Window DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1135 of 2627

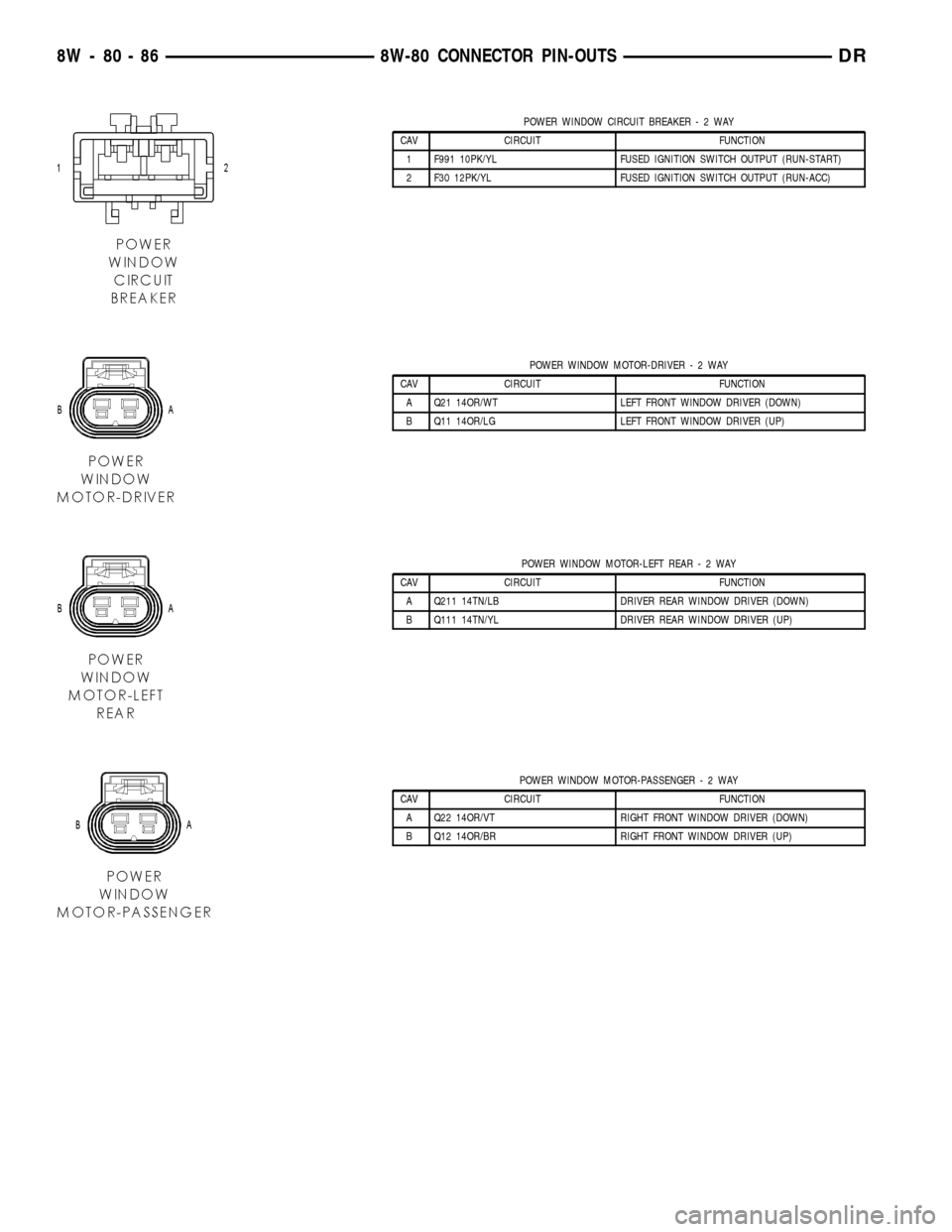

POWER WINDOW CIRCUIT BREAKER-2WAY

CAV CIRCUIT FUNCTION

1 F991 10PK/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

2 F30 12PK/YL FUSED IGNITION SWITCH OUTPUT (RUN-ACC)

POWER WINDOW MOTOR-DRIVER-2WAY

CAV CIRCUIT FUNCTION

A Q21 14OR/WT LEFT FRONT WINDOW DRIVER (DOWN)

B Q11 14OR/LG LEFT FRONT WINDOW DRIVER (UP)

POWER WINDOW MOTOR-LEFT REAR-2WAY

CAV CIRCUIT FUNCTION

A Q211 14TN/LB DRIVER REAR WINDOW DRIVER (DOWN)

B Q111 14TN/YL DRIVER REAR WINDOW DRIVER (UP)

POWER WINDOW MOTOR-PASSENGER-2WAY

CAV CIRCUIT FUNCTION

A Q22 14OR/VT RIGHT FRONT WINDOW DRIVER (DOWN)

B Q12 14OR/BR RIGHT FRONT WINDOW DRIVER (UP)

