harness DODGE RAM 1500 1998 2.G Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 608 of 2627

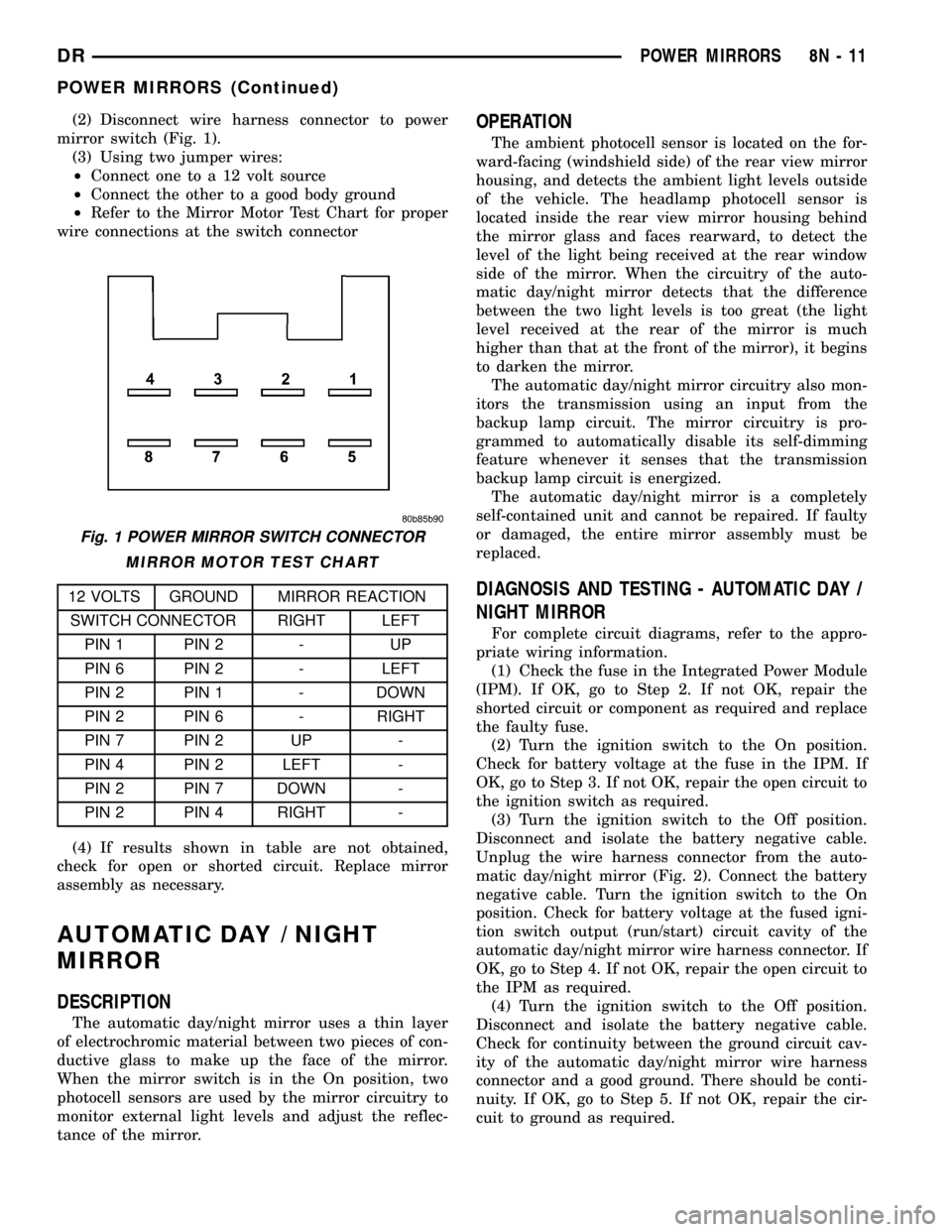

(2) Disconnect wire harness connector to power

mirror switch (Fig. 1).

(3) Using two jumper wires:

²Connect one to a 12 volt source

²Connect the other to a good body ground

²Refer to the Mirror Motor Test Chart for proper

wire connections at the switch connector

MIRROR MOTOR TEST CHART

12 VOLTS GROUND MIRROR REACTION

SWITCH CONNECTOR RIGHT LEFT

PIN 1 PIN 2 - UP

PIN 6 PIN 2 - LEFT

PIN 2 PIN 1 - DOWN

PIN 2 PIN 6 - RIGHT

PIN 7 PIN 2 UP -

PIN 4 PIN 2 LEFT -

PIN 2 PIN 7 DOWN -

PIN 2 PIN 4 RIGHT -

(4) If results shown in table are not obtained,

check for open or shorted circuit. Replace mirror

assembly as necessary.

AUTOMATIC DAY / NIGHT

MIRROR

DESCRIPTION

The automatic day/night mirror uses a thin layer

of electrochromic material between two pieces of con-

ductive glass to make up the face of the mirror.

When the mirror switch is in the On position, two

photocell sensors are used by the mirror circuitry to

monitor external light levels and adjust the reflec-

tance of the mirror.

OPERATION

The ambient photocell sensor is located on the for-

ward-facing (windshield side) of the rear view mirror

housing, and detects the ambient light levels outside

of the vehicle. The headlamp photocell sensor is

located inside the rear view mirror housing behind

the mirror glass and faces rearward, to detect the

level of the light being received at the rear window

side of the mirror. When the circuitry of the auto-

matic day/night mirror detects that the difference

between the two light levels is too great (the light

level received at the rear of the mirror is much

higher than that at the front of the mirror), it begins

to darken the mirror.

The automatic day/night mirror circuitry also mon-

itors the transmission using an input from the

backup lamp circuit. The mirror circuitry is pro-

grammed to automatically disable its self-dimming

feature whenever it senses that the transmission

backup lamp circuit is energized.

The automatic day/night mirror is a completely

self-contained unit and cannot be repaired. If faulty

or damaged, the entire mirror assembly must be

replaced.

DIAGNOSIS AND TESTING - AUTOMATIC DAY /

NIGHT MIRROR

For complete circuit diagrams, refer to the appro-

priate wiring information.

(1) Check the fuse in the Integrated Power Module

(IPM). If OK, go to Step 2. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the IPM. If

OK, go to Step 3. If not OK, repair the open circuit to

the ignition switch as required.

