Hood DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2342 of 2627

(4) Remove the grille. (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL)

(5) Remove the hood lamp and ambient tempera-

ture sensor.

INSTALLATION

(1) Install the hood lamp and ambient temperature

sensor.

(2) Install the grille. (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION)

(3) Install the hood and install the nuts.

(4) Line up the marks made previously and

tighten the nuts to 23 N´m (17 ft. lbs.).

(5) Check the hood fit and adjust if required.

(Refer to 23 - BODY/BODY STRUCTURE/GAP AND

FLUSH - SPECIFICATIONS)

LATCH

REMOVAL

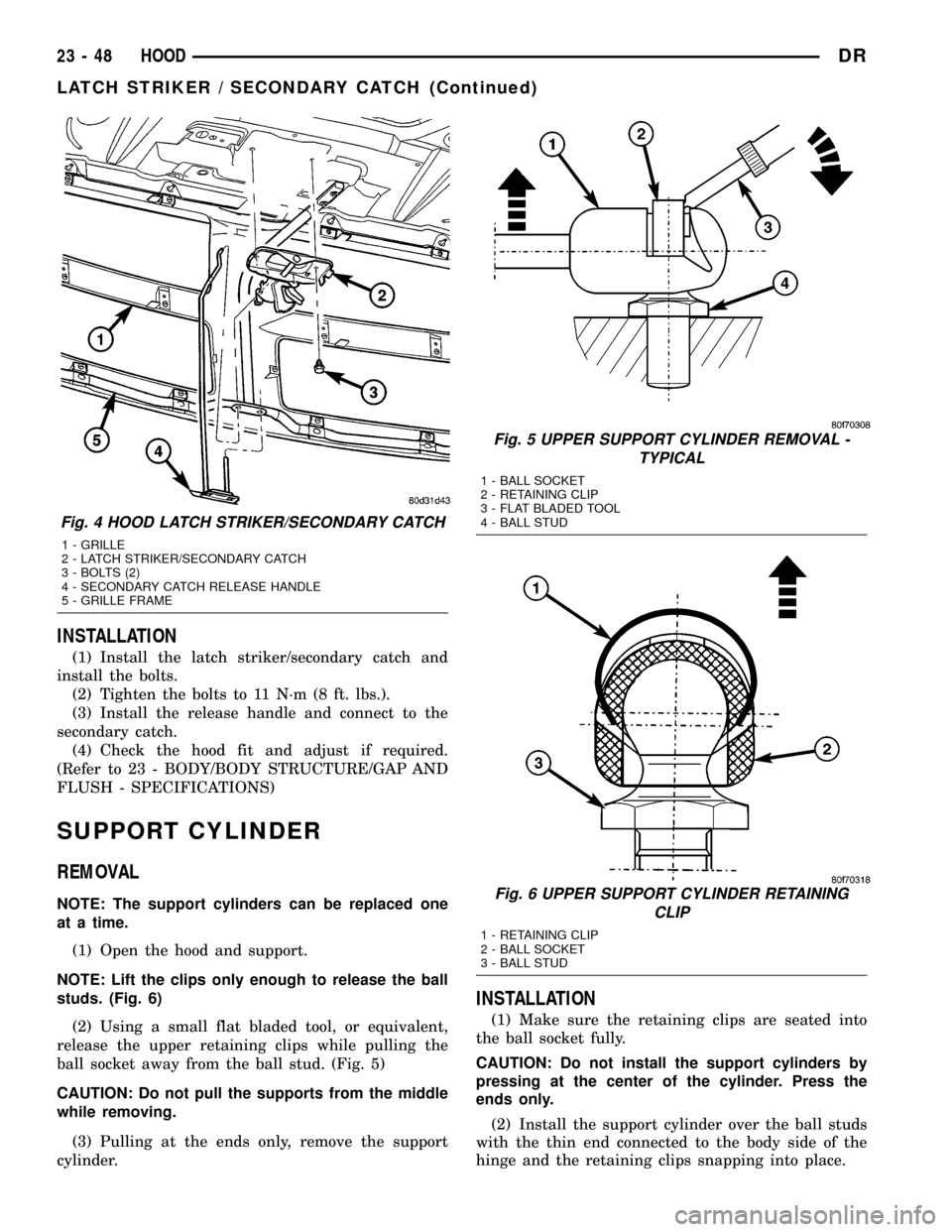

(1) Open the hood.

(2) Using a grease pencil or equivalent, mark the

position of the latch on the radiator crossmember.

(3) Remove the bolts. (Fig. 3)

(4) Disconnect the hood latch cable and remove the

latch.

INSTALLATION

(1) Connect the hood latch cable.

(2) Install the latch lining up the marks made pre-

viously and install the bolts.

(3) Tighten the bolts to 11 N´m (8 ft. lbs.).

(4) Check hood fit and adjust if required. (Refer to

23 - BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

LATCH RELEASE CABLE/

HANDLE ASSEMBLY

REMOVAL

(1) Remove the hood latch. (Refer to 23 - BODY/

HOOD/LATCH - REMOVAL)

(2) Remove the batter tray. (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - REMOVAL)

(3) Disconnect the three cable push pin fasteners.

(4) From inside the cab loosen the two handle

screws and disconnect the handle from the instru-

ment panel bracket.

(5) Separate the grommet at the cowl panel and

remove cable through the cab.

INSTALLATION

(1) Route the cable/handle assembly through the

cowl panel and install the grommet.

(2) Position the handle onto the instrument panel

bracket and tighten the screws.

(3) Route the cable along the fender rails and

install the three push pin fasteners.

(4) Install the latch. (Refer to 23 - BODY/HOOD/

LATCH - INSTALLATION)

(5) Install the battery tray. (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/TRAY - INSTALLATION)

LATCH STRIKER /

SECONDARY CATCH

REMOVAL

(1) Disconnect and remove the secondary release

handle. (Fig. 4)

(2) Remove the two bolts and remove the striker/

catch assembly.