8W - 80 - 86 8W-80 CONNECTOR PIN-OUTSDR

Page 1136 of 2627

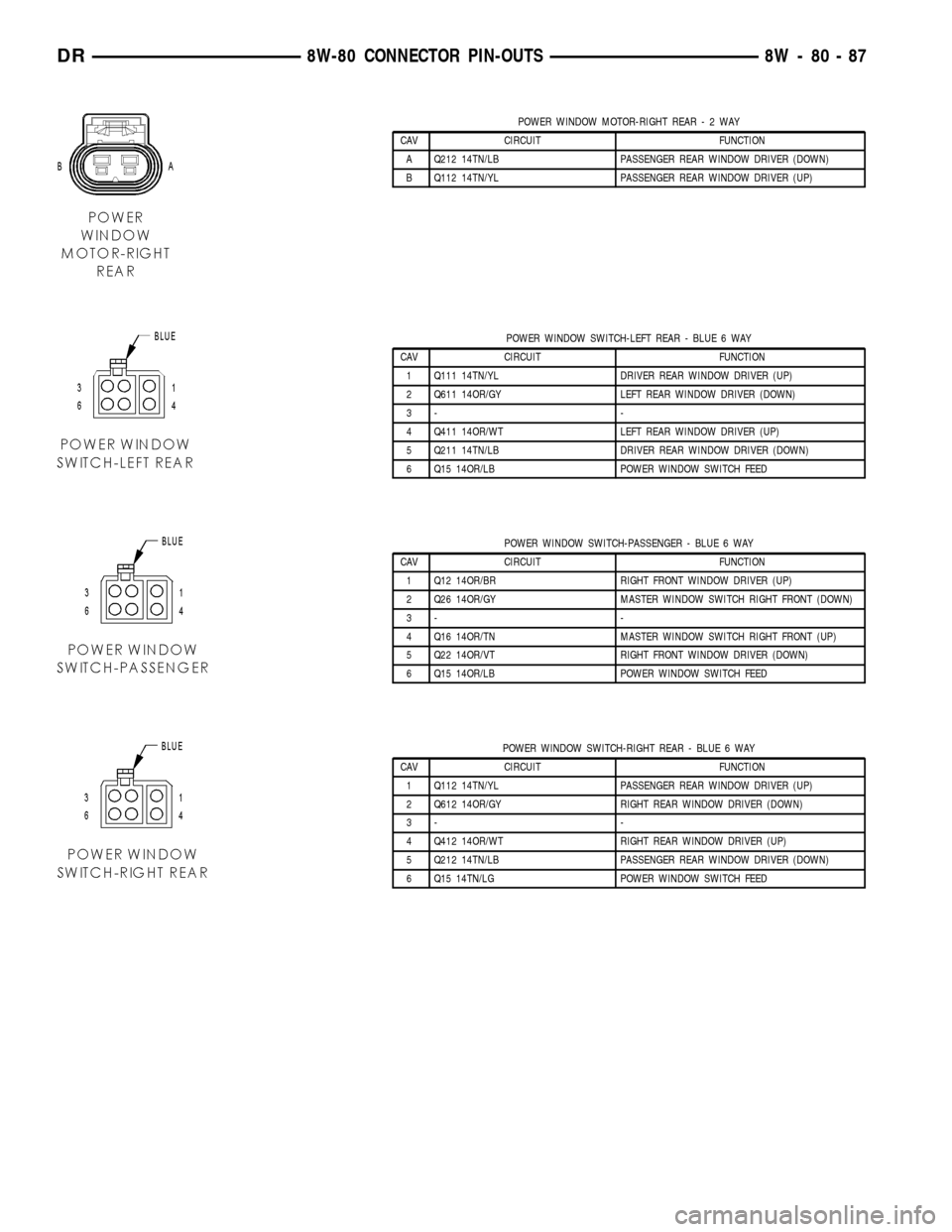

POWER WINDOW MOTOR-RIGHT REAR-2WAY

CAV CIRCUIT FUNCTION

A Q212 14TN/LB PASSENGER REAR WINDOW DRIVER (DOWN)

B Q112 14TN/YL PASSENGER REAR WINDOW DRIVER (UP)

POWER WINDOW SWITCH-LEFT REAR - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 Q111 14TN/YL DRIVER REAR WINDOW DRIVER (UP)

2 Q611 14OR/GY LEFT REAR WINDOW DRIVER (DOWN)

3- -

4 Q411 14OR/WT LEFT REAR WINDOW DRIVER (UP)

5 Q211 14TN/LB DRIVER REAR WINDOW DRIVER (DOWN)

6 Q15 14OR/LB POWER WINDOW SWITCH FEED

POWER WINDOW SWITCH-PASSENGER - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 Q12 14OR/BR RIGHT FRONT WINDOW DRIVER (UP)

2 Q26 14OR/GY MASTER WINDOW SWITCH RIGHT FRONT (DOWN)

3- -

4 Q16 14OR/TN MASTER WINDOW SWITCH RIGHT FRONT (UP)

5 Q22 14OR/VT RIGHT FRONT WINDOW DRIVER (DOWN)

6 Q15 14OR/LB POWER WINDOW SWITCH FEED

POWER WINDOW SWITCH-RIGHT REAR - BLUE 6 WAY

CAV CIRCUIT FUNCTION

1 Q112 14TN/YL PASSENGER REAR WINDOW DRIVER (UP)

2 Q612 14OR/GY RIGHT REAR WINDOW DRIVER (DOWN)

3- -

4 Q412 14OR/WT RIGHT REAR WINDOW DRIVER (UP)

5 Q212 14TN/LB PASSENGER REAR WINDOW DRIVER (DOWN)

6 Q15 14TN/LG POWER WINDOW SWITCH FEED

DR8W-80 CONNECTOR PIN-OUTS 8W - 80 - 87

Page 1159 of 2627

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Mode Door Actuator 2 BK Right Side of HVAC N/S

Multi-Function Switch BK On Steering Column 31

Natural Vacuum Leak Detection

AssemblyBK Rear of Transmission 18, 50

Output Speed Sensor DB Left Side of Transmission 11, 14, 15, 16

Overdrive Switch WT Center of Instrument Panel 35

Overhead Map/Reading Lamp

(Except Base)NAT Center of Headliner N/S

Oxygen Sensor 1/1 Upstream BK Left Front of Side of Transmission 15, 16, 17, 19

Oxygen Sensor 1/2 Downstream NAT Left Rear of Side of Transmission 15, 16, 17, 19

