one DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 2206 of 2627

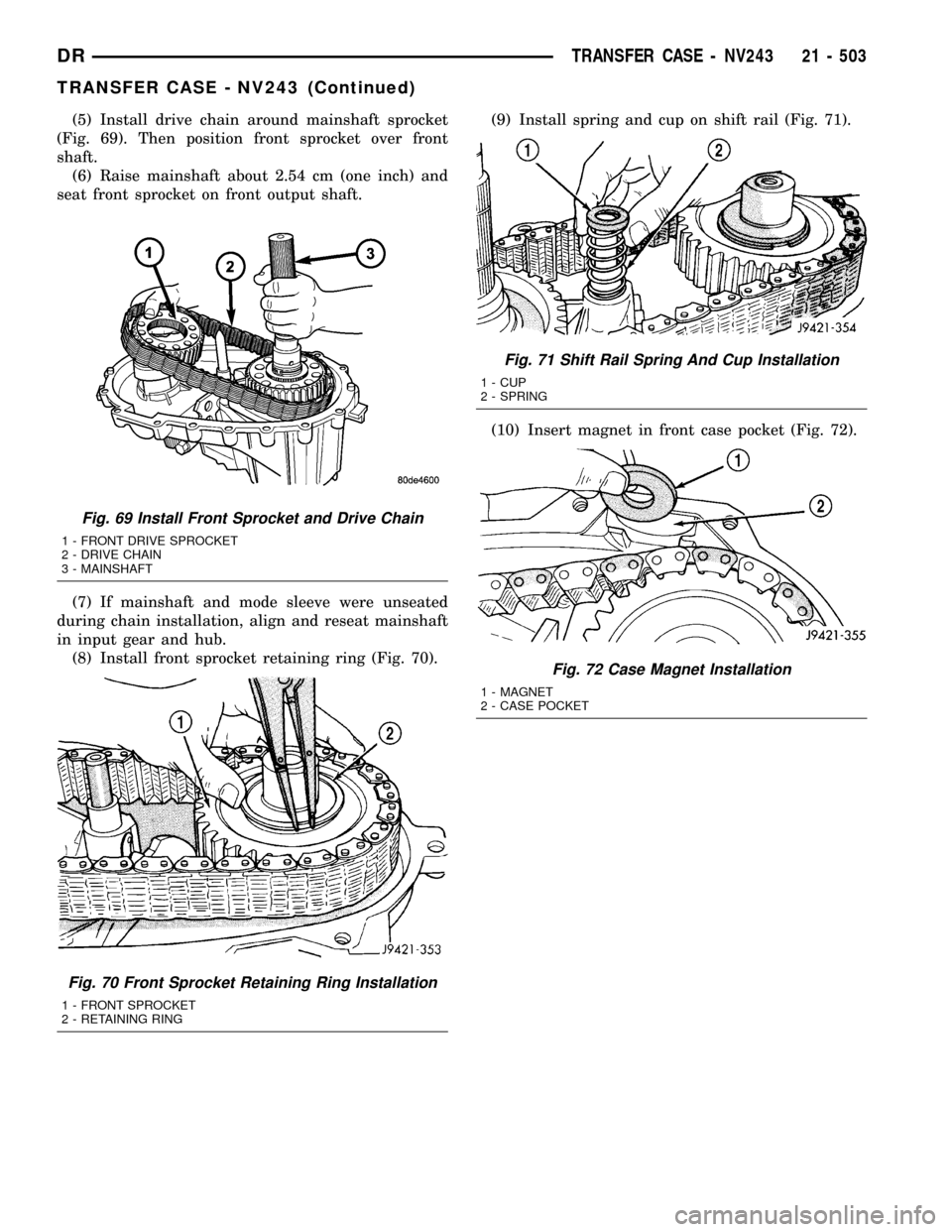

(5) Install drive chain around mainshaft sprocket

(Fig. 69). Then position front sprocket over front

shaft.

(6) Raise mainshaft about 2.54 cm (one inch) and

seat front sprocket on front output shaft.

(7) If mainshaft and mode sleeve were unseated

during chain installation, align and reseat mainshaft

in input gear and hub.

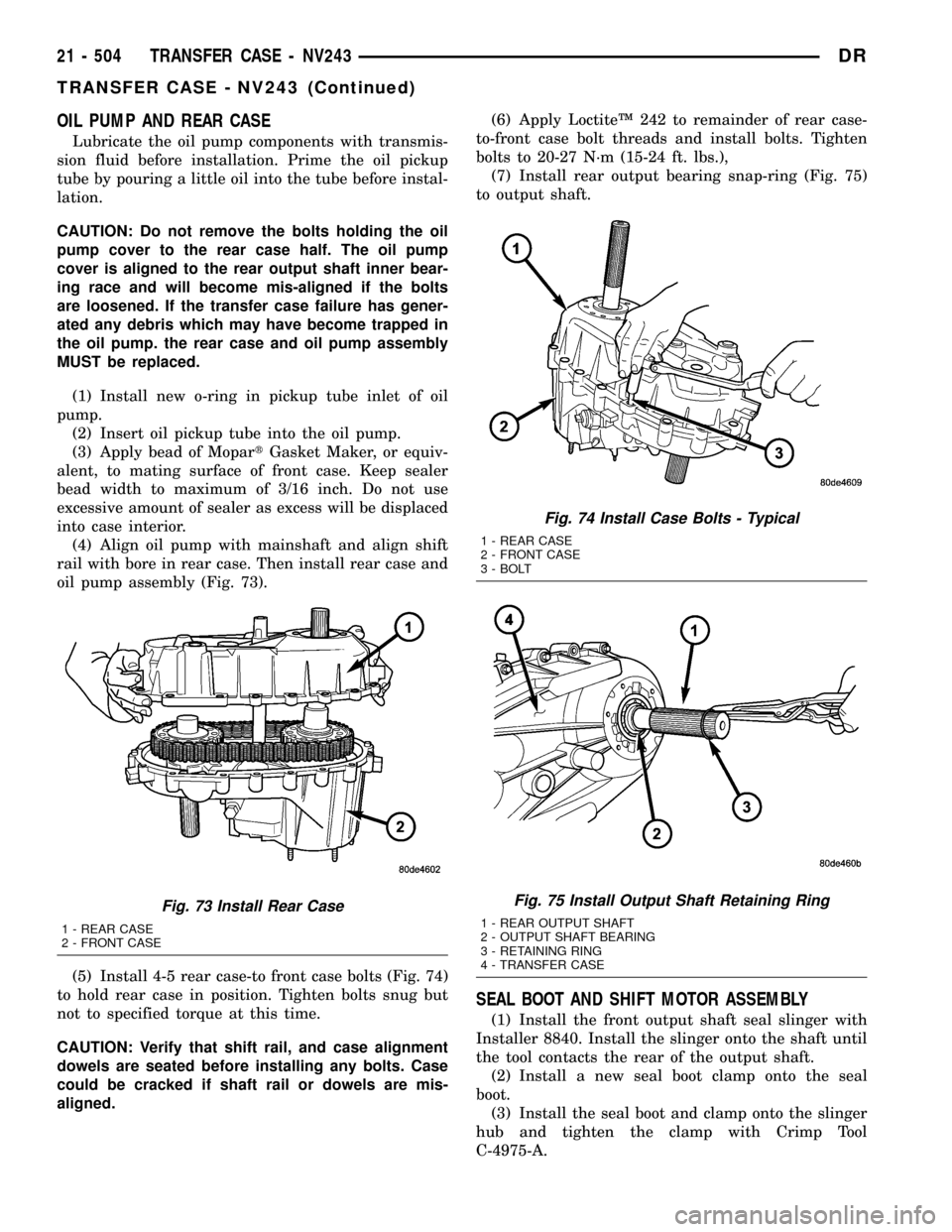

(8) Install front sprocket retaining ring (Fig. 70).(9) Install spring and cup on shift rail (Fig. 71).

