Y case DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2267 of 2627

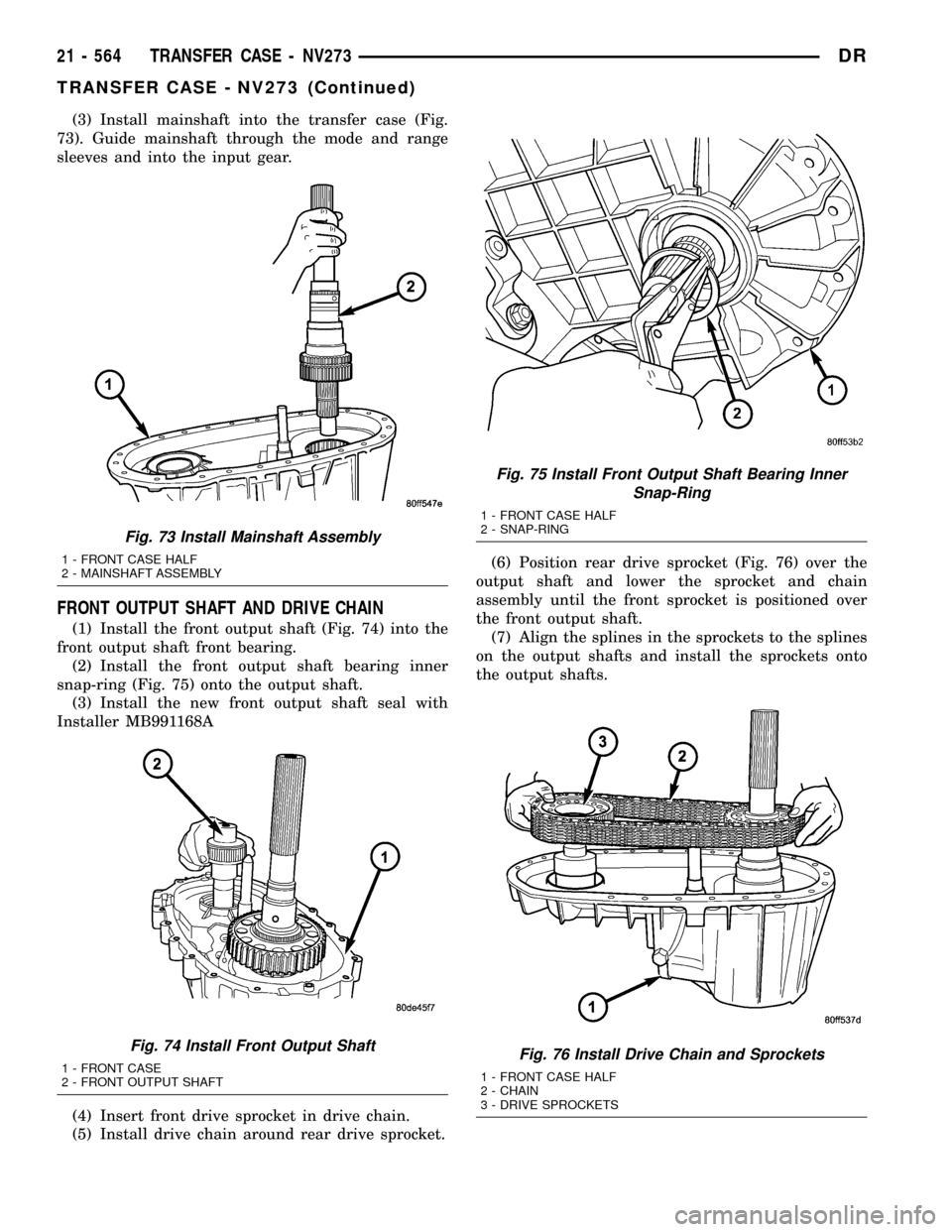

(3) Install mainshaft into the transfer case (Fig.

73). Guide mainshaft through the mode and range

sleeves and into the input gear.

FRONT OUTPUT SHAFT AND DRIVE CHAIN

(1) Install the front output shaft (Fig. 74) into the

front output shaft front bearing.

(2) Install the front output shaft bearing inner

snap-ring (Fig. 75) onto the output shaft.

(3) Install the new front output shaft seal with

Installer MB991168A

(4) Insert front drive sprocket in drive chain.

(5) Install drive chain around rear drive sprocket.(6) Position rear drive sprocket (Fig. 76) over the

output shaft and lower the sprocket and chain

assembly until the front sprocket is positioned over

the front output shaft.

(7) Align the splines in the sprockets to the splines

on the output shafts and install the sprockets onto

the output shafts.

Fig. 73 Install Mainshaft Assembly

1 - FRONT CASE HALF

2 - MAINSHAFT ASSEMBLY

Fig. 74 Install Front Output Shaft

1 - FRONT CASE

2 - FRONT OUTPUT SHAFT

Fig. 75 Install Front Output Shaft Bearing Inner

Snap-Ring

1 - FRONT CASE HALF

2 - SNAP-RING

Fig. 76 Install Drive Chain and Sprockets

1 - FRONT CASE HALF

2 - CHAIN

3 - DRIVE SPROCKETS

21 - 564 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)

