radio DODGE RAM 1500 1998 2.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1095 of 2627

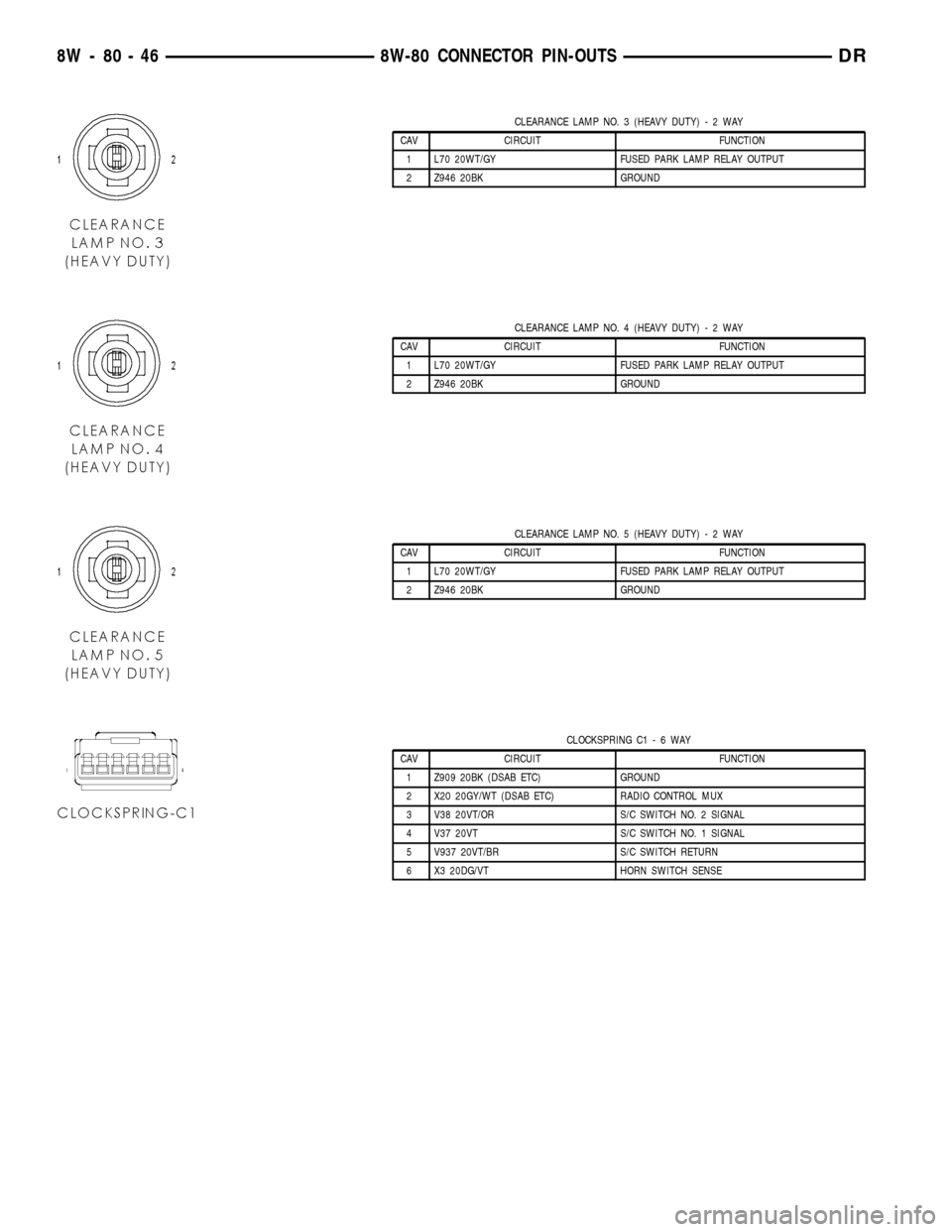

CLEARANCE LAMP NO. 3 (HEAVY DUTY)-2WAY

CAV CIRCUIT FUNCTION

1 L70 20WT/GY FUSED PARK LAMP RELAY OUTPUT

2 Z946 20BK GROUND

CLEARANCE LAMP NO. 4 (HEAVY DUTY)-2WAY

CAV CIRCUIT FUNCTION

1 L70 20WT/GY FUSED PARK LAMP RELAY OUTPUT

2 Z946 20BK GROUND

CLEARANCE LAMP NO. 5 (HEAVY DUTY)-2WAY

CAV CIRCUIT FUNCTION

1 L70 20WT/GY FUSED PARK LAMP RELAY OUTPUT

2 Z946 20BK GROUND

CLOCKSPRING C1-6WAY

CAV CIRCUIT FUNCTION

1 Z909 20BK (DSAB ETC) GROUND

2 X20 20GY/WT (DSAB ETC) RADIO CONTROL MUX

3 V38 20VT/OR S/C SWITCH NO. 2 SIGNAL

4 V37 20VT S/C SWITCH NO. 1 SIGNAL

5 V937 20VT/BR S/C SWITCH RETURN

6 X3 20DG/VT HORN SWITCH SENSE

8W - 80 - 46 8W-80 CONNECTOR PIN-OUTSDR

Page 1096 of 2627

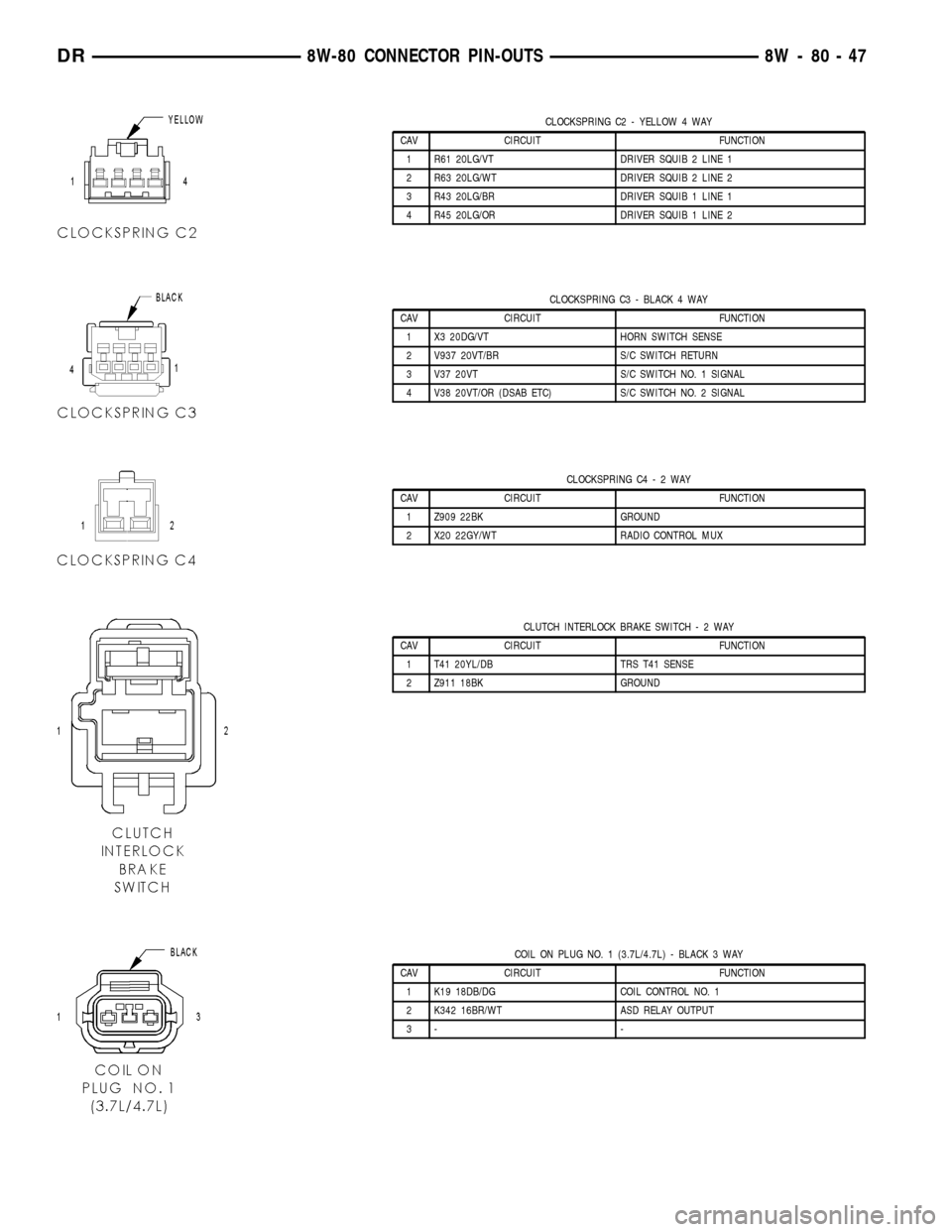

CLOCKSPRING C2 - YELLOW 4 WAY

CAV CIRCUIT FUNCTION

1 R61 20LG/VT DRIVER SQUIB 2 LINE 1

2 R63 20LG/WT DRIVER SQUIB 2 LINE 2

3 R43 20LG/BR DRIVER SQUIB 1 LINE 1

4 R45 20LG/OR DRIVER SQUIB 1 LINE 2

CLOCKSPRING C3 - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 X3 20DG/VT HORN SWITCH SENSE

