Test mode DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 655 of 2627

(4) Reconnect the yellow seat belt tensioner pigtail

wire connector to the body wire harness take out and

connector for the tensioner.

(5) Engage the seat belt tensioner pigtail wire

retainer into the hole in the inner B-pillar sheet

metal.

(6) On the driver side only, reconnect the body

wire harness take out and white connector to the

seat belt tension reducer connector receptacle near

the bottom of the retractor.

(7) Position the seat belt web guide to its mount-

ing location on the inner B-pillar near the belt line.

(8) Install and tighten the screw that secures the

seat belt web guide to the inner B-pillar. Tighten the

screw to 2 N´m (20 in. lbs.).

(9) Reinstall the upper and lower trim onto the

inner B-pillar. (Refer to 23 - BODY/INTERIOR/B-

PILLAR UPPER TRIM - INSTALLATION) and

(Refer to 23 - BODY/INTERIOR/B-PILLAR LOWER

TRIM - INSTALLATION).

(10) Position the seat belt turning loop onto the

height adjuster on the upper inner B-pillar.

(11) Install and tighten the screw that secures the

seat belt turning loop to the height adjuster. Tighten

the screw to 40 N´m (29 ft. lbs.).

(12) Engage the lower snap features of the new

trim cover over the front outboard seat belt turning

loop and, using hand pressure, press firmly and

evenly on the top of the trim cover until it snaps into

place.

(13) Position the lower seat belt anchor to the

lower inner B-pillar.

(14) Install and tighten the screw that secures the

lower seat belt anchor to the B-pillar. Tighten the

screw to 40 N´m (29 ft. lbs.).

(15) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

(16) Move the front seat back to its rearward posi-

tion.INSTALLATION - QUAD CAB

The following procedure is for replacement of a

faulty or damaged front outboard seat belt and

retractor unit, which includes a seat belt tensioner

for this model. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/SEAT BELT TENSIONER - DESCRIP-

TION). The only component of this seat belt and

retractor unit that is available for individual service

replacement is the plastic web stop button that pre-

vents the latch plate from falling to the floor while in

the stored position. Refer to the instructions supplied

with the service kit for the proper web stop button

replacement procedures.

The seat belt retractor on the passenger's side of

all models includes a switchable automatic locking

mechanism. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/AUTOMATIC LOCKING RETRACTOR -

DESCRIPTION).

If the seat belt or retractor is faulty or damaged,

but the seat belt tensioner is not deployed, review

the recommended procedures for handling non-de-

ployed supplemental restraints. (Refer to 8 - ELEC-

TRICAL/RESTRAINTS - STANDARD PROCEDURE

- HANDLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the seat belt tensioner has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the front outboard seat belt and

retractor from the vehicle. (Refer to 8 - ELECTRI-

CAL/RESTRAINTS - STANDARD PROCEDURE -

SERVICE AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

8O - 36 RESTRAINTSDR

FRONT OUTBOARD SEAT BELT & RETRACTOR (Continued)

Page 656 of 2627

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

(1) Position the front outboard seat belt and

retractor to the retractor mounting hole in the lower

inner B-pillar (Fig. 32).

(2) Engage the hooks on the upper retractor

bracket into the slots in the lower inner B-pillar

above the retractor mounting hole.

(3) Install and tighten the screw that secures the

lower retractor bracket to the lower inner B-pillar

below the retractor mounting hole. Tighten the screw

to 40 N´m (29 ft. lbs.).

(4) Reconnect the yellow seat belt tensioner pigtail

wire connector to the body wire harness take out and

connector for the tensioner.

(5) Engage the seat belt tensioner pigtail wire

retainer into the hole in the inner B-pillar sheet

metal.

(6) Position the seat belt web guide to its mount-

ing location on the inner B-pillar near the belt line.

(7) Install and tighten the screw that secures the

seat belt web guide to the inner B-pillar. Tighten the

screw to 2 N´m (20 in. lbs.).

(8) Reinstall the upper and lower trim onto the

inner B-pillar. (Refer to 23 - BODY/INTERIOR/B-

PILLAR UPPER TRIM - INSTALLATION) and

(Refer to 23 - BODY/INTERIOR/B-PILLAR LOWER

TRIM - INSTALLATION).

(9) Position the seat belt turning loop onto the

height adjuster on the upper inner B-pillar.

(10) Install and tighten the screw that secures the

seat belt turning loop to the height adjuster. Tighten

the screw to 40 N´m (29 ft. lbs.).

(11) Engage the lower snap features of the new

trim cover over the front outboard seat belt turningloop and, using hand pressure, press firmly and

evenly on the top of the trim cover until it snaps into

place.

(12) Position the lower seat belt anchor to the floor

panel near the base of the inner B-pillar.

(13) Install and tighten the screw that secures the

lower seat belt anchor to the floor panel near the

base of the inner B-pillar. Tighten the screw to 40

N´m (29 ft. lbs.).

(14) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

(15) Move the front seat back to its rearward posi-

tion.

FRONT OUTBOARD SEAT

BELT BUCKLE

REMOVAL

A traveling front outboard seat belt buckle is

located on the inboard side of each front outboard

seat section (40 percent) used on all models. The seat

belt buckle on the driver's side front seat for all mod-

els also includes a seat belt switch. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT SWITCH -

DESCRIPTION).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

DRRESTRAINTS 8O - 37

FRONT OUTBOARD SEAT BELT & RETRACTOR (Continued)

Page 661 of 2627

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, THE PASSENGER AIRBAG DOOR MUST

NEVER BE PAINTED. REPLACEMENT PASSENGER

AIRBAG UNITS ARE SERVICED WITH DOORS IN

THE ORIGINAL COLORS. PAINT MAY CHANGE THE

WAY IN WHICH THE MATERIAL OF THE AIRBAG

DOOR RESPONDS TO AN AIRBAG DEPLOYMENT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN OCCUPANT INJURIES UPON AIRBAG

DEPLOYMENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, USE EXTREME CARE TO PREVENT ANY

FOREIGN MATERIAL FROM ENTERING THE PAS-

SENGER AIRBAG, OR BECOMING ENTRAPPED

BETWEEN THE PASSENGER AIRBAG CUSHION

AND THE PASSENGER AIRBAG DOOR. FAILURE TO

OBSERVE THIS WARNING COULD RESULT IN

OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.

(1) Carefully position the passenger airbag and

airbag door to the instrument panel as a unit.