Page 2268 of 2627

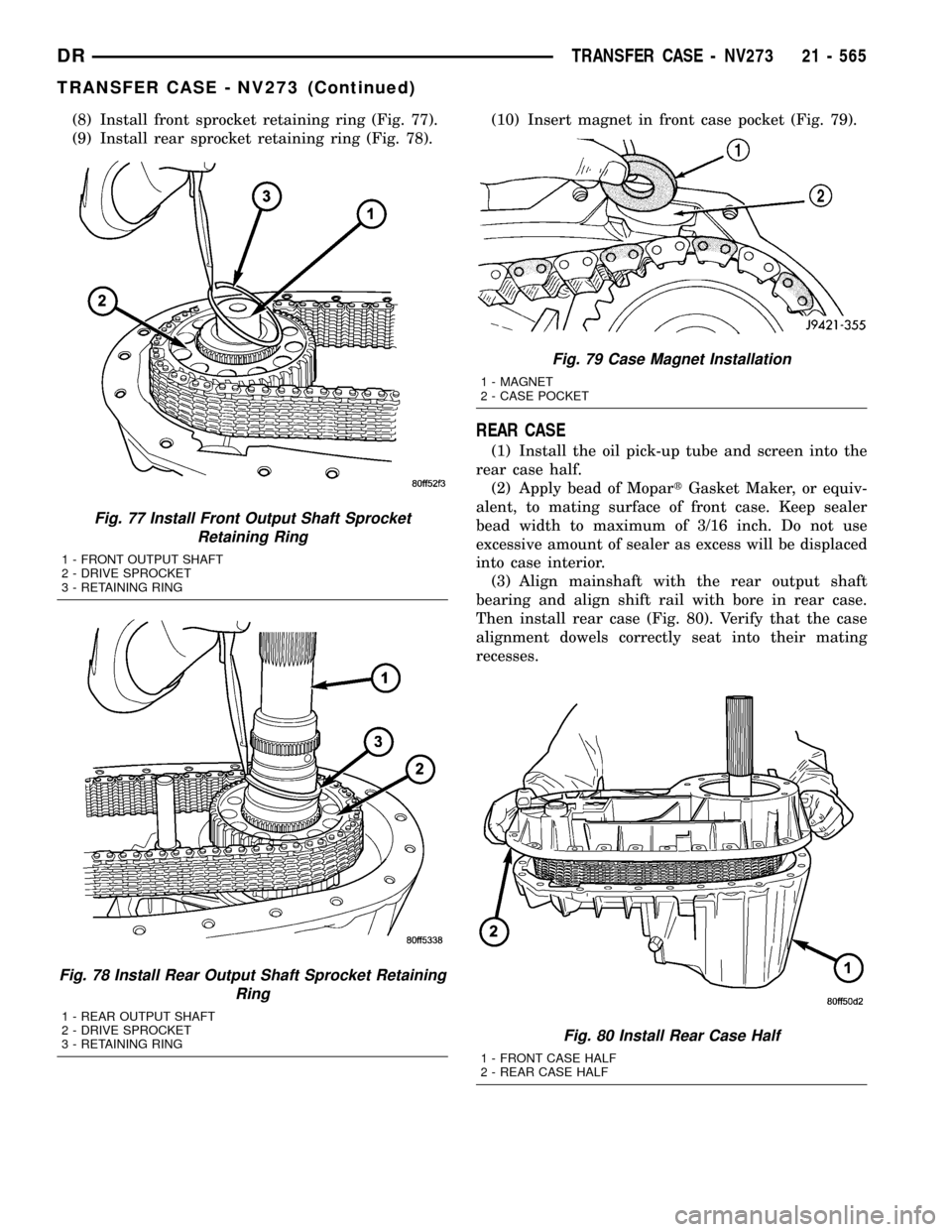

(8) Install front sprocket retaining ring (Fig. 77).

(9) Install rear sprocket retaining ring (Fig. 78).(10) Insert magnet in front case pocket (Fig. 79).

REAR CASE

(1) Install the oil pick-up tube and screen into the

rear case half.

(2) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of front case. Keep sealer

bead width to maximum of 3/16 inch. Do not use

excessive amount of sealer as excess will be displaced

into case interior.

(3) Align mainshaft with the rear output shaft

bearing and align shift rail with bore in rear case.

Then install rear case (Fig. 80). Verify that the case

alignment dowels correctly seat into their mating

recesses.

Fig. 77 Install Front Output Shaft Sprocket

Retaining Ring

1 - FRONT OUTPUT SHAFT

2 - DRIVE SPROCKET

3 - RETAINING RING

Fig. 78 Install Rear Output Shaft Sprocket Retaining

Ring

1 - REAR OUTPUT SHAFT

2 - DRIVE SPROCKET

3 - RETAINING RING

Fig. 79 Case Magnet Installation

1 - MAGNET

2 - CASE POCKET

Fig. 80 Install Rear Case Half

1 - FRONT CASE HALF

2 - REAR CASE HALF

DRTRANSFER CASE - NV273 21 - 565

TRANSFER CASE - NV273 (Continued)

