key battery DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1669 of 2627

(2) Install the upper steering coupling shaft seal

by pushing it in securing the four tangs to the panel

(Fig. 16).

NOTE: Note: A new steering coupling shaft pinch

bolt for the upper and lower shafts must be used.

(3) Install the steering coupler shaft to the column

(Fig. 17).

(4) Install the upper pinch bolt use new bolt and

tighten to 57 N.m (42 ft.lbs).

(5) Install the shaft to the lower coupler (Fig. 17).

(6) Install the lower pinch bolt use new bolt and

tighten to 57 N.m (42 ft.lbs).

(7) Unlock the steering wheel.

(8) Reconnect the negative battery cable.

LOWER STEERING COUPLING

REMOVAL

REMOVAL - ALL LD & HD EXCEPT 4X4 HD

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative meth-

ods of locking the steering wheel for service will

have to be used.

(3) Lock the steering wheel with the tire in the

straight position.

(4) Remove the left front tire and wheel assembly.

(5) Mark both coupler connections for proper

installation.

(6) Remove and discard the upper coupler pinch

bolt.

(7) Remove and discard the lower coupler pinch

bolt.

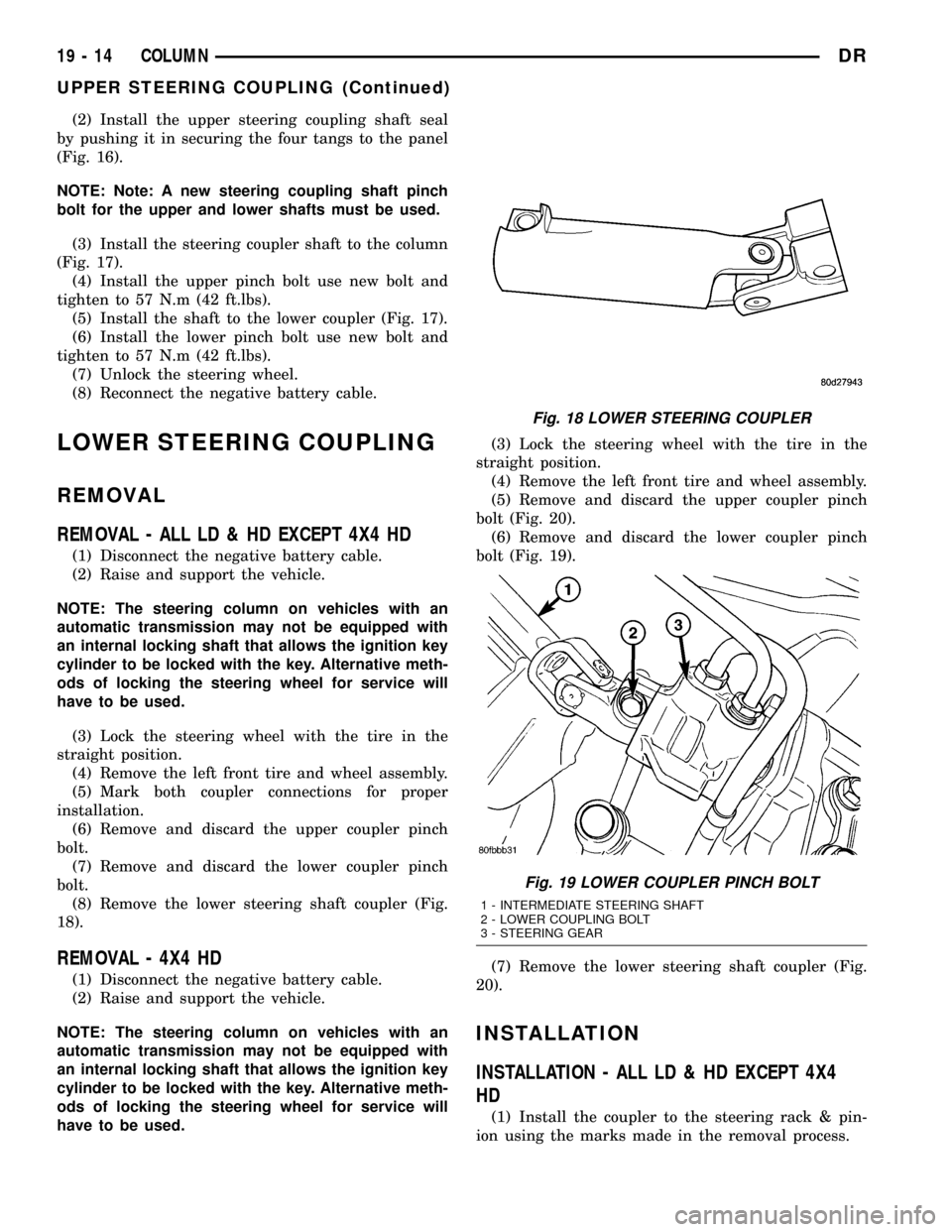

(8) Remove the lower steering shaft coupler (Fig.

18).

REMOVAL - 4X4 HD

(1) Disconnect the negative battery cable.

(2) Raise and support the vehicle.

NOTE: The steering column on vehicles with an

automatic transmission may not be equipped with

an internal locking shaft that allows the ignition key

cylinder to be locked with the key. Alternative meth-

ods of locking the steering wheel for service will

have to be used.(3) Lock the steering wheel with the tire in the

straight position.

(4) Remove the left front tire and wheel assembly.

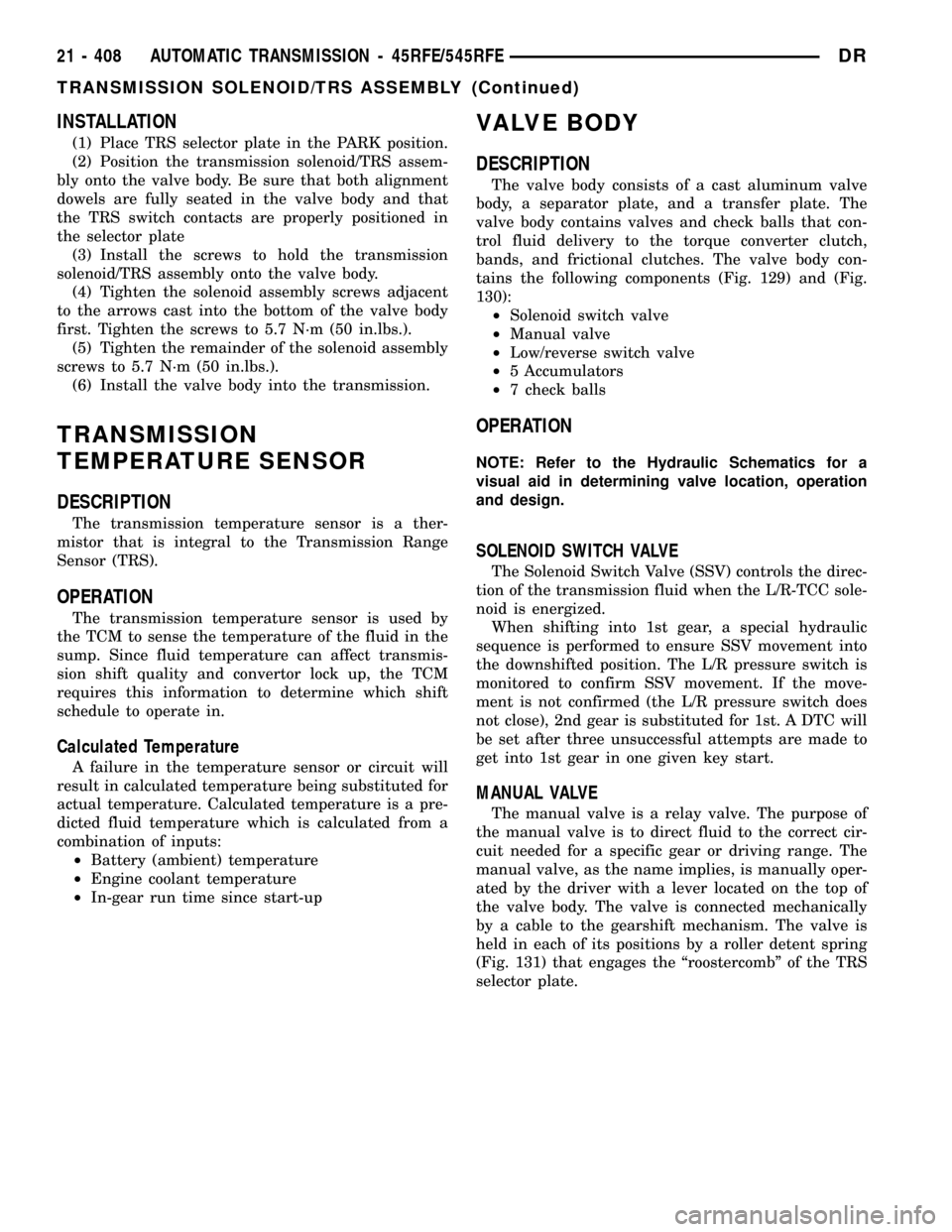

(5) Remove and discard the upper coupler pinch

bolt (Fig. 20).

