Shift solenoid DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 427 of 2627

TRANSMISSION CONTROL

MODULE

DESCRIPTION

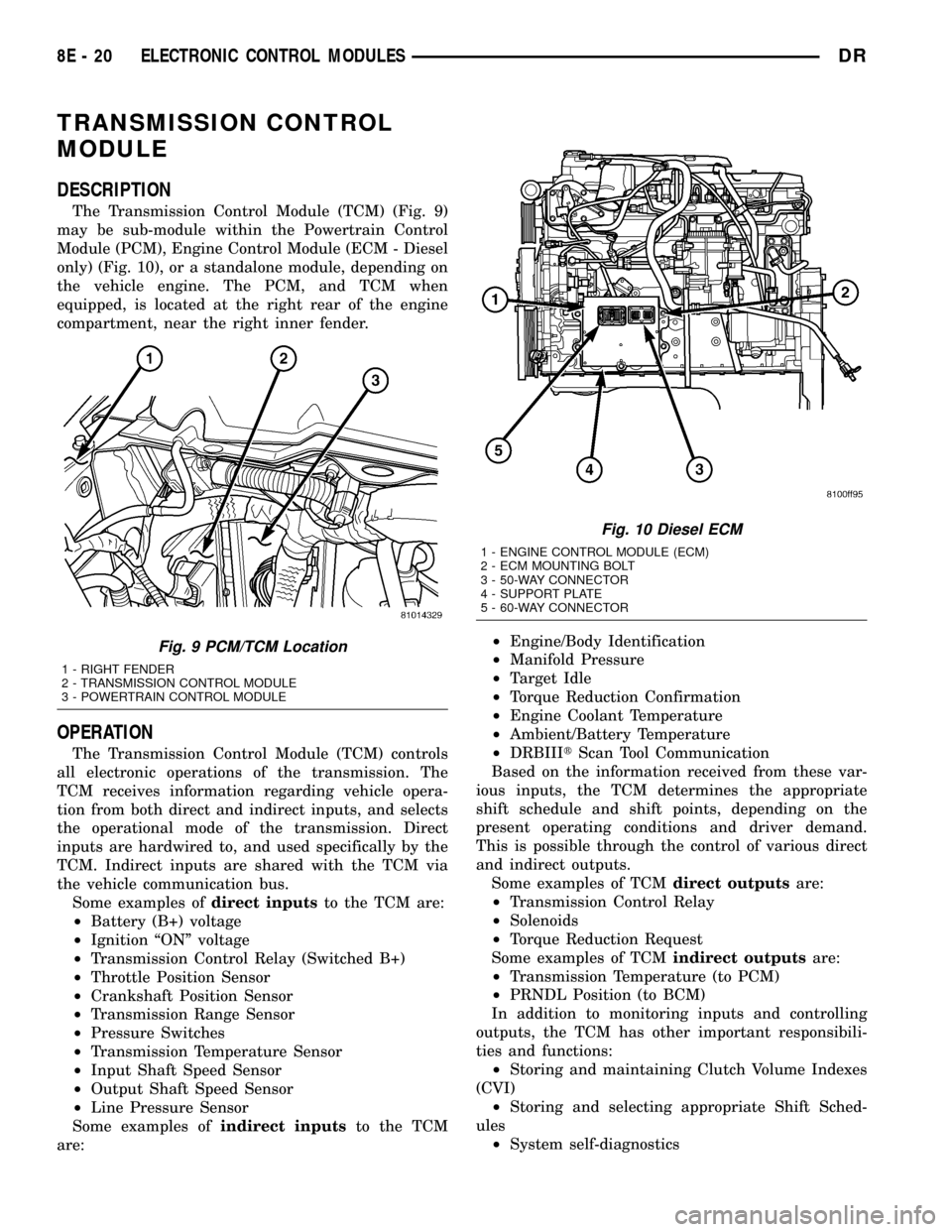

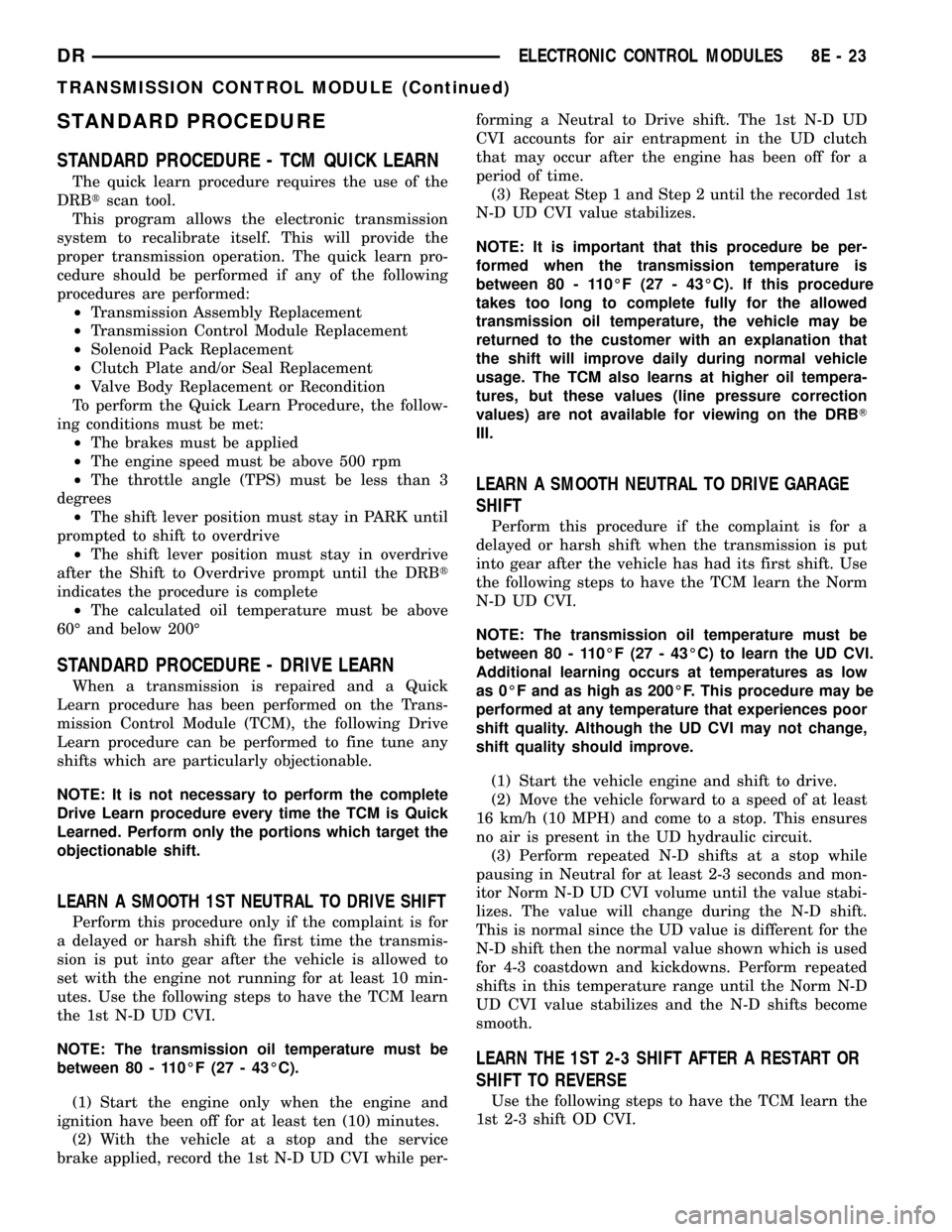

The Transmission Control Module (TCM) (Fig. 9)

may be sub-module within the Powertrain Control

Module (PCM), Engine Control Module (ECM - Diesel

only) (Fig. 10), or a standalone module, depending on

the vehicle engine. The PCM, and TCM when

equipped, is located at the right rear of the engine

compartment, near the right inner fender.

OPERATION

The Transmission Control Module (TCM) controls

all electronic operations of the transmission. The

TCM receives information regarding vehicle opera-

tion from both direct and indirect inputs, and selects

the operational mode of the transmission. Direct

inputs are hardwired to, and used specifically by the

TCM. Indirect inputs are shared with the TCM via

the vehicle communication bus.

