Speed control DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 550 of 2627

the upper edge of the instrument cluster, between

the speedometer and the tachometer. Each turn sig-

nal indicator consists of a stencil-like cutout of the

International Control and Display Symbol icon for

ªTurn Warningº in the opaque layer of the instru-

ment cluster overlay. The dark outer layer of the

overlay prevents these icons from being clearly visi-

ble when they are not illuminated. A green Light

Emitting Diode (LED) behind each turn signal indi-

cator cutout in the opaque layer of the overlay causes

the icon to appear in green through the translucent

outer layer of the overlay when the indicator is illu-

minated from behind by the LED, which is soldered

onto the instrument cluster electronic circuit board.

The turn signal indicators are serviced as a unit with

the instrument cluster.

OPERATION

The turn signal indicators give an indication to the

vehicle operator that the turn signal (left or right

indicator flashing) or hazard warning (both left and

right indicators flashing) have been selected and are

operating. These indicators are controlled by transis-

tors on the instrument cluster electronic circuit board

based upon the cluster programming, a hard wired

multiplex input received by the cluster from the turn

signal and hazard warning switch circuitry of the

multi-function switch on the turn/hazard switch mux

circuit, and electronic messages received from the

Front Control Module (FCM) over the Programmable

Communications Interface (PCI) data bus. Each turn

signal indicator Light Emitting Diode (LED) is com-

pletely controlled by the instrument cluster logic cir-

cuit, and that logic will allow this indicator to

operate whenever the instrument cluster receives a

battery current input on the fused B(+) circuit.

Therefore, each LED can be illuminated regardless of

the ignition switch position. The LED only illumi-

nates when it is provided a path to ground by the

instrument cluster transistor. The instrument cluster

will turn on the turn signal indicators for the follow-

ing reasons:

²Turn Signal-On Input- Each time the cluster

detects a turn signal-on input from the turn signal

switch circuitry of the multi-function switch on the

turn/hazard switch mux circuit, the requested turn

signal lamps and turn signal indicator will be flashed

on and off, and an electromechanical relay soldered

onto the cluster electronic circuit board will produce

a clicking sound to emulate a conventional turn sig-

nal flasher. The turn signals and the turn signal

indicators continue to flash on and off until the clus-

ter receives a turn signal-off input from the multi-

function switch, or until the ignition switch is turned

to the Off position, whichever occurs first.²Hazard Warning-On Input- Each time the

cluster detects a hazard warning-on input from the

hazard warning switch circuitry of the multi-function

switch on the turn/hazard switch mux circuit, all of

the turn signal lamps and both turn signal indicators

will be flashed on and off, and an electromechanical

relay soldered onto the cluster electronic circuit

board will produce a clicking sound to emulate a con-

ventional hazard warning flasher. The turn signals

and the turn signal indicators continue to flash on

and off until the cluster receives a hazard warning-

off input from the multi-function switch.

²Lamp Out Mode- The instrument cluster also

sends electronic turn signal on and off messages to

the FCM over the PCI data bus, and the FCM

flashes the appropriate exterior turn signal lamps. If

the FCM detects an inoperative turn signal lamp or

circuit, it increases the flash rate for the remaining

operative turn signals and sends an electronic mes-

sage back to the instrument cluster. The instrument

cluster then increases the flash rate of the turn sig-

nal indicator(s) and the clicking rate of the electro-

mechanical relay to provide an indication of the

problem to the vehicle operator.

²Actuator Test- Each time the cluster is put

through the actuator test, the turn signal indicators

will be turned on, then off again during the bulb

check portion of the test to confirm the functionality

of each LED and the cluster control circuitry.

The instrument cluster continually monitors the

multi-function switch and electronic messages from

the FCM to determine the proper turn signal and

hazard warning system control. For further diagnosis

of the turn signal indicators or the instrument clus-

ter circuitry that controls the indicators, (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - DIAGNO-

SIS AND TESTING). For proper diagnosis of the

turn signal and hazard warning system, the multi-

function switch, the FCM, the PCI data bus, or the

electronic message inputs to the instrument cluster

that control the turn signal indicators, a DRBIIIt

scan tool is required. Refer to the appropriate diag-

nostic information.

UPSHIFT INDICATOR

DESCRIPTION

An upshift indicator is standard equipment on all

instrument clusters (Fig. 33). However, on vehicles

not equipped with a manual transmission, this indi-

Fig. 33 Upshift Indicator

DRINSTRUMENT CLUSTER 8J - 41

TURN SIGNAL INDICATOR (Continued)

Page 551 of 2627

cator is electronically disabled. The upshift indicator

consists of an upward pointed arrow icon, which

appears on the right side of the electronic gear selec-

tor indicator Vacuum Fluorescent Display (VFD)

unit. The VFD is soldered onto the cluster electronic

circuit board and is visible through a window with a

smoked clear lens located on the lower edge of the

speedometer gauge dial face of the cluster overlay.

The dark lens over the VFD prevents the indicator

from being clearly visible when it is not illuminated.

The icon appears in a blue-green color and at the

same lighting level as the odometer/trip odometer

information when it is illuminated by the instrument

cluster electronic circuit board. The upshift indicator

is serviced as a unit with the instrument cluster.

OPERATION

The upshift indicator gives an indication to the

vehicle operator when the manual transmission

should be shifted to the next highest gear in order to

achieve the best fuel economy. This indicator is con-

trolled by the instrument cluster circuit board based

upon cluster programming and electronic messages

received by the cluster from the Powertrain Control

Module (PCM) on vehicles with a gasoline engine, or

from the Engine Control Module (ECM) on vehicles

with a diesel engine over the Programmable Commu-

nications Interface (PCI) data bus. The upshift indi-

cator is completely controlled by the instrument

cluster logic circuit, and that logic will only allow

this indicator to operate when the instrument cluster

receives a battery current input on the fused ignition

switch output (run-start) circuit. Therefore, the indi-

cator will always be off when the ignition switch is in

any position except On or Start. The indicator only

illuminates when it is switched to ground by the

instrument cluster circuitry. The instrument cluster

will turn on the upshift indicator for the following

reasons:

²Upshift Lamp-On Message- Each time the

cluster receives an upshift lamp-on message from the

PCM or ECM indicating the engine speed and load

conditions are right for a transmission upshift to

occur, the upshift indicator is illuminated. The indi-

cator remains illuminated until the cluster receives

an upshift lamp-off message from the PCM or ECM,

or until the ignition switch is turned to the Off posi-

tion, whichever occurs first. The PCM or ECM will

normally send an upshift lamp-off message three to

five seconds after a lamp-on message, if an upshift is

not performed. The indicator will then remain off

until the vehicle stops accelerating and is brought

back into the range of indicator operation, or until

the transmission is shifted into another gear.

²Actuator Test- Each time the cluster is put

through the actuator test, the upshift indicator willbe turned on, then off again during the VFD portion

of the test to confirm the functionality of the VFD

and the cluster control circuitry.

