Crank DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1234 of 2627

(12) Disconnect heater hoses from heater core and

remove hose assembly.

(13) Disconnect throttle and speed control cables.

(14) Remove upper radiator hose from engine.

(15) Remove lower radiator hose from engine.

(16) Remove radiator/cooling module assembly.

(17) Disconnect the engine to body ground straps

at the left side of cowl.

(18) Disconnect the engine wiring harness at the

following points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(19) Remove coil over plugs.

(20) Release fuel rail pressure.

(21) Remove fuel rail and secure away from

engine.

NOTE: It is not necessary to release the quick con-

nect fitting from the fuel supply line for engine

removal.

(22) Remove the PCV hose.

(23) Remove the breather hoses.

(24) Remove the vacuum hose for the power brake

booster.

(25) Disconnect knock sensors.

(26) Remove engine oil dipstick tube.

(27) Remove intake manifold.

(28) Install engine lifting fixture,special tool#8247,

using original fasteners from the removed intake

manifold, and fuel rail. Torque to factory specifica-

tions.

NOTE: Recheck bolt torque for engine lift plate

before removing engine.

(29) Secure the left and right engine wiring har-

nesses away from engine.

(30) Raise vehicle.

(31) Disconnect oxygen sensor wiring.

(32) Disconnect crankshaft postion sensor.

(33) Disconnect the engine block heater power

cable, if equipped.

(34) Disconnect the front propshaft at the front

differential and secure out of way.

NOTE: It is necessary to disconnect the front prop-

shaft for access to the starter and left side exhaust

flange.(35) Remove the starter.

(36) Remove the ground straps from the left and

right side of the block.

(37) Disconnect the right and left exhaust pipes at

the manifolds and from the crossover, and remove

from the vehicle.

NOTE: The exhaust clamps at the manifolds cannot

be reused. New clamps must be used or leaks may

occur.

(38) Remove the structural cover.

(39) Remove torque convertor bolts, and mark

location for reassembly.

(40) Remove transmission bellhousing to engine

bolts.

(41) Remove left and right engine mount thru

bolts.

(42) Lower the vehicle.

(43) Support the transmission with a suitable jack.

(44) Connect a suitable engine hoist to the engine

lift plate.

(45) Remove engine from vehicle.

INSTALLATION

(1) Position the engine in the vehicle.

(2) Install both left and right side engine mounts

onto engine.

(3) Raise the vehicle.

(4) Install the transmission bellhousing to engine

mounting bolts. Tighten the bolts to 41 N´m (30ft.

lbs.).

(5) Tighten the engine mount thru bolts.

(6) Install the torque convertor bolts.

(7) Connect the ground straps on the left and right

side of the engine.

(8) Install the starter.

(9) Connect the crankshaft position sensor.

(10) Install the engine block heater power cable, if

equipped.

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

(11) Install the structural cover.

NOTE: New clamps must be used on exhaust man-

ifold flanges. Failure to use new clamps may result

in exhaust leaks.

(12) Install the left and right exhaust pipes.

(13) Connect the left and right oxygen sensors.

(14) Lower vehicle.

(15) Remove the engine lift plate.

(16) Connect the knock sensors.

DRENGINE - 3.7L 9 - 11

ENGINE - 3.7L (Continued)

Page 1235 of 2627

(17) Connect the engine to body ground straps at

the left side of the cowl.

(18) Install the intake manifold.

(19) Install the engine oil dipstick tube.

(20) Install the power brake booster vacuum hose.

(21) Install the breather hoses.

(22) Install the PCV hose.

(23) Install the fuel rail.

(24) Install the coil over plugs.

(25) Connect the engine wiring harness at the fol-

lowing points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(26) Reinstall the radiator/cooling module assem-

bly.

(27) Connect lower radiator hose.

(28) Connect upper radiator hose.

(29) Connect throttle and speed control cables.

(30) Install the heater hose assembly.

(31) Install coolant recovery bottle.

(32) Install the power steering pump.

(33) Install the generator.

(34) Install the A/C compressor.

(35) Install the drive belt.

(36) Install the fan shroud with the viscous fan

assembly.

(37) Install the radiator core support bracket.

(38) Install the air cleaner assembly.

(39) Refill the engine cooling system.

(40) Recharge the air conditioning.

(41) Install the hood.

(42) Check and fill engine oil.

(43) Connect the battery negative cable.