Some examples ofdirect inputsto the TCM are:

²Battery (B+) voltage

²Ignition ªONº voltage

²Transmission Control Relay (Switched B+)

²Throttle Position Sensor

²Crankshaft Position Sensor

²Transmission Range Sensor

²Pressure Switches

²Transmission Temperature Sensor

²Input Shaft Speed Sensor

²Output Shaft Speed Sensor

²Line Pressure Sensor

Some examples ofindirect inputsto the TCM

are:²Engine/Body Identification

²Manifold Pressure

²Target Idle

²Torque Reduction Confirmation

²Engine Coolant Temperature

²Ambient/Battery Temperature

²DRBIIItScan Tool Communication

Based on the information received from these var-

ious inputs, the TCM determines the appropriate

shift schedule and shift points, depending on the

present operating conditions and driver demand.

This is possible through the control of various direct

and indirect outputs.

Some examples of TCMdirect outputsare:

²Transmission Control Relay

²Solenoids

²Torque Reduction Request

Some examples of TCMindirect outputsare:

²Transmission Temperature (to PCM)

²PRNDL Position (to BCM)

In addition to monitoring inputs and controlling

outputs, the TCM has other important responsibili-

ties and functions:

²Storing and maintaining Clutch Volume Indexes

(CVI)

²Storing and selecting appropriate Shift Sched-

ules

²System self-diagnostics

Fig. 9 PCM/TCM Location

1 - RIGHT FENDER

2 - TRANSMISSION CONTROL MODULE

3 - POWERTRAIN CONTROL MODULE

Fig. 10 Diesel ECM

1 - ENGINE CONTROL MODULE (ECM)

2 - ECM MOUNTING BOLT

3 - 50-WAY CONNECTOR

4 - SUPPORT PLATE

5 - 60-WAY CONNECTOR

8E - 20 ELECTRONIC CONTROL MODULESDR

Page 430 of 2627

STANDARD PROCEDURE

STANDARD PROCEDURE - TCM QUICK LEARN

The quick learn procedure requires the use of the

DRBtscan tool.

This program allows the electronic transmission

system to recalibrate itself. This will provide the

proper transmission operation. The quick learn pro-

cedure should be performed if any of the following

procedures are performed:

²Transmission Assembly Replacement

²Transmission Control Module Replacement

²Solenoid Pack Replacement

²Clutch Plate and/or Seal Replacement

²Valve Body Replacement or Recondition

To perform the Quick Learn Procedure, the follow-

ing conditions must be met:

²The brakes must be applied

²The engine speed must be above 500 rpm

²The throttle angle (TPS) must be less than 3

degrees

²The shift lever position must stay in PARK until

prompted to shift to overdrive

²The shift lever position must stay in overdrive

after the Shift to Overdrive prompt until the DRBt

indicates the procedure is complete

²The calculated oil temperature must be above

60É and below 200É

STANDARD PROCEDURE - DRIVE LEARN

When a transmission is repaired and a Quick

Learn procedure has been performed on the Trans-

mission Control Module (TCM), the following Drive

Learn procedure can be performed to fine tune any

shifts which are particularly objectionable.

NOTE: It is not necessary to perform the complete

Drive Learn procedure every time the TCM is Quick

Learned. Perform only the portions which target the

objectionable shift.

LEARN A SMOOTH 1ST NEUTRAL TO DRIVE SHIFT

Perform this procedure only if the complaint is for

a delayed or harsh shift the first time the transmis-

sion is put into gear after the vehicle is allowed to

set with the engine not running for at least 10 min-

utes. Use the following steps to have the TCM learn

the 1st N-D UD CVI.

NOTE: The transmission oil temperature must be

between 80 - 110ÉF (27 - 43ÉC).

(1) Start the engine only when the engine and

ignition have been off for at least ten (10) minutes.

(2) With the vehicle at a stop and the service

brake applied, record the 1st N-D UD CVI while per-forming a Neutral to Drive shift. The 1st N-D UD

CVI accounts for air entrapment in the UD clutch

that may occur after the engine has been off for a

period of time.

(3) Repeat Step 1 and Step 2 until the recorded 1st

N-D UD CVI value stabilizes.

NOTE: It is important that this procedure be per-

formed when the transmission temperature is

between 80 - 110ÉF (27 - 43ÉC). If this procedure

takes too long to complete fully for the allowed

transmission oil temperature, the vehicle may be

returned to the customer with an explanation that

the shift will improve daily during normal vehicle

usage. The TCM also learns at higher oil tempera-

tures, but these values (line pressure correction

values) are not available for viewing on the DRBT

III.

LEARN A SMOOTH NEUTRAL TO DRIVE GARAGE

SHIFT

Perform this procedure if the complaint is for a

delayed or harsh shift when the transmission is put

into gear after the vehicle has had its first shift. Use

the following steps to have the TCM learn the Norm

N-D UD CVI.

NOTE: The transmission oil temperature must be

between 80 - 110ÉF (27 - 43ÉC) to learn the UD CVI.

Additional learning occurs at temperatures as low

as 0ÉF and as high as 200ÉF. This procedure may be

performed at any temperature that experiences poor

shift quality. Although the UD CVI may not change,

shift quality should improve.

(1) Start the vehicle engine and shift to drive.

(2) Move the vehicle forward to a speed of at least

16 km/h (10 MPH) and come to a stop. This ensures

no air is present in the UD hydraulic circuit.

(3) Perform repeated N-D shifts at a stop while

pausing in Neutral for at least 2-3 seconds and mon-

itor Norm N-D UD CVI volume until the value stabi-

lizes. The value will change during the N-D shift.

This is normal since the UD value is different for the

N-D shift then the normal value shown which is used

for 4-3 coastdown and kickdowns. Perform repeated

shifts in this temperature range until the Norm N-D

UD CVI value stabilizes and the N-D shifts become

smooth.

LEARN THE 1ST 2-3 SHIFT AFTER A RESTART OR

SHIFT TO REVERSE

Use the following steps to have the TCM learn the

1st 2-3 shift OD CVI.

DRELECTRONIC CONTROL MODULES 8E - 23

TRANSMISSION CONTROL MODULE (Continued)

Page 446 of 2627

Large eyelet type terminals are crimped onto the

opposite end of the battery cable wire and then sol-

der-dipped. The battery positive cable wires have a

red insulating jacket to provide visual identification

and feature a larger female battery terminal clamp

to allow connection to the larger battery positive ter-

minal post. The battery negative cable wires have a

black insulating jacket and a smaller female battery

terminal clamp.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a return path for electrical current gen-

erated by the charging system for restoring the volt-

age potential of the battery. The female battery

terminal clamps on the ends of the battery cable

wires provide a strong and reliable connection of the

battery cable to the battery terminal posts. The ter-

minal pinch bolts allow the female terminal clamps

to be tightened around the male terminal posts on

the top of the battery. The eyelet terminals secured

to the ends of the battery cable wires opposite the

female battery terminal clamps provide secure and

reliable connection of the battery to the vehicle elec-

trical system.

DIAGNOSIS AND TESTING - BATTERY CABLES

A voltage drop test will determine if there is exces-

sive resistance in the battery cable terminal connec-

tions or the battery cables. If excessive resistance is

found in the battery cable connections, the connec-

tion point should be disassembled, cleaned of all cor-

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair.

When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached.EXAM-

PLE:When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

B(+) terminal stud. If you probe the battery positive

terminal post and the battery positive cable eyelet

terminal at the starter solenoid B(+) terminal stud,

you are reading the combined voltage drop in the

battery positive cable terminal clamp-to-terminal

post connection and the battery positive cable.

VOLTAGE DROP TEST

WARNING: MODELS EQUIPPED WITH A DIESEL

ENGINE HAVE AN AUTOMATIC SHUTDOWN (ASD)RELAY LOCATED IN THE POWER DISTRIBUTION

CENTER (PDC). REMOVAL OF THE ASD RELAY

MAY NOT PREVENT THE DIESEL ENGINE FROM

STARTING. BE CERTAIN TO DISCONNECT THE

FUEL SHUTDOWN SOLENOID WIRE HARNESS

CONNECTOR TO PREVENT THE ENGINE FROM

STARTING. FAILURE TO DO SO MAY RESULT IN

PERSONAL INJURY.

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing this

test, be certain that the following procedures are

accomplished:

²The battery is fully-charged and tested (Refer to

8 - ELECTRICAL/BATTERY SYSTEM/BATTERY -

STANDARD PROCEDURE).

²Fully engage the parking brake.

²If the vehicle is equipped with an automatic

transmission, place the gearshift selector lever in the

Park position. If the vehicle is equipped with a man-

ual transmission, place the gearshift selector lever in

the Neutral position and block the clutch pedal in the

fully depressed position.

²Verify that all lamps and accessories are turned

off.

²To prevent a gasoline engine from starting,

remove the Automatic ShutDown (ASD) relay. The

ASD relay is located in the Integrated Power Module

(IPM), in the engine compartment. See the fuse and

relay layout label on the underside of the IPM cover

for ASD relay identification and location.