(6) Remove and discard the lower coupler pinch

bolt (Fig. 19).

(7) Remove the lower steering shaft coupler (Fig.

20).

INSTALLATION

INSTALLATION - ALL LD & HD EXCEPT 4X4

HD

(1) Install the coupler to the steering rack & pin-

ion using the marks made in the removal process.

Fig. 18 LOWER STEERING COUPLER

Fig. 19 LOWER COUPLER PINCH BOLT

1 - INTERMEDIATE STEERING SHAFT

2 - LOWER COUPLING BOLT

3 - STEERING GEAR

19 - 14 COLUMNDR

UPPER STEERING COUPLING (Continued)

Page 2111 of 2627

INSTALLATION

(1) Place TRS selector plate in the PARK position.

(2) Position the transmission solenoid/TRS assem-

bly onto the valve body. Be sure that both alignment

dowels are fully seated in the valve body and that

the TRS switch contacts are properly positioned in

the selector plate

(3) Install the screws to hold the transmission

solenoid/TRS assembly onto the valve body.

(4) Tighten the solenoid assembly screws adjacent

to the arrows cast into the bottom of the valve body

first. Tighten the screws to 5.7 N´m (50 in.lbs.).

(5) Tighten the remainder of the solenoid assembly

screws to 5.7 N´m (50 in.lbs.).

(6) Install the valve body into the transmission.

TRANSMISSION

TEMPERATURE SENSOR

DESCRIPTION

The transmission temperature sensor is a ther-

mistor that is integral to the Transmission Range

Sensor (TRS).

OPERATION

The transmission temperature sensor is used by

the TCM to sense the temperature of the fluid in the

sump. Since fluid temperature can affect transmis-

sion shift quality and convertor lock up, the TCM

requires this information to determine which shift

schedule to operate in.

Calculated Temperature

A failure in the temperature sensor or circuit will

result in calculated temperature being substituted for

actual temperature. Calculated temperature is a pre-

dicted fluid temperature which is calculated from a

combination of inputs:

²Battery (ambient) temperature

²Engine coolant temperature

²In-gear run time since start-up

VALVE BODY

DESCRIPTION

The valve body consists of a cast aluminum valve

body, a separator plate, and a transfer plate. The

valve body contains valves and check balls that con-

trol fluid delivery to the torque converter clutch,

bands, and frictional clutches. The valve body con-

tains the following components (Fig. 129) and (Fig.

130):

²Solenoid switch valve

²Manual valve

²Low/reverse switch valve

²5 Accumulators

²7 check balls

OPERATION

NOTE: Refer to the Hydraulic Schematics for a

visual aid in determining valve location, operation

and design.

SOLENOID SWITCH VALVE

The Solenoid Switch Valve (SSV) controls the direc-

tion of the transmission fluid when the L/R-TCC sole-

noid is energized.

When shifting into 1st gear, a special hydraulic

sequence is performed to ensure SSV movement into

the downshifted position. The L/R pressure switch is

monitored to confirm SSV movement. If the move-

ment is not confirmed (the L/R pressure switch does

not close), 2nd gear is substituted for 1st. A DTC will

be set after three unsuccessful attempts are made to

get into 1st gear in one given key start.

MANUAL VALVE

The manual valve is a relay valve. The purpose of

the manual valve is to direct fluid to the correct cir-

cuit needed for a specific gear or driving range. The

manual valve, as the name implies, is manually oper-

ated by the driver with a lever located on the top of

the valve body. The valve is connected mechanically

by a cable to the gearshift mechanism. The valve is

held in each of its positions by a roller detent spring

(Fig. 131) that engages the ªroostercombº of the TRS

selector plate.

21 - 408 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

TRANSMISSION SOLENOID/TRS ASSEMBLY (Continued)

Page 2497 of 2627

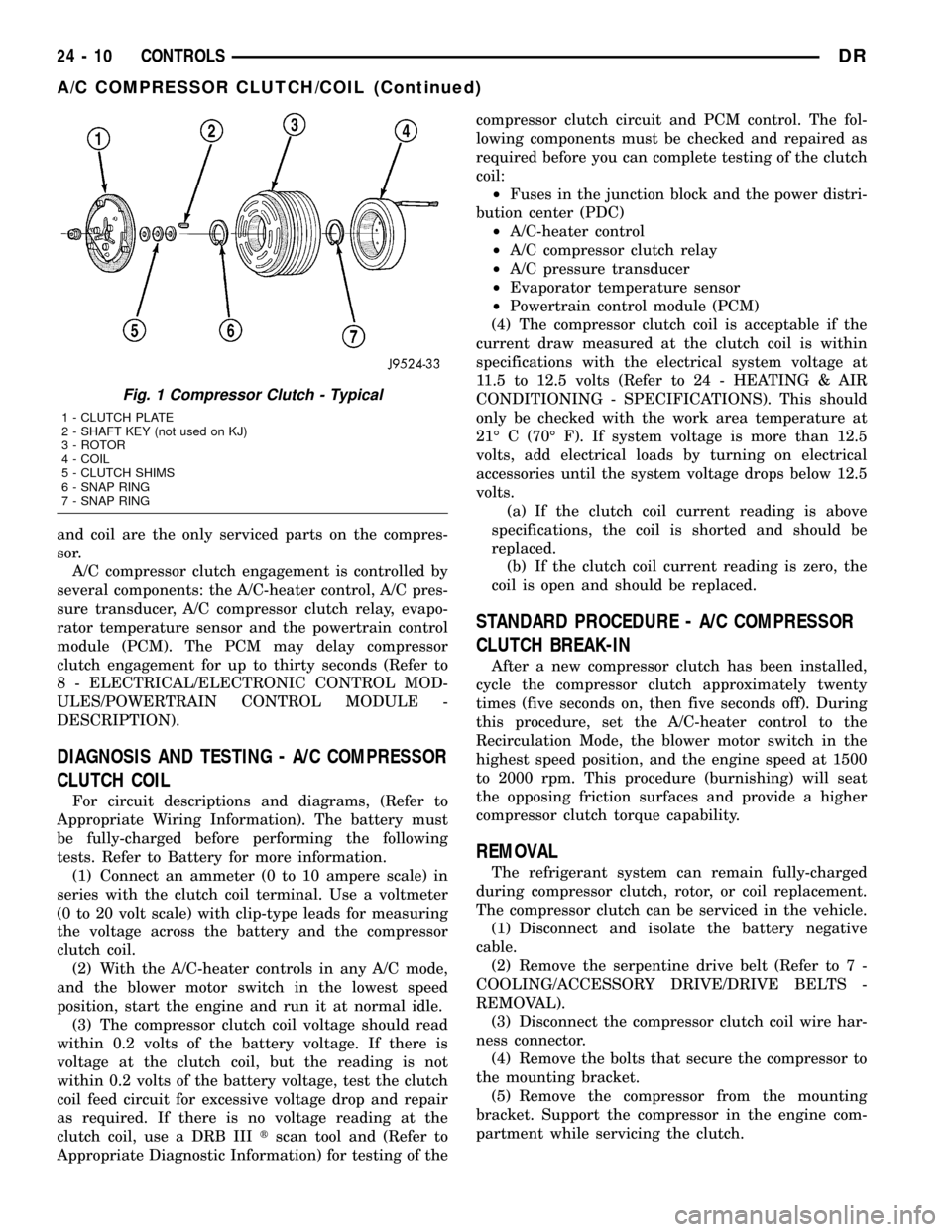

and coil are the only serviced parts on the compres-

sor.