(10) Insert magnet in front case pocket (Fig. 72).

Fig. 69 Install Front Sprocket and Drive Chain

1 - FRONT DRIVE SPROCKET

2 - DRIVE CHAIN

3 - MAINSHAFT

Fig. 70 Front Sprocket Retaining Ring Installation

1 - FRONT SPROCKET

2 - RETAINING RING

Fig. 71 Shift Rail Spring And Cup Installation

1 - CUP

2 - SPRING

Fig. 72 Case Magnet Installation

1 - MAGNET

2 - CASE POCKET

DRTRANSFER CASE - NV243 21 - 503

TRANSFER CASE - NV243 (Continued)

Page 2207 of 2627

OIL PUMP AND REAR CASE

Lubricate the oil pump components with transmis-

sion fluid before installation. Prime the oil pickup

tube by pouring a little oil into the tube before instal-

lation.

CAUTION: Do not remove the bolts holding the oil

pump cover to the rear case half. The oil pump

cover is aligned to the rear output shaft inner bear-

ing race and will become mis-aligned if the bolts

are loosened. If the transfer case failure has gener-

ated any debris which may have become trapped in

the oil pump. the rear case and oil pump assembly

MUST be replaced.

(1) Install new o-ring in pickup tube inlet of oil

pump.

(2) Insert oil pickup tube into the oil pump.

(3) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of front case. Keep sealer

bead width to maximum of 3/16 inch. Do not use

excessive amount of sealer as excess will be displaced

into case interior.

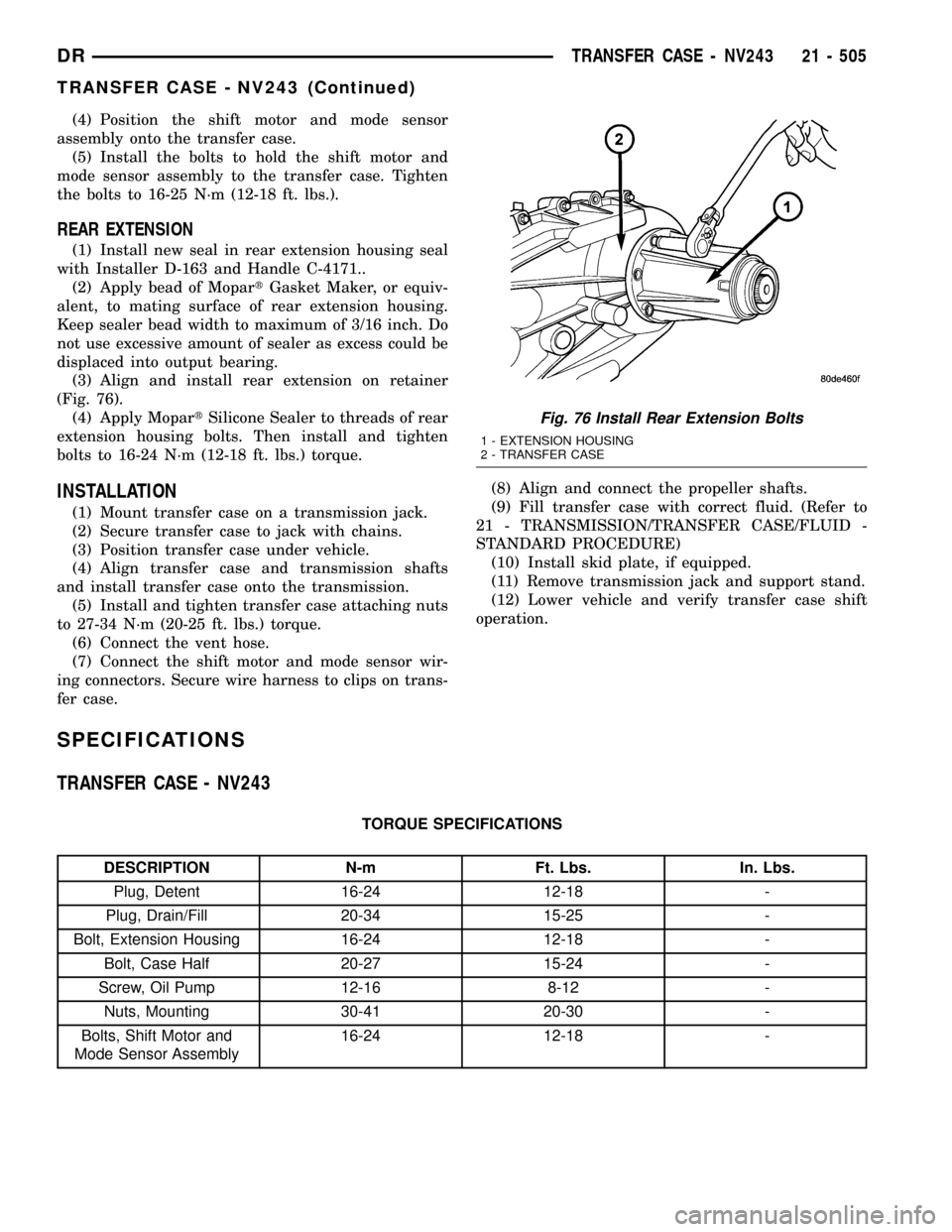

(4) Align oil pump with mainshaft and align shift

rail with bore in rear case. Then install rear case and

oil pump assembly (Fig. 73).

(5) Install 4-5 rear case-to front case bolts (Fig. 74)

to hold rear case in position. Tighten bolts snug but

not to specified torque at this time.

CAUTION: Verify that shift rail, and case alignment

dowels are seated before installing any bolts. Case

could be cracked if shaft rail or dowels are mis-

aligned.(6) Apply LoctiteŸ 242 to remainder of rear case-

to-front case bolt threads and install bolts. Tighten

bolts to 20-27 N´m (15-24 ft. lbs.),

(7) Install rear output bearing snap-ring (Fig. 75)

to output shaft.

SEAL BOOT AND SHIFT MOTOR ASSEMBLY

(1) Install the front output shaft seal slinger with

Installer 8840. Install the slinger onto the shaft until

the tool contacts the rear of the output shaft.

(2) Install a new seal boot clamp onto the seal

boot.

(3) Install the seal boot and clamp onto the slinger

hub and tighten the clamp with Crimp Tool

C-4975-A.