(1) Connect the positive lead of the voltmeter to

the battery negative terminal post. Connect the neg-

ative lead of the voltmeter to the battery negative

cable terminal clamp (Fig. 11). Rotate and hold the

ignition switch in the Start position. Observe the

voltmeter. If voltage is detected, correct the poor con-

nection between the battery negative cable terminal

clamp and the battery negative terminal post.

NOTE: If the vehicle is equipped with two 12v bat-

teries, step #1 must be performed twice, once for

each battery.

(2) Connect the positive lead of the voltmeter to

the battery positive terminal post. Connect the nega-

tive lead of the voltmeter to the battery positive cable

terminal clamp (Fig. 12). Rotate and hold the ignition

switch in the Start position. Observe the voltmeter. If

voltage is detected, correct the poor connection

between the battery positive cable terminal clamp

and the battery positive terminal post.

NOTE: If the vehicle is equipped with two 12v bat-

teries, step #2 must be performed twice, once for

each battery.

DRBATTERY SYSTEM 8F - 15

BATTERY CABLES (Continued)

Page 458 of 2627

If the vehicle is equipped with an automatic trans-

mission, battery voltage is supplied through the low-

amperage control circuit to the coil battery terminal

of the starter relay when the ignition switch is

turned to the Start position. The park/neutral posi-

tion switch is installed in series between the starter

relay coil ground terminal and ground. This normally

open switch prevents the starter relay from being

energized and the starter motor from operating

unless the automatic transmission gear selector is in

the Neutral or Park positions.

When the starter relay coil is energized, the nor-

mally open relay contacts close. The relay contacts

connect the relay common feed terminal to the relay

normally open terminal. The closed relay contacts

energize the starter solenoid coil windings.

The energized solenoid pull-in coil pulls in the sole-

noid plunger. The solenoid plunger pulls the shift

lever in the starter motor. This engages the starter

overrunning clutch and pinion gear with the starter

ring gear.

As the solenoid plunger reaches the end of its

travel, the solenoid contact disc completes the high-

amperage starter feed circuit and energizes the sole-

noid plunger hold-in coil. Current now flows between

the solenoid battery terminal and the starter motor,

energizing the starter.Once the engine starts, the overrunning clutch pro-

tects the starter motor from damage by allowing the

starter pinion gear to spin faster than the pinion

shaft. When the ignition switch is released to the On

position, the starter relay coil is de-energized. This

causes the relay contacts to open. When the relay

contacts open, the starter solenoid plunger hold-in

coil is de-energized.

When the solenoid plunger hold-in coil is de-ener-

gized, the solenoid plunger return spring returns the

plunger to its relaxed position. This causes the con-

tact disc to open the starter feed circuit, and the shift

lever to disengage the overrunning clutch and pinion

gear from the starter ring gear.

DIAGNOSIS AND TESTING - STARTING

SYSTEM

The battery, starting, and charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct starting/

charging system operation, all of the components

involved in these 3 systems must perform within

specifications.

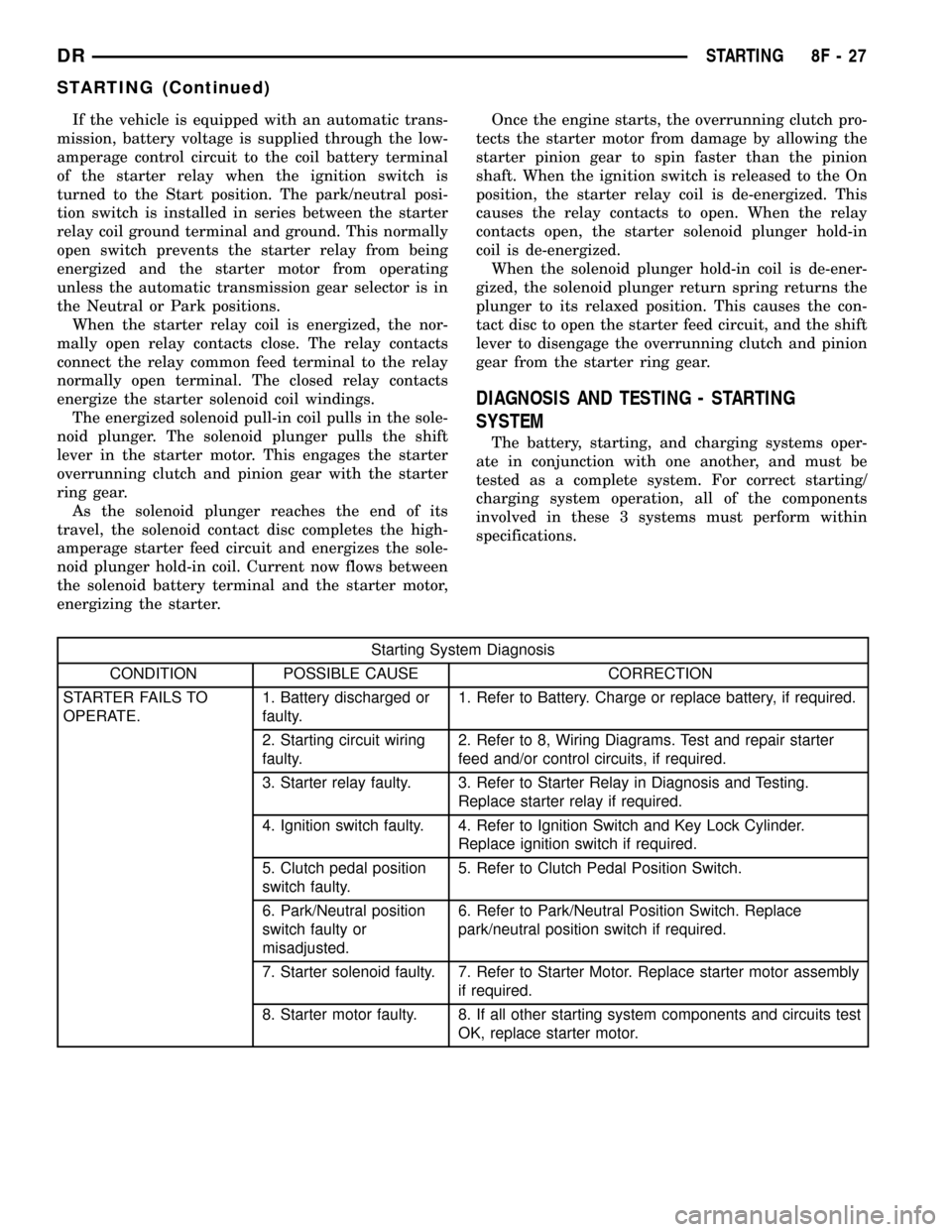

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS TO

OPERATE.1. Battery discharged or

faulty.1. Refer to Battery. Charge or replace battery, if required.

2. Starting circuit wiring

faulty.2. Refer to 8, Wiring Diagrams. Test and repair starter

feed and/or control circuits, if required.

3. Starter relay faulty. 3. Refer to Starter Relay in Diagnosis and Testing.

Replace starter relay if required.

4. Ignition switch faulty. 4. Refer to Ignition Switch and Key Lock Cylinder.

Replace ignition switch if required.

5. Clutch pedal position

switch faulty.5. Refer to Clutch Pedal Position Switch.

6. Park/Neutral position

switch faulty or

misadjusted.6. Refer to Park/Neutral Position Switch. Replace

park/neutral position switch if required.

7. Starter solenoid faulty. 7. Refer to Starter Motor. Replace starter motor assembly

if required.

8. Starter motor faulty. 8. If all other starting system components and circuits test

OK, replace starter motor.

