Spring leaf DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 33 of 2627

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

HOISTING

STANDARD PROCEDURE - HOISTING

Refer to the Owner's Manual for emergency vehicle

lifting procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN A CHASSIS OR DRIVETRAIN COMPO-

NENT IS REMOVED FROM A VEHICLE, THE

CENTER OF GRAVITY IS ALTERED MAKING SOME

HOISTING CONDITIONS UNSTABLE. PROPERLY

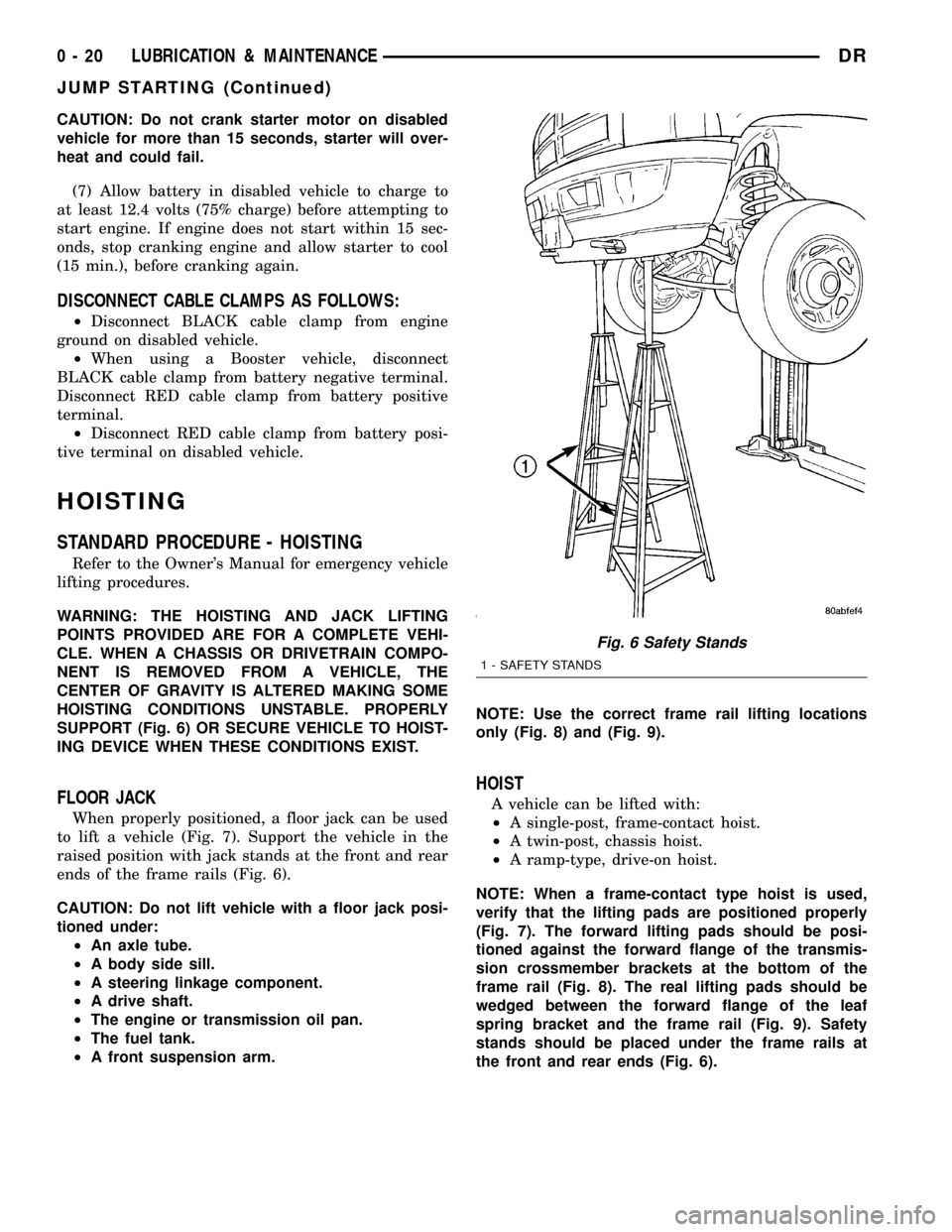

SUPPORT (Fig. 6) OR SECURE VEHICLE TO HOIST-

ING DEVICE WHEN THESE CONDITIONS EXIST.