Fig. 73 Install Rear Case

1 - REAR CASE

2 - FRONT CASE

Fig. 74 Install Case Bolts - Typical

1 - REAR CASE

2 - FRONT CASE

3 - BOLT

Fig. 75 Install Output Shaft Retaining Ring

1 - REAR OUTPUT SHAFT

2 - OUTPUT SHAFT BEARING

3 - RETAINING RING

4 - TRANSFER CASE

21 - 504 TRANSFER CASE - NV243DR

TRANSFER CASE - NV243 (Continued)

Page 2208 of 2627

(4) Position the shift motor and mode sensor

assembly onto the transfer case.

(5) Install the bolts to hold the shift motor and

mode sensor assembly to the transfer case. Tighten

the bolts to 16-25 N´m (12-18 ft. lbs.).

REAR EXTENSION

(1) Install new seal in rear extension housing seal

with Installer D-163 and Handle C-4171..

(2) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of rear extension housing.

Keep sealer bead width to maximum of 3/16 inch. Do

not use excessive amount of sealer as excess could be

displaced into output bearing.

(3) Align and install rear extension on retainer

(Fig. 76).

(4) Apply MopartSilicone Sealer to threads of rear

extension housing bolts. Then install and tighten

bolts to 16-24 N´m (12-18 ft. lbs.) torque.

INSTALLATION

(1) Mount transfer case on a transmission jack.

(2) Secure transfer case to jack with chains.

(3) Position transfer case under vehicle.

(4) Align transfer case and transmission shafts

and install transfer case onto the transmission.

(5) Install and tighten transfer case attaching nuts

to 27-34 N´m (20-25 ft. lbs.) torque.

(6) Connect the vent hose.

(7) Connect the shift motor and mode sensor wir-

ing connectors. Secure wire harness to clips on trans-

fer case.(8) Align and connect the propeller shafts.

(9) Fill transfer case with correct fluid. (Refer to

21 - TRANSMISSION/TRANSFER CASE/FLUID -

STANDARD PROCEDURE)

(10) Install skid plate, if equipped.

(11) Remove transmission jack and support stand.

(12) Lower vehicle and verify transfer case shift

operation.

SPECIFICATIONS

TRANSFER CASE - NV243

TORQUE SPECIFICATIONS

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Plug, Detent 16-24 12-18 -

Plug, Drain/Fill 20-34 15-25 -

Bolt, Extension Housing 16-24 12-18 -

Bolt, Case Half 20-27 15-24 -

Screw, Oil Pump 12-16 8-12 -

Nuts, Mounting 30-41 20-30 -

Bolts, Shift Motor and

Mode Sensor Assembly16-24 12-18 -

Fig. 76 Install Rear Extension Bolts

1 - EXTENSION HOUSING

2 - TRANSFER CASE

DRTRANSFER CASE - NV243 21 - 505

TRANSFER CASE - NV243 (Continued)

Page 2214 of 2627

²A flashing operating mode LED for the desired

gear indicates that a shift to that position has been

requested, but all of the driver controllable conditions

have not been met. This is in an attempt to notify the

driver that the transmission needs to be put into NEU-

TRAL, the vehicle speed is too great, or some other con-

dition outlined (other than a diagnostic failure that

would prevent this shift) elsewhere (Refer to 8 - ELEC-

TRICAL/ELECTRONIC CONTROL MODULES/TRANS-

FER CASE CONTROL MODULE - OPERATION) is not

met. Note that this flashing will continue indefinitely

until the conditions are eventually met, or the selector

switch position is changed, or if diagnostic routines no

longer allow the requested shift.

²If the driver attempts to make a shift into transfer

case NEUTRAL, and any of the driver controllable con-

ditions are not met, the request will be ignored until all

of the conditions are met or until the NEUTRAL select

button is released. Additionally the neutral lamp will

flash, or begin to flash while the button is depressed

and operator controllable conditions are not being met.

All of the LED's except the Neutral will flash if any of

the operator controllable conditions for shifting are not

met while the Neutral button is depressed. This9toggle9

type of feature is necessary because the TCCM would

interpret another request immediately after the shift

into transfer case NEUTRAL has completed.

²No LED's illuminated indicate a fault in the

transfer case control system.

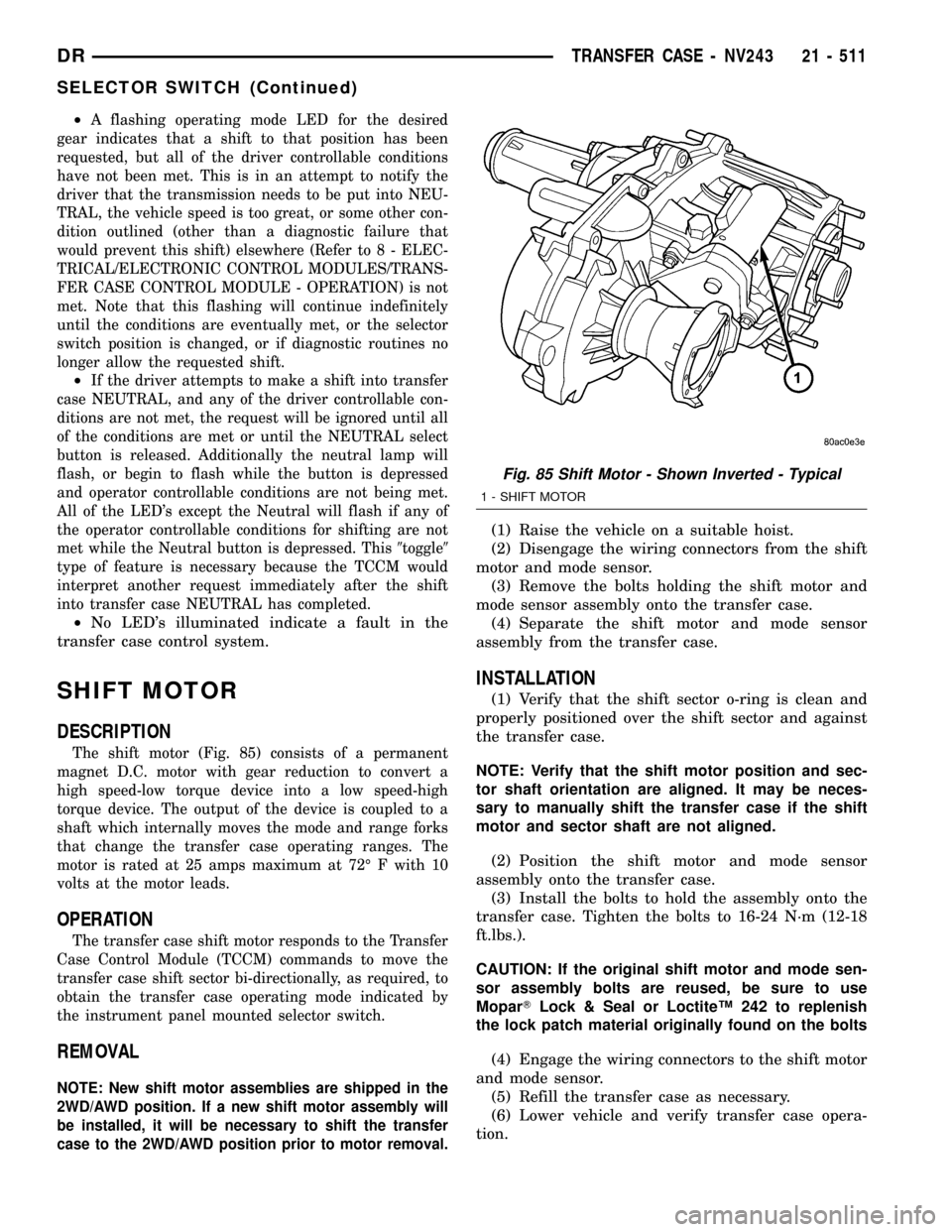

SHIFT MOTOR

DESCRIPTION

The shift motor (Fig. 85) consists of a permanent

magnet D.C. motor with gear reduction to convert a

high speed-low torque device into a low speed-high

torque device. The output of the device is coupled to a

shaft which internally moves the mode and range forks

that change the transfer case operating ranges. The

motor is rated at 25 amps maximum at 72É F with 10

volts at the motor leads.