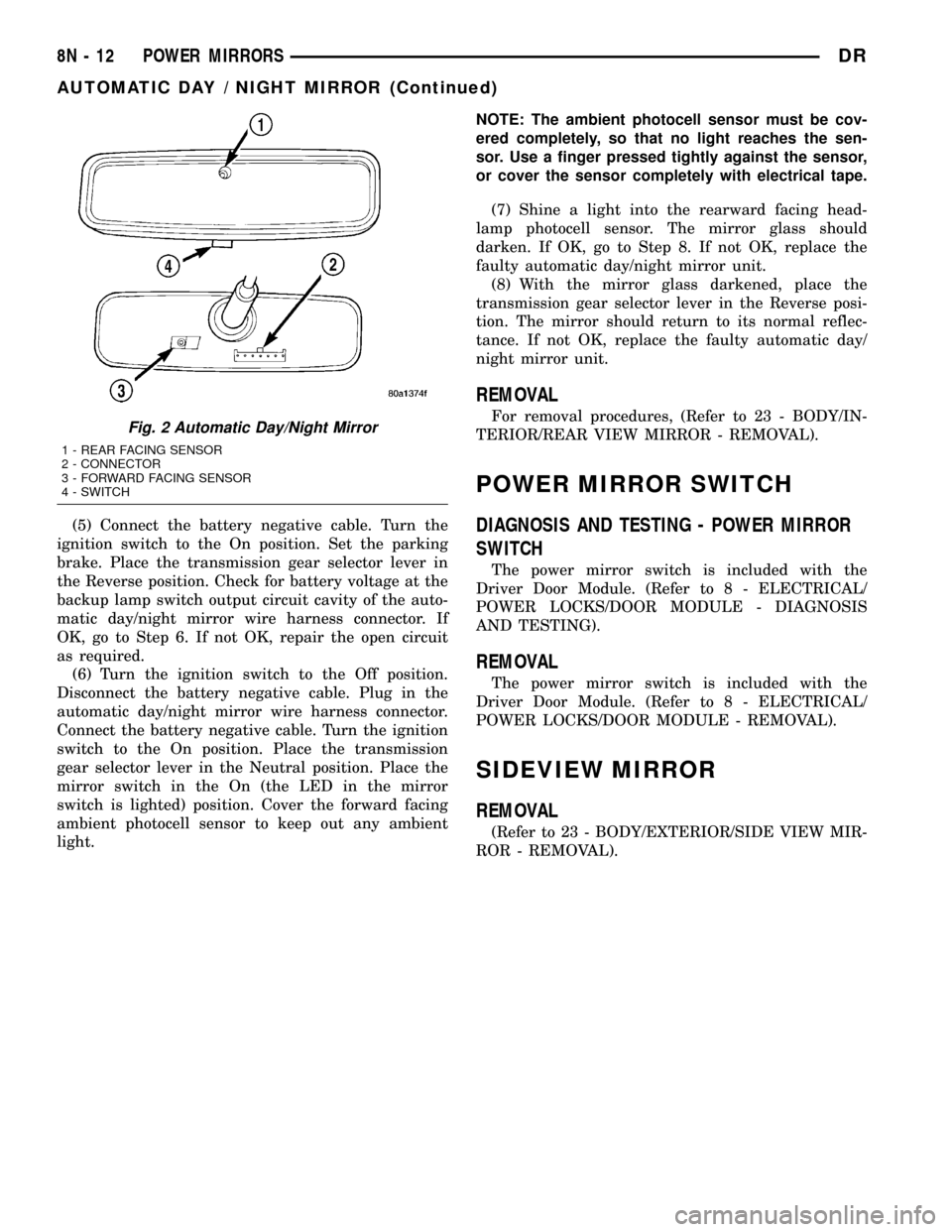

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Unplug the wire harness connector from the auto-

matic day/night mirror (Fig. 2). Connect the battery

negative cable. Turn the ignition switch to the On

position. Check for battery voltage at the fused igni-

tion switch output (run/start) circuit cavity of the

automatic day/night mirror wire harness connector. If

OK, go to Step 4. If not OK, repair the open circuit to

the IPM as required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Check for continuity between the ground circuit cav-

ity of the automatic day/night mirror wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 5. If not OK, repair the cir-

cuit to ground as required.

Fig. 1 POWER MIRROR SWITCH CONNECTOR

DRPOWER MIRRORS 8N - 11

POWER MIRRORS (Continued)

Page 609 of 2627

(5) Connect the battery negative cable. Turn the

ignition switch to the On position. Set the parking

brake. Place the transmission gear selector lever in

the Reverse position. Check for battery voltage at the

backup lamp switch output circuit cavity of the auto-

matic day/night mirror wire harness connector. If

OK, go to Step 6. If not OK, repair the open circuit

as required.

(6) Turn the ignition switch to the Off position.

Disconnect the battery negative cable. Plug in the

automatic day/night mirror wire harness connector.

Connect the battery negative cable. Turn the ignition

switch to the On position. Place the transmission

gear selector lever in the Neutral position. Place the

mirror switch in the On (the LED in the mirror

switch is lighted) position. Cover the forward facing

ambient photocell sensor to keep out any ambient

light.NOTE: The ambient photocell sensor must be cov-

ered completely, so that no light reaches the sen-

sor. Use a finger pressed tightly against the sensor,

or cover the sensor completely with electrical tape.

(7) Shine a light into the rearward facing head-

lamp photocell sensor. The mirror glass should

darken. If OK, go to Step 8. If not OK, replace the

faulty automatic day/night mirror unit.

(8) With the mirror glass darkened, place the

transmission gear selector lever in the Reverse posi-

tion. The mirror should return to its normal reflec-

tance. If not OK, replace the faulty automatic day/

night mirror unit.

REMOVAL

For removal procedures, (Refer to 23 - BODY/IN-

TERIOR/REAR VIEW MIRROR - REMOVAL).

POWER MIRROR SWITCH

DIAGNOSIS AND TESTING - POWER MIRROR

SWITCH

The power mirror switch is included with the

Driver Door Module. (Refer to 8 - ELECTRICAL/

POWER LOCKS/DOOR MODULE - DIAGNOSIS

AND TESTING).

REMOVAL

The power mirror switch is included with the

Driver Door Module. (Refer to 8 - ELECTRICAL/

POWER LOCKS/DOOR MODULE - REMOVAL).

SIDEVIEW MIRROR

REMOVAL

(Refer to 23 - BODY/EXTERIOR/SIDE VIEW MIR-

ROR - REMOVAL).

Fig. 2 Automatic Day/Night Mirror

1 - REAR FACING SENSOR

2 - CONNECTOR

3 - FORWARD FACING SENSOR

4 - SWITCH

8N - 12 POWER MIRRORSDR

AUTOMATIC DAY / NIGHT MIRROR (Continued)

