Front Differential DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 297 of 2627

REMOVAL

(1) Remove the front rotor (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

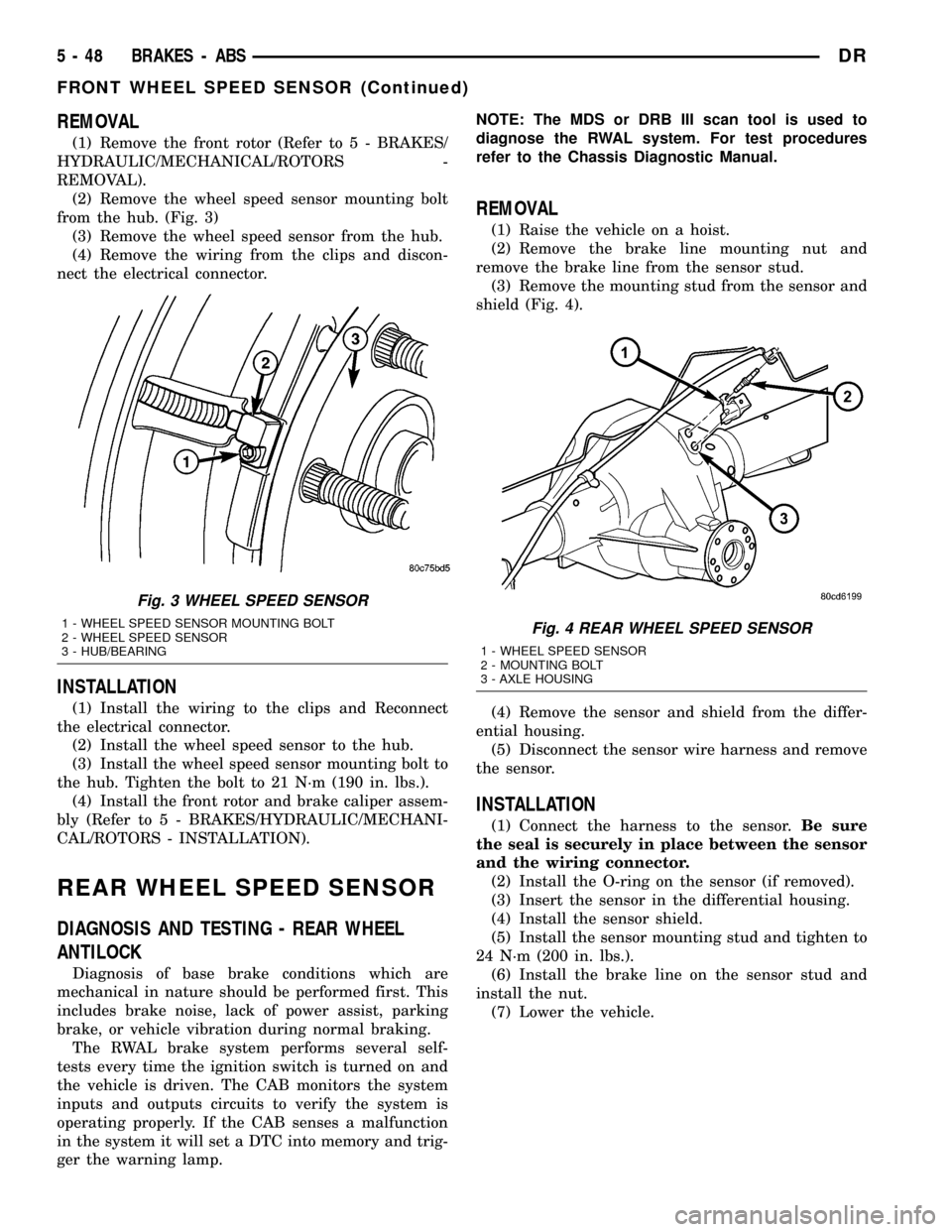

(2) Remove the wheel speed sensor mounting bolt

from the hub. (Fig. 3)

(3) Remove the wheel speed sensor from the hub.

(4) Remove the wiring from the clips and discon-

nect the electrical connector.

INSTALLATION

(1) Install the wiring to the clips and Reconnect

the electrical connector.

(2) Install the wheel speed sensor to the hub.

(3) Install the wheel speed sensor mounting bolt to

the hub. Tighten the bolt to 21 N´m (190 in. lbs.).

(4) Install the front rotor and brake caliper assem-

bly (Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/ROTORS - INSTALLATION).

REAR WHEEL SPEED SENSOR

DIAGNOSIS AND TESTING - REAR WHEEL

ANTILOCK

Diagnosis of base brake conditions which are

mechanical in nature should be performed first. This

includes brake noise, lack of power assist, parking

brake, or vehicle vibration during normal braking.

The RWAL brake system performs several self-

tests every time the ignition switch is turned on and

the vehicle is driven. The CAB monitors the system

inputs and outputs circuits to verify the system is

operating properly. If the CAB senses a malfunction

in the system it will set a DTC into memory and trig-

ger the warning lamp.NOTE: The MDS or DRB III scan tool is used to

diagnose the RWAL system. For test procedures

refer to the Chassis Diagnostic Manual.