Page 2269 of 2627

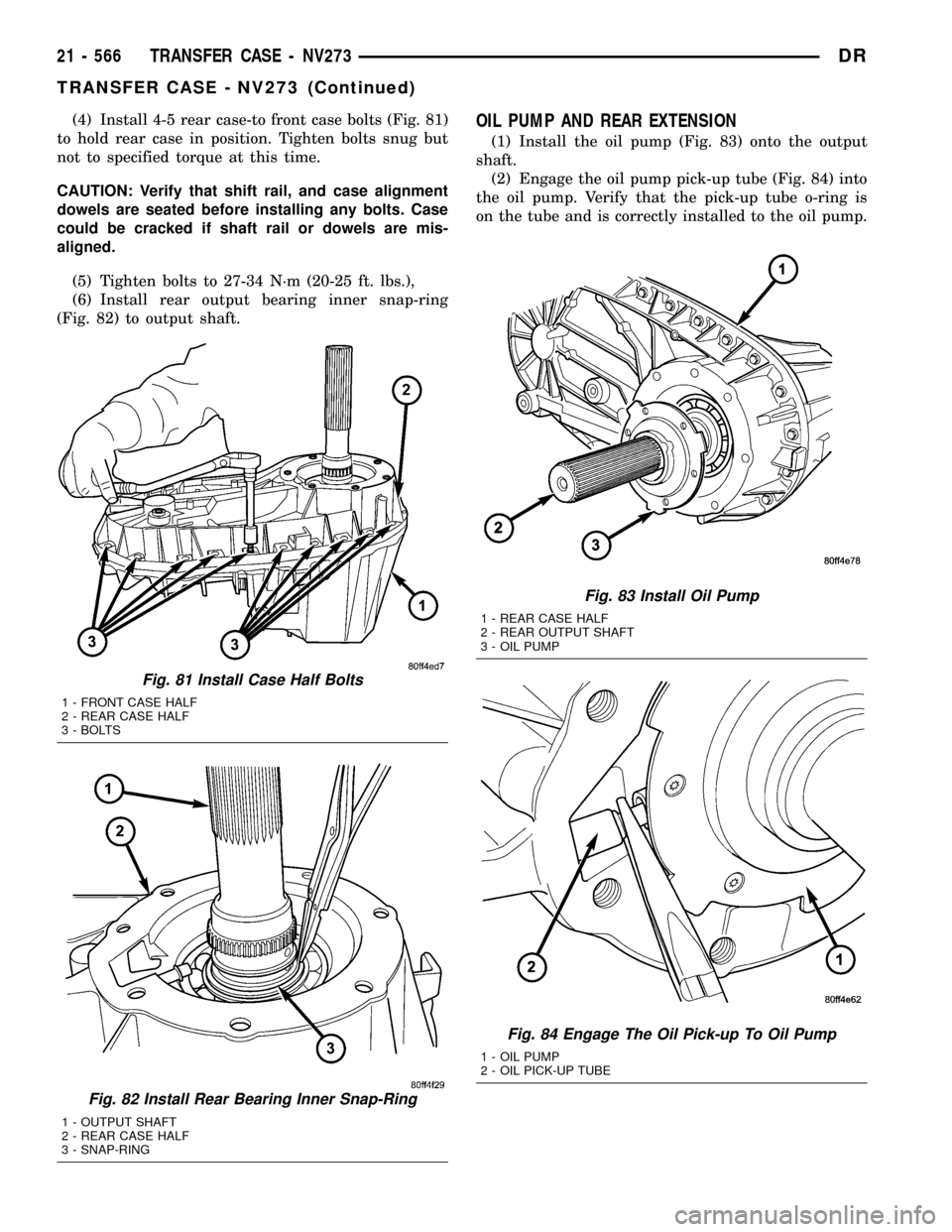

(4) Install 4-5 rear case-to front case bolts (Fig. 81)

to hold rear case in position. Tighten bolts snug but

not to specified torque at this time.

CAUTION: Verify that shift rail, and case alignment

dowels are seated before installing any bolts. Case

could be cracked if shaft rail or dowels are mis-

aligned.

(5) Tighten bolts to 27-34 N´m (20-25 ft. lbs.),

(6) Install rear output bearing inner snap-ring

(Fig. 82) to output shaft.OIL PUMP AND REAR EXTENSION

(1) Install the oil pump (Fig. 83) onto the output

shaft.

(2) Engage the oil pump pick-up tube (Fig. 84) into

the oil pump. Verify that the pick-up tube o-ring is

on the tube and is correctly installed to the oil pump.

Fig. 81 Install Case Half Bolts

1 - FRONT CASE HALF

2 - REAR CASE HALF

3 - BOLTS

Fig. 82 Install Rear Bearing Inner Snap-Ring

1 - OUTPUT SHAFT

2 - REAR CASE HALF

3 - SNAP-RING

Fig. 83 Install Oil Pump

1 - REAR CASE HALF

2 - REAR OUTPUT SHAFT

3 - OIL PUMP

Fig. 84 Engage The Oil Pick-up To Oil Pump

1 - OIL PUMP

2 - OIL PICK-UP TUBE

21 - 566 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)

Page 2270 of 2627

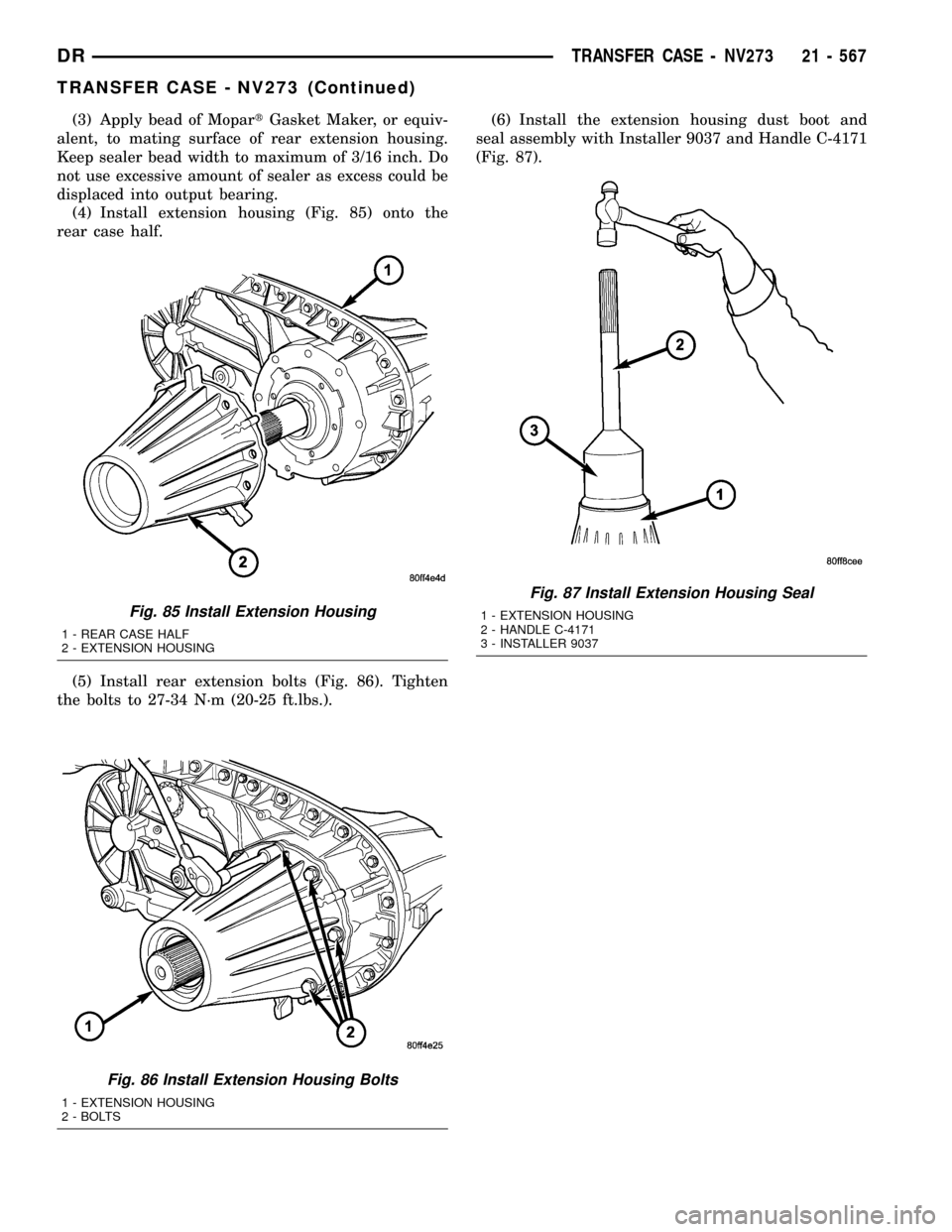

(3) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of rear extension housing.

