starter DODGE RAM 1500 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 1616 of 2627

STANDARD PROCEDURE

STANDARD PROCEDURES - WATER DRAINING

AT FUEL FILTER

Refer to Fuel Filter/Water Separator removal/in-

stallation for procedures.

STANDARD PROCEDURES - CLEANING FUEL

SYSTEM PARTS

CAUTION: Cleanliness cannot be overemphasized

when handling or replacing diesel fuel system com-

ponents. This especially includes the fuel injectors,

high-pressure fuel lines and fuel injection pump.

Very tight tolerances are used with these parts. Dirt

contamination could cause rapid part wear and pos-

sible plugging of fuel injector nozzle tip holes. This

in turn could lead to possible engine misfire.

Always wash/clean any fuel system component

thoroughly before disassembly and then air dry.

Cap or cover any open part after disassembly.

Before assembly, examine each part for dirt, grease

or other contaminants and clean if necessary. When

installing new parts, lubricate them with clean

engine oil or clean diesel fuel only.

STANDARD PROCEDURE - FUEL SYSTEM

PRIMING

A certain amount of air becomes trapped in the

fuel system when fuel system components on the

supply and/or high-pressure side are serviced or

replaced. Fuel system priming is accomplished using

the electric fuel transfer (lift) pump.

Servicing or replacing fuel system components will

not require fuel system priming.

The fuel transfer (lift) pump is self-priming: When

the key is first turned on (without cranking engine),

the pump operates for approximately 1 to 2 second

and then shuts off. The pump will also operate for up

to 25 seconds after the starter is quickly engaged,

and then disengaged without allowing the engine to

start. The pump shuts off immediately if the key is

on and the engine stops running.

(1) Turn key to CRANK position and quickly

release key to ON position before engine starts. This

will operate fuel transfer pump for approximately 25

seconds.

(2) Crank engine. If the engine does not start after

25 seconds, turn key OFF. Repeat previous step until

engine starts.

(3) Fuel system priming is now completed.

(4) Attempt to start engine. If engine will not

start, proceed to following steps.When engine does

start, it may run erratically and be noisy for a

few minutes. This is a normal condition.

CAUTION: Do not engage the starter motor for more

than 30 seconds at a time. Allow two minutes

between cranking intervals.

(5) Perform previous fuel priming procedure steps

using fuel transfer pump. Be sure fuel is present at

fuel tank.

(6) Crank the engine for 30 seconds at a time to

allow fuel system to prime.

WARNING: THE FUEL INJECTION PUMP SUPPLIES

EXTREMELY HIGH FUEL PRESSURE TO EACH INDI-

VIDUAL INJECTOR THROUGH THE HIGH-PRES-

SURE LINES. FUEL UNDER THIS AMOUNT OF

PRESSURE CAN PENETRATE THE SKIN AND

CAUSE PERSONAL INJURY. WEAR SAFETY GOG-

GLES AND ADEQUATE PROTECTIVE CLOTHING.

DO NOT LOOSEN FUEL FITTINGS WHILE ENGINE

IS RUNNING.

WARNING: ENGINE MAY START WHILE CRANKING

STARTER MOTOR.

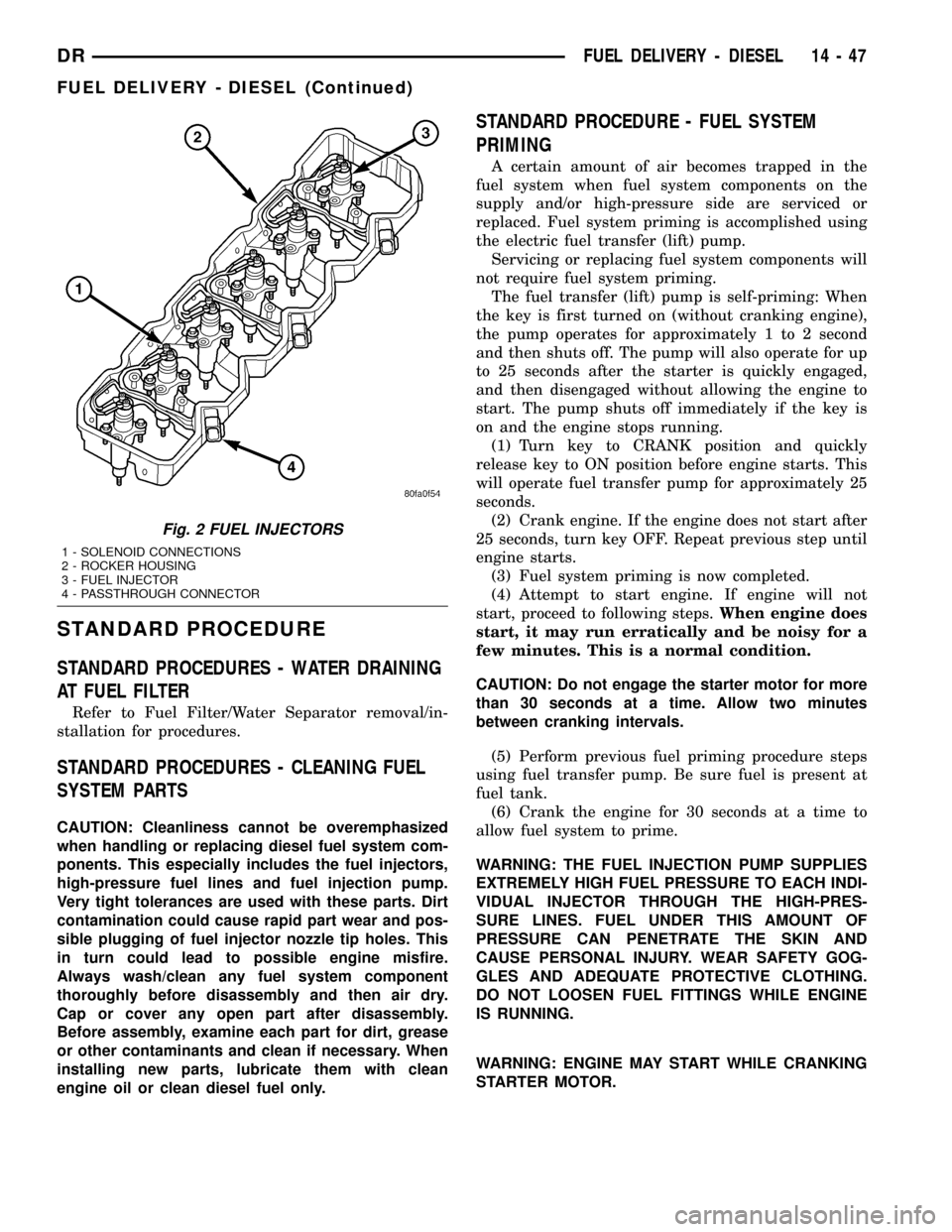

Fig. 2 FUEL INJECTORS

1 - SOLENOID CONNECTIONS

2 - ROCKER HOUSING

3 - FUEL INJECTOR

4 - PASSTHROUGH CONNECTOR

DRFUEL DELIVERY - DIESEL 14 - 47

FUEL DELIVERY - DIESEL (Continued)

Page 1619 of 2627

FUEL FILTER / WATER

SEPARATOR

DESCRIPTION

The fuel filter/water separator assembly is located

on left side of engine above the starter motor. The

assembly also includes the fuel heater, Water-In-Fuel

(WIF) sensor, and fuel transfer pump.