REMOVAL

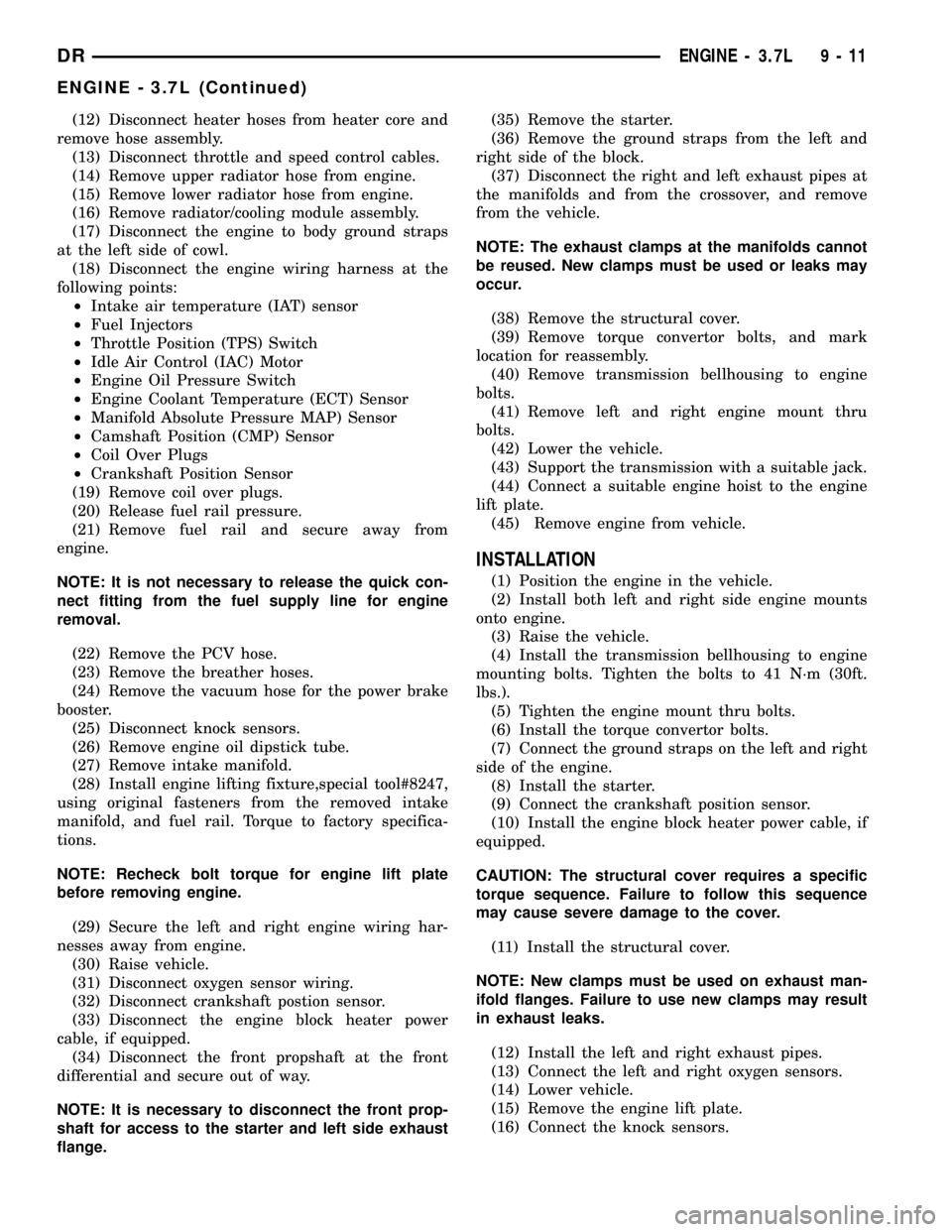

(1) Raise the vehicle on a hoist.

(2) Remove the brake line mounting nut and

remove the brake line from the sensor stud.

(3) Remove the mounting stud from the sensor and

shield (Fig. 4).

(4) Remove the sensor and shield from the differ-

ential housing.

(5) Disconnect the sensor wire harness and remove

the sensor.

INSTALLATION

(1) Connect the harness to the sensor.Be sure

the seal is securely in place between the sensor

and the wiring connector.

(2) Install the O-ring on the sensor (if removed).

(3) Insert the sensor in the differential housing.

(4) Install the sensor shield.

(5) Install the sensor mounting stud and tighten to

24 N´m (200 in. lbs.).

(6) Install the brake line on the sensor stud and

install the nut.

(7) Lower the vehicle.

Fig. 3 WHEEL SPEED SENSOR

1 - WHEEL SPEED SENSOR MOUNTING BOLT

2 - WHEEL SPEED SENSOR

3 - HUB/BEARINGFig. 4 REAR WHEEL SPEED SENSOR

1 - WHEEL SPEED SENSOR

2 - MOUNTING BOLT

3 - AXLE HOUSING

5 - 48 BRAKES - ABSDR

FRONT WHEEL SPEED SENSOR (Continued)

Page 1234 of 2627

(12) Disconnect heater hoses from heater core and

remove hose assembly.

(13) Disconnect throttle and speed control cables.

(14) Remove upper radiator hose from engine.

(15) Remove lower radiator hose from engine.

(16) Remove radiator/cooling module assembly.

(17) Disconnect the engine to body ground straps

at the left side of cowl.

(18) Disconnect the engine wiring harness at the

following points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(19) Remove coil over plugs.

(20) Release fuel rail pressure.

(21) Remove fuel rail and secure away from

engine.

NOTE: It is not necessary to release the quick con-

nect fitting from the fuel supply line for engine

removal.

(22) Remove the PCV hose.

(23) Remove the breather hoses.

(24) Remove the vacuum hose for the power brake

booster.

(25) Disconnect knock sensors.

(26) Remove engine oil dipstick tube.

(27) Remove intake manifold.

(28) Install engine lifting fixture,special tool#8247,

using original fasteners from the removed intake

manifold, and fuel rail. Torque to factory specifica-

tions.

NOTE: Recheck bolt torque for engine lift plate

before removing engine.

(29) Secure the left and right engine wiring har-

nesses away from engine.

(30) Raise vehicle.

(31) Disconnect oxygen sensor wiring.

(32) Disconnect crankshaft postion sensor.

(33) Disconnect the engine block heater power

cable, if equipped.

(34) Disconnect the front propshaft at the front

differential and secure out of way.

NOTE: It is necessary to disconnect the front prop-

shaft for access to the starter and left side exhaust

flange.(35) Remove the starter.

(36) Remove the ground straps from the left and

right side of the block.

(37) Disconnect the right and left exhaust pipes at

the manifolds and from the crossover, and remove

from the vehicle.

NOTE: The exhaust clamps at the manifolds cannot

be reused. New clamps must be used or leaks may

occur.

(38) Remove the structural cover.

(39) Remove torque convertor bolts, and mark

location for reassembly.

(40) Remove transmission bellhousing to engine

bolts.

(41) Remove left and right engine mount thru

bolts.

(42) Lower the vehicle.

(43) Support the transmission with a suitable jack.

(44) Connect a suitable engine hoist to the engine

lift plate.

(45) Remove engine from vehicle.

INSTALLATION

(1) Position the engine in the vehicle.

(2) Install both left and right side engine mounts

onto engine.

(3) Raise the vehicle.

(4) Install the transmission bellhousing to engine

mounting bolts. Tighten the bolts to 41 N´m (30ft.

lbs.).

(5) Tighten the engine mount thru bolts.

(6) Install the torque convertor bolts.

(7) Connect the ground straps on the left and right

side of the engine.

(8) Install the starter.

(9) Connect the crankshaft position sensor.

(10) Install the engine block heater power cable, if

equipped.

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

(11) Install the structural cover.

NOTE: New clamps must be used on exhaust man-

ifold flanges. Failure to use new clamps may result

in exhaust leaks.

(12) Install the left and right exhaust pipes.

(13) Connect the left and right oxygen sensors.

(14) Lower vehicle.

(15) Remove the engine lift plate.

(16) Connect the knock sensors.

DRENGINE - 3.7L 9 - 11

ENGINE - 3.7L (Continued)