(44) Start the engine and check for leaks.SPECIFICATIONS

SPECIFICATIONS - 3.7L ENGINE

GENERAL SPECIFICATIONS

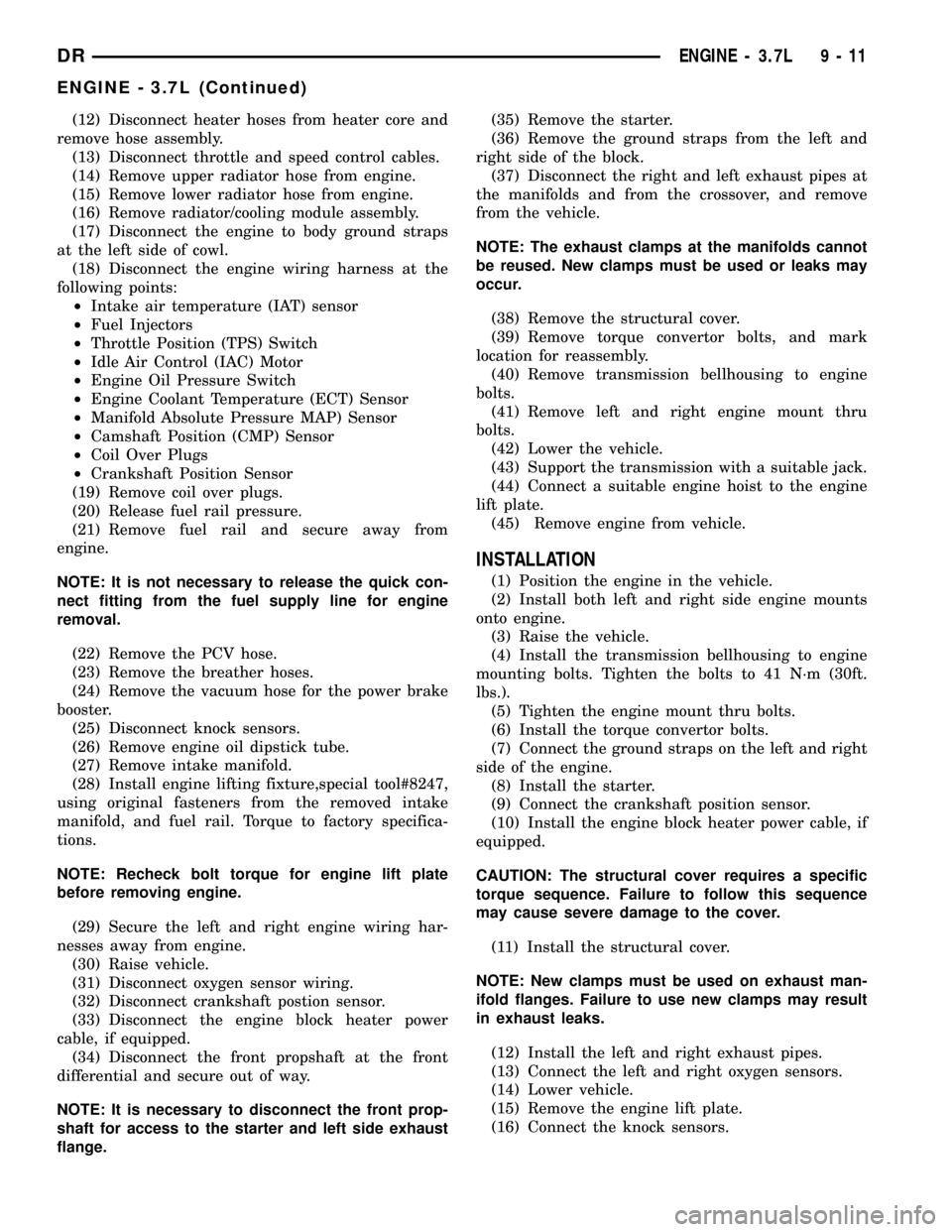

DESCRIPTION SPECIFICATION

Type 90É SOHC V6 12 Valve

Number of

Cylinders4

Firing Order 1-6-5-4-3-2

Lead Cylinder No. 1 Left Bank

Compression

Ratio9.1:1

Max. Variation

Between

Cylinders25%

Metric Standard

Displacement 3.7 Liters 226 Cubic

Inches

Bore 93.0 mm 3.66 in.

Stroke 90.8 mm 3.40 in.

Horsepower 210@5200 RPM

Torque 225ft. lbs.@4200 PRM

Compression

Pressure1172-1551 kPa 170-225 psi

CYLINDER BLOCK

DESCRIPTION SPECIFICATION

Metric Standard

Bore Diameter 93.0 .0075

mm3.6619 0.0003

in.

Out of Round

(MAX)0.076 mm 0.003 in.

Taper (MAX) 0.051 mm 0.002 in.

9 - 12 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1237 of 2627

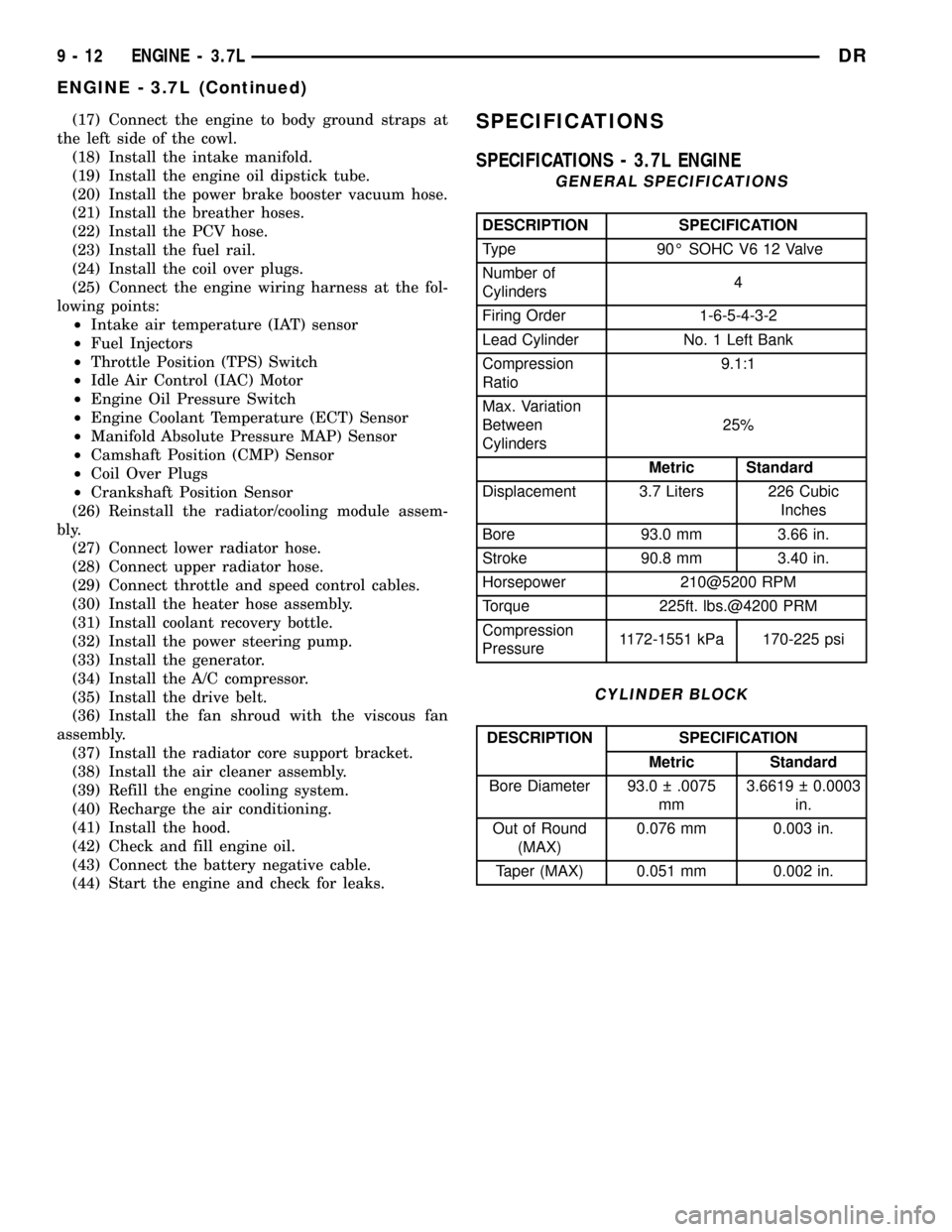

CRANKSHAFT

DESCRIPTION SPECIFICATION

Metric Standard

Main Bearing

Journal

Diameter63.488 - 63.512

mm2.4996 - 2.5005

in.

Bearing

Clearance0.002 - 0.034

mm-

Out of Round

(MAX)0.005 mm 0.0002 in.