FLOOR JACK

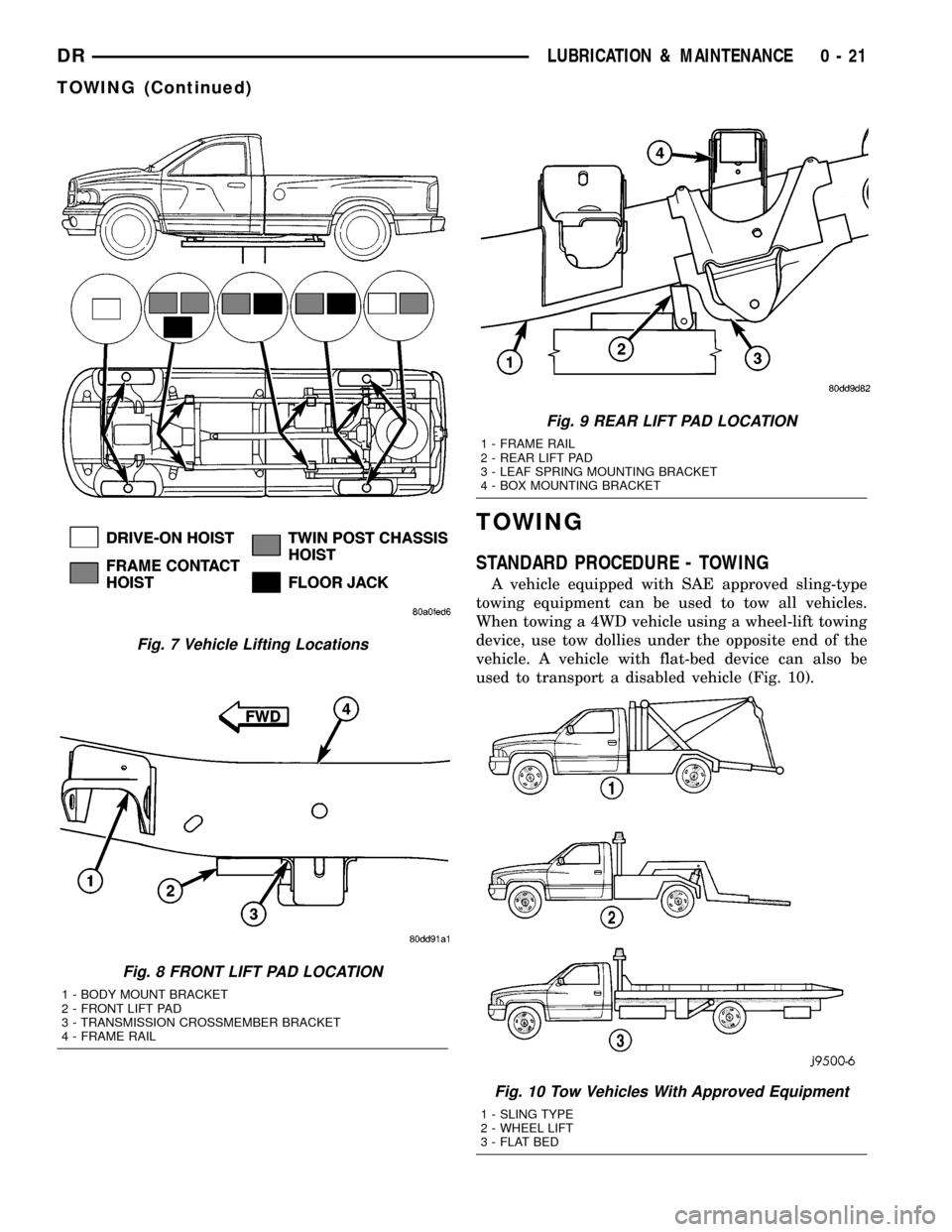

When properly positioned, a floor jack can be used

to lift a vehicle (Fig. 7). Support the vehicle in the

raised position with jack stands at the front and rear

ends of the frame rails (Fig. 6).

CAUTION: Do not lift vehicle with a floor jack posi-

tioned under:

²An axle tube.

²A body side sill.

²A steering linkage component.

²A drive shaft.

²The engine or transmission oil pan.

²The fuel tank.

²A front suspension arm.NOTE: Use the correct frame rail lifting locations

only (Fig. 8) and (Fig. 9).

HOIST

A vehicle can be lifted with:

²A single-post, frame-contact hoist.

²A twin-post, chassis hoist.

²A ramp-type, drive-on hoist.

NOTE: When a frame-contact type hoist is used,

verify that the lifting pads are positioned properly

(Fig. 7). The forward lifting pads should be posi-

tioned against the forward flange of the transmis-

sion crossmember brackets at the bottom of the

frame rail (Fig. 8). The real lifting pads should be

wedged between the forward flange of the leaf

spring bracket and the frame rail (Fig. 9). Safety

stands should be placed under the frame rails at

the front and rear ends (Fig. 6).