Page 1987 of 2627

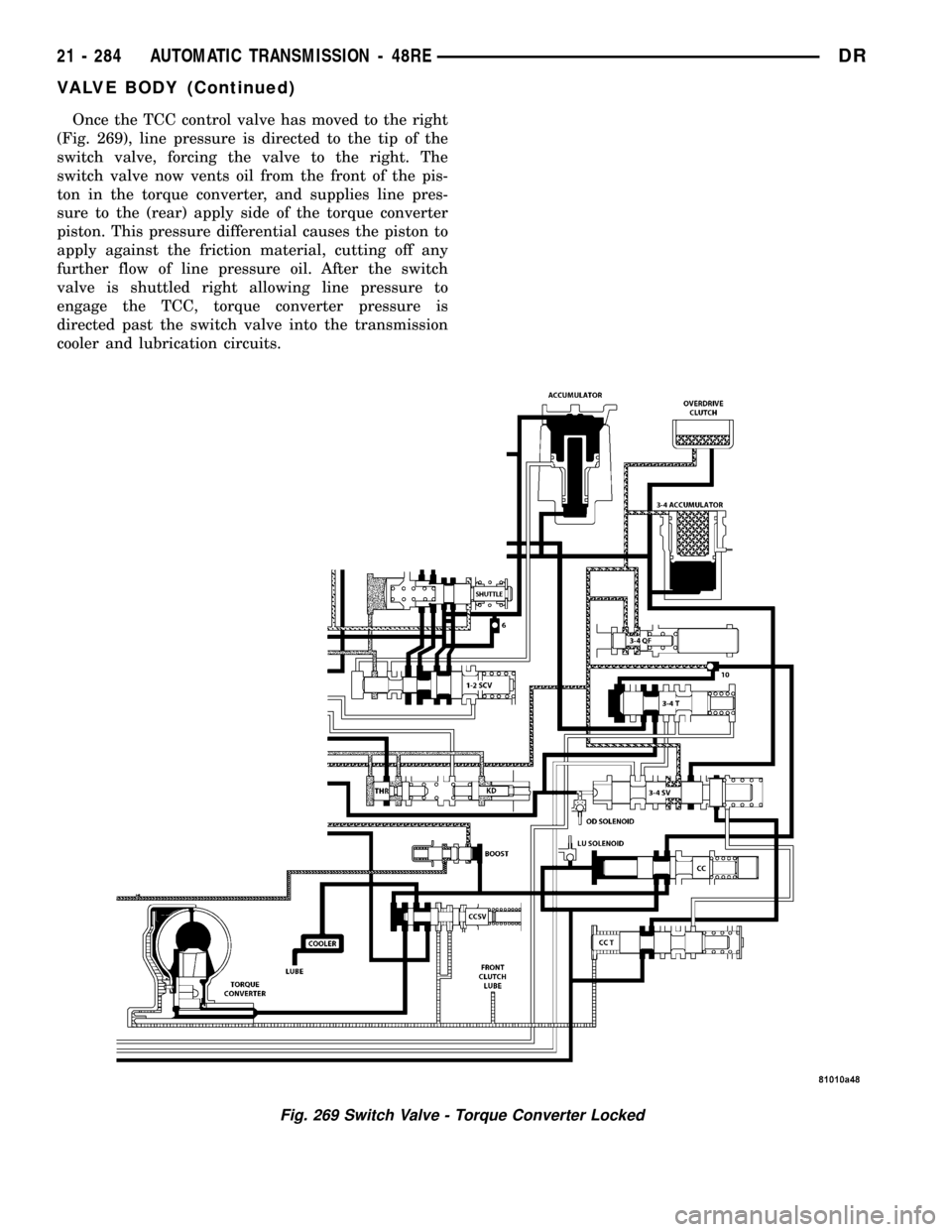

Once the TCC control valve has moved to the right

(Fig. 269), line pressure is directed to the tip of the

switch valve, forcing the valve to the right. The

switch valve now vents oil from the front of the pis-

ton in the torque converter, and supplies line pres-

sure to the (rear) apply side of the torque converter

piston. This pressure differential causes the piston to

apply against the friction material, cutting off any

further flow of line pressure oil. After the switch

valve is shuttled right allowing line pressure to

engage the TCC, torque converter pressure is

directed past the switch valve into the transmission

cooler and lubrication circuits.

Fig. 269 Switch Valve - Torque Converter Locked

21 - 284 AUTOMATIC TRANSMISSION - 48REDR

VALVE BODY (Continued)

Page 2120 of 2627

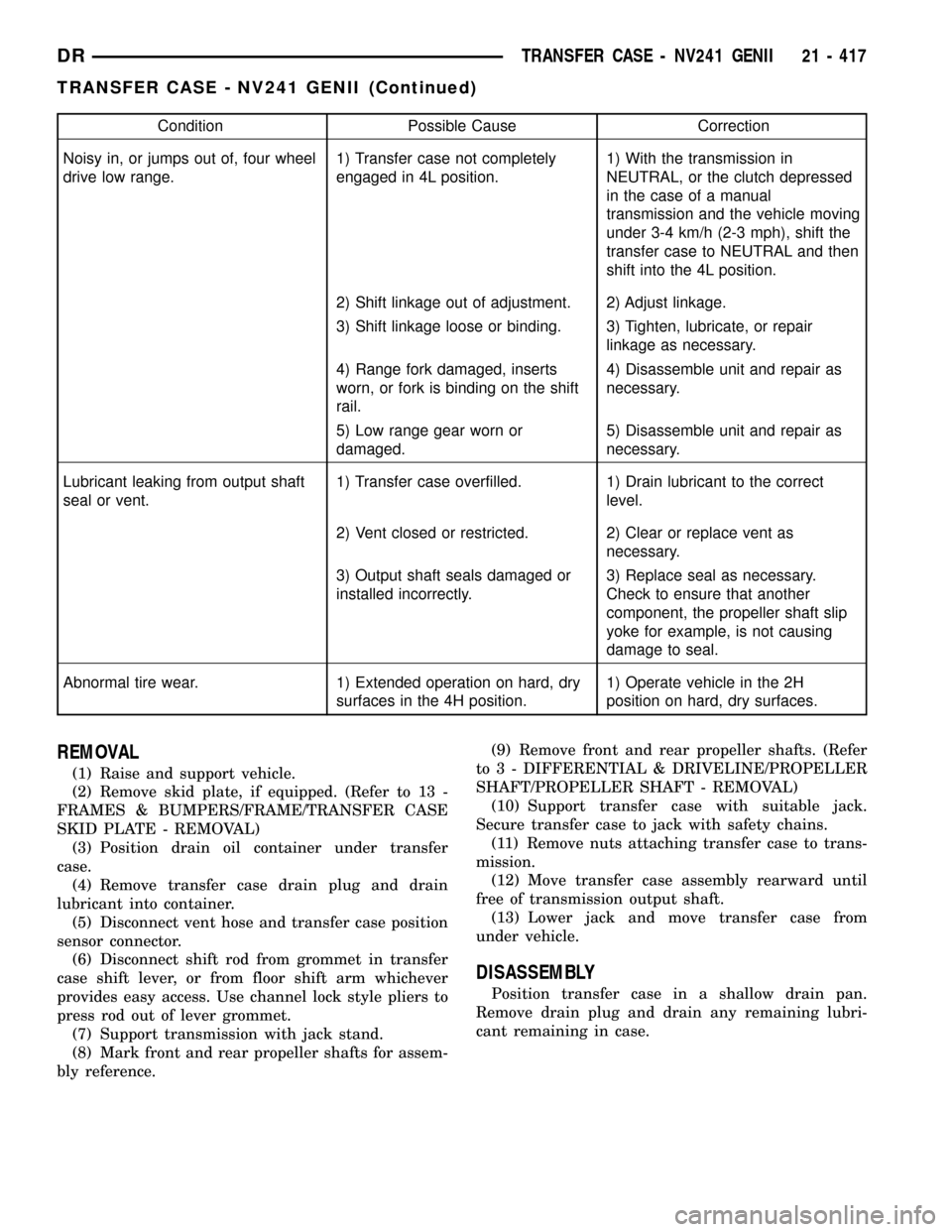

Condition Possible Cause Correction

Noisy in, or jumps out of, four wheel

drive low range.1) Transfer case not completely

engaged in 4L position.1) With the transmission in

NEUTRAL, or the clutch depressed

in the case of a manual

transmission and the vehicle moving

under 3-4 km/h (2-3 mph), shift the

transfer case to NEUTRAL and then

shift into the 4L position.