Oxygen Sensor 2/1 Upstream BK Right Front Side of Transmission 15, 17, 18

Oxygen Sensor 2/2 Downstream BK Right Rear Side of Transmission 15, 17, 18

Park Brake Switch At Park Brake 22, 24

Park/Turn Signal Lamp-Left Front BK At Lamp 23, 28, 29

Park/Turn Signal Lamp-Right Front BK At Lamp 1, 21, 26

Passenger Airbag On/Off Switch Right Side of Instrument Panel 33, 35, 39

Passenger Blend Door Actuator

(Dual Zone)BK Right Side of HVAC N/S

Passenger Lumbar Switch At Passenger Seat N/S

Power Mirror-Left BK At Mirror 41

Power Mirror-Right BK At Mirror 42

Power Outlet RD Center of Instrument Panel 35

Power Outlet-Console BK Center of Instrument Panel N/S

Power Seat Motor-Driver Front

VerticalRD At Driver Seat N/S

Power Seat Motor-Driver Horizontal BK At Driver Seat N/S

Power Seat Motor-Driver Rear

VerticalBK At Driver Seat N/S

Power Seat Switch-Driver BK At Driver Seat N/S

Power Seat Switch-Passenger BK At Passenger Seat N/S

Power Steering Pressure Switch BK Near Power Steering Pump 7

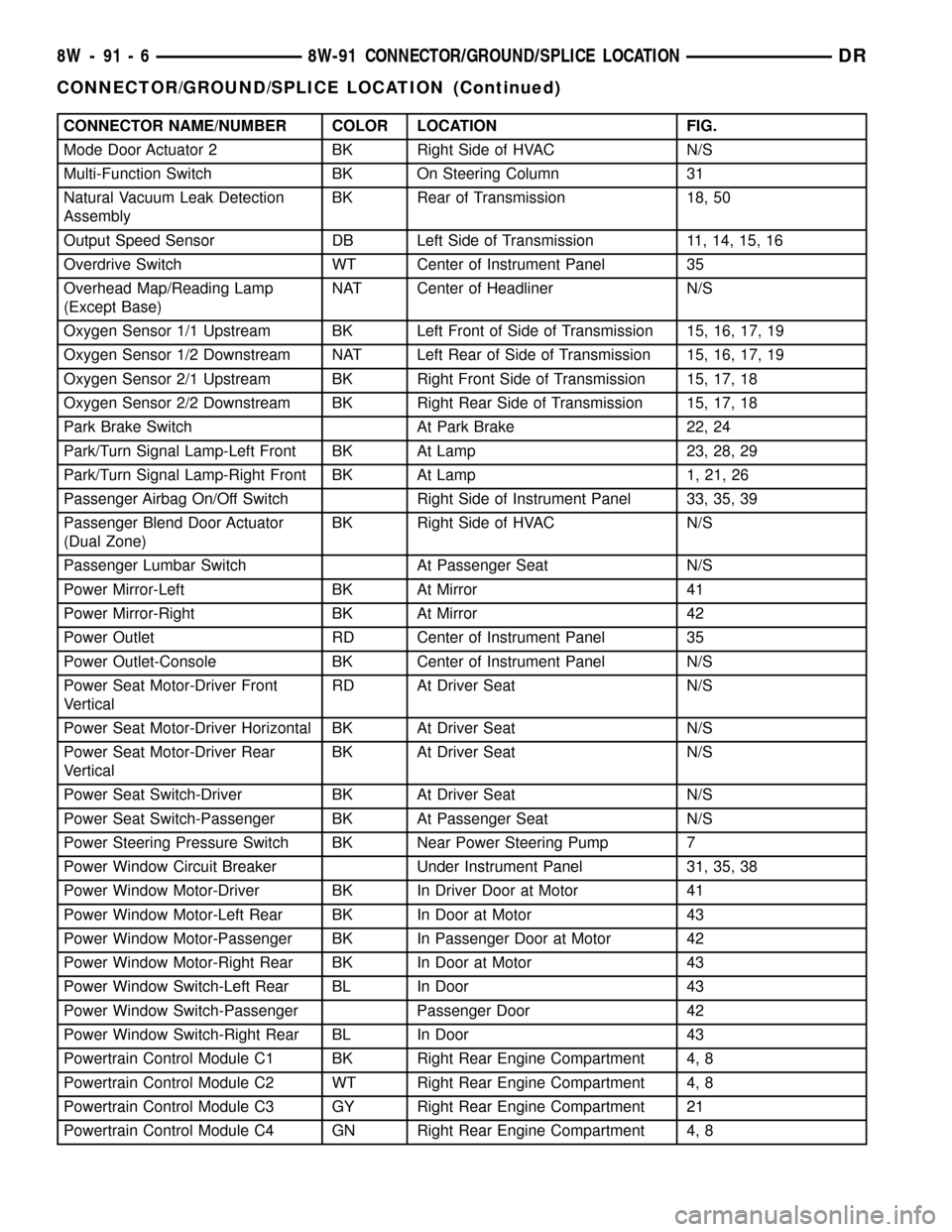

Power Window Circuit Breaker Under Instrument Panel 31, 35, 38

Power Window Motor-Driver BK In Driver Door at Motor 41

Power Window Motor-Left Rear BK In Door at Motor 43

Power Window Motor-Passenger BK In Passenger Door at Motor 42

Power Window Motor-Right Rear BK In Door at Motor 43

Power Window Switch-Left Rear BL In Door 43

Power Window Switch-Passenger Passenger Door 42

Power Window Switch-Right Rear BL In Door 43

Powertrain Control Module C1 BK Right Rear Engine Compartment 4, 8

Powertrain Control Module C2 WT Right Rear Engine Compartment 4, 8

Powertrain Control Module C3 GY Right Rear Engine Compartment 21

Powertrain Control Module C4 GN Right Rear Engine Compartment 4, 8