(2) Reconnect the passenger airbag pigtail wire

connector to the instrument panel wire harness con-

nector for the airbag. This connector is secured to the

inboard side of the airbag housing.Be certain that

the latch on the connector and the red Connec-

tor Position Assurance (CPA) lock are each

fully engaged.

(3) Position the passenger airbag housing and door

unit into the instrument panel.

(4) Using hand pressure, press firmly and evenly

over each of the seven snap features on the upper

and outboard edges of the passenger airbag door

until they snap into their receptacles in the instru-

ment panel base trim.

(5) Reach through and above the glove box opening

to install and tighten the two screws that secure the

passenger airbag front brackets to the instrument

panel structural support (Fig. 37). Tighten the screws

to 6 N´m (55 in. lbs.).

(6) Reach through and above the glove box opening

to install and tighten the two screws that secure the

passenger airbag rear brackets to the upper glove

box opening reinforcement. Tighten the screws to 6

N´m (55 in. lbs.).

(7) Install and tighten the six screws that secure

the inboard and lower flanges of the passenger air-

bag door to the instrument panel (Fig. 36). Tighten

the screws to 2 N´m (20 in. lbs.).

(8) Install and tighten the screw that secures the

mounting tab of the panel outlet housing to the

upper glove box opening reinforcement. Tighten the

screw to 2 N´m (20 in. lbs.).(9) Reinstall the lower surround onto the instru-

ment panel. (Refer to 23 - BODY/INSTRUMENT

PANEL/LOWER SURROUND - INSTALLATION).

(10) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

PASSENGER AIRBAG ON/OFF

SWITCH

DESCRIPTION

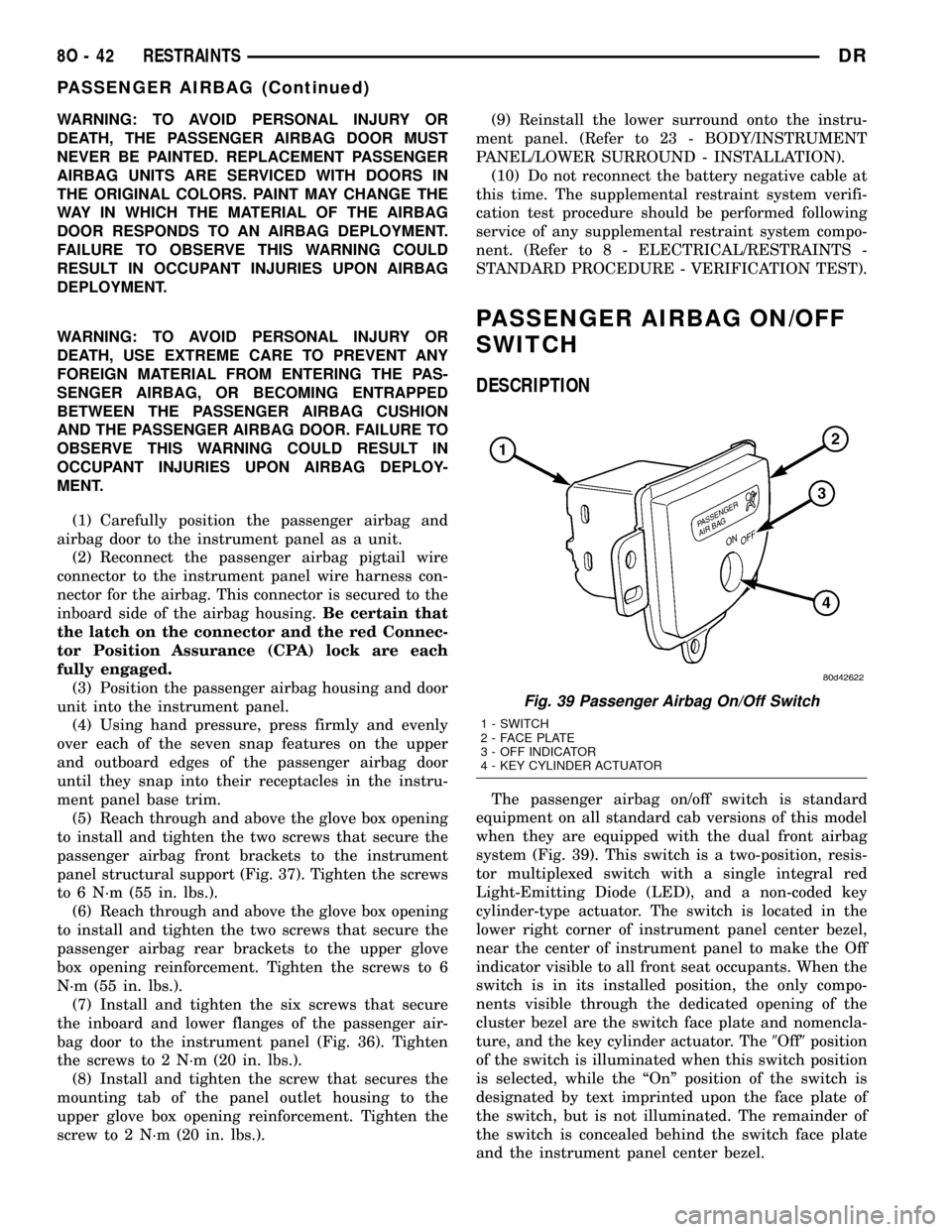

The passenger airbag on/off switch is standard

equipment on all standard cab versions of this model

when they are equipped with the dual front airbag

system (Fig. 39). This switch is a two-position, resis-

tor multiplexed switch with a single integral red

Light-Emitting Diode (LED), and a non-coded key

cylinder-type actuator. The switch is located in the

lower right corner of instrument panel center bezel,

near the center of instrument panel to make the Off

indicator visible to all front seat occupants. When the

switch is in its installed position, the only compo-

nents visible through the dedicated opening of the

cluster bezel are the switch face plate and nomencla-

ture, and the key cylinder actuator. The9Off9position

of the switch is illuminated when this switch position

is selected, while the ªOnº position of the switch is

designated by text imprinted upon the face plate of

the switch, but is not illuminated. The remainder of

the switch is concealed behind the switch face plate

and the instrument panel center bezel.