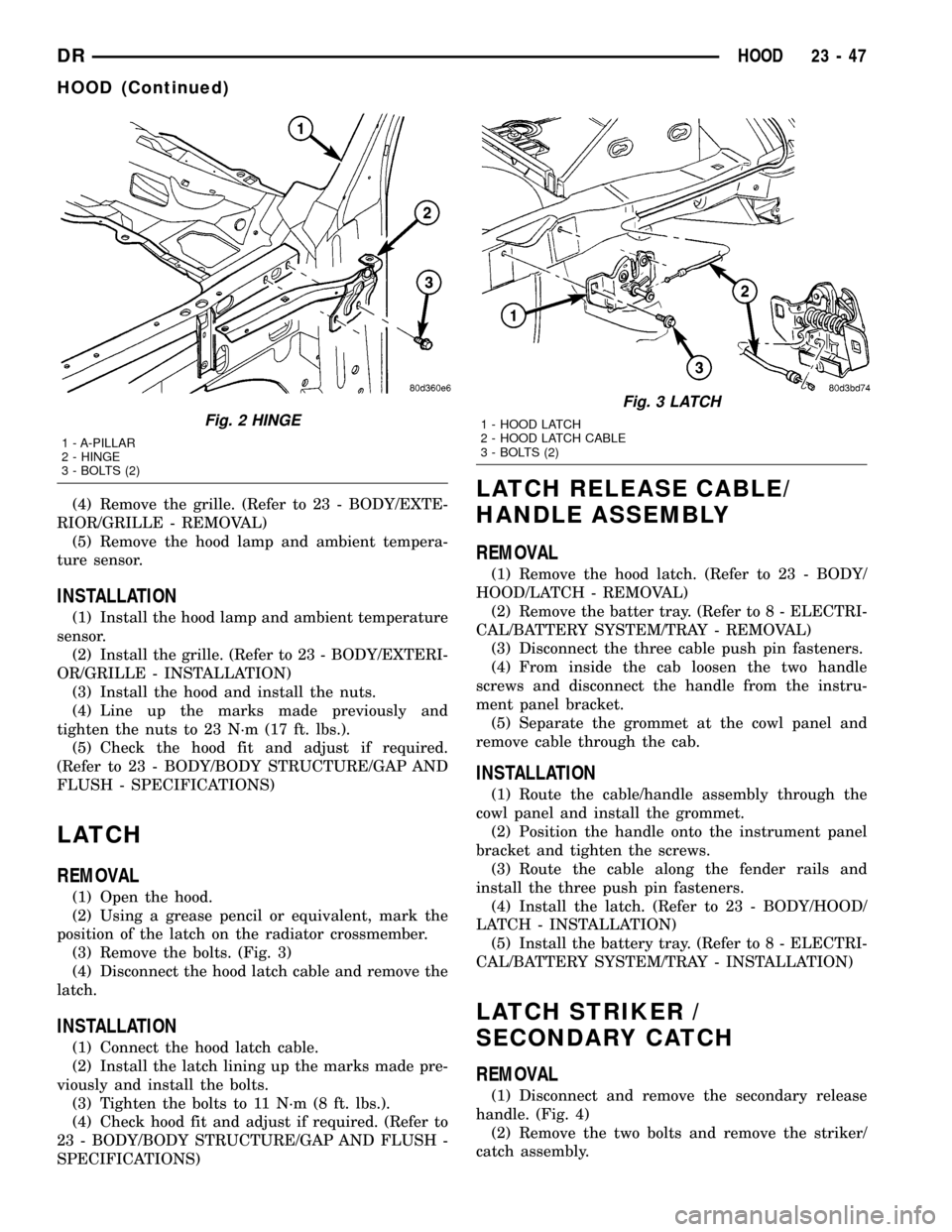

Fig. 2 HINGE

1 - A-PILLAR

2 - HINGE

3 - BOLTS (2)

Fig. 3 LATCH

1 - HOOD LATCH

2 - HOOD LATCH CABLE

3 - BOLTS (2)

DRHOOD 23 - 47

HOOD (Continued)

Page 2343 of 2627

INSTALLATION

(1) Install the latch striker/secondary catch and

install the bolts.

(2) Tighten the bolts to 11 N´m (8 ft. lbs.).

(3) Install the release handle and connect to the

secondary catch.

(4) Check the hood fit and adjust if required.

(Refer to 23 - BODY/BODY STRUCTURE/GAP AND

FLUSH - SPECIFICATIONS)

SUPPORT CYLINDER

REMOVAL

NOTE: The support cylinders can be replaced one

at a time.

(1) Open the hood and support.

NOTE: Lift the clips only enough to release the ball

studs. (Fig. 6)

(2) Using a small flat bladed tool, or equivalent,

release the upper retaining clips while pulling the

ball socket away from the ball stud. (Fig. 5)

CAUTION: Do not pull the supports from the middle

while removing.

(3) Pulling at the ends only, remove the support

cylinder.

INSTALLATION

(1) Make sure the retaining clips are seated into

the ball socket fully.

CAUTION: Do not install the support cylinders by

pressing at the center of the cylinder. Press the

ends only.

(2) Install the support cylinder over the ball studs

with the thin end connected to the body side of the

hinge and the retaining clips snapping into place.

Fig. 4 HOOD LATCH STRIKER/SECONDARY CATCH

1 - GRILLE

2 - LATCH STRIKER/SECONDARY CATCH

3 - BOLTS (2)

4 - SECONDARY CATCH RELEASE HANDLE

5 - GRILLE FRAME

Fig. 5 UPPER SUPPORT CYLINDER REMOVAL -

TYPICAL

1 - BALL SOCKET

2 - RETAINING CLIP

3 - FLAT BLADED TOOL

4 - BALL STUD

Fig. 6 UPPER SUPPORT CYLINDER RETAINING

CLIP

1 - RETAINING CLIP

2 - BALL SOCKET

3 - BALL STUD

23 - 48 HOODDR

LATCH STRIKER / SECONDARY CATCH (Continued)

Page 2348 of 2627

(1) Remove the left a-pillar trim. (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM/GRAB HANDLE

- REMOVAL)

(2) Remove the top cover. (Refer to 23 - BODY/IN-

STRUMENT PANEL/INSTRUMENT PANEL TOP

COVER - REMOVAL)

(3) Disconnect the headliner harness electrical con-

nector at the a-pillar.

(4) Using a trim stick C-4755 or equivalent, from

the notch on the bottom, remove the left side cover.

(Fig. 20)

(5) Remove the steering column. (Refer to 19 -

STEERING/COLUMN - REMOVAL)

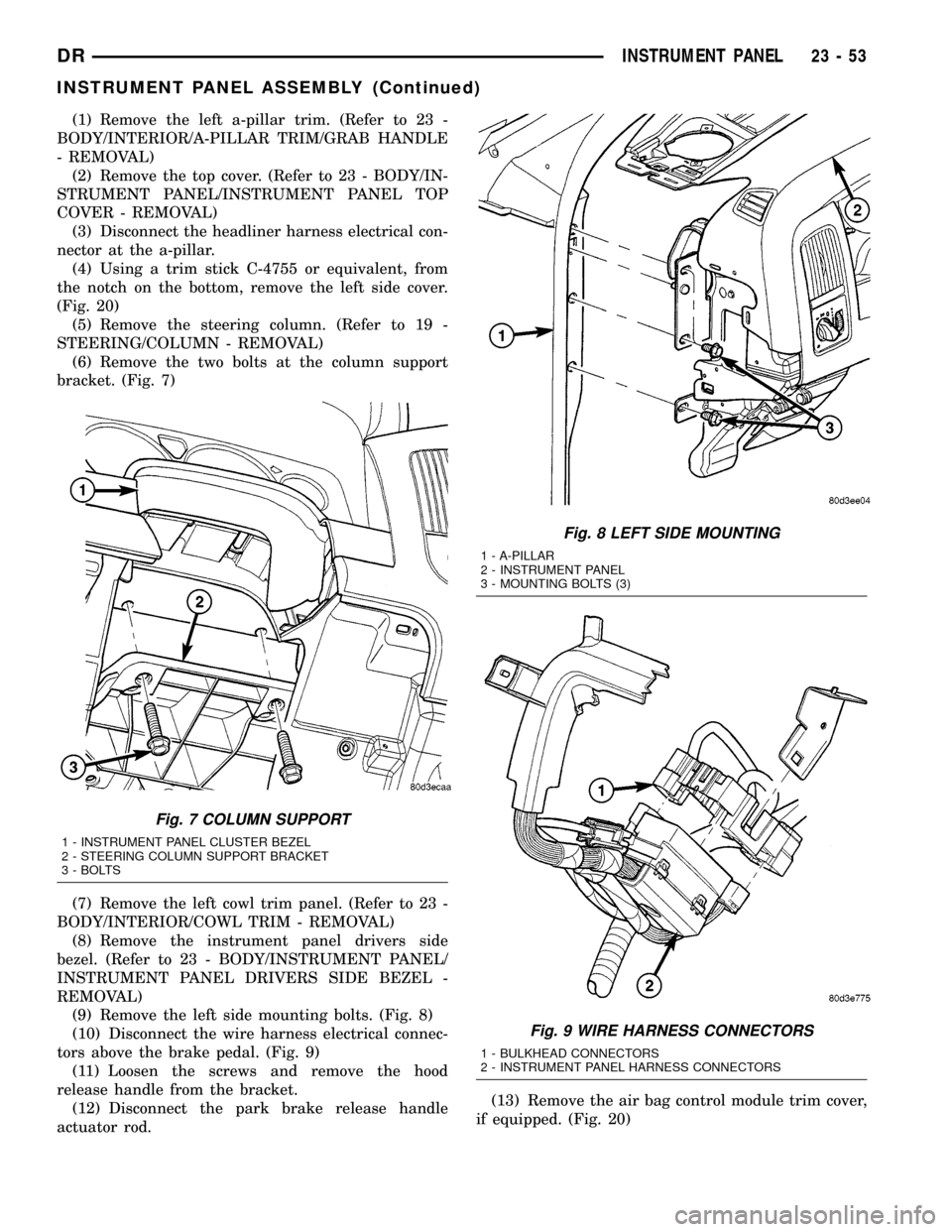

(6) Remove the two bolts at the column support

bracket. (Fig. 7)

(7) Remove the left cowl trim panel. (Refer to 23 -

BODY/INTERIOR/COWL TRIM - REMOVAL)

(8) Remove the instrument panel drivers side

bezel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL DRIVERS SIDE BEZEL -

REMOVAL)

(9) Remove the left side mounting bolts. (Fig. 8)

(10) Disconnect the wire harness electrical connec-

tors above the brake pedal. (Fig. 9)

(11) Loosen the screws and remove the hood

release handle from the bracket.

