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves are made of heat resistant steel and

have chrome plated stems to prevent scuffing. Each

valve is actuated by a roller rocker arm which pivots

on a stationary lash adjuster. All valves use three

bead lock keepers to retain the springs and promote

valve rotation.

STANDARD PROCEDURE - REFACING

NOTE: Valve seats that are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise the cylinder head

must be replaced.

NOTE: When refacing valves and valve seats, it is

important that the correct size valve guide pilot be

used for reseating stones. A true and complete sur-

face must be obtained.

(1) Using a suitable dial indicator measure the

center of the valve seat Total run out must not

exceed 0.051 mm (0.002 in).

(2) Apply a small amount of Prussian blue to the

valve seat, insert the valve into the cylinder head,

while applying light pressure on the valve rotate the

valve. Remove the valve and examine the valve face.

If the blue is transferred below the top edge of the

valve face, lower the valve seat using a 15 degree

stone. If the blue is transferred to the bottom edge of

the valve face, raise the valve seat using a 65 degree

stone.

(3) When the seat is properly positioned the width

of the intake seat must be 1.75 - 2.36 mm (0.0689 -

0.0928 in.) and the exhaust seat must be 1.71 - 2.32

mm (0.0673 - 0.0911 in.).

(4) Check the valve spring installed height after

refacing the valve and seat. The installed height for

both intake and exhaust valve springs must not

exceed 40.74 mm (1.6039 in.).

Fig. 16 CYLINDER HEAD COVER - TYPICAL

1 - SCREWS

2 - CYLINDER HEAD COVER

9 - 28 ENGINE - 3.7LDR

CYLINDER HEAD COVER(S) (Continued)