Taper (MAX) 0.006 mm 0.0004 in.

End Play 0.052 - 0.282

mm0.0021 - 0.0112

in.

End Play (MAX) 0.282 mm 0.0112 in.

Connecting Rod

Journal

Diameter57.908 - 57.892

mm-

Bearing

Clearance0.015 - 0.055 -

Out of Round

(MAX)0.005 mm 0.0002 in.

Taper (MAX) 0.006 mm 0.0002 in.

CAMSHAFT

DESCRIPTION SPECIFICATION

Metric Standard

Bore Diameter 26.02 - 26.04

mm1.0245 - 1.0252

in.

Bearing Journal

Diameter25.975 - 25.995

mm1.0227 - 1.0235

in.

Bearing

Clearance0.025 - 0.065

mm0.001 - 0.0026

in.

Bearing

Clearance

(MAX)0.065 mm 0.0026 in.

End Play .075 - .200 mm 0.003 - 0.0079

in.

End Play (MAX) .200 mm 0.0079 in.

VALVE TIMING

DESCRIPTION SPECIFICATION

Intake

Opens (ATDC) 0.0É

Closes (ATDC) 236É

Duration 236É

Exhaust

Opens (BTDC) 233É

Closes (ATDC) 17É

Duration 250É

Valve Overlap 17É

VALVES

DESCRIPTION SPECIFICATION

Metric Standard

Face Angle 45É - 45.5É

Head Diameter

Intake 48.52 - 48.78

mm1.9103 - 1.9205

in.

Exhaust 36.87 - 37.13

mm1.4516 - 1.4618

in.

Length (Overall)

Intake 113.45 - 114.21

mm4.4666 - 4.4965

in.

Exhaust 114.92 - 115.68

mm4.5244 - 4.5543

in.

Stem Diameter

Intake 6.931 - 6.957

mm0.2729 - 0.2739

in.

Exhaust 6.902 - 6.928

mm0.2717 - 0.2728

in.

Stem-to-Guide

Clearance

Intake 0.018 - 0.069

mm0.0008 - 0.0028

in.

Exhaust 0.047 - 0.098

mm0.0019 - 0.0039

in.

Max. Allowable

Stem-to-Guide

Clearance

(Rocking Method)

Intake 0.069 mm 0.0028 in.

Exhaust 0.098 mm 0.0039 in.

Valve Lift (Zero

Lash)

Intake 12.00 mm () 0.472 in.

Exhaust 10.90 mm 0.4292 in.

9 - 14 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1239 of 2627

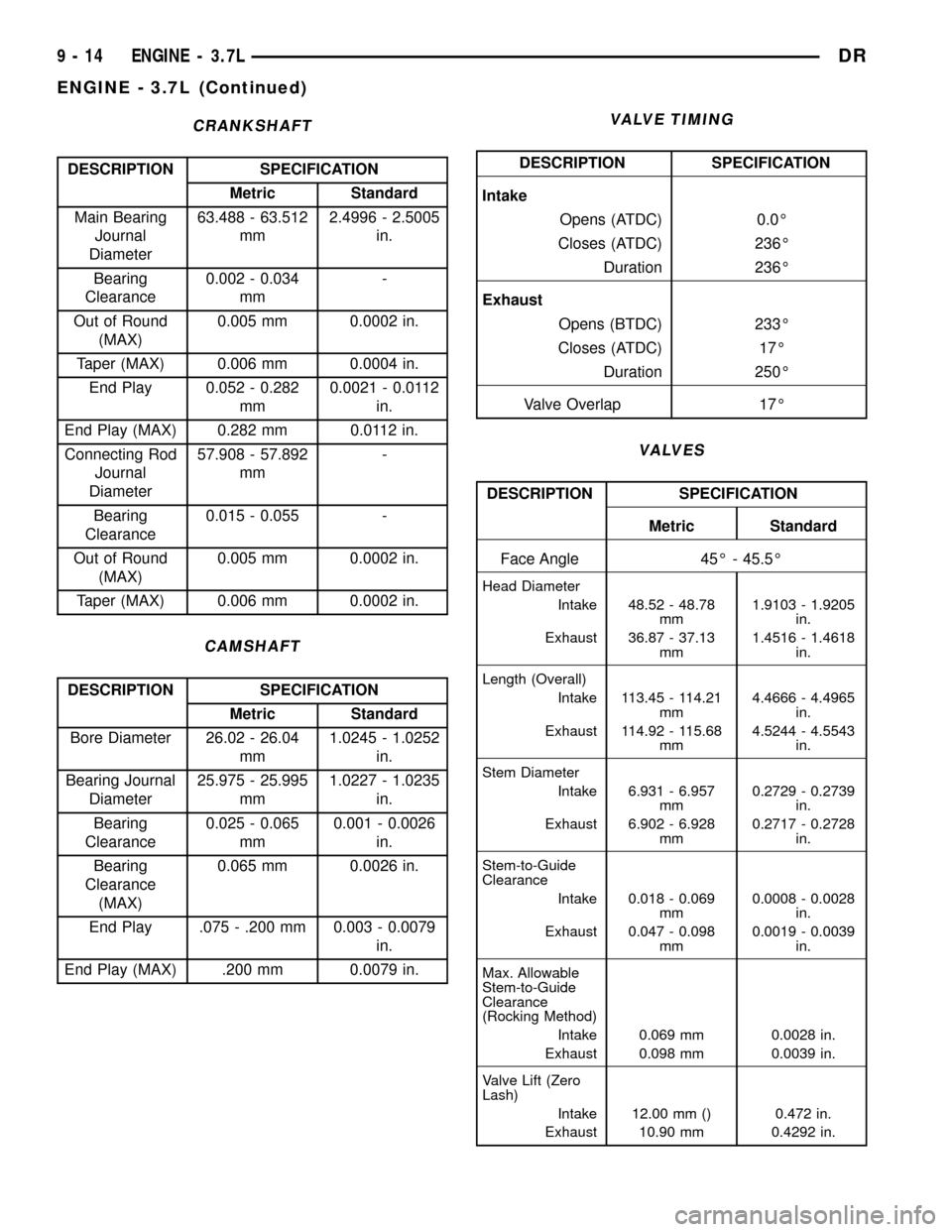

OIL PRESSURE

SPECIFICATION SPECIFICATION

Metric Standard

At Curb Idle

Speed (MIN)*25 kPa 4 psi

@ 3000 rpm 170 - 758 kPa 25 - 110 psi

* CAUTION: If pressure is zero at curb idle, DO

NOT run engine at 3000 rpm.

TORQUE

DESCRIPTION N´m Ft.