Fig. 39 Passenger Airbag On/Off Switch

1 - SWITCH

2 - FACE PLATE

3 - OFF INDICATOR

4 - KEY CYLINDER ACTUATOR

8O - 42 RESTRAINTSDR

PASSENGER AIRBAG (Continued)

Page 663 of 2627

INSTALLATION

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

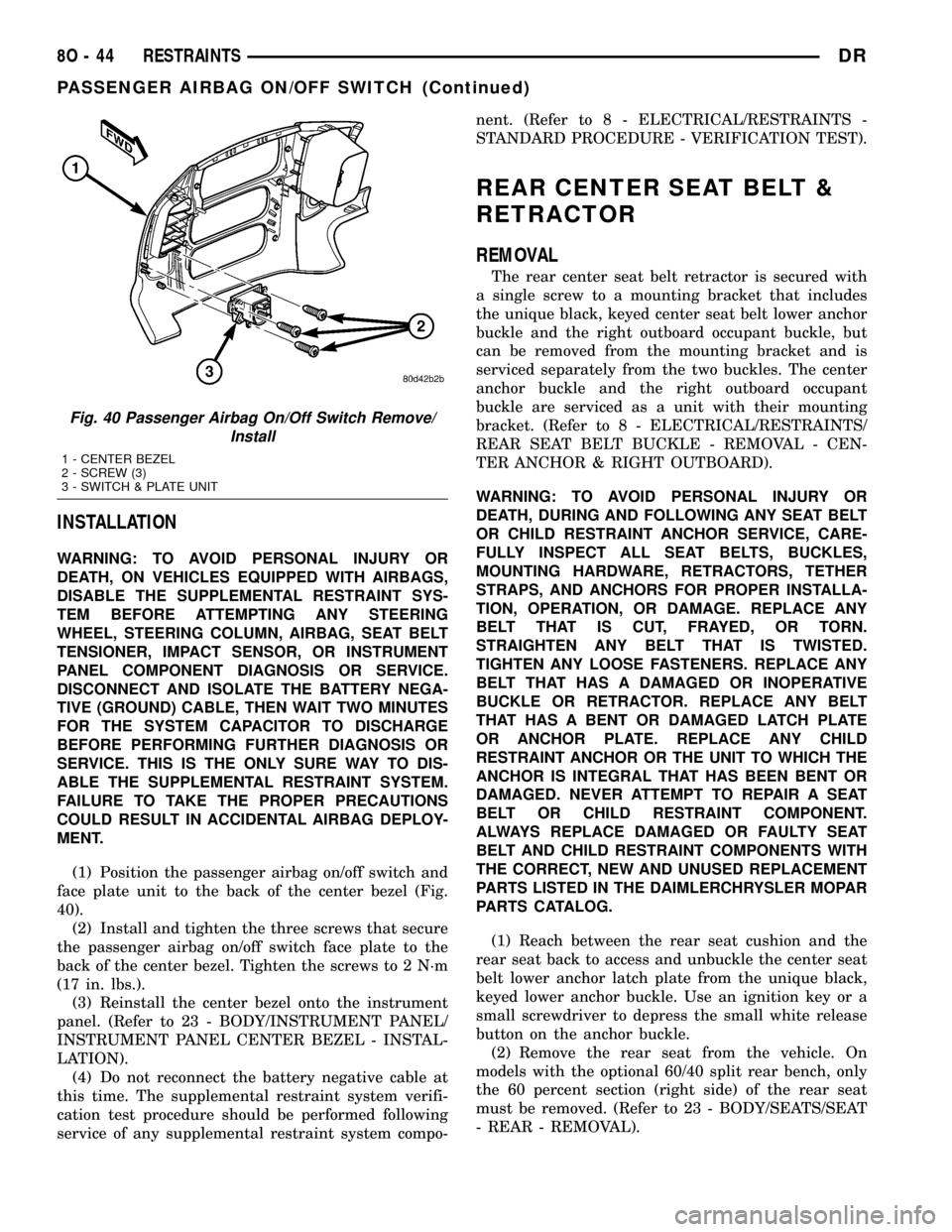

(1) Position the passenger airbag on/off switch and

face plate unit to the back of the center bezel (Fig.

40).

(2) Install and tighten the three screws that secure

the passenger airbag on/off switch face plate to the

back of the center bezel. Tighten the screws to 2 N´m

(17 in. lbs.).

(3) Reinstall the center bezel onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(4) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

REAR CENTER SEAT BELT &

RETRACTOR

REMOVAL

The rear center seat belt retractor is secured with

a single screw to a mounting bracket that includes

the unique black, keyed center seat belt lower anchor

buckle and the right outboard occupant buckle, but

can be removed from the mounting bracket and is

serviced separately from the two buckles. The center

anchor buckle and the right outboard occupant

buckle are serviced as a unit with their mounting

bracket. (Refer to 8 - ELECTRICAL/RESTRAINTS/

REAR SEAT BELT BUCKLE - REMOVAL - CEN-

TER ANCHOR & RIGHT OUTBOARD).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, DURING AND FOLLOWING ANY SEAT BELT

OR CHILD RESTRAINT ANCHOR SERVICE, CARE-

FULLY INSPECT ALL SEAT BELTS, BUCKLES,

MOUNTING HARDWARE, RETRACTORS, TETHER

STRAPS, AND ANCHORS FOR PROPER INSTALLA-

TION, OPERATION, OR DAMAGE. REPLACE ANY

BELT THAT IS CUT, FRAYED, OR TORN.

STRAIGHTEN ANY BELT THAT IS TWISTED.

TIGHTEN ANY LOOSE FASTENERS. REPLACE ANY

BELT THAT HAS A DAMAGED OR INOPERATIVE

BUCKLE OR RETRACTOR. REPLACE ANY BELT

THAT HAS A BENT OR DAMAGED LATCH PLATE

OR ANCHOR PLATE. REPLACE ANY CHILD

RESTRAINT ANCHOR OR THE UNIT TO WHICH THE

ANCHOR IS INTEGRAL THAT HAS BEEN BENT OR

DAMAGED. NEVER ATTEMPT TO REPAIR A SEAT

BELT OR CHILD RESTRAINT COMPONENT.

ALWAYS REPLACE DAMAGED OR FAULTY SEAT

BELT AND CHILD RESTRAINT COMPONENTS WITH

THE CORRECT, NEW AND UNUSED REPLACEMENT

PARTS LISTED IN THE DAIMLERCHRYSLER MOPAR

PARTS CATALOG.

(1) Reach between the rear seat cushion and the

rear seat back to access and unbuckle the center seat

belt lower anchor latch plate from the unique black,

keyed lower anchor buckle. Use an ignition key or a

small screwdriver to depress the small white release

button on the anchor buckle.

(2) Remove the rear seat from the vehicle. On

models with the optional 60/40 split rear bench, only

the 60 percent section (right side) of the rear seat

must be removed. (Refer to 23 - BODY/SEATS/SEAT

- REAR - REMOVAL).

