resistor DODGE RAM 1500 1998 2.G Service Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2518 of 2627

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

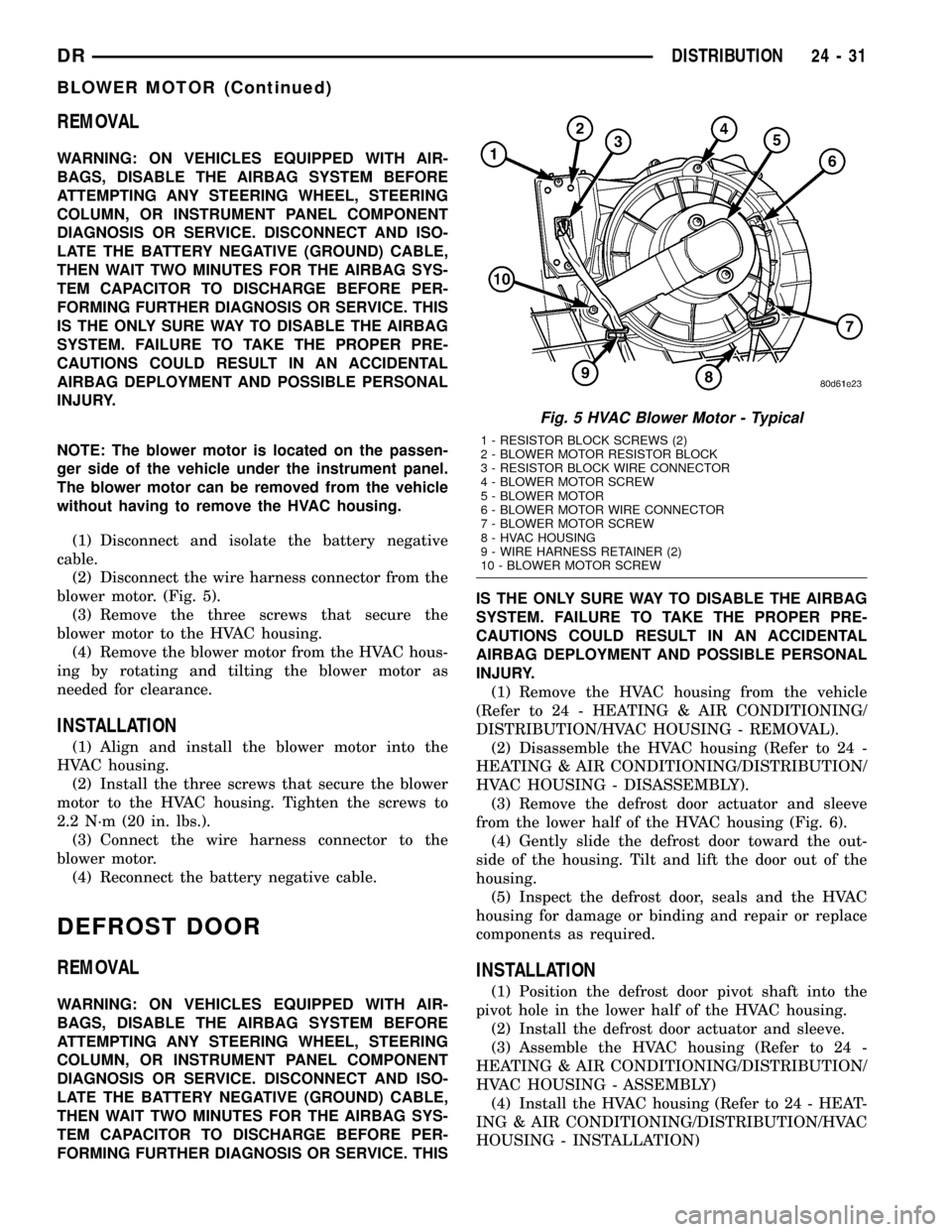

NOTE: The blower motor is located on the passen-

ger side of the vehicle under the instrument panel.

The blower motor can be removed from the vehicle

without having to remove the HVAC housing.

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the wire harness connector from the

blower motor. (Fig. 5).

(3) Remove the three screws that secure the

blower motor to the HVAC housing.

(4) Remove the blower motor from the HVAC hous-

ing by rotating and tilting the blower motor as

needed for clearance.

INSTALLATION

(1) Align and install the blower motor into the

HVAC housing.

(2) Install the three screws that secure the blower

motor to the HVAC housing. Tighten the screws to

2.2 N´m (20 in. lbs.).

(3) Connect the wire harness connector to the

blower motor.

(4) Reconnect the battery negative cable.

DEFROST DOOR

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THISIS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove the HVAC housing from the vehicle

(Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL).

(2) Disassemble the HVAC housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - DISASSEMBLY).

(3) Remove the defrost door actuator and sleeve

from the lower half of the HVAC housing (Fig. 6).

(4) Gently slide the defrost door toward the out-

side of the housing. Tilt and lift the door out of the

housing.

(5) Inspect the defrost door, seals and the HVAC

housing for damage or binding and repair or replace

components as required.

INSTALLATION

(1) Position the defrost door pivot shaft into the

pivot hole in the lower half of the HVAC housing.

(2) Install the defrost door actuator and sleeve.

(3) Assemble the HVAC housing (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - ASSEMBLY)

(4) Install the HVAC housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION)

Fig. 5 HVAC Blower Motor - Typical

1 - RESISTOR BLOCK SCREWS (2)

2 - BLOWER MOTOR RESISTOR BLOCK

3 - RESISTOR BLOCK WIRE CONNECTOR

4 - BLOWER MOTOR SCREW

5 - BLOWER MOTOR

6 - BLOWER MOTOR WIRE CONNECTOR

7 - BLOWER MOTOR SCREW

8 - HVAC HOUSING

9 - WIRE HARNESS RETAINER (2)

10 - BLOWER MOTOR SCREW

DRDISTRIBUTION 24 - 31

BLOWER MOTOR (Continued)

Page 2522 of 2627

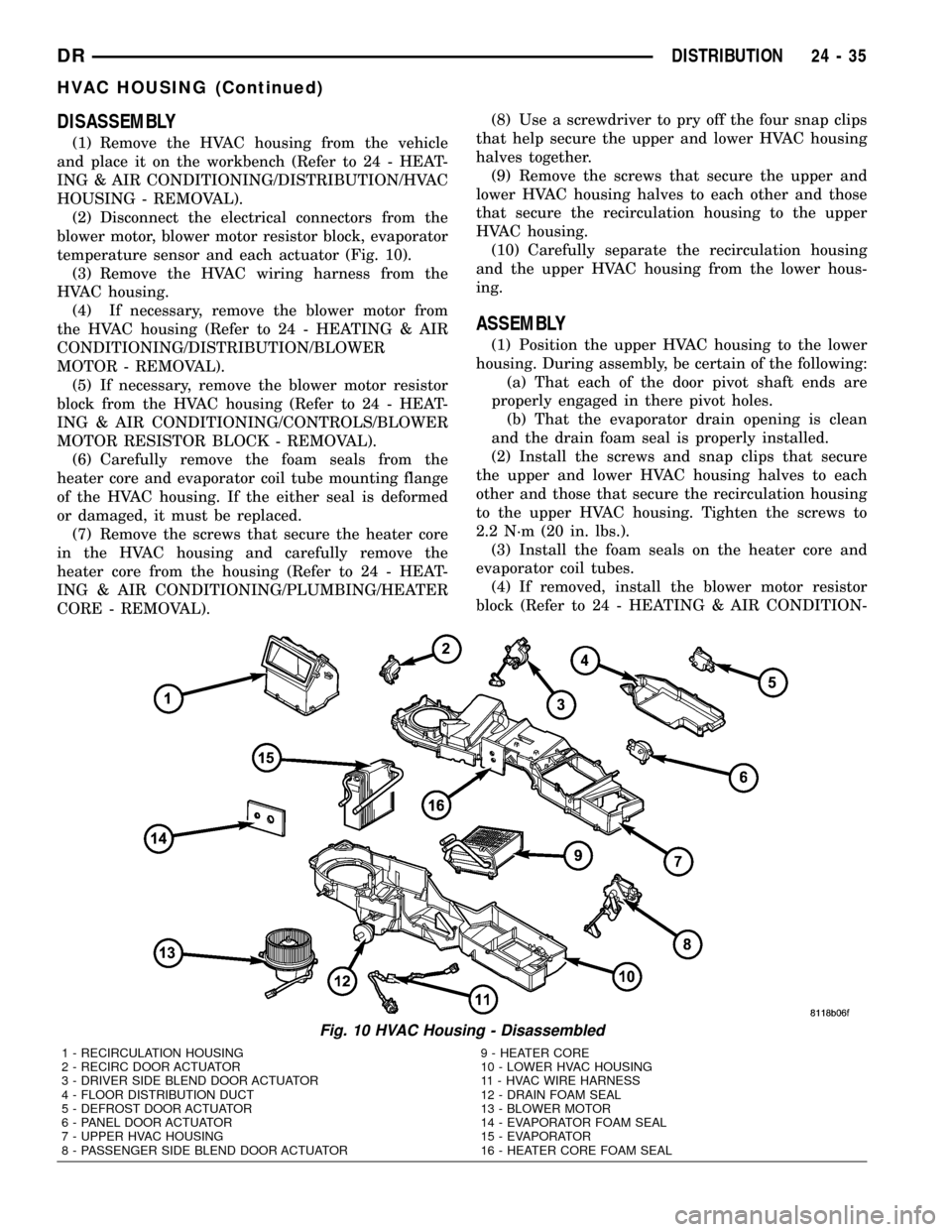

DISASSEMBLY

(1) Remove the HVAC housing from the vehicle

and place it on the workbench (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - REMOVAL).