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONDR

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 2290 of 2627

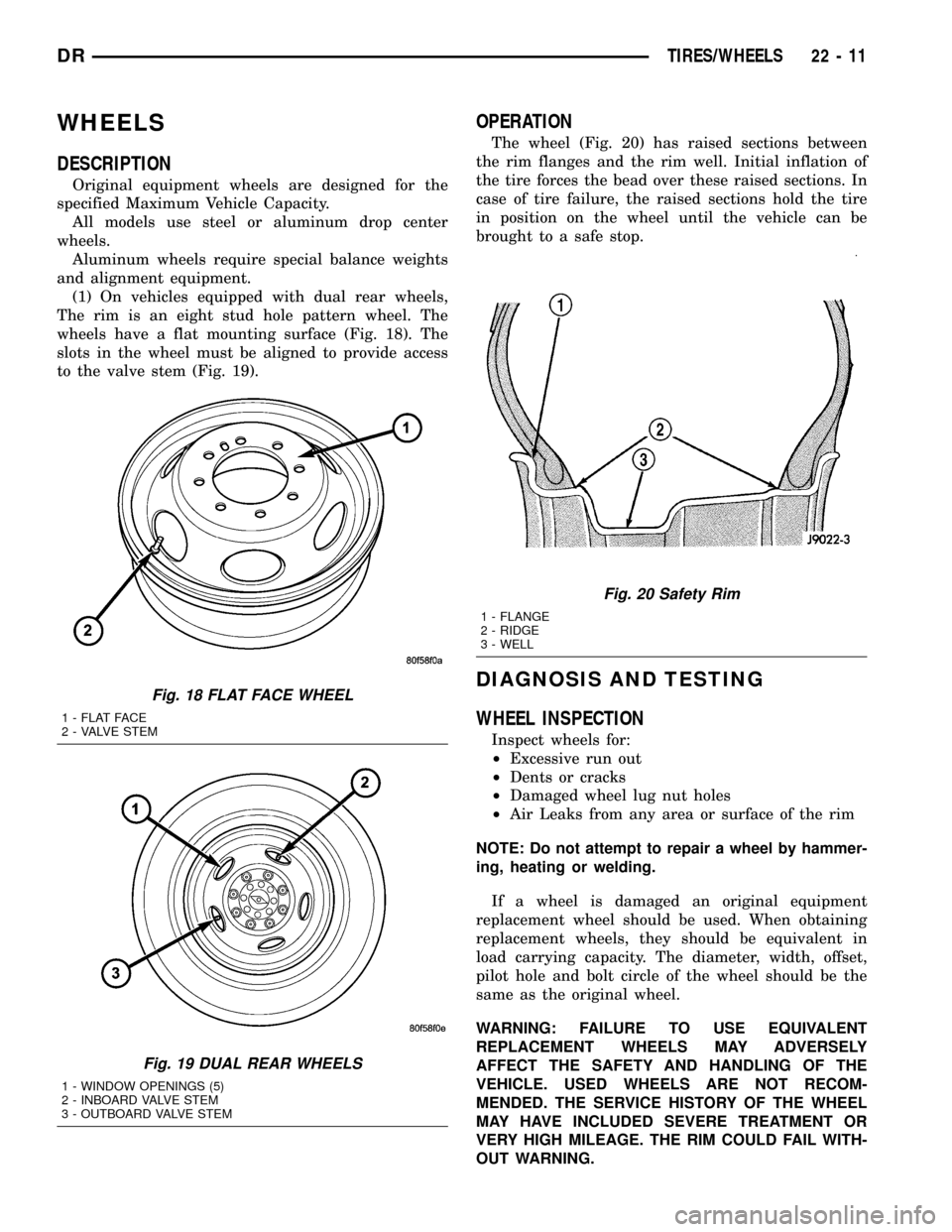

WHEELS

DESCRIPTION

Original equipment wheels are designed for the

specified Maximum Vehicle Capacity.

All models use steel or aluminum drop center

wheels.

Aluminum wheels require special balance weights

and alignment equipment.

(1) On vehicles equipped with dual rear wheels,

The rim is an eight stud hole pattern wheel. The

wheels have a flat mounting surface (Fig. 18). The

slots in the wheel must be aligned to provide access

to the valve stem (Fig. 19).

OPERATION

The wheel (Fig. 20) has raised sections between

the rim flanges and the rim well. Initial inflation of

the tire forces the bead over these raised sections. In

case of tire failure, the raised sections hold the tire

in position on the wheel until the vehicle can be

brought to a safe stop.

DIAGNOSIS AND TESTING

WHEEL INSPECTION

Inspect wheels for:

²Excessive run out

²Dents or cracks

²Damaged wheel lug nut holes

²Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by hammer-

ing, heating or welding.

If a wheel is damaged an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they should be equivalent in

load carrying capacity. The diameter, width, offset,

pilot hole and bolt circle of the wheel should be the

same as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF THE

VEHICLE. USED WHEELS ARE NOT RECOM-

MENDED. THE SERVICE HISTORY OF THE WHEEL

MAY HAVE INCLUDED SEVERE TREATMENT OR

VERY HIGH MILEAGE. THE RIM COULD FAIL WITH-

OUT WARNING.

Fig. 18 FLAT FACE WHEEL

1 - FLAT FACE

2 - VALVE STEM

Fig. 19 DUAL REAR WHEELS

1 - WINDOW OPENINGS (5)