A/C compressor clutch engagement is controlled by

several components: the A/C-heater control, A/C pres-

sure transducer, A/C compressor clutch relay, evapo-

rator temperature sensor and the powertrain control

module (PCM). The PCM may delay compressor

clutch engagement for up to thirty seconds (Refer to

8 - ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION).

DIAGNOSIS AND TESTING - A/C COMPRESSOR

CLUTCH COIL

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information). The battery must

be fully-charged before performing the following

tests. Refer to Battery for more information.

(1) Connect an ammeter (0 to 10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0 to 20 volt scale) with clip-type leads for measuring

the voltage across the battery and the compressor

clutch coil.

(2) With the A/C-heater controls in any A/C mode,

and the blower motor switch in the lowest speed

position, start the engine and run it at normal idle.

(3) The compressor clutch coil voltage should read

within 0.2 volts of the battery voltage. If there is

voltage at the clutch coil, but the reading is not

within 0.2 volts of the battery voltage, test the clutch

coil feed circuit for excessive voltage drop and repair

as required. If there is no voltage reading at the

clutch coil, use a DRB IIItscan tool and (Refer to

Appropriate Diagnostic Information) for testing of thecompressor clutch circuit and PCM control. The fol-

lowing components must be checked and repaired as

required before you can complete testing of the clutch

coil:

²Fuses in the junction block and the power distri-

bution center (PDC)

²A/C-heater control

²A/C compressor clutch relay

²A/C pressure transducer

²Evaporator temperature sensor

²Powertrain control module (PCM)

(4) The compressor clutch coil is acceptable if the

current draw measured at the clutch coil is within

specifications with the electrical system voltage at

11.5 to 12.5 volts (Refer to 24 - HEATING & AIR

CONDITIONING - SPECIFICATIONS). This should

only be checked with the work area temperature at

21É C (70É F). If system voltage is more than 12.5

volts, add electrical loads by turning on electrical

accessories until the system voltage drops below 12.5

volts.

(a) If the clutch coil current reading is above

specifications, the coil is shorted and should be

replaced.

(b) If the clutch coil current reading is zero, the

coil is open and should be replaced.

STANDARD PROCEDURE - A/C COMPRESSOR

CLUTCH BREAK-IN

After a new compressor clutch has been installed,

cycle the compressor clutch approximately twenty

times (five seconds on, then five seconds off). During

this procedure, set the A/C-heater control to the

Recirculation Mode, the blower motor switch in the

highest speed position, and the engine speed at 1500

to 2000 rpm. This procedure (burnishing) will seat

the opposing friction surfaces and provide a higher

compressor clutch torque capability.

REMOVAL

The refrigerant system can remain fully-charged

during compressor clutch, rotor, or coil replacement.

The compressor clutch can be serviced in the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(3) Disconnect the compressor clutch coil wire har-

ness connector.

(4) Remove the bolts that secure the compressor to

the mounting bracket.

(5) Remove the compressor from the mounting

bracket. Support the compressor in the engine com-

partment while servicing the clutch.

Fig. 1 Compressor Clutch - Typical

1 - CLUTCH PLATE

2 - SHAFT KEY (not used on KJ)

3 - ROTOR

4 - COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

24 - 10 CONTROLSDR

A/C COMPRESSOR CLUTCH/COIL (Continued)

Page 2568 of 2627

Trip Indicator

TheTripis essential for running monitors and

extinguishing the MIL. In OBD II terms, a trip is a

set of vehicle operating conditions that must be met

for a specific monitor to run. All trips begin with a

key cycle.

Good Trip

The Good Trip counters are as follows:

²Specific Good Trip

²Fuel System Good Trip

²Misfire Good Trip

²Alternate Good Trip (appears as a Global Good

Trip on DRB III)

²Comprehensive Components

²Major Monitor

²Warm-Up Cycles

Specific Good Trip

The term Good Trip has different meanings

depending on the circumstances:

²If the MIL is OFF, a trip is defined as when the

Oxygen Sensor Monitor and the Catalyst Monitor

have been completed in the same drive cycle.

²If the MIL is ON and a DTC was set by the Fuel

Monitor or Misfire Monitor (both continuous moni-

tors), the vehicle must be operated in the Similar

Condition Window for a specified amount of time.

²If the MIL is ON and a DTC was set by a Task

Manager commanded once-per-trip monitor (such as

the Oxygen Sensor Monitor, Catalyst Monitor, Purge

Flow Monitor, Leak Detection Pump Monitor, EGR

Monitor or Oxygen Sensor Heater Monitor), a good

trip is when the monitor is passed on the next start-

up.

²If the MIL is ON and any other emissions DTC

was set (not an OBD II monitor), a good trip occurs

when the Oxygen Sensor Monitor and Catalyst Mon-

itor have been completed, or two minutes of engine

run time if the Oxygen Sensor Monitor and Catalyst

Monitor have been stopped from running.

Fuel System Good Trip

To count a good trip (three required) and turn off

the MIL, the following conditions must occur:

²Engine in closed loop

²Operating in Similar Conditions Window

²Short Term multiplied by Long Term less than

threshold

²Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will

count a good trip (three required) and turn off the

MIL.

Misfire Good Trip

If the following conditions are met the PCM will

count one good trip (three required) in order to turn

off the MIL:

²Operating in Similar Condition Window

²1000 engine revolutions with no misfireWarm-Up Cycles

Once the MIL has been extinguished by the Good

Trip Counter, the PCM automatically switches to a

Warm-Up Cycle Counter that can be viewed on the

DRB III. Warm-Up Cycles are used to erase DTCs

and Freeze Frames. Forty Warm-Up cycles must

occur in order for the PCM to self-erase a DTC and

Freeze Frame. A Warm-Up Cycle is defined as fol-

lows:

²Engine coolant temperature must start below

and rise above 160É F

²Engine coolant temperature must rise by 40É F

²No further faults occur

Freeze Frame Data Storage

Once a failure occurs, the Task Manager records

several engine operating conditions and stores it in a

Freeze Frame. The Freeze Frame is considered one

frame of information taken by an on-board data

recorder. When a fault occurs, the PCM stores the

input data from various sensors so that technicians

can determine under what vehicle operating condi-

tions the failure occurred.

The data stored in Freeze Frame is usually

recorded when a system fails the first time for two

trip faults. Freeze Frame data will only be overwrit-

ten by a different fault with a higher priority.

CAUTION: Erasing DTCs, either with the DRB III or

by disconnecting the battery, also clears all Freeze

Frame data.

Similar Conditions Window

The Similar Conditions Window displays informa-

tion about engine operation during a monitor. Abso-

lute MAP (engine load) and Engine RPM are stored

in this window when a failure occurs. There are two

different Similar conditions Windows: Fuel System

and Misfire.

FUEL SYSTEM

²Fuel System Similar Conditions WindowÐ

An indicator that 'Absolute MAP When Fuel Sys Fail'

and 'RPM When Fuel Sys Failed' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Fuel Sys FailÐ The

stored MAP reading at the time of failure. Informs

the user at what engine load the failure occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Fuel Sys FailÐ The stored RPM

reading at the time of failure. Informs the user at

what engine RPM the failure occurred.