Page 610 of 2627

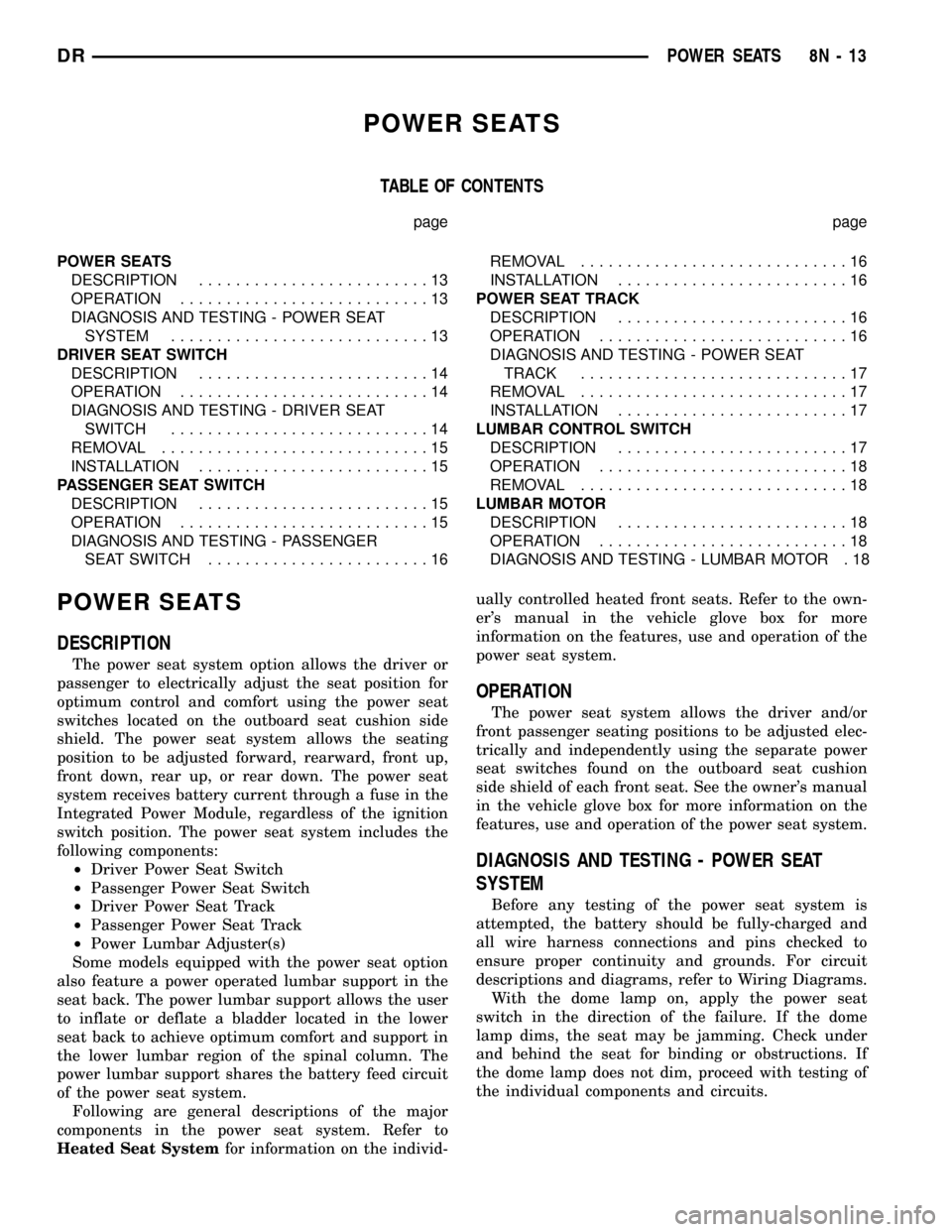

POWER SEATS

TABLE OF CONTENTS

page page

POWER SEATS

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING - POWER SEAT

SYSTEM............................13

DRIVER SEAT SWITCH

DESCRIPTION.........................14

OPERATION...........................14

DIAGNOSIS AND TESTING - DRIVER SEAT

SWITCH............................14

REMOVAL.............................15

INSTALLATION.........................15

PASSENGER SEAT SWITCH

DESCRIPTION.........................15

OPERATION...........................15

DIAGNOSIS AND TESTING - PASSENGER

SEAT SWITCH........................16REMOVAL.............................16

INSTALLATION.........................16

POWER SEAT TRACK

DESCRIPTION.........................16

OPERATION...........................16

DIAGNOSIS AND TESTING - POWER SEAT

TRACK.............................17

REMOVAL.............................17

INSTALLATION.........................17

LUMBAR CONTROL SWITCH

DESCRIPTION.........................17

OPERATION...........................18

REMOVAL.............................18

LUMBAR MOTOR

DESCRIPTION.........................18

OPERATION...........................18

DIAGNOSIS AND TESTING - LUMBAR MOTOR . 18

POWER SEATS

DESCRIPTION

The power seat system option allows the driver or

passenger to electrically adjust the seat position for

optimum control and comfort using the power seat

switches located on the outboard seat cushion side

shield. The power seat system allows the seating

position to be adjusted forward, rearward, front up,

front down, rear up, or rear down. The power seat

system receives battery current through a fuse in the

Integrated Power Module, regardless of the ignition

switch position. The power seat system includes the

following components:

²Driver Power Seat Switch

²Passenger Power Seat Switch

²Driver Power Seat Track

²Passenger Power Seat Track

²Power Lumbar Adjuster(s)

Some models equipped with the power seat option

also feature a power operated lumbar support in the

seat back. The power lumbar support allows the user

to inflate or deflate a bladder located in the lower

seat back to achieve optimum comfort and support in

the lower lumbar region of the spinal column. The

power lumbar support shares the battery feed circuit

of the power seat system.

Following are general descriptions of the major

components in the power seat system. Refer to

Heated Seat Systemfor information on the individ-ually controlled heated front seats. Refer to the own-

er's manual in the vehicle glove box for more

information on the features, use and operation of the

power seat system.

OPERATION

The power seat system allows the driver and/or

front passenger seating positions to be adjusted elec-

trically and independently using the separate power

seat switches found on the outboard seat cushion

side shield of each front seat. See the owner's manual

in the vehicle glove box for more information on the

features, use and operation of the power seat system.

DIAGNOSIS AND TESTING - POWER SEAT

SYSTEM

Before any testing of the power seat system is

attempted, the battery should be fully-charged and

all wire harness connections and pins checked to

ensure proper continuity and grounds. For circuit

descriptions and diagrams, refer to Wiring Diagrams.

With the dome lamp on, apply the power seat

switch in the direction of the failure. If the dome

lamp dims, the seat may be jamming. Check under

and behind the seat for binding or obstructions. If

the dome lamp does not dim, proceed with testing of

the individual components and circuits.

DRPOWER SEATS 8N - 13

Page 612 of 2627

DRIVER POWER SEAT SWITCH TEST TABLE

DRIVER SWITCH

POSITIONCONTINUITY BETWEEN

HORIZONTAL

FORWARDA-L, B-K

HORIZONTAL

REARWARDA-K, B-L

FRONT TILT UP A-M, B-N

FRONT TILT DOWN A-N, B-M

REAR TILT UP A-E, B-J

REAR TILT DOWN A-J, B-E

LUMBAR OFF O-P, O-R, P-R

LUMPAR UP (INFLATE) O-P, Q-R

LUMBAR DOWN

(DEFLATE)O-R, P-Q

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the seat cushion side shield from the

seat. Refer to the Body section of the service manual

for the procedure.

(3) Pull the switch bezel or side shield unit out

from the seat far enough to access the switch wire

harness connector. Gently pry the locking tabs of the

switch away from the wire harness connector and

carefully unplug the connector from the power seat

switch module.

(4) Remove the screws that secure the power seat

switch.

INSTALLATION

(1) Position the power seat switch on the seat

cushion side shield and install the screws that secure

the power seat switch to seat cushion side shield.

(2) Connect the electrical connector.

(3) Install the seat cushion side shield on the seat.

Refer to the Body section of the service manual for

the procedure.

(4) If equipped, install the screw that secures the

recliner lever to the recliner mechanism release shaft

on the outboard side of the front seat.

(5) Connect the battery negative cable.