2 - INBOARD VALVE STEM

3 - OUTBOARD VALVE STEM

Fig. 20 Safety Rim

1 - FLANGE

2 - RIDGE

3 - WELL

DRTIRES/WHEELS 22 - 11

Page 2293 of 2627

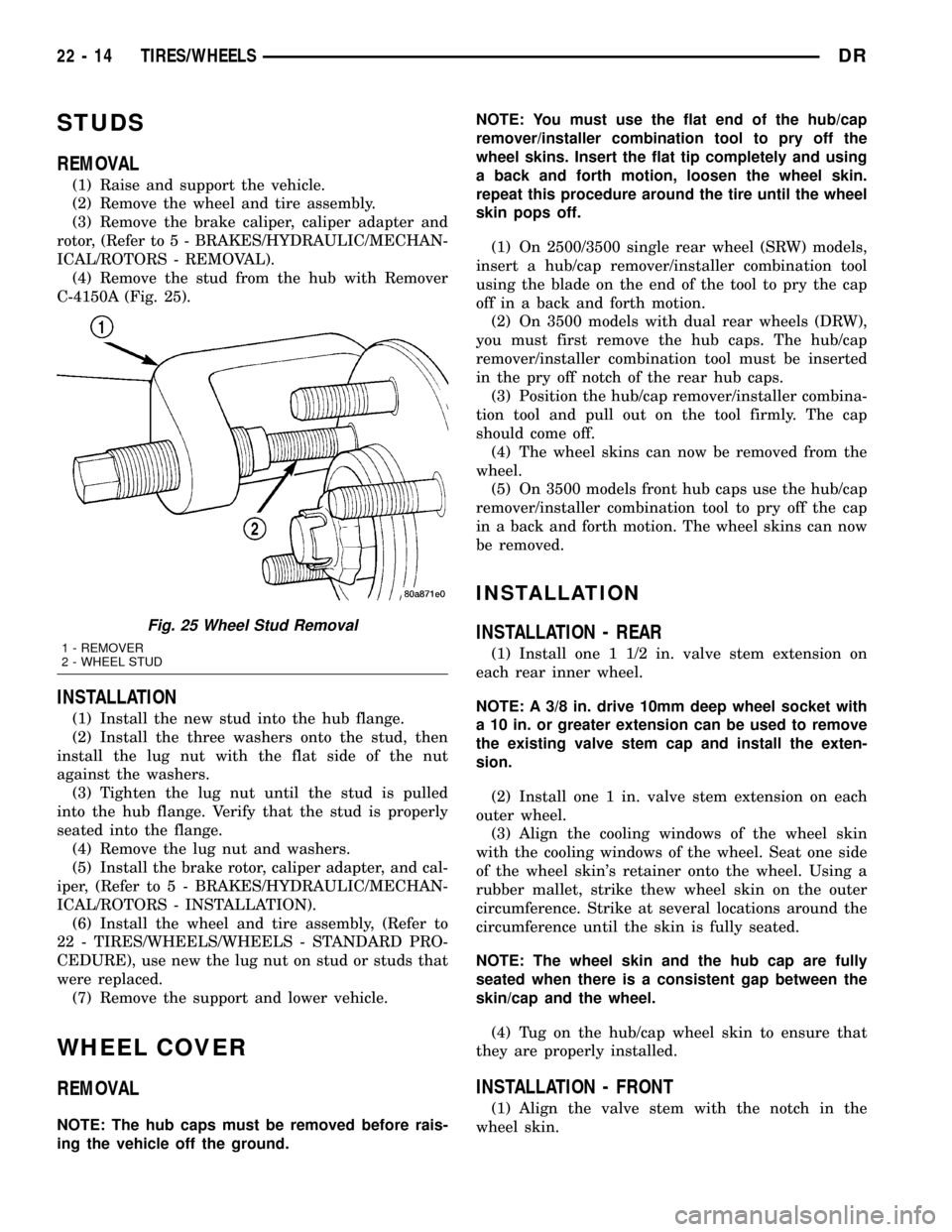

STUDS

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the brake caliper, caliper adapter and

rotor, (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - REMOVAL).

(4) Remove the stud from the hub with Remover

C-4150A (Fig. 25).

INSTALLATION

(1) Install the new stud into the hub flange.

(2) Install the three washers onto the stud, then

install the lug nut with the flat side of the nut

against the washers.

(3) Tighten the lug nut until the stud is pulled

into the hub flange. Verify that the stud is properly

seated into the flange.

(4) Remove the lug nut and washers.

(5) Install the brake rotor, caliper adapter, and cal-

iper, (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - INSTALLATION).

(6) Install the wheel and tire assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE), use new the lug nut on stud or studs that

were replaced.

(7) Remove the support and lower vehicle.

WHEEL COVER

REMOVAL

NOTE: The hub caps must be removed before rais-

ing the vehicle off the ground.NOTE: You must use the flat end of the hub/cap

remover/installer combination tool to pry off the

wheel skins. Insert the flat tip completely and using

a back and forth motion, loosen the wheel skin.

repeat this procedure around the tire until the wheel

skin pops off.

(1) On 2500/3500 single rear wheel (SRW) models,

insert a hub/cap remover/installer combination tool

using the blade on the end of the tool to pry the cap

off in a back and forth motion.

(2) On 3500 models with dual rear wheels (DRW),

you must first remove the hub caps. The hub/cap

remover/installer combination tool must be inserted

in the pry off notch of the rear hub caps.

(3) Position the hub/cap remover/installer combina-

tion tool and pull out on the tool firmly. The cap

should come off.

(4) The wheel skins can now be removed from the

wheel.

(5) On 3500 models front hub caps use the hub/cap

remover/installer combination tool to pry off the cap

in a back and forth motion. The wheel skins can now

be removed.

INSTALLATION

INSTALLATION - REAR

(1) Install one 1 1/2 in. valve stem extension on

each rear inner wheel.

NOTE: A 3/8 in. drive 10mm deep wheel socket with

a 10 in. or greater extension can be used to remove

the existing valve stem cap and install the exten-

sion.

(2) Install one 1 in. valve stem extension on each

outer wheel.

(3) Align the cooling windows of the wheel skin

with the cooling windows of the wheel. Seat one side

of the wheel skin's retainer onto the wheel. Using a

rubber mallet, strike thew wheel skin on the outer

circumference. Strike at several locations around the

circumference until the skin is fully seated.

NOTE: The wheel skin and the hub cap are fully

seated when there is a consistent gap between the

skin/cap and the wheel.

(4) Tug on the hub/cap wheel skin to ensure that

they are properly installed.

INSTALLATION - FRONT

(1) Align the valve stem with the notch in the

wheel skin.

Fig. 25 Wheel Stud Removal

1 - REMOVER

2 - WHEEL STUD

22 - 14 TIRES/WHEELSDR

Page 2297 of 2627

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-

cle. For hoisting recommendations (Refer to LUBRI-

CATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE).

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

DIAGNOSIS AND TESTING - WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during high

cross winds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If compo-

nent alignment or sealing is necessary, refer to the

appropriate section of this group for proper proce-

dures.

23 - 2 BODYDR

BODY (Continued)