DREMISSIONS CONTROL 25 - 7

EMISSIONS CONTROL (Continued)

Page 2607 of 2627

LUBRICATION - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS.......9-187,9-7

LUBRICATION - OPERATION . . . 9-150,9-289,9-61

LUBRICATION - STANDARD PROCEDURE . . 19-34

LUBRICATION - STANDARD PROCEDURE,

BODY...............................23-3

LUMBAR CONTROL SWITCH -

DESCRIPTION.......................8N-17

LUMBAR CONTROL SWITCH -

OPERATION.........................8N-18

LUMBAR CONTROL SWITCH - REMOVAL . 8N-18

LUMBAR MOTOR - DESCRIPTION.......8N-18

LUMBAR MOTOR - DIAGNOSIS AND

TESTING...........................8N-18

LUMBAR MOTOR - OPERATION.........8N-18

LUMBAR SUPPORT HANDLE/BEZEL -

INSTALLATION.......................23-82

LUMBAR SUPPORT HANDLE/BEZEL -

REMOVAL..........................23-82

MAIN BEARING - FITTING - STANDARD

PROCEDURE, CRANKSHAFT.......9-134,9-207

MAIN BEARING CLEARANCE -

STANDARD PROCEDURE...............9-274

MAIN BEARING FITTING, STANDARD

PROCEDURE.........................9-44

MAIN BEARINGS - INSPECTION,

CRANKSHAFT..................9-135,9-208

MAINTENANCE SCHEDULES, 24-VALVE

CUMMINS TURBO DIESEL..............0-12

MALFUNCTION INDICATOR LAMP (MIL) -

DESCRIPTION.......................8J-31

MALFUNCTION INDICATOR LAMP (MIL) -

OPERATION.........................8J-31

MANAGER - DESCRIPTION, TASK.........25-1

MANAGER - OPERATION, TASK..........25-5

MANIFOLD - CLEANING, EXHAUST . 9-163,9-226,

9-298

MANIFOLD - CLEANING, INTAKE . . . 9-160,9-226,

9-297

MANIFOLD - DESCRIPTION, EXHAUST . . . 9-161,

9-226,9-74

MANIFOLD - DESCRIPTION, INTAKE.....9-159,

9-225,9-72

MANIFOLD - INSPECTION, EXHAUST.....9-163,

9-227,9-298

MANIFOLD - INSPECTION, INTAKE . 9-160,9-226,

9-297

MANIFOLD - INSTALLATION, EXHAUST . . . 9-164,

9-227,9-298,9-74

MANIFOLD - INSTALLATION, INTAKE.....9-160,

9-226,9-298,9-73

MANIFOLD - OPERATION, EXHAUST......9-226

MANIFOLD - REMOVAL, EXHAUST . . 9-161,9-226,

9-298,9-74

MANIFOLD - REMOVAL, INTAKE . . . 9-159,9-226,

9-297,9-73

MANIFOLD LEAKAGE - DIAGNOSIS AND

TESTING, INTAKE...............9-159,9-225

MANIFOLD LEAKS - DIAGNOSIS AND

TESTING, INTAKE.....................9-72

MANUAL - INSTALLATION, WINDOW

REGULATOR...................23-27,23-35

MANUAL - REMOVAL, WINDOW

REGULATOR...................23-26,23-35

MANUAL BLEEDING - STANDARD

PROCEDURE..........................5-5

MANUAL TRANSMISSION -

DESCRIPTION.........................0-4

MANUAL TRANSMISSION - NV3500 -

ASSEMBLY..........................21-17

MANUAL TRANSMISSION - NV3500 -

CLEANING..........................21-15

MANUAL TRANSMISSION - NV3500 -

DESCRIPTION........................21-1

MANUAL TRANSMISSION - NV3500 -

DIAGNOSIS AND TESTING..............21-3

MANUAL TRANSMISSION - NV3500 -

DISASSEMBLY........................21-4

MANUAL TRANSMISSION - NV3500 -

INSPECTION

........................21-16

MANUAL TRANSMISSION - NV3500 -

INSTALLATION

.......................21-39

MANUAL TRANSMISSION - NV3500 -

OPERATION

..........................21-1

MANUAL TRANSMISSION - NV3500 -

REMOVAL

...........................21-3

MANUAL TRANSMISSION - NV3500 -

SPECIAL TOOLS

.....................21-40MANUAL TRANSMISSION - NV3500 -

SPECIFICATIONS.....................21-40

MANUAL TRANSMISSION - NV4500 -

ASSEMBLY..........................21-63

MANUAL TRANSMISSION - NV4500 -

CLEANING..........................21-62

MANUAL TRANSMISSION - NV4500 -

DESCRIPTION.......................21-43

MANUAL TRANSMISSION - NV4500 -

DIAGNOSIS AND TESTING.............21-44

MANUAL TRANSMISSION - NV4500 -

DISASSEMBLY.......................21-46

MANUAL TRANSMISSION - NV4500 -

INSPECTION........................21-62

MANUAL TRANSMISSION - NV4500 -

INSTALLATION.......................21-80

MANUAL TRANSMISSION - NV4500 -

OPERATION.........................21-43

MANUAL TRANSMISSION - NV4500 -

REMOVAL..........................21-44

MANUAL TRANSMISSION - NV4500 -

SPECIAL TOOLS.....................21-81

MANUAL TRANSMISSION - NV4500 -

SPECIFICATIONS.....................21-81

MANUAL TRANSMISSION - NV5600 -

ASSEMBLY.........................21-106

MANUAL TRANSMISSION - NV5600 -

DESCRIPTION.......................21-88

MANUAL TRANSMISSION - NV5600 -

DIAGNOSIS AND TESTING.............21-90

MANUAL TRANSMISSION - NV5600 -

DISASSEMBLY.......................21-91

MANUAL TRANSMISSION - NV5600 -

INSPECTION.........................21-106

MANUAL TRANSMISSION - NV5600 -

INSTALLATION......................21-121

MANUAL TRANSMISSION - NV5600 -

OPERATION.........................21-90

MANUAL TRANSMISSION - NV5600 -

REMOVAL..........................21-90

MANUAL TRANSMISSION - NV5600 -

SPECIAL TOOLS....................21-123

MAP SENSOR - DESCRIPTION.....14-32,14-83

MAP SENSOR - INSTALLATION..........14-34

MAP SENSOR - OPERATION............14-32

MAP SENSOR - REMOVAL.............14-33

MARKER LAMP - INSTALLATION,

FENDER............................8L-18

MARKER LAMP - INSTALLATION,

TAILGATE...........................8L-18

MARKER LAMP - REMOVAL, FENDER....8L-17

MARKER LAMP - REMOVAL, TAILGATE . . . 8L-18

MASTER CYLINDER - DESCRIPTION......5-24

MASTER CYLINDER - OPERATION........5-25

MASTER CYLINDER BLEEDING -

STANDARD PROCEDURE................5-26

MASTER CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING..............5-25

MATCH MOUNTING - STANDARD

PROCEDURE.........................22-3

MATCHING TIRE - DESCRIPTION, FULL

SIZE, SPARE WHEEL WITH.............22-15

MATS - INSTALLATION, CARPETS AND

FLOOR.............................23-65

MATS - REMOVAL, CARPETS AND

FLOOR.............................23-65

MEASUREMENT - 4WD (LD) -

STANDARD PROCEDURE, HEIGHT.........2-3

MEASURING TIMING CHAIN WEAR -

STANDARD PROCEDURE...............9-167

MEASURING TIMING CHAIN WEAR,

STANDARD PROCEDURE................9-77

MECHANICAL - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS.....9-185,9-188,

