Headlamp adjustment DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 556 of 2627

LAMPS

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - EXTERIOR............... 1LAMPS/LIGHTING - INTERIOR............... 26

LAMPS/LIGHTING - EXTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION..........................2

OPERATION............................2

DIAGNOSIS AND TESTING - LAMPS/

LIGHTING - EXTERIOR..................3

STANDARD PROCEDURE

SAFETY PRECAUTIONS.................7

SPECIFICATIONS

EXTERIOR LAMPS.....................7

BACKUP LAMP

REMOVAL

REMOVAL - WITH CARGO BOX...........7

REMOVAL - WITHOUT CARGO BOX........7

INSTALLATION

INSTALLATION - WITH CARGO BOX........7

INSTALLATION - WITHOUT CARGO BOX....8

BACKUP LAMP SWITCH

DESCRIPTION..........................8

OPERATION............................8

DIAGNOSIS AND TESTING - BACKUP LAMP

SWITCH.............................8

BRAKE LAMP

REMOVAL

REMOVAL - WITH CARGO BOX...........9

REMOVAL - WITHOUT CARGO BOX........9

INSTALLATION

INSTALLATION - WITH CARGO BOX........9

INSTALLATION - WITHOUT CARGO BOX....9

BRAKE LAMP SWITCH

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - BRAKE LAMP

SWITCH............................10

REMOVAL.............................10

INSTALLATION.........................11

CENTER HIGH MOUNTED STOP LAMP

REMOVAL.............................11INSTALLATION.........................11

CENTER HIGH MOUNTED STOP LAMP UNIT

REMOVAL.............................11

INSTALLATION.........................11

CAB CLEARANCE LAMP

REMOVAL.............................11

INSTALLATION.........................12

FOG LAMP

REMOVAL.............................12

INSTALLATION.........................12

FOG LAMP RELAY

DESCRIPTION.........................12

OPERATION...........................13

REMOVAL.............................13

INSTALLATION.........................13

HAZARD SWITCH

DESCRIPTION.........................14

OPERATION...........................14

HEADLAMP

REMOVAL.............................14

INSTALLATION.........................14

HEADLAMP SWITCH

DESCRIPTION.........................14

OPERATION...........................14

REMOVAL.............................14

INSTALLATION.........................15

HEADLAMP UNIT

REMOVAL.............................15

INSTALLATION.........................15

ADJUSTMENTS........................16

LICENSE PLATE LAMP

REMOVAL.............................17

INSTALLATION.........................17

LICENSE PLATE LAMP UNIT

REMOVAL.............................17

INSTALLATION.........................17

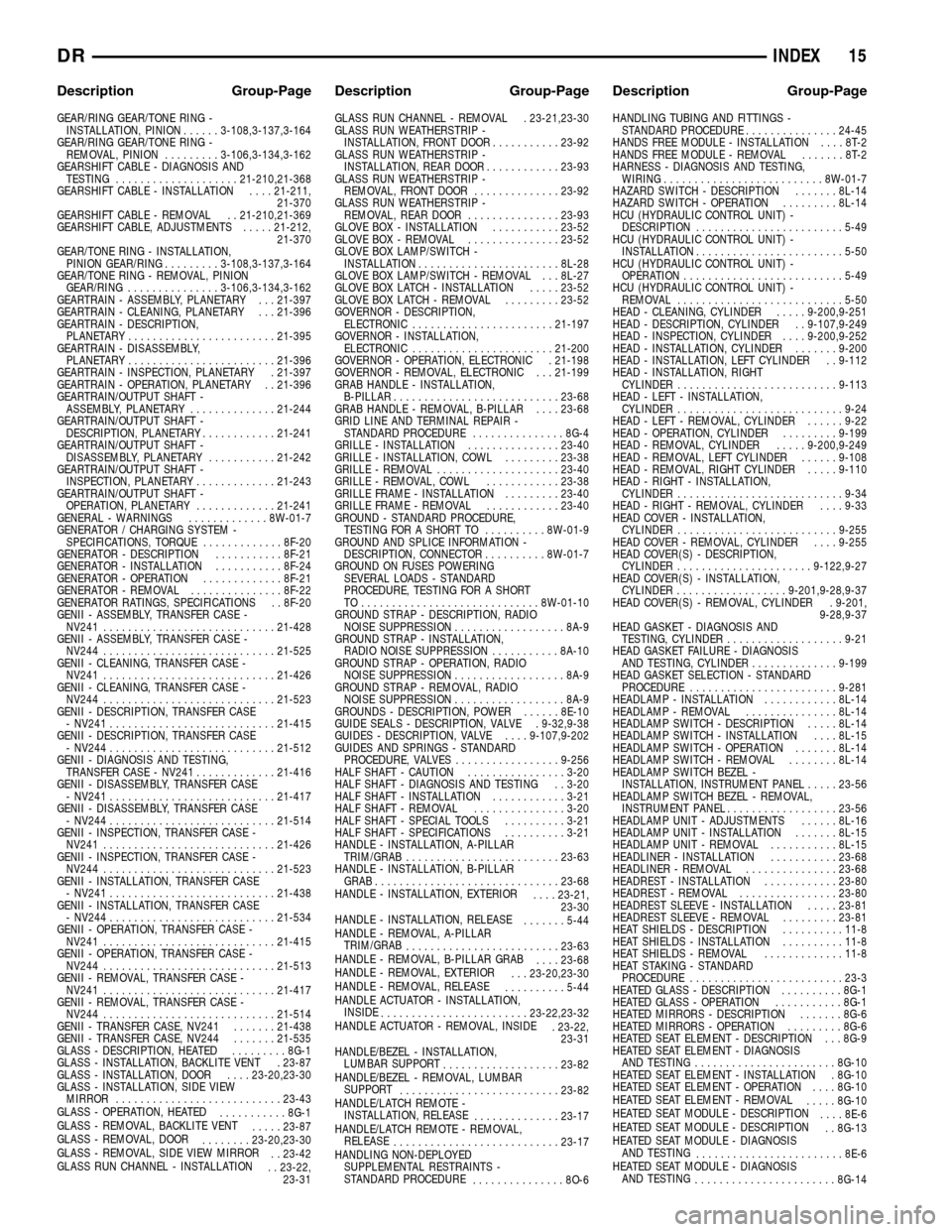

DRLAMPS 8L - 1

Page 571 of 2627

(3) Install the bolts attaching headlamp unit to the

fender (Fig. 11).

(4) Align the seal and install the push pins.

(5) Connect the battery negative cable.

ADJUSTMENTS

Headlamps can be aligned using the screen method

provided in this section.

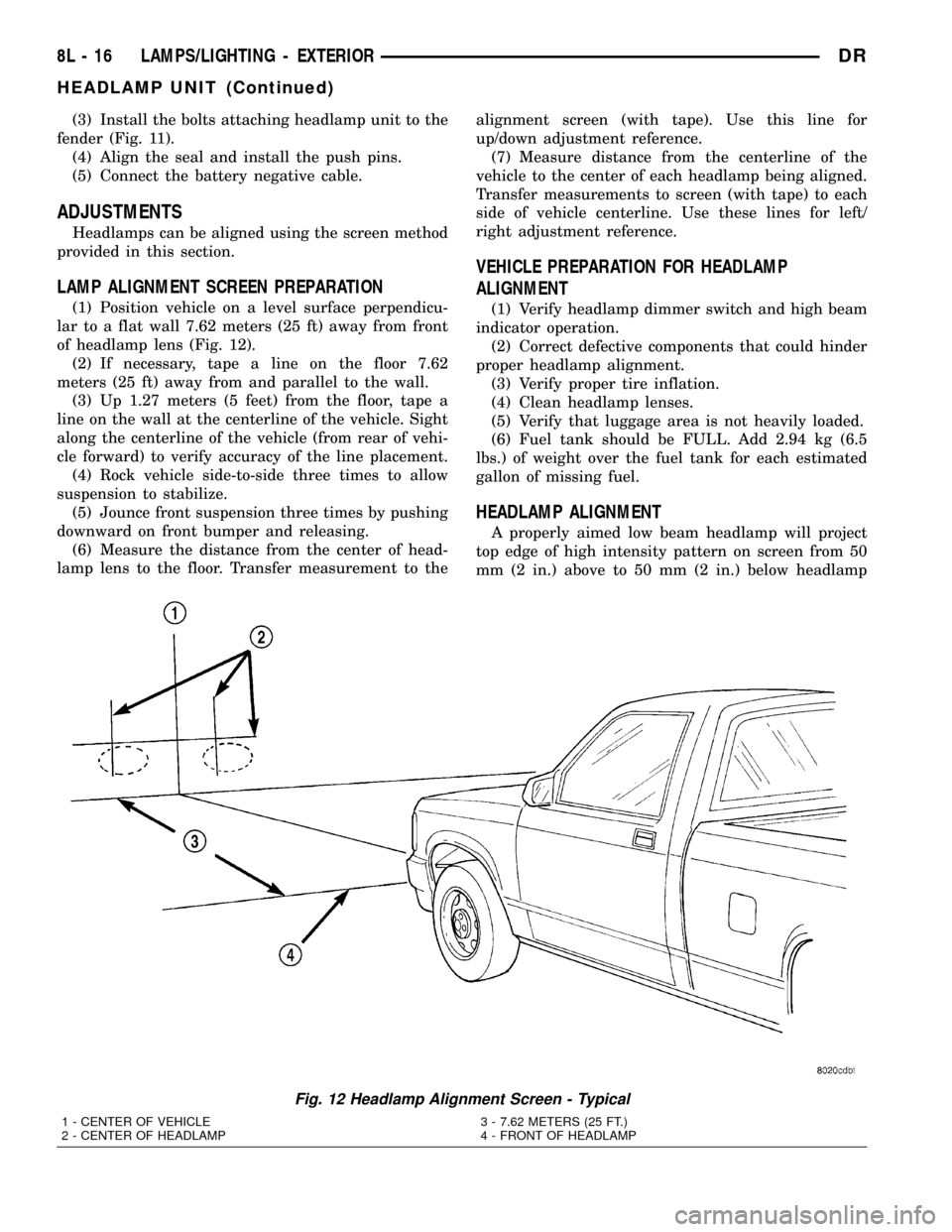

LAMP ALIGNMENT SCREEN PREPARATION

(1) Position vehicle on a level surface perpendicu-

lar to a flat wall 7.62 meters (25 ft) away from front

of headlamp lens (Fig. 12).