Page 2300 of 2627

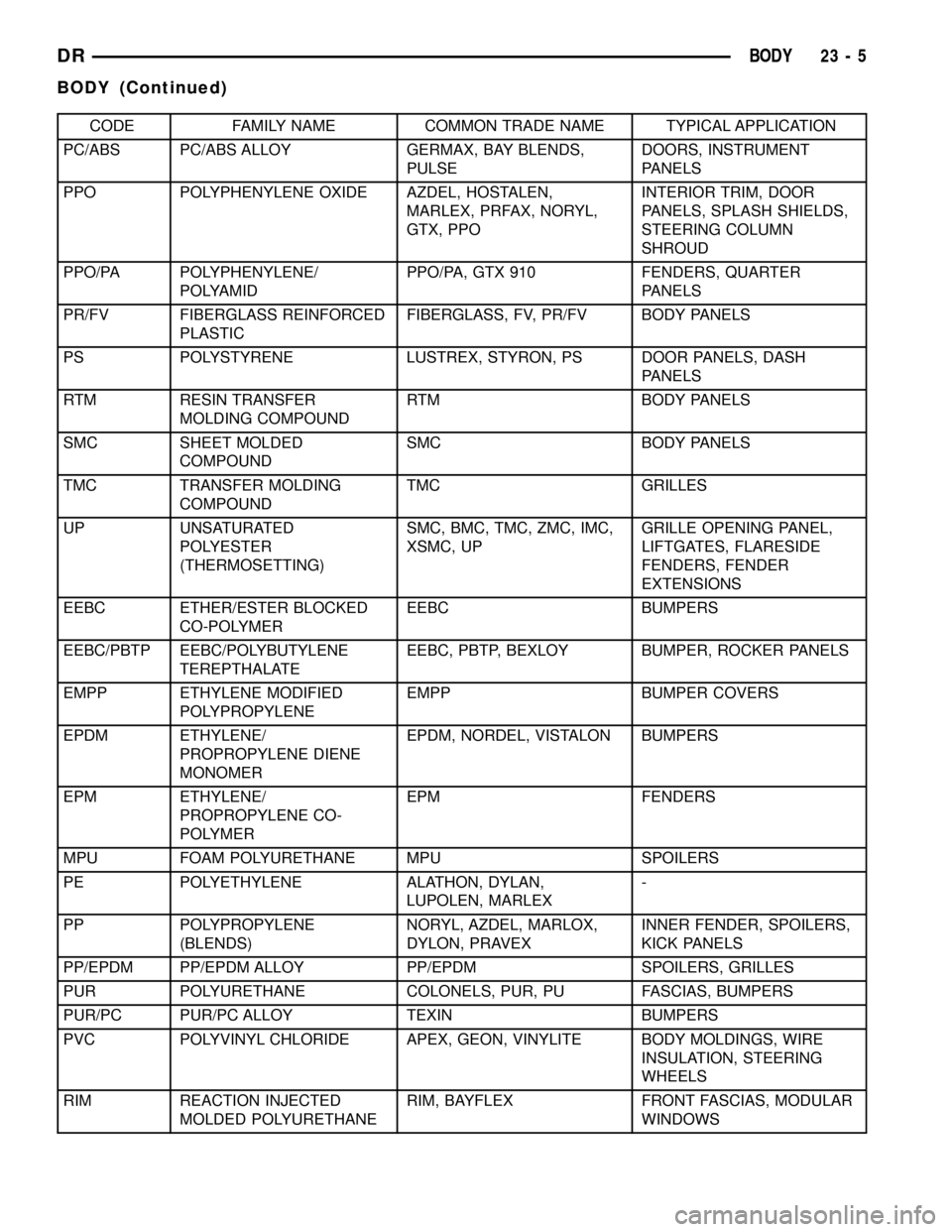

CODE FAMILY NAME COMMON TRADE NAME TYPICAL APPLICATION

PC/ABS PC/ABS ALLOY GERMAX, BAY BLENDS,

PULSEDOORS, INSTRUMENT

PANELS

PPO POLYPHENYLENE OXIDE AZDEL, HOSTALEN,

MARLEX, PRFAX, NORYL,

GTX, PPOINTERIOR TRIM, DOOR

PANELS, SPLASH SHIELDS,

STEERING COLUMN

SHROUD

PPO/PA POLYPHENYLENE/

POLYAMIDPPO/PA, GTX 910 FENDERS, QUARTER

PANELS

PR/FV FIBERGLASS REINFORCED

PLASTICFIBERGLASS, FV, PR/FV BODY PANELS

PS POLYSTYRENE LUSTREX, STYRON, PS DOOR PANELS, DASH

PANELS

RTM RESIN TRANSFER

MOLDING COMPOUNDRTM BODY PANELS

SMC SHEET MOLDED

COMPOUNDSMC BODY PANELS

TMC TRANSFER MOLDING

COMPOUNDTMC GRILLES

UP UNSATURATED

POLYESTER

(THERMOSETTING)SMC, BMC, TMC, ZMC, IMC,

XSMC, UPGRILLE OPENING PANEL,

LIFTGATES, FLARESIDE

FENDERS, FENDER

EXTENSIONS

EEBC ETHER/ESTER BLOCKED

CO-POLYMEREEBC BUMPERS

EEBC/PBTP EEBC/POLYBUTYLENE

TEREPTHALATEEEBC, PBTP, BEXLOY BUMPER, ROCKER PANELS

EMPP ETHYLENE MODIFIED

POLYPROPYLENEEMPP BUMPER COVERS

EPDM ETHYLENE/

PROPROPYLENE DIENE

MONOMEREPDM, NORDEL, VISTALON BUMPERS

EPM ETHYLENE/

PROPROPYLENE CO-

POLYMEREPM FENDERS

MPU FOAM POLYURETHANE MPU SPOILERS

PE POLYETHYLENE ALATHON, DYLAN,

LUPOLEN, MARLEX-

PP POLYPROPYLENE

(BLENDS)NORYL, AZDEL, MARLOX,

DYLON, PRAVEXINNER FENDER, SPOILERS,

KICK PANELS

PP/EPDM PP/EPDM ALLOY PP/EPDM SPOILERS, GRILLES

PUR POLYURETHANE COLONELS, PUR, PU FASCIAS, BUMPERS

PUR/PC PUR/PC ALLOY TEXIN BUMPERS

PVC POLYVINYL CHLORIDE APEX, GEON, VINYLITE BODY MOLDINGS, WIRE

INSULATION, STEERING

WHEELS

RIM REACTION INJECTED

MOLDED POLYURETHANERIM, BAYFLEX FRONT FASCIAS, MODULAR

WINDOWS

DRBODY 23 - 5

BODY (Continued)

Page 2313 of 2627

DOOR - FRONT

TABLE OF CONTENTS

page page

DOOR

REMOVAL.............................18

INSTALLATION.........................18

ADJUSTMENTS

ADJUSTMENT........................19

DOOR GLASS

REMOVAL.............................20

INSTALLATION.........................20

EXTERIOR HANDLE

REMOVAL.............................20

INSTALLATION.........................21

GLASS RUN CHANNEL

REMOVAL.............................21

INSTALLATION.........................22

HINGE

REMOVAL.............................22

INSTALLATION.........................22

INSIDE HANDLE ACTUATOR

REMOVAL.............................22

INSTALLATION.........................22

LATCH

REMOVAL.............................23

INSTALLATION.........................23

ADJUSTMENTS

ADJUSTMENT........................23LATCH STRIKER

REMOVAL.............................23

INSTALLATION.........................23

ADJUSTMENTS

ADJUSTMENT........................24

LOCK CYLINDER

REMOVAL.............................24

INSTALLATION.........................24

TRIM PANEL

REMOVAL.............................24

INSTALLATION.........................24

WATERDAM

REMOVAL.............................25

INSTALLATION.........................25

WINDOW REGULATOR - POWER

REMOVAL.............................25

INSTALLATION.........................26

WINDOW REGULATOR - MANUAL

REMOVAL.............................26

INSTALLATION.........................27

SIDE VIEW MIRROR FLAG

REMOVAL.............................27

INSTALLATION.........................27

DOOR

REMOVAL

(1) Disconnect the door wire harness electrical con-

nector at the A-pillar. (Fig. 1)

(2) Using a grease pencil or equivalent, mark the

outline of the door hinges on the door to aid in instal-

lation.

(3) Support the door with a suitable lifting device.

NOTE: The epoxy bonded washers should not be

seperated from the hinge. If the washers are

removed the door may have to be re-adjusted.