9-233,9-6,9-92

MECHANISM - DESCRIPTION, SHIFT....21-252,

21-398

MECHANISM - INSTALLATION, SHIFT.....21-87

MECHANISM - OPERATION, SHIFT......21-252,

21-398

MECHANISM - REMOVAL, SHIFT

........21-86

METRIC SYSTEM - DESCRIPTION

......Intro.-8

MICRO 420 BATTERY TESTER -

STANDARD PROCEDURE, USING

........8F-12

MILE, SPECIFICATIONS - TIRE

REVOLUTIONS PER

...................22-10

MINI-TRIP COMPUTER - DIAGNOSIS

AND TESTING, COMPASS

..............8M-6MIRROR - DESCRIPTION, AUTOMATIC

DAY / NIGHT........................8N-11

MIRROR - DIAGNOSIS AND TESTING,

AUTOMATIC DAY / NIGHT..............8N-11

MIRROR - INSTALLATION, SIDE VIEW....23-42

MIRROR - OPERATION, AUTOMATIC DAY

/ NIGHT............................8N-11

MIRROR - REMOVAL, AUTOMATIC DAY /

NIGHT.............................8N-12

MIRROR - REMOVAL, REAR VIEW.......23-69

MIRROR - REMOVAL, SIDE VIEW........23-41

MIRROR - REMOVAL, SIDEVIEW........8N-12

MIRROR FLAG - INSTALLATION, SIDE

VIEW..............................23-27

MIRROR FLAG - REMOVAL, SIDE VIEW . . . 23-27

MIRROR GLASS - INSTALLATION, SIDE

VIEW..............................23-43

MIRROR GLASS - REMOVAL, SIDE VIEW . . 23-42

MIRROR SUPPORT BRACKET -

INSTALLATION, REAR VIEW............23-70

MIRROR SWITCH - DIAGNOSIS AND

TESTING, POWER....................8N-12

MIRROR SWITCH - REMOVAL, POWER . . . 8N-12

MIRRORS - DESCRIPTION, HEATED.......8G-6

MIRRORS - DESCRIPTION, POWER......8N-10

MIRRORS - DIAGNOSIS AND TESTING,

POWER............................8N-10

MIRRORS - OPERATION, HEATED........8G-6

MIRRORS - OPERATION, POWER........8N-10

MODE - DESCRIPTION, CIRCUIT

ACTUATION TEST.....................25-1

MODE - DESCRIPTION, STATE DISPLAY

TEST...............................25-1

MODE DOOR - INSTALLATION..........24-38

MODE DOOR - REMOVAL..............24-38

MODE DOOR ACTUATOR - DESCRIPTION . . 24-23

MODE DOOR ACTUATOR -

INSTALLATION.......................24-23

MODE DOOR ACTUATOR - OPERATION . . . 24-23

MODE DOOR ACTUATOR - REMOVAL.....24-23

MODE SENSOR - DESCRIPTION . . 21-509,21-538,

21-573

MODE SENSOR - OPERATION . . . 21-509,21-539,

21-573

MODES OF OPERATION - DESCRIPTION....8E-7

MODES, STANDARD PROCEDURE -

CONFIGURING A NEW MODULE /

SWITCH OPERATING...................8Q-3

MODULE - DESCRIPTION, AIRBAG

CONTROL..........................8O-11

MODULE - DESCRIPTION, DRIVER DOOR . . 8N-5

MODULE - DESCRIPTION, FRONT

CONTROL........................8W-97-5

MODULE - DESCRIPTION, FRONT

CONTROL...........................8E-5

MODULE - DESCRIPTION, FUEL PUMP....14-11

MODULE - DESCRIPTION, FUEL TANK....14-63

MODULE - DESCRIPTION, HEATED SEAT . . . 8E-6

MODULE - DESCRIPTION, HEATED SEAT . . 8G-13

MODULE - DESCRIPTION, INTEGRATED

POWER..........................8W-97-3

MODULE - DESCRIPTION, REMOTE

KEYLESS ENTRY......................8N-7

MODULE - DESCRIPTION, SENTRY KEY

IMMOBILIZER.......................8E-13

MODULE - DESCRIPTION, TRANSFER

CASE CONTROL......................8E-16

MODULE - DESCRIPTION,

TRANSMISSION CONTROL.............8E-20

MODULE - DESCRIPTION, WIPER.......8R-22

MODULE - DIAGNOSIS AND TESTING,

DRIVER DOOR.......................8N-6

MODULE - DIAGNOSIS AND TESTING,

FRONT CONTROL..................8W-97-5

MODULE - DIAGNOSIS AND TESTING,

FRONT CONTROL.....................8E-5

MODULE - DIAGNOSIS AND TESTING,

HEATED SEAT ........................8E-6

MODULE - DIAGNOSIS AND TESTING,

HEATED SEAT

.......................8G-14

MODULE - DIAGNOSIS AND TESTING,

REMOTE KEYLESS ENTRY

..............8N-7

MODULE - INSTALLATION, AIRBAG

CONTROL

..........................8O-13

MODULE - INSTALLATION, DRIVER

DOOR

..............................8N-7

MODULE - INSTALLATION, ENGINE

CONTROL

...........................8E-4

20 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2619 of 2627

SUPPLEMENTAL RESTRAINTS -

STANDARD PROCEDURE, HANDLING

NON-DEPLOYED......................8O-6

SUPPLIES - DESCRIPTION, 5 VOLT......8E-10

SUPPLIES - OPERATION, 5 VOLT........8E-11

SUPPLY TEST - DIAGNOSIS AND

TESTING, VACUUM....................8P-2

SUPPORT - INSTALLATION, SUN VISOR . . . 23-71

SUPPORT - REMOVAL, SUN VISOR......23-70

SUPPORT BRACKET - INSTALLATION,

REAR VIEW MIRROR.................23-70

SUPPORT BRACKET - INSTALLATION,

STEERING COLUMN OPENING..........23-60

SUPPORT BRACKET - REMOVAL,

STEERING COLUMN OPENING..........23-60

SUPPORT CYLINDER - INSTALLATION....23-48

SUPPORT CYLINDER - INSTALLATION,

LOAD FLOOR........................23-72

SUPPORT CYLINDER - REMOVAL........23-48

SUPPORT CYLINDER - REMOVAL, LOAD

FLOOR.............................23-72

SUPPORT HANDLE/BEZEL -

INSTALLATION, LUMBAR..............23-82

SUPPORT HANDLE/BEZEL - REMOVAL,

LUMBAR...........................23-82

SUPPORT PLATE - INSTALLATION........5-36

SUPPORT PLATE - REMOVAL............5-35

SUPPRESSION GROUND STRAP -

DESCRIPTION, RADIO NOISE............8A-9

SUPPRESSION GROUND STRAP -

INSTALLATION, RADIO NOISE...........8A-10

SUPPRESSION GROUND STRAP -

OPERATION, RADIO NOISE..............8A-9

SUPPRESSION GROUND STRAP -

REMOVAL, RADIO NOISE...............8A-9

SURFACE PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET...........9-10

SURROUND - INSTALLATION,

INSTRUMENT PANEL LOWER...........23-59

SURROUND - REMOVAL, INSTRUMENT

PANEL LOWER......................23-59

SUSPENSION - DESCRIPTION, GEAR -

INDEPENDENT FRONT.................19-17

SUSPENSION - INSTALLATION, GEAR -

INDEPENDENT FRONT.................19-18

SUSPENSION - REMOVAL, GEAR -

INDEPENDENT FRONT.................19-17

SUSPENSION - STANDARD PROCEDURE,

ALIGNMENT LINK/COIL..................2-5

SUSPENSION ARM - INSTALLATION,

LOWER.............................2-38

SUSPENSION ARM - REMOVAL, LOWER . . . 2-38

SUSPENSION, SPECIAL TOOLS - FRONT . . . 2-12

SWITCH - DESCRIPTION................8P-7

SWITCH - DESCRIPTION, BACKUP LAMP . . . 8L-8

SWITCH - DESCRIPTION, BLOWER

MOTOR............................24-20