(2) If necessary, tape a line on the floor 7.62

meters (25 ft) away from and parallel to the wall.

(3) Up 1.27 meters (5 feet) from the floor, tape a

line on the wall at the centerline of the vehicle. Sight

along the centerline of the vehicle (from rear of vehi-

cle forward) to verify accuracy of the line placement.

(4) Rock vehicle side-to-side three times to allow

suspension to stabilize.

(5) Jounce front suspension three times by pushing

downward on front bumper and releasing.

(6) Measure the distance from the center of head-

lamp lens to the floor. Transfer measurement to thealignment screen (with tape). Use this line for

up/down adjustment reference.

(7) Measure distance from the centerline of the

vehicle to the center of each headlamp being aligned.

Transfer measurements to screen (with tape) to each

side of vehicle centerline. Use these lines for left/

right adjustment reference.

VEHICLE PREPARATION FOR HEADLAMP

ALIGNMENT

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Correct defective components that could hinder

proper headlamp alignment.

(3) Verify proper tire inflation.

(4) Clean headlamp lenses.

(5) Verify that luggage area is not heavily loaded.

(6) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

HEADLAMP ALIGNMENT

A properly aimed low beam headlamp will project

top edge of high intensity pattern on screen from 50

mm (2 in.) above to 50 mm (2 in.) below headlamp

Fig. 12 Headlamp Alignment Screen - Typical

1 - CENTER OF VEHICLE

2 - CENTER OF HEADLAMP3 - 7.62 METERS (25 FT.)

4 - FRONT OF HEADLAMP

8L - 16 LAMPS/LIGHTING - EXTERIORDR

HEADLAMP UNIT (Continued)

Page 572 of 2627

centerline. The side-to-side outboard edge of high

intensity pattern should be from 150 mm (6 in.) left

to 150 mm (6 in.) right of headlamp centerline (Fig.

12).The preferred headlamp alignment is 1(

down for the up/down adjustment and 0 for the

left/right adjustment.The high beam pattern

should be correct when the low beams are aligned

properly.

To adjust low beam headlamp, rotate vertical align-

ment screw to achieve the specified aim.

LICENSE PLATE LAMP

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Grasp license plate bulb socket and 1/4 turn

left to release from the license plate lamp unit.

(3) Pull bulb from license plate lamp socket.

INSTALLATION

(1) Install the bulb in the socket.

(2) Install the socket in to the license plate lamp

unit and 1/4 turn to lock.

(3) Connect the battery negative cable.

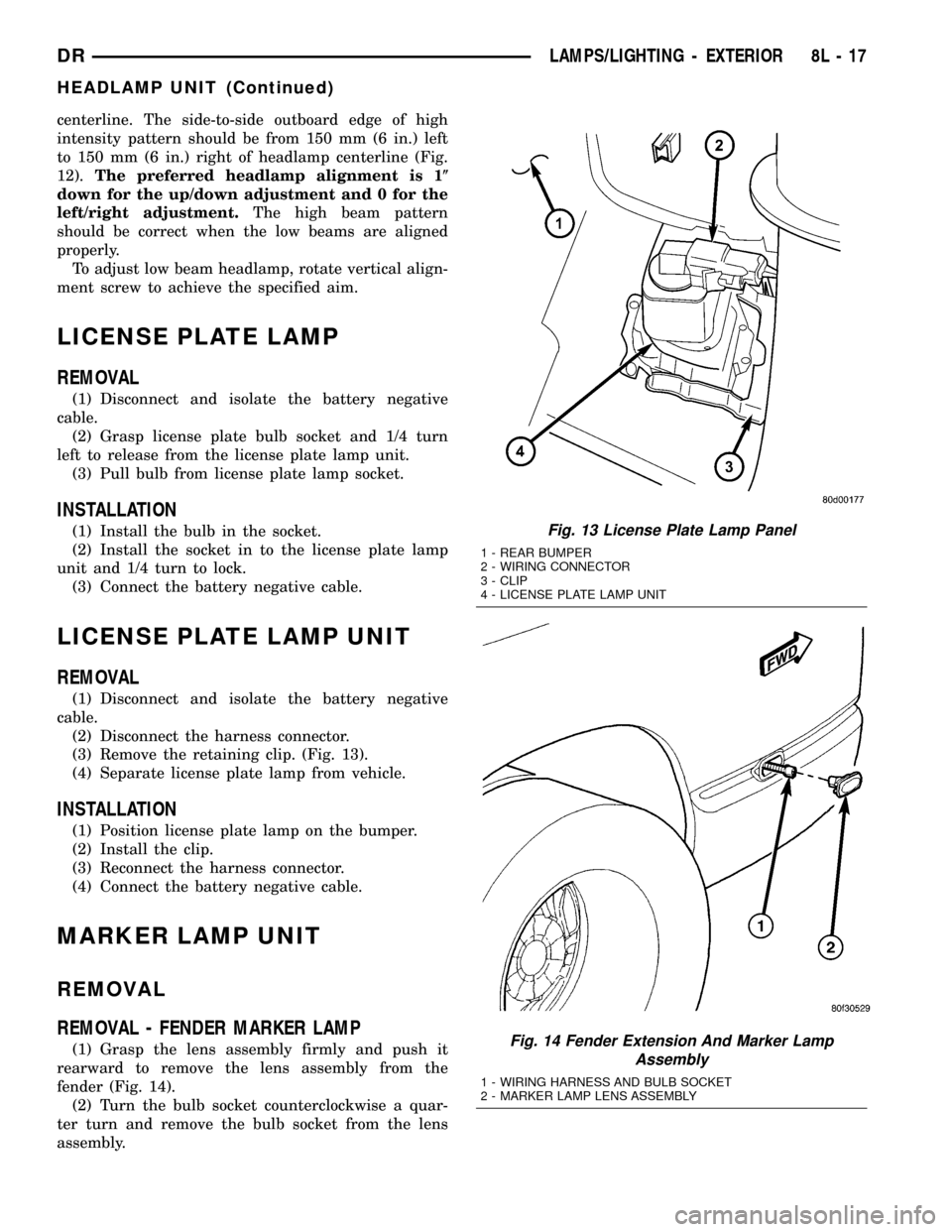

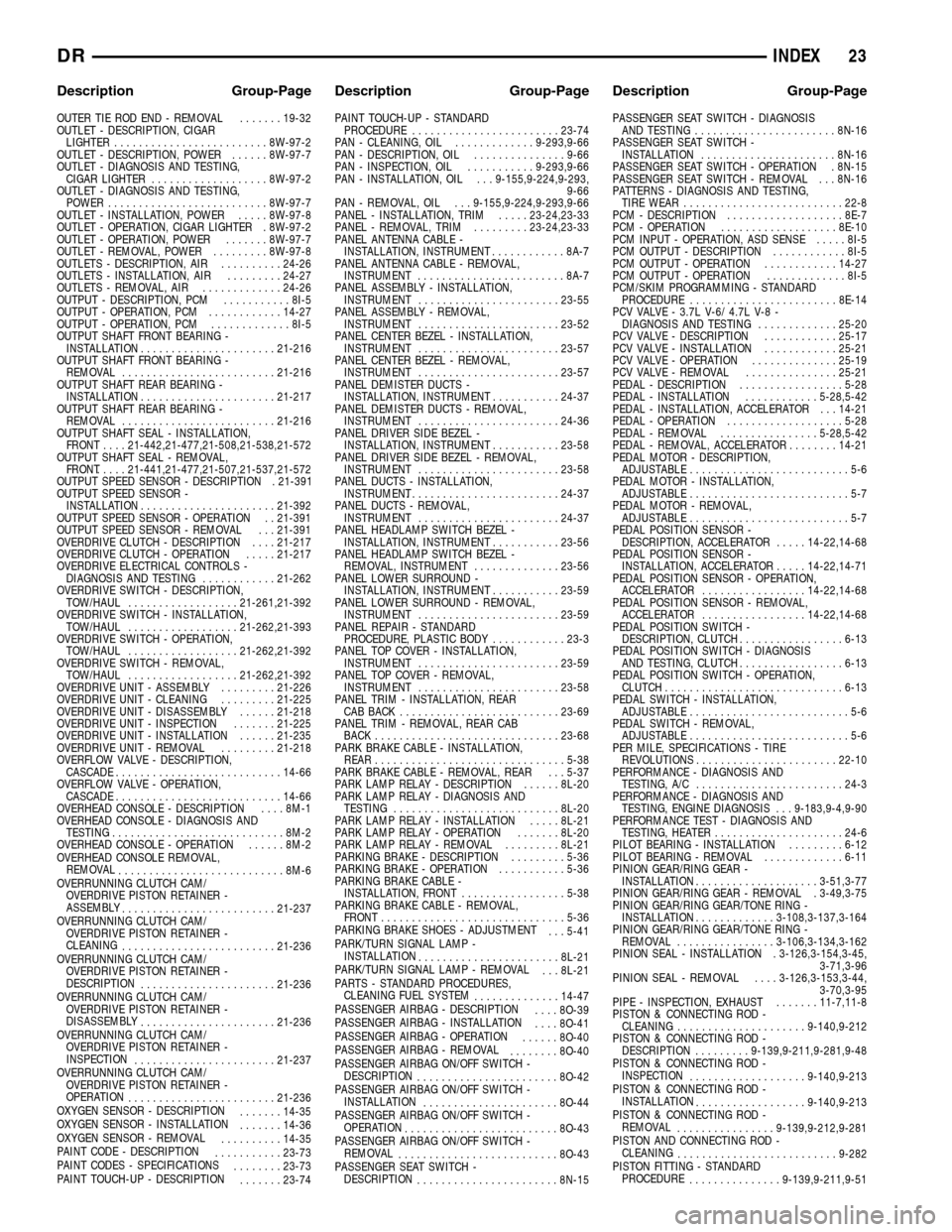

LICENSE PLATE LAMP UNIT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the harness connector.