(4) Remove the nuts and bolts attaching the door

hinges to the door.

INSTALLATION

(1) Support the door with a suitable lifting device

and install the door onto the hinges.

(2) Install the washers, if there were removed pre-

viously, nuts and tighten to 28 N´m (21 ft. lbs.).

(3) Connect the electrical connectors.

(4) Adjust the door as necessary. (Refer to 23 -

BODY/DOOR - FRONT/DOOR - ADJUSTMENTS)

23 - 18 DOOR - FRONTDR

Page 2315 of 2627

(4) Adjust the door to the correct position. (Refer

to 23 - BODY/BODY STRUCTURE/GAP AND

FLUSH - SPECIFICATIONS)

(5) Tighten the door to hinges fasteners to 28 N´m

(21 ft. lbs.).

(6) Tighten the latch striker bolts. (Refer to 23 -

BODY/DOOR - FRONT/LATCH STRIKER - INSTAL-

LATION)

DOOR GLASS

REMOVAL

(1) Remove the waterdam. (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - REMOVAL)

(2) Reinstall the window handle, if equipped.

(3) Remove the window switch from the door trim

panel and reconnect it to the door wire harness, if

equipped.

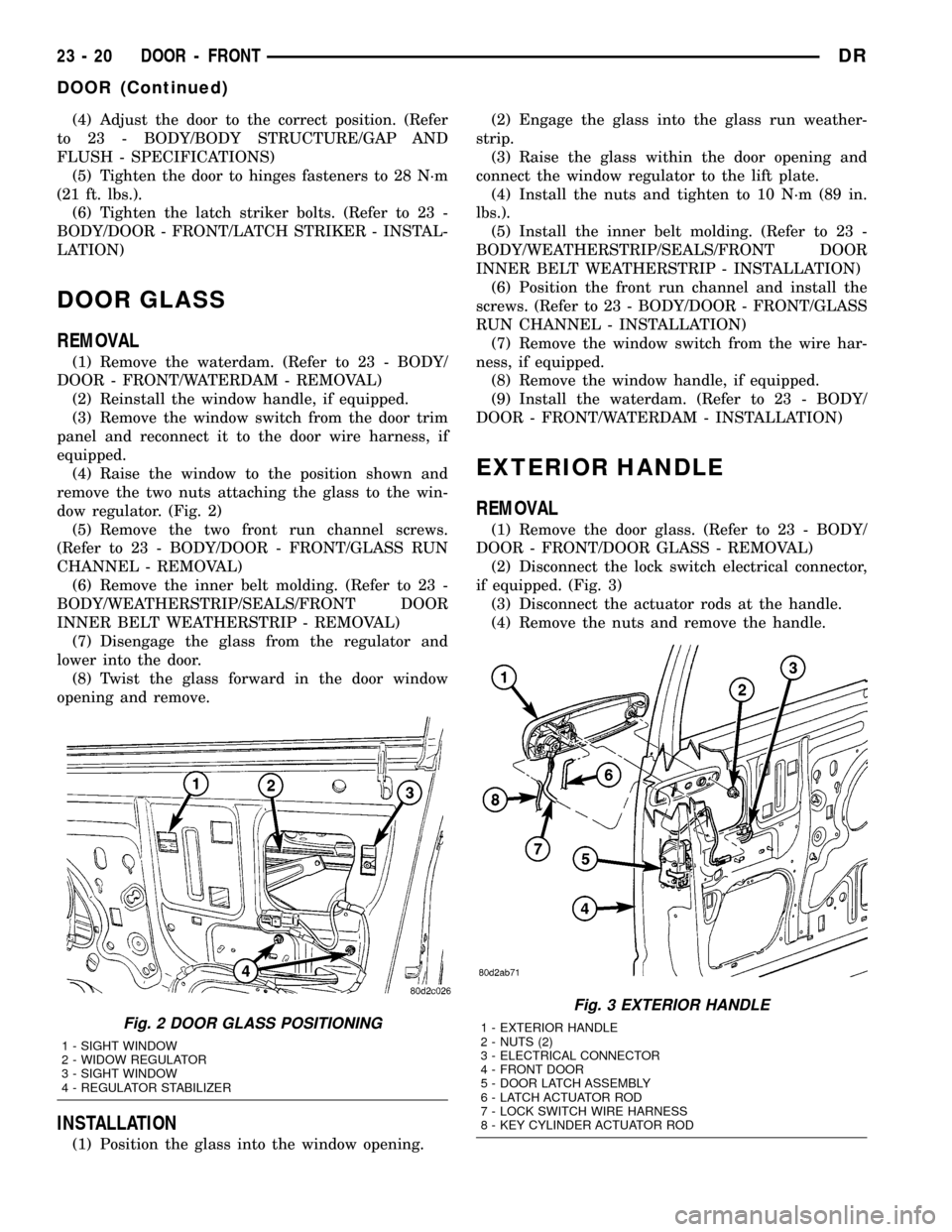

(4) Raise the window to the position shown and

remove the two nuts attaching the glass to the win-

dow regulator. (Fig. 2)

(5) Remove the two front run channel screws.

(Refer to 23 - BODY/DOOR - FRONT/GLASS RUN

CHANNEL - REMOVAL)

(6) Remove the inner belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FRONT DOOR

INNER BELT WEATHERSTRIP - REMOVAL)

(7) Disengage the glass from the regulator and

lower into the door.

(8) Twist the glass forward in the door window

opening and remove.

INSTALLATION

(1) Position the glass into the window opening.(2) Engage the glass into the glass run weather-

strip.

(3) Raise the glass within the door opening and

connect the window regulator to the lift plate.

(4) Install the nuts and tighten to 10 N´m (89 in.

lbs.).

(5) Install the inner belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FRONT DOOR

INNER BELT WEATHERSTRIP - INSTALLATION)

(6) Position the front run channel and install the

screws. (Refer to 23 - BODY/DOOR - FRONT/GLASS

RUN CHANNEL - INSTALLATION)

(7) Remove the window switch from the wire har-

ness, if equipped.

(8) Remove the window handle, if equipped.