OPERATION

The transfer case shift motor responds to the Transfer

Case Control Module (TCCM) commands to move the

transfer case shift sector bi-directionally, as required, to

obtain the transfer case operating mode indicated by

the instrument panel mounted selector switch.

REMOVAL

NOTE: New shift motor assemblies are shipped in the

2WD/AWD position. If a new shift motor assembly will

be installed, it will be necessary to shift the transfer

case to the 2WD/AWD position prior to motor removal.

(1) Raise the vehicle on a suitable hoist.

(2) Disengage the wiring connectors from the shift

motor and mode sensor.

(3) Remove the bolts holding the shift motor and

mode sensor assembly onto the transfer case.

(4) Separate the shift motor and mode sensor

assembly from the transfer case.

INSTALLATION

(1) Verify that the shift sector o-ring is clean and

properly positioned over the shift sector and against

the transfer case.

NOTE: Verify that the shift motor position and sec-

tor shaft orientation are aligned. It may be neces-

sary to manually shift the transfer case if the shift

motor and sector shaft are not aligned.

(2) Position the shift motor and mode sensor

assembly onto the transfer case.

(3) Install the bolts to hold the assembly onto the

transfer case. Tighten the bolts to 16-24 N´m (12-18

ft.lbs.).

CAUTION: If the original shift motor and mode sen-

sor assembly bolts are reused, be sure to use

MoparTLock & Seal or LoctiteŸ 242 to replenish

the lock patch material originally found on the bolts

(4) Engage the wiring connectors to the shift motor

and mode sensor.

(5) Refill the transfer case as necessary.

(6) Lower vehicle and verify transfer case opera-

tion.

Fig. 85 Shift Motor - Shown Inverted - Typical

1 - SHIFT MOTOR

DRTRANSFER CASE - NV243 21 - 511

SELECTOR SWITCH (Continued)

Page 2216 of 2627

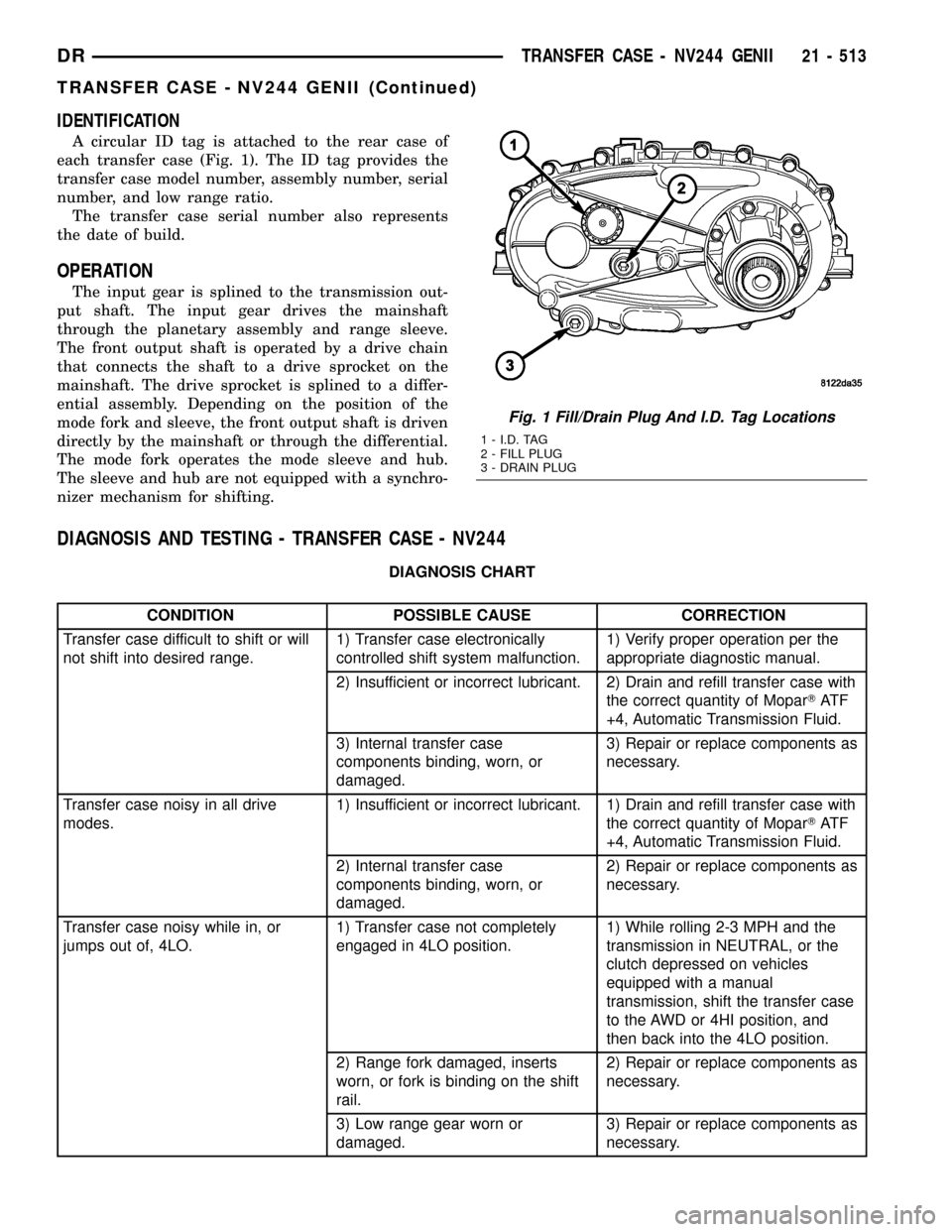

IDENTIFICATION

A circular ID tag is attached to the rear case of

each transfer case (Fig. 1). The ID tag provides the

transfer case model number, assembly number, serial

number, and low range ratio.

The transfer case serial number also represents

the date of build.

OPERATION

The input gear is splined to the transmission out-

put shaft. The input gear drives the mainshaft

through the planetary assembly and range sleeve.

The front output shaft is operated by a drive chain

that connects the shaft to a drive sprocket on the

mainshaft. The drive sprocket is splined to a differ-

ential assembly. Depending on the position of the

mode fork and sleeve, the front output shaft is driven

directly by the mainshaft or through the differential.

The mode fork operates the mode sleeve and hub.