Lbs.In.

Lbs.

Camshaft

Non - Oiled Sprocket Bolt 122 90 -

Bearing Cap Bolts 11 - 100

Counterbalance shaft

retaining bolt28 - 250

Timing Chain Cover-Bolts 58 43 -

Connecting Rod Cap-Bolts 27 20 -

PLUS 90É TURN

Bed Plate-Bolts Refer to Procedure

Crankshaft Damper-Bolt 175 130 -

Cylinder Head-Bolts

M11 Bolts Refer To Procedure

M8 Bolts Refer To Procedure

Cylinder Head Cover-Bolts 12 - 105

Exhaust Manifold-Bolts 25 18 -

Exhaust Manifold Heat

Shield-Nuts8-72

Then loosen 45É

DESCRIPTION N´m Ft.

Lbs.In.

Lbs.

Flexplate-Bolts 95 70 -

Engine Mount Bracket to

Block-Bolts61 45 -

Rear Mount to Transmission-

Bolts46 34 -

Generator Mounting-Bolts

M10 Bolts 54 40 -

M8 Bolts 28 - 250

Intake Manifold-Bolts 12 - 105

Refer to Procedure

for Tightening

Sequence

Oil Pan-Bolts 15 - 130

Oil Pan-Drain Plug 34 25 -

Oil Pump-Bolts 28 - 250

Oil Pump Cover-Bolts 12 - 105

Oil Pickup Tube-Bolt and Nut 28 - 250

Oil Dipstick Tube to Engine

Block-Bolt15 - 130

Oil Fill Tube-Bolts 12 - 105

Timing Chain Guide-Bolts 28 - 250

Timing Chain Tensioner Arm 28 - 250

Hydraulic Tensioner-Bolts 28 - 250

Timing Chain Primary

Tensioner-Bolts28 - 250

Timing Drive Idler Sprocket-

Bolt34 25 -

Thermostat Housing-Bolts 12 - 105

Water Pump-Bolts 58 43 -

9 - 16 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1240 of 2627

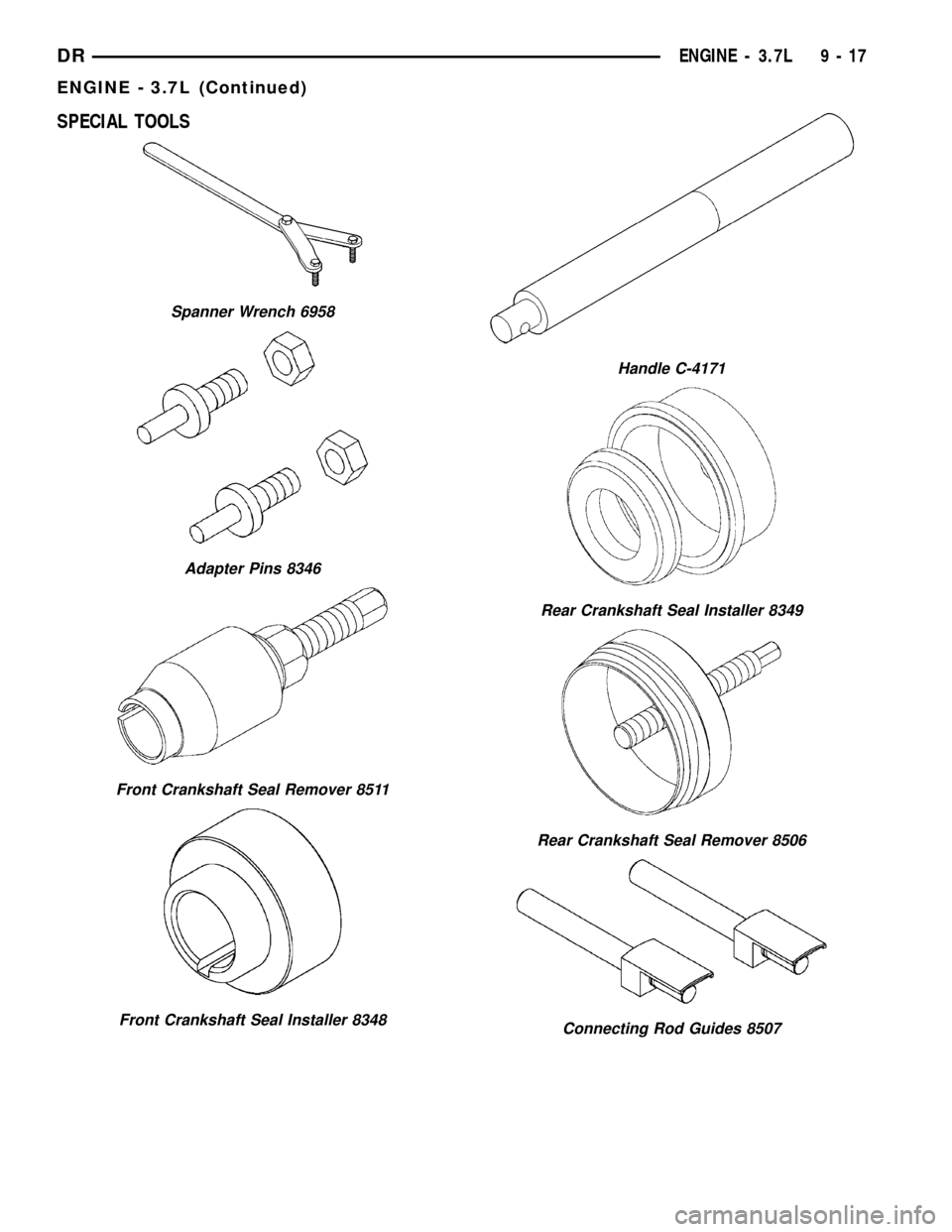

SPECIAL TOOLS

Spanner Wrench 6958

Adapter Pins 8346

Front Crankshaft Seal Remover 8511

Front Crankshaft Seal Installer 8348

Handle C-4171

Rear Crankshaft Seal Installer 8349

Rear Crankshaft Seal Remover 8506

Connecting Rod Guides 8507

DRENGINE - 3.7L 9 - 17

ENGINE - 3.7L (Continued)

