front suspension DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1672 of 2627

GEAR - INDEPENDENT FRONT SUSPENSION

TABLE OF CONTENTS

page page

GEAR - INDEPENDENT FRONT SUSPENSION

DESCRIPTION.........................17

REMOVAL.............................17

INSTALLATION.........................18

SPECIFICATIONS

TORQUE CHART......................19BUSHING

REMOVAL.............................19

INSTALLATION.........................19

GEAR - INDEPENDENT FRONT

SUSPENSION

DESCRIPTION

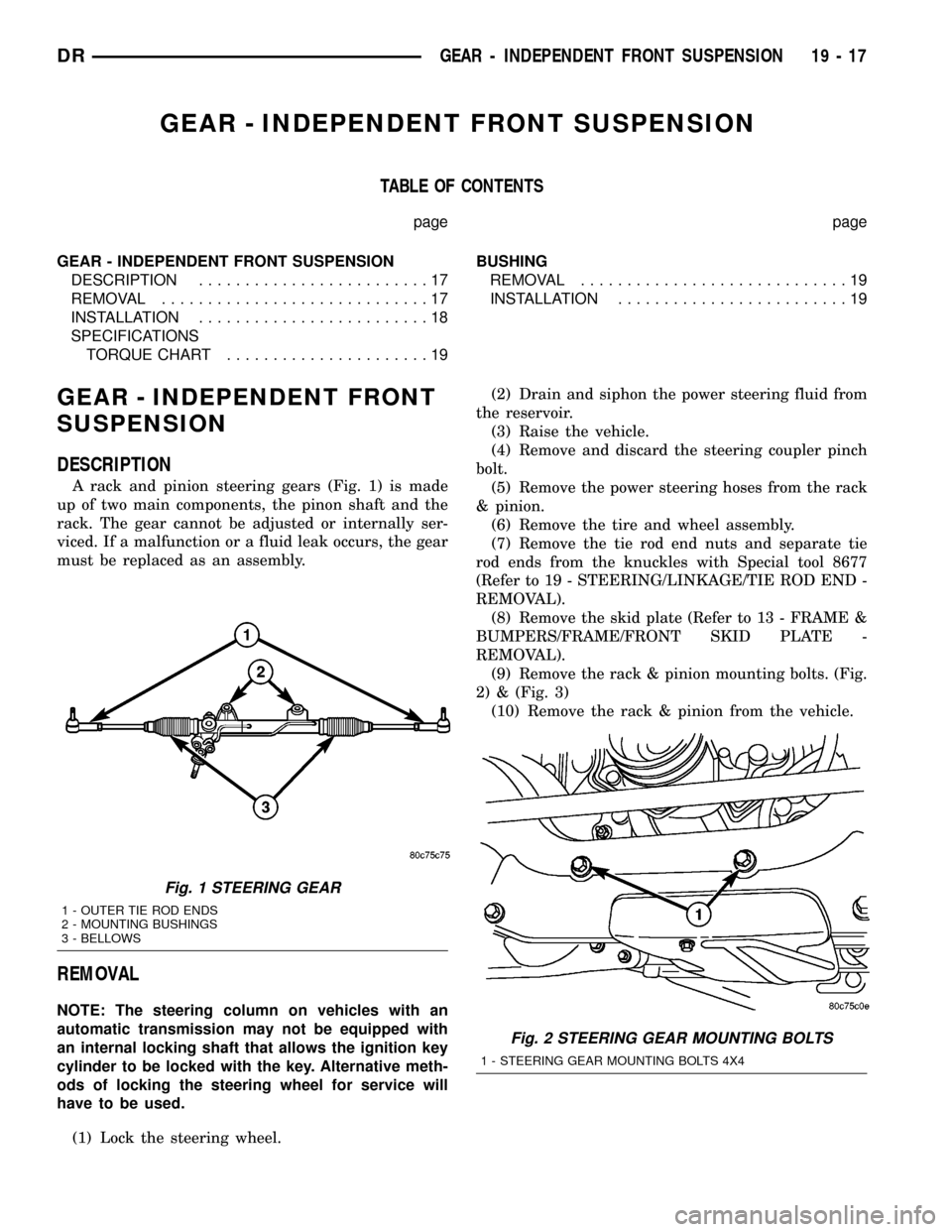

A rack and pinion steering gears (Fig. 1) is made

up of two main components, the pinon shaft and the

rack. The gear cannot be adjusted or internally ser-

viced. If a malfunction or a fluid leak occurs, the gear

must be replaced as an assembly.

REMOVAL

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative meth-

ods of locking the steering wheel for service will

have to be used.

(1) Lock the steering wheel.(2) Drain and siphon the power steering fluid from

the reservoir.

(3) Raise the vehicle.

(4) Remove and discard the steering coupler pinch

bolt.

(5) Remove the power steering hoses from the rack

& pinion.

(6) Remove the tire and wheel assembly.

(7) Remove the tie rod end nuts and separate tie

rod ends from the knuckles with Special tool 8677

(Refer to 19 - STEERING/LINKAGE/TIE ROD END -

REMOVAL).

(8) Remove the skid plate (Refer to 13 - FRAME &

BUMPERS/FRAME/FRONT SKID PLATE -

REMOVAL).