OPERATION

The fuel filter/water separator protects the fuel

injection pump by removing water and contaminants

from the fuel. The construction of the filter/separator

allows fuel to pass through it, but helps prevent

moisture (water) from doing so. Moisture collects at

the bottom of the canister.

Refer to the maintenance schedules in the owners

manual for the recommended fuel filter replacement

intervals.

For draining of water from canister, refer to Fuel

Filter/Water Separator Removal/Installation section.

A Water-In-Fuel (WIF) sensor is attached to the

side of fuel filter housing. Refer to Water-In-Fuel

Sensor Description/Operation.

The fuel heater is installed into the top of the fil-

ter/separator housing. Refer to Fuel Heater Descrip-

tion/Operation.

REMOVAL

Refer to maintenance schedules in this manual, or

the owners manual for recommended fuel filter

replacement intervals.

Draining water from fuel filter/water separa-

tor housing:

The housing drain valve (Fig. 3) serves two pur-

poses. One is topartiallythe drain filter housing of

excess water. The other is tocompletelythe drain

housing for fuel filter, drain valve, heater element, ,

water-in-fuel sensor replacement or transfer pump

replacement.

The filter housing should be partially drained

whenever the water-in-fuel warning lamp remains

illuminated. (Note that lamp will be illuminated for

approximately two seconds when ignition key is ini-

tially placed in ON position for a bulb check).(1) A drain hose (Fig. 3) is located at the bottom of

drain valve. Place drain pan under drain hose.

(2)With engine not running,rotate drain valve

handle counter-clockwise (rearward) to OPEN

(DRAIN) position. Hold drain valve open until all

water and contaminants have been removed and

clean fuel exits.

(3) If drain valve, fuel heater element or Water-In-

Fuel (WIF) sensor is being replaced, drain housing

completely. Dispose of mixture in drain pan according

to applicable regulations.

(4) After draining operation, rotate valve handle

clockwise (forward) to the CLOSE position.

(5)Fuel Filter Replacement:The fuel filter is

located inside of the fuel filter housing.

(a) Clean all debris from around canister.

(b) Remove filter lid (Fig. 4) using a socket.

Attach socket to large hex on top of lid (Fig. 4).

Rotate counter-clockwise for removal. Remove

o-ring. Discard o-ring.

(c) Remove filter element by twisting element

sideways from filter lid.

(6)Water-In-Fuel (WIF) Sensor Replacement:

The WIF sensor is located on the side of the fuel fil-

ter housing (Fig. 3).

(a) Disconnect electrical connector at sensor.

(b) Clean area around sensor.

(c) Remove sensor by rotating counter-clockwise.

(d) Check condition of sensor o-ring. Replace if

damaged.

(7)Fuel Heater Element Replacement:The

heater element is located in the fuel filter housing

(Fig. 3).

(a) Remove fuel filter. See previous steps.

(b) Disconnect electrical connector.

(c) Remove two T-15 Torx head mounting screws

from fuel heater element.

(d) Remove fuel heater.

(8)Drain Valve Replacement:The drain valve

assembly is located on the side of the fuel filter hous-

ing (Fig. 3).

(a) Disconnect drain hose from the fuel drain

valve.

(b) Remove 4 drain valve mounting screws (T-15

Torx head).

(c) Remove drain valve from filter housing.

INSTALLATION

Refer to maintenance schedules for recommended

fuel filter replacement intervals.

(1) Thoroughly clean inside of filter housing, filter

cap and all related components.

(2)Fuel Filter:

(a)The engine has a self-priming low-pres-

sure fuel system. Refer to Standard Proce-

dures-Fuel System Priming.

ENGINE ROTATING (BARRING) TOOL - #7471B

(ALSO PART OF KIT #6860)

14 - 50 FUEL DELIVERY - DIESELDR

FUEL DELIVERY - DIESEL (Continued)