Fig. 6 Safety Stands

1 - SAFETY STANDS

0 - 20 LUBRICATION & MAINTENANCEDR

JUMP STARTING (Continued)

Page 34 of 2627

TOWING

STANDARD PROCEDURE - TOWING

A vehicle equipped with SAE approved sling-type

towing equipment can be used to tow all vehicles.

When towing a 4WD vehicle using a wheel-lift towing

device, use tow dollies under the opposite end of the

vehicle. A vehicle with flat-bed device can also be

used to transport a disabled vehicle (Fig. 10).

Fig. 7 Vehicle Lifting Locations

Fig. 8 FRONT LIFT PAD LOCATION

1 - BODY MOUNT BRACKET

2 - FRONT LIFT PAD

3 - TRANSMISSION CROSSMEMBER BRACKET

4 - FRAME RAIL

Fig. 9 REAR LIFT PAD LOCATION

1 - FRAME RAIL

2 - REAR LIFT PAD

3 - LEAF SPRING MOUNTING BRACKET

4 - BOX MOUNTING BRACKET

Fig. 10 Tow Vehicles With Approved Equipment

1 - SLING TYPE

2 - WHEEL LIFT

3 - FLAT BED

DRLUBRICATION & MAINTENANCE 0 - 21

TOWING (Continued)

Page 76 of 2627

REAR

TABLE OF CONTENTS

page page

REAR

DESCRIPTION.........................41

DIAGNOSIS AND TESTING - SPRING AND

SHOCK.............................41

SPECIFICATIONS

TORQUE CHART......................42

BUSHINGS

REMOVAL.............................43

INSTALLATION.........................43

JOUNCE BUMPER

REMOVAL.............................43

INSTALLATION.........................43

AUXILIARY SPRING BUMPERS (3500)

REMOVAL.............................43INSTALLATION.........................43

SHOCK

REMOVAL.............................43

INSTALLATION.........................43

SPRING

DESCRIPTION.........................44

OPERATION...........................44

REMOVAL.............................44

INSTALLATION.........................44

SPRING TIP INSERTS

REMOVAL.............................44

INSTALLATION.........................45

REAR

DESCRIPTION

The rear suspension is comprised of:

²Shock Absorbers

²Jounce Bumpers

²Leaf Springs

²Auxiliary Leaf Spring (3500 series)

²Auxiliary Spring Bumpers (3500 series)

²Drive Axle

CAUTION: A vehicle should always be loaded so

the vehicle weight center-line is located immedi-

ately forward of the rear axle. Correct vehicle load-

ing provides proper front tire-to-road contact. This

results in maximum vehicle handling stability and

safety. Incorrect vehicle weight distribution can

cause excessive tire tread wear, spring fatigue or

failure, and erratic steering.

CAUTION: Suspension components with rubber/ure-

thane bushings (except stabilizer bar) should be

tightened with the vehicle at normal ride height. It is

important to have the springs supporting the weight

of the vehicle when the fasteners are torqued. If

springs are not at their normal ride position, vehicle

ride comfort could be affected and premature bush-

ing wear may occur.

DIAGNOSIS AND TESTING - SPRING AND

SHOCK

A knocking or rattling noise from a shock absorber

may be caused by movement between mounting

bushings and metal brackets or attaching compo-

nents. These noises can usually be stopped by tight-

ening the attaching nuts. If the noise persists,

inspect for damaged and worn bushings, and attach-

ing components. Repair as necessary if any of these

conditions exist.

A squeaking noise from the shock absorber may be

caused by the hydraulic valving and may be intermit-

tent. This condition is not repairable and the shock

absorber must be replaced.

The shock absorbers are not refillable or adjust-

able. If a malfunction occurs, the shock absorber

must be replaced. To test a shock absorber, hold it in

an upright position and force the piston in and out of

the cylinder four or five times. The action throughout

each stroke should be smooth and even.

The spring eye and shock absorber bushings do not

require any type of lubrication. Do not attempt to

stop spring bushing noise by lubricating them.

Grease and mineral oil-base lubricants will deterio-

rate the bushing rubber.

If the vehicle is used for severe, off-road operation,

the springs should be examined periodically. Check

for broken and shifted leafs, loose and missing clips,

and broken center bolts. Refer to Spring and Shock

Absorber Diagnosis chart for additional information.