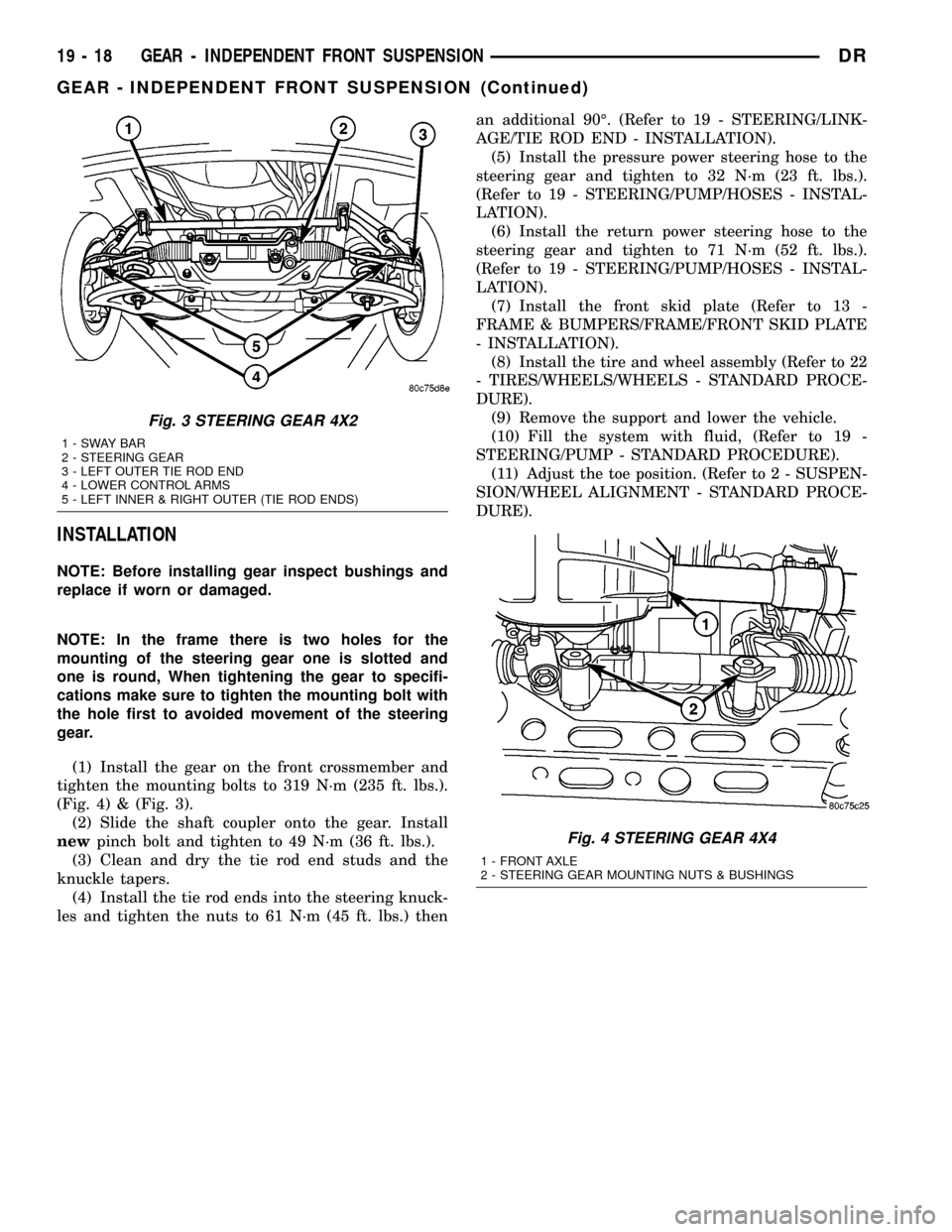

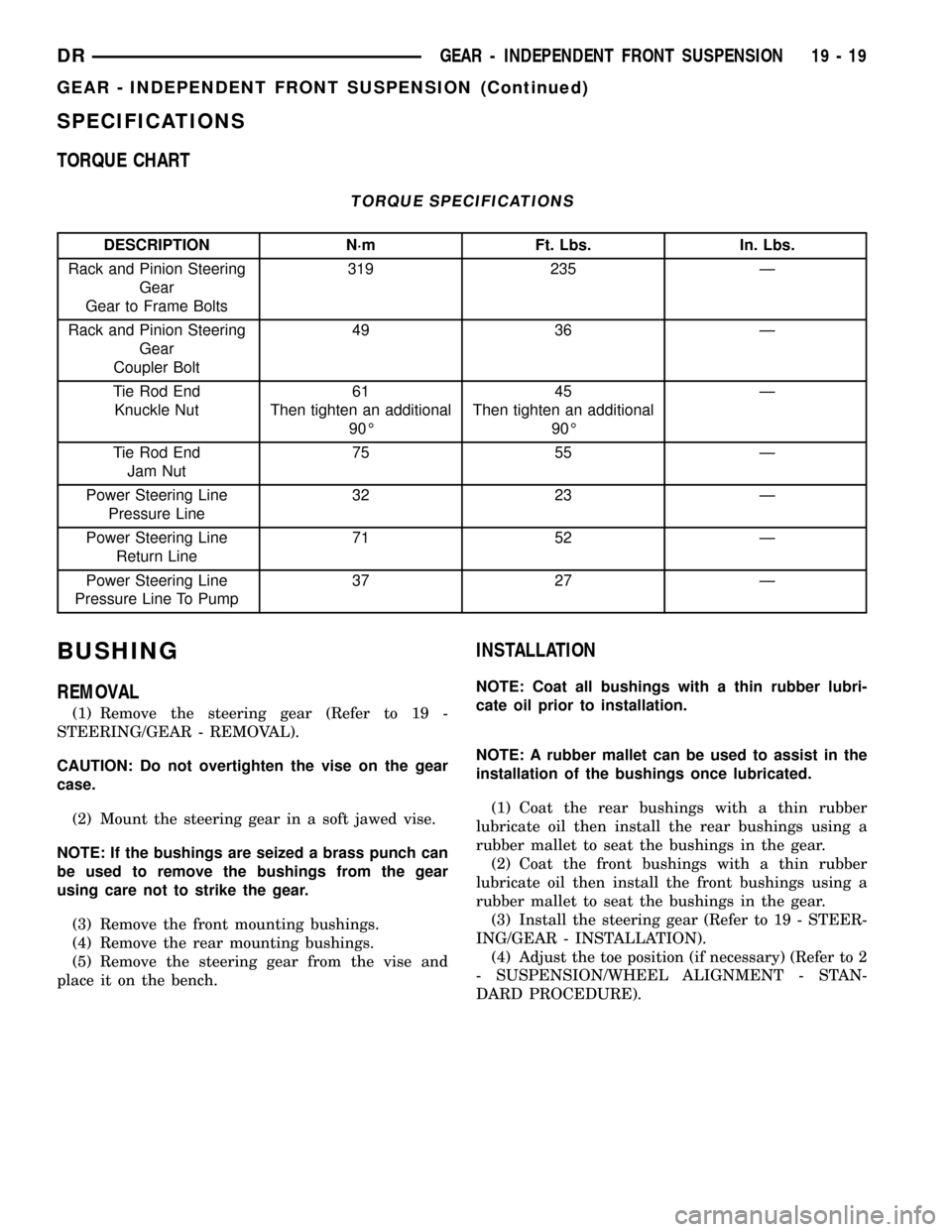

(9) Remove the rack & pinion mounting bolts. (Fig.

2) & (Fig. 3)

(10) Remove the rack & pinion from the vehicle.

Fig. 1 STEERING GEAR

1 - OUTER TIE ROD ENDS

2 - MOUNTING BUSHINGS

3 - BELLOWS

Fig. 2 STEERING GEAR MOUNTING BOLTS

1 - STEERING GEAR MOUNTING BOLTS 4X4

DRGEAR - INDEPENDENT FRONT SUSPENSION 19 - 17

Page 1673 of 2627

INSTALLATION

NOTE: Before installing gear inspect bushings and

replace if worn or damaged.

NOTE: In the frame there is two holes for the

mounting of the steering gear one is slotted and

one is round, When tightening the gear to specifi-

cations make sure to tighten the mounting bolt with

the hole first to avoided movement of the steering

gear.

(1) Install the gear on the front crossmember and

tighten the mounting bolts to 319 N´m (235 ft. lbs.).

(Fig. 4) & (Fig. 3).

(2) Slide the shaft coupler onto the gear. Install

newpinch bolt and tighten to 49 N´m (36 ft. lbs.).

(3) Clean and dry the tie rod end studs and the

knuckle tapers.

(4) Install the tie rod ends into the steering knuck-

les and tighten the nuts to 61 N´m (45 ft. lbs.) thenan additional 90É. (Refer to 19 - STEERING/LINK-

AGE/TIE ROD END - INSTALLATION).

(5) Install the pressure power steering hose to the

steering gear and tighten to 32 N´m (23 ft. lbs.).

(Refer to 19 - STEERING/PUMP/HOSES - INSTAL-

LATION).

(6) Install the return power steering hose to the

steering gear and tighten to 71 N´m (52 ft. lbs.).

(Refer to 19 - STEERING/PUMP/HOSES - INSTAL-

LATION).

(7) Install the front skid plate (Refer to 13 -

FRAME & BUMPERS/FRAME/FRONT SKID PLATE

- INSTALLATION).

(8) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(9) Remove the support and lower the vehicle.

(10) Fill the system with fluid, (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

(11) Adjust the toe position. (Refer to 2 - SUSPEN-

SION/WHEEL ALIGNMENT - STANDARD PROCE-

DURE).

Fig. 3 STEERING GEAR 4X2

1-SWAYBAR

2 - STEERING GEAR

3 - LEFT OUTER TIE ROD END

4 - LOWER CONTROL ARMS

5 - LEFT INNER & RIGHT OUTER (TIE ROD ENDS)

Fig. 4 STEERING GEAR 4X4

1 - FRONT AXLE

2 - STEERING GEAR MOUNTING NUTS & BUSHINGS

19 - 18 GEAR - INDEPENDENT FRONT SUSPENSIONDR

GEAR - INDEPENDENT FRONT SUSPENSION (Continued)

Page 1674 of 2627

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Rack and Pinion Steering

Gear

Gear to Frame Bolts319 235 Ð

Rack and Pinion Steering

Gear

Coupler Bolt49 36 Ð

Tie Rod End

Knuckle Nut61

Then tighten an additional

90É45

Then tighten an additional

90ÉÐ

Tie Rod End

Jam Nut75 55 Ð

Power Steering Line

Pressure Line32 23 Ð

Power Steering Line

Return Line71 52 Ð

Power Steering Line

Pressure Line To Pump37 27 Ð

BUSHING

REMOVAL

(1) Remove the steering gear (Refer to 19 -

STEERING/GEAR - REMOVAL).

CAUTION: Do not overtighten the vise on the gear

case.

(2) Mount the steering gear in a soft jawed vise.

NOTE: If the bushings are seized a brass punch can

be used to remove the bushings from the gear

using care not to strike the gear.

(3) Remove the front mounting bushings.

(4) Remove the rear mounting bushings.

(5) Remove the steering gear from the vise and

place it on the bench.

INSTALLATION

NOTE: Coat all bushings with a thin rubber lubri-

cate oil prior to installation.

NOTE: A rubber mallet can be used to assist in the

installation of the bushings once lubricated.

(1) Coat the rear bushings with a thin rubber

lubricate oil then install the rear bushings using a

rubber mallet to seat the bushings in the gear.

(2) Coat the front bushings with a thin rubber

lubricate oil then install the front bushings using a

rubber mallet to seat the bushings in the gear.

(3) Install the steering gear (Refer to 19 - STEER-

ING/GEAR - INSTALLATION).

(4) Adjust the toe position (if necessary) (Refer to 2

- SUSPENSION/WHEEL ALIGNMENT - STAN-

DARD PROCEDURE).

DRGEAR - INDEPENDENT FRONT SUSPENSION 19 - 19

GEAR - INDEPENDENT FRONT SUSPENSION (Continued)

Page 1687 of 2627

LINKAGE - INDEPENDENT FRONT SUSPENSION

TABLE OF CONTENTS

page page

LINKAGE - INDEPENDENT FRONT

SUSPENSION

DIAGNOSIS AND TESTING - OUTER TIE ROD

END ................................32TIE ROD END

REMOVAL - OUTER TIE ROD END..........32

INSTALLATION - OUTER TIE ROD END......33

LINKAGE - INDEPENDENT

FRONT SUSPENSION

DIAGNOSIS AND TESTING - OUTER TIE ROD

END

NOTE: If the outer tie rod end is equipped with a

lubrication fitting, grease the joint then road test

the vehicle before performing test.

(1) Raise the front of the vehicle. Place safety floor

stands under both lower control arms as far outboard

as possible. Lower the vehicle to allow the stands to

support some or all of the vehicle weight.

(2) Remove the front tires.

(3) Mount a dial indicator solidly to the vehicle

steering knuckle and then zero the dial indicator.

(4) Position indicator plunger on the topside of the

outer tie rod end.

NOTE: The dial indicator plunger must be perpen-

dicular to the machined surface of the outer tie rod

end.

(5) Position a pry bar in order to pry downwards

on the outer tie rod end.

(6) If the travel exceeds 0.5 mm (0.020 in.), replace

the outer tie rod end (Refer to 19 - STEERING/

LINKAGE/TIE ROD END - REMOVAL).

(7) If the outer tie rod end is within specs reinstall

the front tires (Refer to 22 - TIRES/WHEELS/

WHEELS - STANDARD PROCEDURE).