(12) Disconnect the park brake release handle

actuator rod.(13) Remove the air bag control module trim cover,

if equipped. (Fig. 20)

Fig. 7 COLUMN SUPPORT

1 - INSTRUMENT PANEL CLUSTER BEZEL

2 - STEERING COLUMN SUPPORT BRACKET

3 - BOLTS

Fig. 8 LEFT SIDE MOUNTING

1 - A-PILLAR

2 - INSTRUMENT PANEL

3 - MOUNTING BOLTS (3)

Fig. 9 WIRE HARNESS CONNECTORS

1 - BULKHEAD CONNECTORS

2 - INSTRUMENT PANEL HARNESS CONNECTORS

DRINSTRUMENT PANEL 23 - 53

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 2351 of 2627

(8) Install the left a-pillar trim. (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM - INSTALLA-

TION)

(9) Position the left end cap and seat the attach-

ment clips fully.

(10) Install the right side mounting bolts on the

a-pillar and one right mounting bolt on the cowl side

panel and tighten to 12 N´m (9 ft. lbs.).

(11) Install the right a-pillar trim panel. (Refer to

23 - BODY/INTERIOR/A-PILLAR TRIM - INSTAL-

LATION)

(12) Position the right end cap and seat the

attachment clips fully.

(13) Install the one HVAC mounting screw.

(14) Connect the radio antenna.

(15) Connect the two electrical connectors at the

right cowl panel.

(16) Install the right cowl trim cover. (Refer to 23 -

BODY/INTERIOR/COWL TRIM - INSTALLATION)

(17) Connect the air bag control module electrical

connector.

(18) Install the center bracket bolts and tighten to

12 N´m (9 ft. lbs.).

(19) Install the floor console, if equipped. (Refer to

23 - BODY/INTERIOR/FLOOR CONSOLE - INSTAL-

LATION)

(20) Install the air bag control module cover, if

equipped.

(21) Connect the park brake release handle actua-

tor rod.

(22) Install the hood release handle and tighten

the screws.

(23) Install the two bolts at the column support

bracket and tighten to 14 N´m (10 ft. lbs.).

(24) Install the steering column. (Refer to 19 -

STEERING/COLUMN - INSTALLATION)

(25) Connect the wire harness electrical connectors

above the brake pedal.

(26) Install the two top instrument panel bolts and

tighten to 12 N´m (9 ft. lbs.).

(27) Install the four top instrument panel screws.

(28) Install the instrument panel top cover. (Refer

to 23 - BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL TOP COVER - INSTALLATION)

INSTRUMENT PANEL

HEADLAMP SWITCH BEZEL

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

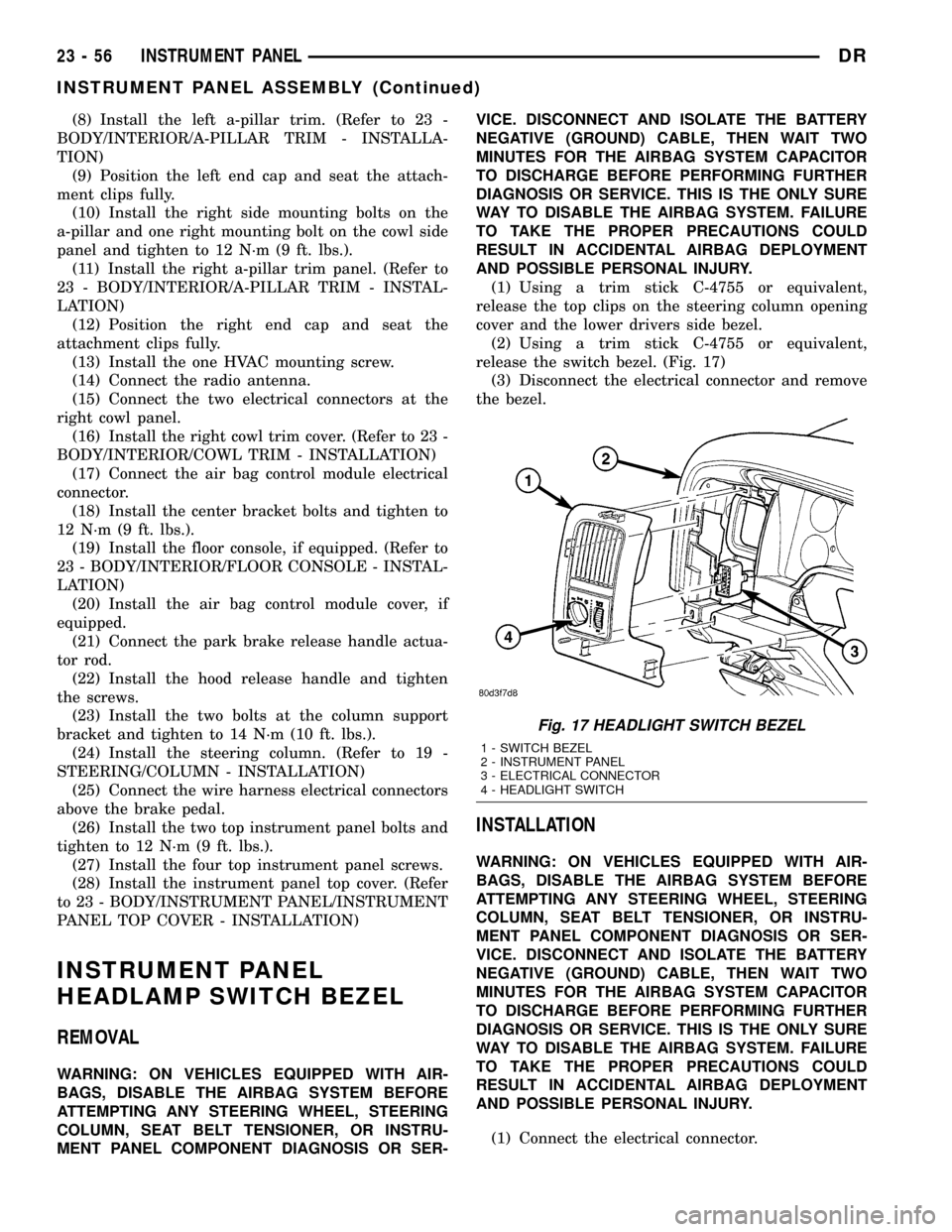

(1) Using a trim stick C-4755 or equivalent,

release the top clips on the steering column opening

cover and the lower drivers side bezel.

(2) Using a trim stick C-4755 or equivalent,

release the switch bezel. (Fig. 17)

(3) Disconnect the electrical connector and remove

the bezel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Connect the electrical connector.

Fig. 17 HEADLIGHT SWITCH BEZEL

1 - SWITCH BEZEL

2 - INSTRUMENT PANEL

3 - ELECTRICAL CONNECTOR

4 - HEADLIGHT SWITCH

23 - 56 INSTRUMENT PANELDR

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 2355 of 2627

(3) Install the storage bin, if equipped. (Refer to 23

- BODY/INSTRUMENT PANEL/STORAGE BIN -

INSTALLATION)

(4) Install the cup holder, if equipped. (Refer to 23

- BODY/INSTRUMENT PANEL/CUP HOLDER -

INSTALLATION)

(5) Install the glove box. (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - INSTALLA-

TION)

(6) Install the ash receiver. (Refer to 23 - BODY/

INSTRUMENT PANEL/ASH RECEIVER - INSTAL-

LATION)

(7) Install the passenger side cowl trim panel.

(Refer to 23 - BODY/INTERIOR/COWL TRIM -

INSTALLATION)

(8) Position the passenger side end cap and seat

fully.