2) Shift linkage out of adjustment. 2) Adjust linkage.

3) Shift linkage loose or binding. 3) Tighten, lubricate, or repair

linkage as necessary.

4) Range fork damaged, inserts

worn, or fork is binding on the shift

rail.4) Disassemble unit and repair as

necessary.

5) Low range gear worn or

damaged.5) Disassemble unit and repair as

necessary.

Lubricant leaking from output shaft

seal or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Vent closed or restricted. 2) Clear or replace vent as

necessary.

3) Output shaft seals damaged or

installed incorrectly.3) Replace seal as necessary.

Check to ensure that another

component, the propeller shaft slip

yoke for example, is not causing

damage to seal.

Abnormal tire wear. 1) Extended operation on hard, dry

surfaces in the 4H position.1) Operate vehicle in the 2H

position on hard, dry surfaces.

REMOVAL

(1) Raise and support vehicle.

(2) Remove skid plate, if equipped. (Refer to 13 -

FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - REMOVAL)

(3) Position drain oil container under transfer

case.

(4) Remove transfer case drain plug and drain

lubricant into container.

(5) Disconnect vent hose and transfer case position

sensor connector.

(6) Disconnect shift rod from grommet in transfer

case shift lever, or from floor shift arm whichever

provides easy access. Use channel lock style pliers to

press rod out of lever grommet.

(7) Support transmission with jack stand.

(8) Mark front and rear propeller shafts for assem-

bly reference.(9) Remove front and rear propeller shafts. (Refer

to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL)

(10) Support transfer case with suitable jack.

Secure transfer case to jack with safety chains.

(11) Remove nuts attaching transfer case to trans-

mission.

(12) Move transfer case assembly rearward until

free of transmission output shaft.

(13) Lower jack and move transfer case from

under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan.

Remove drain plug and drain any remaining lubri-

cant remaining in case.

DRTRANSFER CASE - NV241 GENII 21 - 417

TRANSFER CASE - NV241 GENII (Continued)

Page 2144 of 2627

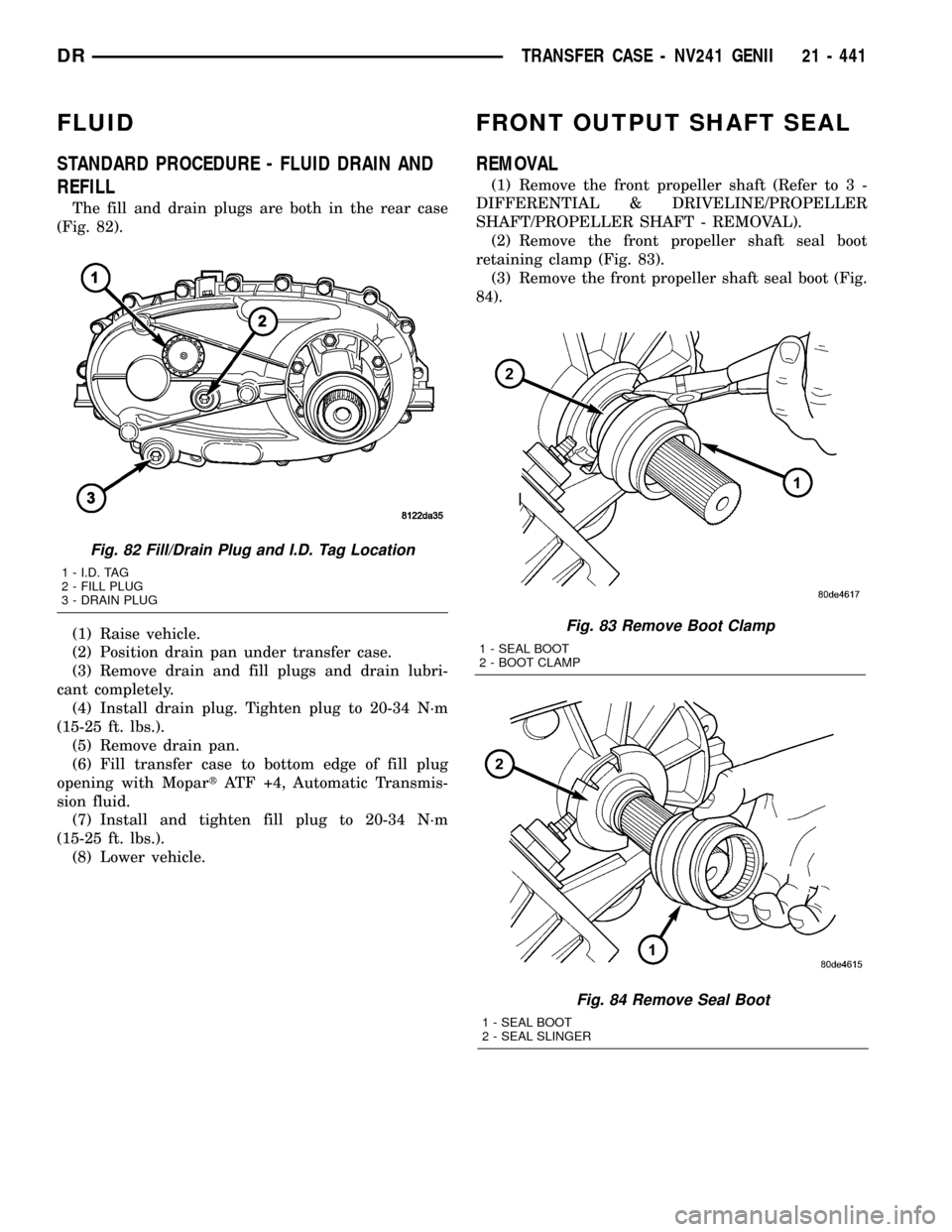

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL

The fill and drain plugs are both in the rear case

(Fig. 82).

(1) Raise vehicle.

(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 20-34 N´m

(15-25 ft. lbs.).

(5) Remove drain pan.

(6) Fill transfer case to bottom edge of fill plug

opening with MopartATF +4, Automatic Transmis-

sion fluid.

(7) Install and tighten fill plug to 20-34 N´m

(15-25 ft. lbs.).

(8) Lower vehicle.

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Remove the front propeller shaft (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL).

(2) Remove the front propeller shaft seal boot

retaining clamp (Fig. 83).

(3) Remove the front propeller shaft seal boot (Fig.

84).

Fig. 83 Remove Boot Clamp

1 - SEAL BOOT

2 - BOOT CLAMP

Fig. 84 Remove Seal Boot

1 - SEAL BOOT

2 - SEAL SLINGER

Fig. 82 Fill/Drain Plug and I.D. Tag Location

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

DRTRANSFER CASE - NV241 GENII 21 - 441

Page 2153 of 2627

REMOVAL

(1) Raise and support vehicle.

(2) Remove skid plate, if equipped. (Refer to 13 -

FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - REMOVAL)

(3) Position drain oil container under transfer

case.

(4) Remove transfer case drain plug and drain

lubricant into container.