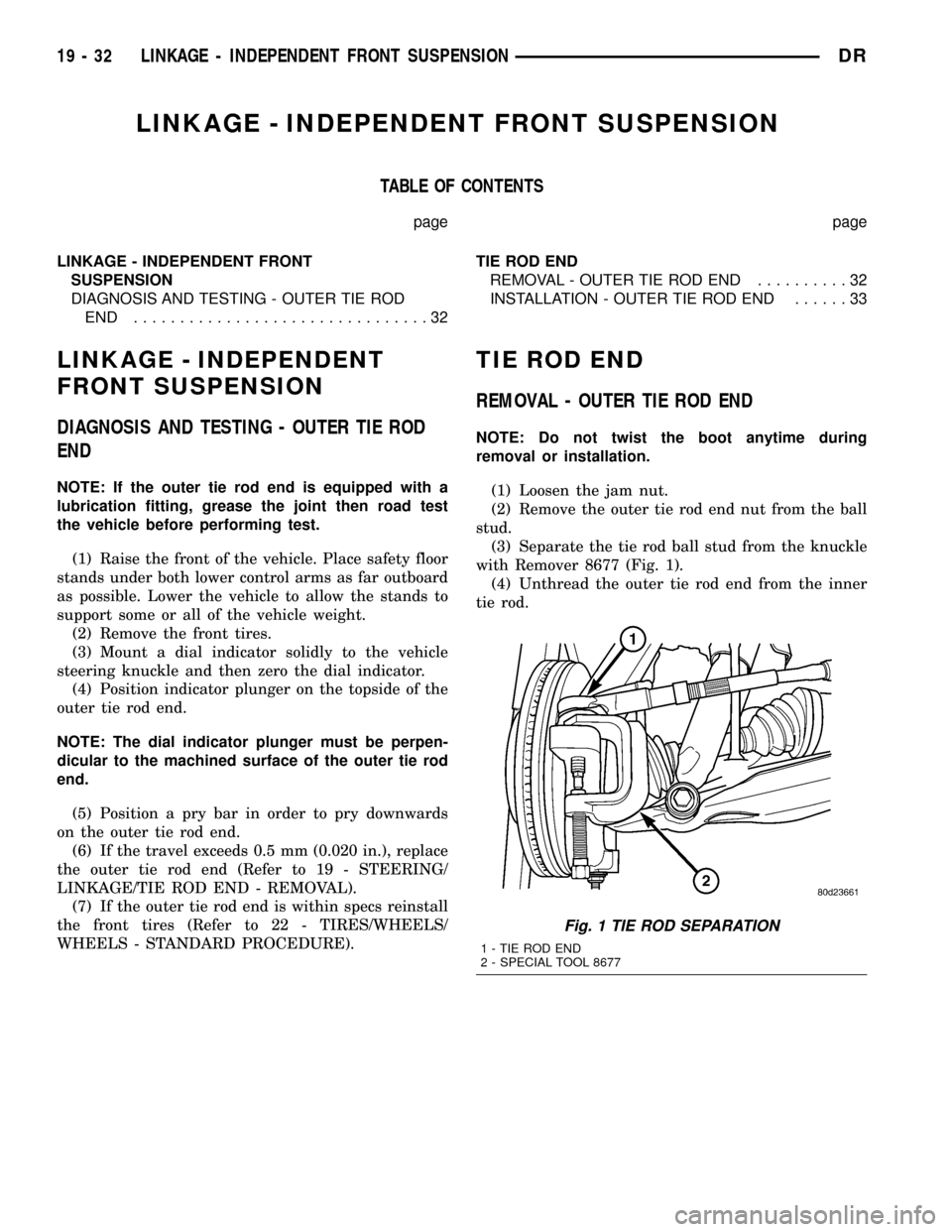

TIE ROD END

REMOVAL - OUTER TIE ROD END

NOTE: Do not twist the boot anytime during

removal or installation.

(1) Loosen the jam nut.

(2) Remove the outer tie rod end nut from the ball

stud.

(3) Separate the tie rod ball stud from the knuckle

with Remover 8677 (Fig. 1).

(4) Unthread the outer tie rod end from the inner

tie rod.

Fig. 1 TIE ROD SEPARATION

1 - TIE ROD END

2 - SPECIAL TOOL 8677

19 - 32 LINKAGE - INDEPENDENT FRONT SUSPENSIONDR

Page 1688 of 2627

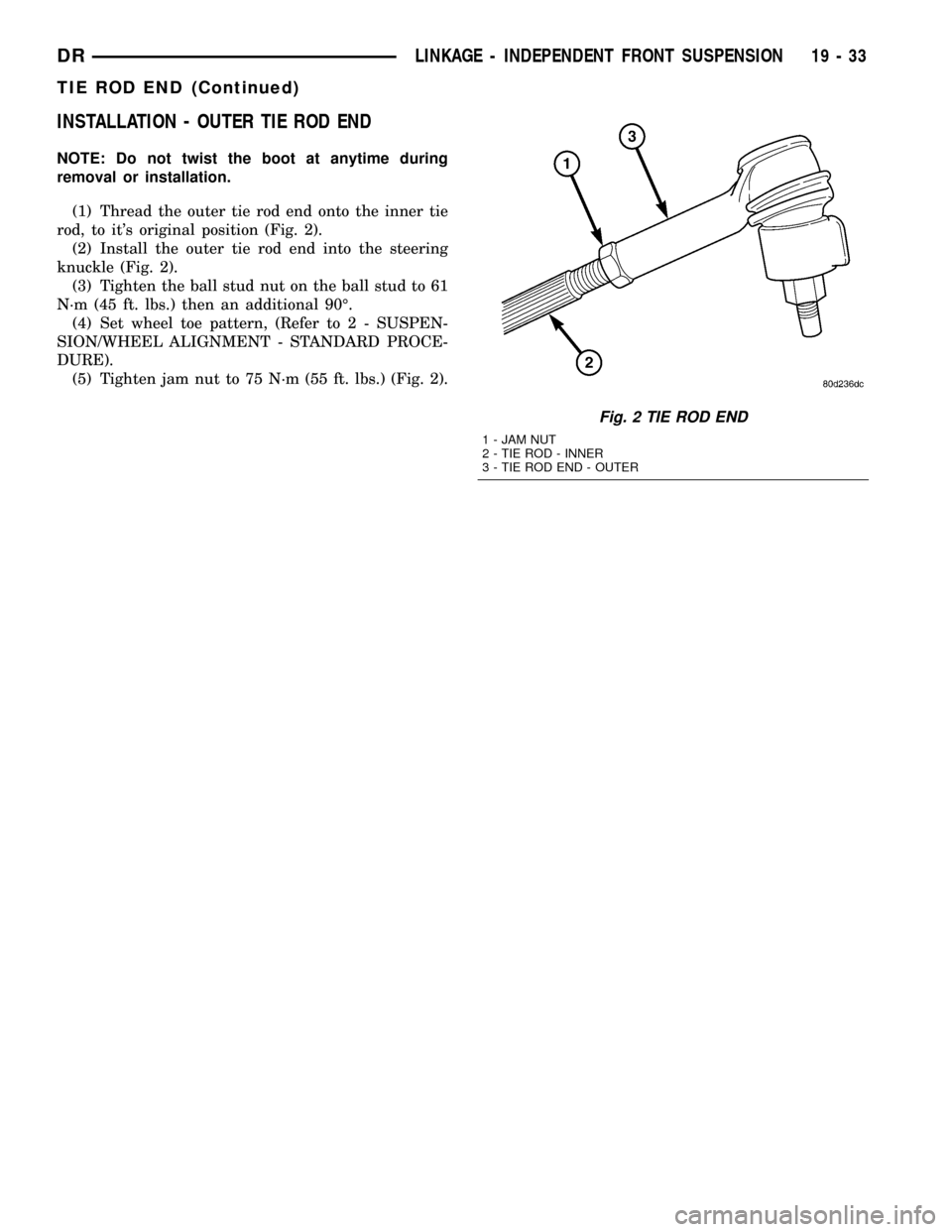

INSTALLATION - OUTER TIE ROD END

NOTE: Do not twist the boot at anytime during

removal or installation.

(1) Thread the outer tie rod end onto the inner tie

rod, to it's original position (Fig. 2).

(2) Install the outer tie rod end into the steering

knuckle (Fig. 2).

(3) Tighten the ball stud nut on the ball stud to 61

N´m (45 ft. lbs.) then an additional 90É.

(4) Set wheel toe pattern, (Refer to 2 - SUSPEN-

SION/WHEEL ALIGNMENT - STANDARD PROCE-

DURE).

(5) Tighten jam nut to 75 N´m (55 ft. lbs.) (Fig. 2).

Fig. 2 TIE ROD END

1 - JAM NUT

2 - TIE ROD - INNER

3 - TIE ROD END - OUTER

DRLINKAGE - INDEPENDENT FRONT SUSPENSION 19 - 33

TIE ROD END (Continued)