DRREAR 2 - 41

Page 77 of 2627

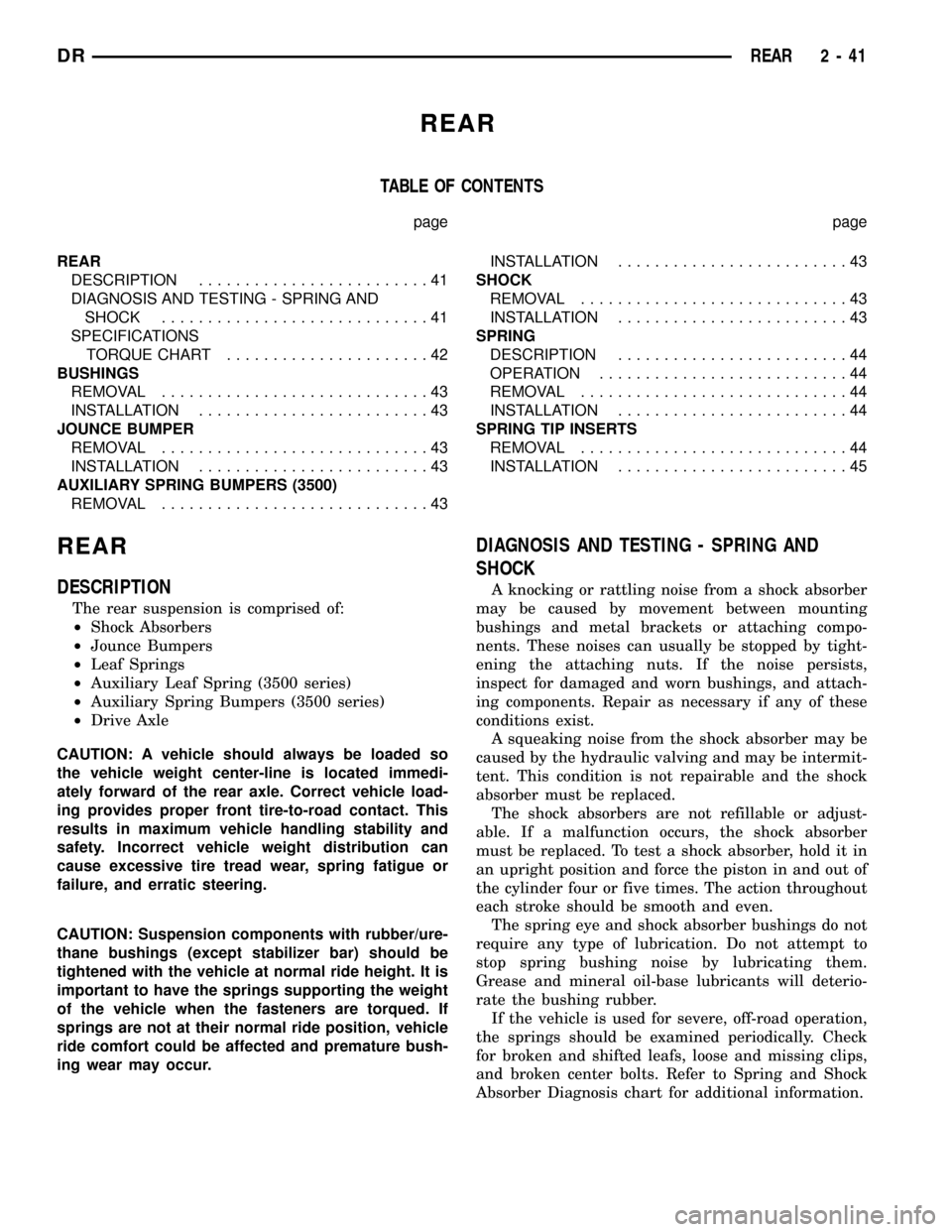

SPRING AND SHOCK ABSORBER

CONDITION POSSIBLE CAUSES CORRECTION

SPRING SAGS 1. Broken leaf. 1. Replace spring.

2. Spring fatigue. 2. Replace spring.

SPRING NOISE 1. Loose spring clamp bolts. 1. Tighten to specification.

2. Worn bushings. 2. Replace bushings.

3. Worn or missing spring tip inserts. 3. Replace spring tip inserts.

SHOCK NOISE 1. Loose mounting fastener. 1. Tighten to specification.