The sleeve and hub are not equipped with a synchro-

nizer mechanism for shifting.

DIAGNOSIS AND TESTING - TRANSFER CASE - NV244

DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

Transfer case difficult to shift or will

not shift into desired range.1) Transfer case electronically

controlled shift system malfunction.1) Verify proper operation per the

appropriate diagnostic manual.

2) Insufficient or incorrect lubricant. 2) Drain and refill transfer case with

the correct quantity of MoparTAT F

+4, Automatic Transmission Fluid.

3) Internal transfer case

components binding, worn, or

damaged.3) Repair or replace components as

necessary.

Transfer case noisy in all drive

modes.1) Insufficient or incorrect lubricant. 1) Drain and refill transfer case with

the correct quantity of MoparTAT F

+4, Automatic Transmission Fluid.

2) Internal transfer case

components binding, worn, or

damaged.2) Repair or replace components as

necessary.

Transfer case noisy while in, or

jumps out of, 4LO.1) Transfer case not completely

engaged in 4LO position.1) While rolling 2-3 MPH and the

transmission in NEUTRAL, or the

clutch depressed on vehicles

equipped with a manual

transmission, shift the transfer case

to the AWD or 4HI position, and

then back into the 4LO position.

2) Range fork damaged, inserts

worn, or fork is binding on the shift

rail.2) Repair or replace components as

necessary.

3) Low range gear worn or

damaged.3) Repair or replace components as

necessary.

Fig. 1 Fill/Drain Plug And I.D. Tag Locations

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

DRTRANSFER CASE - NV244 GENII 21 - 513

TRANSFER CASE - NV244 GENII (Continued)

Page 2226 of 2627

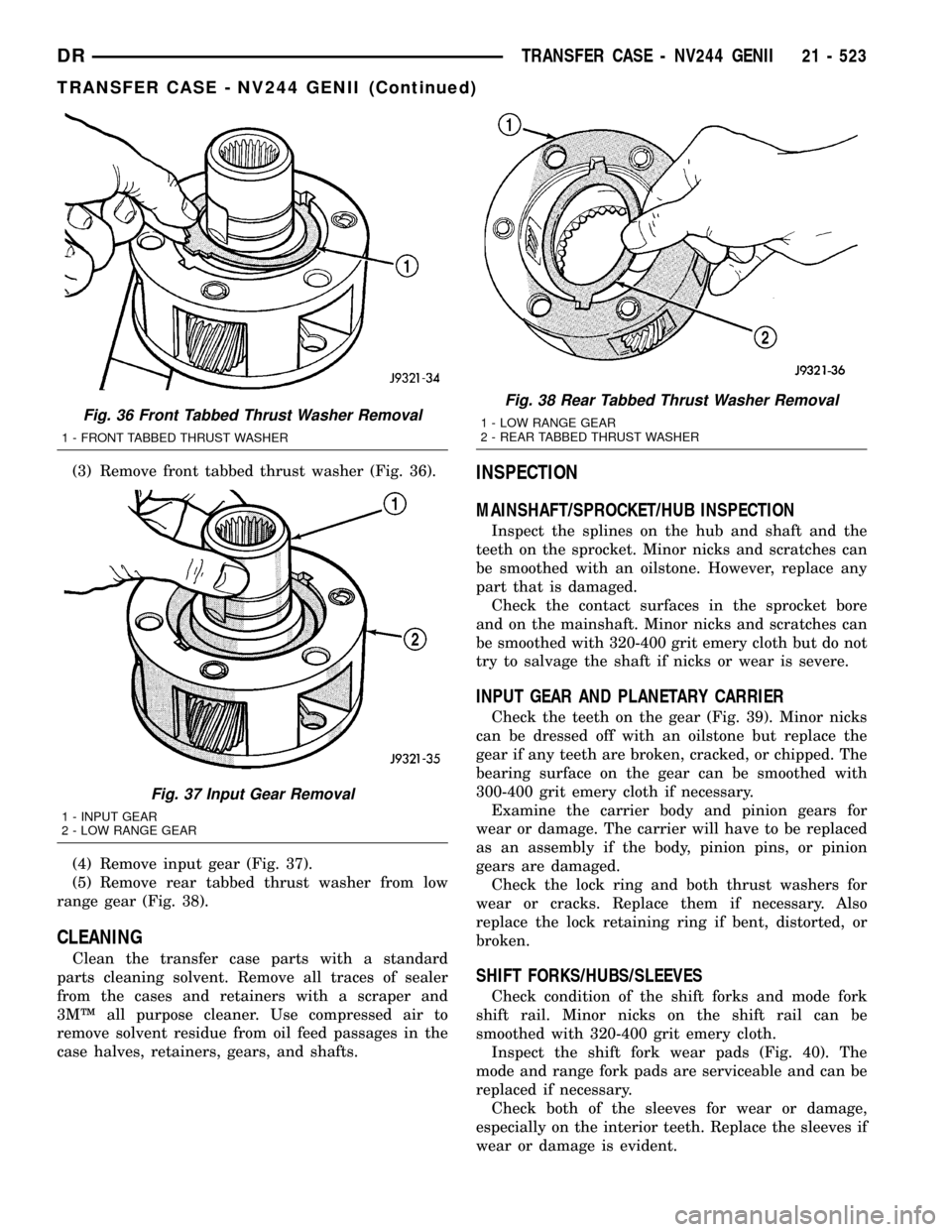

(3) Remove front tabbed thrust washer (Fig. 36).

(4) Remove input gear (Fig. 37).

(5) Remove rear tabbed thrust washer from low

range gear (Fig. 38).

CLEANING

Clean the transfer case parts with a standard

parts cleaning solvent. Remove all traces of sealer

from the cases and retainers with a scraper and

3MŸ all purpose cleaner. Use compressed air to

remove solvent residue from oil feed passages in the

case halves, retainers, gears, and shafts.

INSPECTION

MAINSHAFT/SPROCKET/HUB INSPECTION

Inspect the splines on the hub and shaft and the

teeth on the sprocket. Minor nicks and scratches can

be smoothed with an oilstone. However, replace any

part that is damaged.

Check the contact surfaces in the sprocket bore

and on the mainshaft. Minor nicks and scratches can

be smoothed with 320-400 grit emery cloth but do not

try to salvage the shaft if nicks or wear is severe.