Fig. 40 Passenger Airbag On/Off Switch Remove/

Install

1 - CENTER BEZEL

2 - SCREW (3)

3 - SWITCH & PLATE UNIT

8O - 44 RESTRAINTSDR

PASSENGER AIRBAG ON/OFF SWITCH (Continued)

Page 670 of 2627

(1) Position the center anchor/right outboard occu-

pant buckle and mounting bracket unit onto the rear

floor panel near the base of the cab back panel (Fig.

46).

(2) Install and tighten the two screws that secure

the center anchor/right outboard occupant buckle and

mounting bracket unit to the rear floor panel.

Tighten the screws to 40 N´m (29 ft. lbs.).

(3) Position the rear center seat belt retractor onto

the center anchor/right outboard occupant buckle and

mounting bracket unit (Fig. 45).

(4) Install and tighten the screw that secures the

rear center seat belt retractor to the center anchor/

right outboard occupant buckle and mounting

bracket unit. Tighten the screw to 40 N´m (29 ft.

lbs.).

(5) Reinstall the rear seat into the vehicle. On

models with the optional 60/40 split rear bench, only

the 60 percent section (right side) of the rear seat

must be reinstalled. (Refer to 23 - BODY/SEATS/

SEAT - REAR - INSTALLATION).

(6) Reach between the rear seat cushion and the

rear seat back to access and buckle the rear center

seat belt lower anchor latch plate to the unique

black, keyed lower anchor buckle.

SEAT BELT SWITCH

DESCRIPTION

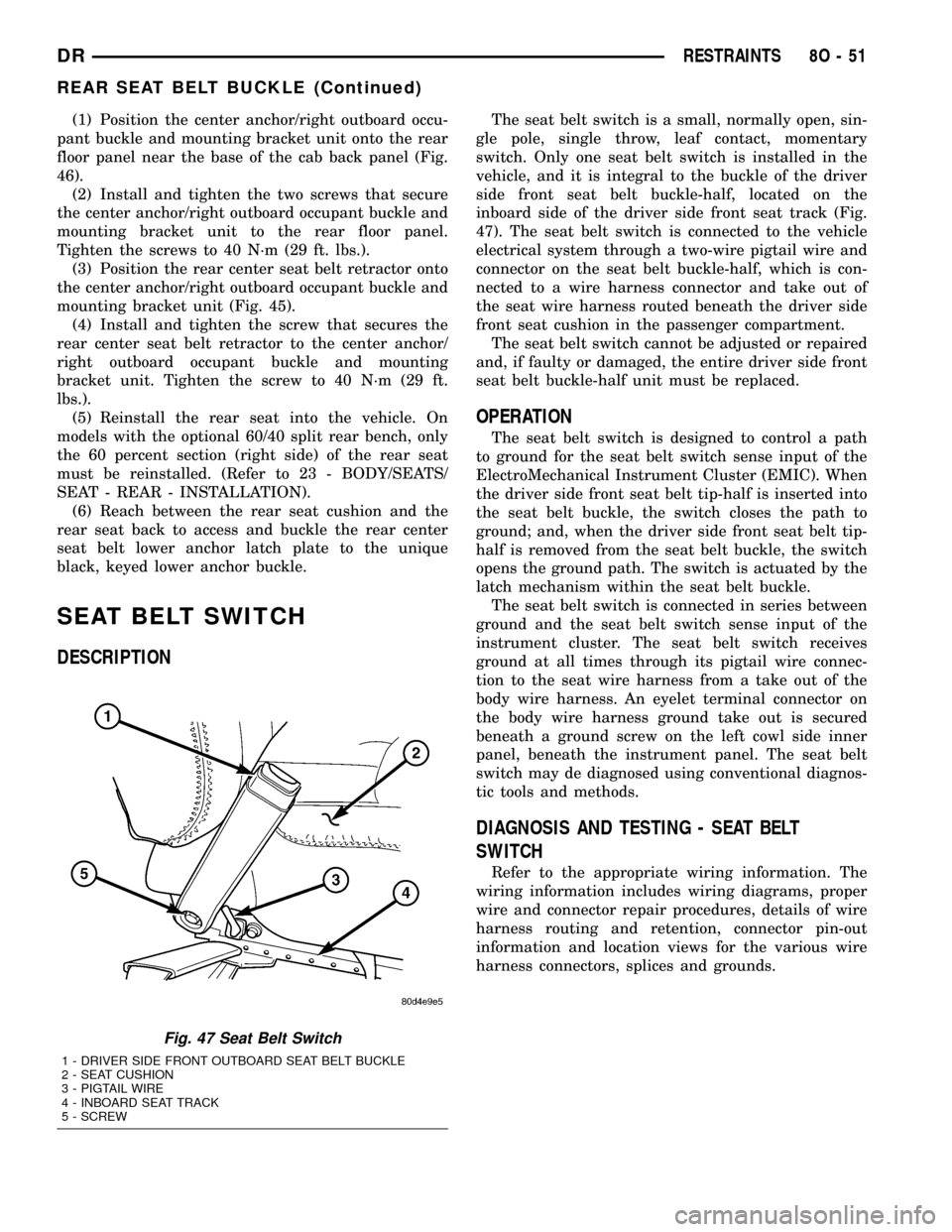

The seat belt switch is a small, normally open, sin-

gle pole, single throw, leaf contact, momentary

switch. Only one seat belt switch is installed in the

vehicle, and it is integral to the buckle of the driver

side front seat belt buckle-half, located on the

inboard side of the driver side front seat track (Fig.

47). The seat belt switch is connected to the vehicle

electrical system through a two-wire pigtail wire and

connector on the seat belt buckle-half, which is con-

nected to a wire harness connector and take out of

the seat wire harness routed beneath the driver side

front seat cushion in the passenger compartment.

The seat belt switch cannot be adjusted or repaired

and, if faulty or damaged, the entire driver side front

seat belt buckle-half unit must be replaced.

OPERATION

The seat belt switch is designed to control a path

to ground for the seat belt switch sense input of the

ElectroMechanical Instrument Cluster (EMIC). When

the driver side front seat belt tip-half is inserted into

the seat belt buckle, the switch closes the path to

ground; and, when the driver side front seat belt tip-

half is removed from the seat belt buckle, the switch

opens the ground path. The switch is actuated by the

latch mechanism within the seat belt buckle.