Page 1633 of 2627

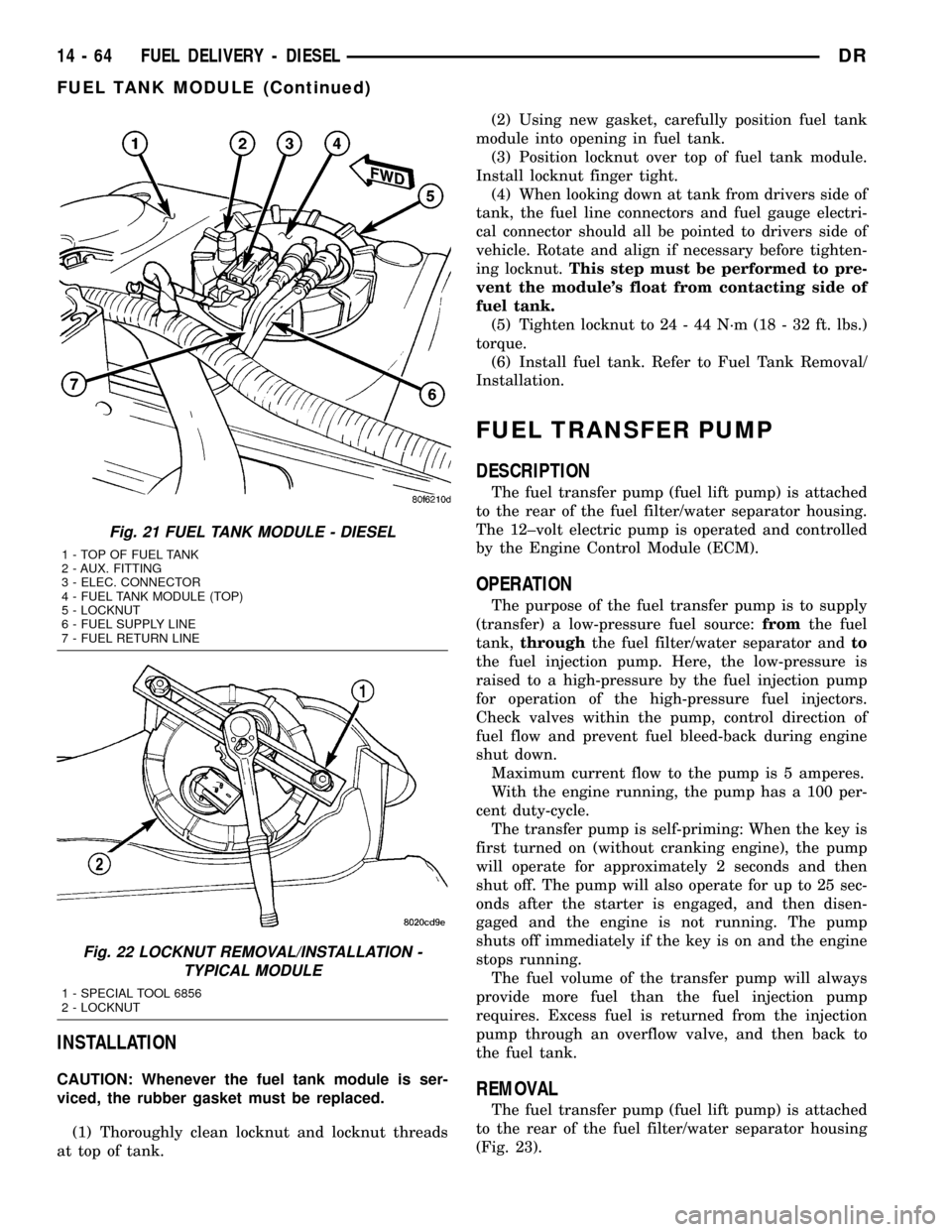

INSTALLATION

CAUTION: Whenever the fuel tank module is ser-

viced, the rubber gasket must be replaced.

(1) Thoroughly clean locknut and locknut threads

at top of tank.(2) Using new gasket, carefully position fuel tank

module into opening in fuel tank.

(3) Position locknut over top of fuel tank module.

Install locknut finger tight.

(4) When looking down at tank from drivers side of

tank, the fuel line connectors and fuel gauge electri-

cal connector should all be pointed to drivers side of

vehicle. Rotate and align if necessary before tighten-

ing locknut.This step must be performed to pre-

vent the module's float from contacting side of

fuel tank.

(5) Tighten locknut to 24 - 44 N´m (18 - 32 ft. lbs.)

torque.

(6) Install fuel tank. Refer to Fuel Tank Removal/

Installation.

FUEL TRANSFER PUMP

DESCRIPTION

The fuel transfer pump (fuel lift pump) is attached

to the rear of the fuel filter/water separator housing.

The 12±volt electric pump is operated and controlled

by the Engine Control Module (ECM).

OPERATION

The purpose of the fuel transfer pump is to supply

(transfer) a low-pressure fuel source:fromthe fuel

tank,throughthe fuel filter/water separator andto

the fuel injection pump. Here, the low-pressure is

raised to a high-pressure by the fuel injection pump

for operation of the high-pressure fuel injectors.

Check valves within the pump, control direction of

fuel flow and prevent fuel bleed-back during engine

shut down.

Maximum current flow to the pump is 5 amperes.

With the engine running, the pump has a 100 per-

cent duty-cycle.

The transfer pump is self-priming: When the key is

first turned on (without cranking engine), the pump

will operate for approximately 2 seconds and then

shut off. The pump will also operate for up to 25 sec-

onds after the starter is engaged, and then disen-

gaged and the engine is not running. The pump

shuts off immediately if the key is on and the engine

stops running.

The fuel volume of the transfer pump will always

provide more fuel than the fuel injection pump

requires. Excess fuel is returned from the injection

pump through an overflow valve, and then back to

the fuel tank.

REMOVAL

The fuel transfer pump (fuel lift pump) is attached

to the rear of the fuel filter/water separator housing

(Fig. 23).

Fig. 21 FUEL TANK MODULE - DIESEL

1 - TOP OF FUEL TANK

2 - AUX. FITTING

3 - ELEC. CONNECTOR

4 - FUEL TANK MODULE (TOP)

5 - LOCKNUT

6 - FUEL SUPPLY LINE

7 - FUEL RETURN LINE

Fig. 22 LOCKNUT REMOVAL/INSTALLATION -

TYPICAL MODULE

1 - SPECIAL TOOL 6856

2 - LOCKNUT

14 - 64 FUEL DELIVERY - DIESELDR

FUEL TANK MODULE (Continued)