Page 1689 of 2627

LINKAGE - LINK/COIL

TABLE OF CONTENTS

page page

LINKAGE - LINK/COIL

DESCRIPTION.........................34

STANDARD PROCEDURE - LUBRICATION....34

SPECIFICATIONS

TORQUE CHART......................35

SPECIAL TOOLS

STEERING LINKAGE...................35

DAMPER

REMOVAL.............................36

INSTALLATION.........................36

DRAG LINK

REMOVAL.............................36INSTALLATION.........................36

PITMAN ARM

REMOVAL.............................36

INSTALLATION.........................37

TIE ROD END

REMOVAL.............................37

INSTALLATION.........................37

TRACK BAR

REMOVAL.............................38

INSTALLATION.........................38

LINKAGE - LINK/COIL

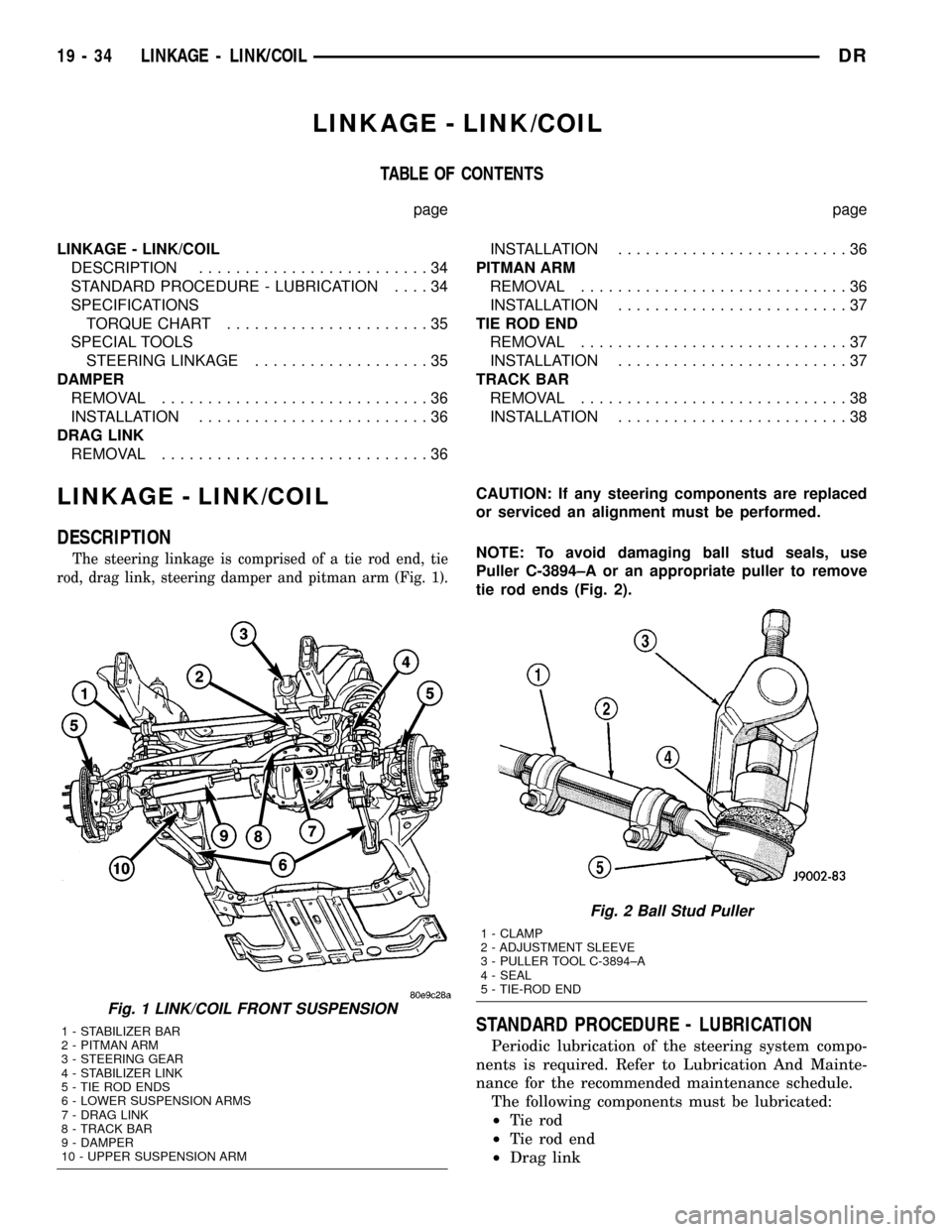

DESCRIPTION

The steering linkage is comprised of a tie rod end, tie

rod, drag link, steering damper and pitman arm (Fig. 1).

CAUTION: If any steering components are replaced

or serviced an alignment must be performed.

NOTE: To avoid damaging ball stud seals, use

Puller C-3894±A or an appropriate puller to remove

tie rod ends (Fig. 2).

STANDARD PROCEDURE - LUBRICATION

Periodic lubrication of the steering system compo-

nents is required. Refer to Lubrication And Mainte-

nance for the recommended maintenance schedule.

The following components must be lubricated:

²Tie rod

²Tie rod end

²Drag link

Fig. 1 LINK/COIL FRONT SUSPENSION

1 - STABILIZER BAR

2 - PITMAN ARM

3 - STEERING GEAR

4 - STABILIZER LINK

5 - TIE ROD ENDS

6 - LOWER SUSPENSION ARMS

7 - DRAG LINK

8 - TRACK BAR

9 - DAMPER

10 - UPPER SUSPENSION ARM

Fig. 2 Ball Stud Puller

1 - CLAMP

2 - ADJUSTMENT SLEEVE

3 - PULLER TOOL C-3894±A

4 - SEAL

5 - TIE-ROD END

19 - 34 LINKAGE - LINK/COILDR

Page 1742 of 2627

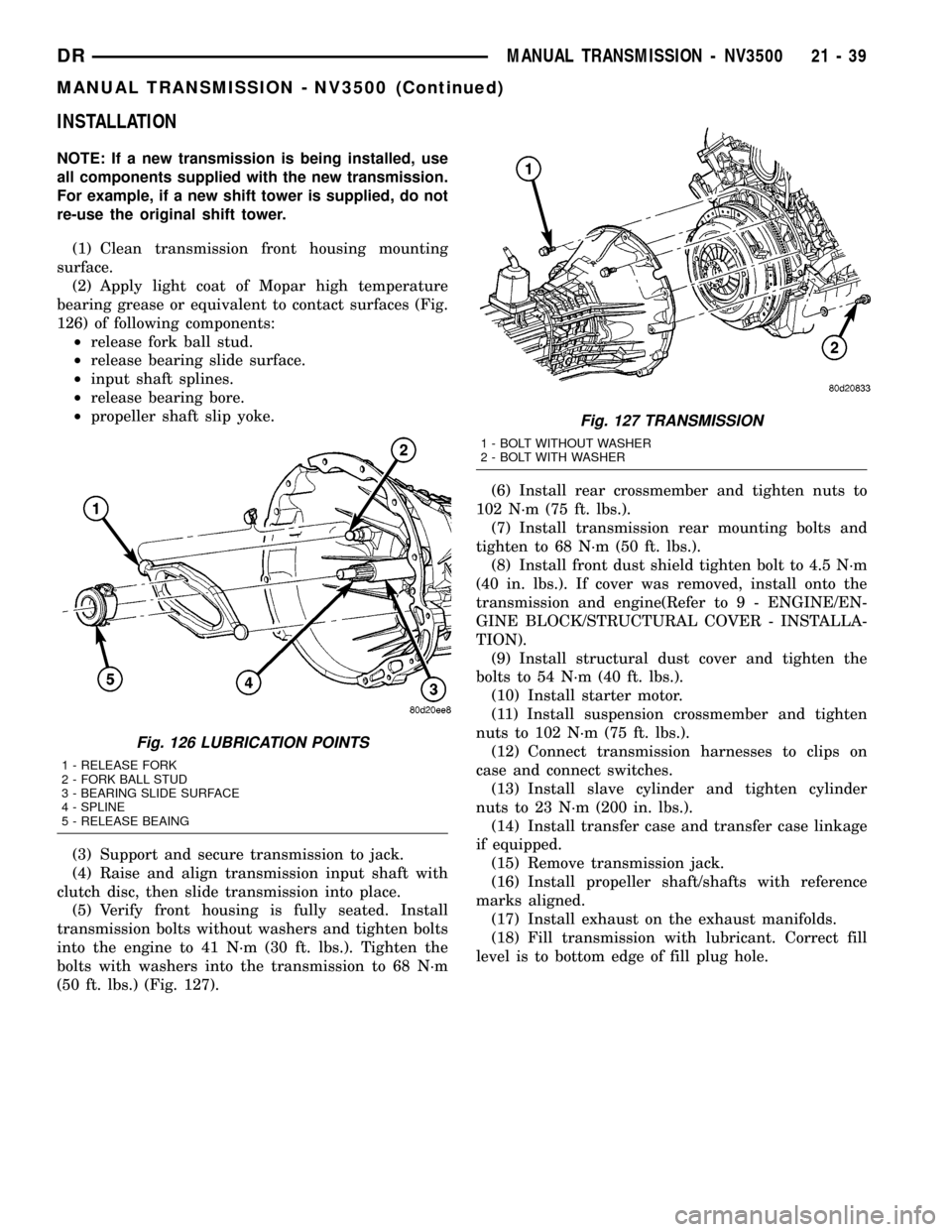

INSTALLATION

NOTE: If a new transmission is being installed, use

all components supplied with the new transmission.

For example, if a new shift tower is supplied, do not

re-use the original shift tower.

(1) Clean transmission front housing mounting

surface.

(2) Apply light coat of Mopar high temperature

bearing grease or equivalent to contact surfaces (Fig.

126) of following components:

²release fork ball stud.

²release bearing slide surface.

²input shaft splines.

²release bearing bore.

²propeller shaft slip yoke.

(3) Support and secure transmission to jack.

(4) Raise and align transmission input shaft with

clutch disc, then slide transmission into place.

(5) Verify front housing is fully seated. Install

transmission bolts without washers and tighten bolts

into the engine to 41 N´m (30 ft. lbs.). Tighten the

bolts with washers into the transmission to 68 N´m

(50 ft. lbs.) (Fig. 127).(6) Install rear crossmember and tighten nuts to

102 N´m (75 ft. lbs.).

(7) Install transmission rear mounting bolts and

tighten to 68 N´m (50 ft. lbs.).

(8) Install front dust shield tighten bolt to 4.5 N´m

(40 in. lbs.). If cover was removed, install onto the

transmission and engine(Refer to 9 - ENGINE/EN-

GINE BLOCK/STRUCTURAL COVER - INSTALLA-

TION).

(9) Install structural dust cover and tighten the

bolts to 54 N´m (40 ft. lbs.).

(10) Install starter motor.

(11) Install suspension crossmember and tighten

nuts to 102 N´m (75 ft. lbs.).

(12) Connect transmission harnesses to clips on

case and connect switches.

(13) Install slave cylinder and tighten cylinder

nuts to 23 N´m (200 in. lbs.).

(14) Install transfer case and transfer case linkage

if equipped.

(15) Remove transmission jack.

(16) Install propeller shaft/shafts with reference

marks aligned.

(17) Install exhaust on the exhaust manifolds.

(18) Fill transmission with lubricant. Correct fill

level is to bottom edge of fill plug hole.