DRSTARTING 8F - 27

STARTING (Continued)

Page 460 of 2627

TESTING

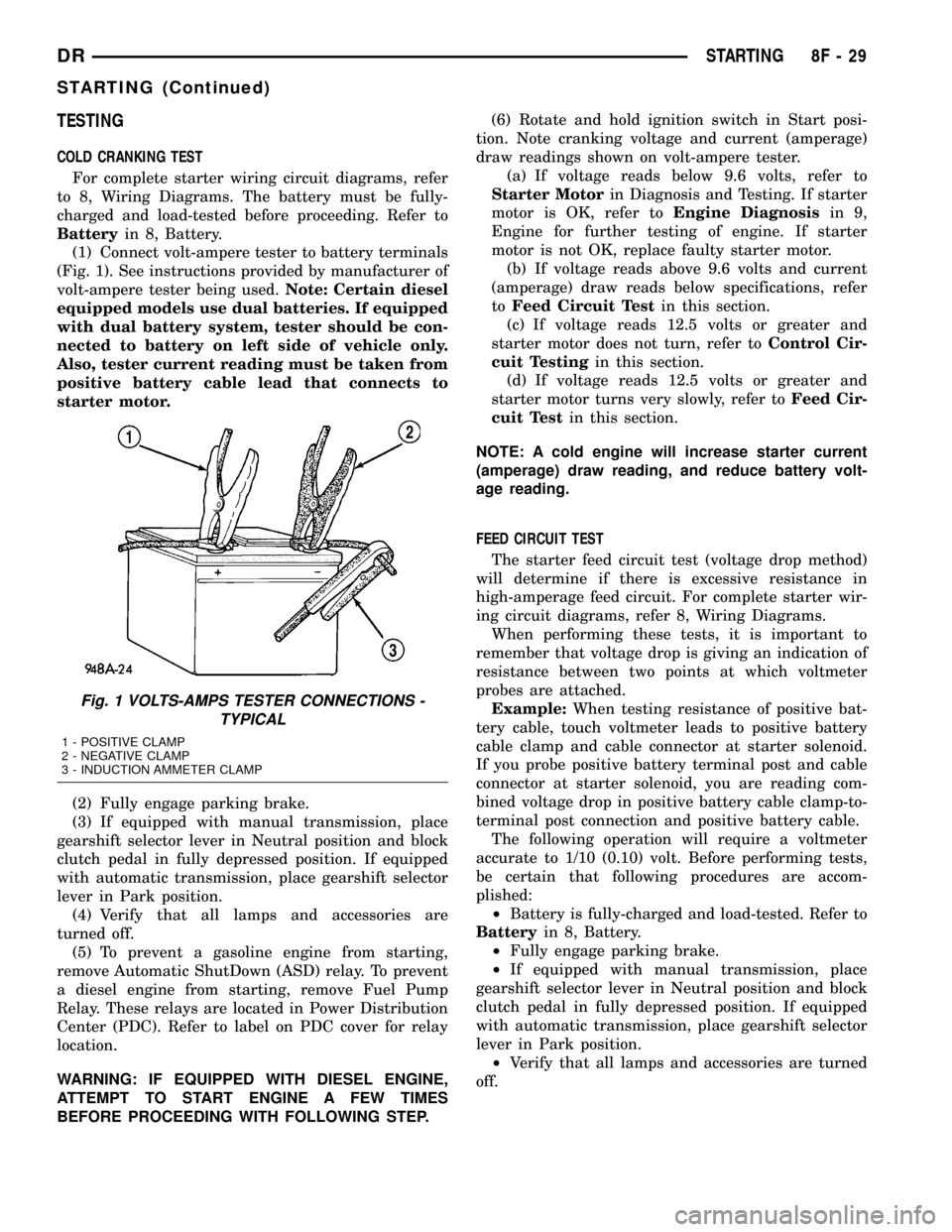

COLD CRANKING TEST

For complete starter wiring circuit diagrams, refer

to 8, Wiring Diagrams. The battery must be fully-

charged and load-tested before proceeding. Refer to

Batteryin 8, Battery.

(1) Connect volt-ampere tester to battery terminals

(Fig. 1). See instructions provided by manufacturer of

volt-ampere tester being used.Note: Certain diesel

equipped models use dual batteries. If equipped

with dual battery system, tester should be con-

nected to battery on left side of vehicle only.

Also, tester current reading must be taken from

positive battery cable lead that connects to

starter motor.

(2) Fully engage parking brake.

(3) If equipped with manual transmission, place

gearshift selector lever in Neutral position and block

clutch pedal in fully depressed position. If equipped

with automatic transmission, place gearshift selector

lever in Park position.

(4) Verify that all lamps and accessories are

turned off.

(5) To prevent a gasoline engine from starting,

remove Automatic ShutDown (ASD) relay. To prevent

a diesel engine from starting, remove Fuel Pump

Relay. These relays are located in Power Distribution

Center (PDC). Refer to label on PDC cover for relay

location.

WARNING: IF EQUIPPED WITH DIESEL ENGINE,

ATTEMPT TO START ENGINE A FEW TIMES

BEFORE PROCEEDING WITH FOLLOWING STEP.(6) Rotate and hold ignition switch in Start posi-

tion. Note cranking voltage and current (amperage)

draw readings shown on volt-ampere tester.

(a) If voltage reads below 9.6 volts, refer to

Starter Motorin Diagnosis and Testing. If starter

motor is OK, refer toEngine Diagnosisin 9,

Engine for further testing of engine. If starter

motor is not OK, replace faulty starter motor.

(b) If voltage reads above 9.6 volts and current

(amperage) draw reads below specifications, refer

toFeed Circuit Testin this section.

(c) If voltage reads 12.5 volts or greater and

starter motor does not turn, refer toControl Cir-

cuit Testingin this section.

(d) If voltage reads 12.5 volts or greater and

starter motor turns very slowly, refer toFeed Cir-

cuit Testin this section.

NOTE: A cold engine will increase starter current

(amperage) draw reading, and reduce battery volt-

age reading.

FEED CIRCUIT TEST

The starter feed circuit test (voltage drop method)

will determine if there is excessive resistance in

high-amperage feed circuit. For complete starter wir-

ing circuit diagrams, refer 8, Wiring Diagrams.

When performing these tests, it is important to

remember that voltage drop is giving an indication of

resistance between two points at which voltmeter

probes are attached.

Example:When testing resistance of positive bat-

tery cable, touch voltmeter leads to positive battery

cable clamp and cable connector at starter solenoid.

If you probe positive battery terminal post and cable

connector at starter solenoid, you are reading com-

bined voltage drop in positive battery cable clamp-to-

terminal post connection and positive battery cable.

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing tests,

be certain that following procedures are accom-

plished:

²Battery is fully-charged and load-tested. Refer to

Batteryin 8, Battery.

²Fully engage parking brake.

²If equipped with manual transmission, place

gearshift selector lever in Neutral position and block

clutch pedal in fully depressed position. If equipped

with automatic transmission, place gearshift selector

lever in Park position.

²Verify that all lamps and accessories are turned

off.

Fig. 1 VOLTS-AMPS TESTER CONNECTIONS -

TYPICAL

1 - POSITIVE CLAMP

2 - NEGATIVE CLAMP

3 - INDUCTION AMMETER CLAMP

DRSTARTING 8F - 29

STARTING (Continued)

Page 467 of 2627

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When electro-

magnetic coil is energized, it draws the movable con-

tact away from normally closed fixed contact, and

holds it against the other (normally open) fixed con-

tact.

When electromagnetic coil is de-energized, spring

pressure returns movable contact to normally closed

position. The resistor or diode is connected in parallel

with electromagnetic coil within relay, and helps to

dissipate voltage spikes produced when coil is de-en-

ergized.