Page 1707 of 2627

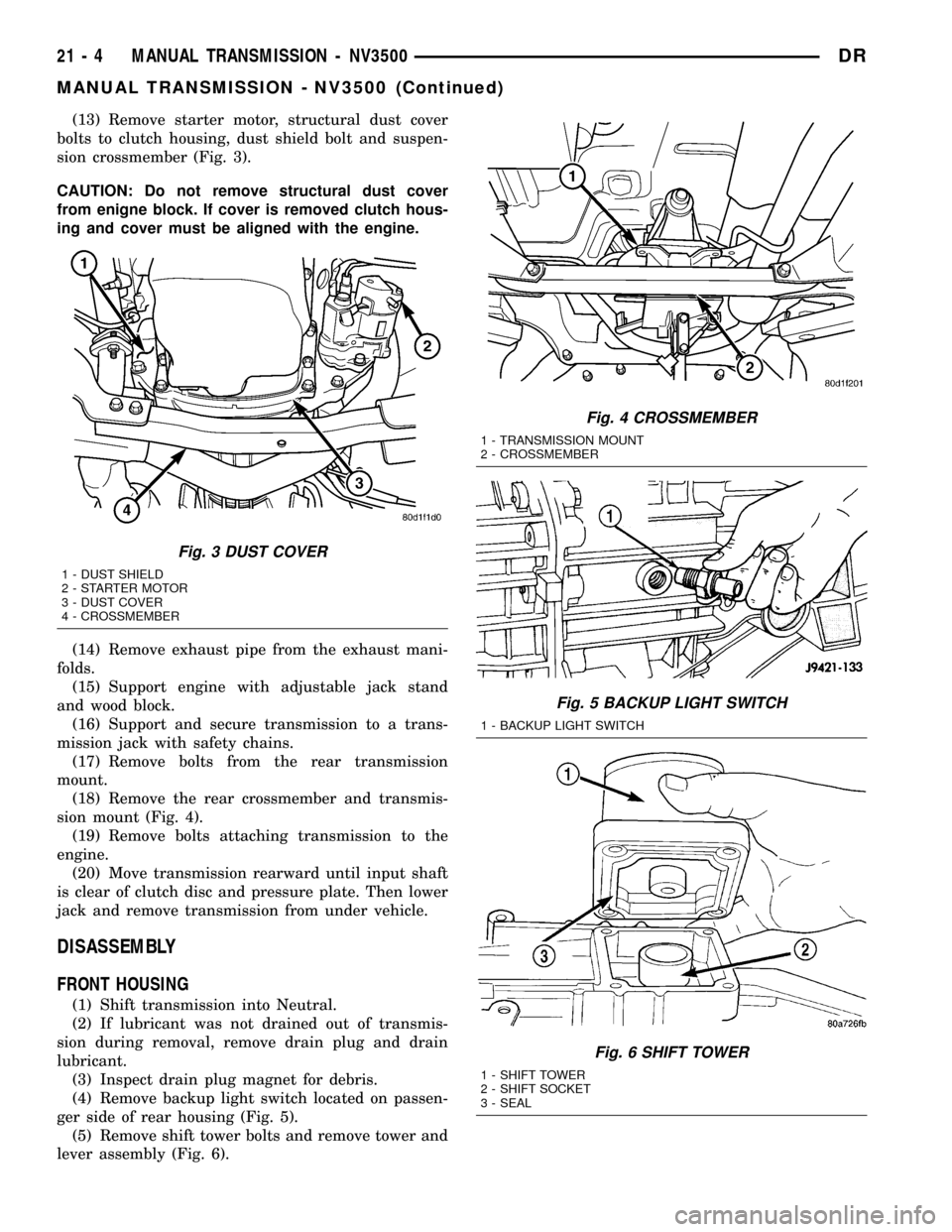

(13) Remove starter motor, structural dust cover

bolts to clutch housing, dust shield bolt and suspen-

sion crossmember (Fig. 3).

CAUTION: Do not remove structural dust cover

from enigne block. If cover is removed clutch hous-

ing and cover must be aligned with the engine.

(14) Remove exhaust pipe from the exhaust mani-

folds.

(15) Support engine with adjustable jack stand

and wood block.

(16) Support and secure transmission to a trans-

mission jack with safety chains.

(17) Remove bolts from the rear transmission

mount.

(18) Remove the rear crossmember and transmis-

sion mount (Fig. 4).

(19) Remove bolts attaching transmission to the

engine.

(20) Move transmission rearward until input shaft

is clear of clutch disc and pressure plate. Then lower

jack and remove transmission from under vehicle.

DISASSEMBLY

FRONT HOUSING

(1) Shift transmission into Neutral.

(2) If lubricant was not drained out of transmis-

sion during removal, remove drain plug and drain

lubricant.

(3) Inspect drain plug magnet for debris.

(4) Remove backup light switch located on passen-

ger side of rear housing (Fig. 5).

(5) Remove shift tower bolts and remove tower and

lever assembly (Fig. 6).

Fig. 3 DUST COVER

1 - DUST SHIELD

2 - STARTER MOTOR

3 - DUST COVER

4 - CROSSMEMBER

Fig. 4 CROSSMEMBER

1 - TRANSMISSION MOUNT

2 - CROSSMEMBER

Fig. 5 BACKUP LIGHT SWITCH

1 - BACKUP LIGHT SWITCH

Fig. 6 SHIFT TOWER

1 - SHIFT TOWER

2 - SHIFT SOCKET

3 - SEAL

21 - 4 MANUAL TRANSMISSION - NV3500DR

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1742 of 2627

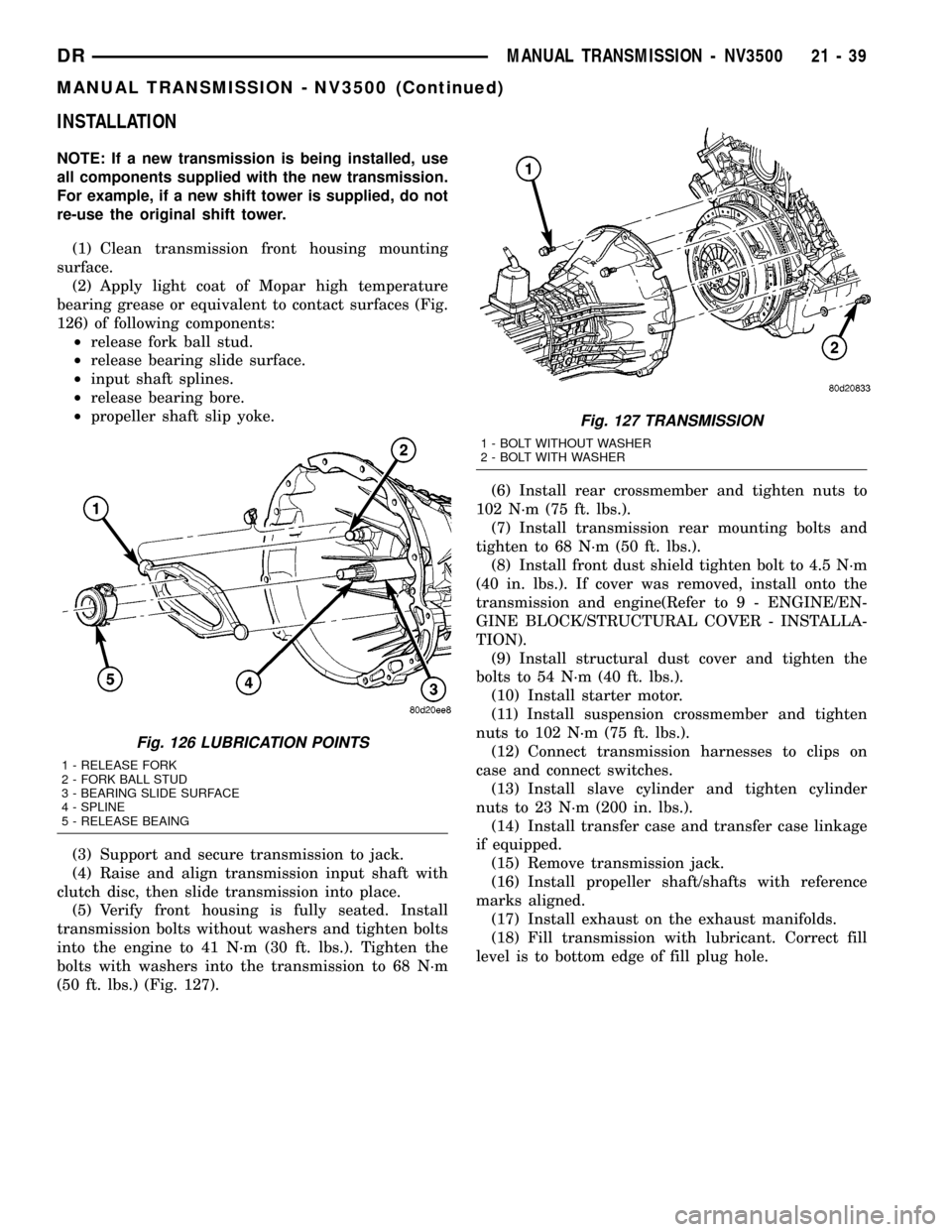

INSTALLATION

NOTE: If a new transmission is being installed, use

all components supplied with the new transmission.