SWITCH - DESCRIPTION, BRAKE LAMP....8L-9

SWITCH - DESCRIPTION, CLUTCH

PEDAL POSITION.....................6-13

SWITCH - DESCRIPTION, DOOR AJAR....8L-27

SWITCH - DESCRIPTION, DRIVER SEAT . . . 8N-14

SWITCH - DESCRIPTION, HAZARD.......8L-14

SWITCH - DESCRIPTION, HEADLAMP....8L-14

SWITCH - DESCRIPTION, HEATED SEAT . . 8G-11

SWITCH - DESCRIPTION, HORN

..........8H-2

SWITCH - DESCRIPTION, IGNITION

.......19-9

SWITCH - DESCRIPTION, KEY-IN

IGNITION

...........................19-11

SWITCH - DESCRIPTION, LUMBAR

CONTROL

..........................8N-17

SWITCH - DESCRIPTION, PASSENGER

AIRBAG ON/OFF

.....................8O-42

SWITCH - DESCRIPTION, PASSENGER

SEAT

..............................8N-15

SWITCH - DESCRIPTION, POWER

STEERING PRESSURE

.................19-46

SWITCH - DESCRIPTION, PTO

.....14-36,14-85

SWITCH - DESCRIPTION, REAR

WINDOW DEFOGGER

..................8G-4

SWITCH - DESCRIPTION, SEAT BELT

.....8O-51

SWITCH - DESCRIPTION, SELECTOR

....21-510,

21-539,21-574

SWITCH - DESCRIPTION, TOW/HAUL

OVERDRIVE

..................21-261,21-392

SWITCH - DESCRIPTION, WASHER

FLUID LEVEL

.........................8R-9SWITCH - DIAGNOSIS AND TESTING,

BACKUP LAMP.......................8L-8

SWITCH - DIAGNOSIS AND TESTING,

BLOWER MOTOR....................24-20

SWITCH - DIAGNOSIS AND TESTING,

BRAKE LAMP.......................8L-10

SWITCH - DIAGNOSIS AND TESTING,

CLUTCH PEDAL POSITION..............6-13

SWITCH - DIAGNOSIS AND TESTING,

DRIVER SEAT.......................8N-14

SWITCH - DIAGNOSIS AND TESTING,

HEATED SEAT .......................8G-12

SWITCH - DIAGNOSIS AND TESTING,

HORN..............................8H-2

SWITCH - DIAGNOSIS AND TESTING,

IGNITION............................19-9

SWITCH - DIAGNOSIS AND TESTING,

MULTI-FUNCTION....................8L-18

SWITCH - DIAGNOSIS AND TESTING,

PASSENGER SEAT....................8N-16

SWITCH - DIAGNOSIS AND TESTING,

POWER LOCK........................8N-4

SWITCH - DIAGNOSIS AND TESTING,

POWER MIRROR....................8N-12

SWITCH - DIAGNOSIS AND TESTING,

SEAT BELT .........................8O-51

SWITCH - DIAGNOSIS AND TESTING,

WINDOW...........................8N-20

SWITCH - INSTALLATION...............8P-8

SWITCH - INSTALLATION, ADJUSTABLE

PEDAL...............................5-6

SWITCH - INSTALLATION, BRAKE LAMP . . 8L-11

SWITCH - INSTALLATION, DRIVER SEAT . . . 8N-15

SWITCH - INSTALLATION, HEADLAMP....8L-15

SWITCH - INSTALLATION, HEATED SEAT . . 8G-13

SWITCH - INSTALLATION, IGNITION......19-11

SWITCH - INSTALLATION, MULTI-

FUNCTION..........................8L-19

SWITCH - INSTALLATION, OIL

PRESSURE.........................9-294

SWITCH - INSTALLATION, PASSENGER

AIRBAG ON/OFF.....................8O-44

SWITCH - INSTALLATION, PASSENGER

SEAT ..............................8N-16

SWITCH - INSTALLATION, POWER LOCK . . . 8N-4

SWITCH - INSTALLATION, TOW/HAUL

OVERDRIVE..................21-262,21-393

SWITCH - INSTALLATION, WASHER

FLUID LEVEL........................8R-11

SWITCH - INSTALLATION, WINDOW.....8N-21

SWITCH - OPERATION.................8P-7

SWITCH - OPERATION, BACKUP LAMP....8L-8

SWITCH - OPERATION, BLOWER MOTOR . . 24-20

SWITCH - OPERATION, BRAKE LAMP......8L-9

SWITCH - OPERATION, CLUTCH PEDAL

POSITION...........................6-13

SWITCH - OPERATION, DOOR AJAR......8L-27

SWITCH - OPERATION, DRIVER SEAT....8N-14

SWITCH - OPERATION, HAZARD.........8L-14

SWITCH - OPERATION, HEADLAMP......8L-14

SWITCH - OPERATION, HEATED SEAT....8G-12

SWITCH - OPERATION, IGNITION.........19-9

SWITCH - OPERATION, LUMBAR

CONTROL..........................8N-18

SWITCH - OPERATION, PASSENGER

AIRBAG ON/OFF.....................8O-43

SWITCH - OPERATION, PASSENGER

SEAT ..............................8N-15

SWITCH - OPERATION, POWER

STEERING PRESSURE.................19-46

SWITCH - OPERATION, PTO.......14-36,14-85

SWITCH - OPERATION, REAR WINDOW

DEFOGGER..........................8G-4

SWITCH - OPERATION, SEAT BELT.......8O-51

SWITCH - OPERATION, SELECTOR.....21-510,

21-540,21-574

SWITCH - OPERATION, TOW/HAUL

OVERDRIVE..................21-262,21-392

SWITCH - OPERATION, WASHER FLUID

LEVEL..............................8R-9

SWITCH - REMOVAL...................8P-8

SWITCH - REMOVAL, ADJUSTABLE

PEDAL...............................5-6

SWITCH - REMOVAL, BRAKE LAMP

......8L-10

SWITCH - REMOVAL, DRIVER SEAT

......8N-15

SWITCH - REMOVAL, HEADLAMP

........8L-14

SWITCH - REMOVAL, HEATED SEAT

......8G-13

SWITCH - REMOVAL, IGNITION

.........19-10SWITCH - REMOVAL, LUMBAR

CONTROL..........................8N-18

SWITCH - REMOVAL, MULTI-FUNCTION . . . 8L-19

SWITCH - REMOVAL, OIL PRESSURE.....9-294

SWITCH - REMOVAL, PASSENGER

AIRBAG ON/OFF.....................8O-43

SWITCH - REMOVAL, PASSENGER SEAT . . 8N-16

SWITCH - REMOVAL, POWER LOCK......8N-4

SWITCH - REMOVAL, POWER MIRROR . . . 8N-12

SWITCH - REMOVAL, TOW/HAUL

OVERDRIVE..................21-262,21-392

SWITCH - REMOVAL, WASHER FLUID

LEVEL.............................8R-10

SWITCH - REMOVAL, WINDOW.........8N-20

SWITCH AND KEY LOCK CYLINDER -

DIAGNOSIS AND TESTING, IGNITION.....19-11

SWITCH BEZEL - INSTALLATION,

INSTRUMENT PANEL HEADLAMP........23-56

SWITCH BEZEL - REMOVAL,

INSTRUMENT PANEL HEADLAMP........23-56

SWITCH OPERATING MODES,

STANDARD PROCEDURE -

CONFIGURING A NEW MODULE..........8Q-3

SWITCH VALVE - DESCRIPTION,

SOLENOID.........................21-398

SWITCH VALVE - OPERATION, SOLENOID . 21-398

SWITCHES - DESCRIPTION, REMOTE.....8A-10

SWITCHES - DIAGNOSIS AND TESTING,

REMOTE...........................8A-11

SWITCHES - INSTALLATION, REMOTE....8A-12

SWITCHES - OPERATION, REMOTE........8A-11

SWITCHES - REMOVAL, REMOTE........8A-12

SYMBOLS - DESCRIPTION,

INTERNATIONAL....................Intro.-5

TACHOMETER - DESCRIPTION..........8J-38

TACHOMETER - OPERATION............8J-38

TAILGATE - INSTALLATION.............23-17

TAILGATE - REMOVAL.................23-17

TAILGATE MARKER LAMP -