2 V937 20VT/BR S/C SWITCH RETURN

3 V37 20VT S/C SWITCH NO. 1 SIGNAL

4 V38 20VT/OR (DSAB ETC) S/C SWITCH NO. 2 SIGNAL

CLOCKSPRING C4-2WAY

CAV CIRCUIT FUNCTION

1 Z909 22BK GROUND

2 X20 22GY/WT RADIO CONTROL MUX

CLUTCH INTERLOCK BRAKE SWITCH-2WAY

CAV CIRCUIT FUNCTION

1 T41 20YL/DB TRS T41 SENSE

2 Z911 18BK GROUND

COIL ON PLUG NO. 1 (3.7L/4.7L) - BLACK 3 WAY

CAV CIRCUIT FUNCTION

1 K19 18DB/DG COIL CONTROL NO. 1

2 K342 16BR/WT ASD RELAY OUTPUT

3- -

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 47

Page 1121 of 2627

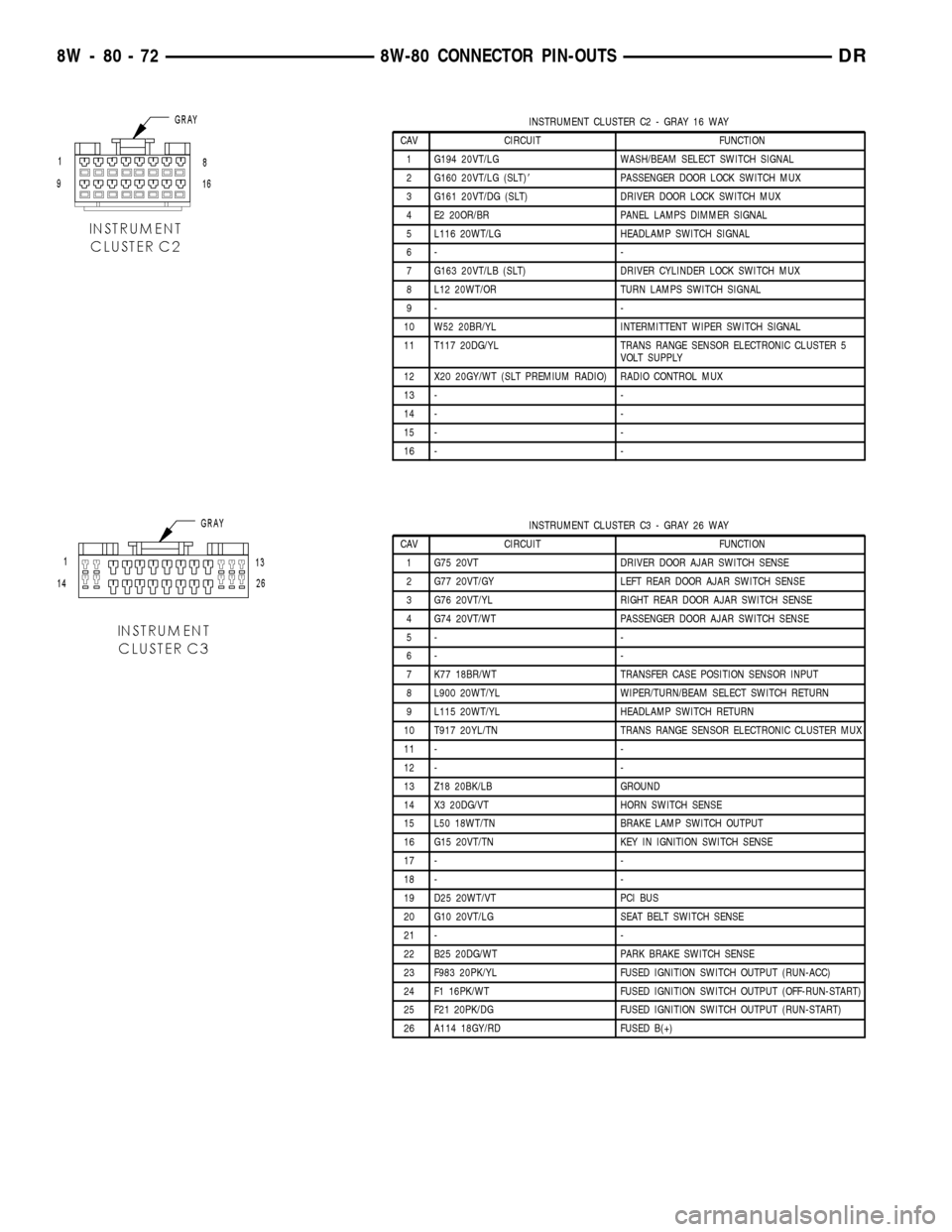

INSTRUMENT CLUSTER C2 - GRAY 16 WAY

CAV CIRCUIT FUNCTION

1 G194 20VT/LG WASH/BEAM SELECT SWITCH SIGNAL

2 G160 20VT/LG (SLT)8PASSENGER DOOR LOCK SWITCH MUX

3 G161 20VT/DG (SLT) DRIVER DOOR LOCK SWITCH MUX

4 E2 20OR/BR PANEL LAMPS DIMMER SIGNAL

5 L116 20WT/LG HEADLAMP SWITCH SIGNAL

6- -

7 G163 20VT/LB (SLT) DRIVER CYLINDER LOCK SWITCH MUX

8 L12 20WT/OR TURN LAMPS SWITCH SIGNAL

9- -

10 W52 20BR/YL INTERMITTENT WIPER SWITCH SIGNAL

11 T117 20DG/YL TRANS RANGE SENSOR ELECTRONIC CLUSTER 5

VOLT SUPPLY

12 X20 20GY/WT (SLT PREMIUM RADIO) RADIO CONTROL MUX

13 - -

14 - -

15 - -

16 - -

INSTRUMENT CLUSTER C3 - GRAY 26 WAY

CAV CIRCUIT FUNCTION

1 G75 20VT DRIVER DOOR AJAR SWITCH SENSE

2 G77 20VT/GY LEFT REAR DOOR AJAR SWITCH SENSE

3 G76 20VT/YL RIGHT REAR DOOR AJAR SWITCH SENSE

4 G74 20VT/WT PASSENGER DOOR AJAR SWITCH SENSE

5- -

6- -

7 K77 18BR/WT TRANSFER CASE POSITION SENSOR INPUT

8 L900 20WT/YL WIPER/TURN/BEAM SELECT SWITCH RETURN

9 L115 20WT/YL HEADLAMP SWITCH RETURN

10 T917 20YL/TN TRANS RANGE SENSOR ELECTRONIC CLUSTER MUX