(3) Remove the retaining clip. (Fig. 13).

(4) Separate license plate lamp from vehicle.

INSTALLATION

(1) Position license plate lamp on the bumper.

(2) Install the clip.

(3) Reconnect the harness connector.

(4) Connect the battery negative cable.

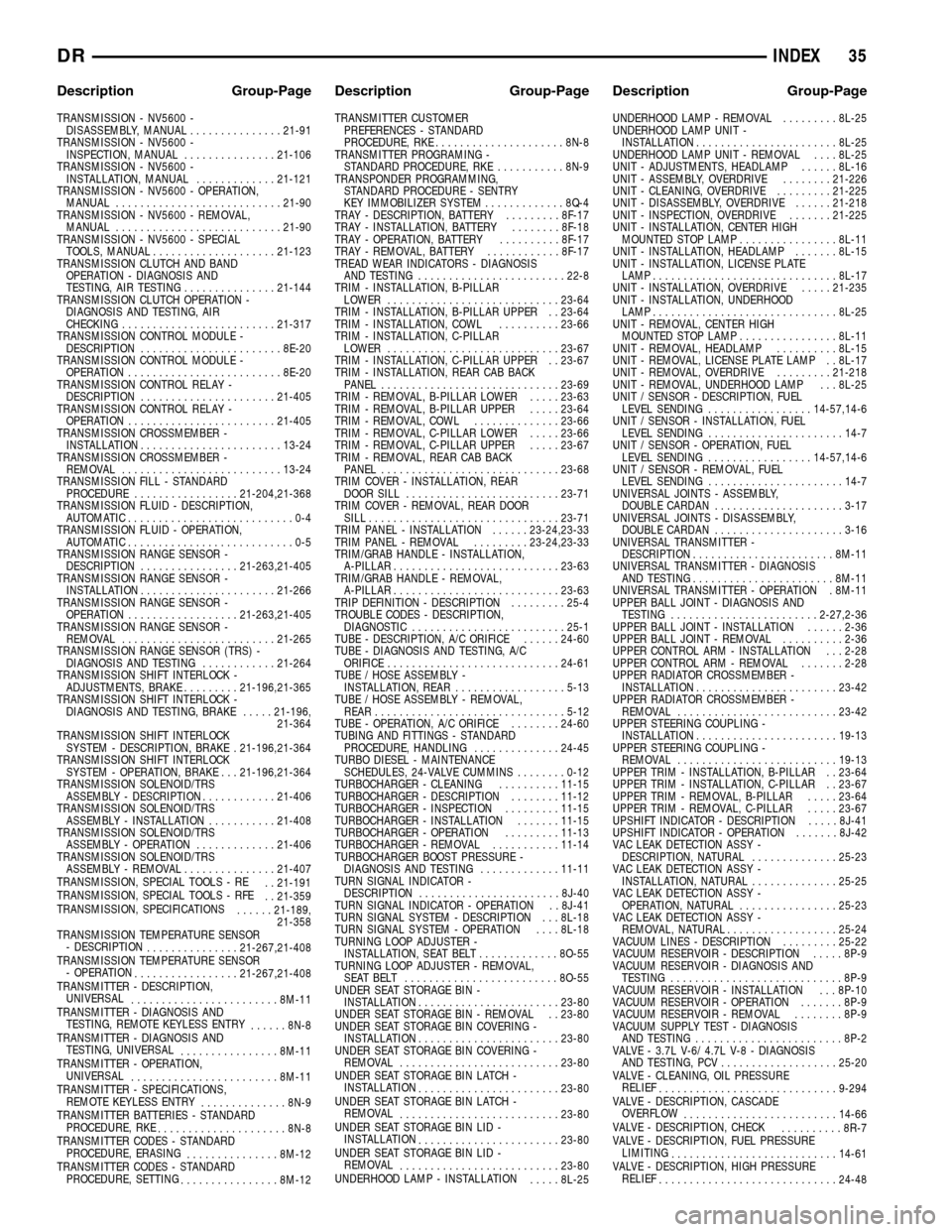

MARKER LAMP UNIT

REMOVAL

REMOVAL - FENDER MARKER LAMP

(1) Grasp the lens assembly firmly and push it

rearward to remove the lens assembly from the

fender (Fig. 14).

(2) Turn the bulb socket counterclockwise a quar-

ter turn and remove the bulb socket from the lens

assembly.

Fig. 13 License Plate Lamp Panel

1 - REAR BUMPER

2 - WIRING CONNECTOR

3 - CLIP

4 - LICENSE PLATE LAMP UNIT

Fig. 14 Fender Extension And Marker Lamp

Assembly

1 - WIRING HARNESS AND BULB SOCKET

2 - MARKER LAMP LENS ASSEMBLY

DRLAMPS/LIGHTING - EXTERIOR 8L - 17

HEADLAMP UNIT (Continued)