INSTALLATION.......................8L-18

TAILGATE MARKER LAMP - REMOVAL....8L-18

TAILPIPE - 5.9L DIESEL - INSPECTION....11-10

TAILPIPE - 5.9L DIESEL - INSTALLATION . . 11-11

TAILPIPE - 5.9L DIESEL - REMOVAL.....11-10

TAILPIPE - INSPECTION...............11-11

TAILPIPE - INSTALLATION..............11-11

TAILPIPE - REMOVAL.................11-11

TANK - DESCRIPTION, FUEL............14-17

TANK - OPERATION, FUEL..............14-17

TANK MODULE - DESCRIPTION, FUEL....14-63

TANK MODULE - INSTALLATION, FUEL....14-64

TANK MODULE - OPERATION, FUEL......14-63

TANK MODULE - REMOVAL, FUEL.......14-63

TAPPETS - DIAGNOSIS AND TESTING,

HYDRAULIC.........................9-210

TAPPETS - INSTALLATION, HYDRAULIC . . . 9-211

TAPPETS - REMOVAL, HYDRAULIC.......9-211

TASK MANAGER - DESCRIPTION.........25-1

TASK MANAGER - OPERATION...........25-5

TCM QUICK LEARN - STANDARD

PROCEDURE........................8E-23

TEMP INDICATOR - DESCRIPTION,

TRANS.............................8J-40

TEMP INDICATOR - OPERATION, TRANS

. . 8J-40

TEMP SENSOR - DESCRIPTION,

AMBIENT

..........................8M-10

TEMP SENSOR - OPERATION, AMBIENT

. . 8M-10

TEMPERATURE GAUGE - DESCRIPTION,

ENGINE

............................8J-24

TEMPERATURE GAUGE - OPERATION,

ENGINE

............................8J-24

TEMPERATURE SENSOR - DESCRIPTION,

BATTERY

...........................8F-21

TEMPERATURE SENSOR - DESCRIPTION,

ENGINE COOLANT

.....................7-38

TEMPERATURE SENSOR - DESCRIPTION,

EVAPORATOR

.......................24-22

TEMPERATURE SENSOR - DESCRIPTION,

INTAKE AIR

.........................14-30

TEMPERATURE SENSOR - DESCRIPTION,

TRANSMISSION

...............21-267,21-408

TEMPERATURE SENSOR - DIAGNOSIS

AND TESTING, AMBIENT

..............8M-10

TEMPERATURE SENSOR -

INSTALLATION, BATTERY

..............8F-21

TEMPERATURE SENSOR -

INSTALLATION, ENGINE COOLANT

........7-41

32 INDEXDR

Description Group-Page Description Group-Page Description Group-Page

Page 2622 of 2627

TRANSMISSION - NV5600 -

DISASSEMBLY, MANUAL...............21-91

TRANSMISSION - NV5600 -

INSPECTION, MANUAL...............21-106

TRANSMISSION - NV5600 -

INSTALLATION, MANUAL.............21-121

TRANSMISSION - NV5600 - OPERATION,

MANUAL...........................21-90

TRANSMISSION - NV5600 - REMOVAL,

MANUAL...........................21-90

TRANSMISSION - NV5600 - SPECIAL

TOOLS, MANUAL....................21-123

TRANSMISSION CLUTCH AND BAND

OPERATION - DIAGNOSIS AND

TESTING, AIR TESTING...............21-144

TRANSMISSION CLUTCH OPERATION -

DIAGNOSIS AND TESTING, AIR

CHECKING.........................21-317

TRANSMISSION CONTROL MODULE -

DESCRIPTION.......................8E-20

TRANSMISSION CONTROL MODULE -

OPERATION.........................8E-20

TRANSMISSION CONTROL RELAY -

DESCRIPTION......................21-405

TRANSMISSION CONTROL RELAY -

OPERATION........................21-405

TRANSMISSION CROSSMEMBER -

INSTALLATION.......................13-24

TRANSMISSION CROSSMEMBER -

REMOVAL..........................13-24

TRANSMISSION FILL - STANDARD

PROCEDURE.................21-204,21-368

TRANSMISSION FLUID - DESCRIPTION,

AUTOMATIC...........................0-4

TRANSMISSION FLUID - OPERATION,

AUTOMATIC...........................0-5

TRANSMISSION RANGE SENSOR -

DESCRIPTION................21-263,21-405

TRANSMISSION RANGE SENSOR -

INSTALLATION......................21-266

TRANSMISSION RANGE SENSOR -

OPERATION..................21-263,21-405

TRANSMISSION RANGE SENSOR -

REMOVAL.........................21-265

TRANSMISSION RANGE SENSOR (TRS) -

DIAGNOSIS AND TESTING............21-264

TRANSMISSION SHIFT INTERLOCK -

ADJUSTMENTS, BRAKE.........21-196,21-365

TRANSMISSION SHIFT INTERLOCK -

DIAGNOSIS AND TESTING, BRAKE.....21-196,

21-364

TRANSMISSION SHIFT INTERLOCK

SYSTEM - DESCRIPTION, BRAKE . 21-196,21-364

TRANSMISSION SHIFT INTERLOCK

SYSTEM - OPERATION, BRAKE . . . 21-196,21-364

TRANSMISSION SOLENOID/TRS

ASSEMBLY - DESCRIPTION............21-406

TRANSMISSION SOLENOID/TRS

ASSEMBLY - INSTALLATION...........21-408

TRANSMISSION SOLENOID/TRS

ASSEMBLY - OPERATION.............21-406

TRANSMISSION SOLENOID/TRS

ASSEMBLY - REMOVAL...............21-407

TRANSMISSION, SPECIAL TOOLS - RE

. . 21-191

TRANSMISSION, SPECIAL TOOLS - RFE

. . 21-359

TRANSMISSION, SPECIFICATIONS

......21-189,

21-358

TRANSMISSION TEMPERATURE SENSOR

- DESCRIPTION

...............21-267,21-408

TRANSMISSION TEMPERATURE SENSOR

- OPERATION

.................21-267,21-408

TRANSMITTER - DESCRIPTION,

UNIVERSAL

........................8M-11

TRANSMITTER - DIAGNOSIS AND

TESTING, REMOTE KEYLESS ENTRY

......8N-8

TRANSMITTER - DIAGNOSIS AND

TESTING, UNIVERSAL

................8M-11

TRANSMITTER - OPERATION,

UNIVERSAL

........................8M-11

TRANSMITTER - SPECIFICATIONS,

REMOTE KEYLESS ENTRY

..............8N-9

TRANSMITTER BATTERIES - STANDARD

PROCEDURE, RKE

.....................8N-8

TRANSMITTER CODES - STANDARD

PROCEDURE, ERASING

...............8M-12

TRANSMITTER CODES - STANDARD

PROCEDURE, SETTING

................8M-12TRANSMITTER CUSTOMER

PREFERENCES - STANDARD

PROCEDURE, RKE.....................8N-8

TRANSMITTER PROGRAMING -

STANDARD PROCEDURE, RKE...........8N-9

TRANSPONDER PROGRAMMING,

STANDARD PROCEDURE - SENTRY

KEY IMMOBILIZER SYSTEM.............8Q-4

TRAY - DESCRIPTION, BATTERY.........8F-17

TRAY - INSTALLATION, BATTERY........8F-18

TRAY - OPERATION, BATTERY..........8F-17

TRAY - REMOVAL, BATTERY............8F-17

TREAD WEAR INDICATORS - DIAGNOSIS

AND TESTING........................22-8

TRIM - INSTALLATION, B-PILLAR

LOWER............................23-64

TRIM - INSTALLATION, B-PILLAR UPPER . . 23-64

TRIM - INSTALLATION, COWL..........23-66

TRIM - INSTALLATION, C-PILLAR

LOWER............................23-67

TRIM - INSTALLATION, C-PILLAR UPPER . . 23-67

TRIM - INSTALLATION, REAR CAB BACK

PANEL.............................23-69