11 - -

12 - -

13 Z18 20BK/LB GROUND

14 X3 20DG/VT HORN SWITCH SENSE

15 L50 18WT/TN BRAKE LAMP SWITCH OUTPUT

16 G15 20VT/TN KEY IN IGNITION SWITCH SENSE

17 - -

18 - -

19 D25 20WT/VT PCI BUS

20 G10 20VT/LG SEAT BELT SWITCH SENSE

21 - -

22 B25 20DG/WT PARK BRAKE SWITCH SENSE

23 F983 20PK/YL FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

24 F1 16PK/WT FUSED IGNITION SWITCH OUTPUT (OFF-RUN-START)

25 F21 20PK/DG FUSED IGNITION SWITCH OUTPUT (RUN-START)

26 A114 18GY/RD FUSED B(+)

8W - 80 - 72 8W-80 CONNECTOR PIN-OUTSDR

Page 1141 of 2627

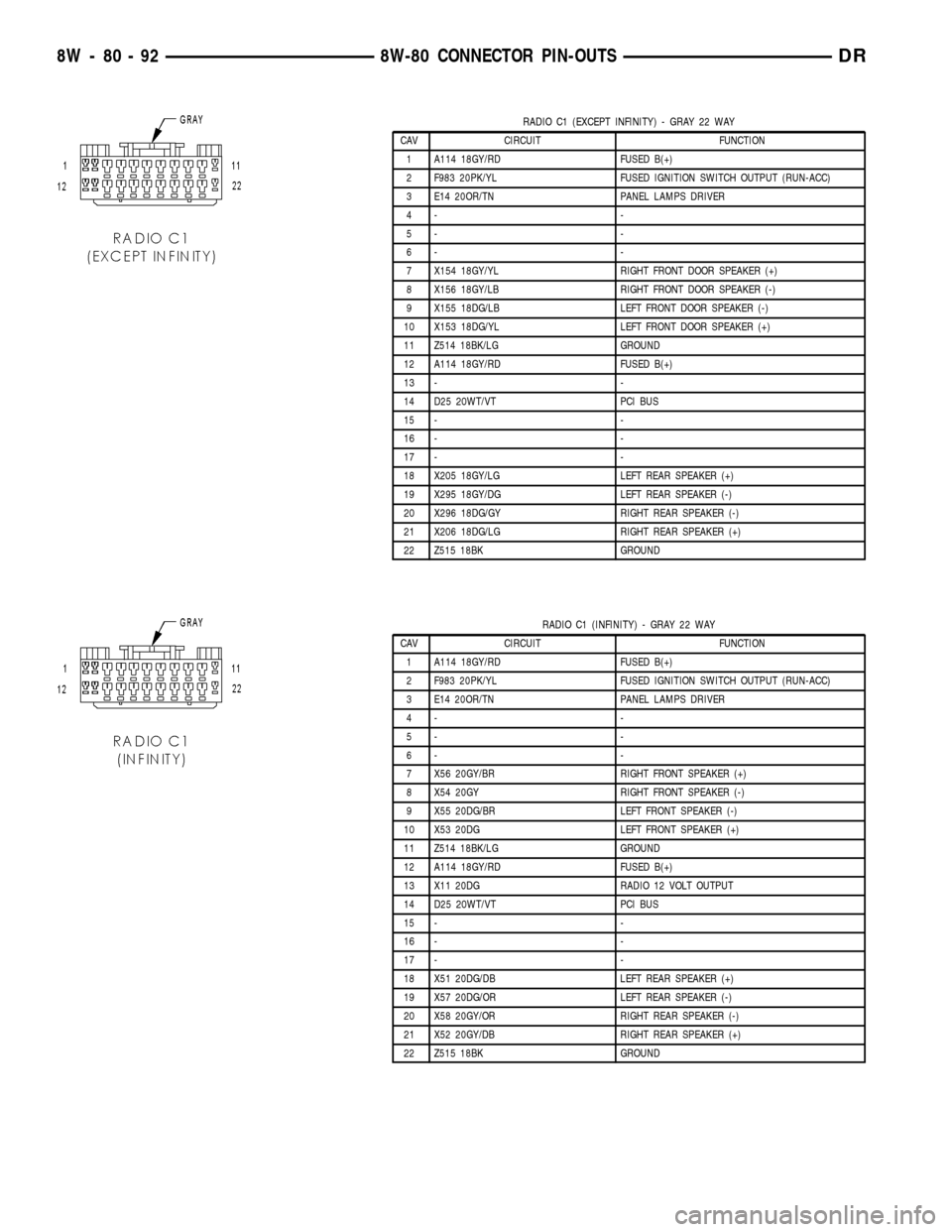

RADIO C1 (EXCEPT INFINITY) - GRAY 22 WAY

CAV CIRCUIT FUNCTION

1 A114 18GY/RD FUSED B(+)

2 F983 20PK/YL FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

3 E14 20OR/TN PANEL LAMPS DRIVER

4- -

5- -

6- -

7 X154 18GY/YL RIGHT FRONT DOOR SPEAKER (+)

8 X156 18GY/LB RIGHT FRONT DOOR SPEAKER (-)

9 X155 18DG/LB LEFT FRONT DOOR SPEAKER (-)

10 X153 18DG/YL LEFT FRONT DOOR SPEAKER (+)

11 Z514 18BK/LG GROUND

12 A114 18GY/RD FUSED B(+)

13 - -

14 D25 20WT/VT PCI BUS

15 - -

16 - -

17 - -

18 X205 18GY/LG LEFT REAR SPEAKER (+)

19 X295 18GY/DG LEFT REAR SPEAKER (-)

20 X296 18DG/GY RIGHT REAR SPEAKER (-)

21 X206 18DG/LG RIGHT REAR SPEAKER (+)

22 Z515 18BK GROUND

RADIO C1 (INFINITY) - GRAY 22 WAY

CAV CIRCUIT FUNCTION

1 A114 18GY/RD FUSED B(+)

2 F983 20PK/YL FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

3 E14 20OR/TN PANEL LAMPS DRIVER

4- -

5- -

6- -

7 X56 20GY/BR RIGHT FRONT SPEAKER (+)

8 X54 20GY RIGHT FRONT SPEAKER (-)

9 X55 20DG/BR LEFT FRONT SPEAKER (-)

10 X53 20DG LEFT FRONT SPEAKER (+)