STEERING COLUMN OPENING

COVER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

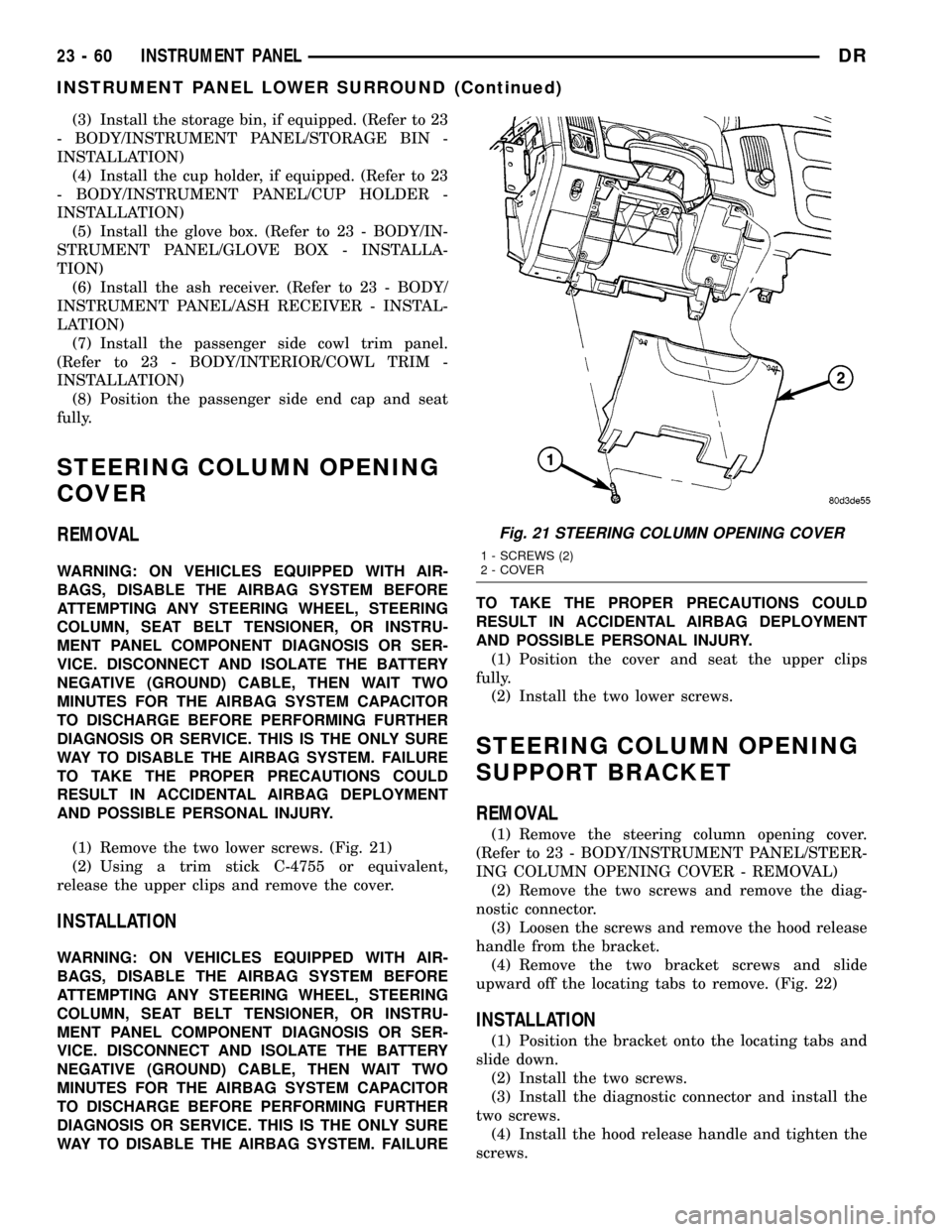

(1) Remove the two lower screws. (Fig. 21)

(2) Using a trim stick C-4755 or equivalent,

release the upper clips and remove the cover.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, SEAT BELT TENSIONER, OR INSTRU-

MENT PANEL COMPONENT DIAGNOSIS OR SER-

VICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO

MINUTES FOR THE AIRBAG SYSTEM CAPACITOR

TO DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURETO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Position the cover and seat the upper clips

fully.

(2) Install the two lower screws.

STEERING COLUMN OPENING

SUPPORT BRACKET

REMOVAL

(1) Remove the steering column opening cover.

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL)

(2) Remove the two screws and remove the diag-

nostic connector.

(3) Loosen the screws and remove the hood release

handle from the bracket.

(4) Remove the two bracket screws and slide

upward off the locating tabs to remove. (Fig. 22)

INSTALLATION

(1) Position the bracket onto the locating tabs and

slide down.

(2) Install the two screws.

(3) Install the diagnostic connector and install the

two screws.

(4) Install the hood release handle and tighten the

screws.

Fig. 21 STEERING COLUMN OPENING COVER

1 - SCREWS (2)

2 - COVER

23 - 60 INSTRUMENT PANELDR

INSTRUMENT PANEL LOWER SURROUND (Continued)

Page 2391 of 2627

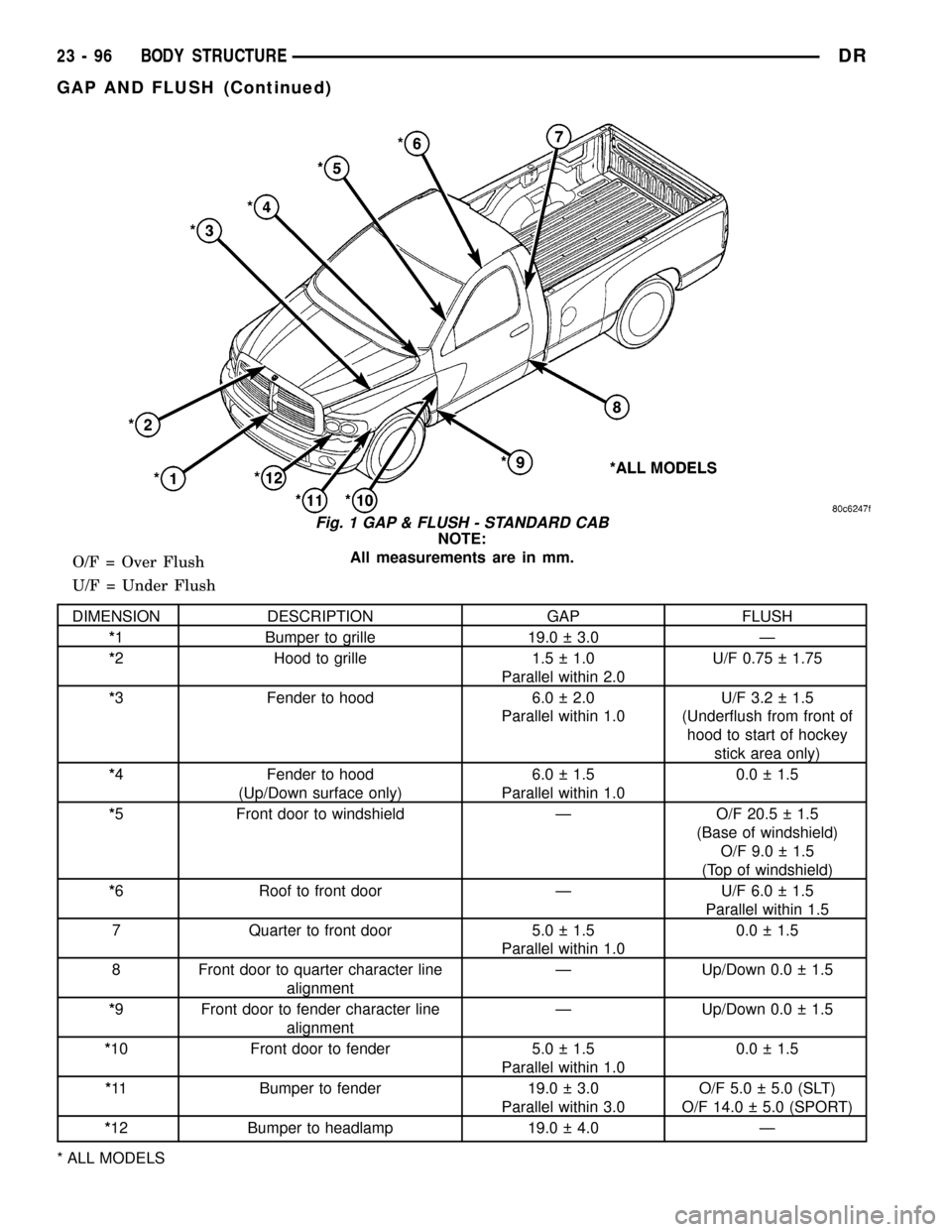

NOTE:

All measurements are in mm.