PASSENGER SEAT SWITCH

DESCRIPTION

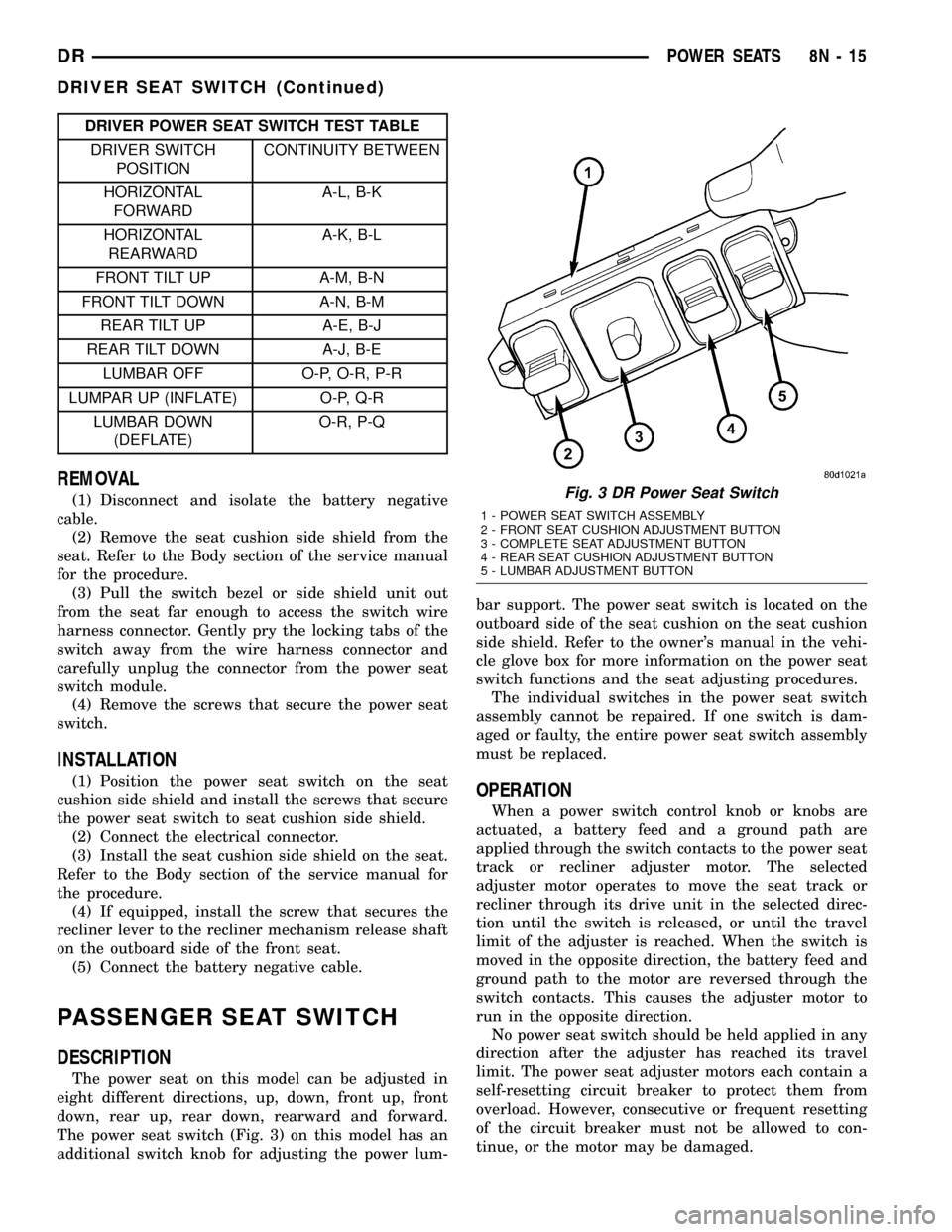

The power seat on this model can be adjusted in

eight different directions, up, down, front up, front

down, rear up, rear down, rearward and forward.

The power seat switch (Fig. 3) on this model has an

additional switch knob for adjusting the power lum-bar support. The power seat switch is located on the

outboard side of the seat cushion on the seat cushion

side shield. Refer to the owner's manual in the vehi-

cle glove box for more information on the power seat

switch functions and the seat adjusting procedures.

The individual switches in the power seat switch

assembly cannot be repaired. If one switch is dam-

aged or faulty, the entire power seat switch assembly

must be replaced.

OPERATION

When a power switch control knob or knobs are

actuated, a battery feed and a ground path are

applied through the switch contacts to the power seat

track or recliner adjuster motor. The selected

adjuster motor operates to move the seat track or

recliner through its drive unit in the selected direc-

tion until the switch is released, or until the travel

limit of the adjuster is reached. When the switch is

moved in the opposite direction, the battery feed and

ground path to the motor are reversed through the

switch contacts. This causes the adjuster motor to

run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

Fig. 3 DR Power Seat Switch

1 - POWER SEAT SWITCH ASSEMBLY

2 - FRONT SEAT CUSHION ADJUSTMENT BUTTON

3 - COMPLETE SEAT ADJUSTMENT BUTTON

4 - REAR SEAT CUSHION ADJUSTMENT BUTTON

5 - LUMBAR ADJUSTMENT BUTTON

DRPOWER SEATS 8N - 15

DRIVER SEAT SWITCH (Continued)