Fig. 126 LUBRICATION POINTS

1 - RELEASE FORK

2 - FORK BALL STUD

3 - BEARING SLIDE SURFACE

4 - SPLINE

5 - RELEASE BEAING

Fig. 127 TRANSMISSION

1 - BOLT WITHOUT WASHER

2 - BOLT WITH WASHER

DRMANUAL TRANSMISSION - NV3500 21 - 39

MANUAL TRANSMISSION - NV3500 (Continued)

Page 2589 of 2627

AIRBAG INDICATOR - OPERATION.......8J-18

AIRBAG ON/OFF SWITCH -

DESCRIPTION, PASSENGER............8O-42

AIRBAG ON/OFF SWITCH -

INSTALLATION, PASSENGER...........8O-44

AIRBAG ON/OFF SWITCH - OPERATION,

PASSENGER........................8O-43

AIRBAG ON/OFF SWITCH - REMOVAL,

PASSENGER........................8O-43

AJAR INDICATOR - DESCRIPTION, DOOR . . 8J-23

AJAR INDICATOR - OPERATION, DOOR . . . 8J-23

AJAR SWITCH - DESCRIPTION, DOOR....8L-27

AJAR SWITCH - OPERATION, DOOR......8L-27

ALIGNMENT - DESCRIPTION, WHEEL.......2-1

ALIGNMENT - OPERATION, WHEEL........2-2

ALIGNMENT LINK/COIL SUSPENSION -

STANDARD PROCEDURE.................2-5

ALIGNMENT, SPECIAL TOOLS - WHEEL.....2-7

ALIGNMENT, SPECIFICATIONS............2-6

ALUMINUM THREAD REPAIR -

STANDARD PROCEDURE........21-158,21-318

AMBIENT TEMP SENSOR - DESCRIPTION . 8M-10

AMBIENT TEMP SENSOR - OPERATION . . 8M-10

AMBIENT TEMPERATURE SENSOR -

DIAGNOSIS AND TESTING.............8M-10

AMBIENT TEMPERATURE SENSOR

CIRCUIT - DIAGNOSIS AND TESTING....8M-10

AMPLIFIER - DESCRIPTION.............8A-3

AMPLIFIER - INSTALLATION.............8A-4

AMPLIFIER - OPERATION...............8A-3

AMPLIFIER - REMOVAL................8A-3

ANCHOR - DESCRIPTION, CHILD

RESTRAINT.........................8O-15

ANCHOR - INSTALLATION, CHILD

RESTRAINT.........................8O-18

ANCHOR - OPERATION, CHILD

RESTRAINT.........................8O-17

ANCHOR - REMOVAL, CHILD RESTRAINT . 8O-17

ANCHOR & RIGHT OUTBOARD -

INSTALLATION, CENTER...............8O-50

ANCHOR & RIGHT OUTBOARD -

REMOVAL, CENTER...................8O-49

ANTENNA - NAVIGATION -

INSTALLATION.......................8A-6

ANTENNA - NAVIGATION - REMOVAL......8A-6

ANTENNA BODY & CABLE -

DESCRIPTION........................8A-4

ANTENNA BODY & CABLE -

INSTALLATION.......................8A-6

ANTENNA BODY & CABLE - OPERATION . . . 8A-4

ANTENNA BODY & CABLE - REMOVAL.....8A-6

ANTENNA BODY AND CABLE -

DIAGNOSIS AND TESTING..............8A-4

ANTENNA CABLE - INSTALLATION,

INSTRUMENT PANEL..................8A-7

ANTENNA CABLE - REMOVAL,

INSTRUMENT PANEL..................8A-7

ANTILOCK - DIAGNOSIS AND TESTING,

REAR WHEEL........................5-48

ANTILOCK BRAKE - DESCRIPTION,

CONTROLLER........................8E-3

ANTILOCK BRAKE - INSTALLATION,

CONTROLLER

........................8E-3

ANTILOCK BRAKE - OPERATION,

CONTROLLER

........................8E-3

ANTILOCK BRAKE - REMOVAL,

CONTROLLER

........................8E-3

A-PILLAR TRIM/GRAB HANDLE -

INSTALLATION

.......................23-63

A-PILLAR TRIM/GRAB HANDLE -

REMOVAL

..........................23-63

A-PILLAR WEATHERSTRIP RETAINER -

INSTALLATION

.......................23-91

A-PILLAR WEATHERSTRIP RETAINER -

REMOVAL

..........................23-91

AREA LEAKS - DIAGNOSIS AND

TESTING, REAR SEAL

........9-137,9-209,9-65

ARM / ADJUSTER ASSEMBLY -

DESCRIPTION, ROCKER

...............9-125

ARM / ADJUSTER ASSEMBLY -

INSTALLATION, ROCKER

...............9-126

ARM / ADJUSTER ASSEMBLY -

REMOVAL, ROCKER

..................9-126

ARM / ADJUSTER ASSY - CLEANING,

ROCKER

............................9-262

ARM / ADJUSTER ASSY - DESCRIPTION,

ROCKER

............................9-261ARM / ADJUSTER ASSY - INSPECTION,

ROCKER............................9-262

ARM / ADJUSTER ASSY -

INSTALLATION, ROCKER..........9-203,9-263

ARM / ADJUSTER ASSY - REMOVAL,

ROCKER......................9-203,9-261

ARM - DESCRIPTION, ROCKER......9-31,9-37

ARM - DESCRIPTION, WIPER...........8R-17

ARM - INSTALLATION, LOWER

SUSPENSION.........................2-38

ARM - INSTALLATION, PITMAN.........19-37

ARM - INSTALLATION, ROCKER..........9-31

ARM - INSTALLATION, UPPER CONTROL . . . 2-28

ARM - INSTALLATION, WIPER..........8R-18

ARM - OPERATION, WIPER............8R-18

ARM - REMOVAL, LOWER SUSPENSION . . . 2-38

ARM - REMOVAL, PITMAN.............19-36

ARM - REMOVAL, ROCKER..........9-31,9-37

ARM - REMOVAL, UPPER CONTROL......2-28

ARM - REMOVAL, WIPER..............8R-18

ARM BUSHINGS - 2WD (LD) -

INSTALLATION, LOWER CONTROL........2-15

ARM BUSHINGS - 2WD (LD) -

REMOVAL, LOWER CONTROL............2-13

ARM BUSHINGS - 4WD (LD) -

INSTALLATION, LOWER CONTROL........2-14

ARM BUSHINGS - 4WD (LD) -

REMOVAL, LOWER CONTROL............2-13

ARMREST / SEAT BACK - INSTALLATION,

CENTER.............................23-77

ARMREST / SEAT BACK - REMOVAL,

CENTER............................23-76

ASD AND FUEL PUMP RELAYS -

DIAGNOSIS AND TESTING...............8I-5

ASD SENSE - PCM INPUT - OPERATION....8I-5

ASH RECEIVER - INSTALLATION.........23-51

ASH RECEIVER - REMOVAL............23-50

AUDIO - DESCRIPTION.................8A-1

AUDIO - DIAGNOSIS AND TESTING.......8A-2

AUDIO - OPERATION...................8A-1

AUTOMATIC DAY / NIGHT MIRROR -

DESCRIPTION.......................8N-11

AUTOMATIC DAY / NIGHT MIRROR -

DIAGNOSIS AND TESTING.............8N-11

AUTOMATIC DAY / NIGHT MIRROR -

OPERATION.........................8N-11

AUTOMATIC DAY / NIGHT MIRROR -

REMOVAL..........................8N-12

AUTOMATIC LOCKING RETRACTOR -

DESCRIPTION.......................8O-14

AUTOMATIC LOCKING RETRACTOR -

OPERATION.........................8O-14

AUTOMATIC TRANSMISSION -

45RFE/545RFE - DESCRIPTION.........21-312

AUTOMATIC TRANSMISSION -

45RFE/545RFE - OPERATION...........21-313

AUTOMATIC TRANSMISSION - 48RE -

DESCRIPTION......................21-132

AUTOMATIC TRANSMISSION - 48RE -

OPERATION........................21-134

AUTOMATIC TRANSMISSION -

DIAGNOSIS AND TESTING......21-140,21-314

AUTOMATIC TRANSMISSION FLUID -

DESCRIPTION.........................0-4

AUTOMATIC TRANSMISSION FLUID -

OPERATION...........................0-5

AUXILIARY SPRING BUMPERS (3500) -

INSTALLATION........................2-43

AUXILIARY SPRING BUMPERS (3500) -

REMOVAL...........................2-43

AXLE - 10 1/2 AA - ADJUSTMENTS,

REAR..............................3-116

AXLE - 10 1/2 AA - DIAGNOSIS AND

TESTING, REAR......................3-112

AXLE - 10 1/2 AA - INSTALLATION,

REAR..............................3-116

AXLE - 10 1/2 AA - REMOVAL, REAR.....3-115

AXLE - 10 1/2 AA - SPECIAL TOOLS,

REAR..............................3-120

AXLE - 10 1/2 AA - SPECIFICATIONS,

REAR

..............................3-120

AXLE - 11 1/2 AA - ADJUSTMENTS,

REAR

..............................3-144

AXLE - 11 1/2 AA - DIAGNOSIS AND

TESTING, REAR

......................3-140

AXLE - 11 1/2 AA - INSTALLATION,

REAR

..............................3-144

AXLE - 11 1/2 AA - REMOVAL, REAR

.....3-143AXLE - 11 1/2 AA - SPECIAL TOOLS,

REAR..............................3-148

AXLE - 11 1/2 AA - SPECIFICATIONS,

REAR..............................3-148

AXLE - 9 1/4 - ADJUSTMENTS, REAR.....3-83

AXLE - 9 1/4 - DIAGNOSIS AND

TESTING, REAR.......................3-80

AXLE - 9 1/4 - INSTALLATION, REAR......3-83

AXLE - 9 1/4 - REMOVAL, REAR..........3-83