On vehicles with a gasoline engine, the PCM con-

tinually monitors the engine speed and load condi-

tions to determine the proper fuel and ignition

requirements. On vehicles with a diesel engine, the

ECM continually monitors the engine speed and load

conditions to determine the proper fuel requirements.

The PCM or ECM then sends the proper upshift indi-

cator lamp-on and lamp-off messages to the instru-

ment cluster. For further diagnosis of the upshift

indicator or the instrument cluster circuitry that con-

trols the indicator, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the PCM, the

ECM, the PCI data bus, or the electronic message

inputs to the instrument cluster that control the

upshift indicator, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

VOLTAGE GAUGE

DESCRIPTION

A voltage gauge is standard equipment on all

instrument clusters. The voltage gauge is located in

the upper left quadrant of the instrument cluster,

above the fuel gauge. The voltage gauge consists of a

movable gauge needle or pointer controlled by the

instrument cluster circuitry and a fixed 90 degree

scale on the cluster overlay that reads left-to-right

from ªLº (or Low) to ªHº (or High) for gasoline

engines. On vehicles with a diesel engine, the scale

reads from ª8º to ª18º volts. An International Control

and Display Symbol icon for ªBattery Charging Con-

ditionº is located on the cluster overlay, directly

below the right end of the gauge scale (Fig. 34). The

voltage gauge graphics are black against a white

field except for a single red graduation at each end of

the gauge scale, making them clearly visible within

the instrument cluster in daylight. When illuminated

from behind by the panel lamps dimmer controlled

cluster illumination lighting with the exterior lamps

turned On, the black graphics appear blue and the

red graphics still appear red. The orange gauge nee-

dle is internally illuminated. Gauge illumination is

provided by replaceable incandescent bulb and bulb

holder units located on the instrument cluster elec-

tronic circuit board. The voltage gauge is serviced as

a unit with the instrument cluster.

Fig. 34 Battery Charging Condition Icon

8J - 42 INSTRUMENT CLUSTERDR

UPSHIFT INDICATOR (Continued)

Page 553 of 2627

WAIT-TO-START INDICATOR

DESCRIPTION

A wait-to-start indicator is only found in the

instrument clusters for vehicles equipped with an

optional diesel engine (Fig. 35). The wait-to-start

indicator is located near the lower edge of the instru-

ment cluster, between the tachometer and the speed-

ometer. The wait-to-start indicator consists of stencil-

like cutout of the International Control and Display

Symbol icon for ªDiesel Preheatº in the opaque layer

of the instrument cluster overlay. The dark outer

layer of the overlay prevents the indicator from being

clearly visible when it is not illuminated. An amber

Light Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the icon to appear

in amber through the translucent outer layer of the

overlay when the indicator is illuminated from

behind by the LED, which is soldered onto the

instrument cluster electronic circuit board. The wait-

to-start indicator is serviced as a unit with the

instrument cluster.

OPERATION

The wait-to-start indicator gives an indication to

the vehicle operator when the air temperature within

the diesel engine intake manifold is too cool for effi-

cient and reliable engine starting, and that the

intake air heater grids are energized in their pre-

heat operating mode. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Engine Control

Module (ECM) over the Programmable Communica-

tions Interface (PCI) data bus. The wait-to-start indi-

cator Light Emitting Diode (LED) is completely

controlled by the instrument cluster logic circuit, and

that logic will only allow this indicator to operate

when the instrument cluster receives a battery cur-

rent input on the fused ignition switch output (run-

start) circuit. Therefore, the LED will always be off

when the ignition switch is in any position except On

or Start. The LED only illuminates when it is pro-

vided a path to ground by the instrument cluster

transistor. The instrument cluster will turn on the

wait-to-start indicator for the following reasons:

²Wait-To-Start Lamp-On Message- Each time

the cluster receives a wait-to-start lamp-on message

from the ECM indicating that the air temperature

within the intake manifold is too cool for efficient

and reliable engine starting, the wait-to-start indica-

tor will be illuminated. The indicator remains illumi-nated until the cluster receives a wait-to-start lamp-

off message, until the ECM detects that the engine is

running or until the ignition switch is turned to the

Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the wait-to-start indicator

will be turned on, then off again during the bulb

check portion of the test to confirm the functionality

of the LED and the cluster control circuitry.

The ECM continually monitors the engine intake

air temperature sensor to determine when the intake

air heater grids should be energized in their pre-heat

operating mode. The ECM then sends the proper

wait-to-start lamp-on and lamp-off messages to the

instrument cluster. For further diagnosis of the wait-

to-start indicator or the instrument cluster circuitry

that controls the indicator, (Refer to 8 - ELECTRI-

CAL/INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the engine intake

air temperature sensor, the intake air heater grid

control circuits, the ECM, the PCI data bus, or the

electronic message inputs to the instrument cluster

that control the wait-to-start indicator, a DRBIIIt

scan tool is required. Refer to the appropriate diag-

nostic information.

WASHER FLUID INDICATOR

DESCRIPTION

A washer fluid indicator is standard equipment on

all instrument clusters. The washer fluid indicator

consists of the words ªLOW WASHº, which appear in

the lower portion of the odometer/trip odometer Vac-

uum-Fluorescent Display (VFD) unit (Fig. 36). The

VFD is soldered onto the cluster electronic circuit

board and is visible through a window with a smoked

clear lens located on the lower edge of the tachome-

ter gauge dial face of the cluster overlay. The dark

lens over the VFD prevents the indicator from being

clearly visible when it is not illuminated. The ªLOW

WASHº text appears in an amber color and at the

same lighting level as the odometer/trip odometer

information when it is illuminated by the instrument

cluster electronic circuit board. The washer fluid

indicator is serviced as a unit with the VFD in the

instrument cluster.

OPERATION

The washer fluid indicator gives an indication to

the vehicle operator that the fluid level in the washer

Fig. 35 Wait-To-Start Indicator

Fig. 36 Washer Fluid Indicator

8J - 44 INSTRUMENT CLUSTERDR

Page 554 of 2627

reservoir is low. This indicator is controlled by the

instrument cluster circuit board based upon cluster

programming and electronic messages received by

the cluster from the Front Control Module (FCM)

over the Programmable Communications Interface

(PCI) data bus. The washer fluid indicator is com-

pletely controlled by the instrument cluster logic cir-

cuit, and that logic will only allow this indicator to

operate when the instrument cluster receives a bat-

tery current input on the fused ignition switch out-

put (run-start) circuit. Therefore, the indicator will

always be off when the ignition switch is in any posi-

tion except On or Start. The indicator only illumi-

nates when it is switched to ground by the

instrument cluster circuitry. The instrument cluster

will turn on the washer fluid indicator for the follow-

ing reasons:

²Washer Fluid Indicator Lamp-On Message-

Each time the cluster receives a washer fluid indica-

tor lamp-on message from the FCM indicating that a

low washer condition has been detected for sixty con-

secutive seconds, the washer fluid indicator is illumi-

nated and a single chime tone is sounded. The

indicator remains illuminated until the cluster

receives a washer fluid indicator lamp-off message

for sixty consecutive seconds from the FCM or until

the ignition switch is turned to the Off position,

whichever occurs first. The chime tone feature will

only repeat during the same ignition cycle if the

washer fluid indicator is cycled off and then on again

by the appropriate washer fluid lamp messages from

the FCM.