TRIM - REMOVAL, B-PILLAR LOWER.....23-63

TRIM - REMOVAL, B-PILLAR UPPER.....23-64

TRIM - REMOVAL, COWL..............23-66

TRIM - REMOVAL, C-PILLAR LOWER.....23-66

TRIM - REMOVAL, C-PILLAR UPPER.....23-67

TRIM - REMOVAL, REAR CAB BACK

PANEL.............................23-68

TRIM COVER - INSTALLATION, REAR

DOOR SILL.........................23-71

TRIM COVER - REMOVAL, REAR DOOR

SILL...............................23-71

TRIM PANEL - INSTALLATION......23-24,23-33

TRIM PANEL - REMOVAL.........23-24,23-33

TRIM/GRAB HANDLE - INSTALLATION,

A-PILLAR...........................23-63

TRIM/GRAB HANDLE - REMOVAL,

A-PILLAR...........................23-63

TRIP DEFINITION - DESCRIPTION.........25-4

TROUBLE CODES - DESCRIPTION,

DIAGNOSTIC.........................25-1

TUBE - DESCRIPTION, A/C ORIFICE......24-60

TUBE - DIAGNOSIS AND TESTING, A/C

ORIFICE............................24-61

TUBE / HOSE ASSEMBLY -

INSTALLATION, REAR..................5-13

TUBE / HOSE ASSEMBLY - REMOVAL,

REAR...............................5-12

TUBE - OPERATION, A/C ORIFICE........24-60

TUBING AND FITTINGS - STANDARD

PROCEDURE, HANDLING..............24-45

TURBO DIESEL - MAINTENANCE

SCHEDULES, 24-VALVE CUMMINS........0-12

TURBOCHARGER - CLEANING..........11-15

TURBOCHARGER - DESCRIPTION........11-12

TURBOCHARGER - INSPECTION.........11-15

TURBOCHARGER - INSTALLATION.......11-15

TURBOCHARGER - OPERATION.........11-13

TURBOCHARGER - REMOVAL...........11-14

TURBOCHARGER BOOST PRESSURE -

DIAGNOSIS AND TESTING.............11-11

TURN SIGNAL INDICATOR -

DESCRIPTION.......................8J-40

TURN SIGNAL INDICATOR - OPERATION . . 8J-41

TURN SIGNAL SYSTEM - DESCRIPTION . . . 8L-18

TURN SIGNAL SYSTEM - OPERATION....8L-18

TURNING LOOP ADJUSTER -

INSTALLATION, SEAT BELT.............8O-55

TURNING LOOP ADJUSTER - REMOVAL,

SEAT BELT .........................8O-55

UNDER SEAT STORAGE BIN -

INSTALLATION.......................23-80

UNDER SEAT STORAGE BIN - REMOVAL . . 23-80

UNDER SEAT STORAGE BIN COVERING -

INSTALLATION.......................23-80

UNDER SEAT STORAGE BIN COVERING -

REMOVAL..........................23-80

UNDER SEAT STORAGE BIN LATCH -

INSTALLATION

.......................23-80

UNDER SEAT STORAGE BIN LATCH -

REMOVAL

..........................23-80

UNDER SEAT STORAGE BIN LID -

INSTALLATION

.......................23-80

UNDER SEAT STORAGE BIN LID -

REMOVAL

..........................23-80

UNDERHOOD LAMP - INSTALLATION

.....8L-25UNDERHOOD LAMP - REMOVAL.........8L-25

UNDERHOOD LAMP UNIT -

INSTALLATION.......................8L-25

UNDERHOOD LAMP UNIT - REMOVAL....8L-25

UNIT - ADJUSTMENTS, HEADLAMP......8L-16

UNIT - ASSEMBLY, OVERDRIVE........21-226

UNIT - CLEANING, OVERDRIVE.........21-225

UNIT - DISASSEMBLY, OVERDRIVE......21-218

UNIT - INSPECTION, OVERDRIVE.......21-225

UNIT - INSTALLATION, CENTER HIGH

MOUNTED STOP LAMP................8L-11

UNIT - INSTALLATION, HEADLAMP.......8L-15

UNIT - INSTALLATION, LICENSE PLATE

LAMP..............................8L-17

UNIT - INSTALLATION, OVERDRIVE.....21-235

UNIT - INSTALLATION, UNDERHOOD

LAMP..............................8L-25

UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP LAMP................8L-11

UNIT - REMOVAL, HEADLAMP..........8L-15

UNIT - REMOVAL, LICENSE PLATE LAMP . . 8L-17

UNIT - REMOVAL, OVERDRIVE.........21-218

UNIT - REMOVAL, UNDERHOOD LAMP . . . 8L-25

UNIT / SENSOR - DESCRIPTION, FUEL

LEVEL SENDING.................14-57,14-6

UNIT / SENSOR - INSTALLATION, FUEL

LEVEL SENDING......................14-7

UNIT / SENSOR - OPERATION, FUEL

LEVEL SENDING.................14-57,14-6

UNIT / SENSOR - REMOVAL, FUEL

LEVEL SENDING......................14-7

UNIVERSAL JOINTS - ASSEMBLY,

DOUBLE CARDAN.....................3-17

UNIVERSAL JOINTS - DISASSEMBLY,

DOUBLE CARDAN.....................3-16

UNIVERSAL TRANSMITTER -

DESCRIPTION.......................8M-11

UNIVERSAL TRANSMITTER - DIAGNOSIS

AND TESTING.......................8M-11

UNIVERSAL TRANSMITTER - OPERATION . 8M-11

UPPER BALL JOINT - DIAGNOSIS AND

TESTING........................2-27,2-36

UPPER BALL JOINT - INSTALLATION......2-36

UPPER BALL JOINT - REMOVAL..........2-36

UPPER CONTROL ARM - INSTALLATION . . . 2-28

UPPER CONTROL ARM - REMOVAL.......2-28

UPPER RADIATOR CROSSMEMBER -

INSTALLATION.......................23-42

UPPER RADIATOR CROSSMEMBER -

REMOVAL..........................23-42

UPPER STEERING COUPLING -

INSTALLATION.......................19-13

UPPER STEERING COUPLING -

REMOVAL..........................19-13

UPPER TRIM - INSTALLATION, B-PILLAR . . 23-64

UPPER TRIM - INSTALLATION, C-PILLAR . . 23-67

UPPER TRIM - REMOVAL, B-PILLAR.....23-64

UPPER TRIM - REMOVAL, C-PILLAR.....23-67

UPSHIFT INDICATOR - DESCRIPTION.....8J-41

UPSHIFT INDICATOR - OPERATION.......8J-42

VAC LEAK DETECTION ASSY -

DESCRIPTION, NATURAL..............25-23

VAC LEAK DETECTION ASSY -

INSTALLATION, NATURAL..............25-25

VAC LEAK DETECTION ASSY -

OPERATION, NATURAL................25-23

VAC LEAK DETECTION ASSY -

REMOVAL, NATURAL..................25-24

VACUUM LINES - DESCRIPTION.........25-22

VACUUM RESERVOIR - DESCRIPTION.....8P-9

VACUUM RESERVOIR - DIAGNOSIS AND

TESTING............................8P-9

VACUUM RESERVOIR - INSTALLATION . . . 8P-10

VACUUM RESERVOIR - OPERATION.......8P-9

VACUUM RESERVOIR - REMOVAL........8P-9

VACUUM SUPPLY TEST - DIAGNOSIS

AND TESTING........................8P-2

VALVE - 3.7L V-6/ 4.7L V-8 - DIAGNOSIS

AND TESTING, PCV...................25-20

VALVE - CLEANING, OIL PRESSURE

RELIEF

.............................9-294

VALVE - DESCRIPTION, CASCADE

OVERFLOW

.........................14-66

VALVE - DESCRIPTION, CHECK

..........8R-7

VALVE - DESCRIPTION, FUEL PRESSURE

LIMITING

...........................14-61

VALVE - DESCRIPTION, HIGH PRESSURE

RELIEF

.............................24-48

DRINDEX 35

Description Group-Page Description Group-Page Description Group-Page