(5) Disconnect vent hose and transfer case position

sensor connector.

(6) Disconnect shift rod from grommet in transfer

case shift lever, or from floor shift arm whichever

provides easy access. Use channel lock style pliers to

press rod out of lever grommet.

(7) Support transmission with jack stand.

(8) Mark front and rear propeller shafts for assem-

bly reference.

(9) Remove front and rear propeller shafts. (Refer

to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL)

(10) Support transfer case with suitable jack.

Secure transfer case to jack with safety chains.

(11) Remove nuts attaching transfer case to trans-

mission.

(12) Move transfer case assembly rearward until

free of transmission output shaft.

(13) Lower jack and move transfer case from

under vehicle.

DISASSEMBLY

Position transfer case in a shallow drain pan.

Remove drain plug and drain any remaining lubri-

cant remaining in case.

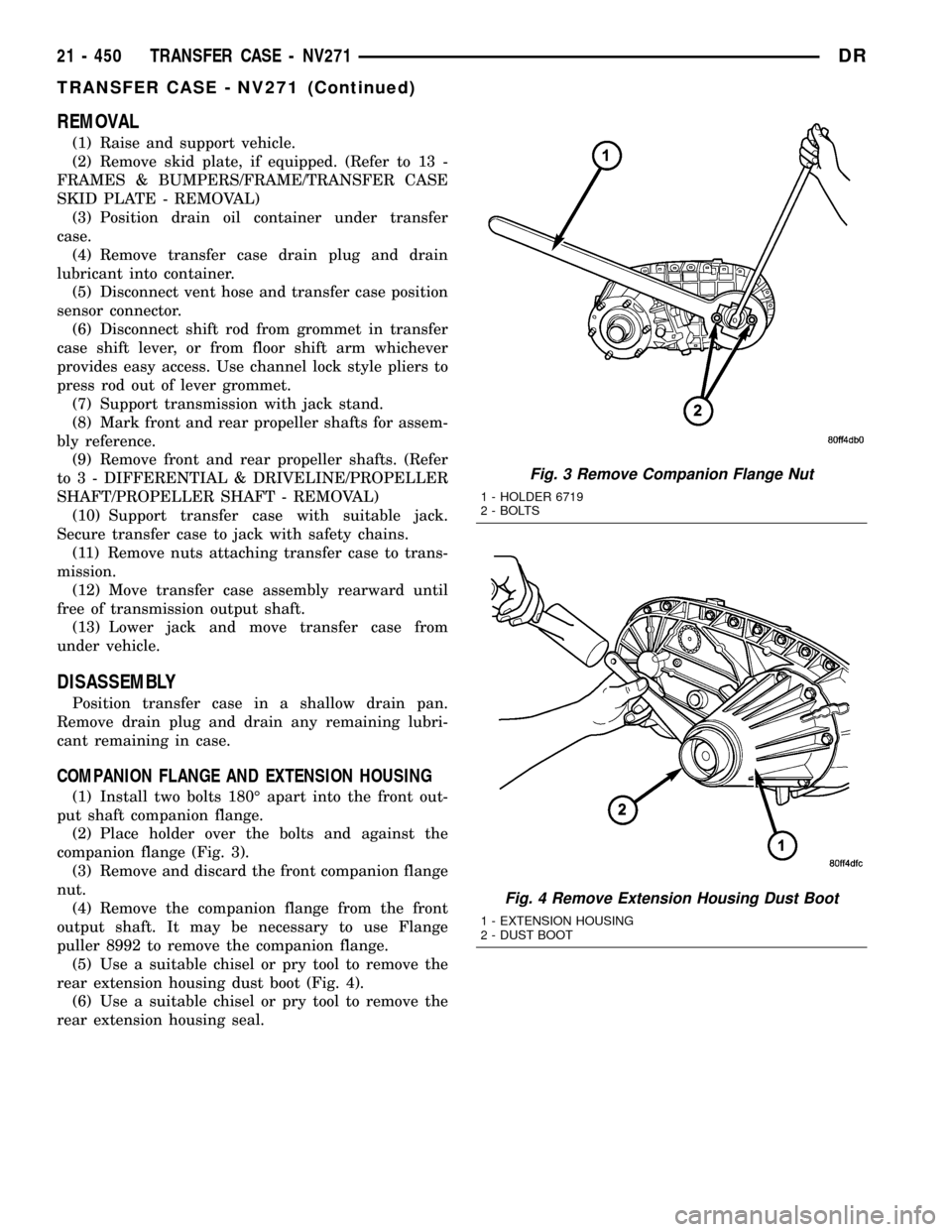

COMPANION FLANGE AND EXTENSION HOUSING

(1) Install two bolts 180É apart into the front out-

put shaft companion flange.

(2) Place holder over the bolts and against the

companion flange (Fig. 3).

(3) Remove and discard the front companion flange

nut.

(4) Remove the companion flange from the front

output shaft. It may be necessary to use Flange

puller 8992 to remove the companion flange.

(5) Use a suitable chisel or pry tool to remove the

rear extension housing dust boot (Fig. 4).

(6) Use a suitable chisel or pry tool to remove the

rear extension housing seal.

Fig. 3 Remove Companion Flange Nut

1 - HOLDER 6719

2 - BOLTS

Fig. 4 Remove Extension Housing Dust Boot

1 - EXTENSION HOUSING

2 - DUST BOOT

21 - 450 TRANSFER CASE - NV271DR

TRANSFER CASE - NV271 (Continued)