2. Worn bushings. 2. Replace shock.

3. Leaking shock. 3. Replace shock.

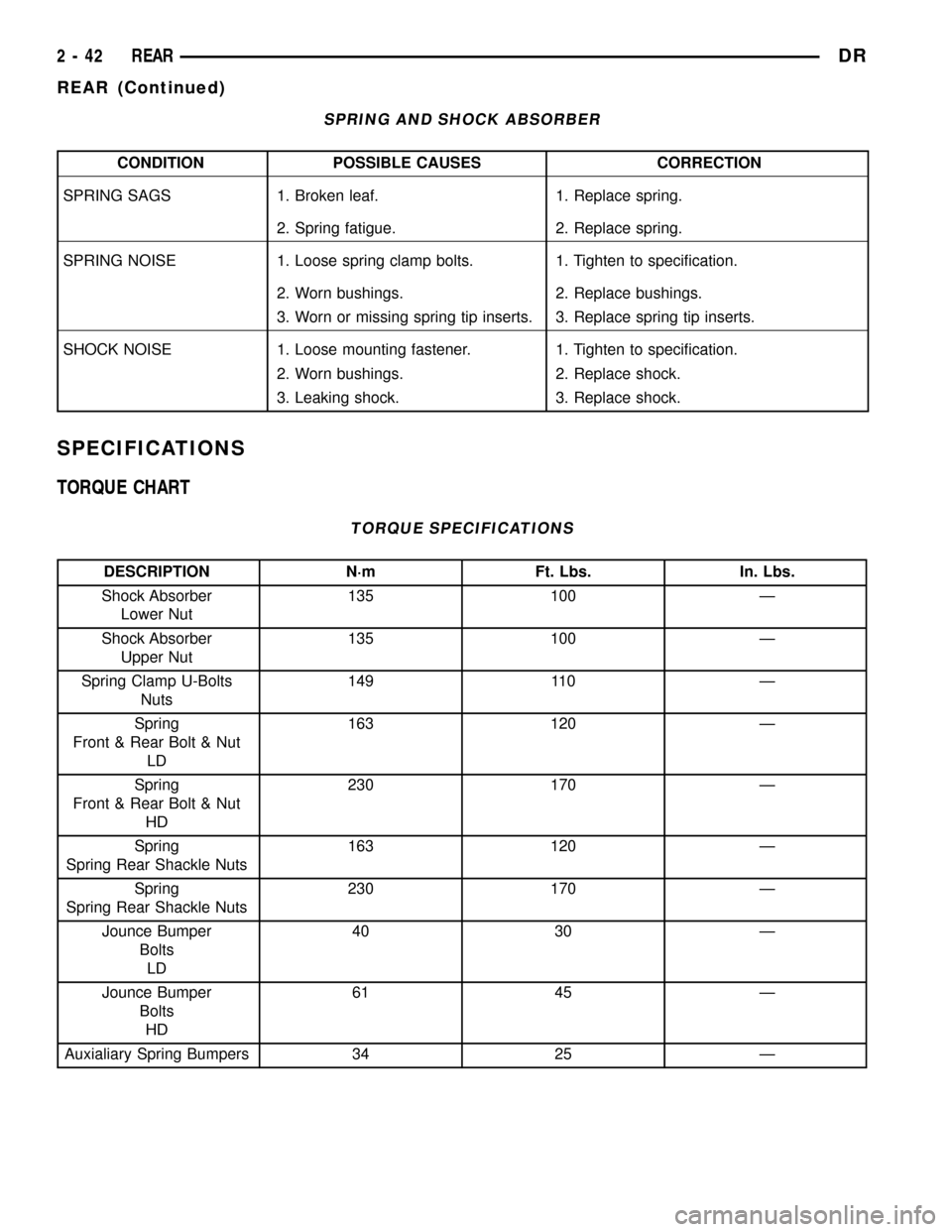

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Shock Absorber

Lower Nut135 100 Ð

Shock Absorber

Upper Nut135 100 Ð

Spring Clamp U-Bolts

Nuts149 110 Ð

Spring

Front & Rear Bolt & Nut

LD163 120 Ð

Spring

Front & Rear Bolt & Nut

HD230 170 Ð

Spring

Spring Rear Shackle Nuts163 120 Ð

Spring

Spring Rear Shackle Nuts230 170 Ð

Jounce Bumper

Bolts

LD40 30 Ð

Jounce Bumper

Bolts

HD61 45 Ð

Auxialiary Spring Bumpers 34 25 Ð

2 - 42 REARDR

REAR (Continued)