²Actuator Test- Each time the cluster is put

through the actuator test, the washer fluid indicator

will be turned on, then off again during the VFD por-

tion of the test to confirm the functionality of the

VFD and the cluster control circuitry.

The FCM continually monitors the washer fluid

level switch in the washer reservoir to determine the

level of the washer fluid. The FCM then sends the

proper washer fluid indicator lamp-on and lamp-off

messages to the instrument cluster. For further diag-

nosis of the washer fluid indicator or the instrument

cluster circuitry that controls the indicator, (Refer to

8 - ELECTRICAL/INSTRUMENT CLUSTER - DIAG-

NOSIS AND TESTING). For proper diagnosis of the

washer fluid level switch, the FCM, the PCI data

bus, or the electronic message inputs to the instru-

ment cluster that control the washer fluid indicator,

a DRBIIItscan tool is required. Refer to the appro-

priate diagnostic information.WATER-IN-FUEL INDICATOR

DESCRIPTION

A water-in-fuel indicator is only found in the

instrument clusters for vehicles equipped with an

optional diesel engine (Fig. 37). The water-in-fuel

indicator is located near the lower edge of the instru-

ment cluster, between the tachometer and the speed-

ometer. The water-in-fuel indicator consists of stencil-

like cutout of the International Control and Display

Symbol icon for ªWater In Fuelº in the opaque layer

of the instrument cluster overlay. The dark outer

layer of the overlay prevents the indicator from being

clearly visible when it is not illuminated. A red Light

Emitting Diode (LED) behind the cutout in the

opaque layer of the overlay causes the icon to appear

in red through the translucent outer layer of the

overlay when the indicator is illuminated from

behind by the LED, which is soldered onto the

instrument cluster electronic circuit board. The

water-in-fuel indicator is serviced as a unit with the

instrument cluster.

OPERATION

The water-in-fuel indicator gives an indication to

the vehicle operator when there is excessive water in

the fuel system. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon the cluster programming and electronic

messages received by the cluster from the Engine

Control Module (ECM) over the Programmable Com-

munications Interface (PCI) data bus. The water-in-

fuel indicator Light Emitting Diode (LED) is

completely controlled by the instrument cluster logic

circuit, and that logic will only allow this indicator to

operate when the instrument cluster receives a bat-

tery current input on the fused ignition switch out-

put (run-start) circuit. Therefore, the LED will

always be off when the ignition switch is in any posi-

tion except On or Start. The LED only illuminates

when it is provided a path to ground by the instru-

ment cluster transistor. The instrument cluster will

turn on the water-in-fuel indicator for the following

reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the water-in-fuel indicator

is illuminated for about two seconds as a bulb test.

²Water-In-Fuel Lamp-On Message- Each time

the cluster receives a water-in-fuel lamp-on message

from the ECM indicating that there is excessive

Fig. 37 Water-In-Fuel Indicator

DRINSTRUMENT CLUSTER 8J - 45

WASHER FLUID INDICATOR (Continued)

Page 564 of 2627

BRAKE LAMP

REMOVAL

REMOVAL - WITH CARGO BOX

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the tail lamp unit (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP UNIT - REMOVAL).

(3) Remove the lamp back plate from the tail lamp

unit.

(4) Release the brake lamp bulb locking tabs and

remove the bulb from the back plate.

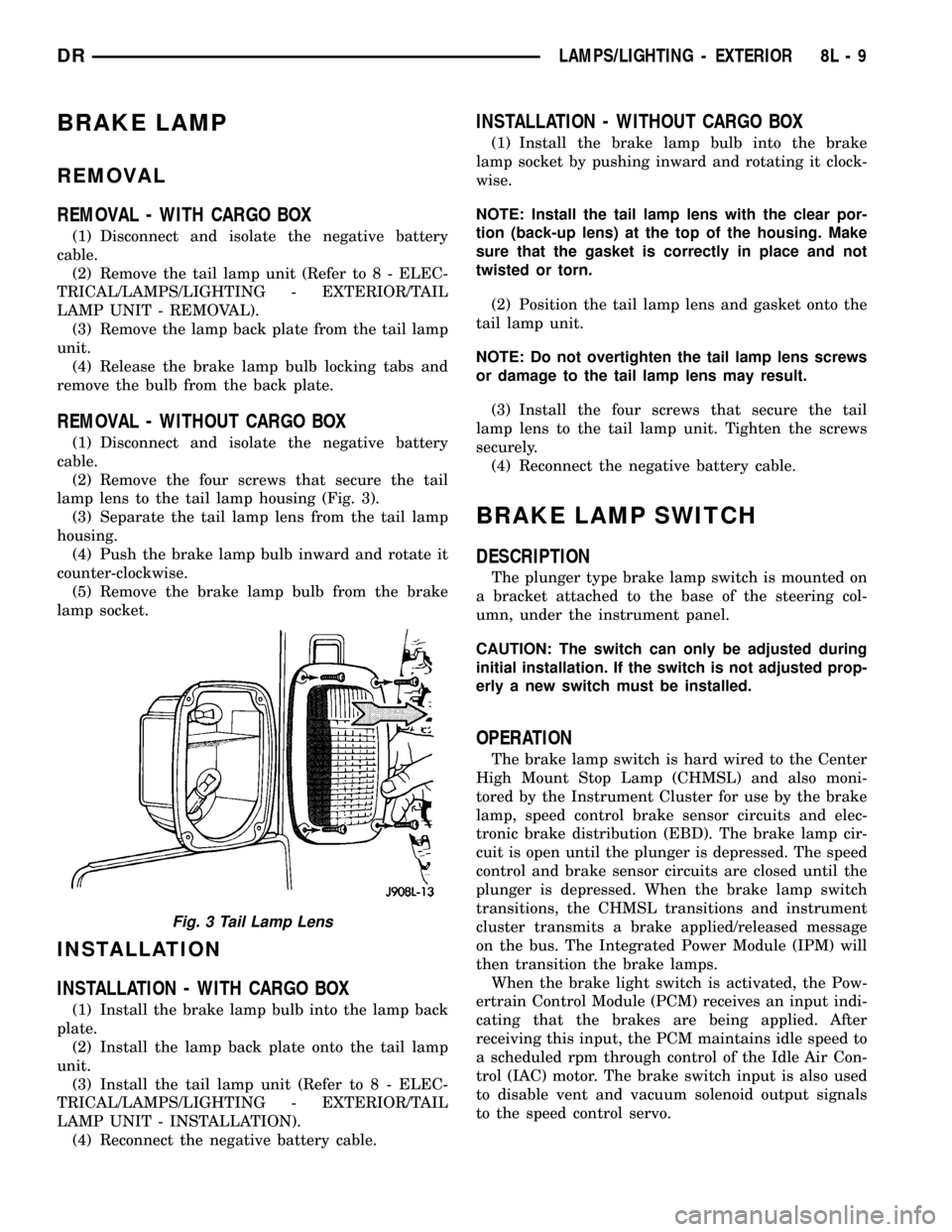

REMOVAL - WITHOUT CARGO BOX

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the four screws that secure the tail

lamp lens to the tail lamp housing (Fig. 3).