Page 2176 of 2627

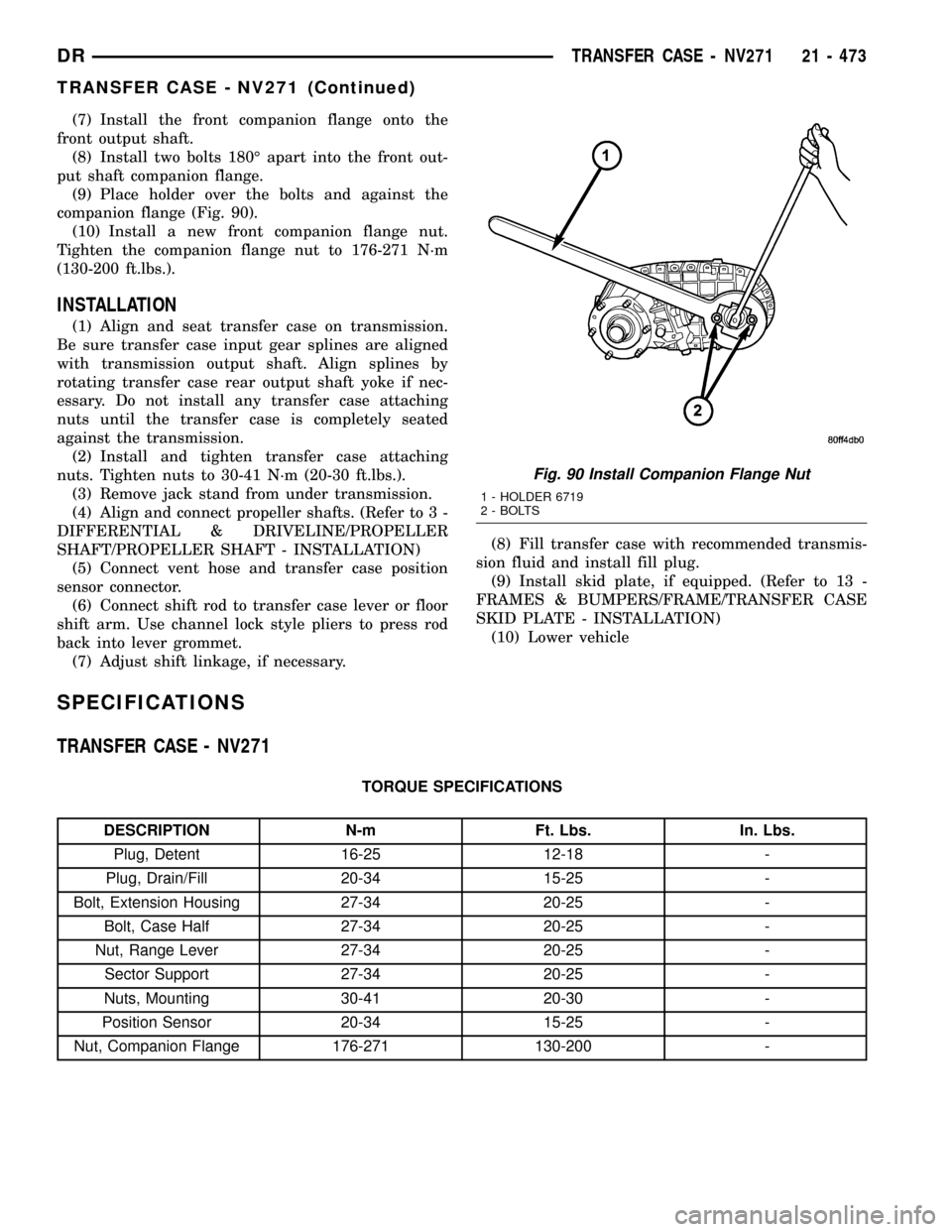

(7) Install the front companion flange onto the

front output shaft.

(8) Install two bolts 180É apart into the front out-

put shaft companion flange.

(9) Place holder over the bolts and against the

companion flange (Fig. 90).

(10) Install a new front companion flange nut.

Tighten the companion flange nut to 176-271 N´m

(130-200 ft.lbs.).

INSTALLATION

(1) Align and seat transfer case on transmission.

Be sure transfer case input gear splines are aligned

with transmission output shaft. Align splines by

rotating transfer case rear output shaft yoke if nec-

essary. Do not install any transfer case attaching

nuts until the transfer case is completely seated

against the transmission.

(2) Install and tighten transfer case attaching

nuts. Tighten nuts to 30-41 N´m (20-30 ft.lbs.).

(3) Remove jack stand from under transmission.

(4) Align and connect propeller shafts. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

(5) Connect vent hose and transfer case position

sensor connector.

(6) Connect shift rod to transfer case lever or floor

shift arm. Use channel lock style pliers to press rod

back into lever grommet.

(7) Adjust shift linkage, if necessary.(8) Fill transfer case with recommended transmis-

sion fluid and install fill plug.

(9) Install skid plate, if equipped. (Refer to 13 -

FRAMES & BUMPERS/FRAME/TRANSFER CASE

SKID PLATE - INSTALLATION)

(10) Lower vehicle

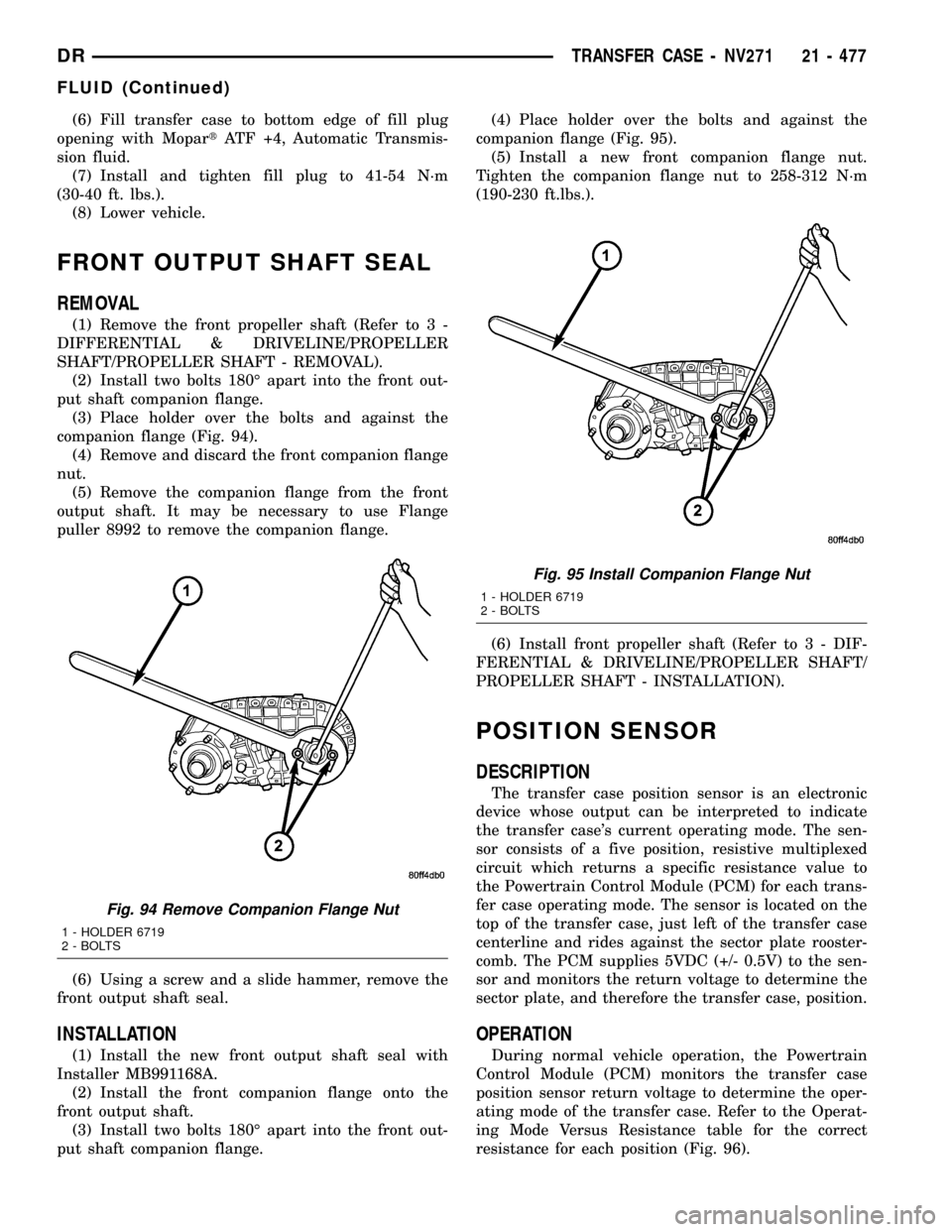

SPECIFICATIONS

TRANSFER CASE - NV271

TORQUE SPECIFICATIONS

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Plug, Detent 16-25 12-18 -

Plug, Drain/Fill 20-34 15-25 -

Bolt, Extension Housing 27-34 20-25 -

Bolt, Case Half 27-34 20-25 -

Nut, Range Lever 27-34 20-25 -

Sector Support 27-34 20-25 -

Nuts, Mounting 30-41 20-30 -

Position Sensor 20-34 15-25 -

Nut, Companion Flange 176-271 130-200 -

Fig. 90 Install Companion Flange Nut

1 - HOLDER 6719

2 - BOLTS

DRTRANSFER CASE - NV271 21 - 473

TRANSFER CASE - NV271 (Continued)

Page 2180 of 2627

(6) Fill transfer case to bottom edge of fill plug

opening with MopartATF +4, Automatic Transmis-

sion fluid.