Page 1241 of 2627

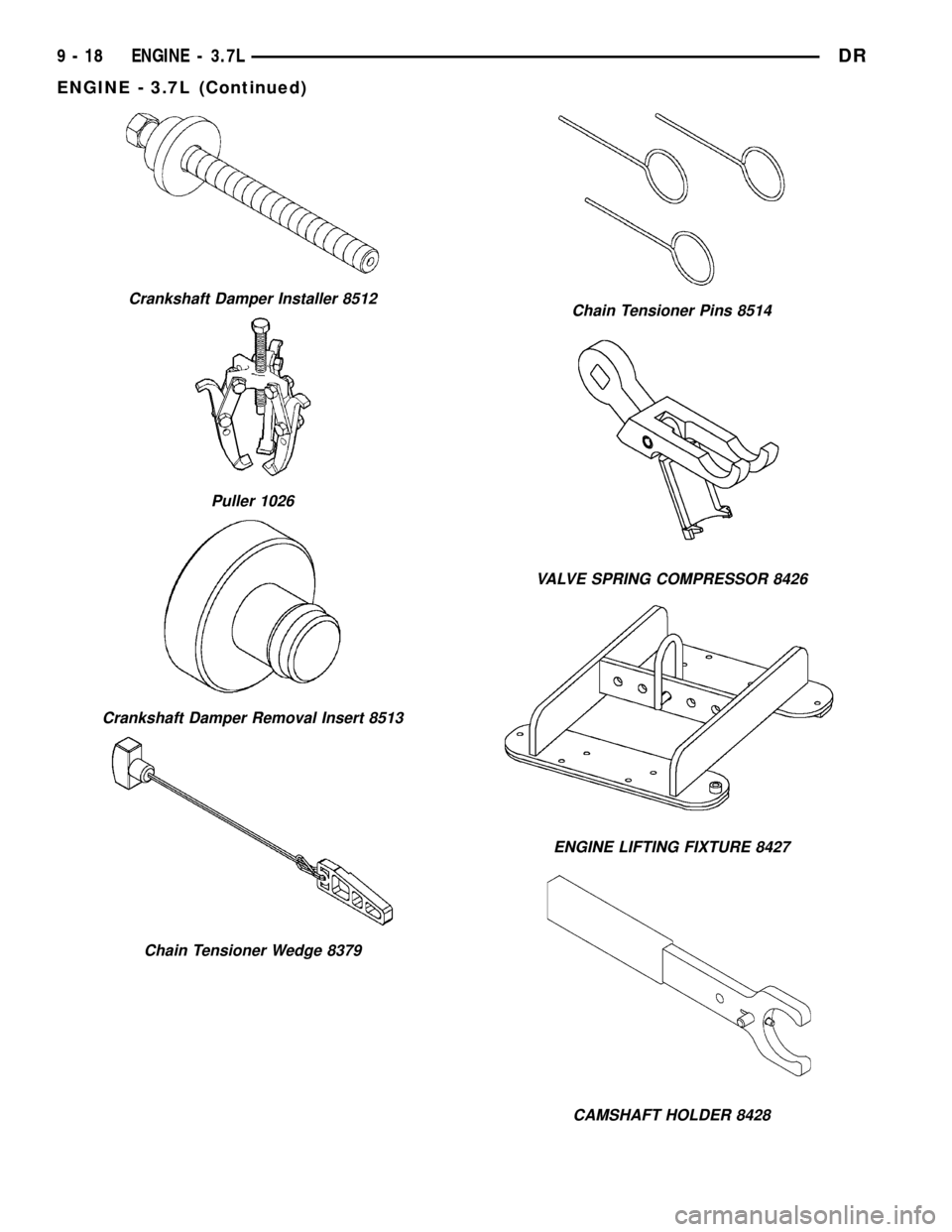

Crankshaft Damper Installer 8512

Puller 1026

Crankshaft Damper Removal Insert 8513

Chain Tensioner Wedge 8379

Chain Tensioner Pins 8514

VALVE SPRING COMPRESSOR 8426

ENGINE LIFTING FIXTURE 8427

CAMSHAFT HOLDER 8428

9 - 18 ENGINE - 3.7LDR

ENGINE - 3.7L (Continued)

Page 1245 of 2627

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50 - 70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the left side

exhaust manifold.

(4) Drain the engine coolant(Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(5) Lower the vehicle.(6) Remove the intake manifold(Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL).

(7) Remove the master cylinder and booster assem-

bly(Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/POWER BRAKE BOOSTER - REMOVAL).

(8) Remove the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(9) Remove the fan shroud and fan blade assem-

bly(Refer to 7 - COOLING/ENGINE/RADIATOR FAN

- REMOVAL).

(10) Remove accessory drive belt(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(11) Remove the power steering pump and set

aside.