Page 1253 of 2627

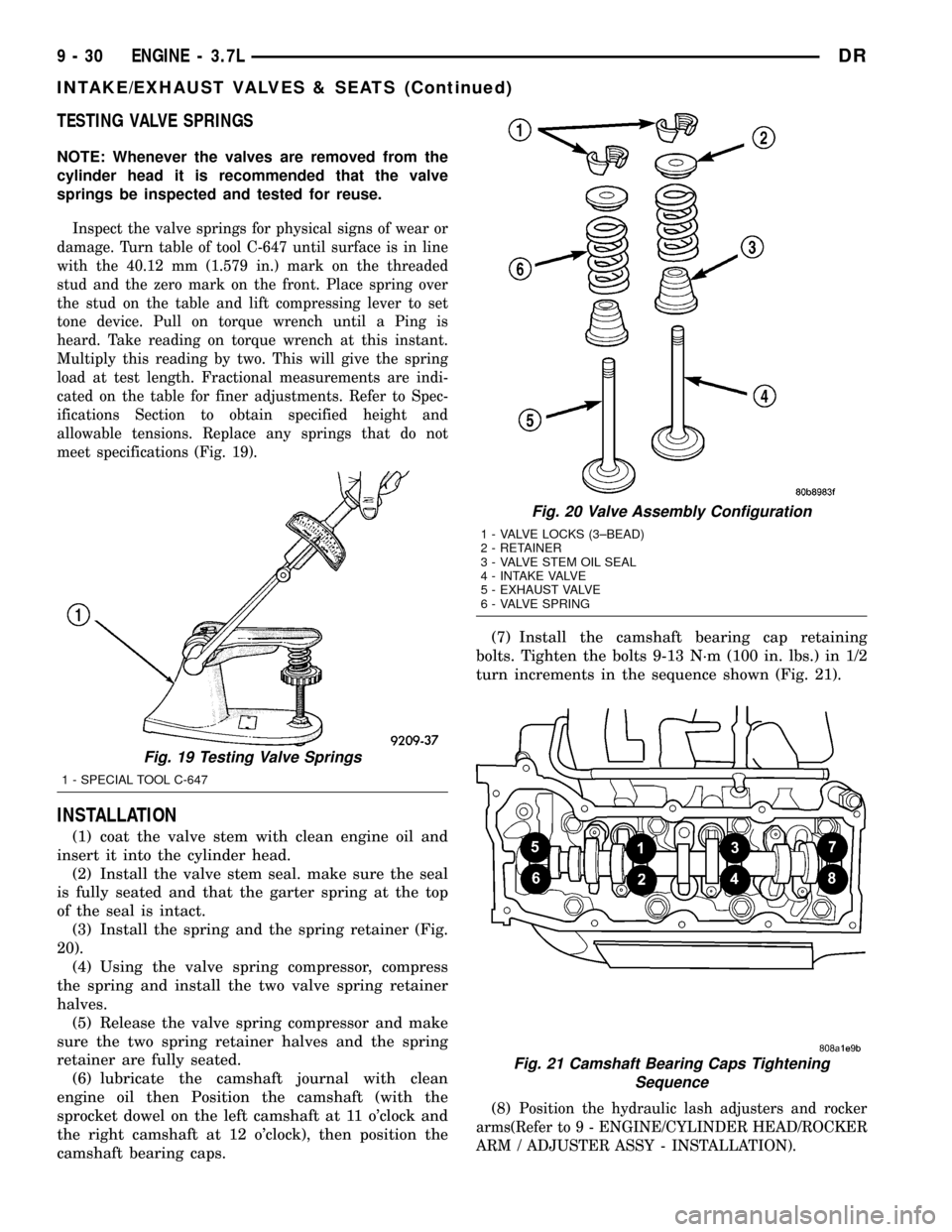

TESTING VALVE SPRINGS

NOTE: Whenever the valves are removed from the

cylinder head it is recommended that the valve

springs be inspected and tested for reuse.

Inspect the valve springs for physical signs of wear or

damage. Turn table of tool C-647 until surface is in line

with the 40.12 mm (1.579 in.) mark on the threaded

stud and the zero mark on the front. Place spring over

the stud on the table and lift compressing lever to set

tone device. Pull on torque wrench until a Ping is

heard. Take reading on torque wrench at this instant.

Multiply this reading by two. This will give the spring

load at test length. Fractional measurements are indi-

cated on the table for finer adjustments. Refer to Spec-

ifications Section to obtain specified height and

allowable tensions. Replace any springs that do not

meet specifications (Fig. 19).

INSTALLATION

(1) coat the valve stem with clean engine oil and

insert it into the cylinder head.

(2) Install the valve stem seal. make sure the seal

is fully seated and that the garter spring at the top

of the seal is intact.

(3) Install the spring and the spring retainer (Fig.

20).

(4) Using the valve spring compressor, compress

the spring and install the two valve spring retainer

halves.

(5) Release the valve spring compressor and make

sure the two spring retainer halves and the spring

retainer are fully seated.

(6) lubricate the camshaft journal with clean

engine oil then Position the camshaft (with the

sprocket dowel on the left camshaft at 11 o'clock and

the right camshaft at 12 o'clock), then position the

camshaft bearing caps.(7) Install the camshaft bearing cap retaining

bolts. Tighten the bolts 9-13 N´m (100 in. lbs.) in 1/2

turn increments in the sequence shown (Fig. 21).

(8)

Position the hydraulic lash adjusters and rocker

arms(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - INSTALLATION).