Keep sealer bead width to maximum of 3/16 inch. Do

not use excessive amount of sealer as excess could be

displaced into output bearing.

(4) Install extension housing (Fig. 85) onto the

rear case half.

(5) Install rear extension bolts (Fig. 86). Tighten

the bolts to 27-34 N´m (20-25 ft.lbs.).(6) Install the extension housing dust boot and

seal assembly with Installer 9037 and Handle C-4171

(Fig. 87).

Fig. 85 Install Extension Housing

1 - REAR CASE HALF

2 - EXTENSION HOUSING

Fig. 86 Install Extension Housing Bolts

1 - EXTENSION HOUSING

2 - BOLTS

Fig. 87 Install Extension Housing Seal

1 - EXTENSION HOUSING

2 - HANDLE C-4171

3 - INSTALLER 9037

DRTRANSFER CASE - NV273 21 - 567

TRANSFER CASE - NV273 (Continued)

Page 2271 of 2627

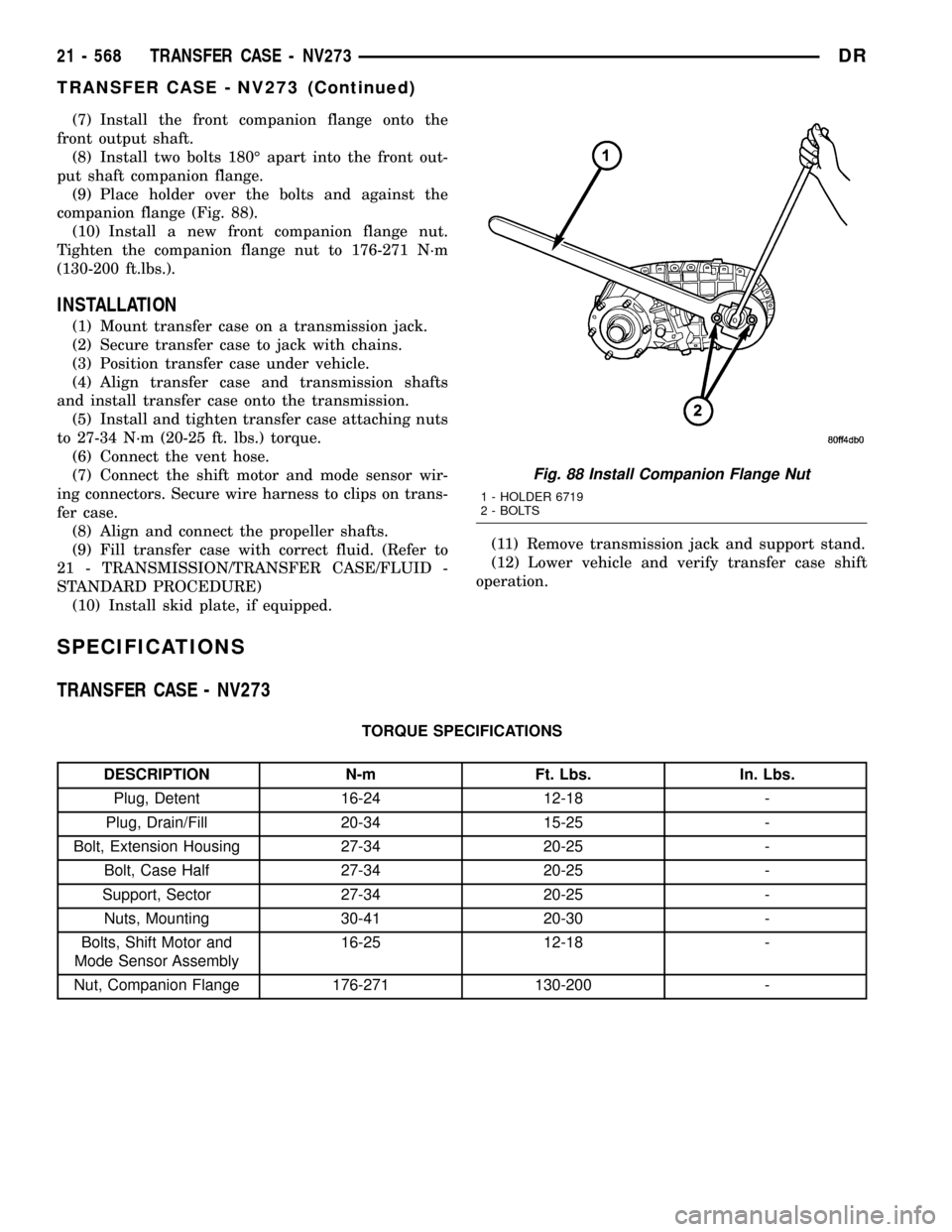

(7) Install the front companion flange onto the

front output shaft.

(8) Install two bolts 180É apart into the front out-

put shaft companion flange.

(9) Place holder over the bolts and against the

companion flange (Fig. 88).

(10) Install a new front companion flange nut.

Tighten the companion flange nut to 176-271 N´m

(130-200 ft.lbs.).

INSTALLATION

(1) Mount transfer case on a transmission jack.

(2) Secure transfer case to jack with chains.

(3) Position transfer case under vehicle.

(4) Align transfer case and transmission shafts

and install transfer case onto the transmission.

(5) Install and tighten transfer case attaching nuts

to 27-34 N´m (20-25 ft. lbs.) torque.

(6) Connect the vent hose.

(7) Connect the shift motor and mode sensor wir-

ing connectors. Secure wire harness to clips on trans-

fer case.

(8) Align and connect the propeller shafts.

(9) Fill transfer case with correct fluid. (Refer to

21 - TRANSMISSION/TRANSFER CASE/FLUID -

STANDARD PROCEDURE)

(10) Install skid plate, if equipped.(11) Remove transmission jack and support stand.

(12) Lower vehicle and verify transfer case shift

operation.