Page 2590 of 2627

BALL JOINT - DIAGNOSIS AND TESTING,

LOWER.........................2-19,2-34

BALL JOINT - DIAGNOSIS AND TESTING,

UPPER..........................2-27,2-36

BALL JOINT - INSTALLATION, LOWER . 2-20,2-35

BALL JOINT - INSTALLATION, UPPER.....2-36

BALL JOINT - REMOVAL, LOWER.....2-19,2-35

BALL JOINT - REMOVAL, UPPER.........2-36

BAND OPERATION - DIAGNOSIS AND

TESTING, AIR TESTING

TRANSMISSION CLUTCH.............21-144

BANDS - ADJUSTMENT...............21-195

BANDS - DESCRIPTION...............21-194

BANDS - OPERATION................21-194

BAR - DESCRIPTION, STABILIZER........2-24

BAR - DESCRIPTION, TORSION..........2-26

BAR - INSTALLATION, STABILIZER....2-25,2-40

BAR - INSTALLATION, TORSION..........2-27

BAR - INSTALLATION, TRACK...........19-38

BAR - OPERATION, STABILIZER..........2-25

BAR - OPERATION, TORSION............2-26

BAR - REMOVAL, STABILIZER.......2-25,2-39

BAR - REMOVAL, TORSION.............2-26

BAR - REMOVAL, TRACK..............19-38

BAR CROSS MEMBER BUSHING -

INSTALLATION, TORSION...............2-15

BAR CROSSMEMBER BUSHING -

REMOVAL, TORSION...................2-13

BASE BRAKE, SPECIFICATIONS...........5-10

BASE BRAKE SYSTEM - DIAGNOSIS AND

TESTING.............................5-2

BASE BRAKES, SPECIAL TOOLS...........5-5

BASECOAT/CLEARCOAT FINISH -

DESCRIPTION.......................23-73

BATTERIES - STANDARD PROCEDURE,

RKE TRANSMITTER...................8N-8

BATTERY - DESCRIPTION...............8F-7

BATTERY - DIAGNOSIS AND TESTING.....8F-7

BATTERY CABLES - DESCRIPTION.......8F-14

BATTERY CABLES - DIAGNOSIS AND

TESTING...........................8F-15

BATTERY CABLES - INSTALLATION.......8F-17

BATTERY CABLES - OPERATION.........8F-15

BATTERY CABLES - REMOVAL..........8F-16

BATTERY CHARGING - STANDARD

PROCEDURE.........................8F-8

BATTERY HOLDDOWN - DESCRIPTION....8F-14

BATTERY HOLDDOWN - INSTALLATION . . . 8F-14

BATTERY HOLDDOWN - OPERATION.....8F-14

BATTERY HOLDDOWN - REMOVAL.......8F-14

BATTERY SYSTEM - CLEANING...........8F-5

BATTERY SYSTEM - DESCRIPTION........8F-1

BATTERY SYSTEM - DIAGNOSIS AND

TESTING............................8F-2

BATTERY SYSTEM - INSPECTION.........8F-5

BATTERY SYSTEM - OPERATION.........8F-2

BATTERY SYSTEM - SPECIFICATIONS......8F-6

BATTERY SYSTEM SPECIAL TOOLS,

SPECIAL TOOLS......................8F-7

BATTERY TEMPERATURE SENSOR -

DESCRIPTION.......................8F-21

BATTERY TEMPERATURE SENSOR -

INSTALLATION.......................8F-21

BATTERY TEMPERATURE SENSOR -

OPERATION.........................8F-21

BATTERY TEMPERATURE SENSOR -

REMOVAL..........................8F-21

BATTERY TESTER - STANDARD

PROCEDURE, USING MICRO 420........8F-12

BATTERY TRAY - DESCRIPTION.........8F-17

BATTERY TRAY - INSTALLATION.........8F-18

BATTERY TRAY - OPERATION...........8F-17

BATTERY TRAY - REMOVAL............8F-17

BEAM INDICATOR - DESCRIPTION, HIGH . . 8J-28

BEAM INDICATOR - OPERATION, HIGH....8J-28

BEARING - ADJUSTMENTS, CENTER.......3-9

BEARING - FITTING - STANDARD

PROCEDURE, CRANKSHAFT MAIN . . 9-134,9-207

BEARING - INSTALLATION, CENTER........3-9

BEARING - INSTALLATION, CLUTCH

RELEASE............................6-10

BEARING - INSTALLATION, HUB

..........2-32

BEARING - INSTALLATION, OUTPUT

SHAFT FRONT

......................21-216

BEARING - INSTALLATION, OUTPUT

SHAFT REAR

.......................21-217

BEARING - INSTALLATION, PILOT

........6-12

BEARING - REMOVAL, CENTER

...........3-9BEARING - REMOVAL, CLUTCH RELEASE . . . 6-9

BEARING - REMOVAL, HUB.............2-31

BEARING - REMOVAL, OUTPUT SHAFT

FRONT............................21-216

BEARING - REMOVAL, OUTPUT SHAFT

REAR.............................21-216

BEARING - REMOVAL, PILOT............6-11

BEARING AND CRANKSHAFT JOURNAL

CLEARANCE - STANDARD

PROCEDURE, CONNECTING ROD........9-272

BEARING CLEARANCE - STANDARD

PROCEDURE, MAIN...................9-274

BEARING FITTING - STANDARD

PROCEDURE, CONNECTING ROD........9-129

BEARING FITTING, STANDARD

PROCEDURE - CONNECTING ROD........9-49

BEARING FITTING, STANDARD

PROCEDURE - MAIN...................9-44

BEARINGS - INSPECTION, CRANKSHAFT

MAIN.........................9-135,9-208

BEARINGS - INSTALLATION, AXLE . . 3-125,3-153,

3-44,3-95

BEARINGS - INSTALLATION, CAMSHAFT . . 9-271

BEARINGS - INSTALLATION,

DIFFERENTIAL CASE . . . 3-106,3-134,3-161,3-48,

3-75

BEARINGS - REMOVAL, AXLE . 3-125,3-152,3-43,

3-95

BEARINGS - REMOVAL, CAMSHAFT......9-268

BEARINGS - REMOVAL, DIFFERENTIAL

CASE............3-105,3-134,3-161,3-48,3-75

BELT - 3.7L / 4.7L - INSTALLATION,

DRIVE................................7-26

BELT - 3.7L / 4.7L - REMOVAL, DRIVE.....7-26

BELT - 5.9L DIESEL - INSTALLATION,

DRIVE..............................7-29

BELT - 5.9L DIESEL - REMOVAL, DRIVE....7-29

BELT / CHAIN COVER(S) -

INSTALLATION, TIMING...........9-171,9-81

BELT / CHAIN COVER(S) - REMOVAL,

TIMING........................9-170,9-81

BELT - DIAGNOSIS AND TESTING,

ACCESSORY DRIVE................7-24,7-27

BELT - INSTALLATION, FRONT CENTER

SEAT ..............................8O-31

BELT - REMOVAL, FRONT CENTER SEAT . . 8O-30

BELT & RETRACTOR - INSTALLATION,

FRONT CENTER SEAT.................8O-29

BELT & RETRACTOR - INSTALLATION,

REAR CENTER SEAT..................8O-45

BELT & RETRACTOR - INSTALLATION,

REAR OUTBOARD SEAT...............8O-47

BELT & RETRACTOR - REMOVAL, FRONT

CENTER SEAT.......................8O-29

BELT & RETRACTOR - REMOVAL, REAR

CENTER SEAT.......................8O-44

BELT & RETRACTOR - REMOVAL, REAR

OUTBOARD SEAT....................8O-46

BELT BUCKLE - INSTALLATION, FRONT

OUTBOARD SEAT....................8O-38

BELT BUCKLE - REMOVAL, FRONT

OUTBOARD SEAT....................8O-37

BELT MOLDING - INSTALLATION, FRONT

DOOR INNER........................23-93

BELT MOLDING - INSTALLATION, FRONT

DOOR OUTER.......................23-93

BELT MOLDING - INSTALLATION, REAR

DOOR INNER........................23-94

BELT MOLDING - INSTALLATION, REAR

DOOR OUTER.......................23-94

BELT MOLDING - REMOVAL, FRONT

DOOR INNER........................23-93

BELT MOLDING - REMOVAL, FRONT

DOOR OUTER.......................23-92

BELT MOLDING - REMOVAL, REAR

DOOR INNER........................23-94

BELT MOLDING - REMOVAL, REAR

DOOR OUTER.......................23-93

BELT SWITCH - DESCRIPTION, SEAT.....8O-51

BELT SWITCH - DIAGNOSIS AND

TESTING, SEAT

......................8O-51

BELT SWITCH - OPERATION, SEAT

.......8O-51

BELT TENSION REDUCER -

DESCRIPTION, SEAT

..................8O-53

BELT TENSION REDUCER - DIAGNOSIS

AND TESTING, SEAT

..................8O-54

BELT TENSION REDUCER - OPERATION,

SEAT

..............................8O-54BELT TENSIONER - 3.7L / 4.7L -

DESCRIPTION........................7-21

BELT TENSIONER - 3.7L / 4.7L -

INSTALLATION........................7-22

BELT TENSIONER - 3.7L / 4.7L -

OPERATION..........................7-21

BELT TENSIONER - 3.7L / 4.7L -

REMOVAL...........................7-21

BELT TENSIONER - 5.9L DIESEL -

DESCRIPTION........................7-23

BELT TENSIONER - 5.9L DIESEL -

INSTALLATION........................7-24

BELT TENSIONER - 5.9L DIESEL -

OPERATION..........................7-23

BELT TENSIONER - 5.9L DIESEL -