The seat belt switch is connected in series between

ground and the seat belt switch sense input of the

instrument cluster. The seat belt switch receives

ground at all times through its pigtail wire connec-

tion to the seat wire harness from a take out of the

body wire harness. An eyelet terminal connector on

the body wire harness ground take out is secured

beneath a ground screw on the left cowl side inner

panel, beneath the instrument panel. The seat belt

switch may de diagnosed using conventional diagnos-

tic tools and methods.

DIAGNOSIS AND TESTING - SEAT BELT

SWITCH

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

Fig. 47 Seat Belt Switch

1 - DRIVER SIDE FRONT OUTBOARD SEAT BELT BUCKLE

2 - SEAT CUSHION

3 - PIGTAIL WIRE

4 - INBOARD SEAT TRACK

5 - SCREW

DRRESTRAINTS 8O - 51

REAR SEAT BELT BUCKLE (Continued)

Page 671 of 2627

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

(1) Disconnect and isolate the battery negative

cable. Disconnect the seat belt switch pigtail wire

connector from the seat wire harness connector for

the seat belt switch on the inboard side of the driver

side front seat forward of the seat belt buckle-half

anchor. Check for continuity between the seat belt

switch sense circuit and the ground circuit cavities of

the seat belt switch pigtail wire connector. There

should be continuity with the seat belt buckled, and

no continuity with the seat belt unbuckled. If OK, go

to Step 2. If not OK, replace the faulty front seat belt

buckle-half assembly.

(2) Check for continuity between the ground cir-

cuit cavity in the seat wire harness connector for the

seat belt switch and a good ground. There should be

continuity. If OK, go to Step 3. If not OK, repair the

open ground circuit to ground (G301) as required.

(3) Remove the instrument cluster from the instru-

ment panel. Check for continuity between the seat

belt switch sense circuit cavity of the seat wire har-

ness connector for the seat belt switch and a good

ground. There should be no continuity. If OK, go to

Step 4. If not OK, repair the shorted seat belt switch

sense circuit between the seat belt switch and the

instrument cluster as required.

(4) Check for continuity between the seat belt

switch sense circuit cavities of the seat wire harness

connector for the seat belt switch and the instrument

panel wire harness connector (Connector C2) for the

instrument cluster. There should be continuity. If

OK, test and replace the faulty instrument cluster as

required. (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). If not OK,

repair the open seat belt switch sense circuit between

the seat belt switch and the instrument cluster as

required.SEAT BELT TENSIONER

DESCRIPTION

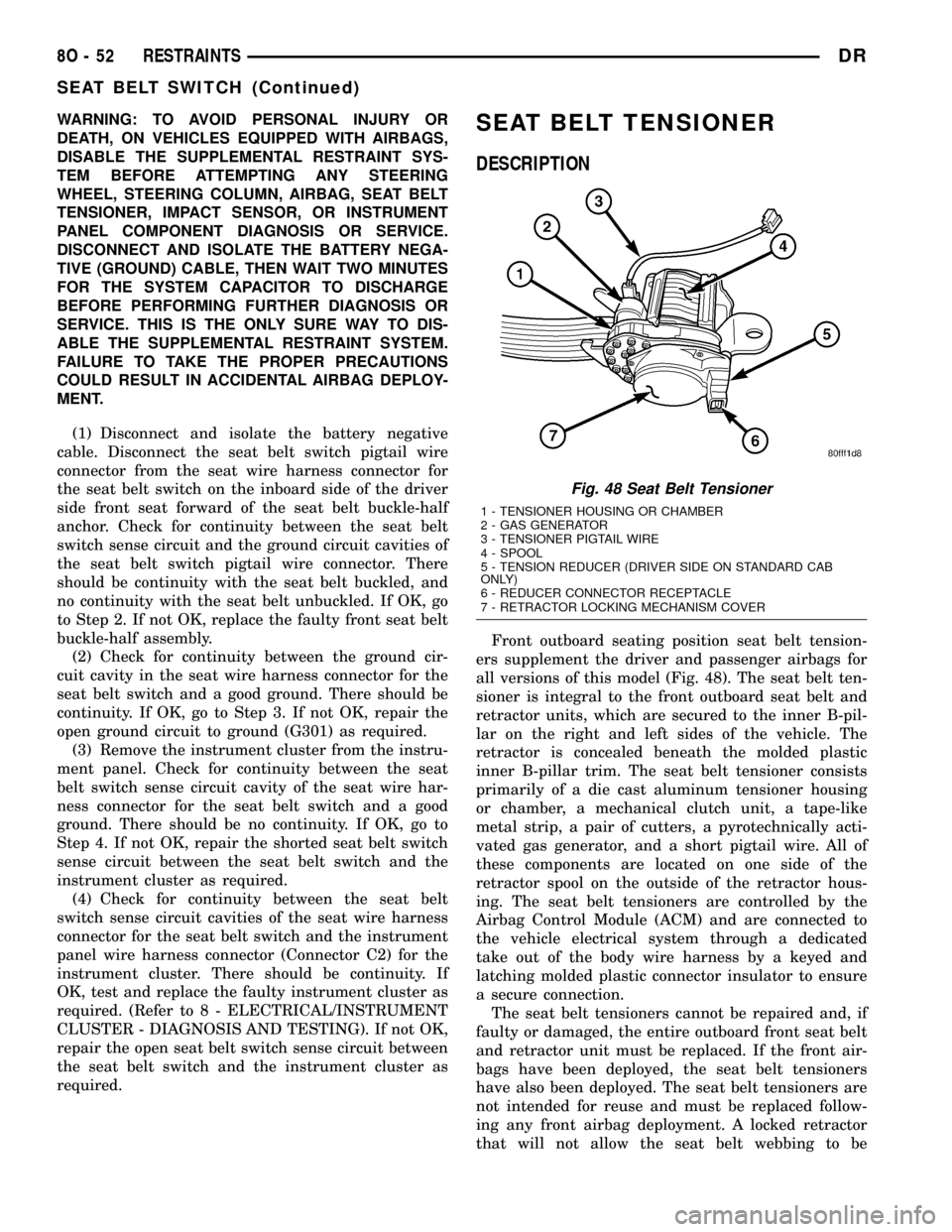

Front outboard seating position seat belt tension-

ers supplement the driver and passenger airbags for

all versions of this model (Fig. 48). The seat belt ten-

sioner is integral to the front outboard seat belt and

retractor units, which are secured to the inner B-pil-

lar on the right and left sides of the vehicle. The

retractor is concealed beneath the molded plastic

inner B-pillar trim. The seat belt tensioner consists

primarily of a die cast aluminum tensioner housing

or chamber, a mechanical clutch unit, a tape-like

metal strip, a pair of cutters, a pyrotechnically acti-

vated gas generator, and a short pigtail wire. All of

these components are located on one side of the

retractor spool on the outside of the retractor hous-

ing. The seat belt tensioners are controlled by the

Airbag Control Module (ACM) and are connected to

the vehicle electrical system through a dedicated

take out of the body wire harness by a keyed and

latching molded plastic connector insulator to ensure

a secure connection.