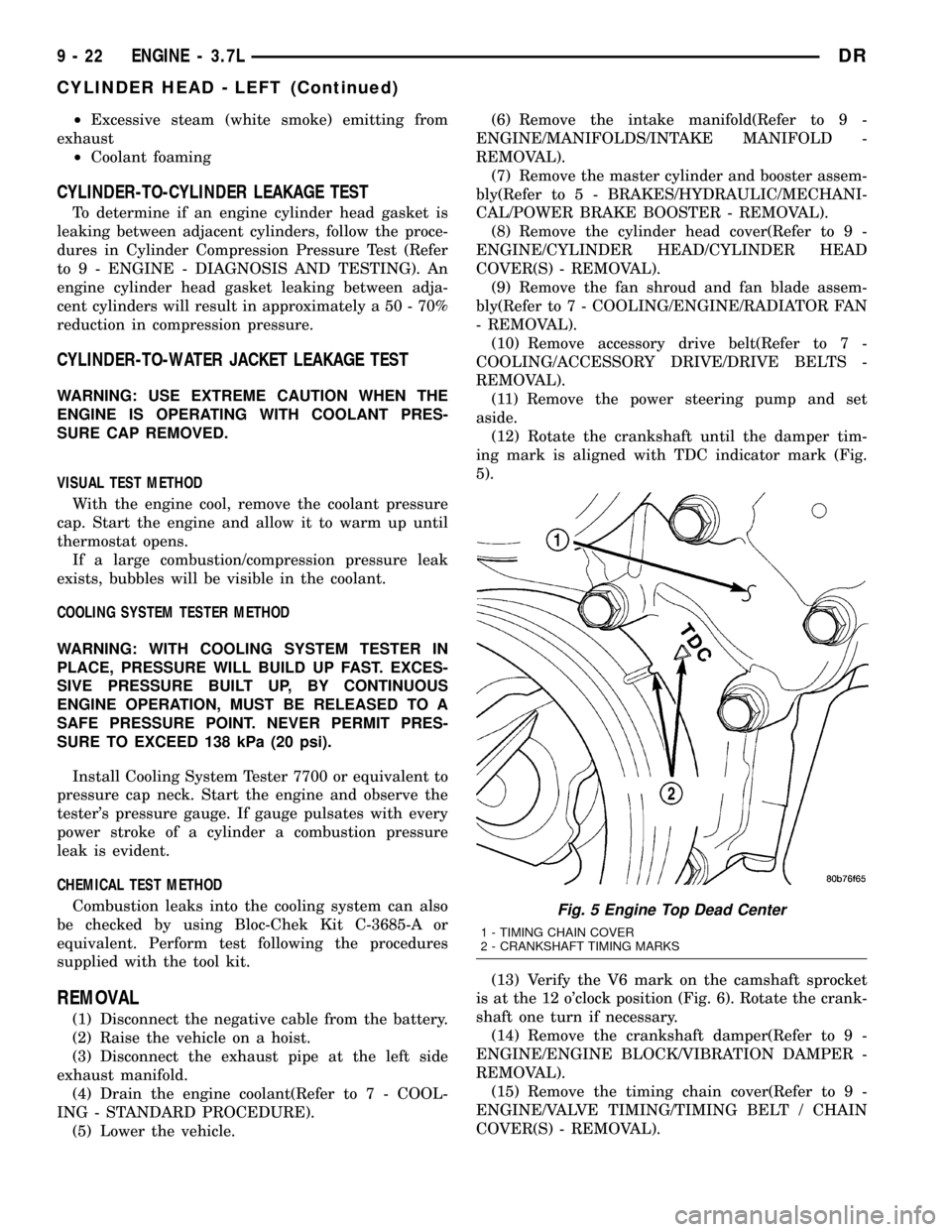

(12) Rotate the crankshaft until the damper tim-

ing mark is aligned with TDC indicator mark (Fig.

5).

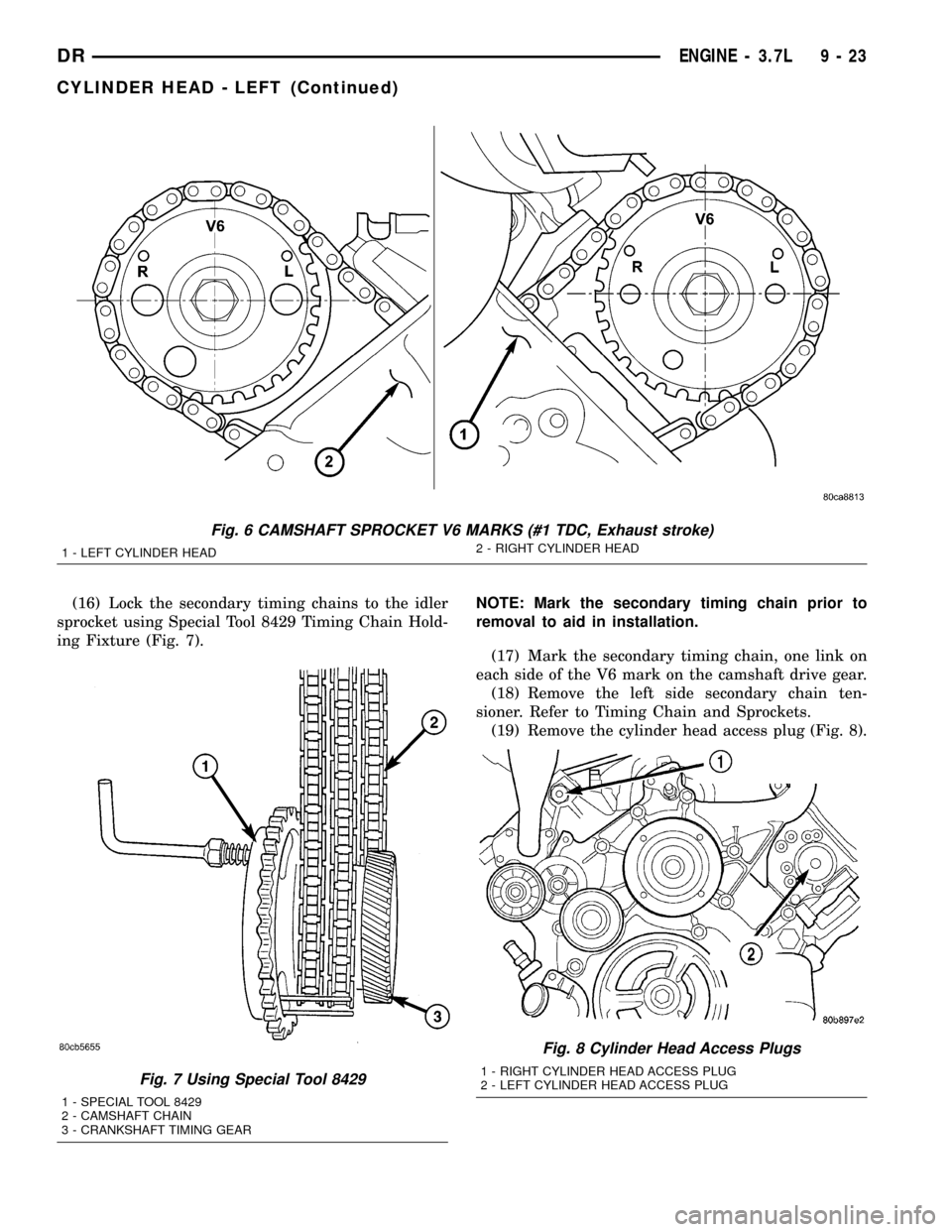

(13) Verify the V6 mark on the camshaft sprocket

is at the 12 o'clock position (Fig. 6). Rotate the crank-

shaft one turn if necessary.

(14) Remove the crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(15) Remove the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

Fig. 5 Engine Top Dead Center

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

9 - 22 ENGINE - 3.7LDR

CYLINDER HEAD - LEFT (Continued)

Page 1246 of 2627

(16) Lock the secondary timing chains to the idler

sprocket using Special Tool 8429 Timing Chain Hold-

ing Fixture (Fig. 7).NOTE: Mark the secondary timing chain prior to

removal to aid in installation.

(17) Mark the secondary timing chain, one link on

each side of the V6 mark on the camshaft drive gear.

(18) Remove the left side secondary chain ten-

sioner. Refer to Timing Chain and Sprockets.

(19) Remove the cylinder head access plug (Fig. 8).