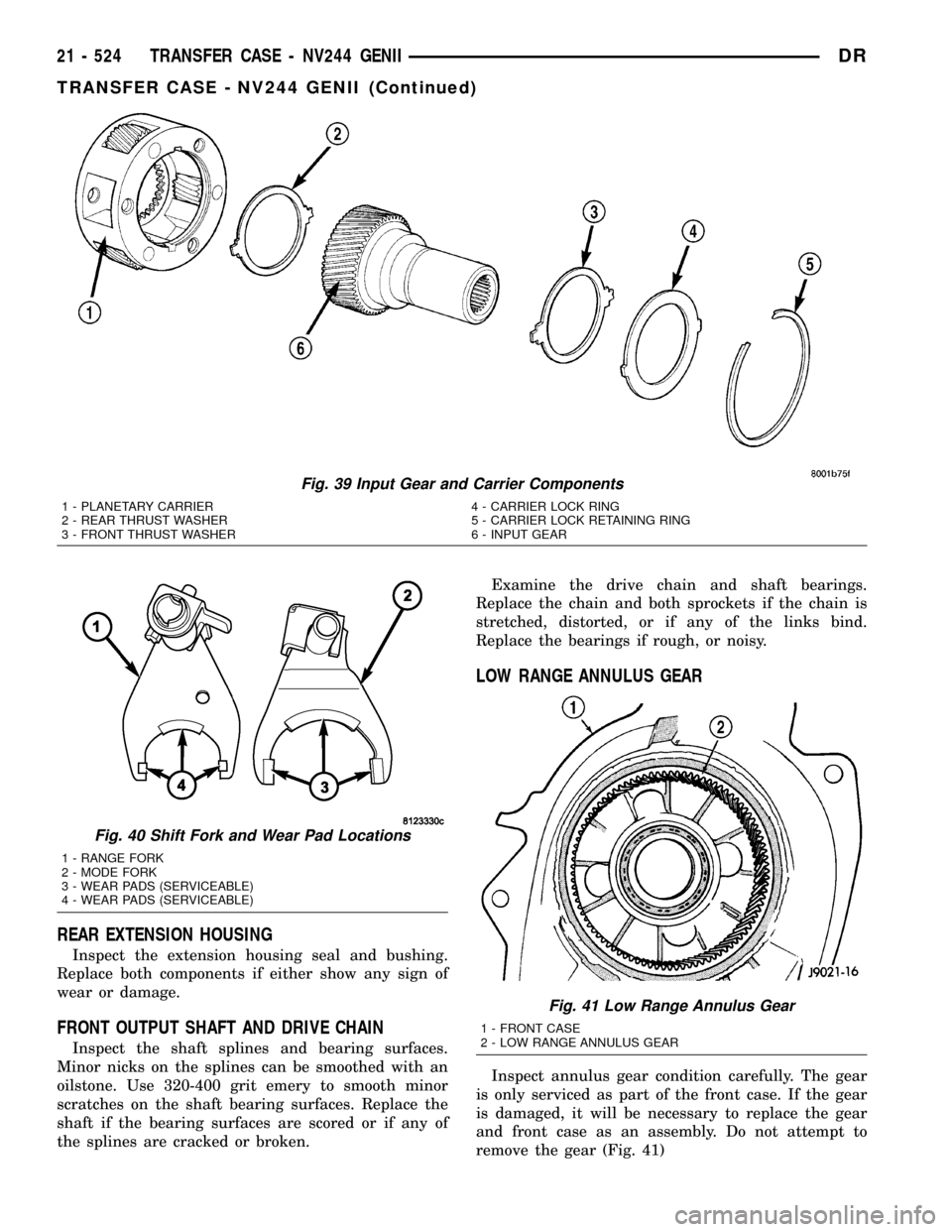

INPUT GEAR AND PLANETARY CARRIER

Check the teeth on the gear (Fig. 39). Minor nicks

can be dressed off with an oilstone but replace the

gear if any teeth are broken, cracked, or chipped. The

bearing surface on the gear can be smoothed with

300-400 grit emery cloth if necessary.

Examine the carrier body and pinion gears for

wear or damage. The carrier will have to be replaced

as an assembly if the body, pinion pins, or pinion

gears are damaged.

Check the lock ring and both thrust washers for

wear or cracks. Replace them if necessary. Also

replace the lock retaining ring if bent, distorted, or

broken.

SHIFT FORKS/HUBS/SLEEVES

Check condition of the shift forks and mode fork

shift rail. Minor nicks on the shift rail can be

smoothed with 320-400 grit emery cloth.

Inspect the shift fork wear pads (Fig. 40). The

mode and range fork pads are serviceable and can be

replaced if necessary.

Check both of the sleeves for wear or damage,

especially on the interior teeth. Replace the sleeves if

wear or damage is evident.

Fig. 36 Front Tabbed Thrust Washer Removal

1 - FRONT TABBED THRUST WASHER

Fig. 37 Input Gear Removal

1 - INPUT GEAR

2 - LOW RANGE GEAR

Fig. 38 Rear Tabbed Thrust Washer Removal

1 - LOW RANGE GEAR

2 - REAR TABBED THRUST WASHER

DRTRANSFER CASE - NV244 GENII 21 - 523

TRANSFER CASE - NV244 GENII (Continued)

Page 2227 of 2627

REAR EXTENSION HOUSING

Inspect the extension housing seal and bushing.

Replace both components if either show any sign of

wear or damage.

FRONT OUTPUT SHAFT AND DRIVE CHAIN

Inspect the shaft splines and bearing surfaces.

Minor nicks on the splines can be smoothed with an

oilstone. Use 320-400 grit emery to smooth minor

scratches on the shaft bearing surfaces. Replace the

shaft if the bearing surfaces are scored or if any of

the splines are cracked or broken.Examine the drive chain and shaft bearings.

Replace the chain and both sprockets if the chain is

stretched, distorted, or if any of the links bind.

Replace the bearings if rough, or noisy.

LOW RANGE ANNULUS GEAR

Inspect annulus gear condition carefully. The gear

is only serviced as part of the front case. If the gear

is damaged, it will be necessary to replace the gear

and front case as an assembly. Do not attempt to

remove the gear (Fig. 41)

Fig. 39 Input Gear and Carrier Components

1 - PLANETARY CARRIER 4 - CARRIER LOCK RING

2 - REAR THRUST WASHER 5 - CARRIER LOCK RETAINING RING

3 - FRONT THRUST WASHER 6 - INPUT GEAR

Fig. 40 Shift Fork and Wear Pad Locations

1 - RANGE FORK

2 - MODE FORK

3 - WEAR PADS (SERVICEABLE)

4 - WEAR PADS (SERVICEABLE)