Fig. 19 Testing Valve Springs

1 - SPECIAL TOOL C-647

Fig. 20 Valve Assembly Configuration

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

Fig. 21 Camshaft Bearing Caps Tightening

Sequence

9 - 30 ENGINE - 3.7LDR

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1324 of 2627

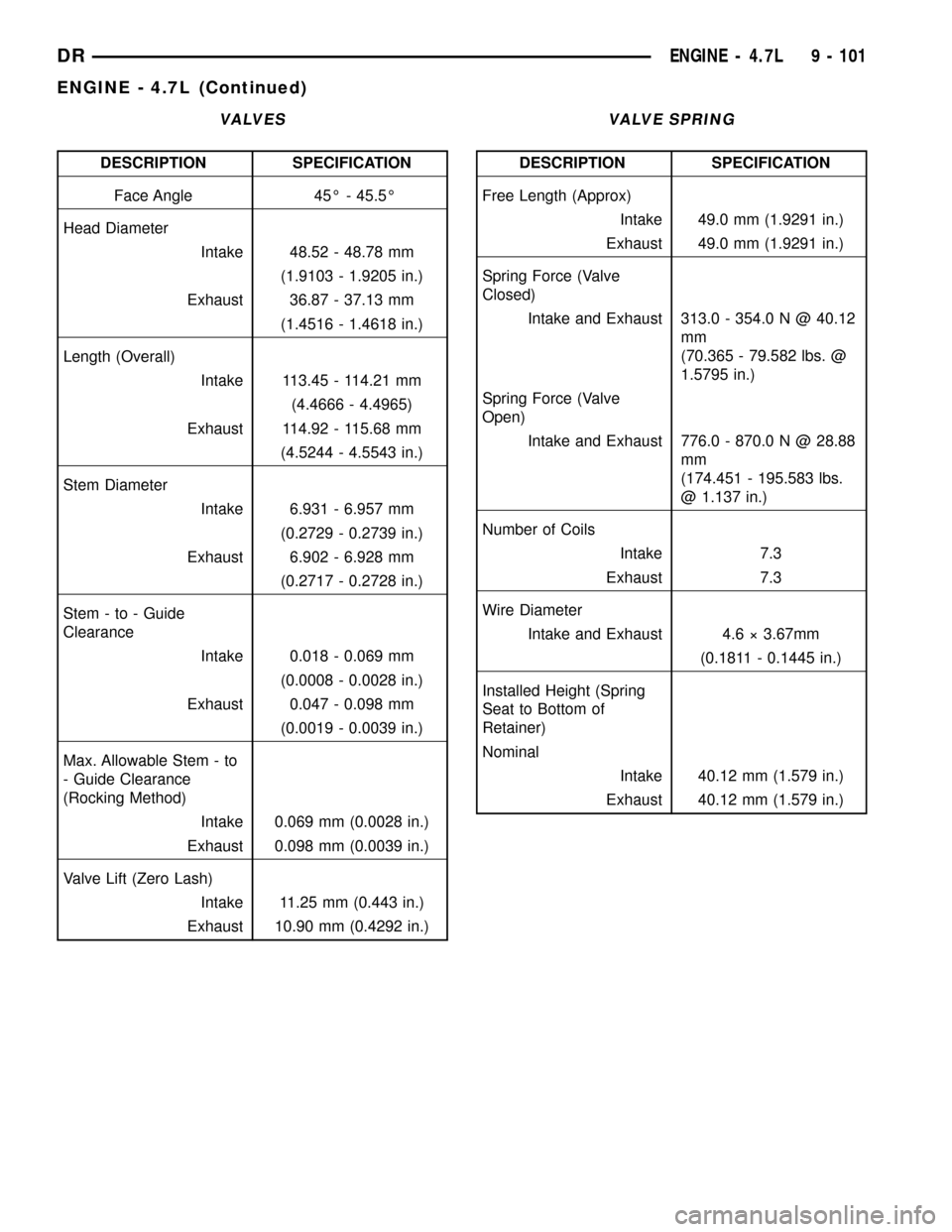

VALVES

DESCRIPTION SPECIFICATION

Face Angle 45É - 45.5É

Head Diameter

Intake 48.52 - 48.78 mm

(1.9103 - 1.9205 in.)

Exhaust 36.87 - 37.13 mm

(1.4516 - 1.4618 in.)

Length (Overall)

Intake 113.45 - 114.21 mm

(4.4666 - 4.4965)

Exhaust 114.92 - 115.68 mm

(4.5244 - 4.5543 in.)

Stem Diameter

Intake 6.931 - 6.957 mm

(0.2729 - 0.2739 in.)

Exhaust 6.902 - 6.928 mm

(0.2717 - 0.2728 in.)

Stem - to - Guide

Clearance

Intake 0.018 - 0.069 mm

(0.0008 - 0.0028 in.)

Exhaust 0.047 - 0.098 mm

(0.0019 - 0.0039 in.)

Max. Allowable Stem - to

- Guide Clearance

(Rocking Method)

Intake 0.069 mm (0.0028 in.)

Exhaust 0.098 mm (0.0039 in.)

Valve Lift (Zero Lash)

Intake 11.25 mm (0.443 in.)

Exhaust 10.90 mm (0.4292 in.)

VALVE SPRING

DESCRIPTION SPECIFICATION

Free Length (Approx)

Intake 49.0 mm (1.9291 in.)

Exhaust 49.0 mm (1.9291 in.)

Spring Force (Valve

Closed)

Intake and Exhaust 313.0 - 354.0 N @ 40.12

mm

(70.365 - 79.582 lbs. @

1.5795 in.)

Spring Force (Valve

Open)

Intake and Exhaust 776.0 - 870.0 N @ 28.88

mm

(174.451 - 195.583 lbs.

@ 1.137 in.)

Number of Coils

Intake 7.3

Exhaust 7.3

Wire Diameter

Intake and Exhaust 4.6 ý 3.67mm

(0.1811 - 0.1445 in.)