Page 613 of 2627

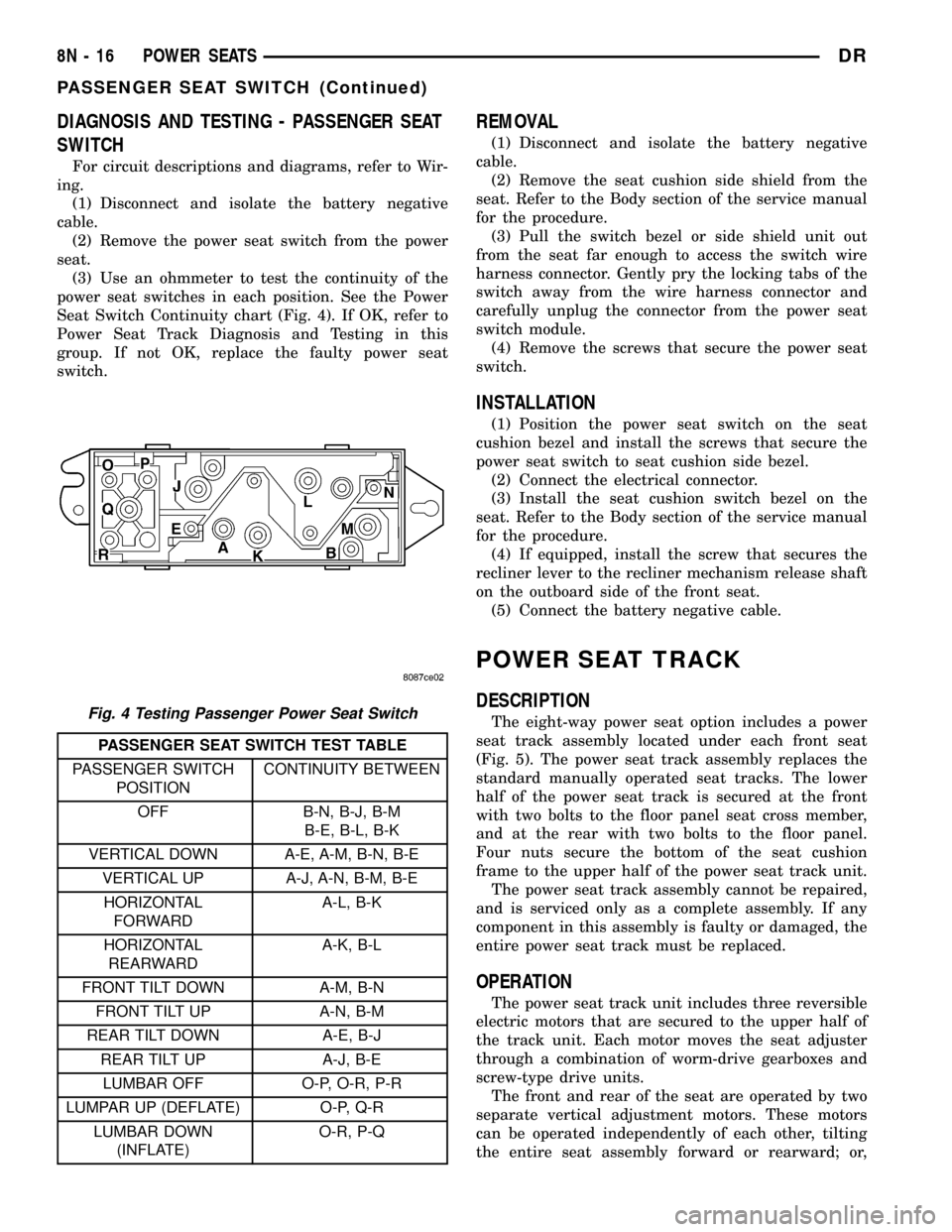

DIAGNOSIS AND TESTING - PASSENGER SEAT

SWITCH

For circuit descriptions and diagrams, refer to Wir-

ing.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the power seat switch from the power

seat.

(3) Use an ohmmeter to test the continuity of the

power seat switches in each position. See the Power

Seat Switch Continuity chart (Fig. 4). If OK, refer to

Power Seat Track Diagnosis and Testing in this

group. If not OK, replace the faulty power seat

switch.

PASSENGER SEAT SWITCH TEST TABLE

PASSENGER SWITCH

POSITIONCONTINUITY BETWEEN

OFF B-N, B-J, B-M

B-E, B-L, B-K

VERTICAL DOWN A-E, A-M, B-N, B-E

VERTICAL UP A-J, A-N, B-M, B-E

HORIZONTAL

FORWARDA-L, B-K

HORIZONTAL

REARWARDA-K, B-L

FRONT TILT DOWN A-M, B-N

FRONT TILT UP A-N, B-M

REAR TILT DOWN A-E, B-J

REAR TILT UP A-J, B-E

LUMBAR OFF O-P, O-R, P-R

LUMPAR UP (DEFLATE) O-P, Q-R

LUMBAR DOWN

(INFLATE)O-R, P-Q

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the seat cushion side shield from the

seat. Refer to the Body section of the service manual

for the procedure.

(3) Pull the switch bezel or side shield unit out

from the seat far enough to access the switch wire

harness connector. Gently pry the locking tabs of the

switch away from the wire harness connector and

carefully unplug the connector from the power seat

switch module.

(4) Remove the screws that secure the power seat

switch.

INSTALLATION

(1) Position the power seat switch on the seat

cushion bezel and install the screws that secure the

power seat switch to seat cushion side bezel.

(2) Connect the electrical connector.

(3) Install the seat cushion switch bezel on the

seat. Refer to the Body section of the service manual

for the procedure.

(4) If equipped, install the screw that secures the

recliner lever to the recliner mechanism release shaft

on the outboard side of the front seat.

(5) Connect the battery negative cable.

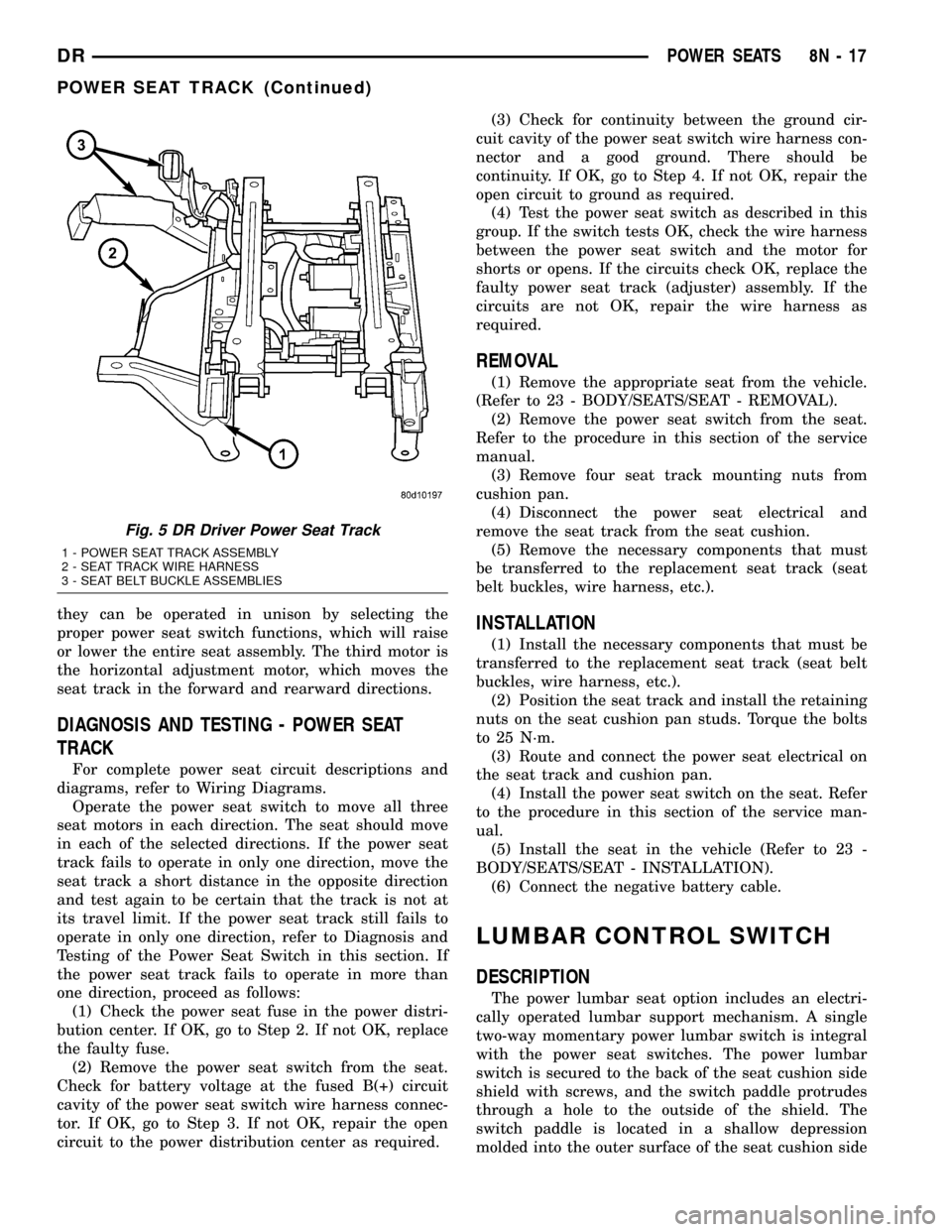

POWER SEAT TRACK

DESCRIPTION

The eight-way power seat option includes a power

seat track assembly located under each front seat

(Fig. 5). The power seat track assembly replaces the

standard manually operated seat tracks. The lower

half of the power seat track is secured at the front

with two bolts to the floor panel seat cross member,

and at the rear with two bolts to the floor panel.