Page 79 of 2627

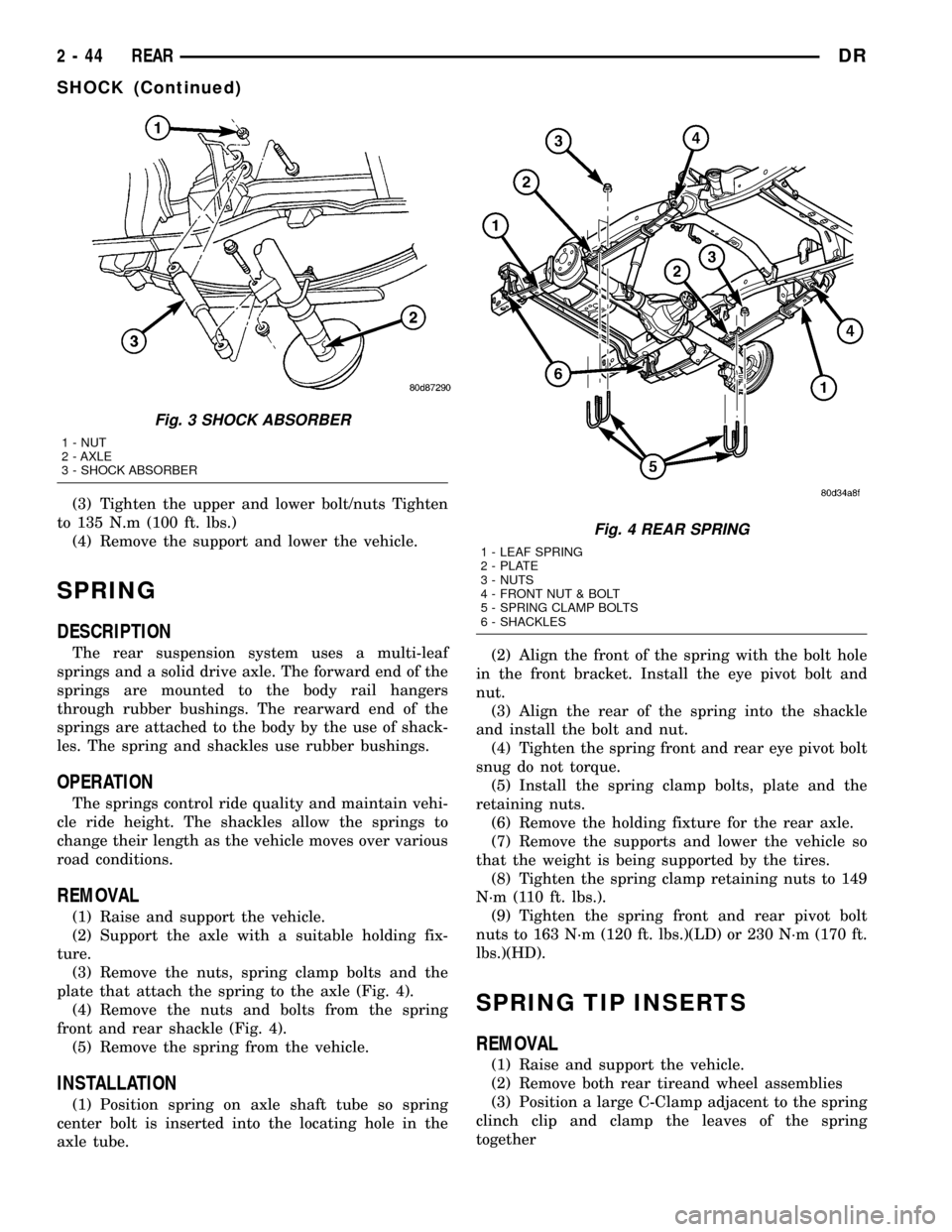

(3) Tighten the upper and lower bolt/nuts Tighten

to 135 N.m (100 ft. lbs.)

(4) Remove the support and lower the vehicle.

SPRING

DESCRIPTION

The rear suspension system uses a multi-leaf

springs and a solid drive axle. The forward end of the

springs are mounted to the body rail hangers

through rubber bushings. The rearward end of the

springs are attached to the body by the use of shack-

les. The spring and shackles use rubber bushings.

OPERATION

The springs control ride quality and maintain vehi-

cle ride height. The shackles allow the springs to

change their length as the vehicle moves over various

road conditions.