REMOVAL...........................7-23

BELT TENSIONER - DESCRIPTION, SEAT . . 8O-52

BELT TENSIONER - OPERATION, SEAT....8O-53

BELT TENSIONER-5.7L - DESCRIPTION....7-22

BELT TENSIONER-5.7L - INSTALLATION....7-23

BELT TENSIONER-5.7L - OPERATION......7-22

BELT TENSIONER-5.7L - REMOVAL.......7-22

BELT TURNING LOOP ADJUSTER -

INSTALLATION, SEAT.................8O-55

BELT TURNING LOOP ADJUSTER -

REMOVAL, SEAT.....................8O-55

BELT/CHAIN AND SPROCKETS -

INSPECTION, TIMING.............9-174,9-84

BELT/CHAIN AND SPROCKETS -

INSTALLATION, TIMING...........9-176,9-85

BELT/CHAIN AND SPROCKETS -

REMOVAL, TIMING.................9-172,9-83

BEZEL - INSTALLATION, CLUSTER.......23-49

BEZEL - INSTALLATION, INSTRUMENT

PANEL CENTER......................23-57

BEZEL - INSTALLATION, INSTRUMENT

PANEL DRIVER SIDE..................23-58

BEZEL - INSTALLATION, INSTRUMENT

PANEL HEADLAMP SWITCH............23-56

BEZEL - REMOVAL, CLUSTER...........23-49

BEZEL - REMOVAL, INSTRUMENT PANEL

CENTER............................23-57

BEZEL - REMOVAL, INSTRUMENT PANEL

DRIVER SIDE........................23-58

BEZEL - REMOVAL, INSTRUMENT PANEL

HEADLAMP SWITCH..................23-56

BIN - INSTALLATION, STORAGE.........23-61

BIN - INSTALLATION, UNDER SEAT

STORAGE...........................23-80

BIN - REMOVAL, STORAGE.............23-61

BIN - REMOVAL, UNDER SEAT STORAGE . . 23-80

BIN COVERING - INSTALLATION, UNDER

SEAT STORAGE......................23-80

BIN COVERING - REMOVAL, UNDER

SEAT STORAGE......................23-80

BIN LATCH - INSTALLATION, UNDER

SEAT STORAGE......................23-80

BIN LATCH - REMOVAL, UNDER SEAT

STORAGE...........................23-80

BIN LID - INSTALLATION, UNDER SEAT

STORAGE...........................23-80

BIN LID - REMOVAL, UNDER SEAT

STORAGE...........................23-80

BLADE - DESCRIPTION, WIPER.........8R-18

BLADE - INSTALLATION, WIPER.........8R-20

BLADE - OPERATION, WIPER...........8R-19

BLADE - REMOVAL, WIPER............8R-19

BLEEDING - STANDARD PROCEDURE......5-31

BLEEDING - STANDARD PROCEDURE,

ABS BRAKE..........................5-46

BLEEDING - STANDARD PROCEDURE,

MANUAL.............................5-5

BLEEDING - STANDARD PROCEDURE,

MASTER CYLINDER...................5-26

BLEEDING - STANDARD PROCEDURE,

PRESSURE...........................5-5

BLEND DOOR - INSTALLATION..........24-27

BLEND DOOR - REMOVAL.............24-27

BLEND DOOR ACTUATOR -

DESCRIPTION.......................24-17

BLEND DOOR ACTUATOR -

INSTALLATION.......................24-18

BLEND DOOR ACTUATOR - OPERATION

. . . 24-17

BLEND DOOR ACTUATOR - REMOVAL

....24-17

BLOCK - CLEANING, ENGINE

. . 9-128,9-205,9-39

BLOCK - DESCRIPTION, BLOWER

MOTOR RESISTOR

...................24-18

BLOCK - DESCRIPTION, ENGINE

.....9-128,9-38

DRINDEX 3

Description Group-Page Description Group-Page Description Group-Page

Page 2602 of 2627

GEAR/RING GEAR/TONE RING -

INSTALLATION, PINION......3-108,3-137,3-164

GEAR/RING GEAR/TONE RING -

REMOVAL, PINION.........3-106,3-134,3-162

GEARSHIFT CABLE - DIAGNOSIS AND

TESTING....................21-210,21-368

GEARSHIFT CABLE - INSTALLATION....21-211,

21-370

GEARSHIFT CABLE - REMOVAL . . 21-210,21-369

GEARSHIFT CABLE, ADJUSTMENTS.....21-212,

21-370

GEAR/TONE RING - INSTALLATION,

PINION GEAR/RING.........3-108,3-137,3-164

GEAR/TONE RING - REMOVAL, PINION

GEAR/RING...............3-106,3-134,3-162

GEARTRAIN - ASSEMBLY, PLANETARY . . . 21-397

GEARTRAIN - CLEANING, PLANETARY . . . 21-396

GEARTRAIN - DESCRIPTION,

PLANETARY........................21-395

GEARTRAIN - DISASSEMBLY,

PLANETARY........................21-396

GEARTRAIN - INSPECTION, PLANETARY . 21-397

GEARTRAIN - OPERATION, PLANETARY . . 21-396

GEARTRAIN/OUTPUT SHAFT -

ASSEMBLY, PLANETARY..............21-244

GEARTRAIN/OUTPUT SHAFT -

DESCRIPTION, PLANETARY............21-241

GEARTRAIN/OUTPUT SHAFT -

DISASSEMBLY, PLANETARY...........21-242

GEARTRAIN/OUTPUT SHAFT -

INSPECTION, PLANETARY.............21-243

GEARTRAIN/OUTPUT SHAFT -

OPERATION, PLANETARY.............21-241

GENERAL - WARNINGS.............8W-01-7

GENERATOR / CHARGING SYSTEM -

SPECIFICATIONS, TORQUE.............8F-20

GENERATOR - DESCRIPTION...........8F-21

GENERATOR - INSTALLATION...........8F-24

GENERATOR - OPERATION.............8F-21

GENERATOR - REMOVAL...............8F-22

GENERATOR RATINGS, SPECIFICATIONS . . 8F-20

GENII - ASSEMBLY, TRANSFER CASE -

NV241............................21-428

GENII - ASSEMBLY, TRANSFER CASE -

NV244............................21-525

GENII - CLEANING, TRANSFER CASE -

NV241............................21-426

GENII - CLEANING, TRANSFER CASE -

NV244............................21-523

GENII - DESCRIPTION, TRANSFER CASE

- NV241...........................21-415

GENII - DESCRIPTION, TRANSFER CASE

- NV244...........................21-512

GENII - DIAGNOSIS AND TESTING,

TRANSFER CASE - NV241.............21-416

GENII - DISASSEMBLY, TRANSFER CASE

- NV241...........................21-417

GENII - DISASSEMBLY, TRANSFER CASE

- NV244...........................21-514

GENII - INSPECTION, TRANSFER CASE -

NV241............................21-426

GENII - INSPECTION, TRANSFER CASE -

NV244............................21-523

GENII - INSTALLATION, TRANSFER CASE

- NV241...........................21-438

GENII - INSTALLATION, TRANSFER CASE

- NV244...........................21-534

GENII - OPERATION, TRANSFER CASE -

NV241............................21-415

GENII - OPERATION, TRANSFER CASE -

NV244............................21-513

GENII - REMOVAL, TRANSFER CASE -

NV241............................21-417

GENII - REMOVAL, TRANSFER CASE -

NV244............................21-514

GENII - TRANSFER CASE, NV241.......21-438

GENII - TRANSFER CASE, NV244.......21-535

GLASS - DESCRIPTION, HEATED.........8G-1

GLASS - INSTALLATION, BACKLITE VENT . 23-87

GLASS - INSTALLATION, DOOR....23-20,23-30

GLASS - INSTALLATION, SIDE VIEW

MIRROR...........................23-43

GLASS - OPERATION, HEATED

...........8G-1

GLASS - REMOVAL, BACKLITE VENT

.....23-87

GLASS - REMOVAL, DOOR

........23-20,23-30

GLASS - REMOVAL, SIDE VIEW MIRROR

. . 23-42

GLASS RUN CHANNEL - INSTALLATION

. . 23-22,

23-31GLASS RUN CHANNEL - REMOVAL . 23-21,23-30

GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT DOOR...........23-92

GLASS RUN WEATHERSTRIP -

INSTALLATION, REAR DOOR............23-93

GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT DOOR..............23-92

GLASS RUN WEATHERSTRIP -

REMOVAL, REAR DOOR...............23-93

GLOVE BOX - INSTALLATION...........23-52

GLOVE BOX - REMOVAL...............23-52

GLOVE BOX LAMP/SWITCH -

INSTALLATION.......................8L-28

GLOVE BOX LAMP/SWITCH - REMOVAL . . . 8L-27

GLOVE BOX LATCH - INSTALLATION.....23-52

GLOVE BOX LATCH - REMOVAL.........23-52

GOVERNOR - DESCRIPTION,

ELECTRONIC.......................21-197

GOVERNOR - INSTALLATION,

ELECTRONIC.......................21-200

GOVERNOR - OPERATION, ELECTRONIC . 21-198

GOVERNOR - REMOVAL, ELECTRONIC . . . 21-199

GRAB HANDLE - INSTALLATION,

B-PILLAR...........................23-68

GRAB HANDLE - REMOVAL, B-PILLAR....23-68

GRID LINE AND TERMINAL REPAIR -

STANDARD PROCEDURE...............8G-4