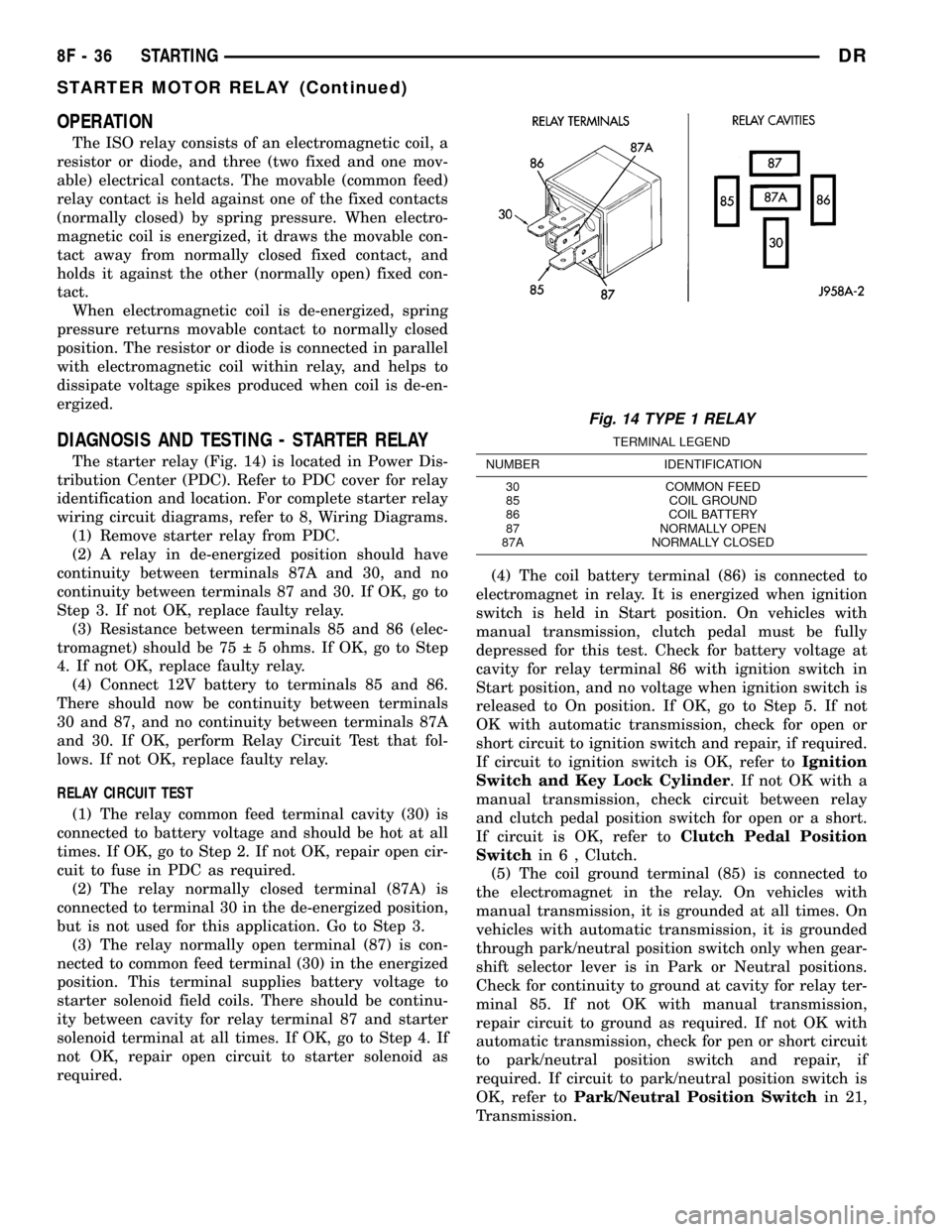

DIAGNOSIS AND TESTING - STARTER RELAY

The starter relay (Fig. 14) is located in Power Dis-

tribution Center (PDC). Refer to PDC cover for relay

identification and location. For complete starter relay

wiring circuit diagrams, refer to 8, Wiring Diagrams.

(1) Remove starter relay from PDC.

(2) A relay in de-energized position should have

continuity between terminals 87A and 30, and no

continuity between terminals 87 and 30. If OK, go to

Step 3. If not OK, replace faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace faulty relay.

(4) Connect 12V battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform Relay Circuit Test that fol-

lows. If not OK, replace faulty relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair open cir-

cuit to fuse in PDC as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to common feed terminal (30) in the energized

position. This terminal supplies battery voltage to

starter solenoid field coils. There should be continu-

ity between cavity for relay terminal 87 and starter

solenoid terminal at all times. If OK, go to Step 4. If

not OK, repair open circuit to starter solenoid as

required.(4) The coil battery terminal (86) is connected to

electromagnet in relay. It is energized when ignition

switch is held in Start position. On vehicles with

manual transmission, clutch pedal must be fully

depressed for this test. Check for battery voltage at

cavity for relay terminal 86 with ignition switch in

Start position, and no voltage when ignition switch is

released to On position. If OK, go to Step 5. If not

OK with automatic transmission, check for open or

short circuit to ignition switch and repair, if required.

If circuit to ignition switch is OK, refer toIgnition

Switch and Key Lock Cylinder. If not OK with a

manual transmission, check circuit between relay

and clutch pedal position switch for open or a short.

If circuit is OK, refer toClutch Pedal Position

Switchin 6 , Clutch.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. On vehicles with

manual transmission, it is grounded at all times. On

vehicles with automatic transmission, it is grounded

through park/neutral position switch only when gear-

shift selector lever is in Park or Neutral positions.

Check for continuity to ground at cavity for relay ter-

minal 85. If not OK with manual transmission,

repair circuit to ground as required. If not OK with

automatic transmission, check for pen or short circuit

to park/neutral position switch and repair, if

required. If circuit to park/neutral position switch is

OK, refer toPark/Neutral Position Switchin 21,

Transmission.

Fig. 14 TYPE 1 RELAY

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

8F - 36 STARTINGDR

STARTER MOTOR RELAY (Continued)

Page 512 of 2627

Sandwiched between the rear cover and the lens,

hood and mask unit is the cluster housing. The

molded plastic cluster housing serves as the carrier

for the cluster circuit board and circuitry, the cluster

connector receptacles, the RKE interface connector,

the gauges, a Light Emitting Diode (LED) for each

cluster indicator, two VFD units, an audible tone

generator, the cluster overlay, the gauge pointers, the

odometer/trip odometer switch and the switch button.

The cluster overlay is a laminated plastic unit. The

dark, visible, outer surface of the overlay is marked

with all of the gauge dial faces and graduations, but

this layer is also translucent. The darkness of this

outer layer prevents the cluster from appearing clut-

tered or busy by concealing the cluster indicators

that are not illuminated, while the translucence of

this layer allows those indicators and icons that are

illuminated to be readily visible. The underlying

layer of the overlay is opaque and allows light from

the LED for each of the various indicators and the

incandescent illumination lamps behind it to be visi-

ble through the outer layer of the overlay only

through predetermined stencil-like cutouts. A rectan-

gular opening in the overlay at the base of both the

speedometer and tachometer dial faces has a smoked

clear lens through which the illuminated VFD units

can be viewed.

Several versions of the EMIC module are offered

on this model. These versions accommodate all of the

variations of optional equipment and regulatory

requirements for the various markets in which the

vehicle will be offered. The microprocessor-based

EMIC utilizes integrated circuitry and information

carried on the Programmable Communications Inter-

face (PCI) data bus network along with several hard

wired analog and multiplexed inputs to monitor sen-

sors and switches throughout the vehicle. In response

to those inputs, the internal circuitry and program-

ming of the EMIC allow it to control and integrate

many electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/COMMUNICATION - DESCRIPTION -

PCI BUS).

Besides typical instrument cluster gauge and indi-

cator support, the electronic functions and features

that the EMIC supports or controls include the fol-

lowing:

²Audible Warnings- The EMIC electronic cir-

cuit board is equipped with an audible tone generator

and programming that allows it to provide various

audible alerts to the vehicle operator, including

chime tones and beep tones. An electromechanical

relay is also soldered onto the circuit board to pro-duce audible clicks that emulate the sound of a con-

ventional turn signal or hazard warning flasher.

(Refer to 8 - ELECTRICAL/CHIME/BUZZER -

DESCRIPTION).

²Brake Lamp Control- The EMIC provides

electronic brake lamp request messages to the Front

Control Module (FCM) located on the Integrated

Power Module (IPM) for brake lamp control, exclud-

ing control of the Center High Mounted Stop Lamp

(CHMSL), which remains controlled by a direct hard

wired output of the brake lamp switch.

²Brake Transmission Shift Interlock Control

- The EMIC monitors inputs from the brake lamp

switch, ignition switch, and the Transmission Range

Sensor (TRS), then controls a high-side driver output

to operate the Brake Transmission Shift Interlock

(BTSI) solenoid that locks and unlocks the automatic

transmission gearshift selector lever on the steering

column.

²Cargo Lamp Control- The EMIC provides

direct control of cargo lamp operation with a load

shedding (battery saver) feature which will automat-

ically turn off the cargo lamp if it remains on after a

timed interval.

²Central Locking- The EMIC provides support

for the central locking feature of the power lock sys-

tem. This feature will lock or unlock all doors based

upon the input from the door cylinder lock switch.

Door cylinder lock switches are used only on models

equipped with the optional Vehicle Theft Security

System (VTSS).

²Door Lock Inhibit- The EMIC inhibits locking

of the doors with the power lock switch when the key

is in the ignition switch and the driver side front

door is ajar. However, operation of the door locks is

not inhibited under the same conditions when the

Lock button of the optional RKE transmitter is

depressed.

²Enhanced Accident Response- The EMIC

monitors an input from the Airbag Control Module

(ACM) and, following an airbag deployment, will

immediately disable the power lock output, unlock all

doors by activating the power unlock output, then

enables the power lock output. This feature, like all

other enhanced accident response features, is depen-

dent upon a functional vehicle electrical system fol-

lowing the vehicle impact event.