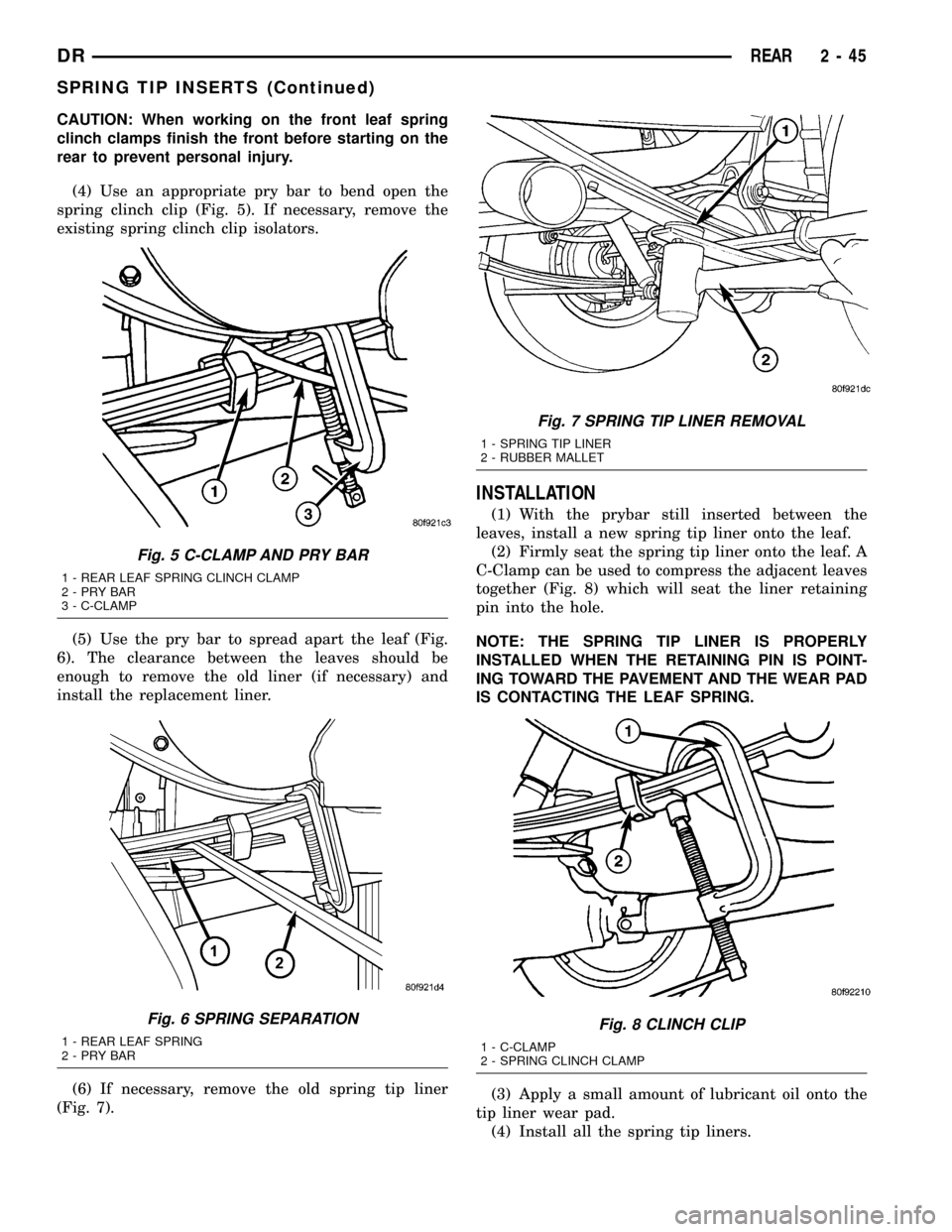

REMOVAL

(1) Raise and support the vehicle.

(2) Support the axle with a suitable holding fix-

ture.

(3) Remove the nuts, spring clamp bolts and the

plate that attach the spring to the axle (Fig. 4).

(4) Remove the nuts and bolts from the spring

front and rear shackle (Fig. 4).

(5) Remove the spring from the vehicle.

INSTALLATION

(1) Position spring on axle shaft tube so spring

center bolt is inserted into the locating hole in the

axle tube.(2) Align the front of the spring with the bolt hole

in the front bracket. Install the eye pivot bolt and

nut.

(3) Align the rear of the spring into the shackle

and install the bolt and nut.

(4) Tighten the spring front and rear eye pivot bolt

snug do not torque.

(5) Install the spring clamp bolts, plate and the

retaining nuts.

(6) Remove the holding fixture for the rear axle.

(7) Remove the supports and lower the vehicle so

that the weight is being supported by the tires.

(8) Tighten the spring clamp retaining nuts to 149

N´m (110 ft. lbs.).