GRILLE - INSTALLATION...............23-40

GRILLE - INSTALLATION, COWL.........23-38

GRILLE - REMOVAL....................23-40

GRILLE - REMOVAL, COWL............23-38

GRILLE FRAME - INSTALLATION.........23-40

GRILLE FRAME - REMOVAL............23-40

GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT TO..........8W-01-9

GROUND AND SPLICE INFORMATION -

DESCRIPTION, CONNECTOR..........8W-01-7

GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT

TO.............................8W-01-10

GROUND STRAP - DESCRIPTION, RADIO

NOISE SUPPRESSION..................8A-9

GROUND STRAP - INSTALLATION,

RADIO NOISE SUPPRESSION...........8A-10

GROUND STRAP - OPERATION, RADIO

NOISE SUPPRESSION..................8A-9

GROUND STRAP - REMOVAL, RADIO

NOISE SUPPRESSION..................8A-9

GROUNDS - DESCRIPTION, POWER......8E-10

GUIDE SEALS - DESCRIPTION, VALVE . 9-32,9-38

GUIDES - DESCRIPTION, VALVE....9-107,9-202

GUIDES AND SPRINGS - STANDARD

PROCEDURE, VALVES.................9-256

HALF SHAFT - CAUTION................3-20

HALF SHAFT - DIAGNOSIS AND TESTING . . 3-20

HALF SHAFT - INSTALLATION............3-21

HALF SHAFT - REMOVAL...............3-20

HALF SHAFT - SPECIAL TOOLS..........3-21

HALF SHAFT - SPECIFICATIONS..........3-21

HANDLE - INSTALLATION, A-PILLAR

TRIM/GRAB.........................23-63

HANDLE - INSTALLATION, B-PILLAR

GRAB..............................23-68

HANDLE - INSTALLATION, EXTERIOR

....23-21,

23-30

HANDLE - INSTALLATION, RELEASE

.......5-44

HANDLE - REMOVAL, A-PILLAR

TRIM/GRAB

.........................23-63

HANDLE - REMOVAL, B-PILLAR GRAB

....23-68

HANDLE - REMOVAL, EXTERIOR

. . . 23-20,23-30

HANDLE - REMOVAL, RELEASE

..........5-44

HANDLE ACTUATOR - INSTALLATION,

INSIDE

........................23-22,23-32

HANDLE ACTUATOR - REMOVAL, INSIDE

. 23-22,

23-31

HANDLE/BEZEL - INSTALLATION,

LUMBAR SUPPORT

...................23-82

HANDLE/BEZEL - REMOVAL, LUMBAR

SUPPORT

..........................23-82

HANDLE/LATCH REMOTE -

INSTALLATION, RELEASE

..............23-17

HANDLE/LATCH REMOTE - REMOVAL,

RELEASE

...........................23-17

HANDLING NON-DEPLOYED

SUPPLEMENTAL RESTRAINTS -

STANDARD PROCEDURE

...............8O-6HANDLING TUBING AND FITTINGS -

STANDARD PROCEDURE...............24-45

HANDS FREE MODULE - INSTALLATION....8T-2

HANDS FREE MODULE - REMOVAL.......8T-2

HARNESS - DIAGNOSIS AND TESTING,

WIRING..........................8W-01-7

HAZARD SWITCH - DESCRIPTION.......8L-14

HAZARD SWITCH - OPERATION.........8L-14

HCU (HYDRAULIC CONTROL UNIT) -

DESCRIPTION........................5-49

HCU (HYDRAULIC CONTROL UNIT) -

INSTALLATION........................5-50

HCU (HYDRAULIC CONTROL UNIT) -

OPERATION..........................5-49

HCU (HYDRAULIC CONTROL UNIT) -

REMOVAL...........................5-50

HEAD - CLEANING, CYLINDER.....9-200,9-251

HEAD - DESCRIPTION, CYLINDER . . 9-107,9-249

HEAD - INSPECTION, CYLINDER....9-200,9-252

HEAD - INSTALLATION, CYLINDER.......9-200

HEAD - INSTALLATION, LEFT CYLINDER . . 9-112

HEAD - INSTALLATION, RIGHT

CYLINDER..........................9-113

HEAD - LEFT - INSTALLATION,

CYLINDER...........................9-24

HEAD - LEFT - REMOVAL, CYLINDER......9-22

HEAD - OPERATION, CYLINDER.........9-199

HEAD - REMOVAL, CYLINDER.....9-200,9-249

HEAD - REMOVAL, LEFT CYLINDER......9-108

HEAD - REMOVAL, RIGHT CYLINDER.....9-110

HEAD - RIGHT - INSTALLATION,

CYLINDER...........................9-34

HEAD - RIGHT - REMOVAL, CYLINDER....9-33

HEAD COVER - INSTALLATION,

CYLINDER..........................9-255

HEAD COVER - REMOVAL, CYLINDER....9-255

HEAD COVER(S) - DESCRIPTION,

CYLINDER......................9-122,9-27

HEAD COVER(S) - INSTALLATION,

CYLINDER..................9-201,9-28,9-37

HEAD COVER(S) - REMOVAL, CYLINDER . 9-201,

9-28,9-37

HEAD GASKET - DIAGNOSIS AND

TESTING, CYLINDER...................9-21

HEAD GASKET FAILURE - DIAGNOSIS

AND TESTING, CYLINDER..............9-199

HEAD GASKET SELECTION - STANDARD

PROCEDURE........................9-281

HEADLAMP - INSTALLATION............8L-14

HEADLAMP - REMOVAL...............8L-14

HEADLAMP SWITCH - DESCRIPTION.....8L-14

HEADLAMP SWITCH - INSTALLATION....8L-15

HEADLAMP SWITCH - OPERATION.......8L-14

HEADLAMP SWITCH - REMOVAL........8L-14

HEADLAMP SWITCH BEZEL -

INSTALLATION, INSTRUMENT PANEL.....23-56

HEADLAMP SWITCH BEZEL - REMOVAL,

INSTRUMENT PANEL..................23-56

HEADLAMP UNIT - ADJUSTMENTS......8L-16

HEADLAMP UNIT - INSTALLATION.......8L-15

HEADLAMP UNIT - REMOVAL...........8L-15

HEADLINER - INSTALLATION...........23-68

HEADLINER - REMOVAL...............23-68

HEADREST - INSTALLATION............23-80

HEADREST - REMOVAL................23-80

HEADREST SLEEVE - INSTALLATION.....23-81

HEADREST SLEEVE - REMOVAL.........23-81

HEAT SHIELDS - DESCRIPTION..........11-8

HEAT SHIELDS - INSTALLATION..........11-8

HEAT SHIELDS - REMOVAL.............11-8

HEAT STAKING - STANDARD

PROCEDURE.........................23-3

HEATED GLASS - DESCRIPTION..........8G-1

HEATED GLASS - OPERATION...........8G-1

HEATED MIRRORS - DESCRIPTION.......8G-6

HEATED MIRRORS - OPERATION.........8G-6

HEATED SEAT ELEMENT - DESCRIPTION . . . 8G-9

HEATED SEAT ELEMENT - DIAGNOSIS

AND TESTING.......................8G-10

HEATED SEAT ELEMENT - INSTALLATION . 8G-10

HEATED SEAT ELEMENT - OPERATION....8G-10

HEATED SEAT ELEMENT - REMOVAL

.....8G-10

HEATED SEAT MODULE - DESCRIPTION

....8E-6

HEATED SEAT MODULE - DESCRIPTION

. . 8G-13

HEATED SEAT MODULE - DIAGNOSIS

AND TESTING

........................8E-6

HEATED SEAT MODULE - DIAGNOSIS

AND TESTING

.......................8G-14

DRINDEX 15

Description Group-Page Description Group-Page Description Group-Page

Page 2610 of 2627

OUTER TIE ROD END - REMOVAL.......19-32

OUTLET - DESCRIPTION, CIGAR

LIGHTER.........................8W-97-2

OUTLET - DESCRIPTION, POWER......8W-97-7

OUTLET - DIAGNOSIS AND TESTING,

CIGAR LIGHTER...................8W-97-2

OUTLET - DIAGNOSIS AND TESTING,

POWER..........................8W-97-7

OUTLET - INSTALLATION, POWER.....8W-97-8

OUTLET - OPERATION, CIGAR LIGHTER . 8W-97-2

OUTLET - OPERATION, POWER.......8W-97-7

OUTLET - REMOVAL, POWER.........8W-97-8

OUTLETS - DESCRIPTION, AIR..........24-26

OUTLETS - INSTALLATION, AIR.........24-27

OUTLETS - REMOVAL, AIR.............24-26

OUTPUT - DESCRIPTION, PCM...........8I-5

OUTPUT - OPERATION, PCM............14-27

OUTPUT - OPERATION, PCM.............8I-5

OUTPUT SHAFT FRONT BEARING -

INSTALLATION......................21-216

OUTPUT SHAFT FRONT BEARING -

REMOVAL.........................21-216

OUTPUT SHAFT REAR BEARING -

INSTALLATION......................21-217

OUTPUT SHAFT REAR BEARING -

REMOVAL.........................21-216

OUTPUT SHAFT SEAL - INSTALLATION,

FRONT....21-442,21-477,21-508,21-538,21-572

OUTPUT SHAFT SEAL - REMOVAL,

FRONT.....21-441,21-477,21-507,21-537,21-572

OUTPUT SPEED SENSOR - DESCRIPTION . 21-391

OUTPUT SPEED SENSOR -

INSTALLATION......................21-392

OUTPUT SPEED SENSOR - OPERATION . . 21-391

OUTPUT SPEED SENSOR - REMOVAL . . . 21-391

OVERDRIVE CLUTCH - DESCRIPTION....21-217

OVERDRIVE CLUTCH - OPERATION.....21-217

OVERDRIVE ELECTRICAL CONTROLS -

DIAGNOSIS AND TESTING............21-262