O/F = Over Flush

U/F = Under Flush

DIMENSION DESCRIPTION GAP FLUSH

*1 Bumper to grille 19.0 3.0 Ð

*2 Hood to grille 1.5 1.0

Parallel within 2.0U/F 0.75 1.75

*3 Fender to hood 6.0 2.0

Parallel within 1.0U/F 3.2 1.5

(Underflush from front of

hood to start of hockey

stick area only)

*4 Fender to hood

(Up/Down surface only)6.0 1.5

Parallel within 1.00.0 1.5

*5 Front door to windshield Ð O/F 20.5 1.5

(Base of windshield)

O/F 9.0 1.5

(Top of windshield)

*6 Roof to front door Ð U/F 6.0 1.5

Parallel within 1.5

7 Quarter to front door 5.0 1.5

Parallel within 1.00.0 1.5

8 Front door to quarter character line

alignmentÐ Up/Down 0.0 1.5

*9 Front door to fender character line

alignmentÐ Up/Down 0.0 1.5

*10 Front door to fender 5.0 1.5

Parallel within 1.00.0 1.5

*11 Bumper to fender 19.0 3.0

Parallel within 3.0O/F 5.0 5.0 (SLT)

O/F 14.0 5.0 (SPORT)

*12 Bumper to headlamp 19.0 4.0 Ð

* ALL MODELS

Fig. 1 GAP & FLUSH - STANDARD CAB

23 - 96 BODY STRUCTUREDR

GAP AND FLUSH (Continued)

Page 2494 of 2627

²Faulty A/C-heater control.

²Faulty related wiring harness or connectors.

²Improper engine coolant temperature.

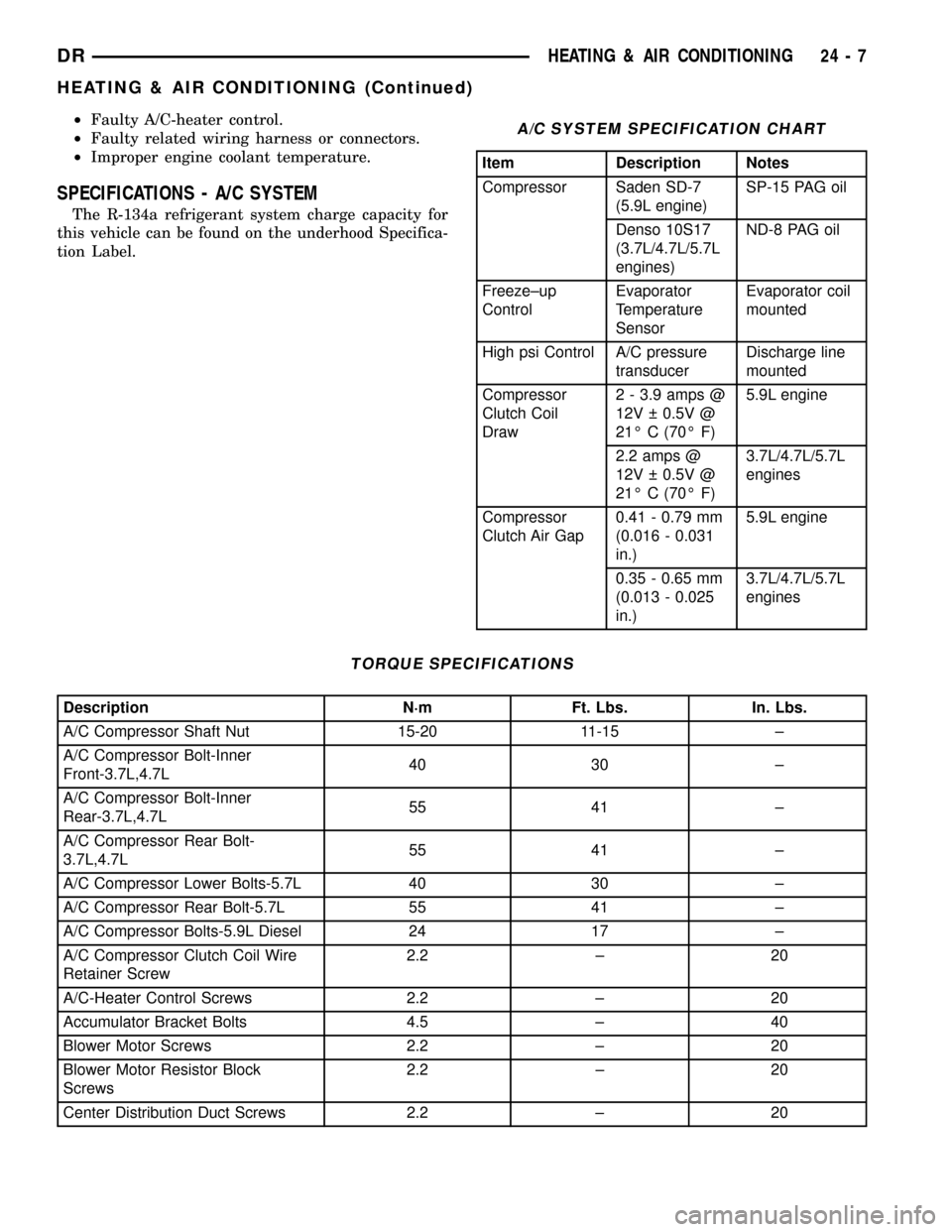

SPECIFICATIONS - A/C SYSTEM

The R-134a refrigerant system charge capacity for

this vehicle can be found on the underhood Specifica-

tion Label.

A/C SYSTEM SPECIFICATION CHART

Item Description Notes

Compressor Saden SD-7

(5.9L engine)SP-15 PAG oil

Denso 10S17

(3.7L/4.7L/5.7L

engines)ND-8 PAG oil

Freeze±up

ControlEvaporator

Temperature

SensorEvaporator coil

mounted

High psi Control A/C pressure

transducerDischarge line

mounted

Compressor

Clutch Coil

Draw2 - 3.9 amps @

12V 0.5V @

21É C (70É F)5.9L engine

2.2 amps @

12V 0.5V @

21É C (70É F)3.7L/4.7L/5.7L

engines

Compressor

Clutch Air Gap0.41 - 0.79 mm

(0.016 - 0.031

in.)5.9L engine

0.35 - 0.65 mm

(0.013 - 0.025

in.)3.7L/4.7L/5.7L

engines

TORQUE SPECIFICATIONS

Description N´m Ft. Lbs. In. Lbs.

A/C Compressor Shaft Nut 15-20 11-15 ±

A/C Compressor Bolt-Inner

Front-3.7L,4.7L40 30 ±

A/C Compressor Bolt-Inner

Rear-3.7L,4.7L55 41 ±

A/C Compressor Rear Bolt-

3.7L,4.7L55 41 ±

A/C Compressor Lower Bolts-5.7L 40 30 ±

A/C Compressor Rear Bolt-5.7L 55 41 ±

A/C Compressor Bolts-5.9L Diesel 24 17 ±

A/C Compressor Clutch Coil Wire

Retainer Screw2.2 ± 20

A/C-Heater Control Screws 2.2 ± 20

Accumulator Bracket Bolts 4.5 ± 40

Blower Motor Screws 2.2 ± 20

Blower Motor Resistor Block

Screws2.2 ± 20

Center Distribution Duct Screws 2.2 ± 20

DRHEATING & AIR CONDITIONING 24 - 7

HEATING & AIR CONDITIONING (Continued)

Page 2535 of 2627

After the system has been tested for leaks and

evacuated, a refrigerant (R-134a) charge can be

injected into the system.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) If using a separate vacuum pump close all

valves before disconnecting pump. Connect manifold

gauge set to the A/C service ports.

NOTE: Always refer to the underhood HVAC Speci-

fication label for the refrigerant fill level of the vehi-

cle being serviced.

(2) Measure refrigerant (refer to capacities). Refer

to the instructions provided with the equipment

being used.