SPECIFICATIONS

TRANSFER CASE - NV273

TORQUE SPECIFICATIONS

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Plug, Detent 16-24 12-18 -

Plug, Drain/Fill 20-34 15-25 -

Bolt, Extension Housing 27-34 20-25 -

Bolt, Case Half 27-34 20-25 -

Support, Sector 27-34 20-25 -

Nuts, Mounting 30-41 20-30 -

Bolts, Shift Motor and

Mode Sensor Assembly16-25 12-18 -

Nut, Companion Flange 176-271 130-200 -

Fig. 88 Install Companion Flange Nut

1 - HOLDER 6719

2 - BOLTS

21 - 568 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)

Page 2272 of 2627

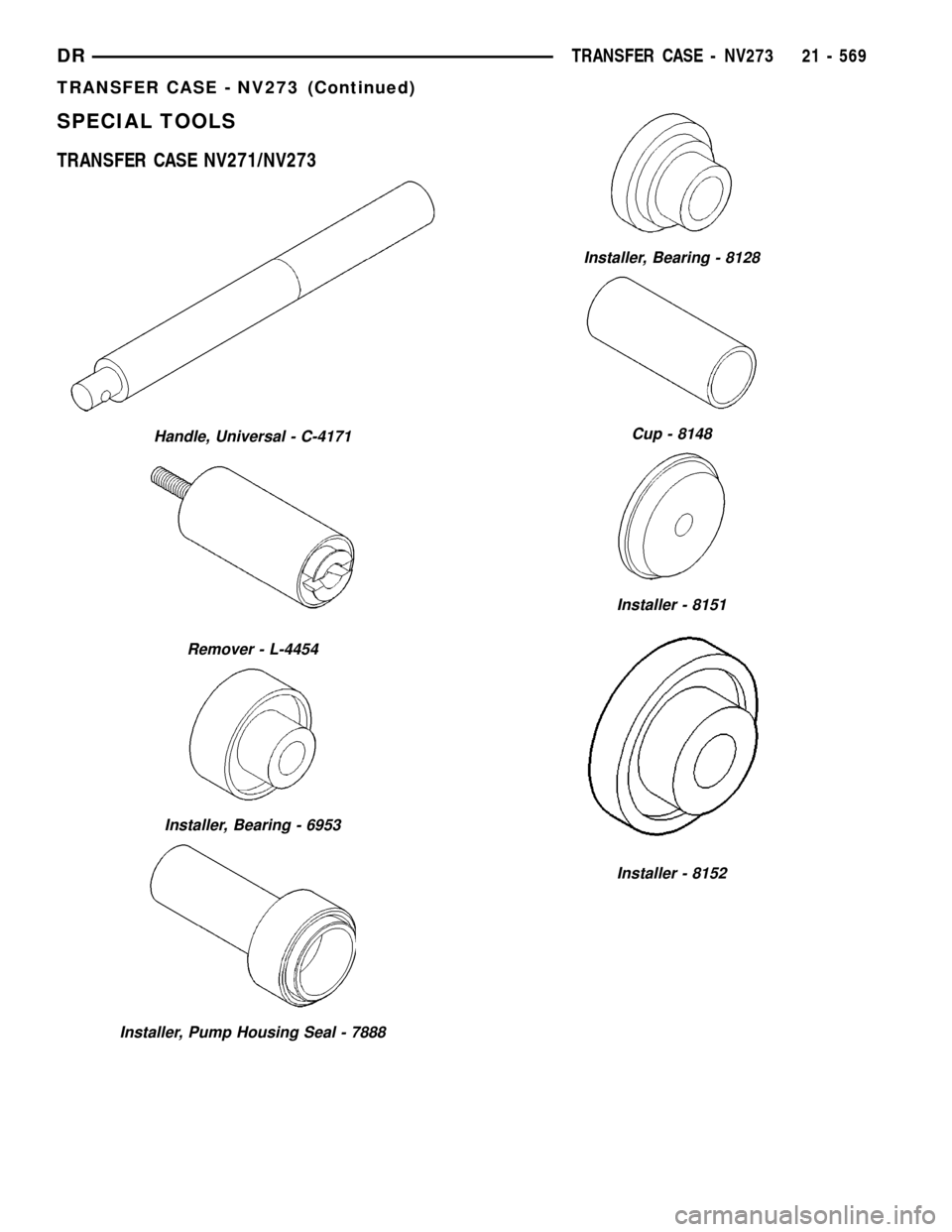

SPECIAL TOOLS

TRANSFER CASE NV271/NV273

Handle, Universal - C-4171

Remover - L-4454

Installer, Bearing - 6953

Installer, Pump Housing Seal - 7888

Installer, Bearing - 8128

Cup - 8148

Installer - 8151

Installer - 8152

DRTRANSFER CASE - NV273 21 - 569

TRANSFER CASE - NV273 (Continued)