(2) Disconnect the electrical connectors from the

blower motor, blower motor resistor block, evaporator

temperature sensor and each actuator (Fig. 10).

(3) Remove the HVAC wiring harness from the

HVAC housing.

(4) If necessary, remove the blower motor from

the HVAC housing (Refer to 24 - HEATING & AIR

CONDITIONING/DISTRIBUTION/BLOWER

MOTOR - REMOVAL).

(5) If necessary, remove the blower motor resistor

block from the HVAC housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/CONTROLS/BLOWER

MOTOR RESISTOR BLOCK - REMOVAL).

(6) Carefully remove the foam seals from the

heater core and evaporator coil tube mounting flange

of the HVAC housing. If the either seal is deformed

or damaged, it must be replaced.

(7) Remove the screws that secure the heater core

in the HVAC housing and carefully remove the

heater core from the housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/HEATER

CORE - REMOVAL).(8) Use a screwdriver to pry off the four snap clips

that help secure the upper and lower HVAC housing

halves together.

(9) Remove the screws that secure the upper and

lower HVAC housing halves to each other and those

that secure the recirculation housing to the upper

HVAC housing.

(10) Carefully separate the recirculation housing

and the upper HVAC housing from the lower hous-

ing.

ASSEMBLY

(1) Position the upper HVAC housing to the lower

housing. During assembly, be certain of the following:

(a) That each of the door pivot shaft ends are

properly engaged in there pivot holes.

(b) That the evaporator drain opening is clean

and the drain foam seal is properly installed.

(2) Install the screws and snap clips that secure

the upper and lower HVAC housing halves to each

other and those that secure the recirculation housing

to the upper HVAC housing. Tighten the screws to

2.2 N´m (20 in. lbs.).

(3) Install the foam seals on the heater core and

evaporator coil tubes.

(4) If removed, install the blower motor resistor

block (Refer to 24 - HEATING & AIR CONDITION-

Fig. 10 HVAC Housing - Disassembled

1 - RECIRCULATION HOUSING

2 - RECIRC DOOR ACTUATOR

3 - DRIVER SIDE BLEND DOOR ACTUATOR

4 - FLOOR DISTRIBUTION DUCT

5 - DEFROST DOOR ACTUATOR

6 - PANEL DOOR ACTUATOR

7 - UPPER HVAC HOUSING

8 - PASSENGER SIDE BLEND DOOR ACTUATOR9 - HEATER CORE

10 - LOWER HVAC HOUSING

11 - HVAC WIRE HARNESS

12 - DRAIN FOAM SEAL

13 - BLOWER MOTOR

14 - EVAPORATOR FOAM SEAL

15 - EVAPORATOR

16 - HEATER CORE FOAM SEAL

DRDISTRIBUTION 24 - 35

HVAC HOUSING (Continued)

Page 2523 of 2627

ING/CONTROLS/BLOWER MOTOR RESISTOR

BLOCK - INSTALLATION).

(5) If removed, install the blower motor (Refer to

24 - HEATING & AIR CONDITIONING/DISTRIBU-

TION/BLOWER MOTOR - INSTALLATION).

(6) Install the HVAC wire harness. Make sure the

wires are routed through all wiring retainers.

(7) Connect the wire harness to the blower motor,

blower motor resistor block, evaporator temperature

sensor and each actuator.

(8) Install the HVAC housing (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION/HVAC

HOUSING - INSTALLATION).

INSTALLATION

WARNING: IF THE VEHICLE IS EQUIPPED WITH AIR

CONDITIONING, REVIEW THE WARNINGS AND

CAUTIONS IN PLUMBING BEFORE PERFORMING

THE FOLLOWING OPERATION. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - WARNING)

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - CAUTION) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION -

REFRIGERANT HOSES/LINES/TUBES PRECAU-

TIONS)

(1) Position the HVAC housing into the vehicle. Be

certain that the evaporator condensate drain tube

and the housing mounting studs are inserted into

their correct locations.

(2) Install the two nuts that secure the HVAC

housing to the mounting studs in the passenger com-

partment. Tighten the nuts to 6.2 N´m (55 in. lbs.).

(3) Install the bolt that secures the HVAC housing

to the floor bracket in the passenger compartment.

Tighten the bolt to 6.2 N´m (55 in. lbs.).

(4) Install the instrument panel (Refer to 23 -

BODY/INSTRUMENT PANEL - INSTALLATION).

(5) Install the two nuts that secure the HVAC

housing to the mounting studs in the engine com-

partment. Tighten the nuts to 6.2 N´m (55 in. lbs.).

(6) Install the powertrain control module (PCM)

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/POWERTRAIN CONTROL MOD-

ULE - INSTALLATION).

(7) Unplug or remove the tape from the heater

core tubes and connect the heater hoses to the heater

core tubes.

(8) Unplug or remove the tape from the opened

refrigerant line fittings and the evaporator outlet

tube and install the accumulator (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/AC-

CUMULATOR - INSTALLATION).

(9) Unplug or remove the tape from the liquid line

and the evaporator inlet tube fittings. Connect the

liquid line coupler to the evaporator inlet tube (Referto 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - STANDARD PROCEDURE - A/C LINE COU-

PLERS).

(10) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE).

(11) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE).

(12) Fill the engine cooling system (Refer to 7 -

COOLING/ENGINE - STANDARD PROCEDURE).

(13) Connect the battery negative cable.

(14) Start the engine and check for proper opera-

tion of the heating and air conditioning systems.

INSTRUMENT PANEL

DEMISTER DUCTS

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove the defroster ducts (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

DEFROSTER DUCTS - REMOVAL).

(2) Remove the two screws that secure the center

distribution duct to the instrument panel support.

(3) Remove the center distribution duct from

instrument panel support, panel ducts and demister

ducts.

(4) Remove the right side panel duct adapter (Fig.

11).

(5) Remove the right side intermediate demister

duct.

(6) Remove the left side intermediate demister

duct.

(7) Remove the left side panel duct adapter.

(8) Remove the instrument panel cover (Refer to

23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - REMOVAL).

24 - 36 DISTRIBUTIONDR

HVAC HOUSING (Continued)

Page 2585 of 2627

The NVLD device is designed with a normally open

vacuum switch, a normally closed solenoid, and a

seal, which is actuated by both the solenoid and a

diaphragm. The NVLD is located on the atmospheric

vent side of the canister. The NVLD assembly may

be mounted on top of the canister outlet, or in-line

between the canister and atmospheric vent filter. The

normally open vacuum switch will close with about 19

H2O (0.25 KPA) vacuum in the evaporative system.

The diaphragm actuates the switch. This is above the

opening point of the fuel inlet check valve in the fill

tube so cap off leaks can be detected. Submerged fill

systems must have recirculation lines that do not

have the in-line normally closed check valve that pro-

tects the system from failed nozzle liquid ingestion,

in order to detect cap off conditions.

The normally closed valve in the NVLD is intended

to maintain the seal on the evaporative system dur-

ing the engine off condition. If vacuum in the evapo-

rative system exceeds 39to 69H2O (0.75 to 1.5 KPA),

the valve will be pulled off the seat, opening the seal.

This will protect the system from excessive vacuum

as well as allowing sufficient purge flow in the event

that the solenoid was to become inoperative.

The solenoid actuates the valve to unseal the can-

ister vent while the engine is running. It also will be

used to close the vent during the medium and large

leak tests and during the purge flow check. This sole-

noid requires initial 1.5 amps of current to pull the

valve open but after 100 ms. will be duty cycled down

to an average of about 150 mA for the remainder of

the drive cycle.

Another feature in the device is a diaphragm that

will open the seal in the NVLD with pressure in the

evaporative system. The device will9blow off9at

about 0.59H2O (0.12 KPA) pressure to permit the

venting of vapors during refueling. An added benefit

to this is that it will also allow the tank to9breathe9

during increasing temperatures, thus limiting the

pressure in the tank to this low level. This is benefi-

cial because the induced vacuum during a subse-

quent declining temperature will achieve the switch

closed (pass threshold) sooner than if the tank had to

decay from a built up pressure.