(9) Install the waterdam. (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - INSTALLATION)

EXTERIOR HANDLE

REMOVAL

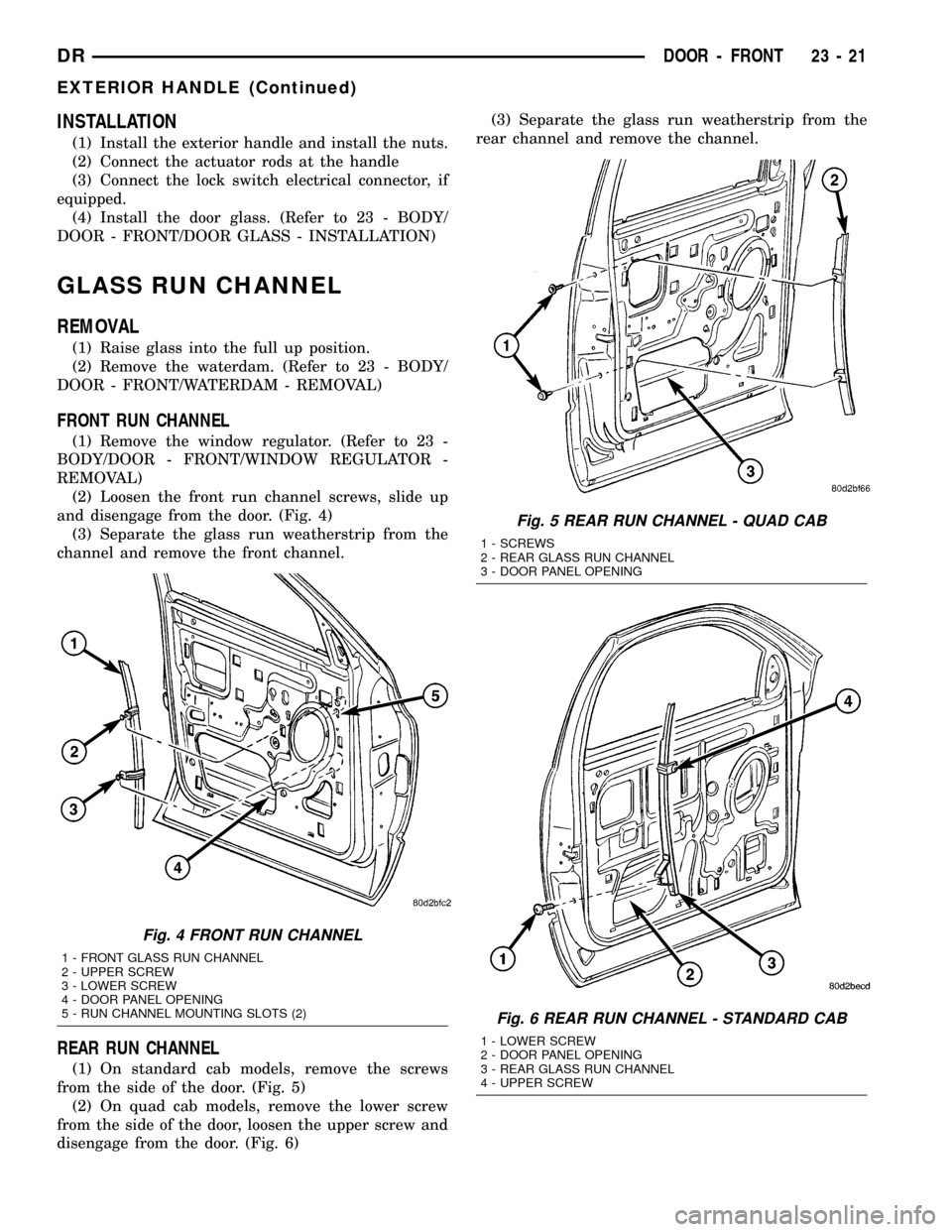

(1) Remove the door glass. (Refer to 23 - BODY/

DOOR - FRONT/DOOR GLASS - REMOVAL)

(2) Disconnect the lock switch electrical connector,

if equipped. (Fig. 3)

(3) Disconnect the actuator rods at the handle.

(4) Remove the nuts and remove the handle.

Fig. 2 DOOR GLASS POSITIONING

1 - SIGHT WINDOW

2 - WIDOW REGULATOR

3 - SIGHT WINDOW

4 - REGULATOR STABILIZER

Fig. 3 EXTERIOR HANDLE

1 - EXTERIOR HANDLE

2 - NUTS (2)

3 - ELECTRICAL CONNECTOR

4 - FRONT DOOR

5 - DOOR LATCH ASSEMBLY

6 - LATCH ACTUATOR ROD

7 - LOCK SWITCH WIRE HARNESS

8 - KEY CYLINDER ACTUATOR ROD

23 - 20 DOOR - FRONTDR

DOOR (Continued)

Page 2316 of 2627

INSTALLATION

(1) Install the exterior handle and install the nuts.

(2) Connect the actuator rods at the handle

(3) Connect the lock switch electrical connector, if

equipped.

(4) Install the door glass. (Refer to 23 - BODY/

DOOR - FRONT/DOOR GLASS - INSTALLATION)

GLASS RUN CHANNEL

REMOVAL

(1) Raise glass into the full up position.

(2) Remove the waterdam. (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - REMOVAL)

FRONT RUN CHANNEL

(1) Remove the window regulator. (Refer to 23 -

BODY/DOOR - FRONT/WINDOW REGULATOR -

REMOVAL)

(2) Loosen the front run channel screws, slide up

and disengage from the door. (Fig. 4)

(3) Separate the glass run weatherstrip from the

channel and remove the front channel.

REAR RUN CHANNEL

(1) On standard cab models, remove the screws

from the side of the door. (Fig. 5)

(2) On quad cab models, remove the lower screw

from the side of the door, loosen the upper screw and

disengage from the door. (Fig. 6)(3) Separate the glass run weatherstrip from the

rear channel and remove the channel.

Fig. 4 FRONT RUN CHANNEL

1 - FRONT GLASS RUN CHANNEL

2 - UPPER SCREW

3 - LOWER SCREW

4 - DOOR PANEL OPENING

5 - RUN CHANNEL MOUNTING SLOTS (2)

Fig. 5 REAR RUN CHANNEL - QUAD CAB

1 - SCREWS

2 - REAR GLASS RUN CHANNEL

3 - DOOR PANEL OPENING

Fig. 6 REAR RUN CHANNEL - STANDARD CAB

1 - LOWER SCREW

2 - DOOR PANEL OPENING

3 - REAR GLASS RUN CHANNEL

4 - UPPER SCREW

DRDOOR - FRONT 23 - 21

EXTERIOR HANDLE (Continued)