OVERDRIVE SWITCH - DESCRIPTION,

TOW/HAUL..................21-261,21-392

OVERDRIVE SWITCH - INSTALLATION,

TOW/HAUL..................21-262,21-393

OVERDRIVE SWITCH - OPERATION,

TOW/HAUL..................21-262,21-392

OVERDRIVE SWITCH - REMOVAL,

TOW/HAUL..................21-262,21-392

OVERDRIVE UNIT - ASSEMBLY.........21-226

OVERDRIVE UNIT - CLEANING.........21-225

OVERDRIVE UNIT - DISASSEMBLY......21-218

OVERDRIVE UNIT - INSPECTION.......21-225

OVERDRIVE UNIT - INSTALLATION......21-235

OVERDRIVE UNIT - REMOVAL.........21-218

OVERFLOW VALVE - DESCRIPTION,

CASCADE...........................14-66

OVERFLOW VALVE - OPERATION,

CASCADE...........................14-66

OVERHEAD CONSOLE - DESCRIPTION....8M-1

OVERHEAD CONSOLE - DIAGNOSIS AND

TESTING............................8M-2

OVERHEAD CONSOLE - OPERATION......8M-2

OVERHEAD CONSOLE REMOVAL,

REMOVAL

...........................8M-6

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON RETAINER -

ASSEMBLY

.........................21-237

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON RETAINER -

CLEANING

.........................21-236

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON RETAINER -

DESCRIPTION

......................21-236

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON RETAINER -

DISASSEMBLY

......................21-236

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON RETAINER -

INSPECTION

.......................21-237

OVERRUNNING CLUTCH CAM/

OVERDRIVE PISTON RETAINER -

OPERATION

........................21-236

OXYGEN SENSOR - DESCRIPTION

.......14-35

OXYGEN SENSOR - INSTALLATION

.......14-36

OXYGEN SENSOR - REMOVAL

..........14-35

PAINT CODE - DESCRIPTION

...........23-73

PAINT CODES - SPECIFICATIONS

........23-73

PAINT TOUCH-UP - DESCRIPTION

.......23-74PAINT TOUCH-UP - STANDARD

PROCEDURE........................23-74

PAN - CLEANING, OIL.............9-293,9-66

PAN - DESCRIPTION, OIL...............9-66

PAN - INSPECTION, OIL...........9-293,9-66

PAN - INSTALLATION, OIL . . . 9-155,9-224,9-293,

9-66

PAN - REMOVAL, OIL . . . 9-155,9-224,9-293,9-66

PANEL - INSTALLATION, TRIM.....23-24,23-33

PANEL - REMOVAL, TRIM.........23-24,23-33

PANEL ANTENNA CABLE -

INSTALLATION, INSTRUMENT............8A-7

PANEL ANTENNA CABLE - REMOVAL,

INSTRUMENT........................8A-7

PANEL ASSEMBLY - INSTALLATION,

INSTRUMENT.......................23-55

PANEL ASSEMBLY - REMOVAL,

INSTRUMENT.......................23-52

PANEL CENTER BEZEL - INSTALLATION,

INSTRUMENT.......................23-57

PANEL CENTER BEZEL - REMOVAL,

INSTRUMENT.......................23-57

PANEL DEMISTER DUCTS -

INSTALLATION, INSTRUMENT...........24-37

PANEL DEMISTER DUCTS - REMOVAL,

INSTRUMENT.......................24-36

PANEL DRIVER SIDE BEZEL -

INSTALLATION, INSTRUMENT...........23-58

PANEL DRIVER SIDE BEZEL - REMOVAL,

INSTRUMENT.......................23-58

PANEL DUCTS - INSTALLATION,

INSTRUMENT.........................24-37

PANEL DUCTS - REMOVAL,

INSTRUMENT.......................24-37

PANEL HEADLAMP SWITCH BEZEL -

INSTALLATION, INSTRUMENT...........23-56

PANEL HEADLAMP SWITCH BEZEL -

REMOVAL, INSTRUMENT..............23-56

PANEL LOWER SURROUND -

INSTALLATION, INSTRUMENT...........23-59

PANEL LOWER SURROUND - REMOVAL,

INSTRUMENT.......................23-59

PANEL REPAIR - STANDARD

PROCEDURE, PLASTIC BODY............23-3

PANEL TOP COVER - INSTALLATION,

INSTRUMENT.......................23-59

PANEL TOP COVER - REMOVAL,

INSTRUMENT.......................23-58

PANEL TRIM - INSTALLATION, REAR

CAB BACK..........................23-69

PANEL TRIM - REMOVAL, REAR CAB

BACK..............................23-68

PARK BRAKE CABLE - INSTALLATION,

REAR...............................5-38

PARK BRAKE CABLE - REMOVAL, REAR . . . 5-37

PARK LAMP RELAY - DESCRIPTION......8L-20

PARK LAMP RELAY - DIAGNOSIS AND

TESTING...........................8L-20

PARK LAMP RELAY - INSTALLATION.....8L-21

PARK LAMP RELAY - OPERATION.......8L-20

PARK LAMP RELAY - REMOVAL.........8L-21

PARKING BRAKE - DESCRIPTION.........5-36

PARKING BRAKE - OPERATION...........5-36

PARKING BRAKE CABLE -

INSTALLATION, FRONT.................5-38

PARKING BRAKE CABLE - REMOVAL,

FRONT..............................5-36

PARKING BRAKE SHOES - ADJUSTMENT

. . . 5-41

PARK/TURN SIGNAL LAMP -

INSTALLATION

.......................8L-21

PARK/TURN SIGNAL LAMP - REMOVAL

. . . 8L-21

PARTS - STANDARD PROCEDURES,

CLEANING FUEL SYSTEM

..............14-47

PASSENGER AIRBAG - DESCRIPTION

....8O-39

PASSENGER AIRBAG - INSTALLATION

....8O-41

PASSENGER AIRBAG - OPERATION

......8O-40

PASSENGER AIRBAG - REMOVAL

........8O-40

PASSENGER AIRBAG ON/OFF SWITCH -

DESCRIPTION

.......................8O-42

PASSENGER AIRBAG ON/OFF SWITCH -

INSTALLATION

......................8O-44

PASSENGER AIRBAG ON/OFF SWITCH -

OPERATION

.........................8O-43

PASSENGER AIRBAG ON/OFF SWITCH -

REMOVAL

..........................8O-43

PASSENGER SEAT SWITCH -

DESCRIPTION

.......................8N-15PASSENGER SEAT SWITCH - DIAGNOSIS

AND TESTING.......................8N-16

PASSENGER SEAT SWITCH -

INSTALLATION......................8N-16

PASSENGER SEAT SWITCH - OPERATION . 8N-15

PASSENGER SEAT SWITCH - REMOVAL . . . 8N-16

PATTERNS - DIAGNOSIS AND TESTING,

TIRE WEAR..........................22-8

PCM - DESCRIPTION...................8E-7

PCM - OPERATION...................8E-10

PCM INPUT - OPERATION, ASD SENSE.....8I-5

PCM OUTPUT - DESCRIPTION............8I-5

PCM OUTPUT - OPERATION............14-27

PCM OUTPUT - OPERATION.............8I-5

PCM/SKIM PROGRAMMING - STANDARD

PROCEDURE........................8E-14

PCV VALVE - 3.7L V-6/ 4.7L V-8 -

DIAGNOSIS AND TESTING.............25-20

PCV VALVE - DESCRIPTION............25-17

PCV VALVE - INSTALLATION............25-21

PCV VALVE - OPERATION..............25-19

PCV VALVE - REMOVAL...............25-21

PEDAL - DESCRIPTION.................5-28

PEDAL - INSTALLATION............5-28,5-42

PEDAL - INSTALLATION, ACCELERATOR . . . 14-21

PEDAL - OPERATION...................5-28

PEDAL - REMOVAL................5-28,5-42

PEDAL - REMOVAL, ACCELERATOR........14-21

PEDAL MOTOR - DESCRIPTION,

ADJUSTABLE..........................5-6

PEDAL MOTOR - INSTALLATION,

ADJUSTABLE..........................5-7

PEDAL MOTOR - REMOVAL,

ADJUSTABLE..........................5-7

PEDAL POSITION SENSOR -

DESCRIPTION, ACCELERATOR.....14-22,14-68

PEDAL POSITION SENSOR -

INSTALLATION, ACCELERATOR.....14-22,14-71

PEDAL POSITION SENSOR - OPERATION,

ACCELERATOR.................14-22,14-68

PEDAL POSITION SENSOR - REMOVAL,

ACCELERATOR.................14-22,14-68

PEDAL POSITION SWITCH -

DESCRIPTION, CLUTCH.................6-13

PEDAL POSITION SWITCH - DIAGNOSIS

AND TESTING, CLUTCH.................6-13

PEDAL POSITION SWITCH - OPERATION,

CLUTCH.............................6-13

PEDAL SWITCH - INSTALLATION,

ADJUSTABLE..........................5-6

PEDAL SWITCH - REMOVAL,

ADJUSTABLE..........................5-6

PER MILE, SPECIFICATIONS - TIRE

REVOLUTIONS.......................22-10

PERFORMANCE - DIAGNOSIS AND

TESTING, A/C........................24-3

PERFORMANCE - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS . . . 9-183,9-4,9-90