(3) Separate the tail lamp lens from the tail lamp

housing.

(4) Push the brake lamp bulb inward and rotate it

counter-clockwise.

(5) Remove the brake lamp bulb from the brake

lamp socket.

INSTALLATION

INSTALLATION - WITH CARGO BOX

(1) Install the brake lamp bulb into the lamp back

plate.

(2) Install the lamp back plate onto the tail lamp

unit.

(3) Install the tail lamp unit (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/TAIL

LAMP UNIT - INSTALLATION).

(4) Reconnect the negative battery cable.

INSTALLATION - WITHOUT CARGO BOX

(1) Install the brake lamp bulb into the brake

lamp socket by pushing inward and rotating it clock-

wise.

NOTE: Install the tail lamp lens with the clear por-

tion (back-up lens) at the top of the housing. Make

sure that the gasket is correctly in place and not

twisted or torn.

(2) Position the tail lamp lens and gasket onto the

tail lamp unit.

NOTE: Do not overtighten the tail lamp lens screws

or damage to the tail lamp lens may result.

(3) Install the four screws that secure the tail

lamp lens to the tail lamp unit. Tighten the screws

securely.

(4) Reconnect the negative battery cable.

BRAKE LAMP SWITCH

DESCRIPTION

The plunger type brake lamp switch is mounted on

a bracket attached to the base of the steering col-

umn, under the instrument panel.

CAUTION: The switch can only be adjusted during

initial installation. If the switch is not adjusted prop-

erly a new switch must be installed.

OPERATION

The brake lamp switch is hard wired to the Center

High Mount Stop Lamp (CHMSL) and also moni-

tored by the Instrument Cluster for use by the brake

lamp, speed control brake sensor circuits and elec-

tronic brake distribution (EBD). The brake lamp cir-

cuit is open until the plunger is depressed. The speed

control and brake sensor circuits are closed until the

plunger is depressed. When the brake lamp switch

transitions, the CHMSL transitions and instrument

cluster transmits a brake applied/released message

on the bus. The Integrated Power Module (IPM) will

then transition the brake lamps.

When the brake light switch is activated, the Pow-

ertrain Control Module (PCM) receives an input indi-

cating that the brakes are being applied. After

receiving this input, the PCM maintains idle speed to

a scheduled rpm through control of the Idle Air Con-

trol (IAC) motor. The brake switch input is also used

to disable vent and vacuum solenoid output signals

to the speed control servo.

Fig. 3 Tail Lamp Lens

DRLAMPS/LIGHTING - EXTERIOR 8L - 9

Page 565 of 2627

Vehicles equipped with the speed control option use

a dual function brake lamp switch. The PCM moni-

tors the state of the dual function brake lamp switch.

The brake switch is equipped with three sets of

contacts, one normally open and the other two nor-

mally closed (brakes disengaged). The PCM sends a

12 volt signal to one of the normally closed contacts

in the brake switch, which is returned to the PCM as

a brake switch state signal. With the contacts closed,

the 12 volt signal is pulled to ground causing the sig-

nal to go low. The low voltage signal, monitored by

the PCM, indicates that the brakes are not applied.

When the brakes are applied, the contacts open,

causing the PCM's output brake signal to go high,

disengaging the speed control, cutting off PCM power

to the speed control solenoids.

The second set of normally closed contacts supplies

12 volts from the PCM any time speed control is

turned on. Through the brake switch, voltage is

routed to the speed control servo solenoids. The

speed control solenoids (vacuum, vent and dump) are

provided this voltage any time the speed control is

ON and the brakes are disengaged.

When the driver applies the brakes, the contacts

open and voltage is interrupted to the solenoids. The

normally open contacts are fed battery voltage. When

the brakes are applied, battery voltage is supplied to

the brake lamps.

The brake lamp switch can only be adjusted once.

That is at the initial installation of the switch. If the

switch is not adjusted properly or has been removed,

a new switch must be installed and adjusted.