11 Z514 18BK/LG GROUND

12 A114 18GY/RD FUSED B(+)

13 X11 20DG RADIO 12 VOLT OUTPUT

14 D25 20WT/VT PCI BUS

15 - -

16 - -

17 - -

18 X51 20DG/DB LEFT REAR SPEAKER (+)

19 X57 20DG/OR LEFT REAR SPEAKER (-)

20 X58 20GY/OR RIGHT REAR SPEAKER (-)

21 X52 20GY/DB RIGHT REAR SPEAKER (+)

22 Z515 18BK GROUND

8W - 80 - 92 8W-80 CONNECTOR PIN-OUTSDR

Page 1142 of 2627

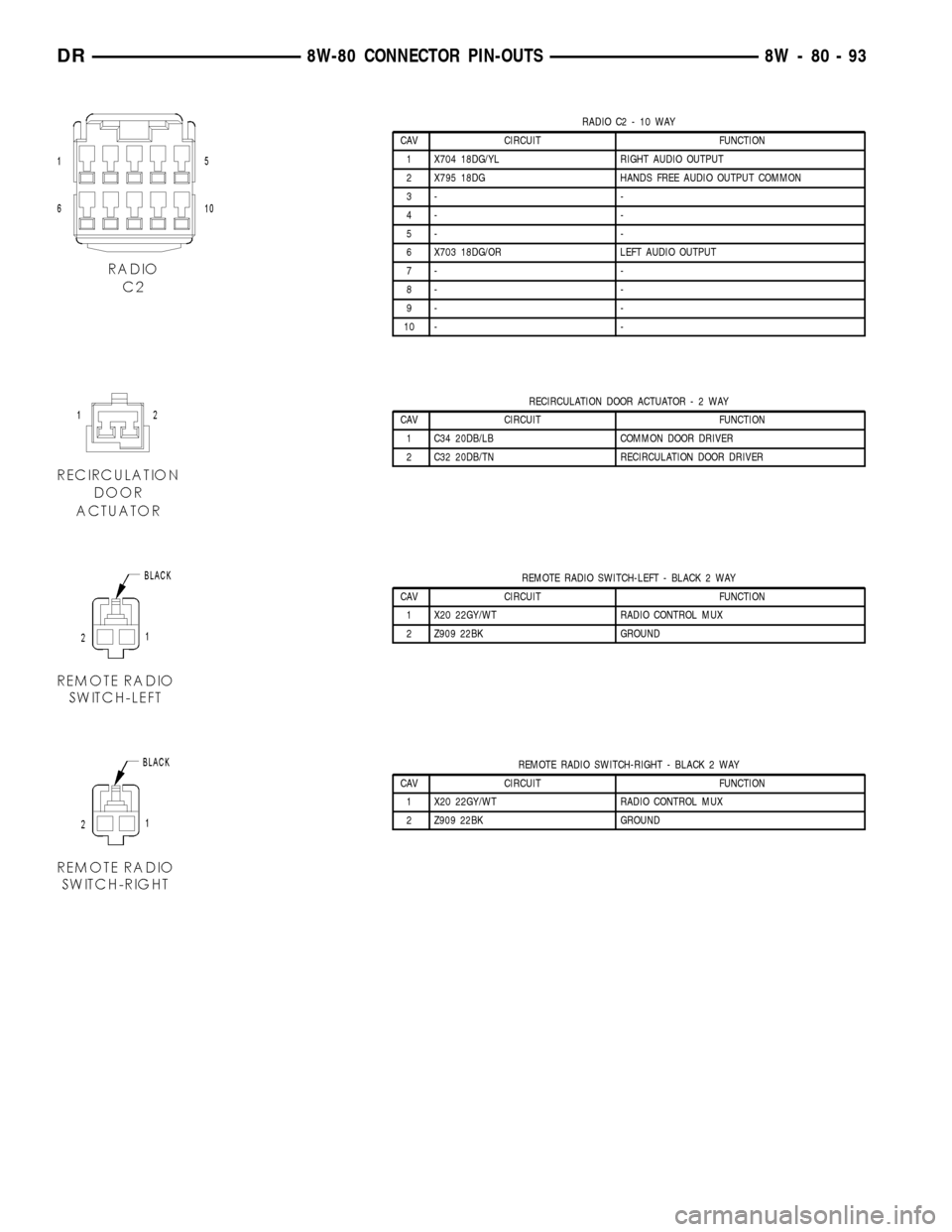

RADIO C2 - 10 WAY

CAV CIRCUIT FUNCTION

1 X704 18DG/YL RIGHT AUDIO OUTPUT

2 X795 18DG HANDS FREE AUDIO OUTPUT COMMON

3- -

4- -

5- -

6 X703 18DG/OR LEFT AUDIO OUTPUT

7- -

8- -

9- -

10 - -

RECIRCULATION DOOR ACTUATOR-2WAY

CAV CIRCUIT FUNCTION

1 C34 20DB/LB COMMON DOOR DRIVER

2 C32 20DB/TN RECIRCULATION DOOR DRIVER

REMOTE RADIO SWITCH-LEFT - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 X20 22GY/WT RADIO CONTROL MUX

2 Z909 22BK GROUND

REMOTE RADIO SWITCH-RIGHT - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 X20 22GY/WT RADIO CONTROL MUX

2 Z909 22BK GROUND

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 93

Page 1160 of 2627

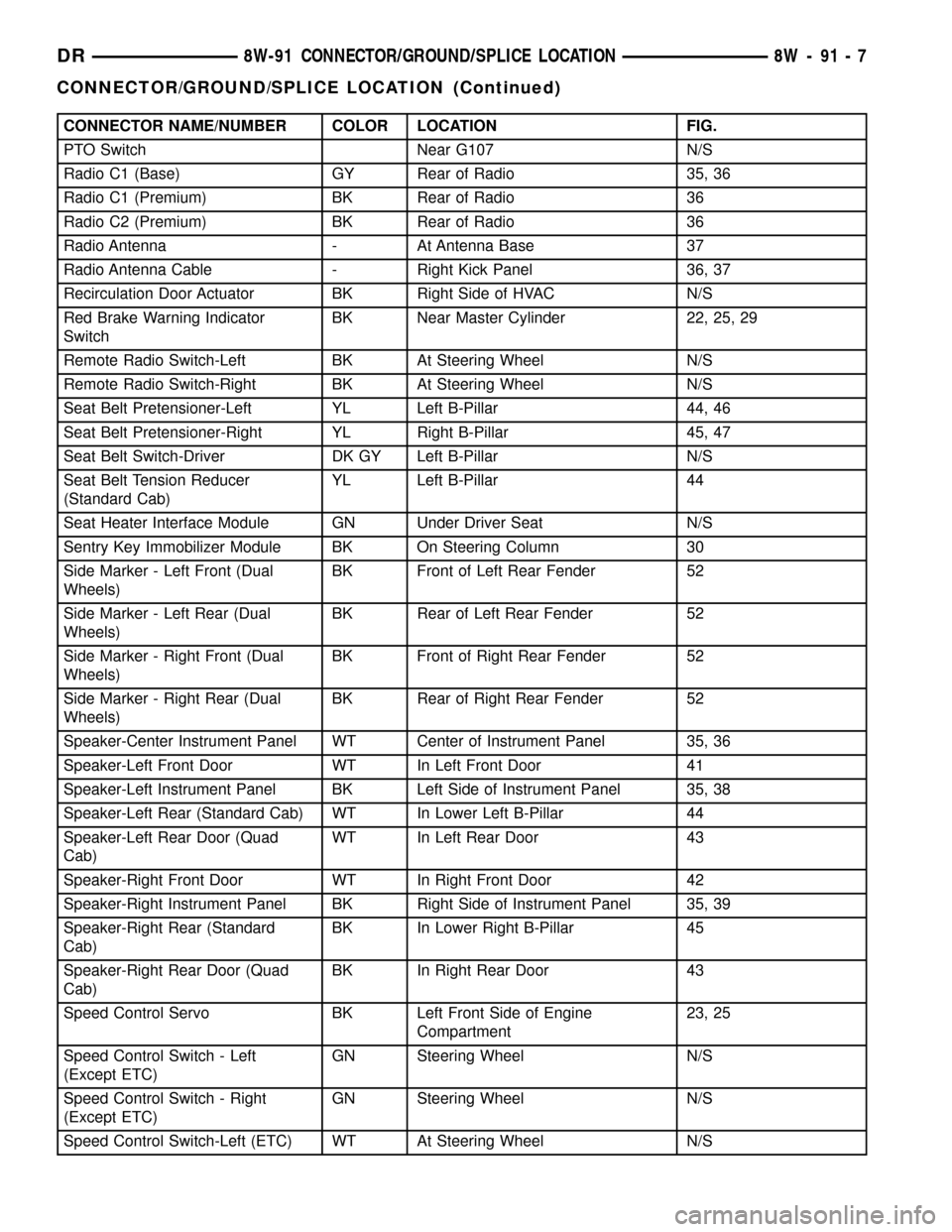

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

PTO Switch Near G107 N/S

Radio C1 (Base) GY Rear of Radio 35, 36

Radio C1 (Premium) BK Rear of Radio 36

Radio C2 (Premium) BK Rear of Radio 36

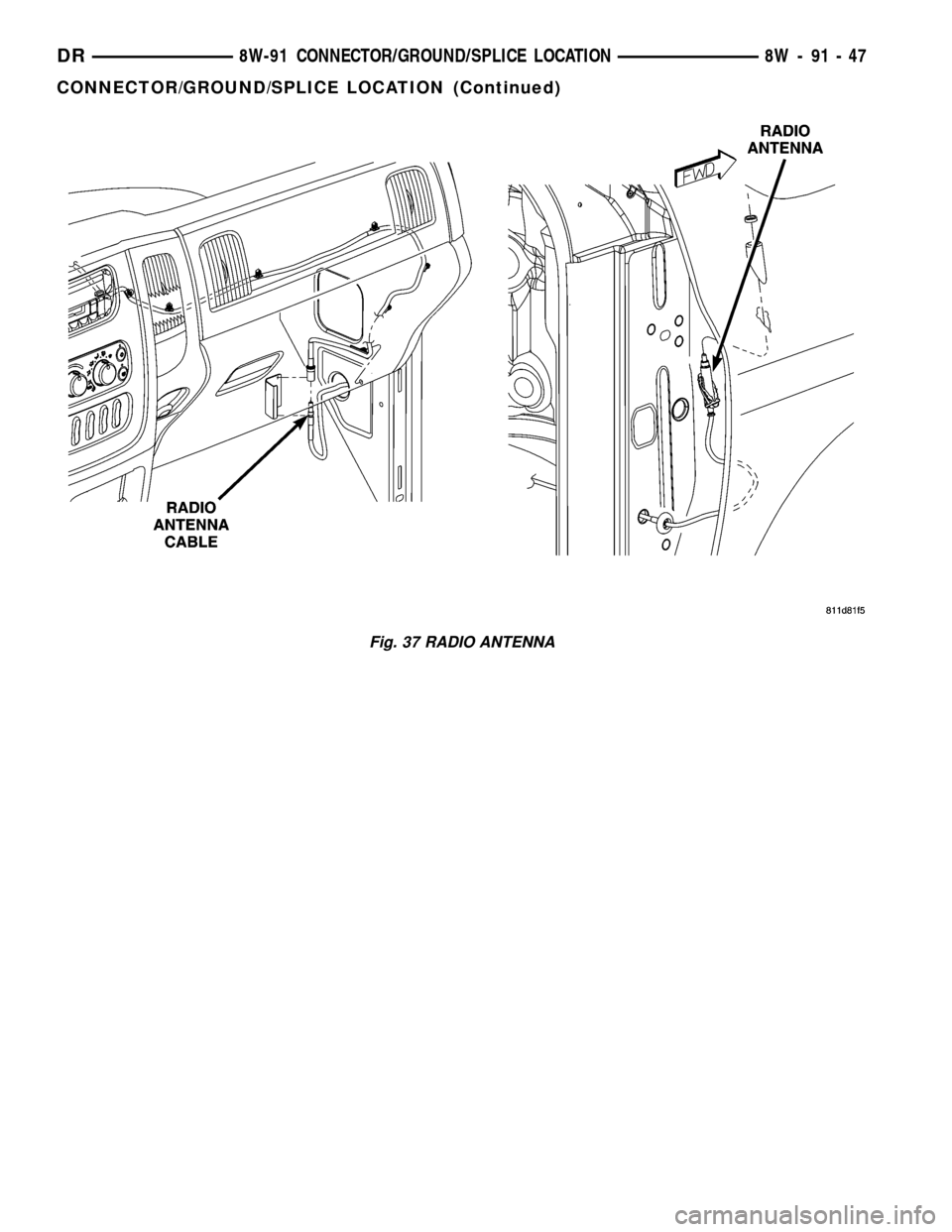

Radio Antenna - At Antenna Base 37

Radio Antenna Cable - Right Kick Panel 36, 37

Recirculation Door Actuator BK Right Side of HVAC N/S

Red Brake Warning Indicator

SwitchBK Near Master Cylinder 22, 25, 29

Remote Radio Switch-Left BK At Steering Wheel N/S