PERFORMANCE TEST - DIAGNOSIS AND

TESTING, HEATER.....................24-6

PILOT BEARING - INSTALLATION.........6-12

PILOT BEARING - REMOVAL.............6-11

PINION GEAR/RING GEAR -

INSTALLATION....................3-51,3-77

PINION GEAR/RING GEAR - REMOVAL . 3-49,3-75

PINION GEAR/RING GEAR/TONE RING -

INSTALLATION.............3-108,3-137,3-164

PINION GEAR/RING GEAR/TONE RING -

REMOVAL................3-106,3-134,3-162

PINION SEAL - INSTALLATION . 3-126,3-154,3-45,

3-71,3-96

PINION SEAL - REMOVAL....3-126,3-153,3-44,

3-70,3-95

PIPE - INSPECTION, EXHAUST.......11-7,11-8

PISTON & CONNECTING ROD -

CLEANING.....................9-140,9-212

PISTON & CONNECTING ROD -

DESCRIPTION.........9-139,9-211,9-281,9-48

PISTON & CONNECTING ROD -

INSPECTION

...................9-140,9-213

PISTON & CONNECTING ROD -

INSTALLATION

..................9-140,9-213

PISTON & CONNECTING ROD -

REMOVAL

................9-139,9-212,9-281

PISTON AND CONNECTING ROD -

CLEANING

..........................9-282

PISTON FITTING - STANDARD

PROCEDURE

...............9-139,9-211,9-51

DRINDEX 23

Description Group-Page Description Group-Page Description Group-Page

Page 2622 of 2627

TRANSMISSION - NV5600 -

DISASSEMBLY, MANUAL...............21-91

TRANSMISSION - NV5600 -

INSPECTION, MANUAL...............21-106

TRANSMISSION - NV5600 -

INSTALLATION, MANUAL.............21-121

TRANSMISSION - NV5600 - OPERATION,

MANUAL...........................21-90

TRANSMISSION - NV5600 - REMOVAL,

MANUAL...........................21-90

TRANSMISSION - NV5600 - SPECIAL

TOOLS, MANUAL....................21-123

TRANSMISSION CLUTCH AND BAND

OPERATION - DIAGNOSIS AND

TESTING, AIR TESTING...............21-144

TRANSMISSION CLUTCH OPERATION -

DIAGNOSIS AND TESTING, AIR

CHECKING.........................21-317

TRANSMISSION CONTROL MODULE -

DESCRIPTION.......................8E-20

TRANSMISSION CONTROL MODULE -

OPERATION.........................8E-20

TRANSMISSION CONTROL RELAY -

DESCRIPTION......................21-405

TRANSMISSION CONTROL RELAY -

OPERATION........................21-405

TRANSMISSION CROSSMEMBER -

INSTALLATION.......................13-24

TRANSMISSION CROSSMEMBER -

REMOVAL..........................13-24

TRANSMISSION FILL - STANDARD

PROCEDURE.................21-204,21-368

TRANSMISSION FLUID - DESCRIPTION,

AUTOMATIC...........................0-4

TRANSMISSION FLUID - OPERATION,

AUTOMATIC...........................0-5

TRANSMISSION RANGE SENSOR -

DESCRIPTION................21-263,21-405

TRANSMISSION RANGE SENSOR -

INSTALLATION......................21-266

TRANSMISSION RANGE SENSOR -

OPERATION..................21-263,21-405

TRANSMISSION RANGE SENSOR -

REMOVAL.........................21-265

TRANSMISSION RANGE SENSOR (TRS) -

DIAGNOSIS AND TESTING............21-264

TRANSMISSION SHIFT INTERLOCK -

ADJUSTMENTS, BRAKE.........21-196,21-365

TRANSMISSION SHIFT INTERLOCK -

DIAGNOSIS AND TESTING, BRAKE.....21-196,

21-364

TRANSMISSION SHIFT INTERLOCK

SYSTEM - DESCRIPTION, BRAKE . 21-196,21-364

TRANSMISSION SHIFT INTERLOCK

SYSTEM - OPERATION, BRAKE . . . 21-196,21-364

TRANSMISSION SOLENOID/TRS

ASSEMBLY - DESCRIPTION............21-406

TRANSMISSION SOLENOID/TRS

ASSEMBLY - INSTALLATION...........21-408

TRANSMISSION SOLENOID/TRS

ASSEMBLY - OPERATION.............21-406

TRANSMISSION SOLENOID/TRS

ASSEMBLY - REMOVAL...............21-407

TRANSMISSION, SPECIAL TOOLS - RE

. . 21-191

TRANSMISSION, SPECIAL TOOLS - RFE

. . 21-359

TRANSMISSION, SPECIFICATIONS

......21-189,

21-358

TRANSMISSION TEMPERATURE SENSOR

- DESCRIPTION

...............21-267,21-408

TRANSMISSION TEMPERATURE SENSOR

- OPERATION

.................21-267,21-408

TRANSMITTER - DESCRIPTION,

UNIVERSAL

........................8M-11

TRANSMITTER - DIAGNOSIS AND

TESTING, REMOTE KEYLESS ENTRY

......8N-8

TRANSMITTER - DIAGNOSIS AND

TESTING, UNIVERSAL

................8M-11

TRANSMITTER - OPERATION,

UNIVERSAL

........................8M-11

TRANSMITTER - SPECIFICATIONS,

REMOTE KEYLESS ENTRY

..............8N-9

TRANSMITTER BATTERIES - STANDARD

PROCEDURE, RKE

.....................8N-8

TRANSMITTER CODES - STANDARD

PROCEDURE, ERASING

...............8M-12

TRANSMITTER CODES - STANDARD

PROCEDURE, SETTING

................8M-12TRANSMITTER CUSTOMER

PREFERENCES - STANDARD

PROCEDURE, RKE.....................8N-8

TRANSMITTER PROGRAMING -

STANDARD PROCEDURE, RKE...........8N-9

TRANSPONDER PROGRAMMING,

STANDARD PROCEDURE - SENTRY

KEY IMMOBILIZER SYSTEM.............8Q-4

TRAY - DESCRIPTION, BATTERY.........8F-17

TRAY - INSTALLATION, BATTERY........8F-18

TRAY - OPERATION, BATTERY..........8F-17

TRAY - REMOVAL, BATTERY............8F-17

TREAD WEAR INDICATORS - DIAGNOSIS

AND TESTING........................22-8

TRIM - INSTALLATION, B-PILLAR

LOWER............................23-64

TRIM - INSTALLATION, B-PILLAR UPPER . . 23-64

TRIM - INSTALLATION, COWL..........23-66

TRIM - INSTALLATION, C-PILLAR

LOWER............................23-67

TRIM - INSTALLATION, C-PILLAR UPPER . . 23-67

TRIM - INSTALLATION, REAR CAB BACK

PANEL.............................23-69

TRIM - REMOVAL, B-PILLAR LOWER.....23-63

TRIM - REMOVAL, B-PILLAR UPPER.....23-64

TRIM - REMOVAL, COWL..............23-66

TRIM - REMOVAL, C-PILLAR LOWER.....23-66

TRIM - REMOVAL, C-PILLAR UPPER.....23-67

TRIM - REMOVAL, REAR CAB BACK

PANEL.............................23-68

TRIM COVER - INSTALLATION, REAR

DOOR SILL.........................23-71

TRIM COVER - REMOVAL, REAR DOOR

SILL...............................23-71

TRIM PANEL - INSTALLATION......23-24,23-33

TRIM PANEL - REMOVAL.........23-24,23-33

TRIM/GRAB HANDLE - INSTALLATION,

A-PILLAR...........................23-63

TRIM/GRAB HANDLE - REMOVAL,

A-PILLAR...........................23-63

TRIP DEFINITION - DESCRIPTION.........25-4

TROUBLE CODES - DESCRIPTION,

DIAGNOSTIC.........................25-1

TUBE - DESCRIPTION, A/C ORIFICE......24-60

TUBE - DIAGNOSIS AND TESTING, A/C

ORIFICE............................24-61

TUBE / HOSE ASSEMBLY -

INSTALLATION, REAR..................5-13

TUBE / HOSE ASSEMBLY - REMOVAL,

REAR...............................5-12

TUBE - OPERATION, A/C ORIFICE........24-60

TUBING AND FITTINGS - STANDARD

PROCEDURE, HANDLING..............24-45

TURBO DIESEL - MAINTENANCE

SCHEDULES, 24-VALVE CUMMINS........0-12

TURBOCHARGER - CLEANING..........11-15

TURBOCHARGER - DESCRIPTION........11-12

TURBOCHARGER - INSPECTION.........11-15

TURBOCHARGER - INSTALLATION.......11-15

TURBOCHARGER - OPERATION.........11-13

TURBOCHARGER - REMOVAL...........11-14

TURBOCHARGER BOOST PRESSURE -

DIAGNOSIS AND TESTING.............11-11

TURN SIGNAL INDICATOR -

DESCRIPTION.......................8J-40

TURN SIGNAL INDICATOR - OPERATION . . 8J-41

TURN SIGNAL SYSTEM - DESCRIPTION . . . 8L-18

TURN SIGNAL SYSTEM - OPERATION....8L-18

TURNING LOOP ADJUSTER -

INSTALLATION, SEAT BELT.............8O-55

TURNING LOOP ADJUSTER - REMOVAL,

SEAT BELT .........................8O-55

UNDER SEAT STORAGE BIN -

INSTALLATION.......................23-80

UNDER SEAT STORAGE BIN - REMOVAL . . 23-80

UNDER SEAT STORAGE BIN COVERING -

INSTALLATION.......................23-80

UNDER SEAT STORAGE BIN COVERING -

REMOVAL..........................23-80

UNDER SEAT STORAGE BIN LATCH -

INSTALLATION

.......................23-80

UNDER SEAT STORAGE BIN LATCH -

REMOVAL

..........................23-80

UNDER SEAT STORAGE BIN LID -

INSTALLATION

.......................23-80

UNDER SEAT STORAGE BIN LID -

REMOVAL

..........................23-80

UNDERHOOD LAMP - INSTALLATION

.....8L-25UNDERHOOD LAMP - REMOVAL.........8L-25

UNDERHOOD LAMP UNIT -

INSTALLATION.......................8L-25

UNDERHOOD LAMP UNIT - REMOVAL....8L-25

UNIT - ADJUSTMENTS, HEADLAMP......8L-16

UNIT - ASSEMBLY, OVERDRIVE........21-226

UNIT - CLEANING, OVERDRIVE.........21-225

UNIT - DISASSEMBLY, OVERDRIVE......21-218

UNIT - INSPECTION, OVERDRIVE.......21-225

UNIT - INSTALLATION, CENTER HIGH

MOUNTED STOP LAMP................8L-11

UNIT - INSTALLATION, HEADLAMP.......8L-15

UNIT - INSTALLATION, LICENSE PLATE

LAMP..............................8L-17

UNIT - INSTALLATION, OVERDRIVE.....21-235

UNIT - INSTALLATION, UNDERHOOD

LAMP..............................8L-25

UNIT - REMOVAL, CENTER HIGH

MOUNTED STOP LAMP................8L-11

UNIT - REMOVAL, HEADLAMP..........8L-15

UNIT - REMOVAL, LICENSE PLATE LAMP . . 8L-17

UNIT - REMOVAL, OVERDRIVE.........21-218

UNIT - REMOVAL, UNDERHOOD LAMP . . . 8L-25

UNIT / SENSOR - DESCRIPTION, FUEL

LEVEL SENDING.................14-57,14-6

UNIT / SENSOR - INSTALLATION, FUEL

LEVEL SENDING......................14-7

UNIT / SENSOR - OPERATION, FUEL

LEVEL SENDING.................14-57,14-6

UNIT / SENSOR - REMOVAL, FUEL

LEVEL SENDING......................14-7

UNIVERSAL JOINTS - ASSEMBLY,

DOUBLE CARDAN.....................3-17

UNIVERSAL JOINTS - DISASSEMBLY,

DOUBLE CARDAN.....................3-16

UNIVERSAL TRANSMITTER -

DESCRIPTION.......................8M-11

UNIVERSAL TRANSMITTER - DIAGNOSIS

AND TESTING.......................8M-11

UNIVERSAL TRANSMITTER - OPERATION . 8M-11

UPPER BALL JOINT - DIAGNOSIS AND

TESTING........................2-27,2-36

UPPER BALL JOINT - INSTALLATION......2-36

UPPER BALL JOINT - REMOVAL..........2-36

UPPER CONTROL ARM - INSTALLATION . . . 2-28

UPPER CONTROL ARM - REMOVAL.......2-28

UPPER RADIATOR CROSSMEMBER -

INSTALLATION.......................23-42

UPPER RADIATOR CROSSMEMBER -

REMOVAL..........................23-42

UPPER STEERING COUPLING -

INSTALLATION.......................19-13

UPPER STEERING COUPLING -

REMOVAL..........................19-13

UPPER TRIM - INSTALLATION, B-PILLAR . . 23-64

UPPER TRIM - INSTALLATION, C-PILLAR . . 23-67

UPPER TRIM - REMOVAL, B-PILLAR.....23-64

UPPER TRIM - REMOVAL, C-PILLAR.....23-67

UPSHIFT INDICATOR - DESCRIPTION.....8J-41

UPSHIFT INDICATOR - OPERATION.......8J-42

VAC LEAK DETECTION ASSY -

DESCRIPTION, NATURAL..............25-23

VAC LEAK DETECTION ASSY -

INSTALLATION, NATURAL..............25-25

VAC LEAK DETECTION ASSY -

OPERATION, NATURAL................25-23

VAC LEAK DETECTION ASSY -

REMOVAL, NATURAL..................25-24

VACUUM LINES - DESCRIPTION.........25-22

VACUUM RESERVOIR - DESCRIPTION.....8P-9

VACUUM RESERVOIR - DIAGNOSIS AND

TESTING............................8P-9

VACUUM RESERVOIR - INSTALLATION . . . 8P-10

VACUUM RESERVOIR - OPERATION.......8P-9

VACUUM RESERVOIR - REMOVAL........8P-9

VACUUM SUPPLY TEST - DIAGNOSIS

AND TESTING........................8P-2

VALVE - 3.7L V-6/ 4.7L V-8 - DIAGNOSIS

AND TESTING, PCV...................25-20

VALVE - CLEANING, OIL PRESSURE

RELIEF

.............................9-294

VALVE - DESCRIPTION, CASCADE

OVERFLOW

.........................14-66

VALVE - DESCRIPTION, CHECK

..........8R-7

VALVE - DESCRIPTION, FUEL PRESSURE

LIMITING

...........................14-61

VALVE - DESCRIPTION, HIGH PRESSURE

RELIEF

.............................24-48

DRINDEX 35

Description Group-Page Description Group-Page Description Group-Page