Installed Height (Spring

Seat to Bottom of

Retainer)

Nominal

Intake 40.12 mm (1.579 in.)

Exhaust 40.12 mm (1.579 in.)

DRENGINE - 4.7L 9 - 101

ENGINE - 4.7L (Continued)

Page 1347 of 2627

REMOVAL

NOTE: The cylinder heads must be removed in

order to perform this procedure.

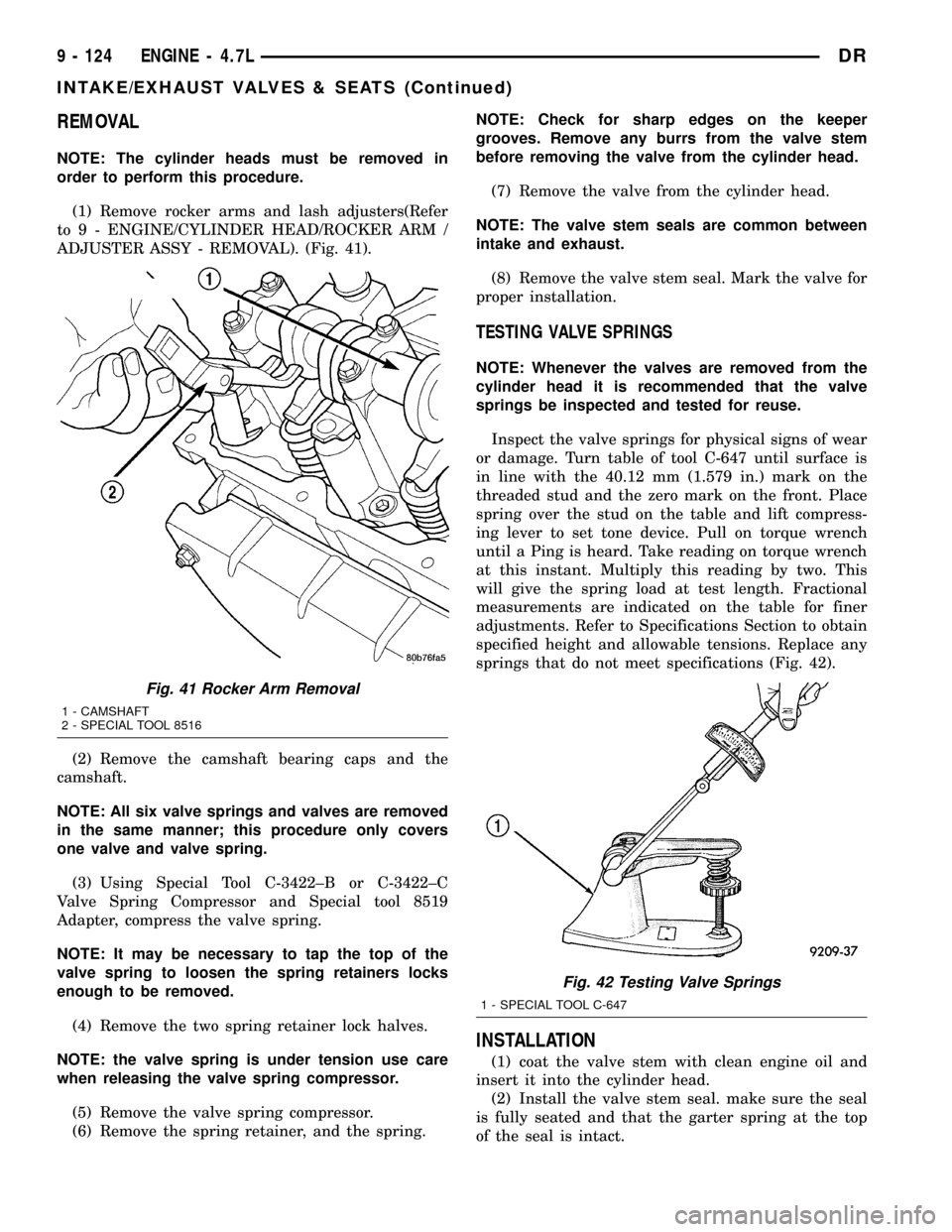

(1) Remove rocker arms and lash adjusters(Refer

to 9 - ENGINE/CYLINDER HEAD/ROCKER ARM /

ADJUSTER ASSY - REMOVAL). (Fig. 41).