The device itself has 3 wires: Switch sense, sole-

noid driver and ground. It also includes a resistor to

protect the switch from a short to battery or a short

to ground. The NGC utilizes a high-side driver to

energize and duty-cycle the solenoid.REMOVAL

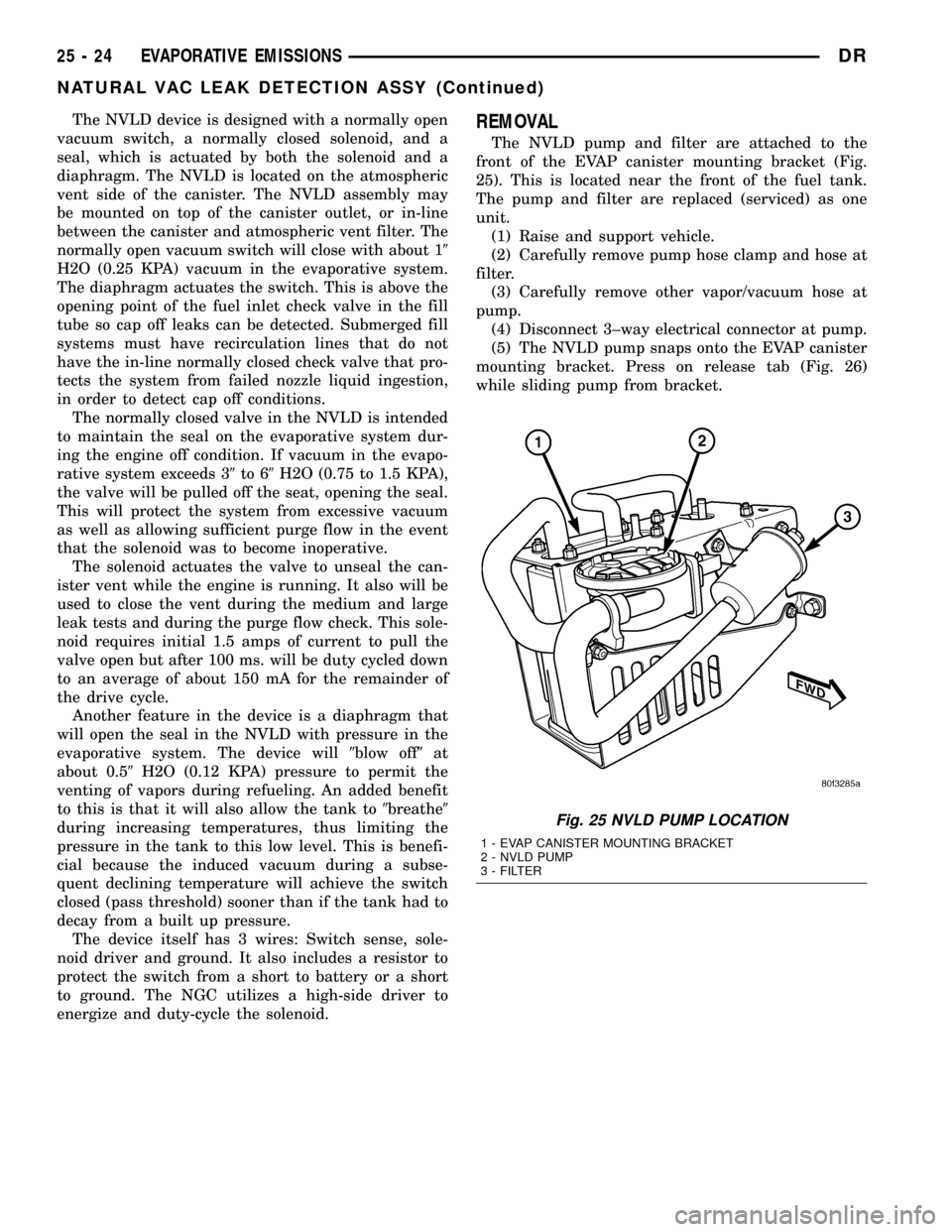

The NVLD pump and filter are attached to the

front of the EVAP canister mounting bracket (Fig.

25). This is located near the front of the fuel tank.

The pump and filter are replaced (serviced) as one

unit.

(1) Raise and support vehicle.

(2) Carefully remove pump hose clamp and hose at

filter.

(3) Carefully remove other vapor/vacuum hose at

pump.

(4) Disconnect 3±way electrical connector at pump.

(5) The NVLD pump snaps onto the EVAP canister

mounting bracket. Press on release tab (Fig. 26)

while sliding pump from bracket.

Fig. 25 NVLD PUMP LOCATION

1 - EVAP CANISTER MOUNTING BRACKET

2 - NVLD PUMP

3 - FILTER

25 - 24 EVAPORATIVE EMISSIONSDR

NATURAL VAC LEAK DETECTION ASSY (Continued)