Four nuts secure the bottom of the seat cushion

frame to the upper half of the power seat track unit.

The power seat track assembly cannot be repaired,

and is serviced only as a complete assembly. If any

component in this assembly is faulty or damaged, the

entire power seat track must be replaced.

OPERATION

The power seat track unit includes three reversible

electric motors that are secured to the upper half of

the track unit. Each motor moves the seat adjuster

through a combination of worm-drive gearboxes and

screw-type drive units.

The front and rear of the seat are operated by two

separate vertical adjustment motors. These motors

can be operated independently of each other, tilting

the entire seat assembly forward or rearward; or,

Fig. 4 Testing Passenger Power Seat Switch

8N - 16 POWER SEATSDR

PASSENGER SEAT SWITCH (Continued)

Page 614 of 2627

they can be operated in unison by selecting the

proper power seat switch functions, which will raise

or lower the entire seat assembly. The third motor is

the horizontal adjustment motor, which moves the

seat track in the forward and rearward directions.

DIAGNOSIS AND TESTING - POWER SEAT

TRACK

For complete power seat circuit descriptions and

diagrams, refer to Wiring Diagrams.

Operate the power seat switch to move all three

seat motors in each direction. The seat should move

in each of the selected directions. If the power seat

track fails to operate in only one direction, move the

seat track a short distance in the opposite direction

and test again to be certain that the track is not at

its travel limit. If the power seat track still fails to

operate in only one direction, refer to Diagnosis and

Testing of the Power Seat Switch in this section. If

the power seat track fails to operate in more than

one direction, proceed as follows:

(1) Check the power seat fuse in the power distri-

bution center. If OK, go to Step 2. If not OK, replace

the faulty fuse.

(2) Remove the power seat switch from the seat.

Check for battery voltage at the fused B(+) circuit

cavity of the power seat switch wire harness connec-

tor. If OK, go to Step 3. If not OK, repair the open

circuit to the power distribution center as required.(3) Check for continuity between the ground cir-

cuit cavity of the power seat switch wire harness con-

nector and a good ground. There should be

continuity. If OK, go to Step 4. If not OK, repair the

open circuit to ground as required.

(4) Test the power seat switch as described in this

group. If the switch tests OK, check the wire harness

between the power seat switch and the motor for

shorts or opens. If the circuits check OK, replace the

faulty power seat track (adjuster) assembly. If the

circuits are not OK, repair the wire harness as

required.

REMOVAL

(1) Remove the appropriate seat from the vehicle.

(Refer to 23 - BODY/SEATS/SEAT - REMOVAL).

(2) Remove the power seat switch from the seat.

Refer to the procedure in this section of the service

manual.

(3) Remove four seat track mounting nuts from

cushion pan.

(4) Disconnect the power seat electrical and

remove the seat track from the seat cushion.

(5) Remove the necessary components that must

be transferred to the replacement seat track (seat

belt buckles, wire harness, etc.).

INSTALLATION

(1) Install the necessary components that must be

transferred to the replacement seat track (seat belt

buckles, wire harness, etc.).

(2) Position the seat track and install the retaining

nuts on the seat cushion pan studs. Torque the bolts

to 25 N´m.

(3) Route and connect the power seat electrical on

the seat track and cushion pan.

(4) Install the power seat switch on the seat. Refer

to the procedure in this section of the service man-

ual.

(5) Install the seat in the vehicle (Refer to 23 -

BODY/SEATS/SEAT - INSTALLATION).

(6) Connect the negative battery cable.

LUMBAR CONTROL SWITCH

DESCRIPTION

The power lumbar seat option includes an electri-

cally operated lumbar support mechanism. A single

two-way momentary power lumbar switch is integral

with the power seat switches. The power lumbar

switch is secured to the back of the seat cushion side

shield with screws, and the switch paddle protrudes

through a hole to the outside of the shield. The

switch paddle is located in a shallow depression

molded into the outer surface of the seat cushion side

Fig. 5 DR Driver Power Seat Track

1 - POWER SEAT TRACK ASSEMBLY

2 - SEAT TRACK WIRE HARNESS

3 - SEAT BELT BUCKLE ASSEMBLIES

DRPOWER SEATS 8N - 17

POWER SEAT TRACK (Continued)

Page 615 of 2627

shield that helps to shroud it from unintentional

actuation when entering or leaving the vehicle.

The power lumbar switches cannot be adjusted or

repaired and, if faulty or damaged, the seat switch

assembly must be replaced.

OPERATION

When the power lumbar switch paddle is actuated,

a battery feed and a ground path are applied through

the switch contacts to the power lumbar adjuster

motor. The motor operates to move the lumbar

adjuster through its drive unit in the selected direc-

tion until the switch is released, or until the travel

limit of the adjuster is reached. When the switch is

moved in the opposite direction, the battery feed and

ground path to the motor are reversed through the

switch contacts. This causes the motor to run in the

opposite direction.

The power lumbar switch should not be held

applied in either direction after the adjuster has

reached its travel limit. The power lumbar adjuster

motor contains a self-resetting circuit breaker to pro-

tect it from overload. However, consecutive or fre-

quent resetting of the circuit breaker must not be

allowed to continue, or the motor may be damaged.

REMOVAL

The power lumbar switch is integral with the other

power seat switches. Refer to the appropriate driver

or passenger power front seat switch removal and/or

installation procedure.

LUMBAR MOTOR

DESCRIPTION

The power lumbar seat option includes an electri-

cally operated lumbar support mechanism. The only

visible evidence of this option is the separate power

lumbar switch control paddle that is located on the

outboard seat cushion switch bezel, next to the other

power seat switch control knobs. The power lumbar

adjuster and motor are concealed beneath the seat

back trim cover and padding, where they are secured

to a molded plastic back panel and to the seat back

frame.

The power lumbar adjuster cannot be repaired, and

is serviced only as a unit with the seat back frame. If

the power lumbar adjuster or the seat back frame

are damaged or faulty, the entire seat back frame

unit must be replaced (Refer to 23 - BODY/SEATS/

SEAT BACK - REMOVAL).

OPERATION

The power lumbar adjuster mechanism includes a

reversible electric motor that is secured to theinboard side of the seat back panel and is connected

to a worm-drive gearbox. The motor and gearbox

operate the lumbar adjuster mechanism in the center

of the seat back driving a nut up or down a fixed

drive screw. The action of this nut extends or con-

tracts the plastic lumbar support band. The more

this band is contracted, the more outward pressure is

applied against the center of the seat back padding,

providing additional lumbar support.

DIAGNOSIS AND TESTING - LUMBAR MOTOR

Actuate the power lumbar switch to move the

power lumbar adjuster in each direction. The power

lumbar adjuster should move in both directions. It

should be noted that the power lumber adjuster nor-

mally operates very quietly and exhibits little visible

movement. If the power lumbar adjuster fails to oper-

ate in only one direction, move the adjuster a short

distance in the opposite direction and test again to be

certain that the adjuster is not at its travel limit. If

the power lumbar adjuster fails to operate in only

one direction, Test the appropriate power seat switch

as described in this group. If the power lumbar

adjuster fails to operate in either direction, perform

the following tests. For complete circuit diagrams,

refer toWiring.