(3) Verify engine is shut off. Open the suction and

discharge valves. Open the charge valve to allow the

refrigerant to flow into the system. When the trans-

fer of refrigerant has stopped, close the suction and

discharge valve.

(4) If all of the charge did not transfer from the

dispensing device, put vehicle controls into the fol-

lowing mode:

²Automatic transmission in park or manual

transmission in neutral

²Engine at idle

²A/C mode control set to outside air

²A/C mode control set to panel mode

²A/C temperature control set to full cool

²Blower motor control set on highest speed

²Vehicle windows closed

If the A/C compressor does not engage, test the

compressor clutch control circuit and correct any fail-

ure (Refer to 8 - ELECTRICAL/WIRING DIAGRAM

INFORMATION - DIAGNOSIS AND TESTING).

(5) Open the suction valve to allow the remaining

refrigerant to transfer to the system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH-PRESSURE) VALVE AT THIS TIME.

(6) Close all valves and test the A/C system perfor-

mance.

(7) Disconnect the charging station or manifold

gauge set. Install the service port caps.

REFRIGERANT CHARGE CAPACITY

The R-134a refrigerant system charge capacity for

this vehicle can be found on the underhood HVAC

specfication tag.

A/C COMPRESSOR

DESCRIPTION

DESCRIPTION - A/C COMPRESSOR

The A/C system on models equipped with the 5.9L

engine use a Sanden SD-7 reciprocating swash plate-

type compressor. This compressor has a fixed dis-

placement of 165 cubic centimeter (10.068 cubic

inches) and has both the suction and discharge ports

located on the cylinder head.

The A/C system on models equipped with the 3.7L,

4.7L and 5.7L engines use a Denso 10S17 reciprocat-

ing swash plate-type compressor. This compressor

has a fixed displacement of 170 cubic centimeter and

has both the suction and discharge ports located on

the cylinder head.

A label identifying the use of R-134a refrigerant is

located on both A/C compressors.

DESCRIPTION - HIGH PRESSURE RELIEF

VALVE

A high pressure relief valve is located on the com-

pressor cylinder head, which is on the rear of the

compressor. This mechanical valve is designed to

vent refrigerant from the system to protect against

damage to the compressor and other system compo-

nents, caused by condenser air flow restriction or an

overcharge of refrigerant.

OPERATION

OPERATION - A/C COMPRESSOR

The A/C compressor is driven by the engine

through an electric clutch, drive pulley and belt

arrangement. The compressor is lubricated by refrig-

erant oil that is circulated throughout the refrigerant

system with the refrigerant.

The compressor draws in low-pressure refrigerant

vapor from the evaporator through its suction port. It

then compresses the refrigerant into a high-pressure,

high-temperature refrigerant vapor, which is then

pumped to the condenser through the compressor dis-

charge port.

The compressor cannot be repaired. If faulty or

damaged, the entire compressor assembly must be

replaced. The compressor clutch, pulley and clutch

coil are available for service.

OPERATION - HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents the system

when a discharge pressure of 3445 to 4135 kPa (500

to 600 psi) or above is reached. The valve closes

24 - 48 PLUMBINGDR

PLUMBING (Continued)

Page 2556 of 2627

designs. Useonlyrefrigerant oil of the same type as

recommended to service the refrigerant system

(always refer to the specification tagincluded

with the replacement A/C compressor or the under-

hood A/C system specification tag).

OPERATION

After performing any refrigerant recovery or recy-

cling operation, always replenish the refrigerant sys-

tem with the same amount of the recommended

refrigerant oil as was removed. Too little refrigerant

oil can cause compressor damage, and too much can

reduce air conditioning system performance.

PAG refrigerant oil is much more hygroscopic than

mineral oil, and will absorb any moisture it comes

into contact with, even moisture in the air. The PAG

oil container should always be kept tightly capped

until it is ready to be used. After use, recap the oil

container immediately to prevent moisture contami-

nation.

STANDARD PROCEDURE - REFRIGERANT OIL

LEVEL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

CAUTION: The refrigerant oil in the R-134a A/C sys-

tem is unique depending on the A/C compressor

used. Use only PAG oils that are designed to work

with R-134a refrigerant and the A/C compressor in

the vehicle. Always refer to the underhood A/C Sys-

tem Specification Label for the correct oil designa-

tion.

It is important to have the correct amount of lubri-

cant in the A/C refrigerant system to ensure proper

lubrication of the A/C compressor. Too little lubricant

will result in damage to the compressor. Too much

lubricant will reduce the cooling capacity of the A/C

system and consequently result in higher discharge

air temperatures.

The lubricant used in the compressor is polyalka-

lene glycol PAG lubricant. Only the refrigerant lubri-

cant approved for use with this vehicle should be

used to service the system. Do not use any other

lubricant. The lubricant container should be kept

tightly capped until it is ready for use. Refrigerant

lubricant will quickly absorb any moisture it comes

in contact with.

It will not be necessary to check the oil level in the

A/C compressor or to add oil, unless there has beenan oil loss. An oil loss may occur due to component

replacement, or a rupture or leak from a refrigerant

line, connector fitting, component or component seal.

If a leak occurs, add 30 milliliters (1 fluid ounce) of

the recommended refrigerant oil to the refrigerant

system after the repair has been made. Refrigerant

oil loss will be evident at the leak point by the pres-

ence of a wet, shiny surface around the leak.