Page 2590 of 2627

BALL JOINT - DIAGNOSIS AND TESTING,

LOWER.........................2-19,2-34

BALL JOINT - DIAGNOSIS AND TESTING,

UPPER..........................2-27,2-36

BALL JOINT - INSTALLATION, LOWER . 2-20,2-35

BALL JOINT - INSTALLATION, UPPER.....2-36

BALL JOINT - REMOVAL, LOWER.....2-19,2-35

BALL JOINT - REMOVAL, UPPER.........2-36

BAND OPERATION - DIAGNOSIS AND

TESTING, AIR TESTING

TRANSMISSION CLUTCH.............21-144

BANDS - ADJUSTMENT...............21-195

BANDS - DESCRIPTION...............21-194

BANDS - OPERATION................21-194

BAR - DESCRIPTION, STABILIZER........2-24

BAR - DESCRIPTION, TORSION..........2-26

BAR - INSTALLATION, STABILIZER....2-25,2-40

BAR - INSTALLATION, TORSION..........2-27

BAR - INSTALLATION, TRACK...........19-38

BAR - OPERATION, STABILIZER..........2-25

BAR - OPERATION, TORSION............2-26

BAR - REMOVAL, STABILIZER.......2-25,2-39

BAR - REMOVAL, TORSION.............2-26

BAR - REMOVAL, TRACK..............19-38

BAR CROSS MEMBER BUSHING -

INSTALLATION, TORSION...............2-15

BAR CROSSMEMBER BUSHING -

REMOVAL, TORSION...................2-13

BASE BRAKE, SPECIFICATIONS...........5-10

BASE BRAKE SYSTEM - DIAGNOSIS AND

TESTING.............................5-2

BASE BRAKES, SPECIAL TOOLS...........5-5

BASECOAT/CLEARCOAT FINISH -

DESCRIPTION.......................23-73

BATTERIES - STANDARD PROCEDURE,

RKE TRANSMITTER...................8N-8

BATTERY - DESCRIPTION...............8F-7

BATTERY - DIAGNOSIS AND TESTING.....8F-7

BATTERY CABLES - DESCRIPTION.......8F-14

BATTERY CABLES - DIAGNOSIS AND

TESTING...........................8F-15

BATTERY CABLES - INSTALLATION.......8F-17

BATTERY CABLES - OPERATION.........8F-15

BATTERY CABLES - REMOVAL..........8F-16

BATTERY CHARGING - STANDARD

PROCEDURE.........................8F-8

BATTERY HOLDDOWN - DESCRIPTION....8F-14

BATTERY HOLDDOWN - INSTALLATION . . . 8F-14

BATTERY HOLDDOWN - OPERATION.....8F-14

BATTERY HOLDDOWN - REMOVAL.......8F-14

BATTERY SYSTEM - CLEANING...........8F-5

BATTERY SYSTEM - DESCRIPTION........8F-1

BATTERY SYSTEM - DIAGNOSIS AND

TESTING............................8F-2

BATTERY SYSTEM - INSPECTION.........8F-5

BATTERY SYSTEM - OPERATION.........8F-2

BATTERY SYSTEM - SPECIFICATIONS......8F-6

BATTERY SYSTEM SPECIAL TOOLS,

SPECIAL TOOLS......................8F-7

BATTERY TEMPERATURE SENSOR -

DESCRIPTION.......................8F-21

BATTERY TEMPERATURE SENSOR -

INSTALLATION.......................8F-21

BATTERY TEMPERATURE SENSOR -

OPERATION.........................8F-21

BATTERY TEMPERATURE SENSOR -

REMOVAL..........................8F-21

BATTERY TESTER - STANDARD

PROCEDURE, USING MICRO 420........8F-12

BATTERY TRAY - DESCRIPTION.........8F-17

BATTERY TRAY - INSTALLATION.........8F-18

BATTERY TRAY - OPERATION...........8F-17

BATTERY TRAY - REMOVAL............8F-17

BEAM INDICATOR - DESCRIPTION, HIGH . . 8J-28

BEAM INDICATOR - OPERATION, HIGH....8J-28

BEARING - ADJUSTMENTS, CENTER.......3-9

BEARING - FITTING - STANDARD

PROCEDURE, CRANKSHAFT MAIN . . 9-134,9-207

BEARING - INSTALLATION, CENTER........3-9

BEARING - INSTALLATION, CLUTCH

RELEASE............................6-10

BEARING - INSTALLATION, HUB

..........2-32

BEARING - INSTALLATION, OUTPUT

SHAFT FRONT

......................21-216

BEARING - INSTALLATION, OUTPUT

SHAFT REAR

.......................21-217

BEARING - INSTALLATION, PILOT

........6-12

BEARING - REMOVAL, CENTER

...........3-9BEARING - REMOVAL, CLUTCH RELEASE . . . 6-9

BEARING - REMOVAL, HUB.............2-31

BEARING - REMOVAL, OUTPUT SHAFT

FRONT............................21-216

BEARING - REMOVAL, OUTPUT SHAFT

REAR.............................21-216

BEARING - REMOVAL, PILOT............6-11

BEARING AND CRANKSHAFT JOURNAL

CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD........9-272

BEARING CLEARANCE - STANDARD

PROCEDURE, MAIN...................9-274

BEARING FITTING - STANDARD

PROCEDURE, CONNECTING ROD........9-129

BEARING FITTING, STANDARD

PROCEDURE - CONNECTING ROD........9-49

BEARING FITTING, STANDARD

PROCEDURE - MAIN...................9-44

BEARINGS - INSPECTION, CRANKSHAFT

MAIN.........................9-135,9-208

BEARINGS - INSTALLATION, AXLE . . 3-125,3-153,

3-44,3-95

BEARINGS - INSTALLATION, CAMSHAFT . . 9-271

BEARINGS - INSTALLATION,

DIFFERENTIAL CASE . . . 3-106,3-134,3-161,3-48,

3-75

BEARINGS - REMOVAL, AXLE . 3-125,3-152,3-43,

3-95

BEARINGS - REMOVAL, CAMSHAFT......9-268

BEARINGS - REMOVAL, DIFFERENTIAL

CASE............3-105,3-134,3-161,3-48,3-75

BELT - 3.7L / 4.7L - INSTALLATION,

DRIVE................................7-26

BELT - 3.7L / 4.7L - REMOVAL, DRIVE.....7-26

BELT - 5.9L DIESEL - INSTALLATION,

DRIVE..............................7-29

BELT - 5.9L DIESEL - REMOVAL, DRIVE....7-29

BELT / CHAIN COVER(S) -

INSTALLATION, TIMING...........9-171,9-81

BELT / CHAIN COVER(S) - REMOVAL,

TIMING........................9-170,9-81

BELT - DIAGNOSIS AND TESTING,

ACCESSORY DRIVE................7-24,7-27

BELT - INSTALLATION, FRONT CENTER

SEAT ..............................8O-31

BELT - REMOVAL, FRONT CENTER SEAT . . 8O-30

BELT & RETRACTOR - INSTALLATION,

FRONT CENTER SEAT.................8O-29

BELT & RETRACTOR - INSTALLATION,

REAR CENTER SEAT..................8O-45

BELT & RETRACTOR - INSTALLATION,

REAR OUTBOARD SEAT...............8O-47

BELT & RETRACTOR - REMOVAL, FRONT

CENTER SEAT.......................8O-29

BELT & RETRACTOR - REMOVAL, REAR

CENTER SEAT.......................8O-44

BELT & RETRACTOR - REMOVAL, REAR

OUTBOARD SEAT....................8O-46

BELT BUCKLE - INSTALLATION, FRONT

OUTBOARD SEAT....................8O-38

BELT BUCKLE - REMOVAL, FRONT

OUTBOARD SEAT....................8O-37

BELT MOLDING - INSTALLATION, FRONT

DOOR INNER........................23-93

BELT MOLDING - INSTALLATION, FRONT

DOOR OUTER.......................23-93

BELT MOLDING - INSTALLATION, REAR

DOOR INNER........................23-94

BELT MOLDING - INSTALLATION, REAR

DOOR OUTER.......................23-94

BELT MOLDING - REMOVAL, FRONT

DOOR INNER........................23-93

BELT MOLDING - REMOVAL, FRONT

DOOR OUTER.......................23-92

BELT MOLDING - REMOVAL, REAR

DOOR INNER........................23-94

BELT MOLDING - REMOVAL, REAR

DOOR OUTER.......................23-93

BELT SWITCH - DESCRIPTION, SEAT.....8O-51

BELT SWITCH - DIAGNOSIS AND

TESTING, SEAT

......................8O-51

BELT SWITCH - OPERATION, SEAT

.......8O-51

BELT TENSION REDUCER -

DESCRIPTION, SEAT

..................8O-53

BELT TENSION REDUCER - DIAGNOSIS

AND TESTING, SEAT

..................8O-54

BELT TENSION REDUCER - OPERATION,

SEAT

..............................8O-54BELT TENSIONER - 3.7L / 4.7L -

DESCRIPTION........................7-21

BELT TENSIONER - 3.7L / 4.7L -

INSTALLATION........................7-22

BELT TENSIONER - 3.7L / 4.7L -

OPERATION..........................7-21

BELT TENSIONER - 3.7L / 4.7L -

REMOVAL...........................7-21

BELT TENSIONER - 5.9L DIESEL -

DESCRIPTION........................7-23

BELT TENSIONER - 5.9L DIESEL -

INSTALLATION........................7-24

BELT TENSIONER - 5.9L DIESEL -

OPERATION..........................7-23

BELT TENSIONER - 5.9L DIESEL -

REMOVAL...........................7-23

BELT TENSIONER - DESCRIPTION, SEAT . . 8O-52

BELT TENSIONER - OPERATION, SEAT....8O-53

BELT TENSIONER-5.7L - DESCRIPTION....7-22

BELT TENSIONER-5.7L - INSTALLATION....7-23

BELT TENSIONER-5.7L - OPERATION......7-22

BELT TENSIONER-5.7L - REMOVAL.......7-22

BELT TURNING LOOP ADJUSTER -

INSTALLATION, SEAT.................8O-55

BELT TURNING LOOP ADJUSTER -

REMOVAL, SEAT.....................8O-55

BELT/CHAIN AND SPROCKETS -

INSPECTION, TIMING.............9-174,9-84

BELT/CHAIN AND SPROCKETS -

INSTALLATION, TIMING...........9-176,9-85

BELT/CHAIN AND SPROCKETS -

REMOVAL, TIMING.................9-172,9-83

BEZEL - INSTALLATION, CLUSTER.......23-49

BEZEL - INSTALLATION, INSTRUMENT

PANEL CENTER......................23-57

BEZEL - INSTALLATION, INSTRUMENT