Page 2273 of 2627

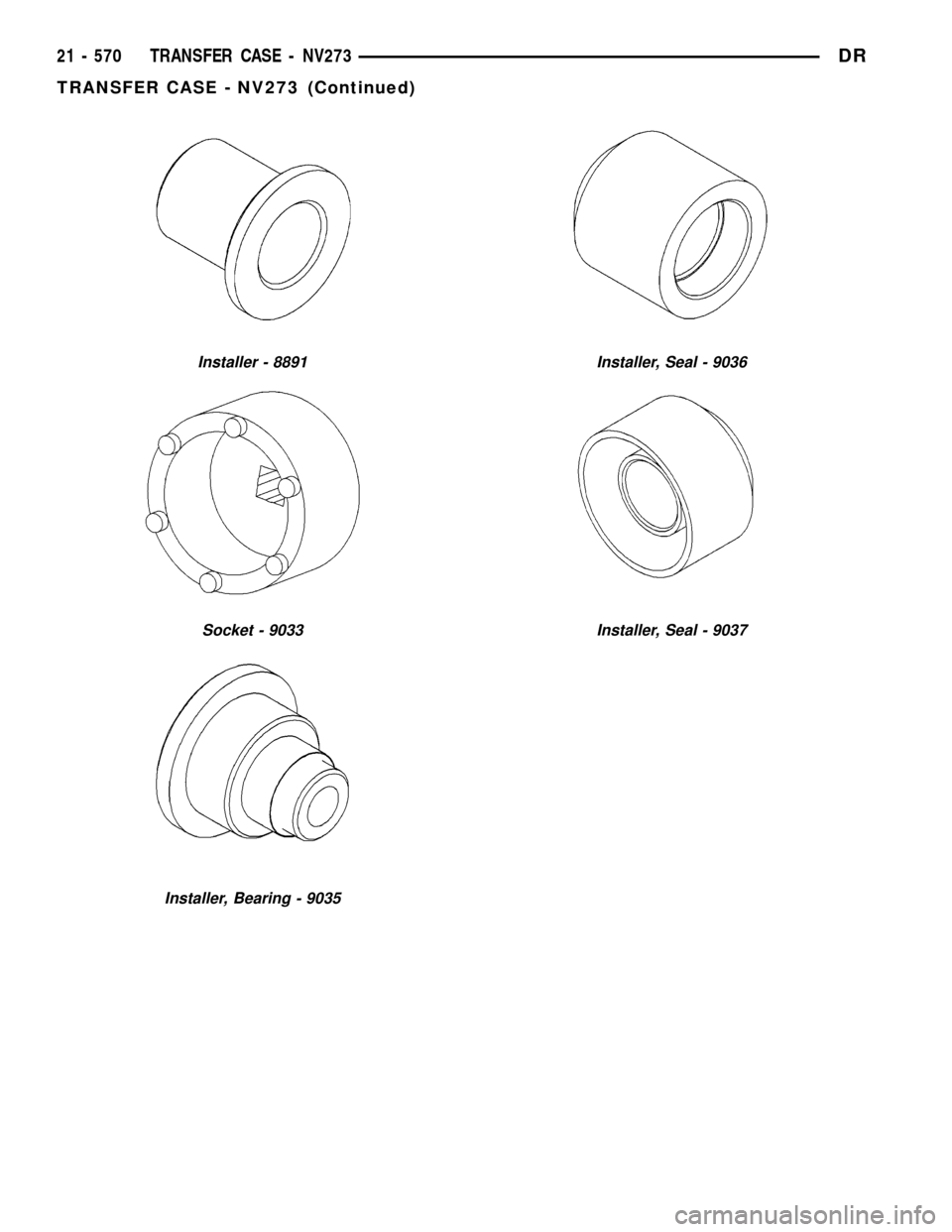

Installer - 8891

Socket - 9033

Installer, Bearing - 9035

Installer, Seal - 9036

Installer, Seal - 9037

21 - 570 TRANSFER CASE - NV273DR

TRANSFER CASE - NV273 (Continued)

Page 2274 of 2627

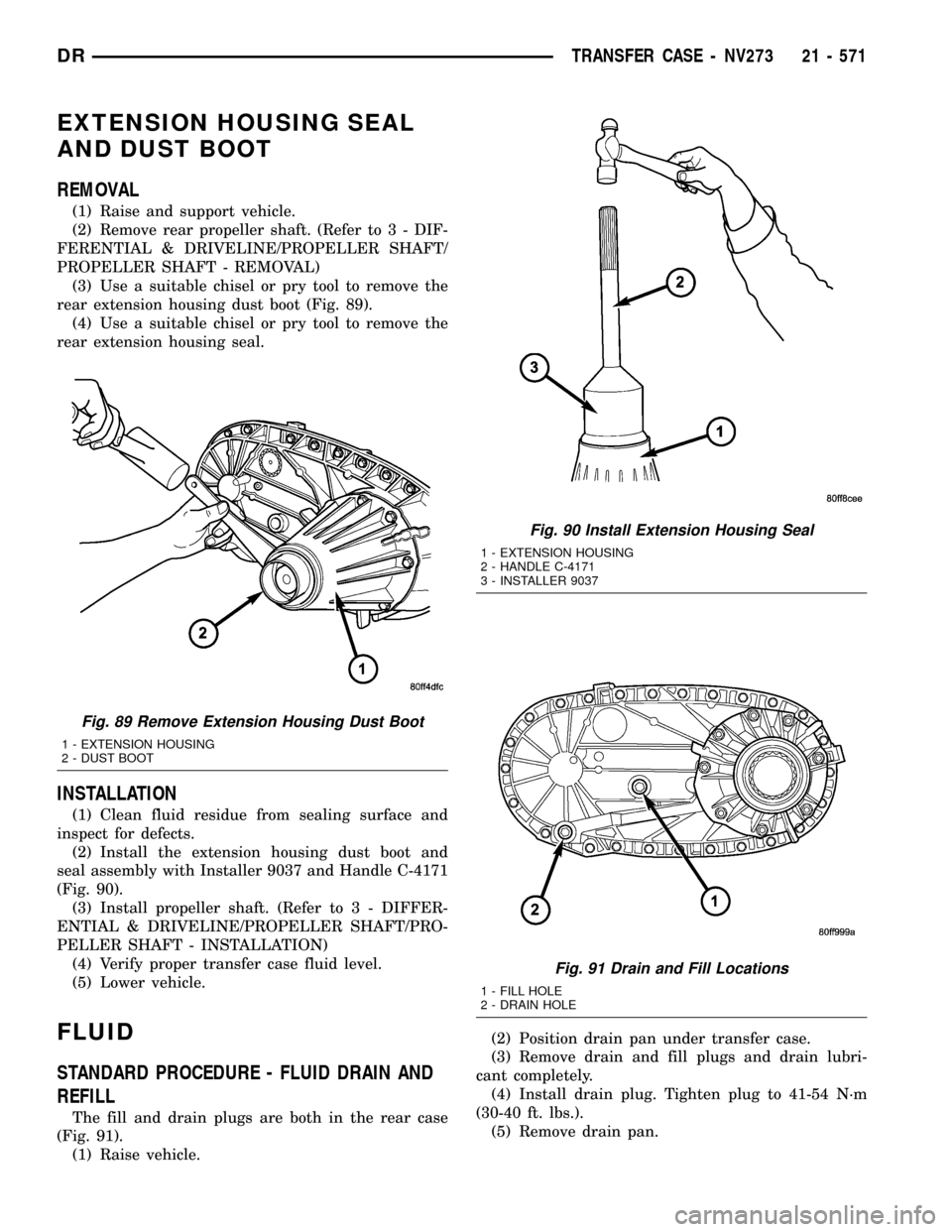

EXTENSION HOUSING SEAL

AND DUST BOOT

REMOVAL

(1) Raise and support vehicle.