(2) Remove the camshaft bearing caps and the

camshaft.

NOTE: All six valve springs and valves are removed

in the same manner; this procedure only covers

one valve and valve spring.

(3) Using Special Tool C-3422±B or C-3422±C

Valve Spring Compressor and Special tool 8519

Adapter, compress the valve spring.

NOTE: It may be necessary to tap the top of the

valve spring to loosen the spring retainers locks

enough to be removed.

(4) Remove the two spring retainer lock halves.

NOTE: the valve spring is under tension use care

when releasing the valve spring compressor.

(5) Remove the valve spring compressor.

(6) Remove the spring retainer, and the spring.NOTE: Check for sharp edges on the keeper

grooves. Remove any burrs from the valve stem

before removing the valve from the cylinder head.

(7) Remove the valve from the cylinder head.

NOTE: The valve stem seals are common between

intake and exhaust.

(8) Remove the valve stem seal. Mark the valve for

proper installation.

TESTING VALVE SPRINGS

NOTE: Whenever the valves are removed from the

cylinder head it is recommended that the valve

springs be inspected and tested for reuse.

Inspect the valve springs for physical signs of wear

or damage. Turn table of tool C-647 until surface is

in line with the 40.12 mm (1.579 in.) mark on the

threaded stud and the zero mark on the front. Place

spring over the stud on the table and lift compress-

ing lever to set tone device. Pull on torque wrench

until a Ping is heard. Take reading on torque wrench

at this instant. Multiply this reading by two. This

will give the spring load at test length. Fractional

measurements are indicated on the table for finer

adjustments. Refer to Specifications Section to obtain

specified height and allowable tensions. Replace any

springs that do not meet specifications (Fig. 42).

INSTALLATION

(1) coat the valve stem with clean engine oil and

insert it into the cylinder head.

(2) Install the valve stem seal. make sure the seal

is fully seated and that the garter spring at the top

of the seal is intact.