DIAGNOSIS AND TESTING - BRAKE LAMP

SWITCH

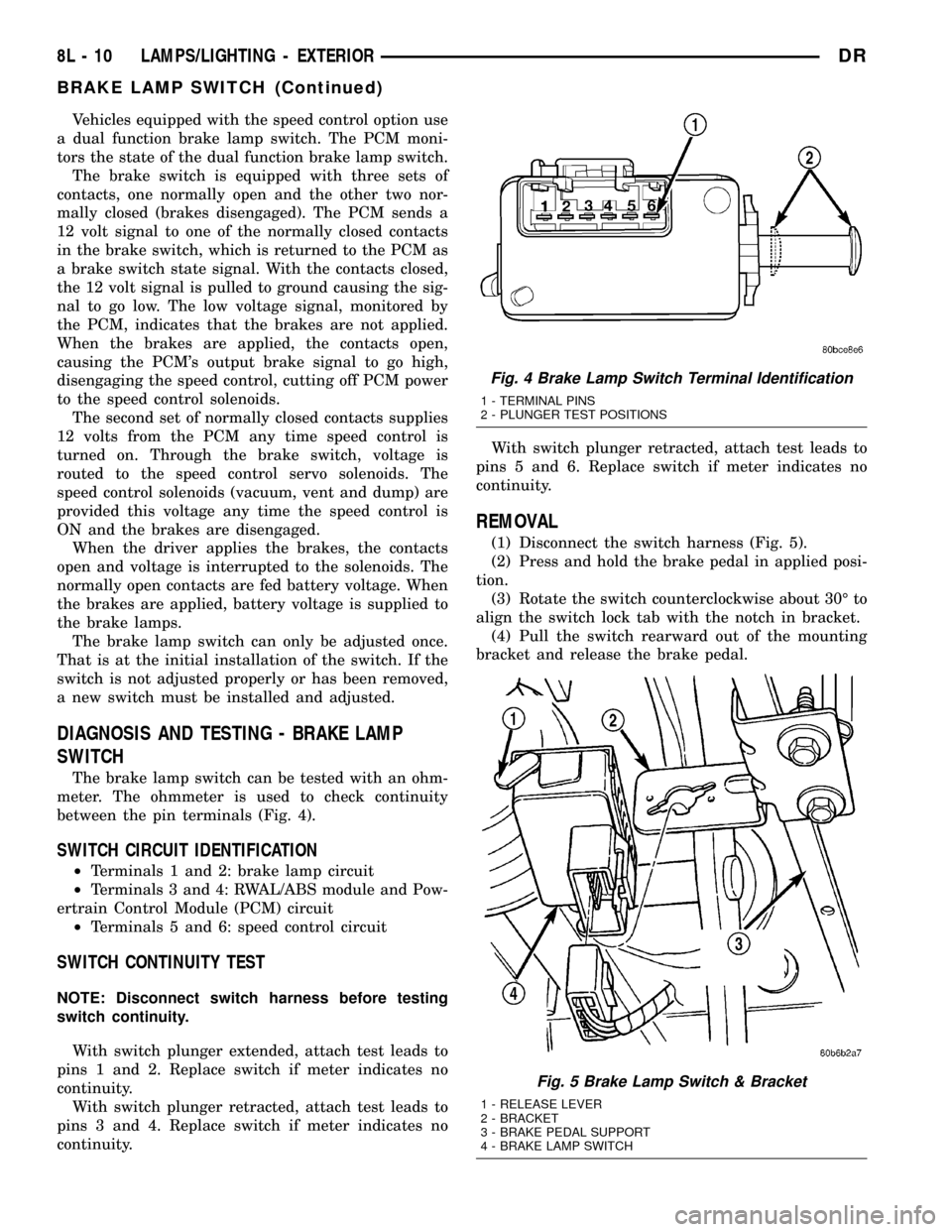

The brake lamp switch can be tested with an ohm-

meter. The ohmmeter is used to check continuity

between the pin terminals (Fig. 4).

SWITCH CIRCUIT IDENTIFICATION

²Terminals 1 and 2: brake lamp circuit

²Terminals 3 and 4: RWAL/ABS module and Pow-

ertrain Control Module (PCM) circuit

²Terminals 5 and 6: speed control circuit

SWITCH CONTINUITY TEST

NOTE: Disconnect switch harness before testing

switch continuity.

With switch plunger extended, attach test leads to

pins 1 and 2. Replace switch if meter indicates no

continuity.

With switch plunger retracted, attach test leads to

pins 3 and 4. Replace switch if meter indicates no

continuity.With switch plunger retracted, attach test leads to

pins 5 and 6. Replace switch if meter indicates no

continuity.

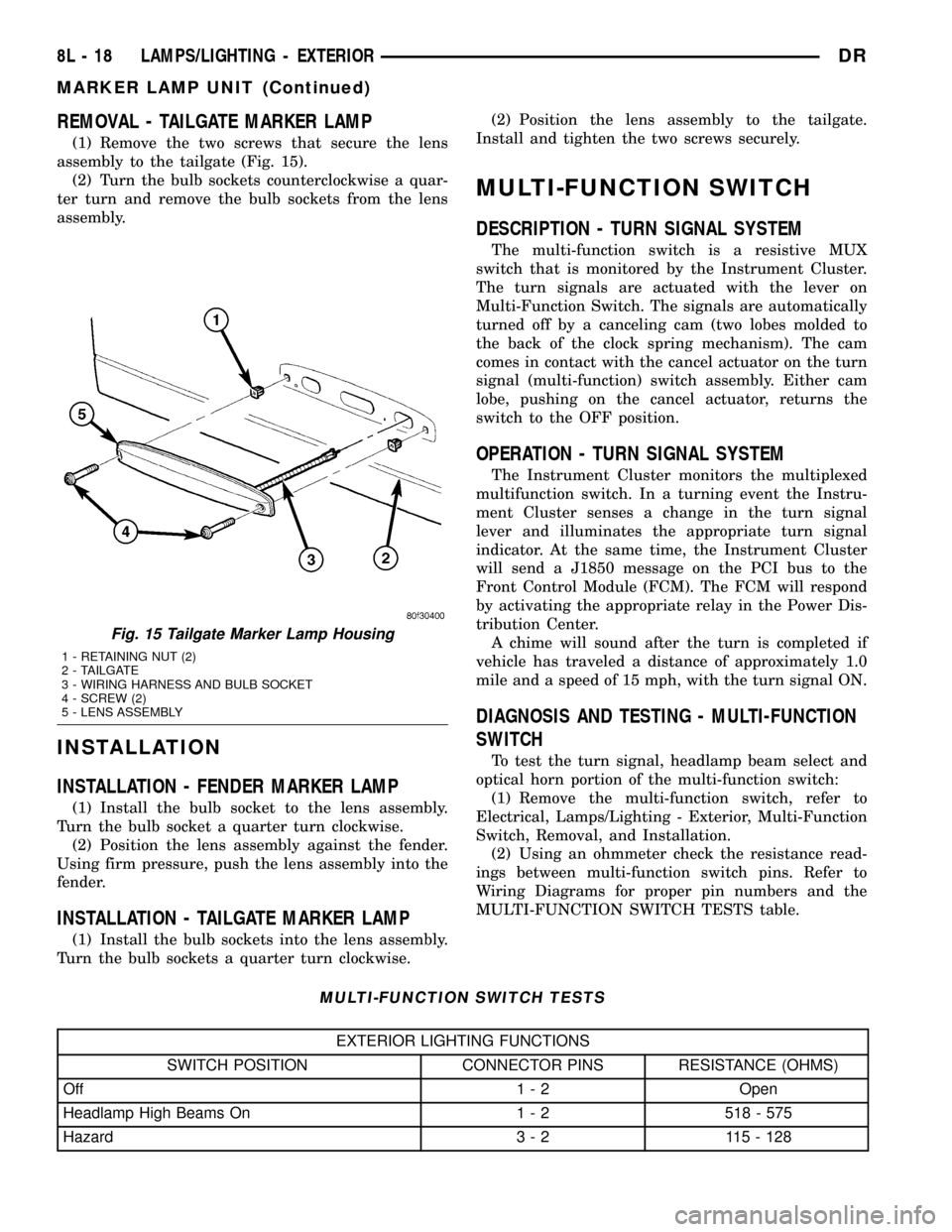

REMOVAL

(1) Disconnect the switch harness (Fig. 5).

(2) Press and hold the brake pedal in applied posi-

tion.

(3) Rotate the switch counterclockwise about 30É to

align the switch lock tab with the notch in bracket.

(4) Pull the switch rearward out of the mounting

bracket and release the brake pedal.