(2) Remove rear propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Use a suitable chisel or pry tool to remove the

rear extension housing dust boot (Fig. 89).

(4) Use a suitable chisel or pry tool to remove the

rear extension housing seal.

INSTALLATION

(1) Clean fluid residue from sealing surface and

inspect for defects.

(2) Install the extension housing dust boot and

seal assembly with Installer 9037 and Handle C-4171

(Fig. 90).

(3) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - INSTALLATION)

(4) Verify proper transfer case fluid level.

(5) Lower vehicle.

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL

The fill and drain plugs are both in the rear case

(Fig. 91).

(1) Raise vehicle.(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 41-54 N´m

(30-40 ft. lbs.).

(5) Remove drain pan.

Fig. 89 Remove Extension Housing Dust Boot

1 - EXTENSION HOUSING

2 - DUST BOOT

Fig. 90 Install Extension Housing Seal

1 - EXTENSION HOUSING

2 - HANDLE C-4171

3 - INSTALLER 9037

Fig. 91 Drain and Fill Locations

1 - FILL HOLE

2 - DRAIN HOLE

DRTRANSFER CASE - NV273 21 - 571

Page 2275 of 2627

(6) Fill transfer case to bottom edge of fill plug

opening with MopartATF +4, Automatic Transmis-

sion fluid.

(7) Install and tighten fill plug to 41-54 N´m

(30-40 ft. lbs.).

(8) Lower vehicle.

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Remove the front propeller shaft (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL).

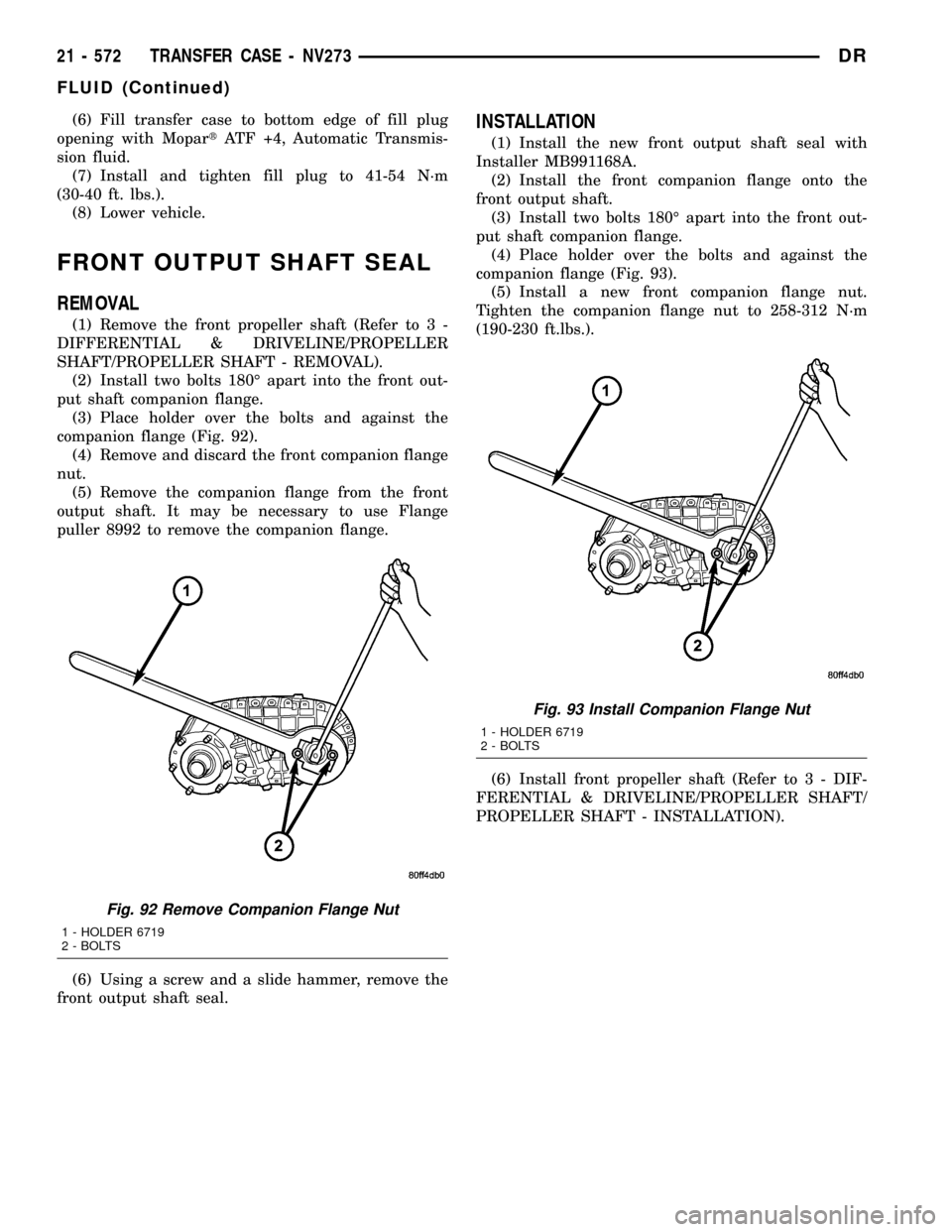

(2) Install two bolts 180É apart into the front out-

put shaft companion flange.

(3) Place holder over the bolts and against the

companion flange (Fig. 92).

(4) Remove and discard the front companion flange

nut.

(5) Remove the companion flange from the front

output shaft. It may be necessary to use Flange

puller 8992 to remove the companion flange.

(6) Using a screw and a slide hammer, remove the

front output shaft seal.

INSTALLATION

(1) Install the new front output shaft seal with

Installer MB991168A.

(2) Install the front companion flange onto the

front output shaft.

(3) Install two bolts 180É apart into the front out-

put shaft companion flange.

(4) Place holder over the bolts and against the

companion flange (Fig. 93).

(5) Install a new front companion flange nut.

Tighten the companion flange nut to 258-312 N´m

(190-230 ft.lbs.).

(6) Install front propeller shaft (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION).