(7) Install and tighten fill plug to 41-54 N´m

(30-40 ft. lbs.).

(8) Lower vehicle.

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Remove the front propeller shaft (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL).

(2) Install two bolts 180É apart into the front out-

put shaft companion flange.

(3) Place holder over the bolts and against the

companion flange (Fig. 94).

(4) Remove and discard the front companion flange

nut.

(5) Remove the companion flange from the front

output shaft. It may be necessary to use Flange

puller 8992 to remove the companion flange.

(6) Using a screw and a slide hammer, remove the

front output shaft seal.

INSTALLATION

(1) Install the new front output shaft seal with

Installer MB991168A.

(2) Install the front companion flange onto the

front output shaft.

(3) Install two bolts 180É apart into the front out-

put shaft companion flange.(4) Place holder over the bolts and against the

companion flange (Fig. 95).

(5) Install a new front companion flange nut.

Tighten the companion flange nut to 258-312 N´m

(190-230 ft.lbs.).

(6) Install front propeller shaft (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION).

POSITION SENSOR

DESCRIPTION

The transfer case position sensor is an electronic

device whose output can be interpreted to indicate

the transfer case's current operating mode. The sen-

sor consists of a five position, resistive multiplexed

circuit which returns a specific resistance value to

the Powertrain Control Module (PCM) for each trans-

fer case operating mode. The sensor is located on the

top of the transfer case, just left of the transfer case

centerline and rides against the sector plate rooster-

comb. The PCM supplies 5VDC (+/- 0.5V) to the sen-

sor and monitors the return voltage to determine the

sector plate, and therefore the transfer case, position.

OPERATION

During normal vehicle operation, the Powertrain

Control Module (PCM) monitors the transfer case

position sensor return voltage to determine the oper-

ating mode of the transfer case. Refer to the Operat-

ing Mode Versus Resistance table for the correct

resistance for each position (Fig. 96).

Fig. 94 Remove Companion Flange Nut

1 - HOLDER 6719

2 - BOLTS

Fig. 95 Install Companion Flange Nut

1 - HOLDER 6719

2 - BOLTS

DRTRANSFER CASE - NV271 21 - 477

FLUID (Continued)

Page 2210 of 2627

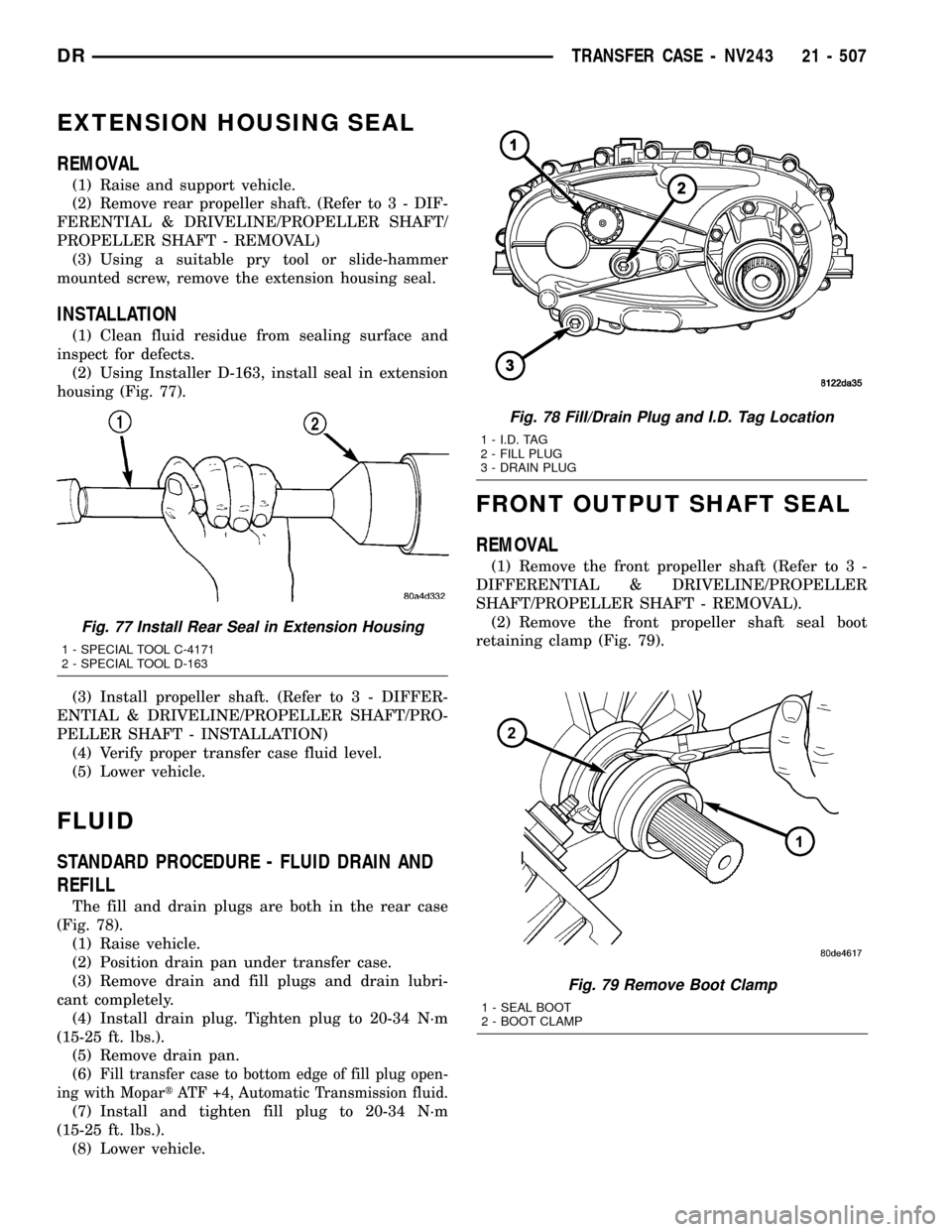

EXTENSION HOUSING SEAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove rear propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Using a suitable pry tool or slide-hammer

mounted screw, remove the extension housing seal.

INSTALLATION

(1) Clean fluid residue from sealing surface and

inspect for defects.

(2) Using Installer D-163, install seal in extension

housing (Fig. 77).

(3) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT/PRO-

PELLER SHAFT - INSTALLATION)

(4) Verify proper transfer case fluid level.

(5) Lower vehicle.