Fig. 6 CAMSHAFT SPROCKET V6 MARKS (#1 TDC, Exhaust stroke)

1 - LEFT CYLINDER HEAD2 - RIGHT CYLINDER HEAD

Fig. 7 Using Special Tool 8429

1 - SPECIAL TOOL 8429

2 - CAMSHAFT CHAIN

3 - CRANKSHAFT TIMING GEAR

Fig. 8 Cylinder Head Access Plugs

1 - RIGHT CYLINDER HEAD ACCESS PLUG

2 - LEFT CYLINDER HEAD ACCESS PLUG

DRENGINE - 3.7L 9 - 23

CYLINDER HEAD - LEFT (Continued)

Page 1248 of 2627

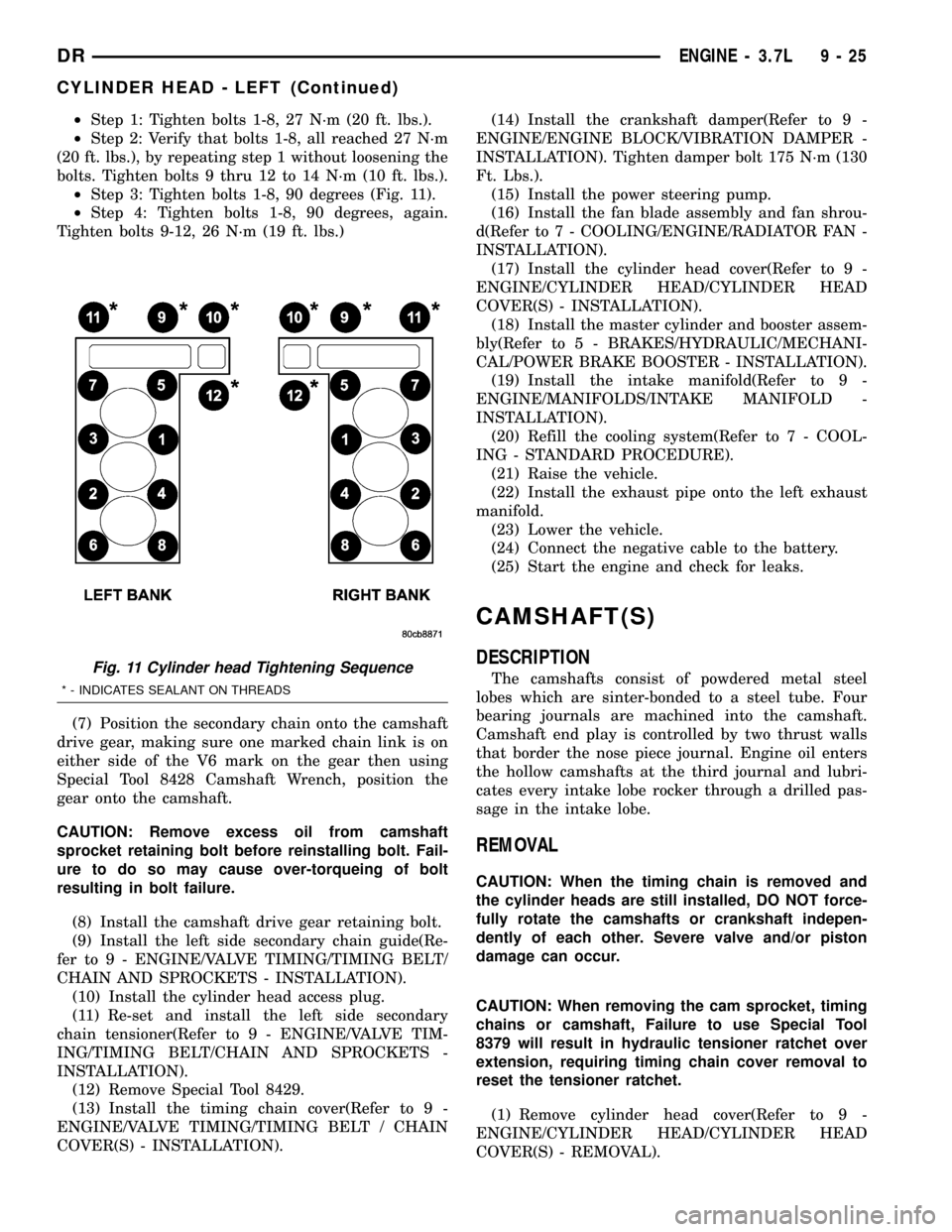

²Step 1: Tighten bolts 1-8, 27 N´m (20 ft. lbs.).

²Step 2: Verify that bolts 1-8, all reached 27 N´m

(20 ft. lbs.), by repeating step 1 without loosening the

bolts. Tighten bolts 9 thru 12 to 14 N´m (10 ft. lbs.).

²Step 3: Tighten bolts 1-8, 90 degrees (Fig. 11).

²Step 4: Tighten bolts 1-8, 90 degrees, again.

Tighten bolts 9-12, 26 N´m (19 ft. lbs.)

(7) Position the secondary chain onto the camshaft

drive gear, making sure one marked chain link is on

either side of the V6 mark on the gear then using

Special Tool 8428 Camshaft Wrench, position the

gear onto the camshaft.

CAUTION: Remove excess oil from camshaft

sprocket retaining bolt before reinstalling bolt. Fail-

ure to do so may cause over-torqueing of bolt

resulting in bolt failure.

(8) Install the camshaft drive gear retaining bolt.

(9) Install the left side secondary chain guide(Re-

fer to 9 - ENGINE/VALVE TIMING/TIMING BELT/

CHAIN AND SPROCKETS - INSTALLATION).

(10) Install the cylinder head access plug.

(11) Re-set and install the left side secondary

chain tensioner(Refer to 9 - ENGINE/VALVE TIM-

ING/TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION).

(12) Remove Special Tool 8429.

(13) Install the timing chain cover(Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).(14) Install the crankshaft damper(Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION). Tighten damper bolt 175 N´m (130

Ft. Lbs.).

(15) Install the power steering pump.

(16) Install the fan blade assembly and fan shrou-

d(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

INSTALLATION).

(17) Install the cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

(18) Install the master cylinder and booster assem-

bly(Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/POWER BRAKE BOOSTER - INSTALLATION).

(19) Install the intake manifold(Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(20) Refill the cooling system(Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(21) Raise the vehicle.

(22) Install the exhaust pipe onto the left exhaust

manifold.

(23) Lower the vehicle.

(24) Connect the negative cable to the battery.

(25) Start the engine and check for leaks.

CAMSHAFT(S)

DESCRIPTION

The camshafts consist of powdered metal steel

lobes which are sinter-bonded to a steel tube. Four

bearing journals are machined into the camshaft.

Camshaft end play is controlled by two thrust walls

that border the nose piece journal. Engine oil enters

the hollow camshafts at the third journal and lubri-

cates every intake lobe rocker through a drilled pas-

sage in the intake lobe.