For example, if a new shift tower is supplied, do not

re-use the original shift tower.

(1) Clean transmission front housing mounting

surface.

(2) Apply light coat of Mopar high temperature

bearing grease or equivalent to contact surfaces (Fig.

126) of following components:

²release fork ball stud.

²release bearing slide surface.

²input shaft splines.

²release bearing bore.

²propeller shaft slip yoke.

(3) Support and secure transmission to jack.

(4) Raise and align transmission input shaft with

clutch disc, then slide transmission into place.

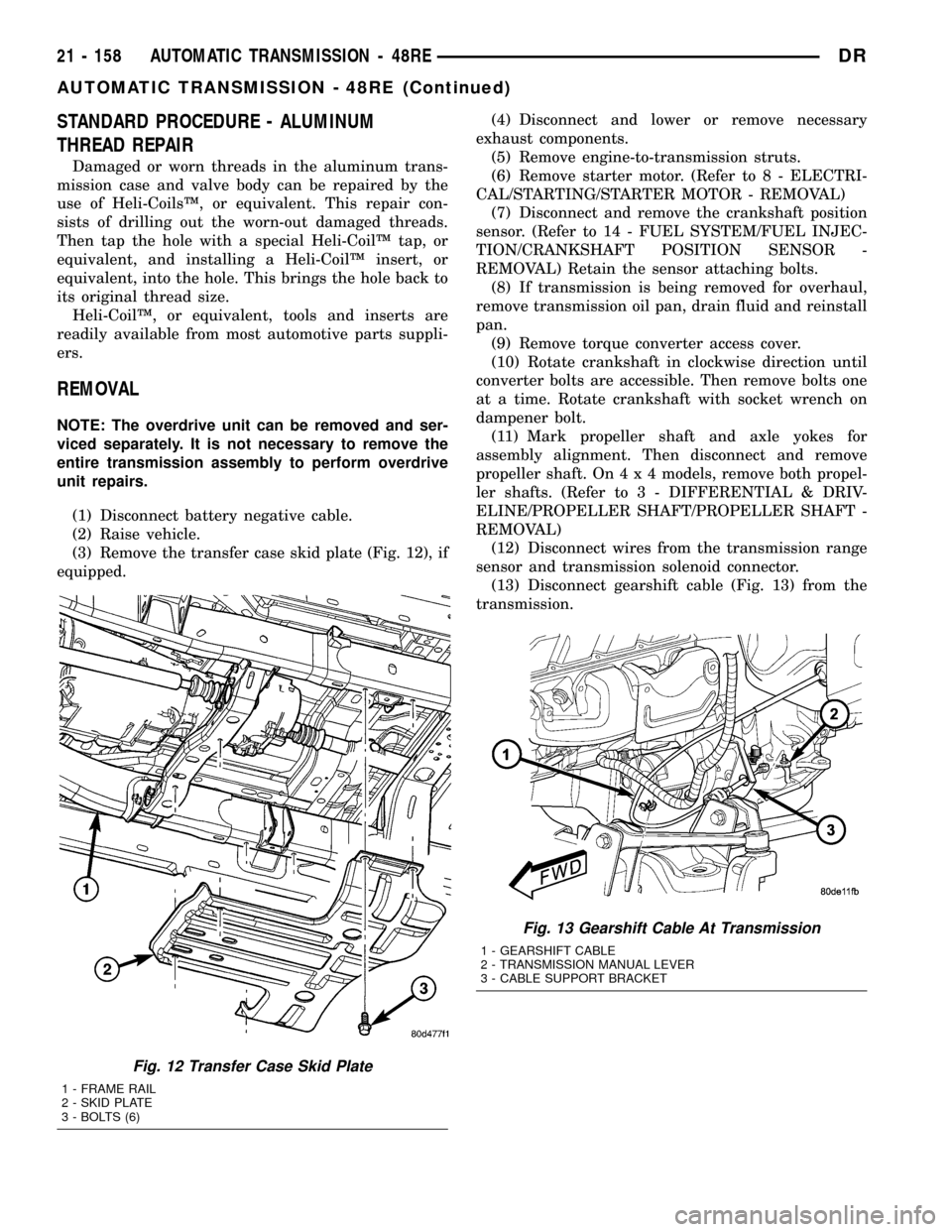

(5) Verify front housing is fully seated. Install

transmission bolts without washers and tighten bolts

into the engine to 41 N´m (30 ft. lbs.). Tighten the

bolts with washers into the transmission to 68 N´m

(50 ft. lbs.) (Fig. 127).(6) Install rear crossmember and tighten nuts to

102 N´m (75 ft. lbs.).

(7) Install transmission rear mounting bolts and

tighten to 68 N´m (50 ft. lbs.).

(8) Install front dust shield tighten bolt to 4.5 N´m

(40 in. lbs.). If cover was removed, install onto the

transmission and engine(Refer to 9 - ENGINE/EN-

GINE BLOCK/STRUCTURAL COVER - INSTALLA-

TION).

(9) Install structural dust cover and tighten the

bolts to 54 N´m (40 ft. lbs.).

(10) Install starter motor.

(11) Install suspension crossmember and tighten

nuts to 102 N´m (75 ft. lbs.).

(12) Connect transmission harnesses to clips on

case and connect switches.

(13) Install slave cylinder and tighten cylinder

nuts to 23 N´m (200 in. lbs.).

(14) Install transfer case and transfer case linkage

if equipped.

(15) Remove transmission jack.

(16) Install propeller shaft/shafts with reference

marks aligned.

(17) Install exhaust on the exhaust manifolds.

(18) Fill transmission with lubricant. Correct fill

level is to bottom edge of fill plug hole.