AXLE - 9 1/4 - SPECIAL TOOLS, REAR.....3-90

AXLE - 9 1/4 - SPECIFICATIONS, REAR....3-90

AXLE - 9 1/4 AA - ADJUSTMENTS,

FRONT..............................3-59

AXLE - 9 1/4 AA - DIAGNOSIS AND

TESTING, FRONT......................3-54

AXLE - 9 1/4 AA - INSTALLATION,

FRONT..............................3-58

AXLE - 9 1/4 AA - REMOVAL, FRONT......3-57

AXLE - 9 1/4 AA - SPECIAL TOOLS,

FRONT..............................3-64

AXLE - 9 1/4 AA - SPECIFICATIONS,

FRONT..............................3-63

AXLE - C205F - ADJUSTMENTS, FRONT....3-32

AXLE - C205F - DIAGNOSIS AND

TESTING, FRONT......................3-27

AXLE - C205F - INSTALLATION, FRONT....3-31

AXLE - C205F - REMOVAL, FRONT........3-31

AXLE - C205F - SPECIAL TOOLS, FRONT . . . 3-40

AXLE - C205F - SPECIFICATIONS, FRONT . . . 3-39

AXLE - DESCRIPTION.....................0-4

AXLE BEARINGS - INSTALLATION . . 3-125,3-153,

3-44,3-95

AXLE BEARINGS - REMOVAL . . 3-125,3-152,3-43,

3-95

AXLE SHAFT SEALS - INSTALLATION . 3-43,3-70,

3-94

AXLE SHAFT SEALS - REMOVAL . 3-43,3-69,3-94

AXLE SHAFTS - ASSEMBLY.............3-69

AXLE SHAFTS - DISASSEMBLY...........3-68

AXLE SHAFTS - INSTALLATION....3-124,3-152,

3-43,3-69,3-94

AXLE SHAFTS - REMOVAL....3-124,3-152,3-43,

3-67,3-93

BACK - INSTALLATION, CENTER

ARMREST / SEAT....................23-77

BACK - REAR - INSTALLATION, SEAT.....23-83

BACK - REAR - REMOVAL, SEAT........23-83

BACK - REMOVAL, CENTER ARMREST /

SEAT ..............................23-76

BACK CUSHION / COVER - FRONT -

INSTALLATION, SEAT.................23-82

BACK CUSHION / COVER - FRONT -

REMOVAL, SEAT.....................23-82

BACK CUSHION / COVER - REAR -

INSTALLATION, SEAT.................23-84

BACK CUSHION / COVER - REAR -

REMOVAL, SEAT.....................23-84

BACK HINGE - INSTALLATION, CENTER

SEAT ..............................23-79

BACK HINGE - REMOVAL, CENTER SEAT . . 23-78

BACK INERTIA HINGE COVER -

INSTALLATION, CENTER SEAT..........23-77

BACK INERTIA HINGE COVER -

REMOVAL, CENTER SEAT..............23-77

BACK LID - INSTALLATION, CENTER

SEAT ..............................23-79

BACK LID - REMOVAL, CENTER SEAT....23-79

BACK PANEL TRIM - INSTALLATION,

REAR CAB..........................23-69

BACK PANEL TRIM - REMOVAL, REAR

CAB

...............................23-68

BACK REAR - FOOTMANS LOOP

BRACKETS - INSTALLATION, SEAT

.......23-85

BACK REAR - FOOTMANS LOOP

BRACKETS - REMOVAL, SEAT

...........23-85

BACKLITE - INSTALLATION

.............23-86

BACKLITE - REMOVAL

.................23-86

BACKLITE VENT GLASS - INSTALLATION

. . 23-87

BACKLITE VENT GLASS - REMOVAL

......23-87

BACKUP LAMP SWITCH - DESCRIPTION

. . . 8L-8

BACKUP LAMP SWITCH - DIAGNOSIS

AND TESTING

........................8L-8

BACKUP LAMP SWITCH - OPERATION

.....8L-8

BALANCE - STANDARD PROCEDURE,

TIRE AND WHEEL

.....................22-4

BALANCE SHAFT - INSTALLATION

........9-80

BALANCE SHAFT - REMOVAL

............9-80

2 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2601 of 2627

FRONT SERVO - DESCRIPTION.........21-208

FRONT SERVO - DISASSEMBLY........21-209

FRONT SERVO - INSPECTION..........21-209

FRONT SERVO - OPERATION..........21-208

FRONT SKID PLATE - INSTALLATION.....13-23

FRONT SKID PLATE - REMOVAL.........13-23

FRONT SUSPENSION - DESCRIPTION,

GEAR - INDEPENDENT................19-17

FRONT SUSPENSION - INSTALLATION,

GEAR - INDEPENDENT................19-18

FRONT SUSPENSION - REMOVAL, GEAR

- INDEPENDENT.....................19-17

FRONT SUSPENSION, SPECIAL TOOLS....2-12

FRONT TOW HOOK ASSEMBLY -

INSTALLATION.......................13-23

FRONT TOW HOOK ASSEMBLY -

REMOVAL..........................13-23

FRONT WHEEL SPEED SENSOR -

DESCRIPTION........................5-47

FRONT WHEEL SPEED SENSOR -

INSTALLATION........................5-48

FRONT WHEEL SPEED SENSOR -

OPERATION..........................5-47

FRONT WHEEL SPEED SENSOR -

REMOVAL...........................5-48

FRONT WHEELHOUSE SPLASH SHIELD -

INSTALLATION.......................23-41

FRONT WHEELHOUSE SPLASH SHIELD -

REMOVAL..........................23-41

FUEL CONTROL ACTUATOR -

DESCRIPTION.......................14-74

FUEL CONTROL ACTUATOR -

OPERATION.........................14-74

FUEL CONTROL ACTUATOR - REMOVAL . . . 14-74

FUEL DELIVERY - GAS - DESCRIPTION....14-1

FUEL DELIVERY - GAS - OPERATION......14-2

FUEL DRAIN CIRCUIT - OPERATION......14-67

FUEL FILL DOOR - INSTALLATION.......23-39

FUEL FILL DOOR - REMOVAL...........23-39

FUEL FILLER CAP - DESCRIPTION.......25-13

FUEL FILLER CAP - OPERATION.........25-13

FUEL FILTER - STANDARD

PROCEDURES, WATER DRAINING AT.....14-47

FUEL FILTER / WATER SEPARATOR -

DESCRIPTION.......................14-50

FUEL FILTER / WATER SEPARATOR -

INSTALLATION.......................14-50

FUEL FILTER / WATER SEPARATOR -

OPERATION.........................14-50

FUEL FILTER / WATER SEPARATOR -

REMOVAL..........................14-50

FUEL FILTER/PRESSURE REGULATOR -

DESCRIPTION........................14-5

FUEL FILTER/PRESSURE REGULATOR -

OPERATION..........................14-6

FUEL GAUGE - DESCRIPTION...........8J-26

FUEL GAUGE - OPERATION.............8J-26

FUEL HEATER - DESCRIPTION..........14-51

FUEL HEATER - DIAGNOSIS AND

TESTING...........................14-52

FUEL HEATER - OPERATION............14-51

FUEL HEATER RELAY - DESCRIPTION....14-52

FUEL HEATER RELAY - INSTALLATION....14-53

FUEL HEATER RELAY - OPERATION......14-52

FUEL HEATER RELAY - REMOVAL........14-52

FUEL INDICATOR - DESCRIPTION, LOW . . . 8J-30

FUEL INDICATOR - OPERATION, LOW.....8J-30

FUEL INJECTION PUMP - DESCRIPTION . . 14-53

FUEL INJECTION PUMP - INSTALLATION . . 14-55

FUEL INJECTION PUMP - OPERATION....14-53

FUEL INJECTION PUMP - REMOVAL......14-54

FUEL INJECTION PUMP TIMING -

DIAGNOSIS AND TESTING.............14-53

FUEL INJECTOR - DESCRIPTION....14-26,14-74

FUEL INJECTOR - INSTALLATION........14-77

FUEL INJECTOR - OPERATION.....14-26,14-74

FUEL INJECTOR - REMOVAL............14-75

FUEL INJECTOR FIRING ORDER, DIESEL . . 14-48

FUEL INJECTOR RAIL - DESCRIPTION....14-78

FUEL INJECTOR RAIL - INSTALLATION....14-78

FUEL INJECTOR RAIL - OPERATION

......14-78

FUEL INJECTOR RAIL - REMOVAL

.......14-78

FUEL LEVEL SENDING UNIT / SENSOR -

DESCRIPTION

...................14-57,14-6

FUEL LEVEL SENDING UNIT / SENSOR -

INSTALLATION

........................14-7

FUEL LEVEL SENDING UNIT / SENSOR -

OPERATION

.....................14-57,14-6FUEL LEVEL SENDING UNIT / SENSOR -

REMOVAL...........................14-7

FUEL LINE LEAKS - DIAGNOSIS AND

TESTING, HIGH-PRESSURE.............14-58

FUEL LINES - DESCRIPTION........14-57,14-7

FUEL LINES - INSTALLATION...........14-60

FUEL LINES - OPERATION..............14-57

FUEL LINES - REMOVAL...............14-58

FUEL PRESSURE LIMITING VALVE -

DESCRIPTION.......................14-61

FUEL PRESSURE LIMITING VALVE -

INSTALLATION.......................14-61

FUEL PRESSURE LIMITING VALVE -

OPERATION.........................14-61

FUEL PRESSURE LIMITING VALVE -

REMOVAL..........................14-61

FUEL PRESSURE SENSOR -

DESCRIPTION.......................14-60

FUEL PRESSURE SENSOR -

INSTALLATION.......................14-61