Fig. 92 Remove Companion Flange Nut

1 - HOLDER 6719

2 - BOLTS

Fig. 93 Install Companion Flange Nut

1 - HOLDER 6719

2 - BOLTS

21 - 572 TRANSFER CASE - NV273DR

FLUID (Continued)

Page 2276 of 2627

MODE SENSOR

DESCRIPTION

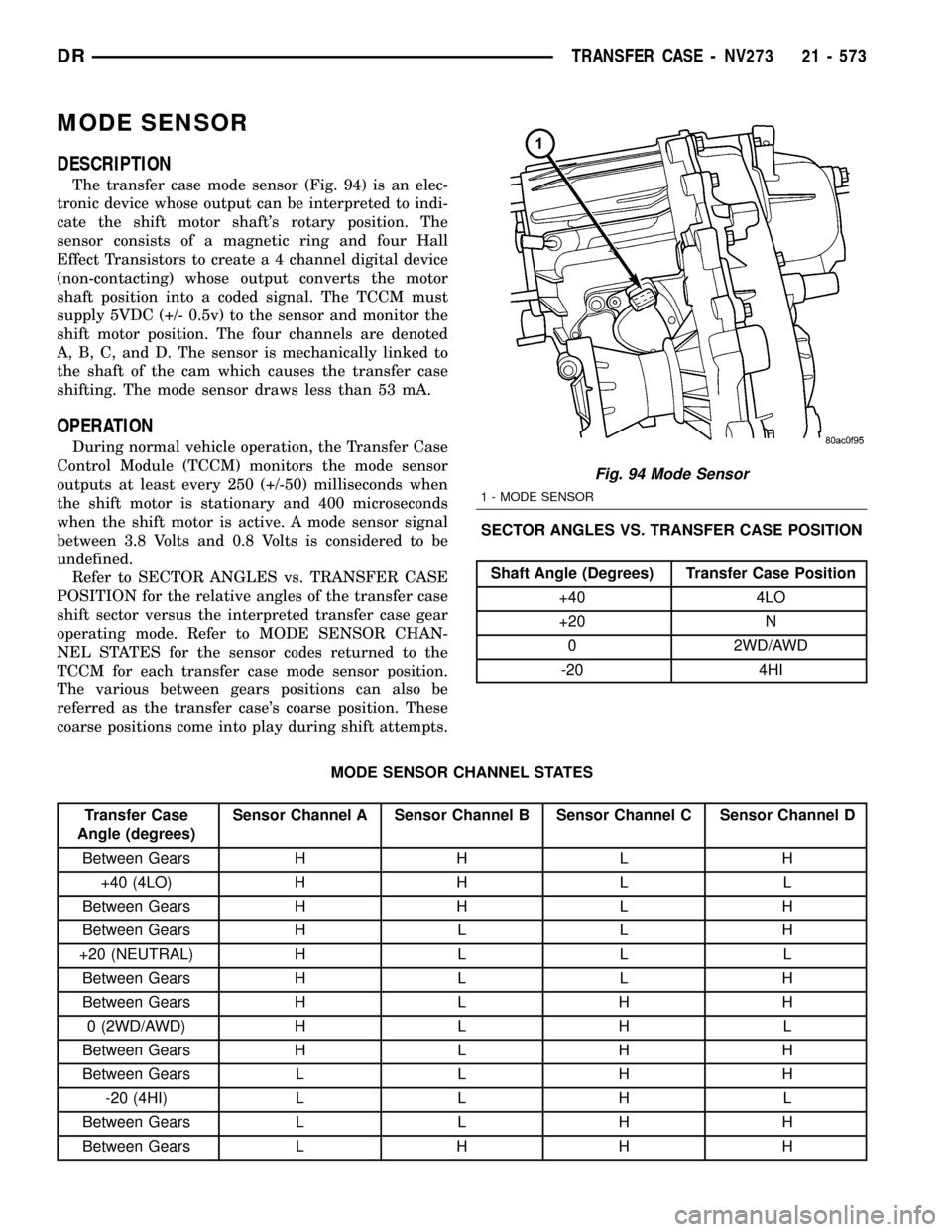

The transfer case mode sensor (Fig. 94) is an elec-

tronic device whose output can be interpreted to indi-

cate the shift motor shaft's rotary position. The

sensor consists of a magnetic ring and four Hall

Effect Transistors to create a 4 channel digital device

(non-contacting) whose output converts the motor

shaft position into a coded signal. The TCCM must

supply 5VDC (+/- 0.5v) to the sensor and monitor the

shift motor position. The four channels are denoted

A, B, C, and D. The sensor is mechanically linked to

the shaft of the cam which causes the transfer case

shifting. The mode sensor draws less than 53 mA.

OPERATION

During normal vehicle operation, the Transfer Case

Control Module (TCCM) monitors the mode sensor

outputs at least every 250 (+/-50) milliseconds when

the shift motor is stationary and 400 microseconds

when the shift motor is active. A mode sensor signal

between 3.8 Volts and 0.8 Volts is considered to be

undefined.

Refer to SECTOR ANGLES vs. TRANSFER CASE

POSITION for the relative angles of the transfer case

shift sector versus the interpreted transfer case gear

operating mode. Refer to MODE SENSOR CHAN-

NEL STATES for the sensor codes returned to the

TCCM for each transfer case mode sensor position.

The various between gears positions can also be

referred as the transfer case's coarse position. These

coarse positions come into play during shift attempts.SECTOR ANGLES VS. TRANSFER CASE POSITION

Shaft Angle (Degrees) Transfer Case Position

+40 4LO

+20 N

0 2WD/AWD

-20 4HI

MODE SENSOR CHANNEL STATES

Transfer Case

Angle (degrees)Sensor Channel A Sensor Channel B Sensor Channel C Sensor Channel D

Between Gears H H L H

+40 (4LO) H H L L

Between Gears H H L H

Between Gears H L L H

+20 (NEUTRAL) H L L L

Between Gears H L L H

Between Gears H L H H

0 (2WD/AWD) H L H L

Between Gears H L H H

Between Gears L L H H

-20 (4HI) L L H L

Between Gears L L H H

Between Gears L H H H

Fig. 94 Mode Sensor

1 - MODE SENSOR

DRTRANSFER CASE - NV273 21 - 573