Remote Radio Switch-Right BK At Steering Wheel N/S

Seat Belt Pretensioner-Left YL Left B-Pillar 44, 46

Seat Belt Pretensioner-Right YL Right B-Pillar 45, 47

Seat Belt Switch-Driver DK GY Left B-Pillar N/S

Seat Belt Tension Reducer

(Standard Cab)YL Left B-Pillar 44

Seat Heater Interface Module GN Under Driver Seat N/S

Sentry Key Immobilizer Module BK On Steering Column 30

Side Marker - Left Front (Dual

Wheels)BK Front of Left Rear Fender 52

Side Marker - Left Rear (Dual

Wheels)BK Rear of Left Rear Fender 52

Side Marker - Right Front (Dual

Wheels)BK Front of Right Rear Fender 52

Side Marker - Right Rear (Dual

Wheels)BK Rear of Right Rear Fender 52

Speaker-Center Instrument Panel WT Center of Instrument Panel 35, 36

Speaker-Left Front Door WT In Left Front Door 41

Speaker-Left Instrument Panel BK Left Side of Instrument Panel 35, 38

Speaker-Left Rear (Standard Cab) WT In Lower Left B-Pillar 44

Speaker-Left Rear Door (Quad

Cab)WT In Left Rear Door 43

Speaker-Right Front Door WT In Right Front Door 42

Speaker-Right Instrument Panel BK Right Side of Instrument Panel 35, 39

Speaker-Right Rear (Standard

Cab)BK In Lower Right B-Pillar 45

Speaker-Right Rear Door (Quad

Cab)BK In Right Rear Door 43

Speed Control Servo BK Left Front Side of Engine

Compartment23, 25

Speed Control Switch - Left

(Except ETC)GN Steering Wheel N/S

Speed Control Switch - Right

(Except ETC)GN Steering Wheel N/S

Speed Control Switch-Left (ETC) WT At Steering Wheel N/S

DR8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1200 of 2627

Fig. 37 RADIO ANTENNA

DR8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 47