Fig. 126 LUBRICATION POINTS

1 - RELEASE FORK

2 - FORK BALL STUD

3 - BEARING SLIDE SURFACE

4 - SPLINE

5 - RELEASE BEAING

Fig. 127 TRANSMISSION

1 - BOLT WITHOUT WASHER

2 - BOLT WITH WASHER

DRMANUAL TRANSMISSION - NV3500 21 - 39

MANUAL TRANSMISSION - NV3500 (Continued)

Page 1861 of 2627

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum trans-

mission case and valve body can be repaired by the

use of Heli-CoilsŸ, or equivalent. This repair con-

sists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-CoilŸ tap, or

equivalent, and installing a Heli-CoilŸ insert, or

equivalent, into the hole. This brings the hole back to

its original thread size.

Heli-CoilŸ, or equivalent, tools and inserts are

readily available from most automotive parts suppli-

ers.

REMOVAL

NOTE: The overdrive unit can be removed and ser-

viced separately. It is not necessary to remove the

entire transmission assembly to perform overdrive

unit repairs.

(1) Disconnect battery negative cable.

(2) Raise vehicle.

(3) Remove the transfer case skid plate (Fig. 12), if

equipped.(4) Disconnect and lower or remove necessary

exhaust components.

(5) Remove engine-to-transmission struts.

(6) Remove starter motor. (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

(7) Disconnect and remove the crankshaft position

sensor. (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION/CRANKSHAFT POSITION SENSOR -

REMOVAL) Retain the sensor attaching bolts.

(8) If transmission is being removed for overhaul,

remove transmission oil pan, drain fluid and reinstall

pan.

(9) Remove torque converter access cover.

(10) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.

(11) Mark propeller shaft and axle yokes for

assembly alignment. Then disconnect and remove

propeller shaft. On4x4models, remove both propel-

ler shafts. (Refer to 3 - DIFFERENTIAL & DRIV-

ELINE/PROPELLER SHAFT/PROPELLER SHAFT -

REMOVAL)

(12) Disconnect wires from the transmission range

sensor and transmission solenoid connector.

(13) Disconnect gearshift cable (Fig. 13) from the

transmission.

Fig. 12 Transfer Case Skid Plate

1 - FRAME RAIL

2 - SKID PLATE

3 - BOLTS (6)

Fig. 13 Gearshift Cable At Transmission

1 - GEARSHIFT CABLE

2 - TRANSMISSION MANUAL LEVER

3 - CABLE SUPPORT BRACKET

21 - 158 AUTOMATIC TRANSMISSION - 48REDR

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1878 of 2627

(13) Install bolts attaching converter housing to

engine.

(14) Install rear support.

(15) Install the rear transmission crossmember.

(16) Lower transmission onto crossmember and

install bolts attaching transmission mount to cross-

member.

(17) Remove engine support fixture.

(18) Install the transfer case, if equipped.

(19) Install crankshaft position sensor. (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/CRANKSHAFT

POSITION SENSOR - INSTALLATION)

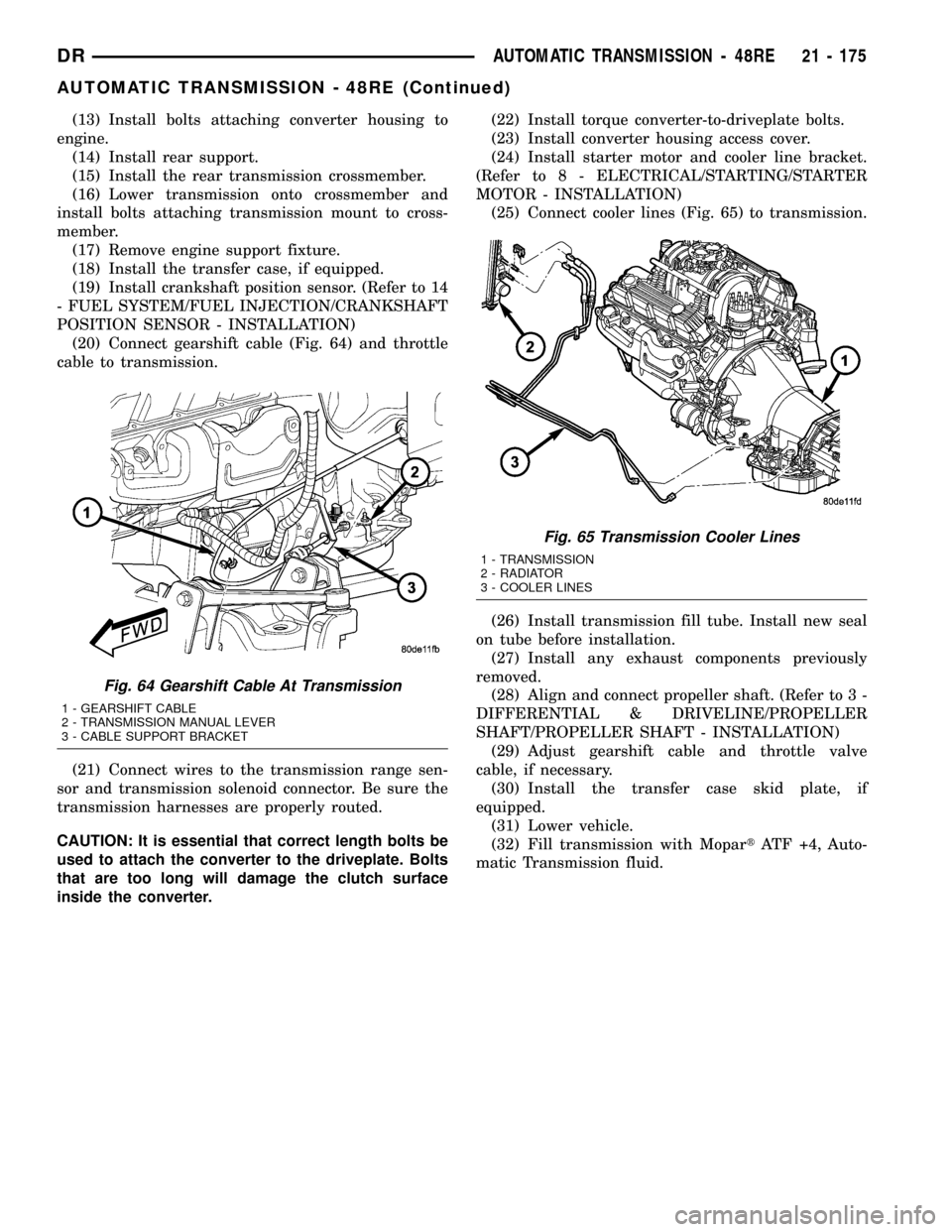

(20) Connect gearshift cable (Fig. 64) and throttle

cable to transmission.