²Exterior Lighting Control- The EMIC pro-

vides electronic head lamp and/or park lamp request

messages to the Front Control Module (FCM) located

on the Integrated Power Module (IPM) for the appro-

priate exterior lamp control of standard head and

park lamps, as well as optional front fog lamps. This

includes support for headlamp beam selection and

the optical horn feature, also known as flash-to-pass.

DRINSTRUMENT CLUSTER 8J - 3

INSTRUMENT CLUSTER (Continued)

Page 744 of 2627

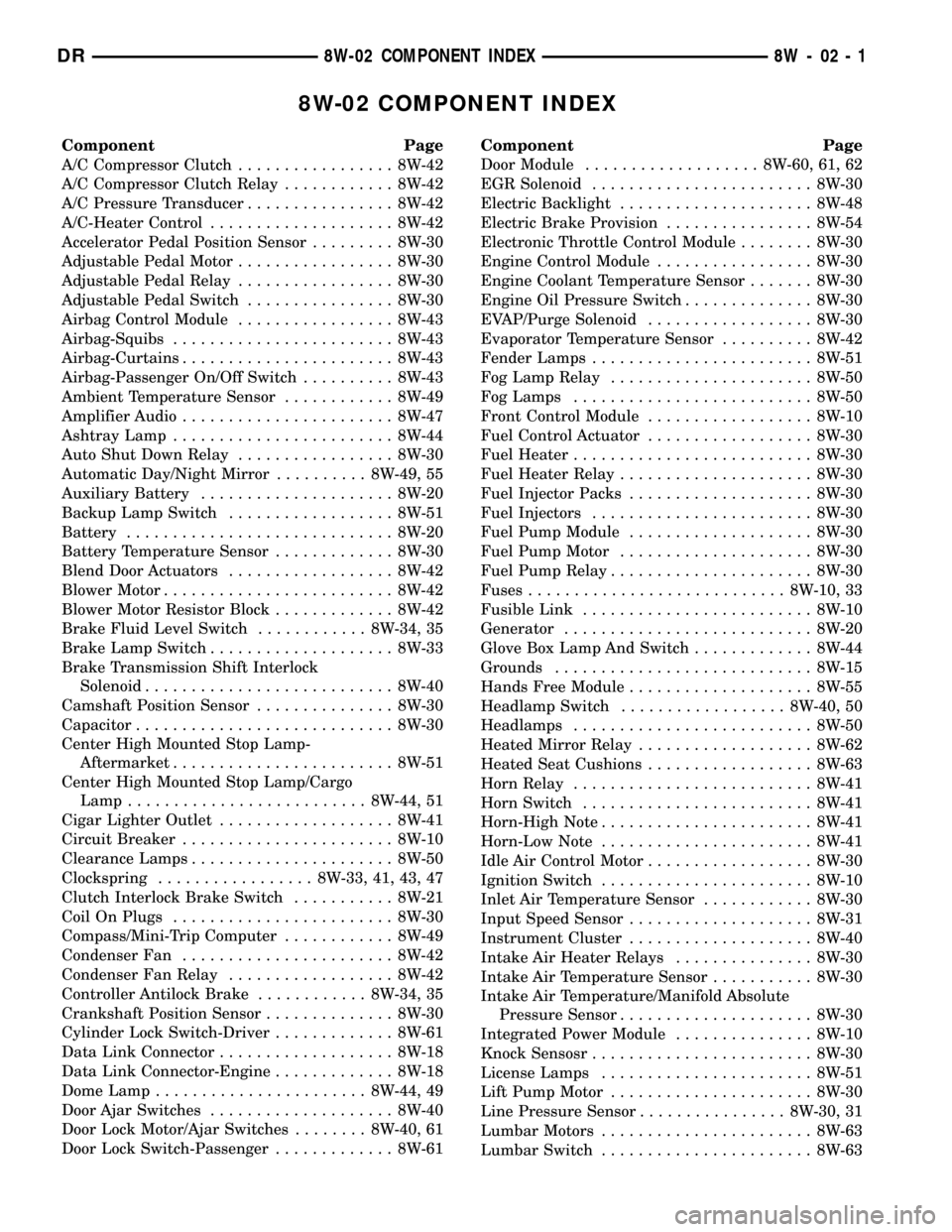

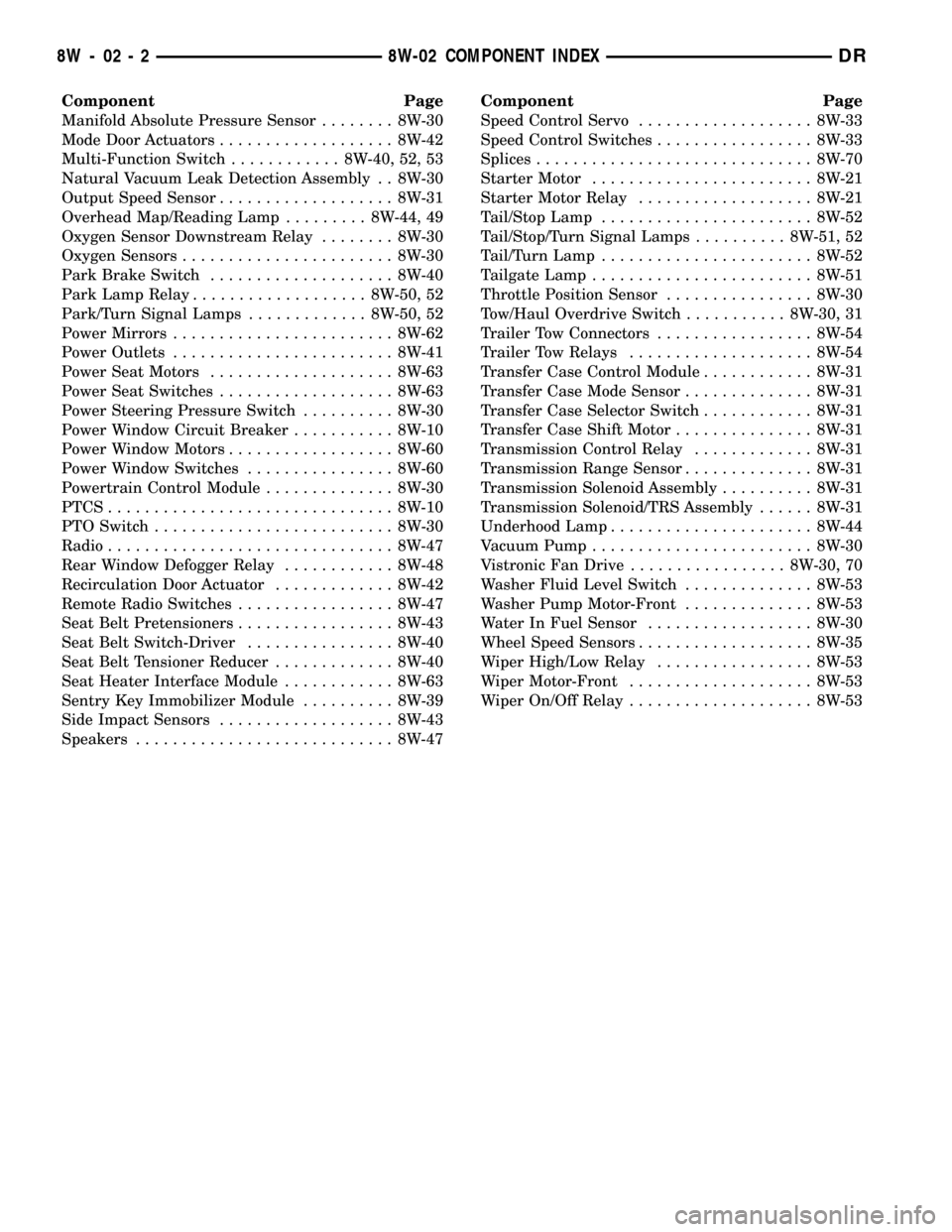

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch................. 8W-42

A/C Compressor Clutch Relay............ 8W-42

A/C Pressure Transducer................ 8W-42

A/C-Heater Control.................... 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Adjustable Pedal Motor................. 8W-30