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1221 of 2627

requires the use of a DRB IIItscan tool and the

proper Body Diagnostic Procedures manual.

Before any testing of the front control module is

attempted, the battery should be fully charged and

all wire harness and ground connections inspected

around the affected areas on the vehicle.

REMOVAL

(1) Disconnect the positive and negative battery

cables from the battery.

(2) Partially remove the integrated power module

from the engine compartment (Refer to 8 - ELECTRI-

CAL/POWER DISTRIBUTION/INTEGRATED

POWER MODULE - REMOVAL).

(3) Remove the front control module retaining

screws.

(4) Using both hands, pull the front control module

straightfrom the integrated power module assembly

to disconnect the 49-way electrical connector and

remove the front control module from the vehicle.

INSTALLATION

(1) Install the front control module on the inte-

grated power module assembly by pushing the

49-way electrical connector straight in.

(2) Install the front control module retaining

screws. Torque the screws to 7 in. lbs.

(3) Install the integrated power module (Refer to 8

- ELECTRICAL/POWER DISTRIBUTION/INTE-

GRATED POWER MODULE - INSTALLATION).

(4) Connect the positive and negative battery

cables.

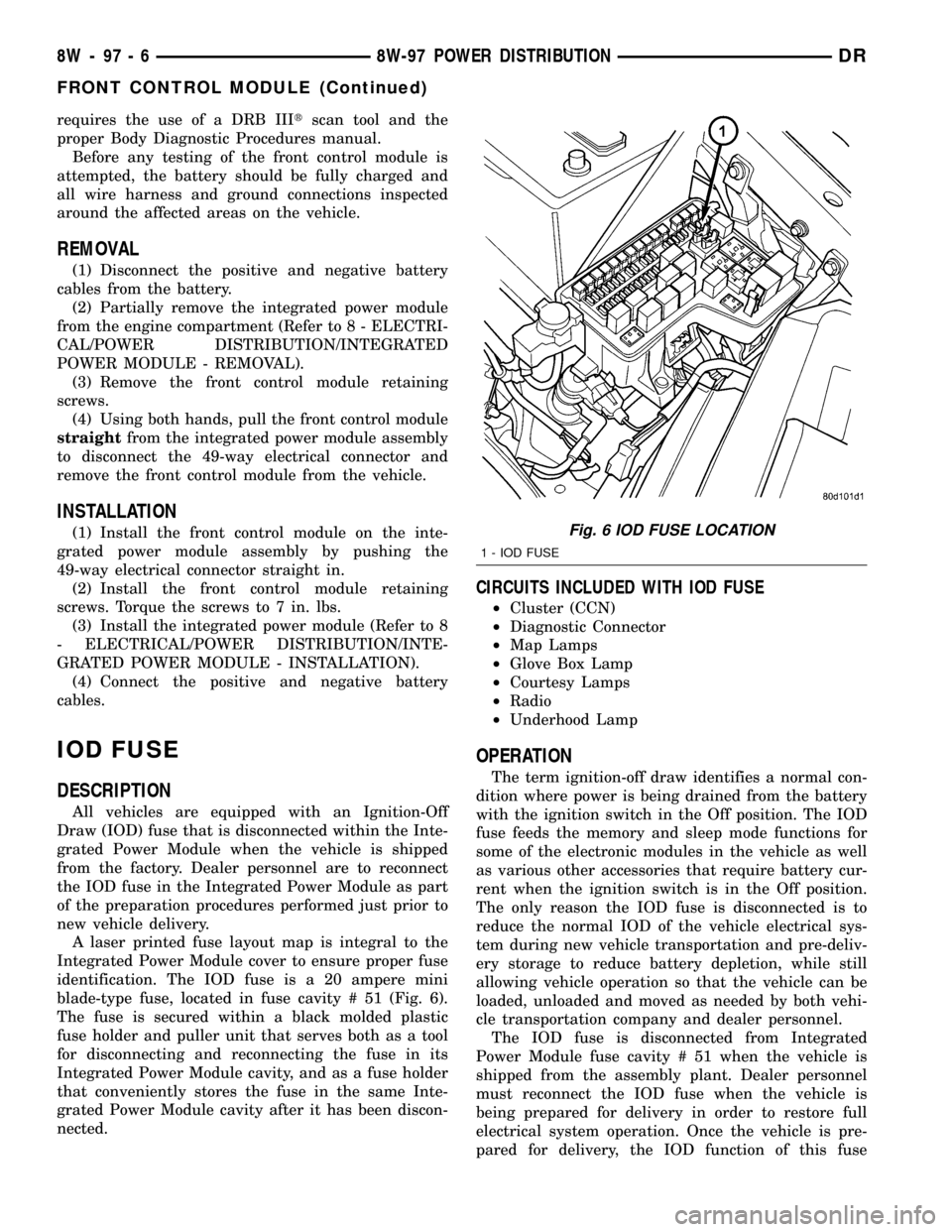

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is disconnected within the Inte-

grated Power Module when the vehicle is shipped

from the factory. Dealer personnel are to reconnect

the IOD fuse in the Integrated Power Module as part

of the preparation procedures performed just prior to

new vehicle delivery.