The seat belt tensioners cannot be repaired and, if

faulty or damaged, the entire outboard front seat belt

and retractor unit must be replaced. If the front air-

bags have been deployed, the seat belt tensioners

have also been deployed. The seat belt tensioners are

not intended for reuse and must be replaced follow-

ing any front airbag deployment. A locked retractor

that will not allow the seat belt webbing to be

Fig. 48 Seat Belt Tensioner

1 - TENSIONER HOUSING OR CHAMBER

2 - GAS GENERATOR

3 - TENSIONER PIGTAIL WIRE

4 - SPOOL

5 - TENSION REDUCER (DRIVER SIDE ON STANDARD CAB

ONLY)

6 - REDUCER CONNECTOR RECEPTACLE

7 - RETRACTOR LOCKING MECHANISM COVER

8O - 52 RESTRAINTSDR

SEAT BELT SWITCH (Continued)

Page 673 of 2627

OPERATION

The seat belt tension reducer is controlled by a

ground signal received from the seat belt switch on

the seat belt switch sense circuit and a battery cur-

rent signal received from the ignition switch on the

fused ignition switch output (run-accessory) circuit.

When the seat belt switch is closed (the driver side

front seat belt is fastened) and the ignition switch is

in the On or Accessory positions, the seat belt tension

reducer solenoid is energized. When the solenoid is

energized, it actuates a mechanism within the driver

side front outboard seat belt retractor to reduce the

normal recoil spring tension exerted by the retractor

spool, which is designed to reel in the seat belt web-

bing onto the spool. When the driver side seat belt is

unbuckled or if the ignition switch is turned to any

position except On or Accessory, the tension reducer

solenoid is de-energized and the normal recoil spring

tension of the retractor is restored.

The action of the seat belt tension reducer results

in improved seat belt comfort for the driver. Reducing

the seat belt retractor recoil spring tension is desir-

able on standard cab models of this vehicle and not

on the quad cab model due to the different mounting

position required for the seat belt turning loop on the

B-pillar relative to the driver's seat position on the

standard cab model. The seat belt tension reducer

may be diagnosed using conventional diagnostic tools

and methods.

DIAGNOSIS AND TESTING - SEAT BELT

TENSION REDUCER

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, SEAT BELT

TENSIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.(1) Disconnect and isolate the battery negative

cable. Disconnect the body wire harness connector for

the seat belt tension reducer from the tension

reducer connector receptacle on the driver side front

outboard seat belt and retractor unit. Using an ohm-

meter, measure the resistance between the seat belt

switch sense circuit terminal pin and the fused igni-

tion switch output (run-accessory) circuit terminal

pin in the tension reducer connector receptacle on

the retractor. Resistance through the tension reducer

solenoid coil should be 53 ohms at 20É C (68É F). If

OK, go to Step 2. If not OK, replace the faulty driver

side front outboard seat belt and retractor unit.

(2) Check for continuity between the seat belt

switch sense circuit cavity of the body wire harness

connector for the seat belt tension reducer and a good

ground. There should be continuity with the driver

side front seat belt buckled, and no continuity with

the driver side front seat belt unbuckled. If OK, go to

Step 3. If not OK, repair the shorted or open seat

belt switch sense circuit between the tension reducer

and the seat belt switch as required.

(3) Reconnect the battery negative cable. Check for

battery current at the fused ignition switch output

(run-accessory) circuit of the body wire harness con-

nector for the seat belt tension reducer. There should

be battery current with the ignition switch in the On

or Accessory positions, and no battery current with

the ignition switch in any other position. If not OK,

repair the shorted or open fused ignition switch out-

put (run-accessory) circuit between the tension

reducer and the ignition switch as required.

8O - 54 RESTRAINTSDR

SEAT BELT TENSION REDUCER (Continued)

Page 690 of 2627

VACUUM RESERVOIR

DESCRIPTION

The vacuum reservoir is a plastic storage tank con-

nected to an engine vacuum source by vacuum lines.

A vacuum reservoir is not used with diesel engines or

the 5.7L gas powered engine.

OPERATION

The vacuum reservoir is used to supply the vac-

uum needed to maintain proper speed control opera-

tion when engine vacuum drops, such as in climbing

a grade while driving. A one-way check valve is used

in the vacuum line between the reservoir and the

vacuum source. This check valve is used to trap

engine vacuum in the reservoir. On certain vehicle

applications, this reservoir is shared with the heat-

ing/air-conditioning system. The vacuum reservoir

cannot be repaired and must be replaced if faulty.

DIAGNOSIS AND TESTING - VACUUM

RESERVOIR

(1) Disconnect vacuum hose at speed control servo

and install a vacuum gauge into the disconnected

hose.

(2) Start engine and observe gauge at idle. Vac-

uum gauge should read at least ten inches of mer-

cury.

(3) If vacuum is less than ten inches of mercury,

determine source of leak. Check vacuum line to

engine for leaks. Also check actual engine intake

manifold vacuum. If manifold vacuum does not meet

this requirement, check for poor engine performance

and repair as necessary.

(4) If vacuum line to engine is not leaking, check

for leak at vacuum reservoir. To locate and gain

access to reservoir, refer to Vacuum Reservoir Remov-

al/Installation in this group. Disconnect vacuum line

at reservoir and connect a hand-operated vacuum

pump to reservoir fitting. Apply vacuum. Reservoir

vacuum should not bleed off. If vacuum is being lost,

replace reservoir.

(5) Verify operation of one-way check valve and

check it for leaks.Certain models may be

equipped with 2 check-valves.

(a) Locate one-way check valve. The valve is

located in vacuum line between vacuum reservoir

and engine vacuum source. Disconnect vacuum

hoses (lines) at each end of valve.(b) Connect a hand-operated vacuum pump to

reservoir end of check valve. Apply vacuum. Vac-

uum should not bleed off. If vacuum is being lost,

replace one-way check valve.

(c) Connect a hand-operated vacuum pump to

vacuum source end of check valve. Apply vacuum.