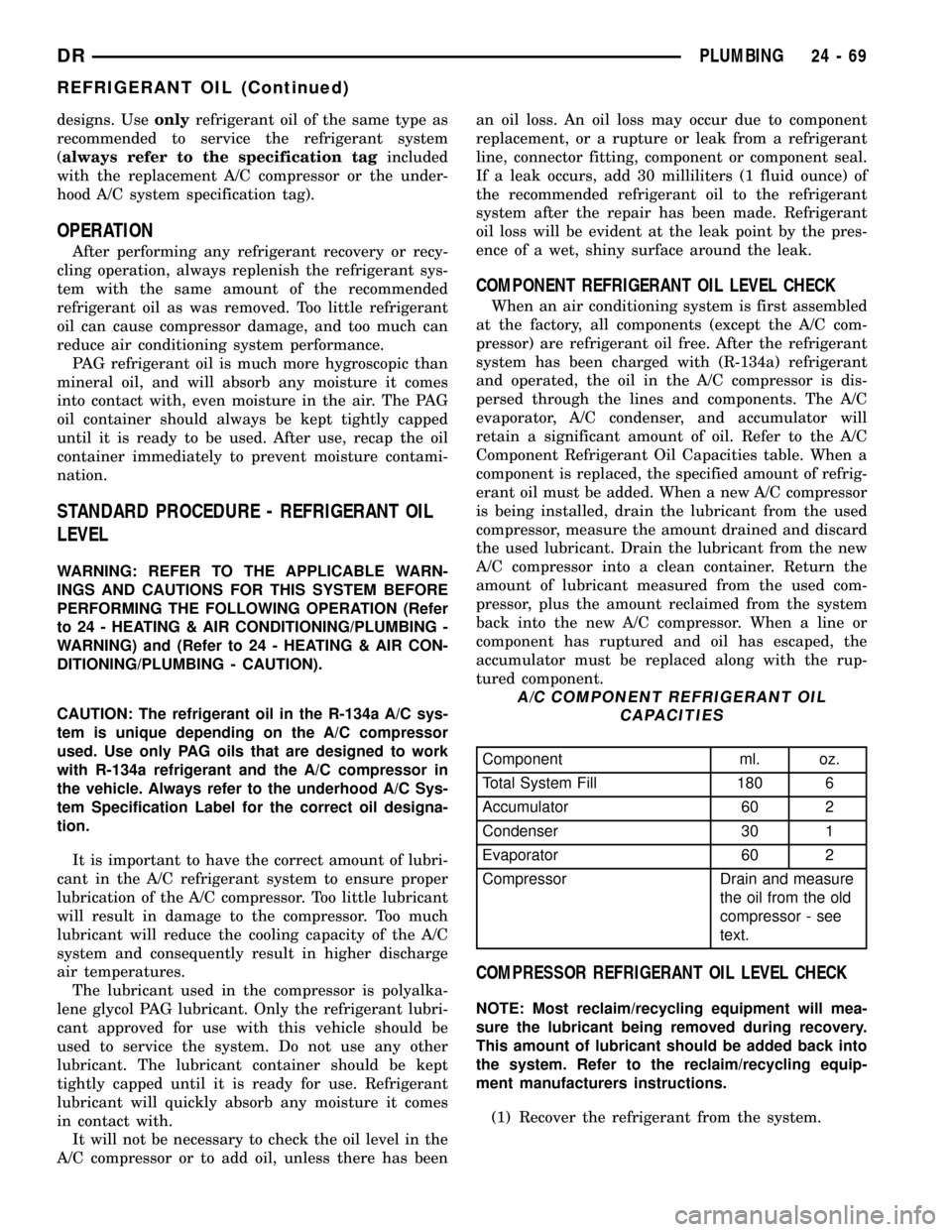

COMPONENT REFRIGERANT OIL LEVEL CHECK

When an air conditioning system is first assembled

at the factory, all components (except the A/C com-

pressor) are refrigerant oil free. After the refrigerant

system has been charged with (R-134a) refrigerant

and operated, the oil in the A/C compressor is dis-

persed through the lines and components. The A/C

evaporator, A/C condenser, and accumulator will

retain a significant amount of oil. Refer to the A/C

Component Refrigerant Oil Capacities table. When a

component is replaced, the specified amount of refrig-

erant oil must be added. When a new A/C compressor

is being installed, drain the lubricant from the used

compressor, measure the amount drained and discard

the used lubricant. Drain the lubricant from the new

A/C compressor into a clean container. Return the

amount of lubricant measured from the used com-

pressor, plus the amount reclaimed from the system

back into the new A/C compressor. When a line or

component has ruptured and oil has escaped, the

accumulator must be replaced along with the rup-

tured component.

A/C COMPONENT REFRIGERANT OIL

CAPACITIES

Component ml. oz.

Total System Fill 180 6

Accumulator 60 2

Condenser 30 1

Evaporator 60 2

Compressor Drain and measure

the oil from the old

compressor - see

text.

COMPRESSOR REFRIGERANT OIL LEVEL CHECK

NOTE: Most reclaim/recycling equipment will mea-

sure the lubricant being removed during recovery.

This amount of lubricant should be added back into

the system. Refer to the reclaim/recycling equip-

ment manufacturers instructions.

(1) Recover the refrigerant from the system.

DRPLUMBING 24 - 69

REFRIGERANT OIL (Continued)

Page 2603 of 2627

HEATED SEAT MODULE - INSTALLATION . . . 8E-7

HEATED SEAT MODULE - INSTALLATION . . 8G-15

HEATED SEAT MODULE - OPERATION.....8E-6

HEATED SEAT MODULE - OPERATION....8G-14

HEATED SEAT MODULE - REMOVAL.......8E-7

HEATED SEAT MODULE - REMOVAL.....8G-15

HEATED SEAT SENSOR - DESCRIPTION . . . 8G-11

HEATED SEAT SENSOR - DIAGNOSIS

AND TESTING.......................8G-11

HEATED SEAT SENSOR - OPERATION....8G-11

HEATED SEAT SENSOR - REMOVAL......8G-11

HEATED SEAT SWITCH - DESCRIPTION . . . 8G-11

HEATED SEAT SWITCH - DIAGNOSIS

AND TESTING.......................8G-12

HEATED SEAT SWITCH - INSTALLATION . . 8G-13

HEATED SEAT SWITCH - OPERATION.....8G-12

HEATED SEAT SWITCH - REMOVAL......8G-13

HEATED SEAT SYSTEM - DESCRIPTION....8G-7

HEATED SEAT SYSTEM - DIAGNOSIS

AND TESTING........................8G-8

HEATED SEAT SYSTEM - OPERATION.....8G-8

HEATER - 5.9L DIESEL - DESCRIPTION,

ENGINE BLOCK.......................7-37

HEATER - 5.9L DIESEL - INSTALLATION,

ENGINE BLOCK.......................7-38

HEATER - 5.9L DIESEL - OPERATION,

ENGINE BLOCK.......................7-38

HEATER - 5.9L DIESEL - REMOVAL,

ENGINE BLOCK.........................7-38

HEATER - DESCRIPTION, ENGINE BLOCK . . . 7-36

HEATER - DESCRIPTION, FUEL..........14-51

HEATER - DESCRIPTION, INTAKE AIR.....14-80

HEATER - DIAGNOSIS AND TESTING,

ENGINE BLOCK.......................7-36

HEATER - DIAGNOSIS AND TESTING,

FUEL..............................14-52

HEATER - INSTALLATION, ENGINE

BLOCK..............................7-37

HEATER - INSTALLATION, INTAKE AIR....14-80

HEATER - OPERATION, ENGINE BLOCK....7-36

HEATER - OPERATION, FUEL............14-51

HEATER - OPERATION, INTAKE AIR......14-80

HEATER - REMOVAL, ENGINE BLOCK......7-37

HEATER - REMOVAL, INTAKE AIR........14-80

HEATER AND AIR CONDITIONER -

DESCRIPTION........................24-1

HEATER AND AIR CONDITIONER -

OPERATION..........................24-1

HEATER CONTROL - DESCRIPTION, A/C . . . 24-14

HEATER CONTROL - INSTALLATION, A/C . . 24-15

HEATER CONTROL - REMOVAL, A/C......24-15

HEATER CORE - DESCRIPTION..........24-63

HEATER CORE - INSTALLATION.........24-63

HEATER CORE - OPERATION............24-63

HEATER CORE - REMOVAL.............24-63

HEATER INLET HOSE - INSTALLATION....24-64

HEATER INLET HOSE - REMOVAL........24-64

HEATER PERFORMANCE TEST -

DIAGNOSIS AND TESTING..............24-6

HEATER RELAY - DESCRIPTION, FUEL....14-52

HEATER RELAY - DESCRIPTION, INTAKE

AIR ...............................14-82

HEATER RELAY - INSTALLATION, FUEL . . . 14-53

HEATER RELAY - INSTALLATION, INTAKE

AIR ...............................14-82

HEATER RELAY - OPERATION, FUEL......14-52

HEATER RELAY - OPERATION, INTAKE

AIR ...............................14-82

HEATER RELAY - REMOVAL, FUEL.......14-52

HEATER RELAY - REMOVAL, INTAKE AIR . . 14-82

HEATER RETURN HOSE - INSTALLATION . . 24-65

HEATER RETURN HOSE - REMOVAL......24-64

HEIGHT ADJUSTMENT - 4WD (LD) -

STANDARD PROCEDURE.................2-3

HEIGHT MEASUREMENT - 4WD (LD) -

STANDARD PROCEDURE.................2-3

HEMI ENGINE - INSTALLATION, 3.7L/4.7L

AND 5.7L......................24-59,24-73

HEMI ENGINE - REMOVAL, 3.7L/4.7L

AND 5.7L......................24-57,24-71

HIGH BEAM INDICATOR - DESCRIPTION

. . 8J-28

HIGH BEAM INDICATOR - OPERATION

....8J-28

HIGH MOUNTED STOP LAMP -

INSTALLATION, CENTER

...............8L-11

HIGH MOUNTED STOP LAMP -

REMOVAL, CENTER

...................8L-11

HIGH MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER

...............8L-11HIGH MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER...................8L-11