A laser printed fuse layout map is integral to the

Integrated Power Module cover to ensure proper fuse

identification. The IOD fuse is a 20 ampere mini

blade-type fuse, located in fuse cavity # 51 (Fig. 6).

The fuse is secured within a black molded plastic

fuse holder and puller unit that serves both as a tool

for disconnecting and reconnecting the fuse in its

Integrated Power Module cavity, and as a fuse holder

that conveniently stores the fuse in the same Inte-

grated Power Module cavity after it has been discon-

nected.

CIRCUITS INCLUDED WITH IOD FUSE

²Cluster (CCN)

²Diagnostic Connector

²Map Lamps

²Glove Box Lamp

²Courtesy Lamps

²Radio

²Underhood Lamp

OPERATION

The term ignition-off draw identifies a normal con-

dition where power is being drained from the battery

with the ignition switch in the Off position. The IOD

fuse feeds the memory and sleep mode functions for

some of the electronic modules in the vehicle as well

as various other accessories that require battery cur-

rent when the ignition switch is in the Off position.

The only reason the IOD fuse is disconnected is to

reduce the normal IOD of the vehicle electrical sys-

tem during new vehicle transportation and pre-deliv-

ery storage to reduce battery depletion, while still

allowing vehicle operation so that the vehicle can be

loaded, unloaded and moved as needed by both vehi-

cle transportation company and dealer personnel.

The IOD fuse is disconnected from Integrated

Power Module fuse cavity # 51 when the vehicle is

shipped from the assembly plant. Dealer personnel

must reconnect the IOD fuse when the vehicle is

being prepared for delivery in order to restore full

electrical system operation. Once the vehicle is pre-

pared for delivery, the IOD function of this fuse

Fig. 6 IOD FUSE LOCATION

1 - IOD FUSE

8W - 97 - 6 8W-97 POWER DISTRIBUTIONDR

FRONT CONTROL MODULE (Continued)

Page 1296 of 2627

(1) Start the engine.

(2) Spray a small stream of water (spray bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove resonator assembly and air inlet hose.

(3) Disconnect throttle and speed control cables.

(4) Disconnect electrical connectors for the follow-

ing components: Refer to FUEL SYSTEM for compo-

nent locations.

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

(5) Disconnect vapor purge hose, brake booster

hose, speed control servo hose, positive crankcase

ventilation (PCV) hose.

(6) Disconnect generator electrical connections.

(7) Disconnect air conditioning compressor electri-

cal connections.

(8) Disconnect left and right radio suppressor

straps.

(9) Disconnect and remove ignition coil towers.

(10) Remove top oil dipstick tube retaining bolt

and ground strap.

(11) Bleed fuel system (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY - STANDARD PROCE-

DURE).

(12) Remove fuel rail.

(13) Remove throttle body assembly and mounting

bracket.

(14) Drain cooling system below coolant tempera-

ture level (Refer to 7 - COOLING - STANDARD

PROCEDURE).

(15) Remove the heater hoses from the engine

front cover and the heater core.

(16) Unclip and remove heater hoses and tubes

from intake manifold.

(17) Remove coolant temperature sensor (Refer to

7 - COOLING/ENGINE/ENGINE COOLANT TEMP

SENSOR - REMOVAL).

(18) Remove intake manifold retaining fasteners in

reverse order of tightening sequence.

(19) Remove intake manifold.

INSTALLATION

(1) Install intake manifold gaskets.

(2) Install intake manifold.

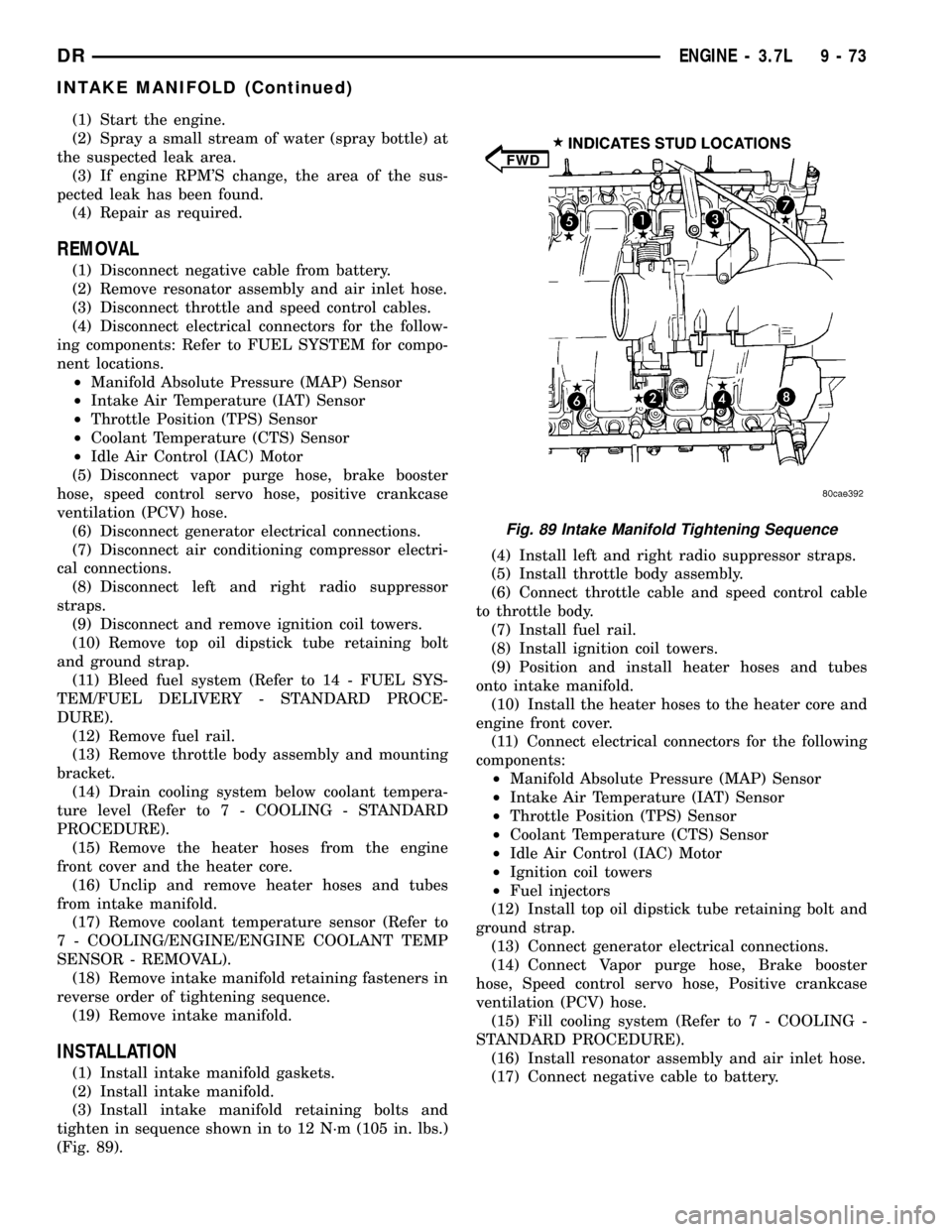

(3) Install intake manifold retaining bolts and

tighten in sequence shown in to 12 N´m (105 in. lbs.)