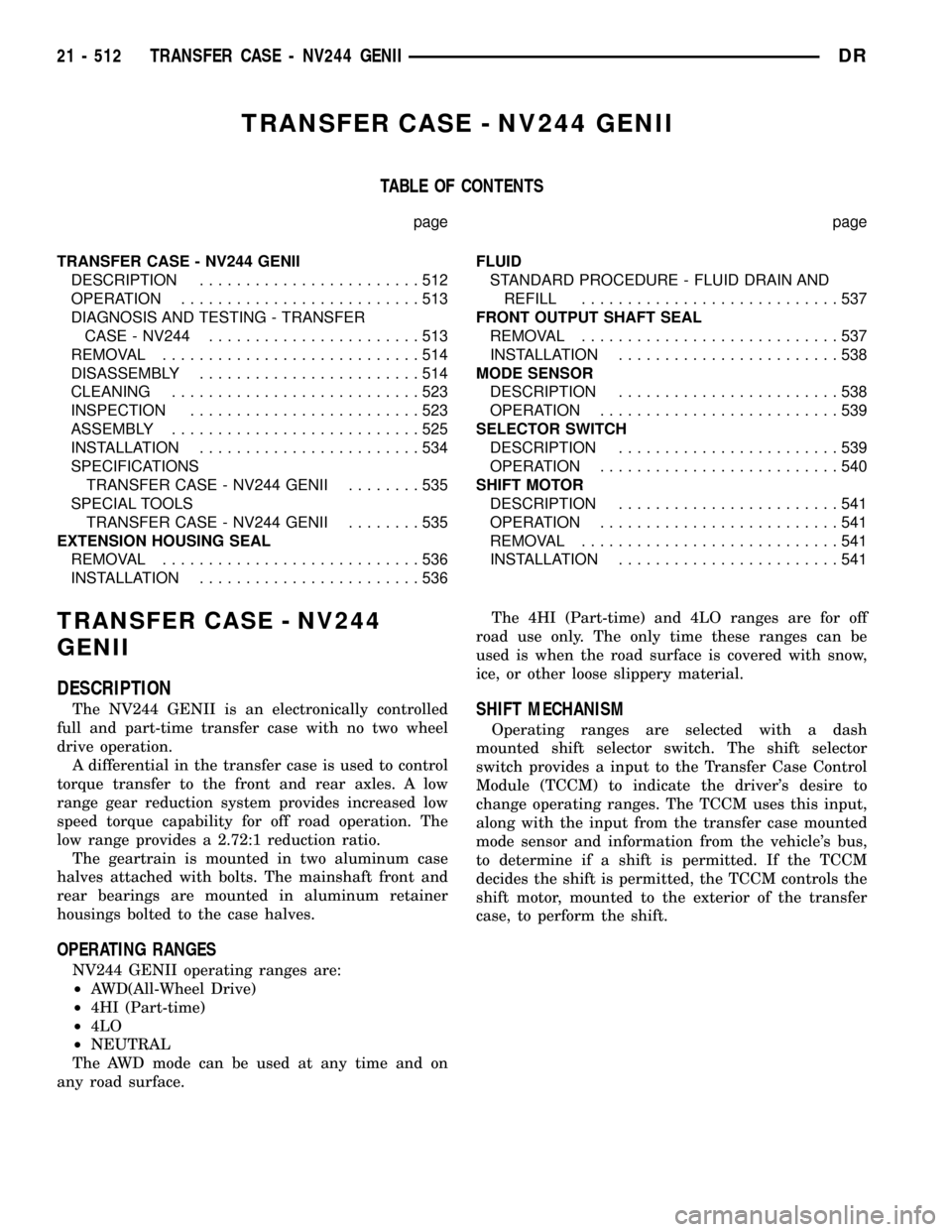

FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL

The fill and drain plugs are both in the rear case

(Fig. 78).

(1) Raise vehicle.

(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 20-34 N´m

(15-25 ft. lbs.).

(5) Remove drain pan.

(6)

Fill transfer case to bottom edge of fill plug open-

ing with MopartATF +4, Automatic Transmission fluid.

(7) Install and tighten fill plug to 20-34 N´m

(15-25 ft. lbs.).

(8) Lower vehicle.

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Remove the front propeller shaft (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - REMOVAL).

(2) Remove the front propeller shaft seal boot

retaining clamp (Fig. 79).

Fig. 79 Remove Boot Clamp

1 - SEAL BOOT

2 - BOOT CLAMP

Fig. 77 Install Rear Seal in Extension Housing

1 - SPECIAL TOOL C-4171

2 - SPECIAL TOOL D-163

Fig. 78 Fill/Drain Plug and I.D. Tag Location

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

DRTRANSFER CASE - NV243 21 - 507

Page 2215 of 2627

TRANSFER CASE - NV244 GENII

TABLE OF CONTENTS

page page

TRANSFER CASE - NV244 GENII

DESCRIPTION........................512

OPERATION..........................513

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV244.......................513

REMOVAL............................514

DISASSEMBLY........................514

CLEANING...........................523

INSPECTION.........................523

ASSEMBLY...........................525

INSTALLATION........................534

SPECIFICATIONS

TRANSFER CASE - NV244 GENII........535

SPECIAL TOOLS

TRANSFER CASE - NV244 GENII........535

EXTENSION HOUSING SEAL

REMOVAL............................536

INSTALLATION........................536FLUID

STANDARD PROCEDURE - FLUID DRAIN AND

REFILL............................537

FRONT OUTPUT SHAFT SEAL

REMOVAL............................537

INSTALLATION........................538

MODE SENSOR

DESCRIPTION........................538

OPERATION..........................539

SELECTOR SWITCH

DESCRIPTION........................539

OPERATION..........................540

SHIFT MOTOR

DESCRIPTION........................541

OPERATION..........................541

REMOVAL............................541

INSTALLATION........................541

TRANSFER CASE - NV244

GENII

DESCRIPTION

The NV244 GENII is an electronically controlled

full and part-time transfer case with no two wheel

drive operation.

A differential in the transfer case is used to control

torque transfer to the front and rear axles. A low

range gear reduction system provides increased low

speed torque capability for off road operation. The

low range provides a 2.72:1 reduction ratio.

The geartrain is mounted in two aluminum case

halves attached with bolts. The mainshaft front and

rear bearings are mounted in aluminum retainer

housings bolted to the case halves.

OPERATING RANGES

NV244 GENII operating ranges are:

²AWD(All-Wheel Drive)

²4HI (Part-time)

²4LO

²NEUTRAL

The AWD mode can be used at any time and on

any road surface.The 4HI (Part-time) and 4LO ranges are for off

road use only. The only time these ranges can be

used is when the road surface is covered with snow,

ice, or other loose slippery material.

SHIFT MECHANISM

Operating ranges are selected with a dash

mounted shift selector switch. The shift selector

switch provides a input to the Transfer Case Control

Module (TCCM) to indicate the driver's desire to

change operating ranges. The TCCM uses this input,

along with the input from the transfer case mounted

mode sensor and information from the vehicle's bus,

to determine if a shift is permitted. If the TCCM

decides the shift is permitted, the TCCM controls the

shift motor, mounted to the exterior of the transfer

case, to perform the shift.

21 - 512 TRANSFER CASE - NV244 GENIIDR