Adjustable Pedal Relay................. 8W-30

Adjustable Pedal Switch................ 8W-30

Airbag Control Module................. 8W-43

Airbag-Squibs........................ 8W-43

Airbag-Curtains....................... 8W-43

Airbag-Passenger On/Off Switch.......... 8W-43

Ambient Temperature Sensor............ 8W-49

Amplifier Audio....................... 8W-47

Ashtray Lamp........................ 8W-44

Auto Shut Down Relay................. 8W-30

Automatic Day/Night Mirror.......... 8W-49, 55

Auxiliary Battery..................... 8W-20

Backup Lamp Switch.................. 8W-51

Battery............................. 8W-20

Battery Temperature Sensor............. 8W-30

Blend Door Actuators.................. 8W-42

Blower Motor......................... 8W-42

Blower Motor Resistor Block............. 8W-42

Brake Fluid Level Switch............ 8W-34, 35

Brake Lamp Switch.................... 8W-33

Brake Transmission Shift Interlock

Solenoid........................... 8W-40

Camshaft Position Sensor............... 8W-30

Capacitor............................ 8W-30

Center High Mounted Stop Lamp-

Aftermarket........................ 8W-51

Center High Mounted Stop Lamp/Cargo

Lamp.......................... 8W-44, 51

Cigar Lighter Outlet................... 8W-41

Circuit Breaker....................... 8W-10

Clearance Lamps...................... 8W-50

Clockspring................. 8W-33, 41, 43, 47

Clutch Interlock Brake Switch........... 8W-21

Coil On Plugs........................ 8W-30

Compass/Mini-Trip Computer............ 8W-49

Condenser Fan....................... 8W-42

Condenser Fan Relay.................. 8W-42

Controller Antilock Brake............ 8W-34, 35

Crankshaft Position Sensor.............. 8W-30

Cylinder Lock Switch-Driver............. 8W-61

Data Link Connector................... 8W-18

Data Link Connector-Engine............. 8W-18

Dome Lamp....................... 8W-44, 49

Door Ajar Switches.................... 8W-40

Door Lock Motor/Ajar Switches........ 8W-40, 61

Door Lock Switch-Passenger............. 8W-61Component Page

Door Module................... 8W-60, 61, 62

EGR Solenoid........................ 8W-30

Electric Backlight..................... 8W-48

Electric Brake Provision................ 8W-54

Electronic Throttle Control Module........ 8W-30

Engine Control Module................. 8W-30

Engine Coolant Temperature Sensor....... 8W-30

Engine Oil Pressure Switch.............. 8W-30

EVAP/Purge Solenoid.................. 8W-30

Evaporator Temperature Sensor.......... 8W-42

Fender Lamps........................ 8W-51

Fog Lamp Relay...................... 8W-50

Fog Lamps.......................... 8W-50

Front Control Module.................. 8W-10

Fuel Control Actuator.................. 8W-30

Fuel Heater.......................... 8W-30

Fuel Heater Relay..................... 8W-30

Fuel Injector Packs.................... 8W-30

Fuel Injectors........................ 8W-30

Fuel Pump Module.................... 8W-30

Fuel Pump Motor..................... 8W-30

Fuel Pump Relay...................... 8W-30

Fuses............................ 8W-10, 33

Fusible Link......................... 8W-10

Generator........................... 8W-20

Glove Box Lamp And Switch............. 8W-44

Grounds............................ 8W-15

Hands Free Module.................... 8W-55

Headlamp Switch.................. 8W-40, 50

Headlamps.......................... 8W-50

Heated Mirror Relay................... 8W-62

Heated Seat Cushions.................. 8W-63

Horn Relay.......................... 8W-41

Horn Switch......................... 8W-41

Horn-High Note....................... 8W-41

Horn-Low Note....................... 8W-41

Idle Air Control Motor.................. 8W-30

Ignition Switch....................... 8W-10

Inlet Air Temperature Sensor............ 8W-30

Input Speed Sensor.................... 8W-31

Instrument Cluster.................... 8W-40

Intake Air Heater Relays............... 8W-30

Intake Air Temperature Sensor........... 8W-30

Intake Air Temperature/Manifold Absolute

Pressure Sensor..................... 8W-30

Integrated Power Module............... 8W-10

Knock Sensosr........................ 8W-30

License Lamps....................... 8W-51

Lift Pump Motor...................... 8W-30

Line Pressure Sensor................ 8W-30, 31

Lumbar Motors....................... 8W-63

Lumbar Switch....................... 8W-63

DR8W-02 COMPONENT INDEX 8W - 02 - 1

Page 745 of 2627

Component Page

Manifold Absolute Pressure Sensor........ 8W-30

Mode Door Actuators................... 8W-42

Multi-Function Switch............ 8W-40, 52, 53

Natural Vacuum Leak Detection Assembly . . 8W-30

Output Speed Sensor................... 8W-31

Overhead Map/Reading Lamp......... 8W-44, 49

Oxygen Sensor Downstream Relay........ 8W-30

Oxygen Sensors....................... 8W-30

Park Brake Switch.................... 8W-40

Park Lamp Relay................... 8W-50, 52

Park/Turn Signal Lamps............. 8W-50, 52

Power Mirrors........................ 8W-62

Power Outlets........................ 8W-41

Power Seat Motors.................... 8W-63

Power Seat Switches................... 8W-63

Power Steering Pressure Switch.......... 8W-30

Power Window Circuit Breaker........... 8W-10

Power Window Motors.................. 8W-60

Power Window Switches................ 8W-60

Powertrain Control Module.............. 8W-30

PTCS............................... 8W-10

PTO Switch.......................... 8W-30

Radio............................... 8W-47

Rear Window Defogger Relay............ 8W-48

Recirculation Door Actuator............. 8W-42

Remote Radio Switches................. 8W-47

Seat Belt Pretensioners................. 8W-43

Seat Belt Switch-Driver................ 8W-40

Seat Belt Tensioner Reducer............. 8W-40

Seat Heater Interface Module............ 8W-63

Sentry Key Immobilizer Module.......... 8W-39

Side Impact Sensors................... 8W-43

Speakers............................ 8W-47Component Page

Speed Control Servo................... 8W-33

Speed Control Switches................. 8W-33

Splices.............................. 8W-70

Starter Motor........................ 8W-21

Starter Motor Relay................... 8W-21

Tail/Stop Lamp....................... 8W-52

Tail/Stop/Turn Signal Lamps.......... 8W-51, 52

Tail/Turn Lamp....................... 8W-52

Tailgate Lamp........................ 8W-51

Throttle Position Sensor................ 8W-30

Tow/Haul Overdrive Switch........... 8W-30, 31

Trailer Tow Connectors................. 8W-54

Trailer Tow Relays.................... 8W-54