Fig. 41 Low Range Annulus Gear

1 - FRONT CASE

2 - LOW RANGE ANNULUS GEAR

21 - 524 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2229 of 2627

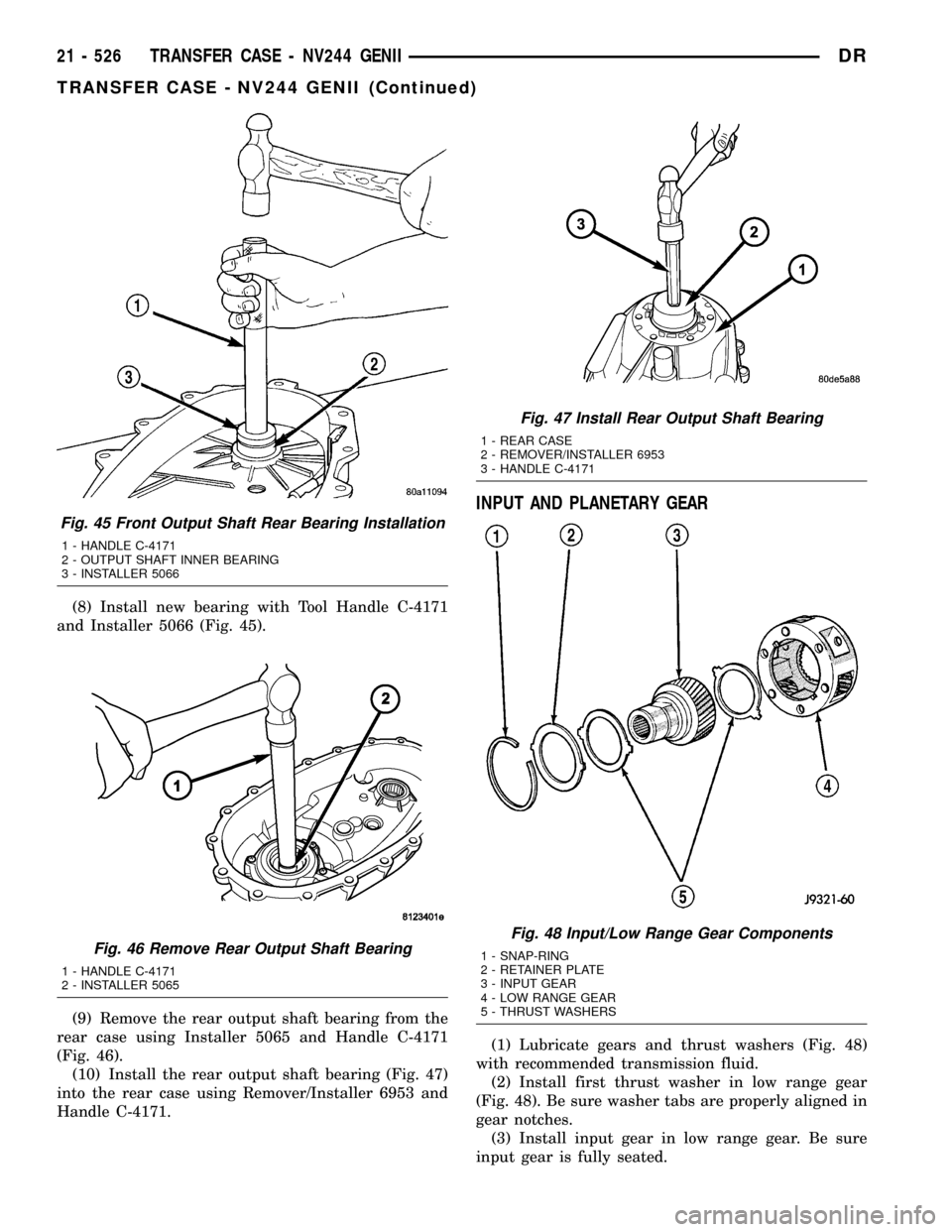

(8) Install new bearing with Tool Handle C-4171

and Installer 5066 (Fig. 45).

(9) Remove the rear output shaft bearing from the

rear case using Installer 5065 and Handle C-4171

(Fig. 46).

(10) Install the rear output shaft bearing (Fig. 47)

into the rear case using Remover/Installer 6953 and

Handle C-4171.

INPUT AND PLANETARY GEAR

(1) Lubricate gears and thrust washers (Fig. 48)

with recommended transmission fluid.

(2) Install first thrust washer in low range gear

(Fig. 48). Be sure washer tabs are properly aligned in

gear notches.

(3) Install input gear in low range gear. Be sure

input gear is fully seated.

Fig. 45 Front Output Shaft Rear Bearing Installation

1 - HANDLE C-4171

2 - OUTPUT SHAFT INNER BEARING

3 - INSTALLER 5066

Fig. 46 Remove Rear Output Shaft Bearing

1 - HANDLE C-4171

2 - INSTALLER 5065

Fig. 47 Install Rear Output Shaft Bearing

1 - REAR CASE

2 - REMOVER/INSTALLER 6953

3 - HANDLE C-4171

Fig. 48 Input/Low Range Gear Components

1 - SNAP-RING

2 - RETAINER PLATE

3 - INPUT GEAR

4 - LOW RANGE GEAR

5 - THRUST WASHERS

21 - 526 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2235 of 2627

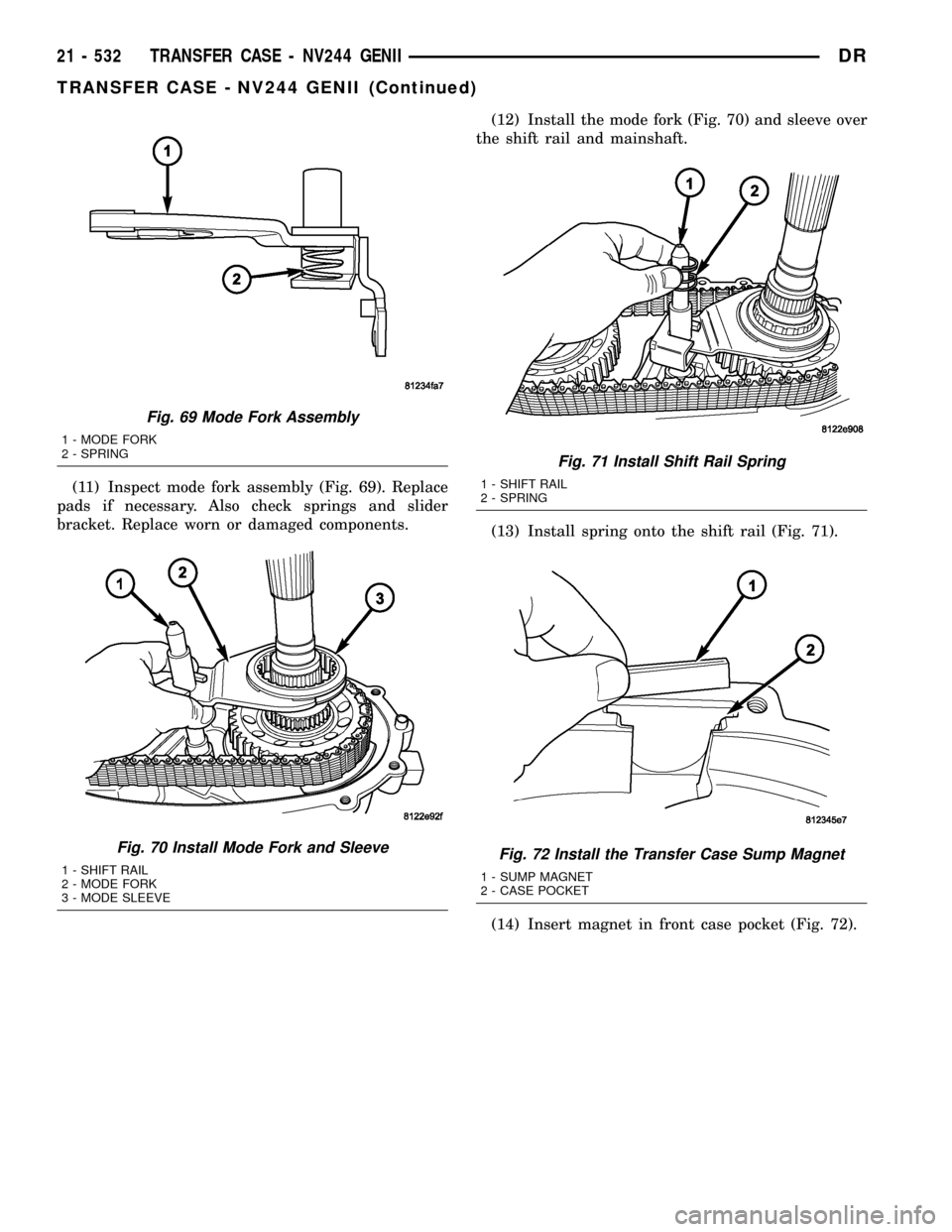

(11) Inspect mode fork assembly (Fig. 69). Replace

pads if necessary. Also check springs and slider

bracket. Replace worn or damaged components.(12) Install the mode fork (Fig. 70) and sleeve over

the shift rail and mainshaft.