(21) Connect wires to the transmission range sen-

sor and transmission solenoid connector. Be sure the

transmission harnesses are properly routed.

CAUTION: It is essential that correct length bolts be

used to attach the converter to the driveplate. Bolts

that are too long will damage the clutch surface

inside the converter.(22) Install torque converter-to-driveplate bolts.

(23) Install converter housing access cover.

(24) Install starter motor and cooler line bracket.

(Refer to 8 - ELECTRICAL/STARTING/STARTER

MOTOR - INSTALLATION)

(25) Connect cooler lines (Fig. 65) to transmission.

(26) Install transmission fill tube. Install new seal

on tube before installation.

(27) Install any exhaust components previously

removed.

(28) Align and connect propeller shaft. (Refer to 3 -

DIFFERENTIAL & DRIVELINE/PROPELLER

SHAFT/PROPELLER SHAFT - INSTALLATION)

(29) Adjust gearshift cable and throttle valve

cable, if necessary.

(30) Install the transfer case skid plate, if

equipped.

(31) Lower vehicle.

(32) Fill transmission with MopartATF +4, Auto-

matic Transmission fluid.

Fig. 64 Gearshift Cable At Transmission

1 - GEARSHIFT CABLE

2 - TRANSMISSION MANUAL LEVER

3 - CABLE SUPPORT BRACKET

Fig. 65 Transmission Cooler Lines

1 - TRANSMISSION

2 - RADIATOR

3 - COOLER LINES

DRAUTOMATIC TRANSMISSION - 48RE 21 - 175

AUTOMATIC TRANSMISSION - 48RE (Continued)

Page 1966 of 2627

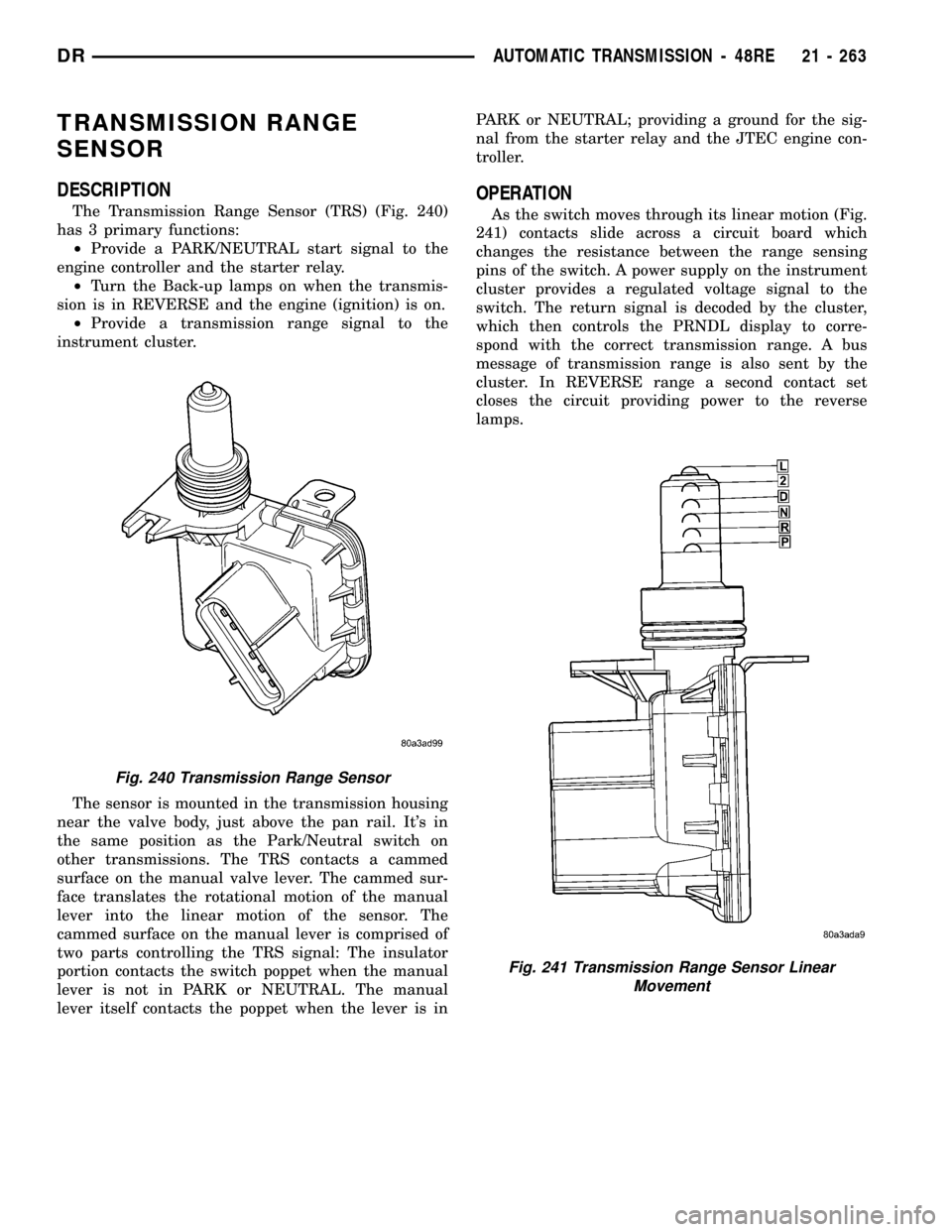

TRANSMISSION RANGE

SENSOR

DESCRIPTION

The Transmission Range Sensor (TRS) (Fig. 240)

has 3 primary functions:

²Provide a PARK/NEUTRAL start signal to the

engine controller and the starter relay.

²Turn the Back-up lamps on when the transmis-

sion is in REVERSE and the engine (ignition) is on.

²Provide a transmission range signal to the

instrument cluster.

The sensor is mounted in the transmission housing

near the valve body, just above the pan rail. It's in

the same position as the Park/Neutral switch on

other transmissions. The TRS contacts a cammed

surface on the manual valve lever. The cammed sur-

face translates the rotational motion of the manual

lever into the linear motion of the sensor. The

cammed surface on the manual lever is comprised of

two parts controlling the TRS signal: The insulator

portion contacts the switch poppet when the manual

lever is not in PARK or NEUTRAL. The manual

lever itself contacts the poppet when the lever is inPARK or NEUTRAL; providing a ground for the sig-

nal from the starter relay and the JTEC engine con-

troller.