(Fig. 89).(4) Install left and right radio suppressor straps.

(5) Install throttle body assembly.

(6) Connect throttle cable and speed control cable

to throttle body.

(7) Install fuel rail.

(8) Install ignition coil towers.

(9) Position and install heater hoses and tubes

onto intake manifold.

(10) Install the heater hoses to the heater core and

engine front cover.

(11) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(12) Install top oil dipstick tube retaining bolt and

ground strap.

(13) Connect generator electrical connections.

(14) Connect Vapor purge hose, Brake booster

hose, Speed control servo hose, Positive crankcase

ventilation (PCV) hose.

(15) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(16) Install resonator assembly and air inlet hose.

(17) Connect negative cable to battery.

Fig. 89 Intake Manifold Tightening Sequence

DRENGINE - 3.7L 9 - 73

INTAKE MANIFOLD (Continued)

Page 1382 of 2627

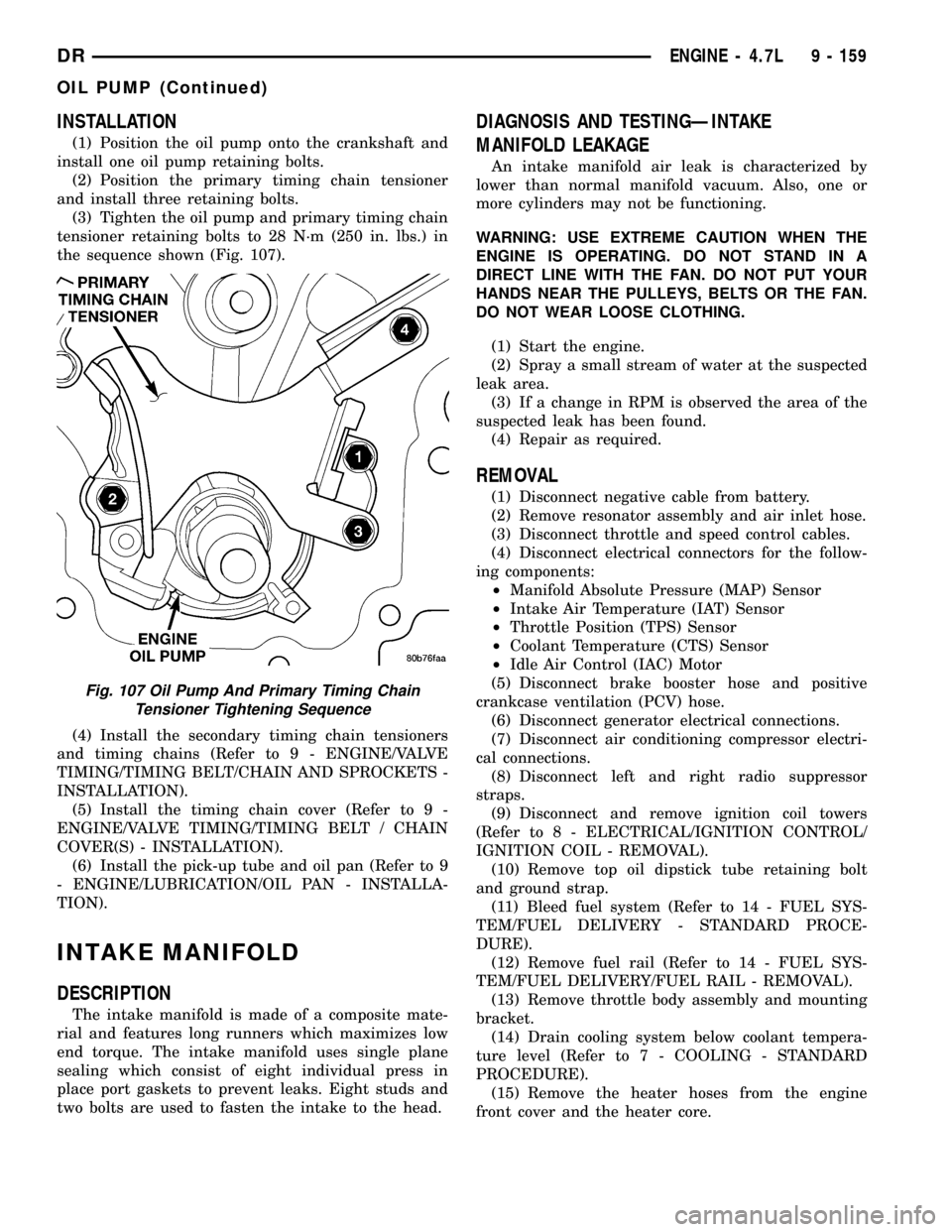

INSTALLATION

(1) Position the oil pump onto the crankshaft and

install one oil pump retaining bolts.

(2) Position the primary timing chain tensioner

and install three retaining bolts.

(3) Tighten the oil pump and primary timing chain

tensioner retaining bolts to 28 N´m (250 in. lbs.) in

the sequence shown (Fig. 107).

(4) Install the secondary timing chain tensioners

and timing chains (Refer to 9 - ENGINE/VALVE

TIMING/TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION).

(5) Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(6) Install the pick-up tube and oil pan (Refer to 9

- ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

INTAKE MANIFOLD

DESCRIPTION

The intake manifold is made of a composite mate-

rial and features long runners which maximizes low

end torque. The intake manifold uses single plane

sealing which consist of eight individual press in

place port gaskets to prevent leaks. Eight studs and

two bolts are used to fasten the intake to the head.

DIAGNOSIS AND TESTINGÐINTAKE

MANIFOLD LEAKAGE

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPM is observed the area of the

suspected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove resonator assembly and air inlet hose.

(3) Disconnect throttle and speed control cables.

(4) Disconnect electrical connectors for the follow-

ing components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

(5) Disconnect brake booster hose and positive

crankcase ventilation (PCV) hose.

(6) Disconnect generator electrical connections.

(7) Disconnect air conditioning compressor electri-

cal connections.

(8) Disconnect left and right radio suppressor

straps.

(9) Disconnect and remove ignition coil towers

(Refer to 8 - ELECTRICAL/IGNITION CONTROL/

IGNITION COIL - REMOVAL).

(10) Remove top oil dipstick tube retaining bolt

and ground strap.

(11) Bleed fuel system (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY - STANDARD PROCE-

DURE).

(12) Remove fuel rail (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL RAIL - REMOVAL).

(13) Remove throttle body assembly and mounting

bracket.

(14) Drain cooling system below coolant tempera-

ture level (Refer to 7 - COOLING - STANDARD

PROCEDURE).

(15) Remove the heater hoses from the engine

front cover and the heater core.

Fig. 107 Oil Pump And Primary Timing Chain

Tensioner Tightening Sequence

DRENGINE - 4.7L 9 - 159

OIL PUMP (Continued)