PANEL DRIVER SIDE..................23-58

BEZEL - INSTALLATION, INSTRUMENT

PANEL HEADLAMP SWITCH............23-56

BEZEL - REMOVAL, CLUSTER...........23-49

BEZEL - REMOVAL, INSTRUMENT PANEL

CENTER............................23-57

BEZEL - REMOVAL, INSTRUMENT PANEL

DRIVER SIDE........................23-58

BEZEL - REMOVAL, INSTRUMENT PANEL

HEADLAMP SWITCH..................23-56

BIN - INSTALLATION, STORAGE.........23-61

BIN - INSTALLATION, UNDER SEAT

STORAGE...........................23-80

BIN - REMOVAL, STORAGE.............23-61

BIN - REMOVAL, UNDER SEAT STORAGE . . 23-80

BIN COVERING - INSTALLATION, UNDER

SEAT STORAGE......................23-80

BIN COVERING - REMOVAL, UNDER

SEAT STORAGE......................23-80

BIN LATCH - INSTALLATION, UNDER

SEAT STORAGE......................23-80

BIN LATCH - REMOVAL, UNDER SEAT

STORAGE...........................23-80

BIN LID - INSTALLATION, UNDER SEAT

STORAGE...........................23-80

BIN LID - REMOVAL, UNDER SEAT

STORAGE...........................23-80

BLADE - DESCRIPTION, WIPER.........8R-18

BLADE - INSTALLATION, WIPER.........8R-20

BLADE - OPERATION, WIPER...........8R-19

BLADE - REMOVAL, WIPER............8R-19

BLEEDING - STANDARD PROCEDURE......5-31

BLEEDING - STANDARD PROCEDURE,

ABS BRAKE..........................5-46

BLEEDING - STANDARD PROCEDURE,

MANUAL.............................5-5

BLEEDING - STANDARD PROCEDURE,

MASTER CYLINDER...................5-26

BLEEDING - STANDARD PROCEDURE,

PRESSURE...........................5-5

BLEND DOOR - INSTALLATION..........24-27

BLEND DOOR - REMOVAL.............24-27

BLEND DOOR ACTUATOR -

DESCRIPTION.......................24-17

BLEND DOOR ACTUATOR -

INSTALLATION.......................24-18

BLEND DOOR ACTUATOR - OPERATION

. . . 24-17

BLEND DOOR ACTUATOR - REMOVAL

....24-17

BLOCK - CLEANING, ENGINE

. . 9-128,9-205,9-39

BLOCK - DESCRIPTION, BLOWER

MOTOR RESISTOR

...................24-18

BLOCK - DESCRIPTION, ENGINE

.....9-128,9-38

DRINDEX 3

Description Group-Page Description Group-Page Description Group-Page

Page 2591 of 2627

BLOCK - DIAGNOSIS AND TESTING,

BLOWER MOTOR RESISTOR............24-19

BLOCK - INSPECTION, ENGINE . 9-128,9-205,9-39

BLOCK - INSTALLATION, BLOWER

MOTOR RESISTOR...................24-19

BLOCK - INSTALLATION, BRAKE

JUNCTION...........................5-24

BLOCK - OPERATION, BLOWER MOTOR

RESISTOR..........................24-18

BLOCK - REMOVAL, BLOWER MOTOR

RESISTOR..........................24-19

BLOCK - REMOVAL, BRAKE JUNCTION....5-24

BLOCK HEATER - 5.9L DIESEL -

DESCRIPTION, ENGINE.................7-37

BLOCK HEATER - 5.9L DIESEL -

INSTALLATION, ENGINE................7-38

BLOCK HEATER - 5.9L DIESEL -

OPERATION, ENGINE...................7-38

BLOCK HEATER - 5.9L DIESEL -

REMOVAL, ENGINE....................7-38

BLOCK HEATER - DESCRIPTION, ENGINE . . . 7-36

BLOCK HEATER - DIAGNOSIS AND

TESTING, ENGINE.....................7-36

BLOCK HEATER - INSTALLATION,

ENGINE.............................7-37

BLOCK HEATER - OPERATION, ENGINE....7-36

BLOCK HEATER - REMOVAL, ENGINE......7-37

BLOCK REFACING - STANDARD

PROCEDURE, CYLINDER...............9-264

BLOWER MOTOR - DESCRIPTION.......24-28

BLOWER MOTOR - DIAGNOSIS AND

TESTING.............................24-28

BLOWER MOTOR - INSTALLATION.......24-31

BLOWER MOTOR - OPERATION.........24-28

BLOWER MOTOR - REMOVAL...........24-31

BLOWER MOTOR RESISTOR BLOCK -

DESCRIPTION.......................24-18

BLOWER MOTOR RESISTOR BLOCK -

DIAGNOSIS AND TESTING.............24-19

BLOWER MOTOR RESISTOR BLOCK -

INSTALLATION.......................24-19

BLOWER MOTOR RESISTOR BLOCK -

OPERATION.........................24-18

BLOWER MOTOR RESISTOR BLOCK -

REMOVAL..........................24-19

BLOWER MOTOR SWITCH -

DESCRIPTION.......................24-20

BLOWER MOTOR SWITCH - DIAGNOSIS

AND TESTING.......................24-20

BLOWER MOTOR SWITCH - OPERATION . . 24-20

BODY - ADJUSTMENTS, VALVE........21-310

BODY - ASSEMBLY, VALVE......21-299,21-414

BODY & CABLE - DESCRIPTION,

ANTENNA...........................8A-4

BODY & CABLE - INSTALLATION,

ANTENNA...........................8A-6

BODY & CABLE - OPERATION, ANTENNA . . . 8A-4

BODY & CABLE - REMOVAL, ANTENNA....8A-6

BODY - CLEANING, VALVE......21-298,21-412

BODY - DESCRIPTION, THROTTLE.......14-36

BODY - DESCRIPTION, VALVE....21-267,21-408

BODY - DISASSEMBLY, VALVE . . . 21-287,21-410

BODY - INSPECTION, VALVE.....21-298,21-413

BODY - INSTALLATION, THROTTLE.......14-37

BODY - INSTALLATION, VALVE . . . 21-309,21-414

BODY - OPERATION, THROTTLE.........14-36

BODY - OPERATION, VALVE.....21-272,21-408

BODY - REMOVAL, THROTTLE..........14-36

BODY - REMOVAL, VALVE.......21-286,21-410

BODY AND CABLE - DIAGNOSIS AND

TESTING, ANTENNA

...................8A-4

BODY CODE PLATE - DESCRIPTION

.....Intro.-3

BODY ISOLATORS - INSTALLATION

......23-37

BODY ISOLATORS - REMOVAL

..........23-36

BODY LUBRICATION - STANDARD

PROCEDURE

.........................23-3

BODY OPENING DIMENSIONS -

SPECIFICATIONS

.....................23-99

BODY PANEL REPAIR - STANDARD

PROCEDURE, PLASTIC

.................23-3

BODY SIDE MOLDINGS - INSTALLATION

. . 23-36

BODY SIDE MOLDINGS - REMOVAL

......23-36

BODY, SPECIAL TOOLS

................23-14

BODY VENT - INSTALLATION

...........23-71

BODY VENT - REMOVAL

...............23-71

BOOST PRESSURE - DIAGNOSIS AND

TESTING, TURBOCHARGER

.............11-11BOOSTER - DESCRIPTION, POWER

BRAKE..............................5-29

BOOSTER - DIAGNOSIS AND TESTING,

HYDRAULIC..........................5-30

BOOSTER - DIAGNOSIS AND TESTING,

MASTER CYLINDER/POWER.............5-25

BOOSTER - INSTALLATION, HYDRO-

BOOST BRAKE........................5-32

BOOSTER - INSTALLATION, POWER

BRAKE..............................5-29

BOOSTER - OPERATION, POWER BRAKE . . . 5-29

BOOSTER - REMOVAL, HYDRO-BOOST

BRAKE..............................5-31

BOOSTER - REMOVAL, POWER BRAKE....5-29

BOOT - INSTALLATION, 4WD FLOOR

SHIFT..............................23-62

BOOT - INSTALLATION, EXTENSION

HOUSING SEAL AND DUST......21-476,21-571

BOOT - REMOVAL, 4WD FLOOR SHIFT....23-62

BOOT - REMOVAL, EXTENSION HOUSING

SEAL AND DUST..............21-476,21-571

BORE - DE-GLAZE - STANDARD

PROCEDURE, CYLINDER...............9-264

BORE HONING - STANDARD

PROCEDURE, CYLINDER...........9-128,9-38

BORE REPAIR - STANDARD

PROCEDURE, CAM...................9-267

BORE REPAIR - STANDARD

PROCEDURE, CYLINDER...............9-265

BOX - INSTALLATION, CARGO..........23-37

BOX - INSTALLATION, GLOVE...........23-52

BOX - INSTALLATION, WITH CARGO . 8L-22,8L-23,

8L-24,8L-7,8L-9

BOX - INSTALLATION, WITHOUT CARGO . . 8L-22,

8L-23,8L-24,8L-8,8L-9

BOX - REMOVAL, CARGO..............23-37

BOX - REMOVAL, GLOVE..............23-52

BOX - REMOVAL, WITH CARGO....8L-22,8L-24,

8L-7,8L-9

BOX - REMOVAL, WITHOUT CARGO.....8L-22,

8L-23,8L-24,8L-7,8L-9

BOX - TIE DOWN - INSTALLATION,

CARGO............................23-38

BOX - TIE DOWN - REMOVAL, CARGO....23-38

BOX LAMP/SWITCH - INSTALLATION,

GLOVE.............................8L-28

BOX LAMP/SWITCH - REMOVAL, GLOVE . . 8L-27

BOX LATCH - INSTALLATION, GLOVE.....23-52

BOX LATCH - REMOVAL, GLOVE.........23-52

B-PILLAR GRAB HANDLE -

INSTALLATION.......................23-68

B-PILLAR GRAB HANDLE - REMOVAL....23-68

B-PILLAR LOWER TRIM - INSTALLATION . . 23-64

B-PILLAR LOWER TRIM - REMOVAL.....23-63

B-PILLAR UPPER TRIM - INSTALLATION . . 23-64

B-PILLAR UPPER TRIM - REMOVAL......23-64

BRACKET - INSTALLATION, REAR VIEW

MIRROR SUPPORT...................23-70

BRACKET - INSTALLATION, STEERING

COLUMN OPENING SUPPORT...........23-60

BRACKET - REMOVAL, STEERING

COLUMN OPENING SUPPORT...........23-60

BRACKETS - INSTALLATION, SEAT BACK

REAR - FOOTMANS LOOP..............23-85

BRACKETS - REMOVAL, SEAT BACK

REAR - FOOTMANS LOOP..............23-85

BRAKE - CLEANING, REAR DRUM IN

HAT ................................5-39

BRAKE - DESCRIPTION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - DESCRIPTION, PARKING........5-36