Vacuum should flow through valve. If vacuum is

not flowing, replace one-way check valve. Seal the

fitting at opposite end of valve with a finger and

apply vacuum. If vacuum will not hold, diaphragm

within check valve has ruptured. Replace valve.

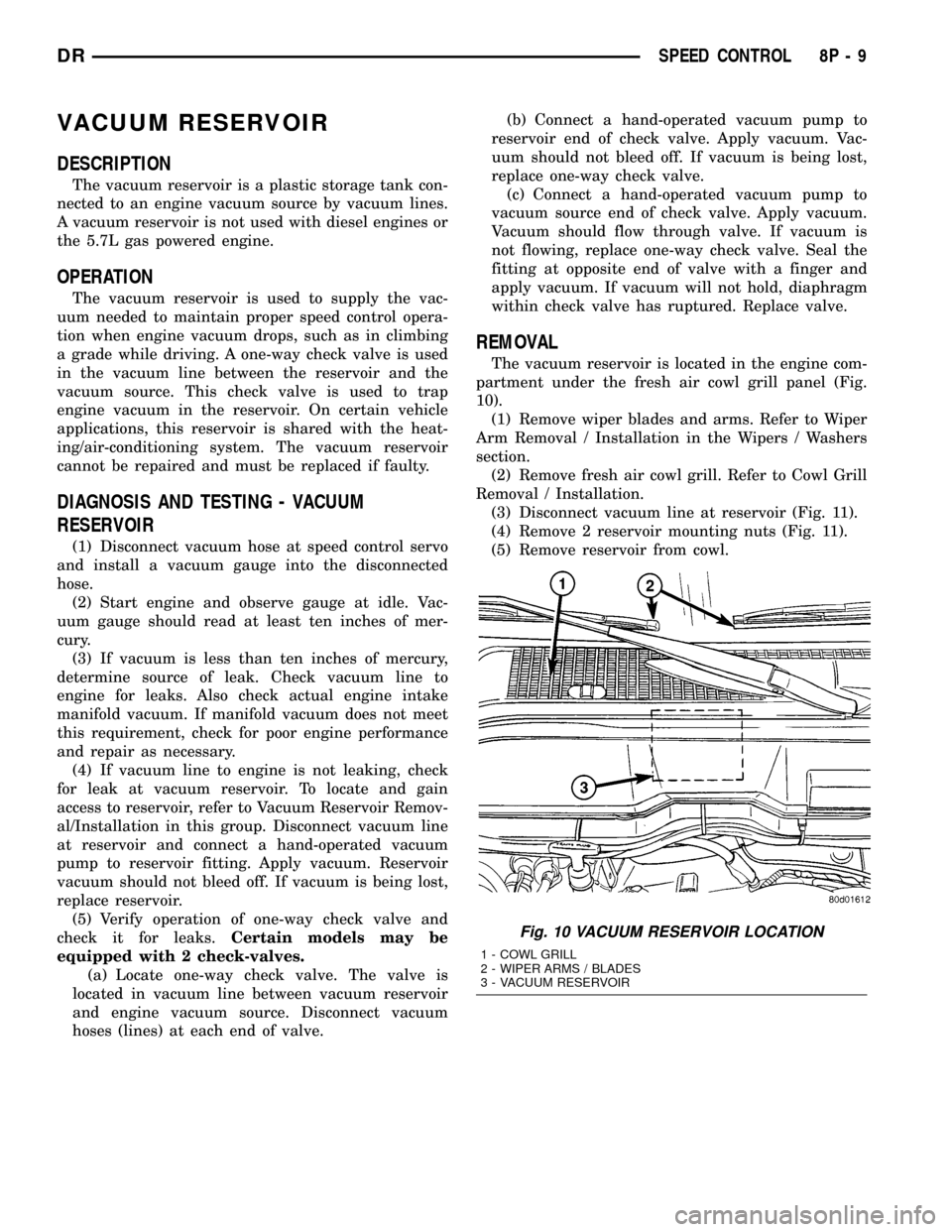

REMOVAL

The vacuum reservoir is located in the engine com-

partment under the fresh air cowl grill panel (Fig.

10).

(1) Remove wiper blades and arms. Refer to Wiper

Arm Removal / Installation in the Wipers / Washers

section.

(2) Remove fresh air cowl grill. Refer to Cowl Grill

Removal / Installation.

(3) Disconnect vacuum line at reservoir (Fig. 11).

(4) Remove 2 reservoir mounting nuts (Fig. 11).

(5) Remove reservoir from cowl.

Fig. 10 VACUUM RESERVOIR LOCATION

1 - COWL GRILL

2 - WIPER ARMS / BLADES

3 - VACUUM RESERVOIR

DRSPEED CONTROL 8P - 9

Page 692 of 2627

VEHICLE THEFT SECURITY

TABLE OF CONTENTS

page page

VEHICLE THEFT SECURITY

DESCRIPTION

DESCRIPTION - VEHICLE THEFT/

SECURITY SYSTEM....................1

DESCRIPTION - SENTRY KEY

IMMOBILIZER SYSTEM (SKIS)............1

DESCRIPTION ± SENTRY KEY

IMMOBILIZER MODULE (SKIM)............1

OPERATION

OPERATION - VEHICLE THEFT/SECURITY

SYSTEM.............................1

OPERATION - SENTRY KEY IMMOBILIZER

SYSTEM (SKIS)........................2

OPERATION ± SENTRY KEY IMMOBILIZER

MODULE (SKIM).......................2DIAGNOSIS AND TESTING

VEHICLE THEFT SECURITY SYSTEM......3

STANDARD PROCEDURE

CONFIGURING A NEW MODULE / SWITCH

OPERATING MODES....................3

SENTRY KEY IMMOBILIZER SYSTEM

INITIALIZATION........................3

SENTRY KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING..........4

SENTRY KEY IMMOBILIZER SYSTEM

INDICATOR LAMP

DESCRIPTION..........................5

OPERATION............................5

VEHICLE THEFT SECURITY

DESCRIPTION

DESCRIPTION - VEHICLE THEFT/SECURITY

SYSTEM

The Vehicle Theft/Security System (VTSS) is

designed to protect against whole vehicle theft. The

system monitors the vehicle doors and ignition for

unauthorized operation.

The VTSS activates:

²Sounding of the horn

²Flashing of the park lamps

²Flashing of the head lamps

The Remote Keyless Entry (RKE) has 1 mode of

operation,CUSTOMER USAGEmode. The cus-

tomer usage mode provides full functionality of the

module and is the mode in which the RKE module

should be operating when used by the customer.