Fig. 4 Brake Lamp Switch Terminal Identification

1 - TERMINAL PINS

2 - PLUNGER TEST POSITIONS

Fig. 5 Brake Lamp Switch & Bracket

1 - RELEASE LEVER

2 - BRACKET

3 - BRAKE PEDAL SUPPORT

4 - BRAKE LAMP SWITCH

8L - 10 LAMPS/LIGHTING - EXTERIORDR

BRAKE LAMP SWITCH (Continued)

Page 573 of 2627

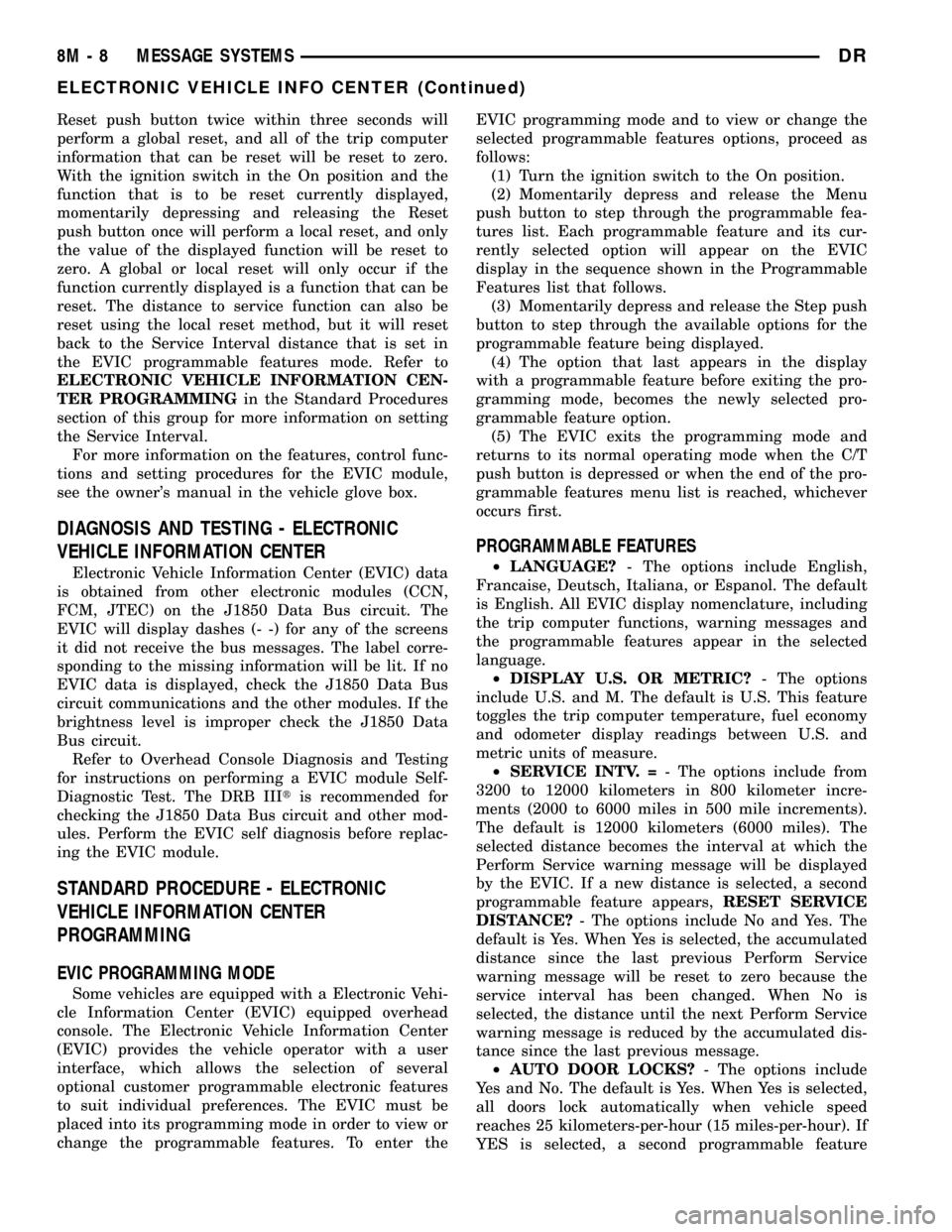

REMOVAL - TAILGATE MARKER LAMP

(1) Remove the two screws that secure the lens

assembly to the tailgate (Fig. 15).

(2) Turn the bulb sockets counterclockwise a quar-

ter turn and remove the bulb sockets from the lens

assembly.

INSTALLATION

INSTALLATION - FENDER MARKER LAMP

(1) Install the bulb socket to the lens assembly.

Turn the bulb socket a quarter turn clockwise.

(2) Position the lens assembly against the fender.

Using firm pressure, push the lens assembly into the

fender.

INSTALLATION - TAILGATE MARKER LAMP

(1) Install the bulb sockets into the lens assembly.

Turn the bulb sockets a quarter turn clockwise.(2) Position the lens assembly to the tailgate.

Install and tighten the two screws securely.

MULTI-FUNCTION SWITCH

DESCRIPTION - TURN SIGNAL SYSTEM

The multi-function switch is a resistive MUX

switch that is monitored by the Instrument Cluster.

The turn signals are actuated with the lever on

Multi-Function Switch. The signals are automatically

turned off by a canceling cam (two lobes molded to

the back of the clock spring mechanism). The cam

comes in contact with the cancel actuator on the turn

signal (multi-function) switch assembly. Either cam

lobe, pushing on the cancel actuator, returns the

switch to the OFF position.

OPERATION - TURN SIGNAL SYSTEM

The Instrument Cluster monitors the multiplexed

multifunction switch. In a turning event the Instru-

ment Cluster senses a change in the turn signal

lever and illuminates the appropriate turn signal

indicator. At the same time, the Instrument Cluster

will send a J1850 message on the PCI bus to the

Front Control Module (FCM). The FCM will respond

by activating the appropriate relay in the Power Dis-

tribution Center.

A chime will sound after the turn is completed if

vehicle has traveled a distance of approximately 1.0

mile and a speed of 15 mph, with the turn signal ON.

DIAGNOSIS AND TESTING - MULTI-FUNCTION

SWITCH

To test the turn signal, headlamp beam select and

optical horn portion of the multi-function switch:

(1) Remove the multi-function switch, refer to

Electrical, Lamps/Lighting - Exterior, Multi-Function

Switch, Removal, and Installation.

(2) Using an ohmmeter check the resistance read-

ings between multi-function switch pins. Refer to

Wiring Diagrams for proper pin numbers and the

MULTI-FUNCTION SWITCH TESTS table.

MULTI-FUNCTION SWITCH TESTS

EXTERIOR LIGHTING FUNCTIONS

SWITCH POSITION CONNECTOR PINS RESISTANCE (OHMS)

Off 1 - 2 Open

Headlamp High Beams On 1 - 2 518 - 575

Hazard 3 - 2 115 - 128

Fig. 15 Tailgate Marker Lamp Housing

1 - RETAINING NUT (2)

2 - TAILGATE

3 - WIRING HARNESS AND BULB SOCKET

4 - SCREW (2)

5 - LENS ASSEMBLY

8L - 18 LAMPS/LIGHTING - EXTERIORDR

MARKER LAMP UNIT (Continued)

Page 593 of 2627

Reset push button twice within three seconds will

perform a global reset, and all of the trip computer

information that can be reset will be reset to zero.

With the ignition switch in the On position and the

function that is to be reset currently displayed,

momentarily depressing and releasing the Reset

push button once will perform a local reset, and only

the value of the displayed function will be reset to

zero. A global or local reset will only occur if the

function currently displayed is a function that can be

reset. The distance to service function can also be

reset using the local reset method, but it will reset

back to the Service Interval distance that is set in

the EVIC programmable features mode. Refer to

ELECTRONIC VEHICLE INFORMATION CEN-

TER PROGRAMMINGin the Standard Procedures

section of this group for more information on setting

the Service Interval.