BRAKE - INSPECTION, REAR DRUM IN

HAT ................................5-39

BRAKE - INSTALLATION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - OPERATION, CONTROLLER

ANTILOCK...........................8E-3

BRAKE - OPERATION, PARKING..........5-36

BRAKE - REMOVAL, CONTROLLER

ANTILOCK

...........................8E-3

BRAKE BLEEDING - STANDARD

PROCEDURE, ABS

.....................5-46

BRAKE BOOSTER - DESCRIPTION,

POWER

.............................5-29

BRAKE BOOSTER - INSTALLATION,

HYDRO-BOOST

.......................5-32

BRAKE BOOSTER - INSTALLATION,

POWER

.............................5-29BRAKE BOOSTER - OPERATION, POWER . . . 5-29

BRAKE BOOSTER - REMOVAL,

HYDRO-BOOST.......................5-31

BRAKE BOOSTER - REMOVAL, POWER....5-29

BRAKE CABLE - INSTALLATION, FRONT

PARKING............................5-38

BRAKE CABLE - INSTALLATION, REAR

PARK...............................5-38

BRAKE CABLE - REMOVAL, FRONT

PARKING............................5-36

BRAKE CABLE - REMOVAL, REAR PARK . . . 5-37

BRAKE CALIPER ADAPTER MOUNT -

INSTALLATION, DISC...................5-22

BRAKE CALIPERS - DESCRIPTION, DISC . . . 5-16

BRAKE CALIPERS - OPERATION, DISC.....5-16

BRAKE FLUID CONTAMINATION -

DIAGNOSIS AND TESTING..............5-23

BRAKE FLUID LEVEL - STANDARD

PROCEDURE.........................5-23

BRAKE FLUID, SPECIFICATIONS..........5-23

BRAKE HOSE - INSTALLATION, FRONT.....5-13

BRAKE HOSE - INSTALLATION, REAR......5-12

BRAKE HOSE - REMOVAL, REAR.........5-11

BRAKE INDICATOR - DESCRIPTION,

BRAKE/PARK........................8J-19

BRAKE INDICATOR - DIAGNOSIS AND

TESTING...........................8J-20

BRAKE INDICATOR - OPERATION,

BRAKE/PARK........................8J-19

BRAKE JUNCTION BLOCK -

INSTALLATION.........................5-24

BRAKE JUNCTION BLOCK - REMOVAL.....5-24

BRAKE LAMP SWITCH - DESCRIPTION....8L-9

BRAKE LAMP SWITCH - DIAGNOSIS

AND TESTING.......................8L-10

BRAKE LAMP SWITCH - INSTALLATION . . . 8L-11

BRAKE LAMP SWITCH - OPERATION......8L-9

BRAKE LAMP SWITCH - REMOVAL......8L-10

BRAKE PROPORTIONING -

DESCRIPTION, ELECTRONIC VARIABLE....5-49

BRAKE PROPORTIONING - OPERATION,

ELECTRONIC VARIABLE................5-49

BRAKE ROTOR, DIAGNOSIS AND

TESTING - DISC......................5-32

BRAKE SHOES - ADJUSTMENT, PARKING . . 5-41

BRAKE, SPECIFICATIONS - BASE.........5-10

BRAKE SYSTEM - DIAGNOSIS AND

TESTING, BASE........................5-2

BRAKE TRANSMISSION SHIFT

INTERLOCK - ADJUSTMENTS....21-196,21-365

BRAKE TRANSMISSION SHIFT

INTERLOCK - DIAGNOSIS AND

TESTING....................21-196,21-364

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - DESCRIPTION . . . 21-196,

21-364

BRAKE TRANSMISSION SHIFT

INTERLOCK SYSTEM - OPERATION.....21-196,

21-364

BRAKE/PARK BRAKE INDICATOR -

DESCRIPTION.......................8J-19

BRAKE/PARK BRAKE INDICATOR -

OPERATION.........................8J-19

BRAKES - ABS - DESCRIPTION...........5-45

BRAKES - ABS - OPERATION............5-45

BRAKES, SPECIAL TOOLS - BASE.........5-5

BREAK-IN - STANDARD PROCEDURE,

A/C COMPRESSOR CLUTCH............24-10

BREATHER - INSTALLATION,

CRANKCASE

........................9-243

BREATHER - REMOVAL, CRANKCASE

.....9-242

BUCKLE - INSTALLATION, FRONT

OUTBOARD SEAT BELT

................8O-38

BUCKLE - REMOVAL, FRONT OUTBOARD

SEAT BELT

.........................8O-37

BUILT-IN INDICATOR TEST - STANDARD

PROCEDURE

........................8F-10

BUMPER - INSTALLATION, FRONT

........13-2

BUMPER - INSTALLATION, JOUNCE

.......2-43

BUMPER - INSTALLATION, REAR

.........13-4

BUMPER - REMOVAL, FRONT

............13-2

BUMPER - REMOVAL, JOUNCE

...........2-43

BUMPER - REMOVAL, REAR

.............13-3

BUMPERS (3500) - INSTALLATION,

AUXILIARY SPRING

....................2-43

BUMPERS (3500) - REMOVAL,

AUXILIARY SPRING

....................2-43

4 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2608 of 2627

MODULE - INSTALLATION, FRONT

CONTROL........................8W-97-6

MODULE - INSTALLATION, FRONT

CONTROL...........................8E-5

MODULE - INSTALLATION, FUEL PUMP . . . 14-12

MODULE - INSTALLATION, FUEL TANK....14-64

MODULE - INSTALLATION, HANDS FREE . . . 8T-2

MODULE - INSTALLATION, HEATED SEAT . . . 8E-7

MODULE - INSTALLATION, HEATED SEAT . 8G-15

MODULE - INSTALLATION, INTEGRATED

POWER..........................8W-97-4

MODULE - INSTALLATION, REMOTE

KEYLESS ENTRY......................8N-8

MODULE - INSTALLATION, SENTRY KEY

IMMOBILIZER.......................8E-15

MODULE - INSTALLATION, WIPER.......8R-23

MODULE - OPERATION, AIRBAG

CONTROL..........................8O-11

MODULE - OPERATION, DRIVER DOOR....8N-5

MODULE - OPERATION, FRONT

CONTROL........................8W-97-5

MODULE - OPERATION, FRONT

CONTROL...........................8E-5

MODULE - OPERATION, FUEL PUMP.....14-11

MODULE - OPERATION, FUEL TANK......14-63

MODULE - OPERATION, HEATED SEAT.....8E-6

MODULE - OPERATION, HEATED SEAT....8G-14

MODULE - OPERATION, INTEGRATED

POWER..........................8W-97-3

MODULE - OPERATION, REMOTE

KEYLESS ENTRY......................8N-7

MODULE - OPERATION, SENTRY KEY

IMMOBILIZER.......................8E-13

MODULE - OPERATION, TRANSFER CASE

CONTROL..........................8E-16

MODULE - OPERATION, TRANSMISSION

CONTROL..........................8E-20

MODULE - OPERATION, WIPER.........8R-23

MODULE - REMOVAL, AIRBAG CONTROL . 8O-12

MODULE - REMOVAL, DRIVER DOOR.....8N-7

MODULE - REMOVAL, ENGINE CONTROL . . . 8E-4

MODULE - REMOVAL, FRONT CONTROL . 8W-97-6

MODULE - REMOVAL, FRONT CONTROL . . . 8E-5

MODULE - REMOVAL, FUEL PUMP.......14-12

MODULE - REMOVAL, FUEL TANK.......14-63

MODULE - REMOVAL, HANDS FREE.......8T-2

MODULE - REMOVAL, HEATED SEAT......8E-7

MODULE - REMOVAL, HEATED SEAT.....8G-15

MODULE - REMOVAL, INTEGRATED

POWER..........................8W-97-3

MODULE - REMOVAL, REMOTE KEYLESS

ENTRY..............................8N-7

MODULE - REMOVAL, SENTRY KEY

IMMOBILIZER.......................8E-15

MODULE - REMOVAL, WIPER...........8R-23

MODULE / SWITCH OPERATING MODES,

STANDARD PROCEDURE -

CONFIGURING A NEW.................8Q-3

MODULE LAMP REPLACEMENT -

STANDARD PROCEDURE...............8M-3

MODULE LENS REPLACEMENT -

STANDARD PROCEDURE...............8M-3

MODULE (SKIM) - DESCRIPTION,

SENTRY KEY IMMOBILIZER.............8Q-1

MODULE (SKIM) - OPERATION, SENTRY

KEY IMMOBILIZER

....................8Q-2

MOLDING - INSTALLATION, FRONT

DOOR INNER BELT

...................23-93

MOLDING - INSTALLATION, FRONT

DOOR OUTER BELT

...................23-93

MOLDING - INSTALLATION, REAR DOOR

INNER BELT

.........................23-94

MOLDING - INSTALLATION, REAR DOOR

OUTER BELT

........................23-94

MOLDING - REMOVAL, FRONT DOOR

INNER BELT

.........................23-93

MOLDING - REMOVAL, FRONT DOOR

OUTER BELT

........................23-92

MOLDING - REMOVAL, REAR DOOR

INNER BELT

.........................23-94

MOLDING - REMOVAL, REAR DOOR

OUTER BELT

........................23-93

MOLDINGS - INSTALLATION, BODY SIDE

. . 23-36

MOLDINGS - REMOVAL, BODY SIDE

.....23-36

MONITORED SYSTEMS - DESCRIPTION

....25-2

MONITORS - DESCRIPTION,

COMPONENT

.........................25-4MOTOR - DESCRIPTION, ADJUSTABLE

PEDAL...............................5-6

MOTOR - DESCRIPTION, BLOWER.......24-28

MOTOR - DESCRIPTION, DOOR LOCK.....8N-4

MOTOR - DESCRIPTION, IDLE AIR

CONTROL..........................14-28

MOTOR - DESCRIPTION, LUMBAR.......8N-18

MOTOR - DESCRIPTION, SHIFT . . 21-511,21-541,

21-575

MOTOR - DIAGNOSIS AND TESTING,

BLOWER...........................24-28

MOTOR - DIAGNOSIS AND TESTING,

DOOR LOCK.........................8N-4

MOTOR - DIAGNOSIS AND TESTING,

LUMBAR...........................8N-18

MOTOR - DIAGNOSIS AND TESTING,

STARTER ...........................8F-32

MOTOR - INSTALLATION, ADJUSTABLE

PEDAL...............................5-7