DESCRIPTION - SENTRY KEY IMMOBILIZER

SYSTEM (SKIS)

The Sentry Key Immobilizer System (SKIS) is

designed to provide passive protection against unau-

thorized vehicle use by preventing the engine from

operating while the system is armed. The primary

components of this system are the Sentry Key Immo-

bilizer Module (SKIM), the Sentry Key transponder,

the Vehicle Theft/Security System (VTSS) indicator

LED, and the Powertrain Control Module (PCM).The SKIM is installed on the steering column near

the ignition lock cylinder. The transponder is located

under the molded rubber cap on the head of the igni-

tion key. The VTSS indicator LED is located in the

instrument cluster.

DESCRIPTION ± SENTRY KEY IMMOBILIZER

MODULE (SKIM)

The Sentry Key Immobilizer Module (SKIM) con-

tains a Radio Frequency (RF) transceiver and a cen-

tral processing unit, which includes the Sentry Key

Immobilizer System (SKIS) program logic. The SKIS

programming enables the SKIM to program and

retain in memory the codes of at least two, but no

more than eight electronically coded Sentry Key

transponders. The SKIS programming also enables

the SKIM to communicate over the Programmable

Communication Interface (PCI) bus network with the

Powertrain Control Module (PCM), and/or the

DRBIIItscan tool.

OPERATION

OPERATION - VEHICLE THEFT/SECURITY

SYSTEM

When in theCustomer Usagemode of operation,

the system is armed when the vehicle is locked using

the:

²Power Door Lock Switches

²Remote Keyless Entry (RKE) Transmitter

²Key Cylinder Switches

DRVEHICLE THEFT SECURITY 8Q - 1

Page 693 of 2627

After the vehicle is locked and the last door is

closed, the VTSS indicator in the instrument cluster

will flash quickly for 16 seconds, indicating that the

arming is in process. After 16 seconds, the LED will

continue to flash at a slower rate indicating that the

system is armed.

VTSS disarming occurs upon normal vehicle entry

by unlocking either door via the key cylinder or RKE

transmitter, or by starting the vehicle with a valid

Sentry Key. This disarming will also halt the alarm

once it has been activated.

A tamper alert exists to notify the driver that the

system has been activated. This alert consists of 3

horn pulses and the security telltale flashing for 30

seconds when the vehicle is disarmed. The tamper

alert will not occur if disarmed while alarming.

The VTSS will not arm by mechanically locking the

vehicle doors. This will manually override the sys-

tem.

OPERATION - SENTRY KEY IMMOBILIZER

SYSTEM (SKIS)

The SKIS includes two valid Sentry Key transpon-

ders from the factory. These two Sentry Keys can be

used to program additional non-coded blank Sentry

Keys. These blank keys can be cut to match a valid

ignition key, but the engine will not start unless the

key transponder is also programmed to the vehicle.

The SKIS will recognize no more than eight valid

Sentry Key transponders at any one time.

The SKIS performs a self-test each time the igni-

tion switch is turned to the ON position, and will

store Diagnostic Trouble Codes (DTC's) if a system

malfunction is detected. The SKIS can be diagnosed,

and any stored DTC can be retrieved using a

DRBIIItscan tool as described in the proper Power-

train Diagnostic Procedures manual.

OPERATION ± SENTRY KEY IMMOBILIZER

MODULE (SKIM)

The SKIM transmits and receives RF signals

through a tuned antenna enclosed within a molded

plastic ring formation that is integral to the SKIM

housing. When the SKIM is properly installed on the

steering column, the antenna ring is oriented around

the circumference of the ignition lock cylinder hous-

ing. This antenna ring must be located within eight

millimeters (0.31 inches) of the Sentry Key in order

to ensure proper RF communication between the

SKIM and the Sentry Key transponder.

For added system security, each SKIM is pro-

grammed with a unique ªSecret Keyº code and a

security code. The SKIM keeps the ªSecret Keyº code

in memory. The SKIM also sends the ªSecret Keyº

code to each of the programmed Sentry Key tran-

sponders. The security code is used by the assemblyplant to access the SKIS for initialization, or by the

dealer technician to access the system for service.

The SKIM also stores in its memory the Vehicle

Identification Number (VIN), which it learns through

a PCI bus message from the PCM during initializa-

tion.

The SKIM and the PCM both use software that

includes a rolling code algorithm strategy, which

helps to reduce the possibility of unauthorized SKIS

disarming. The rolling code algorithm ensures secu-

rity by preventing an override of the SKIS through

the unauthorized substitution of the SKIM or the

PCM. However, the use of this strategy also means

that replacement of either the SKIM or the PCM

units will require a system initialization procedure to

restore system operation.

When the ignition switch is turned to the ON or

START positions, the SKIM transmits an RF signal

to excite the Sentry Key transponder. The SKIM then

listens for a return RF signal from the transponder

of the Sentry Key that is inserted in the ignition lock

cylinder. If the SKIM receives an RF signal with

valid ªSecret Keyº and transponder identification

codes, the SKIM sends a ªvalid keyº message to the

PCM over the PCI bus. If the SKIM receives an

invalid RF signal or no response, it sends ªinvalid

keyº messages to the PCM. The PCM will enable or

disable engine operation based upon the status of the

SKIM messages.

The SKIM also sends messages to the Instrument

Cluster which controls the VTSS indicator. The

SKIM sends messages to the Instrument Cluster to

turn the indicator on for about three seconds when

the ignition switch is turned to the ON position as a

ªbulbº test. After completion of the ªbulbº test, the

SKIM sends bus messages to keep the indicator off

for a duration of about one second. Then the SKIM

sends messages to turn the indicator on or off based

upon the results of the SKIS self-tests. If the VTSS

indicator comes on and stays on after the ªbulb testº,

it indicates that the SKIM has detected a system

malfunction and/or that the SKIS has become inoper-

ative.

If the SKIM detects an invalid key when the igni-

tion switch is turned to the ON position, it sends

messages to flash the VTSS indicator. The SKIM can

also send messages to flash the indicator to serve as

an indication to the customer that the SKIS has been

placed in its ªCustomer Learnº programming mode.

See Sentry Key Immobilizer System Transponder

Programming in this section for more information on

the ªCustomer Learnº programming mode.

For diagnosis or initialization of the SKIM and the

PCM, a DRBIIItscan tool and the proper Powertrain

Diagnostic Procedures manual are required. The

8Q - 2 VEHICLE THEFT SECURITYDR

VEHICLE THEFT SECURITY (Continued)