FUEL PRESSURE SENSOR - OPERATION . . 14-60

FUEL PRESSURE SENSOR - REMOVAL....14-60

FUEL PUMP - DESCRIPTION............14-11

FUEL PUMP - OPERATION.............14-11

FUEL PUMP MODULE - DESCRIPTION....14-11

FUEL PUMP MODULE - INSTALLATION . . . 14-12

FUEL PUMP MODULE - OPERATION......14-11

FUEL PUMP MODULE - REMOVAL.......14-12

FUEL PUMP RELAY - DESCRIPTION......14-27

FUEL PUMP RELAY - INSTALLATION.....14-28

FUEL PUMP RELAY - OPERATION........14-27

FUEL PUMP RELAY - REMOVAL.........14-28

FUEL PUMP RELAYS - DIAGNOSIS AND

TESTING, ASD........................8I-5

FUEL RAIL - DESCRIPTION.............14-12

FUEL RAIL - INSTALLATION............14-15

FUEL RAIL - OPERATION...............14-12

FUEL RAIL - REMOVAL................14-13

FUEL REQUIREMENTS - DIESEL ENGINE

- DESCRIPTION........................0-1

FUEL SENSOR - DESCRIPTION, WATER

IN ................................14-66

FUEL SENSOR - OPERATION, WATER IN . . 14-66

FUEL SENSOR - REMOVAL, WATER IN....14-66

FUEL SYSTEM - DESCRIPTION, DIESEL . . . 14-45

FUEL SYSTEM - DIESEL ENGINE -

TORQUE............................14-48

FUEL SYSTEM - EXCEPT DIESEL -

TORQUE............................14-3

FUEL SYSTEM PARTS - STANDARD

PROCEDURES, CLEANING..............14-47

FUEL SYSTEM PRESSURE RELEASE -

STANDARD PROCEDURE................14-2

FUEL SYSTEM PRESSURE,

SPECIFICATIONS......................14-3

FUEL SYSTEM PRIMING - STANDARD

PROCEDURE........................14-47

FUEL SYSTEM, SPECIAL TOOLS..........14-5

FUEL SYSTEM, SPECIAL TOOLS -

DIESEL............................14-49

FUEL TANK - DESCRIPTION............14-17

FUEL TANK - OPERATION..............14-17

FUEL TANK MODULE - DESCRIPTION.....14-63

FUEL TANK MODULE - INSTALLATION....14-64

FUEL TANK MODULE - OPERATION......14-63

FUEL TANK MODULE - REMOVAL........14-63

FUEL TRANSFER PUMP - DESCRIPTION . . 14-64

FUEL TRANSFER PUMP - INSTALLATION . . 14-65

FUEL TRANSFER PUMP - OPERATION....14-64

FUEL TRANSFER PUMP - REMOVAL......14-64

FULL SIZE, SPARE WHEEL WITH

MATCHING TIRE - DESCRIPTION........22-15

FUNCTIONS - DESCRIPTION, CIRCUIT . . 8W-01-6

FUSE - DESCRIPTION, IOD...........8W-97-6

FUSE - INSTALLATION, IOD..........8W-97-7

FUSE - OPERATION, IOD.............8W-97-6

FUSE - REMOVAL, IOD..............8W-97-7

FUSES POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON......8W-01-10

GAP AND FLUSH - SPECIFICATIONS......23-95

GAS ENGINE - DIAGNOSIS AND TESTING

. . 11-4

GAS ENGINE - INSTALLATION

...........19-26

GAS ENGINE - REMOVAL

..............19-25

GAS ENGINES - CLEANING, RADIATOR

FAN

................................7-34

GAS ENGINES - DESCRIPTION, COOLANT

RECOVERY CONTAINER

................7-33GAS ENGINES - INSPECTION, RADIATOR

FAN ................................7-34

GAS ENGINES - INSTALLATION,

COOLANT RECOVERY CONTAINER........7-33

GAS ENGINES - INSTALLATION,

RADIATOR FAN.......................7-34

GAS ENGINES - OPERATION, COOLANT

RECOVERY CONTAINER................7-33

GAS ENGINES - REMOVAL, COOLANT

RECOVERY CONTAINER................7-33

GAS ENGINES - REMOVAL, RADIATOR

FAN ................................7-33

GAS ENGINES - STANDARD

PROCEDURE, DRAINING COOLING

SYSTEM - ALL........................7-17

GAS ENGINES - STANDARD

PROCEDURE, REFILLING COOLING

SYSTEM - ALL........................7-18

GASKET - DIAGNOSIS AND TESTING,

CYLINDER HEAD......................9-21

GASKET FAILURE - DIAGNOSIS AND

TESTING, CYLINDER HEAD.............9-199

GASKET SELECTION - STANDARD

PROCEDURE, HEAD...................9-281

GASKET SURFACE PREPARATION -

STANDARD PROCEDURE, ENGINE........9-10

GASKETS AND SEALERS - STANDARD

PROCEDURE, FORM-IN-PLACE . . . 9-239,9-9,9-94

GAUGE - DESCRIPTION, ENGINE

TEMPERATURE......................8J-24

GAUGE - DESCRIPTION, FUEL...........8J-26

GAUGE - DESCRIPTION, OIL PRESSURE . . 8J-33

GAUGE - DESCRIPTION, VOLTAGE.......8J-42

GAUGE - OPERATION, ENGINE

TEMPERATURE......................8J-24

GAUGE - OPERATION, FUEL............8J-26

GAUGE - OPERATION, OIL PRESSURE....8J-33

GAUGE - OPERATION, VOLTAGE.........8J-43

GAUGES - DIAGNOSIS AND TESTING,

PRESSURE..........................22-7

GAUGES INDICATOR - DESCRIPTION,

CHECK.............................8J-21

GAUGES INDICATOR - OPERATION,

CHECK.............................8J-21

GEAR - DESCRIPTION, CRANKSHAFT.....9-273

GEAR - INDEPENDENT FRONT

SUSPENSION - DESCRIPTION...........19-17

GEAR - INDEPENDENT FRONT

SUSPENSION - INSTALLATION..........19-18

GEAR - INDEPENDENT FRONT

SUSPENSION - REMOVAL..............19-17

GEAR - INSTALLATION................9-273

GEAR - INSTALLATION, PINION

GEAR/RING......................3-51,3-77

GEAR - LINK/COIL - DESCRIPTION.......19-20

GEAR - LINK/COIL - INSTALLATION......19-21

GEAR - LINK/COIL - OPERATION........19-20

GEAR - LINK/COIL - REMOVAL..........19-20

GEAR - REMOVAL....................9-273

GEAR - REMOVAL, PINION GEAR/RING....3-49,

3-75

GEAR HOUSING - INSTALLATION........9-300

GEAR HOUSING - REMOVAL............9-299

GEAR HOUSING COVER - INSTALLATION . . 9-301

GEAR HOUSING COVER - REMOVAL

.....9-301

GEAR INPUT SHAFT SEAL -

INSTALLATION, STEERING

.............19-29

GEAR INPUT SHAFT SEAL - REMOVAL,

STEERING

..........................19-27

GEAR SELECTOR INDICATOR -

DESCRIPTION

.......................8J-27

GEAR SELECTOR INDICATOR -

OPERATION

.........................8J-27

GEAR SHIFT LEVER - INSTALLATION

.....19-12

GEAR SHIFT LEVER - REMOVAL

.........19-12

GEAR, SPECIAL TOOLS - POWER

STEERING

..........................19-23

GEAR, SPECIFICATIONS - POWER

STEERING

..........................19-22

GEAR TO COOLER - INSTALLATION,

RETURN HOSE

.................19-44,19-45

GEAR TO COOLER - REMOVAL, RETURN

HOSE

.........................19-44,19-45

GEAR/RING GEAR - INSTALLATION,

PINION

.........................3-51,3-77

GEAR/RING GEAR - REMOVAL, PINION

....3-49,

3-75

14 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2604 of 2627

IGNITION CIRCUIT SENSE -

DESCRIPTION.......................8E-10

IGNITION CIRCUIT SENSE - OPERATION . . 8E-11

IGNITION COIL - DESCRIPTION..........8I-11

IGNITION COIL - INSTALLATION.........8I-14

IGNITION COIL - OPERATION............8I-12

IGNITION COIL - REMOVAL.............8I-13

IGNITION COIL CAPACITOR -

DESCRIPTION........................8I-21

IGNITION COIL CAPACITOR -

INSTALLATION.......................8I-21

IGNITION COIL CAPACITOR - OPERATION . . 8I-21

IGNITION COIL CAPACITOR - REMOVAL . . . 8I-21

IGNITION COIL RESISTANCE, 3.7L V-6.....8I-5

IGNITION COIL RESISTANCE, 4.7L V-8.....8I-5

IGNITION COIL RESISTANCE, 5.7L V-8.....8I-5

IGNITION CONTROL - DESCRIPTION.......8I-1

IGNITION SWITCH - DESCRIPTION........19-9

IGNITION SWITCH - DESCRIPTION,

KEY-IN.............................19-11

IGNITION SWITCH - DIAGNOSIS AND

TESTING............................19-9

IGNITION SWITCH - INSTALLATION......19-11

IGNITION SWITCH - OPERATION.........19-9

IGNITION SWITCH - REMOVAL..........19-10

IGNITION SWITCH AND KEY LOCK

CYLINDER - DIAGNOSIS AND TESTING . . . 19-11

IGNITION TIMING, SPECIFICATIONS.......8I-5

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE........................8F-11