Fig. 41 Rocker Arm Removal

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

Fig. 42 Testing Valve Springs

1 - SPECIAL TOOL C-647

9 - 124 ENGINE - 4.7LDR

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1418 of 2627

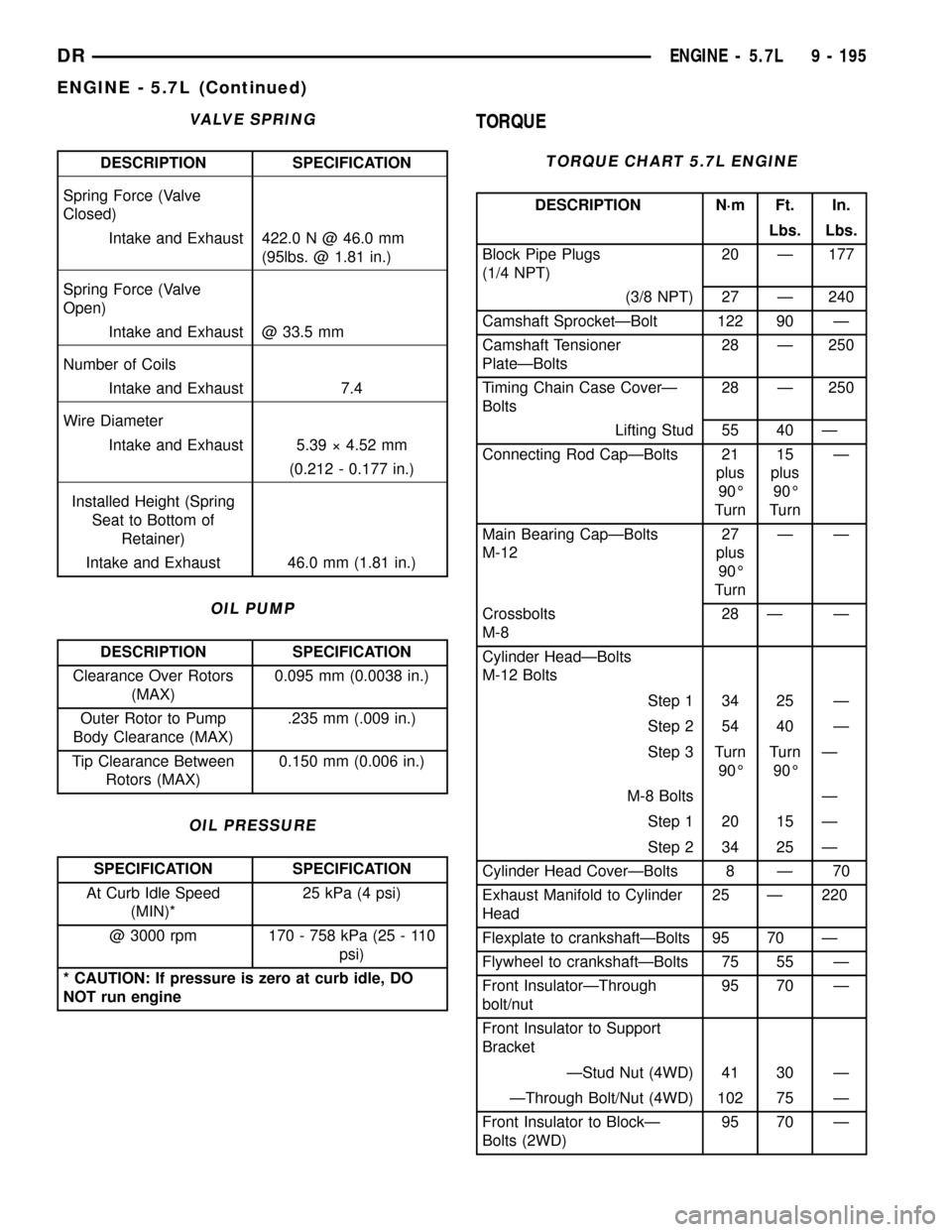

VALVE SPRING

DESCRIPTION SPECIFICATION

Spring Force (Valve

Closed)

Intake and Exhaust 422.0 N @ 46.0 mm

(95lbs. @ 1.81 in.)

Spring Force (Valve

Open)

Intake and Exhaust @ 33.5 mm

Number of Coils

Intake and Exhaust 7.4

Wire Diameter

Intake and Exhaust 5.39 ý 4.52 mm

(0.212 - 0.177 in.)

Installed Height (Spring

Seat to Bottom of

Retainer)

Intake and Exhaust 46.0 mm (1.81 in.)

OIL PUMP

DESCRIPTION SPECIFICATION

Clearance Over Rotors

(MAX)0.095 mm (0.0038 in.)

Outer Rotor to Pump

Body Clearance (MAX).235 mm (.009 in.)

Tip Clearance Between

Rotors (MAX)0.150 mm (0.006 in.)

OIL PRESSURE

SPECIFICATION SPECIFICATION

At Curb Idle Speed

(MIN)*25 kPa (4 psi)

@ 3000 rpm 170 - 758 kPa (25 - 110

psi)

* CAUTION: If pressure is zero at curb idle, DO

NOT run engine

TORQUE

TORQUE CHART 5.7L ENGINE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Block Pipe Plugs

(1/4 NPT)20 Ð 177

(3/8 NPT) 27 Ð 240

Camshaft SprocketÐBolt 122 90 Ð

Camshaft Tensioner

PlateÐBolts28 Ð 250

Timing Chain Case CoverÐ

Bolts28 Ð 250

Lifting Stud 55 40 Ð

Connecting Rod CapÐBolts 21

plus

90É

Turn15

plus

90É

TurnÐ

Main Bearing CapÐBolts

M-1227

plus

90É

TurnÐÐ

Crossbolts

M-828 Ð Ð

Cylinder HeadÐBolts

M-12 Bolts

Step 1 34 25 Ð

Step 2 54 40 Ð

Step 3 Turn

90ÉTurn

90ÉÐ

M-8 Bolts Ð

Step 1 20 15 Ð

Step 2 34 25 Ð

Cylinder Head CoverÐBolts 8 Ð 70

Exhaust Manifold to Cylinder

Head25 Ð 220

Flexplate to crankshaftÐBolts 95 70 Ð

Flywheel to crankshaftÐBolts 75 55 Ð

Front InsulatorÐThrough

bolt/nut95 70 Ð

Front Insulator to Support

Bracket

ÐStud Nut (4WD) 41 30 Ð

ÐThrough Bolt/Nut (4WD) 102 75 Ð

Front Insulator to BlockÐ

Bolts (2WD)95 70 Ð

DRENGINE - 5.7L 9 - 195

ENGINE - 5.7L (Continued)