Transfer Case Control Module............ 8W-31

Transfer Case Mode Sensor.............. 8W-31

Transfer Case Selector Switch............ 8W-31

Transfer Case Shift Motor............... 8W-31

Transmission Control Relay............. 8W-31

Transmission Range Sensor.............. 8W-31

Transmission Solenoid Assembly.......... 8W-31

Transmission Solenoid/TRS Assembly...... 8W-31

Underhood Lamp...................... 8W-44

Vacuum Pump........................ 8W-30

Vistronic Fan Drive................. 8W-30, 70

Washer Fluid Level Switch.............. 8W-53

Washer Pump Motor-Front.............. 8W-53

Water In Fuel Sensor.................. 8W-30

Wheel Speed Sensors................... 8W-35

Wiper High/Low Relay................. 8W-53

Wiper Motor-Front.................... 8W-53

Wiper On/Off Relay.................... 8W-53

8W - 02 - 2 8W-02 COMPONENT INDEXDR

Page 798 of 2627

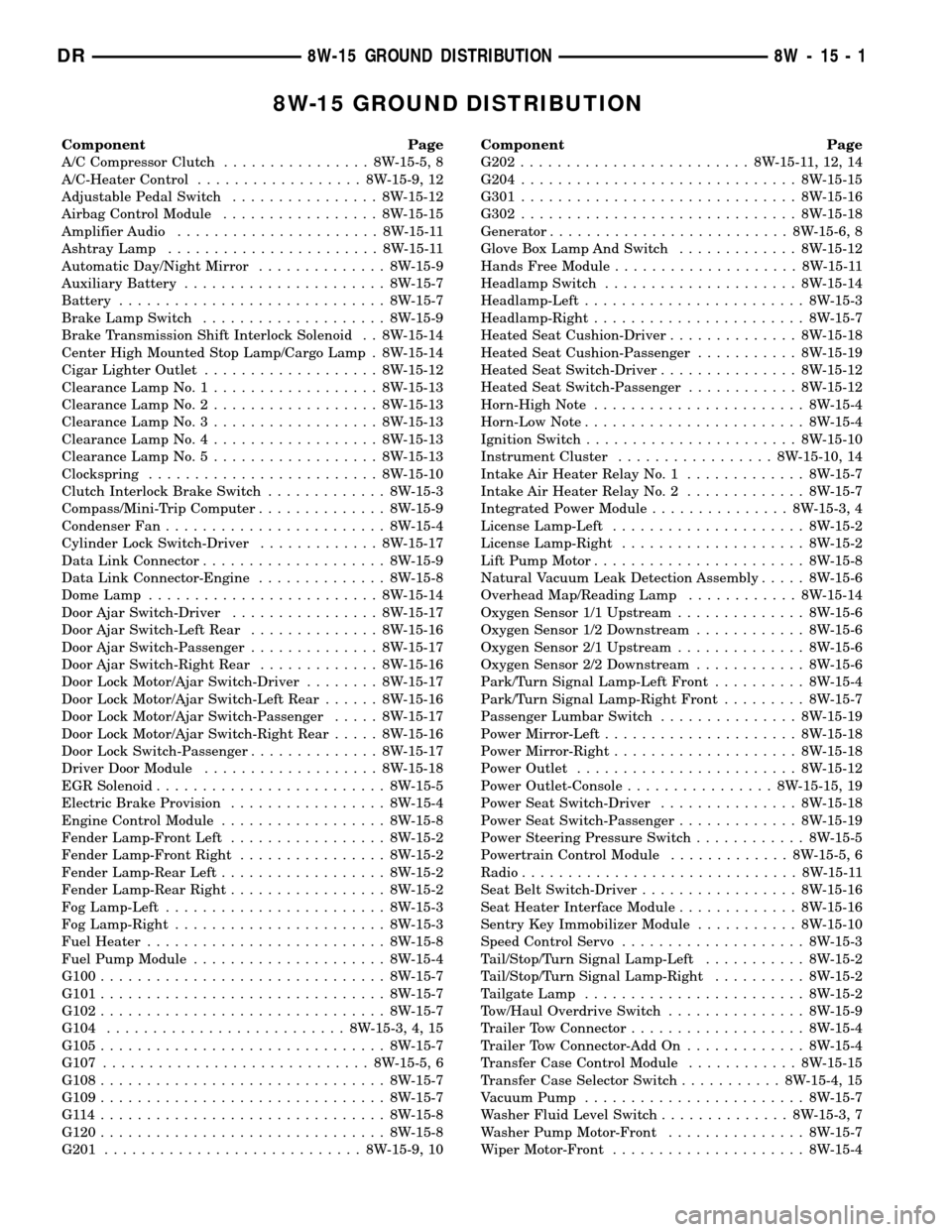

8W-15 GROUND DISTRIBUTION

Component Page

A/C Compressor Clutch................ 8W-15-5, 8

A/C-Heater Control.................. 8W-15-9, 12

Adjustable Pedal Switch................ 8W-15-12

Airbag Control Module................. 8W-15-15

Amplifier Audio...................... 8W-15-11

Ashtray Lamp....................... 8W-15-11

Automatic Day/Night Mirror.............. 8W-15-9

Auxiliary Battery...................... 8W-15-7

Battery............................. 8W-15-7

Brake Lamp Switch.................... 8W-15-9

Brake Transmission Shift Interlock Solenoid . . 8W-15-14

Center High Mounted Stop Lamp/Cargo Lamp . 8W-15-14

Cigar Lighter Outlet................... 8W-15-12

Clearance Lamp No. 1.................. 8W-15-13

Clearance Lamp No. 2.................. 8W-15-13

Clearance Lamp No. 3.................. 8W-15-13

Clearance Lamp No. 4.................. 8W-15-13

Clearance Lamp No. 5.................. 8W-15-13

Clockspring......................... 8W-15-10

Clutch Interlock Brake Switch............. 8W-15-3

Compass/Mini-Trip Computer.............. 8W-15-9

Condenser Fan........................ 8W-15-4

Cylinder Lock Switch-Driver............. 8W-15-17

Data Link Connector.................... 8W-15-9

Data Link Connector-Engine.............. 8W-15-8

Dome Lamp......................... 8W-15-14

Door Ajar Switch-Driver................ 8W-15-17

Door Ajar Switch-Left Rear.............. 8W-15-16

Door Ajar Switch-Passenger.............. 8W-15-17

Door Ajar Switch-Right Rear............. 8W-15-16

Door Lock Motor/Ajar Switch-Driver........ 8W-15-17

Door Lock Motor/Ajar Switch-Left Rear...... 8W-15-16

Door Lock Motor/Ajar Switch-Passenger..... 8W-15-17

Door Lock Motor/Ajar Switch-Right Rear..... 8W-15-16

Door Lock Switch-Passenger.............. 8W-15-17

Driver Door Module................... 8W-15-18

EGR Solenoid......................... 8W-15-5

Electric Brake Provision................. 8W-15-4

Engine Control Module.................. 8W-15-8

Fender Lamp-Front Left................. 8W-15-2

Fender Lamp-Front Right................ 8W-15-2

Fender Lamp-Rear Left.................. 8W-15-2

Fender Lamp-Rear Right................. 8W-15-2

Fog Lamp-Left........................ 8W-15-3

Fog Lamp-Right....................... 8W-15-3

Fuel Heater.......................... 8W-15-8

Fuel Pump Module..................... 8W-15-4

G100............................... 8W-15-7

G101............................... 8W-15-7

G102............................... 8W-15-7

G104.......................... 8W-15-3, 4, 15

G105............................... 8W-15-7

G107............................. 8W-15-5, 6

G108............................... 8W-15-7

G109............................... 8W-15-7

G114............................... 8W-15-8

G120............................... 8W-15-8

G201............................ 8W-15-9, 10Component Page

G202......................... 8W-15-11, 12, 14

G204.............................. 8W-15-15

G301.............................. 8W-15-16

G302.............................. 8W-15-18

Generator.......................... 8W-15-6, 8

Glove Box Lamp And Switch............. 8W-15-12

Hands Free Module.................... 8W-15-11

Headlamp Switch..................... 8W-15-14

Headlamp-Left........................ 8W-15-3

Headlamp-Right....................... 8W-15-7

Heated Seat Cushion-Driver.............. 8W-15-18

Heated Seat Cushion-Passenger........... 8W-15-19

Heated Seat Switch-Driver............... 8W-15-12

Heated Seat Switch-Passenger............ 8W-15-12

Horn-High Note....................... 8W-15-4

Horn-Low Note........................ 8W-15-4

Ignition Switch....................... 8W-15-10

Instrument Cluster................. 8W-15-10, 14

Intake Air Heater Relay No. 1............. 8W-15-7

Intake Air Heater Relay No. 2............. 8W-15-7

Integrated Power Module............... 8W-15-3, 4

License Lamp-Left..................... 8W-15-2

License Lamp-Right.................... 8W-15-2

Lift Pump Motor....................... 8W-15-8

Natural Vacuum Leak Detection Assembly..... 8W-15-6

Overhead Map/Reading Lamp............ 8W-15-14

Oxygen Sensor 1/1 Upstream.............. 8W-15-6

Oxygen Sensor 1/2 Downstream............ 8W-15-6

Oxygen Sensor 2/1 Upstream.............. 8W-15-6

Oxygen Sensor 2/2 Downstream............ 8W-15-6

Park/Turn Signal Lamp-Left Front.......... 8W-15-4

Park/Turn Signal Lamp-Right Front......... 8W-15-7

Passenger Lumbar Switch............... 8W-15-19

Power Mirror-Left..................... 8W-15-18

Power Mirror-Right.................... 8W-15-18

Power Outlet........................ 8W-15-12

Power Outlet-Console................ 8W-15-15, 19

Power Seat Switch-Driver............... 8W-15-18

Power Seat Switch-Passenger............. 8W-15-19

Power Steering Pressure Switch............ 8W-15-5

Powertrain Control Module............. 8W-15-5, 6

Radio.............................. 8W-15-11

Seat Belt Switch-Driver................. 8W-15-16

Seat Heater Interface Module............. 8W-15-16

Sentry Key Immobilizer Module........... 8W-15-10

Speed Control Servo.................... 8W-15-3

Tail/Stop/Turn Signal Lamp-Left........... 8W-15-2

Tail/Stop/Turn Signal Lamp-Right.......... 8W-15-2

Tailgate Lamp........................ 8W-15-2

Tow/Haul Overdrive Switch............... 8W-15-9

Trailer Tow Connector................... 8W-15-4

Trailer Tow Connector-Add On............. 8W-15-4

Transfer Case Control Module............ 8W-15-15

Transfer Case Selector Switch........... 8W-15-4, 15

Vacuum Pump........................ 8W-15-7

Washer Fluid Level Switch.............. 8W-15-3, 7

Washer Pump Motor-Front............... 8W-15-7

Wiper Motor-Front..................... 8W-15-4

DR8W-15 GROUND DISTRIBUTION 8W - 15 - 1