For more information on the features, control func-

tions and setting procedures for the EVIC module,

see the owner's manual in the vehicle glove box.

DIAGNOSIS AND TESTING - ELECTRONIC

VEHICLE INFORMATION CENTER

Electronic Vehicle Information Center (EVIC) data

is obtained from other electronic modules (CCN,

FCM, JTEC) on the J1850 Data Bus circuit. The

EVIC will display dashes (- -) for any of the screens

it did not receive the bus messages. The label corre-

sponding to the missing information will be lit. If no

EVIC data is displayed, check the J1850 Data Bus

circuit communications and the other modules. If the

brightness level is improper check the J1850 Data

Bus circuit.

Refer to Overhead Console Diagnosis and Testing

for instructions on performing a EVIC module Self-

Diagnostic Test. The DRB IIItis recommended for

checking the J1850 Data Bus circuit and other mod-

ules. Perform the EVIC self diagnosis before replac-

ing the EVIC module.

STANDARD PROCEDURE - ELECTRONIC

VEHICLE INFORMATION CENTER

PROGRAMMING

EVIC PROGRAMMING MODE

Some vehicles are equipped with a Electronic Vehi-

cle Information Center (EVIC) equipped overhead

console. The Electronic Vehicle Information Center

(EVIC) provides the vehicle operator with a user

interface, which allows the selection of several

optional customer programmable electronic features

to suit individual preferences. The EVIC must be

placed into its programming mode in order to view or

change the programmable features. To enter theEVIC programming mode and to view or change the

selected programmable features options, proceed as

follows:

(1) Turn the ignition switch to the On position.

(2) Momentarily depress and release the Menu

push button to step through the programmable fea-

tures list. Each programmable feature and its cur-

rently selected option will appear on the EVIC

display in the sequence shown in the Programmable

Features list that follows.

(3) Momentarily depress and release the Step push

button to step through the available options for the

programmable feature being displayed.

(4) The option that last appears in the display

with a programmable feature before exiting the pro-

gramming mode, becomes the newly selected pro-

grammable feature option.

(5) The EVIC exits the programming mode and

returns to its normal operating mode when the C/T

push button is depressed or when the end of the pro-

grammable features menu list is reached, whichever

occurs first.

PROGRAMMABLE FEATURES

²LANGUAGE?- The options include English,

Francaise, Deutsch, Italiana, or Espanol. The default

is English. All EVIC display nomenclature, including

the trip computer functions, warning messages and

the programmable features appear in the selected

language.

²DISPLAY U.S. OR METRIC?- The options

include U.S. and M. The default is U.S. This feature

toggles the trip computer temperature, fuel economy

and odometer display readings between U.S. and

metric units of measure.

²SERVICE INTV. =- The options include from

3200 to 12000 kilometers in 800 kilometer incre-

ments (2000 to 6000 miles in 500 mile increments).

The default is 12000 kilometers (6000 miles). The

selected distance becomes the interval at which the

Perform Service warning message will be displayed

by the EVIC. If a new distance is selected, a second

programmable feature appears,RESET SERVICE

DISTANCE?- The options include No and Yes. The

default is Yes. When Yes is selected, the accumulated

distance since the last previous Perform Service

warning message will be reset to zero because the

service interval has been changed. When No is

selected, the distance until the next Perform Service

warning message is reduced by the accumulated dis-

tance since the last previous message.

²AUTO DOOR LOCKS?- The options include

Yes and No. The default is Yes. When Yes is selected,

all doors lock automatically when vehicle speed

reaches 25 kilometers-per-hour (15 miles-per-hour). If

YES is selected, a second programmable feature

8M - 8 MESSAGE SYSTEMSDR

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 624 of 2627

Airbag Control Module (ACM). An airbag indicator in

the ElectroMechanical Instrument Cluster (EMIC)

illuminates for about six seconds as a bulb test each

time the ignition switch is turned to the On or Start

positions. Following the bulb test, the airbag indica-

tor is turned on or off by the ACM to indicate the

status of the supplemental restraint system. If the

airbag indicator comes on at any time other than

during the bulb test, it indicates that there is a prob-

lem in the supplemental restraint system electrical

circuits. Such a problem may cause airbags not to

deploy when required, or to deploy when not

required.

Deployment of the supplemental restraints

depends upon the angle and severity of an impact.

Deployment is not based upon vehicle speed; rather,

deployment is based upon the rate of deceleration as

measured by the forces of gravity (G force) upon the

impact sensors. When an impact is severe enough,

the microprocessor in the ACM signals the inflator of

the appropriate airbag units to deploy their airbag

cushions. The outboard front seat belt tensioners are

provided with a deployment signal by the ACM in

conjunction with the driver and passenger front air-

bags. During a frontal vehicle impact, the knee block-

ers work in concert with properly fastened and

adjusted seat belts to restrain both the driver and

the front seat passenger in the proper position for an

airbag deployment. The knee blockers also absorb

and distribute the crash energy from the driver and

the front seat passenger to the structure of the

instrument panel. The seat belt tensioner removes

the slack from the outboard front seat belts to pro-

vide further assurance that the driver and front seat

passenger are properly positioned and restrained for

an airbag deployment.

Typically, the vehicle occupants recall more about

the events preceding and following a collision than

they do of an airbag deployment itself. This is

because the airbag deployment and deflation occur

very rapidly. In a typical 48 kilometer-per-hour (30

mile-per-hour) barrier impact, from the moment of

impact until the airbags are fully inflated takes

about 40 milliseconds. Within one to two seconds

from the moment of impact, the airbags are almost

entirely deflated. The times cited for these events are

approximations, which apply only to a barrier impact

at the given speed. Actual times will vary somewhat,

depending upon the vehicle speed, impact angle,

severity of the impact, and the type of collision.

When the ACM monitors a problem in any of the

supplemental restraint system circuits or compo-

nents, including the seat belt tensioners, it stores a

fault code or Diagnostic Trouble Code (DTC) in its

memory circuit and sends an electronic message to

the EMIC to turn on the airbag indicator. Propertesting of the supplemental restraint system compo-

nents, the Programmable Communications Interface

(PCI) data bus, the electronic message inputs to and

outputs from the EMIC or the ACM, as well as the

retrieval or erasure of a DTC from the ACM or EMIC

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of all of the factory-installed passive restraints.