IMMOBILIZER MODULE - DESCRIPTION,

SENTRY KEY........................8E-13

IMMOBILIZER MODULE - INSTALLATION,

SENTRY KEY........................8E-15

IMMOBILIZER MODULE - OPERATION,

SENTRY KEY........................8E-13

IMMOBILIZER MODULE - REMOVAL,

SENTRY KEY........................8E-15

IMMOBILIZER MODULE (SKIM) -

DESCRIPTION, SENTRY KEY.............8Q-1

IMMOBILIZER MODULE (SKIM) -

OPERATION, SENTRY KEY..............8Q-2

IMMOBILIZER SYSTEM INDICATOR

LAMP - DESCRIPTION, SENTRY KEY......8Q-5

IMMOBILIZER SYSTEM INDICATOR

LAMP - OPERATION, SENTRY KEY........8Q-5

IMMOBILIZER SYSTEM INITIALIZATION,

STANDARD PROCEDURE - SENTRY

KEY................................8Q-3

IMMOBILIZER SYSTEM (SKIS) -

DESCRIPTION, SENTRY KEY.............8Q-1

IMMOBILIZER SYSTEM (SKIS) -

OPERATION, SENTRY KEY..............8Q-2

IMMOBILIZER SYSTEM TRANSPONDER

PROGRAMMING, STANDARD

PROCEDURE - SENTRY KEY.............8Q-4

IMPACT SENSOR - DESCRIPTION, SIDE . . 8O-59

IMPACT SENSOR - OPERATION, SIDE....8O-59

INCORRECT FLUID LEVEL - DIAGNOSIS

AND TESTING, EFFECTS OF......21-201,21-366

INDEPENDENT FRONT SUSPENSION -

DESCRIPTION, GEAR..................19-17

INDEPENDENT FRONT SUSPENSION -

INSTALLATION, GEAR.................19-18

INDEPENDENT FRONT SUSPENSION -

REMOVAL, GEAR.....................19-17

INDICATOR - DESCRIPTION, ABS........8J-17

INDICATOR - DESCRIPTION, AIRBAG.....8J-18

INDICATOR - DESCRIPTION, BRAKE/

PARK BRAKE........................8J-19

INDICATOR - DESCRIPTION, CARGO

LAMP

..............................8J-20

INDICATOR - DESCRIPTION, CHECK

GAUGES

............................8J-21

INDICATOR - DESCRIPTION, CRUISE

.....8J-22

INDICATOR - DESCRIPTION, DOOR AJAR

. . 8J-23

INDICATOR - DESCRIPTION, ETC

........8J-25

INDICATOR - DESCRIPTION, GEAR

SELECTOR

..........................8J-27

INDICATOR - DESCRIPTION, HIGH BEAM

. . 8J-28

INDICATOR - DESCRIPTION, LAMP OUT

. . . 8J-29

INDICATOR - DESCRIPTION, LOW FUEL

. . . 8J-30

INDICATOR - DESCRIPTION, SEATBELT

. . . 8J-34

INDICATOR - DESCRIPTION, SECURITY

. . . 8J-35

INDICATOR - DESCRIPTION, SERVICE

4WD

...............................8J-36

INDICATOR - DESCRIPTION, TOW/HAUL

. . . 8J-39INDICATOR - DESCRIPTION, TRANS

TEMP..............................8J-40

INDICATOR - DESCRIPTION, TURN

SIGNAL............................8J-40

INDICATOR - DESCRIPTION, UPSHIFT....8J-41

INDICATOR - DESCRIPTION, WAIT-TO-

START .............................8J-44

INDICATOR - DESCRIPTION, WASHER

FLUID..............................8J-44

INDICATOR - DESCRIPTION, WATER-IN-

FUEL..............................8J-45

INDICATOR - DIAGNOSIS AND TESTING,

BRAKE.............................8J-20

INDICATOR - OPERATION, ABS..........8J-17

INDICATOR - OPERATION, AIRBAG.......8J-18

INDICATOR - OPERATION, BRAKE/PARK

BRAKE.............................8J-19

INDICATOR - OPERATION, CARGO LAMP . . 8J-20

INDICATOR - OPERATION, CHECK

GAUGES............................8J-21

INDICATOR - OPERATION, CRUISE.......8J-22

INDICATOR - OPERATION, DOOR AJAR . . . 8J-23

INDICATOR - OPERATION, ETC..........8J-25

INDICATOR - OPERATION, GEAR

SELECTOR..........................8J-27

INDICATOR - OPERATION, HIGH BEAM....8J-28

INDICATOR - OPERATION, LAMP OUT....8J-29

INDICATOR - OPERATION, LOW FUEL.....8J-30

INDICATOR - OPERATION, SEATBELT.....8J-34

INDICATOR - OPERATION, SECURITY......8J-36

INDICATOR - OPERATION, SERVICE 4WD . . 8J-37

INDICATOR - OPERATION, TOW/HAUL....8J-39

INDICATOR - OPERATION, TRANS TEMP . . 8J-40

INDICATOR - OPERATION, TURN SIGNAL . . 8J-41

INDICATOR - OPERATION, UPSHIFT......8J-42

INDICATOR - OPERATION, WAIT-TO-

START .............................8J-44

INDICATOR - OPERATION, WASHER

FLUID..............................8J-44

INDICATOR - OPERATION, WATER-IN-

FUEL..............................8J-45

INDICATOR LAMP - DESCRIPTION,

SENTRY KEY IMMOBILIZER SYSTEM......8Q-5

INDICATOR LAMP - OPERATION,

SENTRY KEY IMMOBILIZER SYSTEM......8Q-5

INDICATOR LAMP (MIL) - DESCRIPTION,

MALFUNCTION.......................8J-31

INDICATOR LAMP (MIL) - OPERATION,

MALFUNCTION.......................8J-31

INDICATOR TEST - STANDARD

PROCEDURE, BUILT-IN................8F-10

INDICATORS - DIAGNOSIS AND

TESTING, TREAD WEAR................22-8

INERTIA HINGE COVER - INSTALLATION,

CENTER SEAT BACK..................23-77

INERTIA HINGE COVER - REMOVAL,

CENTER SEAT BACK..................23-77

INFLATION PRESSURES - DESCRIPTION,

TIRE................................22-7

INFO CENTER - DESCRIPTION,

ELECTRONIC VEHICLE.................8M-7

INFO CENTER - INSTALLATION,

ELECTRONIC VEHICLE.................8M-9

INFO CENTER - OPERATION,

ELECTRONIC VEHICLE.................8M-7

INFO CENTER - REMOVAL, ELECTRONIC

VEHICLE............................8M-9

INITIAL OPERATION - STANDARD

PROCEDURE, POWER STEERING

PUMP.............................19-40

INITIALIZATION, STANDARD PROCEDURE

- SENTRY KEY IMMOBILIZER SYSTEM....8Q-3

INJECTED RINGS - ASSEMBLY, WITH......3-13

INJECTED RINGS - DISASSEMBLY, WITH . . . 3-11

INJECTION PUMP - DESCRIPTION, FUEL . . 14-53

INJECTION PUMP - INSTALLATION, FUEL . 14-55

INJECTION PUMP - OPERATION, FUEL....14-53

INJECTION PUMP - REMOVAL, FUEL.....14-54

INJECTION PUMP TIMING - DIAGNOSIS

AND TESTING, FUEL..................14-53

INJECTOR - DESCRIPTION, FUEL . . . 14-26,14-74

INJECTOR - INSTALLATION, FUEL........14-77

INJECTOR - OPERATION, FUEL

.....14-26,14-74

INJECTOR - REMOVAL, FUEL

...........14-75

INJECTOR FIRING ORDER, DIESEL -

FUEL

..............................14-48

INJECTOR RAIL - DESCRIPTION, FUEL

....14-78

INJECTOR RAIL - INSTALLATION, FUEL

. . . 14-78INJECTOR RAIL - OPERATION, FUEL.....14-78

INJECTOR RAIL - REMOVAL, FUEL.......14-78

INLET AIR TEMPERATURE SENSOR/

PRESSURE SENSOR - DESCRIPTION.....14-79

INLET AIR TEMPERATURE SENSOR/

PRESSURE SENSOR - INSTALLATION.....14-79

INLET AIR TEMPERATURE SENSOR/

PRESSURE SENSOR - OPERATION.......14-79

INLET AIR TEMPERATURE SENSOR/

PRESSURE SENSOR - REMOVAL........14-79

INLET FILTER - INSTALLATION..........14-20

INLET FILTER - REMOVAL..............14-20

INLET HOSE - INSTALLATION, HEATER....24-64

INLET HOSE - REMOVAL, HEATER.......24-64

INNER BELT MOLDING - INSTALLATION,

FRONT DOOR.......................23-93

INNER BELT MOLDING - INSTALLATION,

REAR DOOR........................23-94

INNER BELT MOLDING - REMOVAL,

FRONT DOOR.......................23-93

INNER BELT MOLDING - REMOVAL,

REAR DOOR........................23-94

INPUT - OPERATION, ASD SENSE - PCM . . . 8I-5

INPUT CLUTCH ASSEMBLY - ASSEMBLY . 21-378

INPUT CLUTCH ASSEMBLY -

DESCRIPTION......................21-373

INPUT CLUTCH ASSEMBLY -

DISASSEMBLY......................21-374

INPUT CLUTCH ASSEMBLY - OPERATION . 21-373

INPUT SHAFT SEAL - INSTALLATION,

STEERING GEAR.......................19-29

INPUT SHAFT SEAL - REMOVAL,

STEERING GEAR.....................19-27

INPUT SPEED SENSOR - DESCRIPTION . . 21-382

INPUT SPEED SENSOR - INSTALLATION . 21-382

INPUT SPEED SENSOR - OPERATION....21-382

INPUT SPEED SENSOR - REMOVAL.....21-382

INSERTS - INSTALLATION, SPRING TIP....2-45

INSERTS - REMOVAL, SPRING TIP........2-44

INSIDE HANDLE ACTUATOR -

INSTALLATION..................23-22,23-32

INSIDE HANDLE ACTUATOR - REMOVAL . . 23-22,

23-31

INSTRUMENT CLUSTER - ASSEMBLY.....8J-15

INSTRUMENT CLUSTER - DESCRIPTION . . . 8J-2

INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING.......................8J-10

INSTRUMENT CLUSTER - DISASSEMBLY . . 8J-14

INSTRUMENT CLUSTER - INSTALLATION . . 8J-16

INSTRUMENT CLUSTER - OPERATION.....8J-6

INSTRUMENT CLUSTER - REMOVAL.....8J-14

INSTRUMENT PANEL ANTENNA CABLE -

INSTALLATION.......................8A-7

INSTRUMENT PANEL ANTENNA CABLE -

REMOVAL...........................8A-7

INSTRUMENT PANEL ASSEMBLY -

INSTALLATION.......................23-55

INSTRUMENT PANEL ASSEMBLY -

REMOVAL..........................23-52

INSTRUMENT PANEL CENTER BEZEL -

INSTALLATION.......................23-57

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL..........................23-57

INSTRUMENT PANEL DEMISTER DUCTS

- INSTALLATION.....................24-37

INSTRUMENT PANEL DEMISTER DUCTS

- REMOVAL.........................24-36

INSTRUMENT PANEL DRIVER SIDE

BEZEL - INSTALLATION................23-58

INSTRUMENT PANEL DRIVER SIDE

BEZEL - REMOVAL...................23-58

INSTRUMENT PANEL DUCTS -

INSTALLATION.......................24-37

INSTRUMENT PANEL DUCTS - REMOVAL . 24-37

INSTRUMENT PANEL HEADLAMP

SWITCH BEZEL - INSTALLATION.........23-56

INSTRUMENT PANEL HEADLAMP

SWITCH BEZEL - REMOVAL............23-56

INSTRUMENT PANEL LOWER

SURROUND - INSTALLATION...........23-59

INSTRUMENT PANEL LOWER

SURROUND - REMOVAL

...............23-59

INSTRUMENT PANEL TOP COVER -

INSTALLATION

.......................23-59

INSTRUMENT PANEL TOP COVER -

REMOVAL

..........................23-58

INTAKE AIR HEATER - DESCRIPTION

.....14-80

INTAKE AIR HEATER - INSTALLATION

.....14-80

DRINDEX 17

Description Group-Page Description Group-Page Description Group-Page