OPERATION

As the switch moves through its linear motion (Fig.

241) contacts slide across a circuit board which

changes the resistance between the range sensing

pins of the switch. A power supply on the instrument

cluster provides a regulated voltage signal to the

switch. The return signal is decoded by the cluster,

which then controls the PRNDL display to corre-

spond with the correct transmission range. A bus

message of transmission range is also sent by the

cluster. In REVERSE range a second contact set

closes the circuit providing power to the reverse

lamps.

Fig. 240 Transmission Range Sensor

Fig. 241 Transmission Range Sensor Linear

Movement

DRAUTOMATIC TRANSMISSION - 48RE 21 - 263

Page 2022 of 2627

(10) Remove the starter motor.

(11) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.

(12) Disengage the output speed sensor connector

from the output speed sensor (Fig. 9).

(13) Disengage the input speed sensor connector

from the input speed sensor (Fig. 10).(14) Disengage the transmission solenoid/TRS

assembly connector from the transmission solenoid/

TRS assembly (Fig. 11).

(15) Disengage the line pressure sensor connector

from the line pressure sensor (Fig. 12).

Fig. 9 Disconnect Output Speed Sensor

1 - TRANSMISSION

2 - OUTPUT SPEED SENSOR

Fig. 10 Disconnect Input Speed Sensor

1 - TRANSMISSION

2 - INPUT SPEED SENSOR

Fig. 11 Disconnect Transmission Solenoid/TRS

Assembly

1 - TRANSMISSION

2 - TRANSMISSION SOLENOID/TRS ASSEMBLY

Fig. 12 Disconnect Line Pressure Sensor

1 - TRANSMISSION

2 - LINE PRESSURE SENSOR

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 319

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2039 of 2627

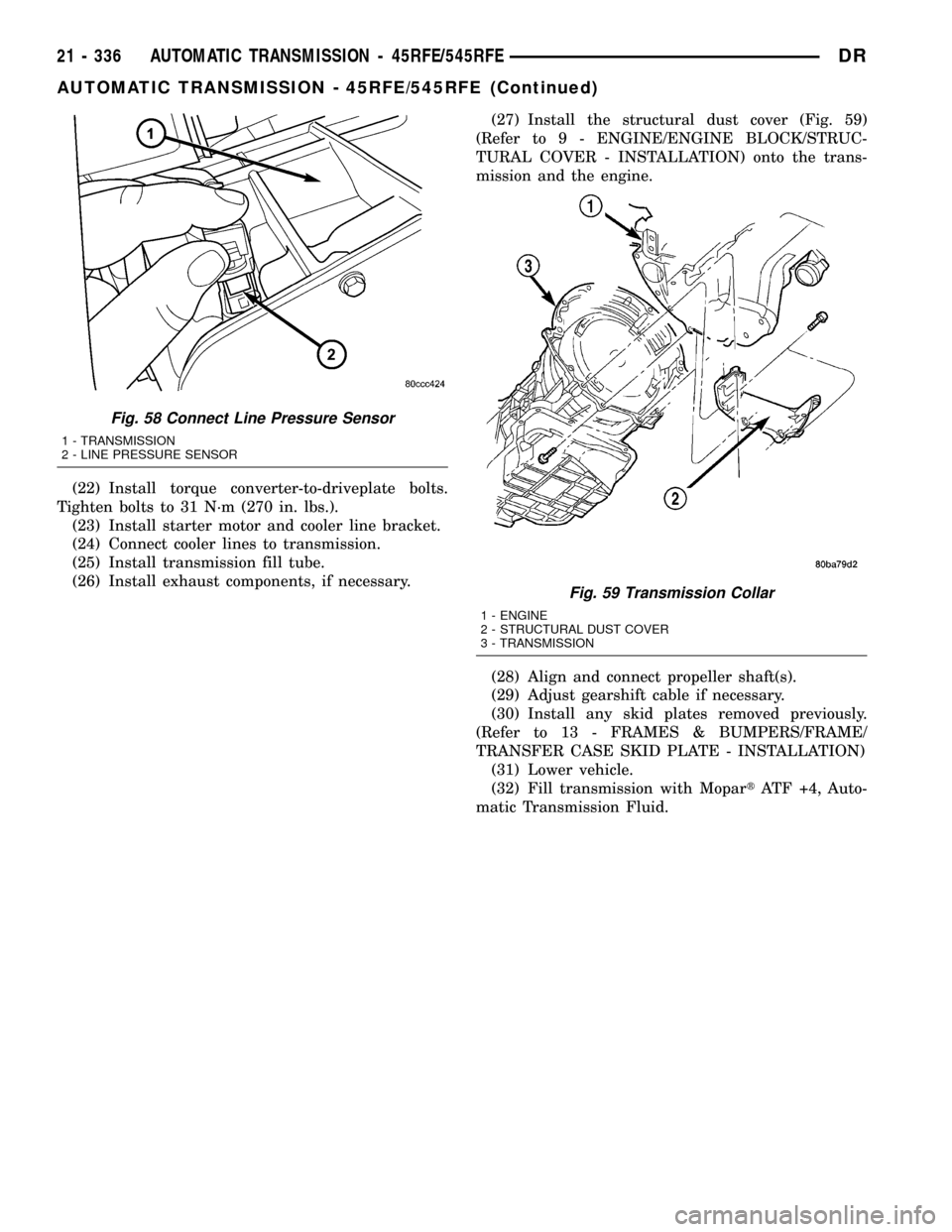

(22) Install torque converter-to-driveplate bolts.

Tighten bolts to 31 N´m (270 in. lbs.).

(23) Install starter motor and cooler line bracket.

(24) Connect cooler lines to transmission.

(25) Install transmission fill tube.

(26) Install exhaust components, if necessary.(27) Install the structural dust cover (Fig. 59)

(Refer to 9 - ENGINE/ENGINE BLOCK/STRUC-

TURAL COVER - INSTALLATION) onto the trans-

mission and the engine.

(28) Align and connect propeller shaft(s).

(29) Adjust gearshift cable if necessary.

(30) Install any skid plates removed previously.

(Refer to 13 - FRAMES & BUMPERS/FRAME/

TRANSFER CASE SKID PLATE - INSTALLATION)

(31) Lower vehicle.

(32) Fill transmission with MopartATF +4, Auto-

matic Transmission Fluid.

Fig. 58 Connect Line Pressure Sensor

1 - TRANSMISSION

2 - LINE PRESSURE SENSOR

Fig. 59 Transmission Collar

1 - ENGINE

2 - STRUCTURAL DUST COVER

3 - TRANSMISSION

21 - 336 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)