WARNING

WARNINGS - RESTRAINT SYSTEM

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

DRRESTRAINTS 8O - 5

RESTRAINTS (Continued)

Page 638 of 2627

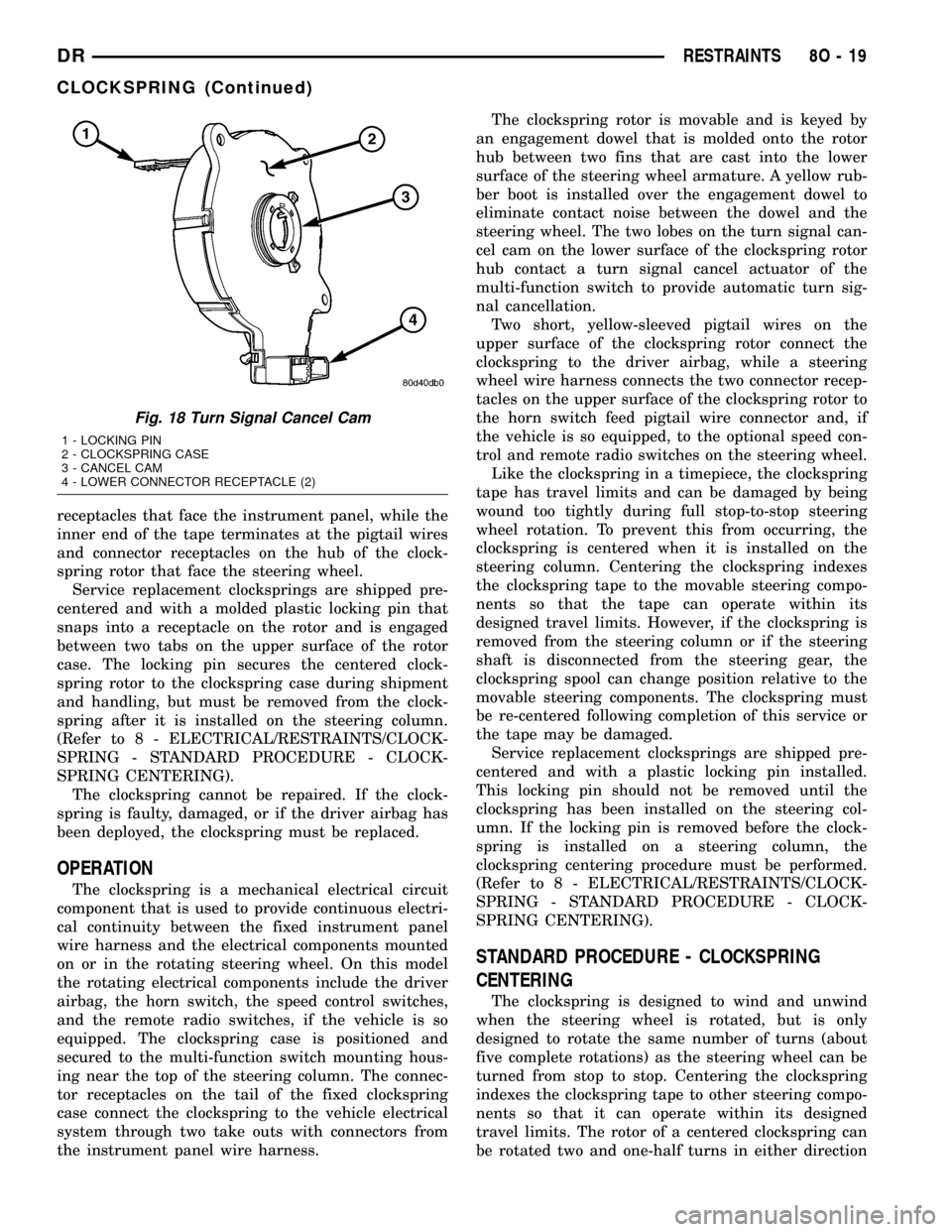

receptacles that face the instrument panel, while the

inner end of the tape terminates at the pigtail wires

and connector receptacles on the hub of the clock-

spring rotor that face the steering wheel.

Service replacement clocksprings are shipped pre-

centered and with a molded plastic locking pin that

snaps into a receptacle on the rotor and is engaged

between two tabs on the upper surface of the rotor

case. The locking pin secures the centered clock-

spring rotor to the clockspring case during shipment

and handling, but must be removed from the clock-

spring after it is installed on the steering column.

(Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCK-

SPRING - STANDARD PROCEDURE - CLOCK-

SPRING CENTERING).

The clockspring cannot be repaired. If the clock-

spring is faulty, damaged, or if the driver airbag has

been deployed, the clockspring must be replaced.

OPERATION

The clockspring is a mechanical electrical circuit

component that is used to provide continuous electri-

cal continuity between the fixed instrument panel

wire harness and the electrical components mounted

on or in the rotating steering wheel. On this model

the rotating electrical components include the driver

airbag, the horn switch, the speed control switches,

and the remote radio switches, if the vehicle is so

equipped. The clockspring case is positioned and

secured to the multi-function switch mounting hous-

ing near the top of the steering column. The connec-

tor receptacles on the tail of the fixed clockspring

case connect the clockspring to the vehicle electrical

system through two take outs with connectors from

the instrument panel wire harness.The clockspring rotor is movable and is keyed by

an engagement dowel that is molded onto the rotor

hub between two fins that are cast into the lower

surface of the steering wheel armature. A yellow rub-

ber boot is installed over the engagement dowel to

eliminate contact noise between the dowel and the

steering wheel. The two lobes on the turn signal can-

cel cam on the lower surface of the clockspring rotor

hub contact a turn signal cancel actuator of the

multi-function switch to provide automatic turn sig-

nal cancellation.

Two short, yellow-sleeved pigtail wires on the

upper surface of the clockspring rotor connect the

clockspring to the driver airbag, while a steering

wheel wire harness connects the two connector recep-

tacles on the upper surface of the clockspring rotor to

the horn switch feed pigtail wire connector and, if

the vehicle is so equipped, to the optional speed con-

trol and remote radio switches on the steering wheel.

Like the clockspring in a timepiece, the clockspring

tape has travel limits and can be damaged by being

wound too tightly during full stop-to-stop steering

wheel rotation. To prevent this from occurring, the

clockspring is centered when it is installed on the

steering column. Centering the clockspring indexes

the clockspring tape to the movable steering compo-

nents so that the tape can operate within its

designed travel limits. However, if the clockspring is

removed from the steering column or if the steering

shaft is disconnected from the steering gear, the

clockspring spool can change position relative to the

movable steering components. The clockspring must

be re-centered following completion of this service or

the tape may be damaged.

Service replacement clocksprings are shipped pre-

centered and with a plastic locking pin installed.

This locking pin should not be removed until the

clockspring has been installed on the steering col-

umn. If the locking pin is removed before the clock-

spring is installed on a steering column, the

clockspring centering procedure must be performed.

(Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCK-

SPRING - STANDARD PROCEDURE - CLOCK-

SPRING CENTERING).

STANDARD PROCEDURE - CLOCKSPRING

CENTERING

The clockspring is designed to wind and unwind

when the steering wheel is rotated, but is only

designed to rotate the same number of turns (about

five complete rotations) as the steering wheel can be

turned from stop to stop. Centering the clockspring

indexes the clockspring tape to other steering compo-

nents so that it can operate within its designed

travel limits. The rotor of a centered clockspring can

be rotated two and one-half turns in either direction

Fig. 18 Turn Signal Cancel Cam

1 - LOCKING PIN

2 - CLOCKSPRING CASE

3 - CANCEL CAM

4 - LOWER CONNECTOR RECEPTACLE (2)

DRRESTRAINTS 8O - 19

CLOCKSPRING (Continued)