REMOVAL

CAUTION: When the timing chain is removed and

the cylinder heads are still installed, DO NOT force-

fully rotate the camshafts or crankshaft indepen-

dently of each other. Severe valve and/or piston

damage can occur.

CAUTION: When removing the cam sprocket, timing

chains or camshaft, Failure to use Special Tool

8379 will result in hydraulic tensioner ratchet over

extension, requiring timing chain cover removal to

reset the tensioner ratchet.

(1) Remove cylinder head cover(Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

Fig. 11 Cylinder head Tightening Sequence

* - INDICATES SEALANT ON THREADS

DRENGINE - 3.7L 9 - 25

CYLINDER HEAD - LEFT (Continued)

Page 1254 of 2627

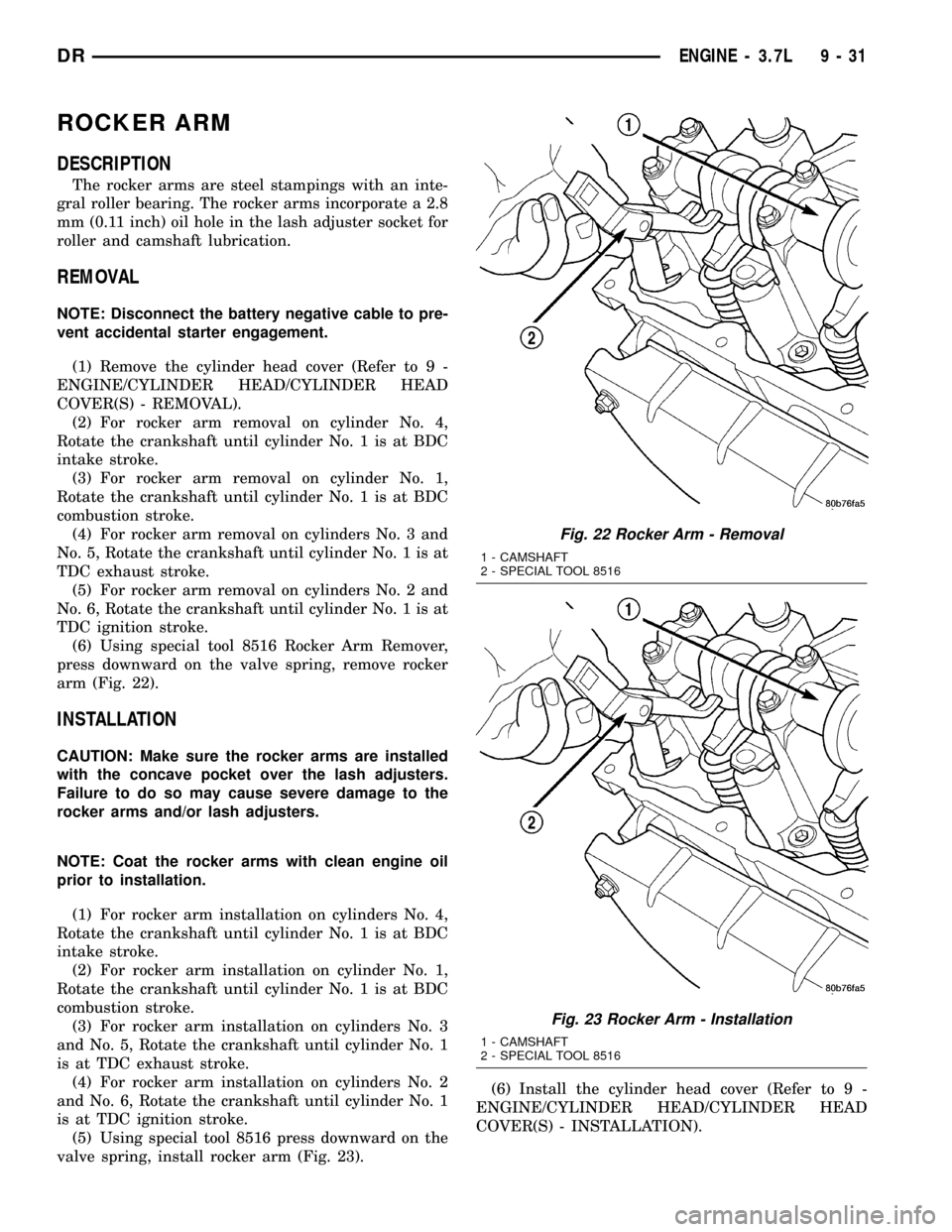

ROCKER ARM

DESCRIPTION

The rocker arms are steel stampings with an inte-

gral roller bearing. The rocker arms incorporate a 2.8

mm (0.11 inch) oil hole in the lash adjuster socket for

roller and camshaft lubrication.

REMOVAL

NOTE: Disconnect the battery negative cable to pre-

vent accidental starter engagement.

(1) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(2) For rocker arm removal on cylinder No. 4,

Rotate the crankshaft until cylinder No. 1 is at BDC

intake stroke.

(3) For rocker arm removal on cylinder No. 1,

Rotate the crankshaft until cylinder No. 1 is at BDC

combustion stroke.

(4) For rocker arm removal on cylinders No. 3 and

No. 5, Rotate the crankshaft until cylinder No. 1 is at

TDC exhaust stroke.

(5) For rocker arm removal on cylinders No. 2 and

No. 6, Rotate the crankshaft until cylinder No. 1 is at

TDC ignition stroke.

(6) Using special tool 8516 Rocker Arm Remover,

press downward on the valve spring, remove rocker

arm (Fig. 22).

INSTALLATION

CAUTION: Make sure the rocker arms are installed

with the concave pocket over the lash adjusters.

Failure to do so may cause severe damage to the

rocker arms and/or lash adjusters.

NOTE: Coat the rocker arms with clean engine oil

prior to installation.

(1) For rocker arm installation on cylinders No. 4,

Rotate the crankshaft until cylinder No. 1 is at BDC

intake stroke.

(2) For rocker arm installation on cylinder No. 1,

Rotate the crankshaft until cylinder No. 1 is at BDC

combustion stroke.

(3) For rocker arm installation on cylinders No. 3

and No. 5, Rotate the crankshaft until cylinder No. 1

is at TDC exhaust stroke.

(4) For rocker arm installation on cylinders No. 2

and No. 6, Rotate the crankshaft until cylinder No. 1

is at TDC ignition stroke.

(5) Using special tool 8516 press downward on the

valve spring, install rocker arm (Fig. 23).(6) Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

Fig. 22 Rocker Arm - Removal

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

Fig. 23 Rocker Arm - Installation

1 - CAMSHAFT

2 - SPECIAL TOOL 8516

DRENGINE - 3.7L 9 - 31