(1) Check the power seat circuit breaker. If OK, go

to Step 2. If not OK, replace the faulty power seat

circuit breaker.

(2) Check for battery voltage at the power seat cir-

cuit breaker. If OK, go to Step 3. If not OK, repair

the open fused B(+) circuit to the fuse in the Inte-

grated Power Module as required.

(3) Remove the outboard seat cushion side shield

from the seat. Disconnect the seat wire harness con-

nector from the power lumbar switch connector

receptacle. Check for battery voltage at the fused

B(+) circuit cavity of the power seat wire harness

connector for the power lumbar switch. If OK, go to

Step 4. If not OK, repair the open fused B(+) circuit

to the power seat as required.

(4) Check for continuity between the ground cir-

cuit cavity of the power seat wire harness connector

for the power lumbar switch and a good ground.

There should be continuity. If OK, go to Step 5. If not

OK, repair the open ground circuit to ground as

required.

(5) Test the power lumbar switch. . If the switch

tests OK, test the circuits of the power seat wire har-

ness between the power lumbar adjuster motor and

the power lumbar switch for shorts or opens. If the

circuits check OK, replace the faulty seat back frame

assembly. If the circuits are not OK, repair the power

seat wire harness as required.

8N - 18 POWER SEATSDR

LUMBAR CONTROL SWITCH (Continued)

Page 616 of 2627

POWER WINDOWS

TABLE OF CONTENTS

page page

POWER WINDOWS

DESCRIPTION.........................19

OPERATION...........................19

DIAGNOSIS AND TESTING - POWER

WINDOWS...........................19

WINDOW MOTOR

REMOVAL.............................20WINDOW SWITCH

DIAGNOSIS AND TESTING - WINDOW

SWITCH............................20

REMOVAL.............................20

INSTALLATION.........................21

POWER WINDOWS

DESCRIPTION

The power window system allows each of the door

windows to be raised and lowered electrically by

actuating a switch on each door panel. A master

switch on the drivers door allows the driver to raise

or lower each of the passenger door windows and to

lock out the individual switches on the passenger

doors from operation. The power window system

receives battery feed through a fuse in the Integrated

Power Module (IPM) and a circuit breaker located in

the instrument panel wiring harness near the park

brake pedal, only when the ignition switch is in the

RUN or ACCESSORY position.

OPERATION

WINDOW SWITCH

The power window switches control the battery

and ground feeds to the power window motors. The

passenger door power window switches receive their

battery and ground feeds through the circuitry of the

drivers window switch. When the power window lock-

out switch is in the Lock position, the battery feed

for the passenger door window switches is inter-

rupted.

WINDOW MOTOR

Window motors use permanent type magnets. The

B+ and ground applied at the motor terminal pins

will cause the motor to rotate in one direction.

Reversing current through the motor terminals will

cause the motor to rotate in the opposite direction.

DIAGNOSIS AND TESTING - POWER

WINDOWS

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to the front switch.

(1) Remove the Driver Door Module (Refer to 8 -

ELECTRICAL/POWER LOCKS/DOOR MODULE -

REMOVAL).

(2) Disconnect wire connector from back of power

window switch.

(3) Switch ignition to the ON position.

(4) Connect the clip end of a 12 volt test light to

Pin 14 of the window switch harness connector.

Touch the test light probe to Pin 10.

²If the test light illuminates, the wiring circuit

between the battery and switch is OK.

²If the lamp does not illuminate, first check the

fuse in the Integrated Power Module (IPM). Check

the circuit breaker located near the park brake

pedal. If fuse and circuit breaker are OK, then check

for a broken wire.

Refer to the appropriate wiring information.

POWER WINDOW MOTOR TEST

If the power window motor is receiving proper cur-

rent and ground and does not operate, proceed with

motor test.

(1) Remove front door trim panel as necessary to

gain access to power window motor wire connector

(Refer to 23 - BODY/DOOR - FRONT/TRIM PANEL -

REMOVAL).

(2) Disconnect power window motor wire connector

from door harness.

(3) Using two jumper wires, connect one to a bat-

tery (+) source and the other to a good ground (-).

(4) Connect the Negative (-) jumper probe to one of

the motor connector terminals.

DRPOWER WINDOWS 8N - 19

Page 617 of 2627

(5) Momentarily touch the Positive (+) jumper

probe to the other motor connector terminal.

When positive probe is connected the motor should

rotate in one direction to either move window up or

down. If window is all the way up or down the motor

will grunt and the inner door panel will flex when

actuated in that one direction.

(6) Reverse jumper probes at the motor connector

terminals and window should now move in opposite

direction. If window does not move or grunt, replace

the motor.

If window moved completely up or down, reverse

the jumper probes and cycle window to the opposite

position to verify full operation.

If motor grunts and does not move, verify that reg-

ulator is not binding.

WINDOW MOTOR

REMOVAL

The window motor is serviced with the window

regulator (Refer to 23 - BODY/DOOR - FRONT/WIN-

DOW REGULATOR - REMOVAL) or (Refer to 23 -

BODY/DOORS - REAR/WINDOW REGULATOR -

REMOVAL).

WINDOW SWITCH

DIAGNOSIS AND TESTING - WINDOW SWITCH

The Light-Emitting Diode (LED) illumination

lamps for all of the power window and lock switch

and bezel unit switch paddles receive battery current

through the power window circuit breaker in the

junction block. If all of the LEDs are inoperative in

both the power window and lock switch units and the

power windows are inoperative, (Refer to 8 - ELEC-

TRICAL/POWER WINDOWS - DIAGNOSIS AND

TESTING). If the power windows operate, but any or

all of the LEDs are inoperative, the power window

and lock switch units with the inoperative LED(s) is

faulty and must be replaced. For complete circuit dia-

grams, refer to the appropriate wiring information.

(1) Check the fuse in the Integrated Power Module

(IPM) and the circuit breaker located near the park

brake pedal. If OK, go to Step 2. If not OK, replace

the faulty fuse or circuit breaker.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the Inte-

grated Power Module (IPM). If OK, turn the ignition

switch to the Off position and go to Step 3. If not OK,

check circuit breaker and repair the circuit to the

ignition switch as required.

(3) Disconnect and isolate the battery negative

cable. Remove the power window switch unit fromthe door trim panel (passenger doors). The drivers

door switch is included with the Driver Door Module

(Refer to 8 - ELECTRICAL/POWER LOCKS/DOOR

MODULE - DIAGNOSIS AND TESTING) for service

procedures. Unplug the wire harness connector from

the switch unit.