HIGH PRESSURE RELIEF VALVE -

DESCRIPTION.......................24-48

HIGH PRESSURE RELIEF VALVE -

OPERATION.........................24-48

HIGH SPEEDS - DESCRIPTION, TIRE

PRESSURE..........................22-7

HIGH/LOW RELAY - DESCRIPTION,

WIPER.............................8R-20

HIGH/LOW RELAY - DIAGNOSIS AND

TESTING, WIPER.....................8R-21

HIGH/LOW RELAY - INSTALLATION,

WIPER.............................8R-22

HIGH/LOW RELAY - OPERATION, WIPER . . 8R-20

HIGH/LOW RELAY - REMOVAL, WIPER . . . 8R-21

HIGH-PRESSURE FUEL LINE LEAKS -

DIAGNOSIS AND TESTING.............14-58

HINGE - INSTALLATION.....23-16,23-22,23-31,

23-46

HINGE - INSTALLATION, CENTER SEAT

BACK..............................23-79

HINGE - REMOVAL....23-16,23-22,23-31,23-46

HINGE - REMOVAL, CENTER SEAT BACK . . 23-78

HINGE COVER - INSTALLATION, CENTER

SEAT BACK INERTIA..................23-77

HINGE COVER - REMOVAL, CENTER

SEAT BACK INERTIA..................23-77

HITCH - INSTALLATION, TRAILER........13-25

HITCH - REMOVAL, TRAILER...........13-25

HOAT COOLANT - DESCRIPTION..........7-32

HOISTING - STANDARD PROCEDURE......0-20

HOLDDOWN - DESCRIPTION, BATTERY . . . 8F-14

HOLDDOWN - INSTALLATION, BATTERY . . . 8F-14

HOLDDOWN - OPERATION, BATTERY.....8F-14

HOLDDOWN - REMOVAL, BATTERY......8F-14

HOLDER - INSTALLATION, CUP.........23-51

HOLDER - REMOVAL, CUP.............23-51

HOLDING CLUTCHES - DESCRIPTION....21-371

HOLDING CLUTCHES - OPERATION.....21-372

HOLE PLUG - INSTALLATION, CAMSHAFT

CORE..............................9-206

HOLE PLUG - REMOVAL, CAMSHAFT

CORE..............................9-205

HOLE REPAIR - DESCRIPTION,

THREADED........................Intro.-8

HONING - STANDARD PROCEDURE,

CYLINDER BORE.................9-128,9-38

HOOD - INSTALLATION................23-47

HOOD - REMOVAL....................23-46

HOOK - INSTALLATION, COAT...........23-66

HOOK - REMOVAL, COAT..............23-66

HOOK ASSEMBLY - INSTALLATION,

FRONT TOW........................13-23

HOOK ASSEMBLY - REMOVAL, FRONT

TOW ..............................13-23

HORN - DIAGNOSIS AND TESTING.......8H-1

HORN - INSTALLATION.................8H-2

HORN - REMOVAL....................8H-2

HORN SWITCH - DESCRIPTION..........8H-2

HORN SWITCH - DIAGNOSIS AND

TESTING............................8H-2

HORN SYSTEM - DESCRIPTION..........8H-1

HORN SYSTEM - DIAGNOSIS AND

TESTING............................8H-1

HORN SYSTEM - OPERATION............8H-1

HOSE - GEAR TO COOLER -

INSTALLATION, RETURN..........19-44,19-45

HOSE - GEAR TO COOLER - REMOVAL,

RETURN......................19-44,19-45

HOSE - INSTALLATION, FRONT BRAKE.....5-13

HOSE - INSTALLATION, HEATER INLET....24-64

HOSE - INSTALLATION, HEATER RETURN . 24-65

HOSE - INSTALLATION, PRESSURE . 19-44,19-45

HOSE - INSTALLATION, REAR BRAKE......5-12

HOSE - REMOVAL, FRONT..............5-12

HOSE - REMOVAL, HEATER INLET.......24-64

HOSE - REMOVAL, HEATER RETURN.....24-64

HOSE - REMOVAL, PRESSURE.....19-44,19-45

HOSE - REMOVAL, REAR BRAKE

.........5-11

HOSE - RESERVOIR TO COOLER -

INSTALLATION, RETURN

..........19-44,19-45

HOSE - RESERVOIR TO COOLER -

REMOVAL, RETURN

.............19-44,19-45

HOSE ASSEMBLY - INSTALLATION, REAR

TUBE

...............................5-13

HOSE ASSEMBLY - REMOVAL, REAR

TUBE

...............................5-12HOSE CLAMPS - DESCRIPTION...........7-3

HOSE CLAMPS - OPERATION.............7-5

HOSES/TUBES - DESCRIPTION, WASHER . 8R-11

HOSES/TUBES - OPERATION, WASHER . . . 8R-11

HOUSING - ASSEMBLY, HVAC...........24-35

HOUSING - DIAGNOSIS AND TESTING,

CLUTCH..............................6-7

HOUSING - DISASSEMBLY, HVAC........24-35

HOUSING - INSTALLATION, CLUTCH.......6-9

HOUSING - INSTALLATION, GEAR........9-300

HOUSING - INSTALLATION, HVAC........24-36

HOUSING - INSTALLATION, ROCKER.....9-255

HOUSING - REMOVAL, CLUTCH...........6-9

HOUSING - REMOVAL, GEAR...........9-299

HOUSING - REMOVAL, HVAC...........24-34

HOUSING - REMOVAL, ROCKER.........9-255

HOUSING BUSHING AND SEAL -

INSTALLATION, EXTENSION...........21-440

HOUSING BUSHING AND SEAL -

REMOVAL, EXTENSION...............21-440

HOUSING COVER - INSTALLATION, GEAR . 9-301

HOUSING COVER - REMOVAL, GEAR.....9-301

HOUSING FLUID LEAK - DIAGNOSIS AND

TESTING, CONVERTER.........21-144,21-318

HOUSING SEAL - INSTALLATION,

ADAPTER...............21-128,21-364,21-85

HOUSING SEAL - INSTALLATION,

EXTENSION . 21-128,21-201,21-507,21-536,21-85

HOUSING SEAL - REMOVAL, ADAPTER . . 21-128,

21-364,21-85

HOUSING SEAL - REMOVAL,

EXTENSION . 21-128,21-201,21-507,21-536,21-85

HOUSING SEAL AND DUST BOOT -

INSTALLATION, EXTENSION.....21-476,21-571

HOUSING SEAL AND DUST BOOT -

REMOVAL, EXTENSION.........21-476,21-571

HOW TO USE WIRING DIAGRAMS -

DESCRIPTION.....................8W-01-1

H-SECTION REPLACEMENT - STANDARD

PROCEDURE, REAR FRAME............13-13

HUB / BEARING - INSTALLATION.........2-32

HUB / BEARING - REMOVAL.............2-31

HVAC HOUSING - ASSEMBLY...........24-35

HVAC HOUSING - DISASSEMBLY........24-35

HVAC HOUSING - INSTALLATION........24-36

HVAC HOUSING - REMOVAL............24-34

HYDRAULIC BOOSTER - DIAGNOSIS

AND TESTING........................5-30

HYDRAULIC LASH ADJUSTER -

DIAGNOSIS AND TESTING.........9-125,9-32

HYDRAULIC PRESSURE TEST -

DIAGNOSIS AND TESTING......21-141,21-316

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS..............21-176,21-337

HYDRAULIC TAPPETS - DIAGNOSIS AND

TESTING...........................9-210

HYDRAULIC TAPPETS - INSTALLATION . . . 9-211

HYDRAULIC TAPPETS - REMOVAL.......9-211

HYDROBOOST - INSTALLATION..........5-27

HYDROBOOST - INSTALLATION, ALL

EXCEPT.............................5-27

HYDROBOOST - REMOVAL..............5-26

HYDROBOOST - REMOVAL, ALL EXCEPT . . . 5-26

HYDRO-BOOST BRAKE BOOSTER -

INSTALLATION........................5-32

HYDRO-BOOST BRAKE BOOSTER -

REMOVAL

...........................5-31

HYDROFORM FENDER RAIL REPAIR -

STANDARD PROCEDURE

...............13-11

HYDROSTATIC LOCK - STANDARD

PROCEDURE

...................9-190,9-240

IDENTIFICATION - DESCRIPTION,

FASTENER

.........................Intro.-5

IDENTIFICATION AND INFORMATION -

DESCRIPTION, SECTION

.............8W-01-6

IDENTIFICATION NUMBER -

DESCRIPTION, VEHICLE

..............Intro.-1

IDLE AIR CONTROL MOTOR -

DESCRIPTION

.......................14-28

IDLE AIR CONTROL MOTOR -

INSTALLATION

.......................14-29

IDLE AIR CONTROL MOTOR -

OPERATION

.........................14-28

IDLE AIR CONTROL MOTOR - REMOVAL

. . 14-29

IDLER SHAFT - INSTALLATION

......9-179,9-81

IDLER SHAFT - REMOVAL

..........9-179,9-81

IGNITION - SPECIFICATIONS, TORQUE

.....8I-3

16 INDEXDR

Description Group-Page Description Group-Page Description Group-Page