MOTOR - INSTALLATION, BLOWER......24-31

MOTOR - INSTALLATION, IDLE AIR

CONTROL..........................14-29

MOTOR - INSTALLATION, SHIFT . 21-511,21-541,

21-575

MOTOR - INSTALLATION, STARTER......8F-34

MOTOR - OPERATION, BLOWER.........24-28

MOTOR - OPERATION, DOOR LOCK.......8N-4

MOTOR - OPERATION, IDLE AIR

CONTROL..........................14-28

MOTOR - OPERATION, LUMBAR........8N-18

MOTOR - OPERATION, SHIFT.....21-511,21-541,

21-575

MOTOR - REMOVAL, ADJUSTABLE

PEDAL...............................5-7

MOTOR - REMOVAL, BLOWER..........24-31

MOTOR - REMOVAL, IDLE AIR CONTROL . . 14-29

MOTOR - REMOVAL, SHIFT.....21-511,21-541,

21-575

MOTOR - REMOVAL, STARTER..........8F-33

MOTOR - REMOVAL, WINDOW..........8N-20

MOTOR RELAY - DESCRIPTION,

STARTER ...........................8F-35

MOTOR RELAY - INSTALLATION,

STARTER ...........................8F-37

MOTOR RELAY - OPERATION, STARTER . . . 8F-36

MOTOR RELAY - REMOVAL, STARTER....8F-37

MOTOR RESISTOR BLOCK -

DESCRIPTION, BLOWER...............24-18

MOTOR RESISTOR BLOCK - DIAGNOSIS

AND TESTING, BLOWER...............24-19

MOTOR RESISTOR BLOCK -

INSTALLATION, BLOWER..............24-19

MOTOR RESISTOR BLOCK - OPERATION,

BLOWER...........................24-18

MOTOR RESISTOR BLOCK - REMOVAL,

BLOWER...........................24-19

MOTOR SWITCH - DESCRIPTION,

BLOWER...........................24-20

MOTOR SWITCH - DIAGNOSIS AND

TESTING, BLOWER...................24-20

MOTOR SWITCH - OPERATION, BLOWER . . 24-20

MOUNT - INSTALLATION, DISC BRAKE

CALIPER ADAPTER....................5-22

MOUNT - INSTALLATION, FRONT . . . 9-147,9-218,

9-287,9-59

MOUNT - INSTALLATION, REAR

....9-149,9-220,

9-288,9-61

MOUNT - REMOVAL, FRONT

. 9-146,9-217,9-286,

9-58

MOUNT - REMOVAL, REAR

. . 9-149,9-220,9-288,

9-61

MOUNTED STOP LAMP - INSTALLATION,

CENTER HIGH

.......................8L-11

MOUNTED STOP LAMP - REMOVAL,

CENTER HIGH

.......................8L-11

MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER HIGH

..........8L-11

MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER HIGH

..............8L-11

MOUNTING - STANDARD PROCEDURE,

MATCH

.............................22-3

MUFFLER - 5.9L DIESEL - INSTALLATION

. 11-10

MUFFLER - 5.9L DIESEL - REMOVAL

.....11-10

MUFFLER - INSTALLATION

..............11-9

MUFFLER - REMOVAL

..................11-9

MULTI-FUNCTION SWITCH - DIAGNOSIS

AND TESTING

.......................8L-18MULTI-FUNCTION SWITCH -

INSTALLATION.......................8L-19

MULTI-FUNCTION SWITCH - REMOVAL . . . 8L-19

NAME PLATES - INSTALLATION,

EXTERIOR..........................23-38

NAME PLATES - REMOVAL, EXTERIOR....23-38

NATURAL VAC LEAK DETECTION ASSY -

DESCRIPTION.......................25-23

NATURAL VAC LEAK DETECTION ASSY -

INSTALLATION.......................25-25

NATURAL VAC LEAK DETECTION ASSY -

OPERATION.........................25-23

NATURAL VAC LEAK DETECTION ASSY -

REMOVAL..........................25-24

NAVIGATION - INSTALLATION, ANTENNA . . . 8A-6

NAVIGATION - REMOVAL, ANTENNA......8A-6

NAVIGATION/TELECOMMUNICATION -

DESCRIPTION........................8T-1

NAVIGATION/TELECOMMUNICATION -

OPERATION..........................8T-1

NECK SEAL - DIAGNOSIS AND TESTING,

RADIATOR CAP-TO-FILLER..............7-58

NEW MODULE / SWITCH OPERATING

MODES, STANDARD PROCEDURE -

CONFIGURING A......................8Q-3

NIGHT MIRROR - DESCRIPTION,

AUTOMATIC DAY.....................8N-11

NIGHT MIRROR - DIAGNOSIS AND

TESTING, AUTOMATIC DAY.............8N-11

NIGHT MIRROR - OPERATION,

AUTOMATIC DAY.....................8N-11

NIGHT MIRROR - REMOVAL,

AUTOMATIC DAY......................8N-12

NOISE - DIAGNOSIS AND TESTING,

WIND...............................23-2

NOISE OR VIBRATION - DIAGNOSIS AND

TESTING, TIRE.......................22-7

NOISE SUPPRESSION GROUND STRAP -

DESCRIPTION, RADIO..................8A-9

NOISE SUPPRESSION GROUND STRAP -

INSTALLATION, RADIO................8A-10

NOISE SUPPRESSION GROUND STRAP -

OPERATION, RADIO...................8A-9

NOISE SUPPRESSION GROUND STRAP -

REMOVAL, RADIO.....................8A-9

NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS - STANDARD

PROCEDURE, HANDLING...............8O-6

NON-MONITORED CIRCUITS -

OPERATION..........................25-8

NOZZLE - DESCRIPTION, WASHER......8R-11

NOZZLE - INSTALLATION, WASHER......8R-12

NOZZLE - OPERATION, WASHER........8R-12

NOZZLE - REMOVAL, WASHER..........8R-12

NUMBER - DESCRIPTION, VEHICLE

IDENTIFICATION....................Intro.-1

NV241 GENII - ASSEMBLY, TRANSFER

CASE.............................21-428

NV241 GENII - CLEANING, TRANSFER

CASE.............................21-426

NV241 GENII - DESCRIPTION, TRANSFER

CASE.............................21-415

NV241 GENII - DIAGNOSIS AND

TESTING, TRANSFER CASE............21-416

NV241 GENII - DISASSEMBLY,

TRANSFER CASE....................21-417

NV241 GENII - INSPECTION, TRANSFER

CASE.............................21-426

NV241 GENII - INSTALLATION,

TRANSFER CASE....................21-438

NV241 GENII - OPERATION, TRANSFER

CASE.............................21-415

NV241 GENII - REMOVAL, TRANSFER

CASE.............................21-417

NV241 GENII - TRANSFER CASE........21-438

NV241/NV243 - TRANSFER CASE.......21-439

NV243 - ASSEMBLY, TRANSFER CASE . . . 21-496

NV243 - CLEANING, TRANSFER CASE . . . 21-493

NV243 - DESCRIPTION, TRANSFER CASE . 21-482

NV243 - DIAGNOSIS AND TESTING,

TRANSFER CASE....................21-483

NV243 - DISASSEMBLY, TRANSFER

CASE

.............................21-484

NV243 - INSPECTION, TRANSFER CASE

. . 21-493

NV243 - INSTALLATION, TRANSFER

CASE

.............................21-505

NV243 - OPERATION, TRANSFER CASE

. . 21-483

NV243 - REMOVAL, TRANSFER CASE

....21-484

DRINDEX 21

Description Group-Page Description Group-Page Description Group-Page

Page 2614 of 2627

RELAY - DESCRIPTION, STARTER

MOTOR............................8F-35

RELAY - DESCRIPTION, TRANSMISSION

CONTROL.........................21-405

RELAY - DESCRIPTION, WIPER

HIGH/LOW..........................8R-20

RELAY - DESCRIPTION, WIPER ON/OFF . . . 8R-24

RELAY - DIAGNOSIS AND TESTING,

PARK LAMP.........................8L-20

RELAY - DIAGNOSIS AND TESTING,

STARTER ...........................8F-36

RELAY - DIAGNOSIS AND TESTING,

WIPER HIGH/LOW...................8R-21

RELAY - DIAGNOSIS AND TESTING,

WIPER ON/OFF......................8R-25

RELAY - INSTALLATION, A/C

COMPRESSOR CLUTCH...............24-14

RELAY - INSTALLATION, FOG LAMP......8L-13

RELAY - INSTALLATION, FUEL HEATER . . . 14-53

RELAY - INSTALLATION, FUEL PUMP.....14-28

RELAY - INSTALLATION, INTAKE AIR

HEATER ............................14-82

RELAY - INSTALLATION, PARK LAMP.....8L-21

RELAY - INSTALLATION, REAR WINDOW

DEFOGGER..........................8G-4

RELAY - INSTALLATION, STARTER

MOTOR............................8F-37

RELAY - INSTALLATION, WIPER

HIGH/LOW..........................8R-22

RELAY - INSTALLATION, WIPER ON/OFF . . 8R-26

RELAY - OPERATION, A/C COMPRESSOR

CLUTCH.............................24-13

RELAY - OPERATION, FOG LAMP........8L-13

RELAY - OPERATION, FUEL HEATER......14-52

RELAY - OPERATION, FUEL PUMP.......14-27

RELAY - OPERATION, INTAKE AIR

HEATER ............................14-82

RELAY - OPERATION, PARK LAMP.......8L-20

RELAY - OPERATION, REAR WINDOW

DEFOGGER..........................8G-3

RELAY - OPERATION, STARTER MOTOR . . . 8F-36

RELAY - OPERATION, TRANSMISSION

CONTROL.........................21-405

RELAY - OPERATION, WIPER HIGH/LOW . . 8R-20

RELAY - OPERATION, WIPER ON/OFF....8R-25

RELAY - REMOVAL, A/C COMPRESSOR

CLUTCH............................24-14

RELAY - REMOVAL, FOG LAMP.........8L-13

RELAY - REMOVAL, FUEL HEATER.......14-52

RELAY - REMOVAL, FUEL PUMP........14-28

RELAY - REMOVAL, INTAKE AIR HEATER . . 14-82

RELAY - REMOVAL, PARK LAMP........8L-21

RELAY - REMOVAL, REAR WINDOW