(13) Install spring onto the shift rail (Fig. 71).

(14) Insert magnet in front case pocket (Fig. 72).

Fig. 69 Mode Fork Assembly

1 - MODE FORK

2 - SPRING

Fig. 70 Install Mode Fork and Sleeve

1 - SHIFT RAIL

2 - MODE FORK

3 - MODE SLEEVE

Fig. 71 Install Shift Rail Spring

1 - SHIFT RAIL

2 - SPRING

Fig. 72 Install the Transfer Case Sump Magnet

1 - SUMP MAGNET

2 - CASE POCKET

21 - 532 TRANSFER CASE - NV244 GENIIDR

TRANSFER CASE - NV244 GENII (Continued)

Page 2236 of 2627

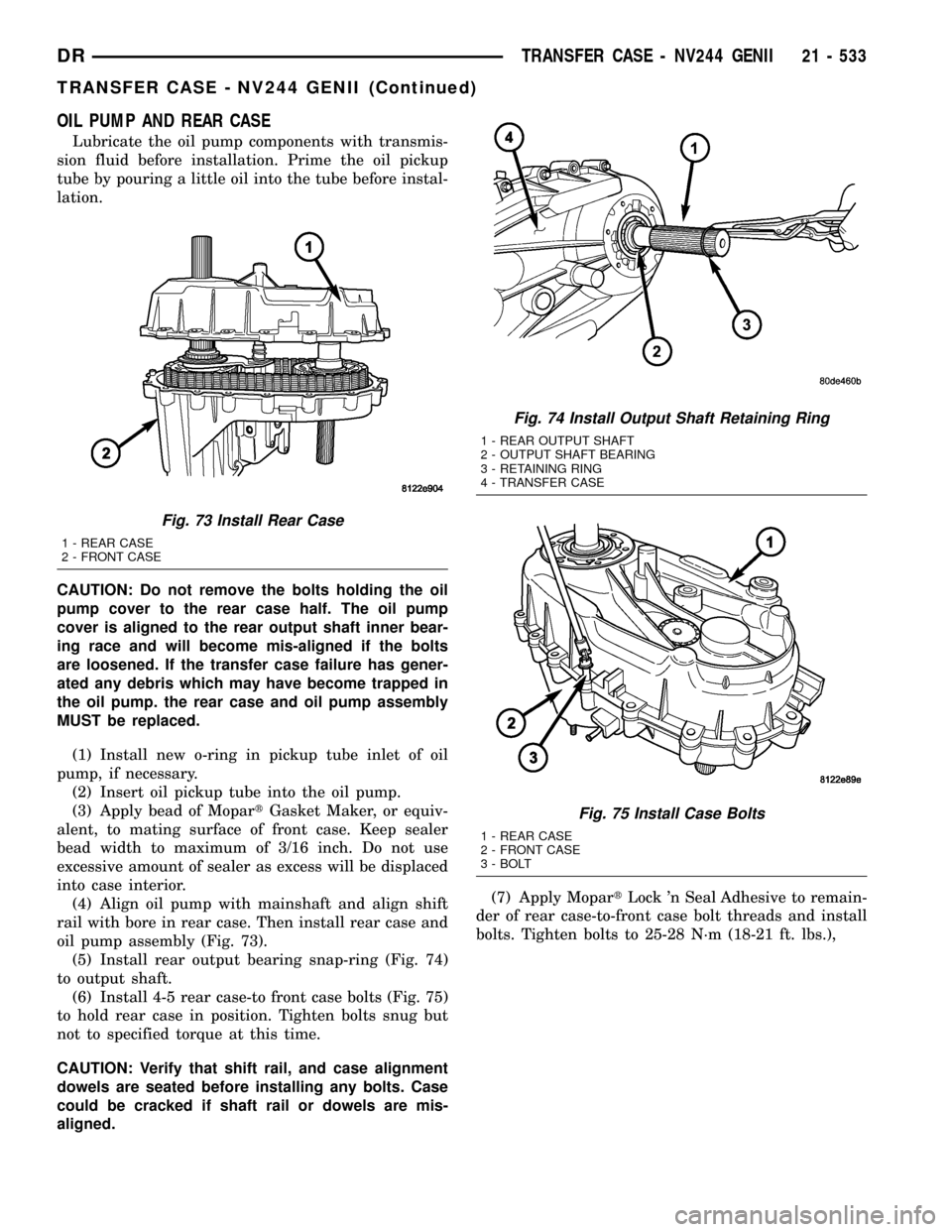

OIL PUMP AND REAR CASE

Lubricate the oil pump components with transmis-

sion fluid before installation. Prime the oil pickup

tube by pouring a little oil into the tube before instal-

lation.

CAUTION: Do not remove the bolts holding the oil

pump cover to the rear case half. The oil pump

cover is aligned to the rear output shaft inner bear-

ing race and will become mis-aligned if the bolts

are loosened. If the transfer case failure has gener-

ated any debris which may have become trapped in

the oil pump. the rear case and oil pump assembly

MUST be replaced.

(1) Install new o-ring in pickup tube inlet of oil

pump, if necessary.

(2) Insert oil pickup tube into the oil pump.

(3) Apply bead of MopartGasket Maker, or equiv-

alent, to mating surface of front case. Keep sealer

bead width to maximum of 3/16 inch. Do not use

excessive amount of sealer as excess will be displaced

into case interior.

(4) Align oil pump with mainshaft and align shift

rail with bore in rear case. Then install rear case and

oil pump assembly (Fig. 73).

(5) Install rear output bearing snap-ring (Fig. 74)

to output shaft.

(6) Install 4-5 rear case-to front case bolts (Fig. 75)

to hold rear case in position. Tighten bolts snug but

not to specified torque at this time.

CAUTION: Verify that shift rail, and case alignment

dowels are seated before installing any bolts. Case

could be cracked if shaft rail or dowels are mis-

aligned.(7) Apply MopartLock 'n Seal Adhesive to remain-

der of rear case-to-front case bolt threads and install

bolts. Tighten bolts to 25-28 N´m (18-21 ft. lbs.),

Fig. 73 Install Rear Case

1 - REAR CASE

2 - FRONT CASE

Fig. 74 Install Output Shaft Retaining Ring

1 - REAR OUTPUT SHAFT

2 - OUTPUT SHAFT BEARING

3 - RETAINING RING

4 - TRANSFER CASE

Fig. 75 Install Case Bolts

1 - REAR CASE

2 - FRONT CASE

3 - BOLT

DRTRANSFER CASE - NV244 GENII 21 - 533

TRANSFER CASE - NV244 GENII (Continued)