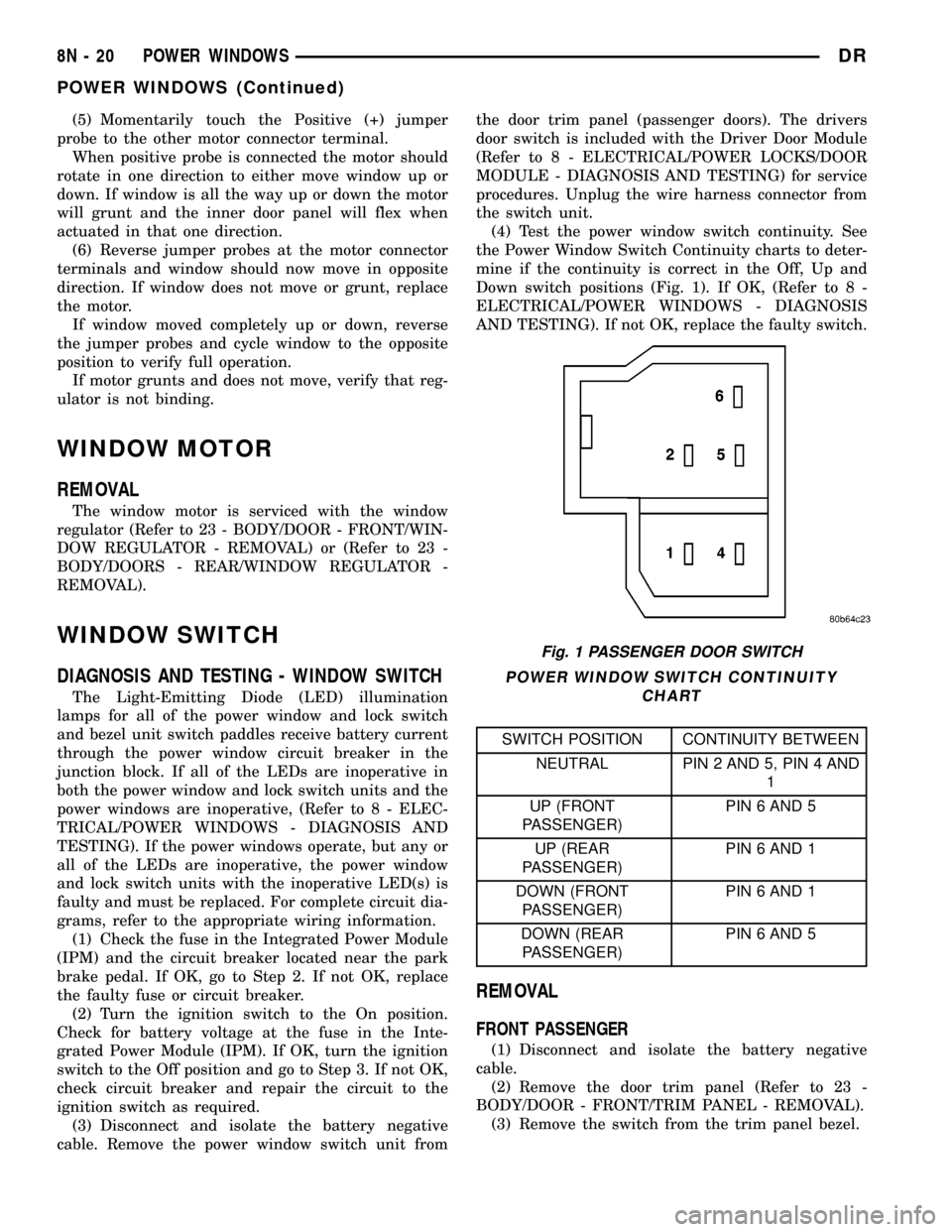

(4) Test the power window switch continuity. See

the Power Window Switch Continuity charts to deter-

mine if the continuity is correct in the Off, Up and

Down switch positions (Fig. 1). If OK, (Refer to 8 -

ELECTRICAL/POWER WINDOWS - DIAGNOSIS

AND TESTING). If not OK, replace the faulty switch.

POWER WINDOW SWITCH CONTINUITY

CHART

SWITCH POSITION CONTINUITY BETWEEN

NEUTRAL PIN 2 AND 5, PIN 4 AND

1

UP (FRONT

PASSENGER)PIN 6 AND 5

UP (REAR

PASSENGER)PIN 6 AND 1

DOWN (FRONT

PASSENGER)PIN 6 AND 1

DOWN (REAR

PASSENGER)PIN 6 AND 5

REMOVAL

FRONT PASSENGER

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door trim panel (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL).

(3) Remove the switch from the trim panel bezel.

Fig. 1 PASSENGER DOOR SWITCH

8N - 20 POWER WINDOWSDR

POWER WINDOWS (Continued)

Page 623 of 2627

²Airbag Indicator- The airbag indicator is inte-

gral to the ElectroMechanical Instrument Cluster

(EMIC), which is located on the instrument panel in

front of the driver.

²Clockspring- The clockspring is located near

the top of the steering column, directly beneath the

steering wheel.

²Driver Airbag- The driver airbag is located in

the center of the steering wheel, beneath the driver

airbag trim cover.

²Driver Knee Blocker- The driver knee blocker

is a structural unit secured to the back side of and

integral to the instrument panel steering column

opening cover.

²Passenger Airbag- The passenger airbag is

located on the instrument panel, beneath the passen-

ger airbag door on the instrument panel above the

glove box on the passenger side of the vehicle.

²Passenger Airbag On/Off Switch- Standard

cab models without a rear seat are equipped with a

passenger airbag on/off switch, which is located on

the right side of the instrument panel center bezel.

²Passenger Knee Blocker- The passenger knee

blocker is a structural reinforcement that is integral

to and concealed within the glove box door.

²Seat Belt Tensioner- The seat belt tensioner

is integral to the front outboard seat belt retractor

units on vehicles equipped with dual front airbags.

²Side Impact Sensor- Two side impact sensors

are used on vehicles equipped with the optional side

curtain airbags, one left side and one right side. One

sensor is located behind the B-pillar trim near the

base of each B-pillar.

²Side Curtain Airbag- In vehicles equipped

with this option, a side curtain airbag is located on

each inside roof side rail above the headliner, and

extends from the A-pillar to the B-pillar on standard

cab models, and from the A-pillar to the C-pillar on

quad cab models.The ACM and the EMIC each contain a central

processing unit and programming that allow them to

communicate with each other using the Programma-

ble Communications Interface (PCI) data bus net-

work. This method of communication is used by the

ACM for control of the airbag indicator on all models

equipped with dual front airbags. (Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/

COMMUNICATION - DESCRIPTION).

Hard wired circuitry connects the supplemental

restraint system components to each other through

the electrical system of the vehicle. These hard wired

circuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system,

and to the supplemental restraint system compo-

nents through the use of a combination of soldered

splices, splice block connectors, and many different

types of wire harness terminal connectors and insu-

lators. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

OPERATION

ACTIVE RESTRAINTS

The primary passenger restraints in this or any

other vehicle are the standard equipment factory-in-

stalled seat belts and child restraint anchors. Seat

belts and child restraint anchors are referred to as

an active restraint because the vehicle occupants are

required to physically fasten and properly adjust

these restraints in order to benefit from them. See

the owner's manual in the vehicle glove box for more

information on the features, use and operation of all

of the factory-installed active restraints.

PASSIVE RESTRAINTS

The passive restraints are referred to as a supple-

mental restraint system because they were designed

and are intended to enhance the protection for the

occupants of the vehicleonlywhen used in conjunc-

tion with the seat belts. They are referred to as pas-

sive restraints because the vehicle occupants are not

required to do anything to make them operate; how-

ever, the vehicle occupants must be wearing their

seat belts in order to obtain the maximum safety

benefit from the factory-installed supplemental

restraint system.

The supplemental restraint system electrical cir-

cuits are continuously monitored and controlled by a

microprocessor and software contained within the

Fig. 2 SRS Logo

8O - 4 RESTRAINTSDR

RESTRAINTS (Continued)