DEFOGGER..........................8G-3

RELAY - REMOVAL, STARTER MOTOR....8F-37

RELAY - REMOVAL, WIPER HIGH/LOW . . . 8R-21

RELAY - REMOVAL, WIPER ON/OFF......8R-26

RELAYS - DIAGNOSIS AND TESTING,

ASD AND FUEL PUMP..................8I-5

RELEASE - INSTALLATION, TILT LEVER

KNOB..............................19-16

RELEASE - REMOVAL, TILT LEVER KNOB . . 19-16

RELEASE - STANDARD PROCEDURE,

FUEL SYSTEM PRESSURE..............14-2

RELEASE BEARING - INSTALLATION,

CLUTCH

.............................6-10

RELEASE BEARING - REMOVAL, CLUTCH

...6-9

RELEASE CABLE/HANDLE ASSEMBLY -

INSTALLATION, LATCH

................23-47

RELEASE CABLE/HANDLE ASSEMBLY -

REMOVAL, LATCH

....................23-47

RELEASE HANDLE - INSTALLATION

.......5-44

RELEASE HANDLE - REMOVAL

...........5-44

RELEASE HANDLE/LATCH REMOTE -

INSTALLATION

.......................23-17

RELEASE HANDLE/LATCH REMOTE -

REMOVAL

..........................23-17

RELIEF VALVE - CLEANING, OIL

PRESSURE

.........................9-294

RELIEF VALVE - DESCRIPTION, HIGH

PRESSURE

.........................24-48

RELIEF VALVE - INSPECTION, OIL

PRESSURE

.........................9-294

RELIEF VALVE - INSTALLATION, OIL

PRESSURE

.........................9-294

RELIEF VALVE - OPERATION, HIGH

PRESSURE

.........................24-48RELIEF VALVE - REMOVAL, OIL

PRESSURE.........................9-294

REMINDER PROGRAMMING -

STANDARD PROCEDURE, ENHANCED

SEATBELT..........................8J-35

REMOTE - INSTALLATION, RELEASE

HANDLE/LATCH......................23-17

REMOTE - REMOVAL, RELEASE

HANDLE/LATCH......................23-17

REMOTE KEYLESS ENTRY MODULE -

DESCRIPTION........................8N-7

REMOTE KEYLESS ENTRY MODULE -

DIAGNOSIS AND TESTING..............8N-7

REMOTE KEYLESS ENTRY MODULE -

INSTALLATION.......................8N-8

REMOTE KEYLESS ENTRY MODULE -

OPERATION..........................8N-7

REMOTE KEYLESS ENTRY MODULE -

REMOVAL...........................8N-7

REMOTE KEYLESS ENTRY

TRANSMITTER - DIAGNOSIS AND

TESTING............................8N-8

REMOTE KEYLESS ENTRY

TRANSMITTER - SPECIFICATIONS........8N-9

REMOTE SWITCHES - DESCRIPTION.....8A-10

REMOTE SWITCHES - DIAGNOSIS AND

TESTING...........................8A-11

REMOTE SWITCHES - INSTALLATION.....8A-12

REMOTE SWITCHES - OPERATION.......8A-11

REMOTE SWITCHES - REMOVAL........8A-12

REMOVAL/INSTALLATION, REMOVAL.....25-13

REMOVAL/INSTALLATION, REMOVAL.....14-52,

14-57,14-66

REPAIR - DESCRIPTION, THREADED

HOLE.............................Intro.-8

REPAIR - STANDARD PROCEDURE,

ALUMINUM THREAD...........21-158,21-318

REPAIR - STANDARD PROCEDURE, CAM

BORE..............................9-267

REPAIR - STANDARD PROCEDURE,

CYLINDER BORE.....................9-265

REPAIR - STANDARD PROCEDURE, GRID

LINE AND TERMINAL..................8G-4

REPAIR - STANDARD PROCEDURE,

HYDROFORM FENDER RAIL............13-11

REPAIR - STANDARD PROCEDURE,

PLASTIC BODY PANEL.................23-3

REPAIR DAMAGED OR WORN THREADS

- STANDARD PROCEDURE . 9-190,9-240,9-9,9-94

REPAIRING LEAKS - STANDARD

PROCEDURE........................22-10

REQUIREMENTS - DESCRIPTION,

ENGINE COOLING SYSTEM..............24-1

REQUIREMENTS - DIESEL ENGINE -

DESCRIPTION, FUEL....................0-1

RESERVOIR - DESCRIPTION, VACUUM....8P-9

RESERVOIR - DESCRIPTION, WASHER . . . 8R-14

RESERVOIR - DIAGNOSIS AND TESTING,

VACUUM............................8P-9

RESERVOIR - INSTALLATION...........19-47

RESERVOIR - INSTALLATION, FLUID......5-24

RESERVOIR - INSTALLATION, VACUUM . . . 8P-10

RESERVOIR - OPERATION, VACUUM......8P-9

RESERVOIR - OPERATION, WASHER.....8R-15

RESERVOIR - REMOVAL...............19-47

RESERVOIR - REMOVAL, FLUID..........5-23

RESERVOIR - REMOVAL, VACUUM........8P-9

RESERVOIR TO COOLER -

INSTALLATION, RETURN HOSE.....19-44,19-45

RESERVOIR TO COOLER - REMOVAL,

RETURN HOSE.................19-44,19-45

RESISTANCE, 3.7L V-6 - IGNITION COIL....8I-5

RESISTANCE, 4.7L V-8 - IGNITION COIL....8I-5

RESISTANCE, 5.7L V-8 - IGNITION COIL....8I-5

RESISTANCE, SPECIFICATIONS - SPARK

PLUG CABLE.........................8I-4

RESISTOR BLOCK - DESCRIPTION,

BLOWER MOTOR....................24-18

RESISTOR BLOCK - DIAGNOSIS AND

TESTING, BLOWER MOTOR

............24-19

RESISTOR BLOCK - INSTALLATION,

BLOWER MOTOR

....................24-19

RESISTOR BLOCK - OPERATION,

BLOWER MOTOR

....................24-18

RESISTOR BLOCK - REMOVAL, BLOWER

MOTOR

............................24-19

RESTRAINT ANCHOR - DESCRIPTION,

CHILD

.............................8O-15RESTRAINT ANCHOR - INSTALLATION,

CHILD.............................8O-18

RESTRAINT ANCHOR - OPERATION,

CHILD.............................8O-17

RESTRAINT ANCHOR - REMOVAL, CHILD . 8O-17

RESTRAINT DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A

SUPPLEMENTAL......................8O-7

RESTRAINT SYSTEM - DIAGNOSIS AND

TESTING, SUPPLEMENTAL..............8O-6

RESTRAINT SYSTEM - WARNINGS.......8O-5

RESTRAINTS - DESCRIPTION............8O-2

RESTRAINTS - OPERATION.............8O-4

RESTRAINTS - STANDARD PROCEDURE,

HANDLING NON-DEPLOYED

SUPPLEMENTAL......................8O-6

RETAINER - ASSEMBLY, OVERRUNNING

CLUTCH CAM/OVERDRIVE PISTON......21-237

RETAINER - CLEANING, OVERRUNNING

CLUTCH CAM/OVERDRIVE PISTON......21-236

RETAINER - DESCRIPTION,

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON.................21-236

RETAINER - DISASSEMBLY,

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON.................21-236

RETAINER - INSPECTION,

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON.................21-237

RETAINER - INSTALLATION, A-PILLAR

WEATHERSTRIP.....................23-91

RETAINER - INSTALLATION,

CRANKSHAFT REAR OIL SEAL.....9-210,9-277

RETAINER - INSTALLATION, DRIP RAIL

WEATHERSTRIP.....................23-92

RETAINER - OPERATION, OVERRUNNING

CLUTCH CAM/OVERDRIVE PISTON......21-236

RETAINER - REMOVAL, A-PILLAR

WEATHERSTRIP.....................23-91

RETAINER - REMOVAL, CRANKSHAFT

REAR OIL SEAL.................9-209,9-277

RETAINER - REMOVAL, DRIP RAIL

WEATHERSTRIP.....................23-92

RETAINER/BULKHEAD - ASSEMBLY, 4C . . 21-363

RETAINER/BULKHEAD - DISASSEMBLY,

4C ...............................21-362

RETRACTOR - DESCRIPTION,

AUTOMATIC LOCKING.................8O-14

RETRACTOR - INSTALLATION, FRONT

CENTER SEAT BELT..................8O-29

RETRACTOR - INSTALLATION, REAR

CENTER SEAT BELT..................8O-45

RETRACTOR - INSTALLATION, REAR

OUTBOARD SEAT BELT................8O-47

RETRACTOR - OPERATION, AUTOMATIC

LOCKING...........................8O-14

RETRACTOR - REMOVAL, FRONT

CENTER SEAT BELT..................8O-29

RETRACTOR - REMOVAL, REAR CENTER

SEAT BELT .........................8O-44

RETRACTOR - REMOVAL, REAR

OUTBOARD SEAT BELT................8O-46

RETURN - DESCRIPTION, SENSOR.......8E-10

RETURN HOSE - GEAR TO COOLER -

INSTALLATION..................19-44,19-45

RETURN HOSE - GEAR TO COOLER -

REMOVAL.....................19-44,19-45

RETURN HOSE - INSTALLATION, HEATER . 24-65

RETURN HOSE - REMOVAL, HEATER.....24-64

RETURN HOSE - RESERVOIR TO

COOLER - INSTALLATION.........19-44,19-45

RETURN HOSE - RESERVOIR TO

COOLER - REMOVAL.............19-44,19-45

REVOLUTIONS PER MILE,

SPECIFICATIONS - TIRE...............22-10

RFE TRANSMISSION, SPECIAL TOOLS . . . 21-359

RING - INSTALLATION, PINION

GEAR/RING GEAR/TONE.....3-108,3-137,3-164

RING - REMOVAL, PINION GEAR/RING

GEAR/TONE...............3-106,3-134,3-162

RING FITTING - STANDARD

PROCEDURE, PISTON . . . 9-142,9-213,9-284,9-53

RINGS - ASSEMBLY, WITH INJECTED

......3-13

RINGS - ASSEMBLY, WITH SNAP

.........3-12

RINGS - DISASSEMBLY, WITH INJECTED

. . . 3-11

RINGS - DISASSEMBLY, WITH SNAP

......3-10

RKE TRANSMITTER BATTERIES -

STANDARD PROCEDURE

...............8N-8

DRINDEX 27

Description Group-Page Description Group-Page Description Group-Page