(9) Tighten the spring front and rear pivot bolt

nuts to 163 N´m (120 ft. lbs.)(LD) or 230 N´m (170 ft.

lbs.)(HD).

SPRING TIP INSERTS

REMOVAL

(1) Raise and support the vehicle.

(2) Remove both rear tireand wheel assemblies

(3) Position a large C-Clamp adjacent to the spring

clinch clip and clamp the leaves of the spring

together

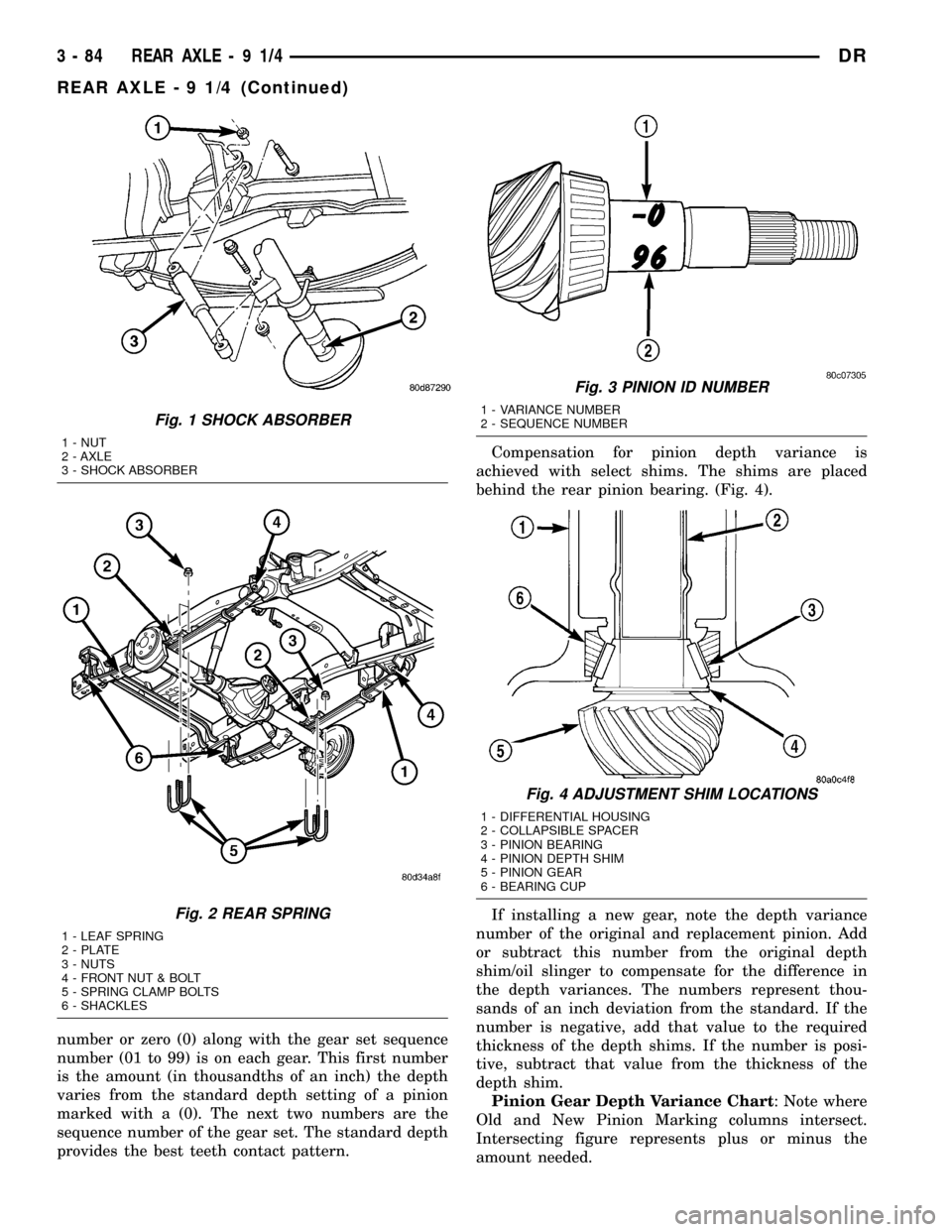

Fig. 3 SHOCK ABSORBER

1 - NUT

2 - AXLE

3 - SHOCK ABSORBER

Fig. 4 REAR SPRING

1 - LEAF SPRING

2 - PLATE

3 - NUTS

4 - FRONT NUT & BOLT

5 - SPRING CLAMP BOLTS

6 - SHACKLES

2 - 44 REARDR

SHOCK (Continued)

Page 80 of 2627

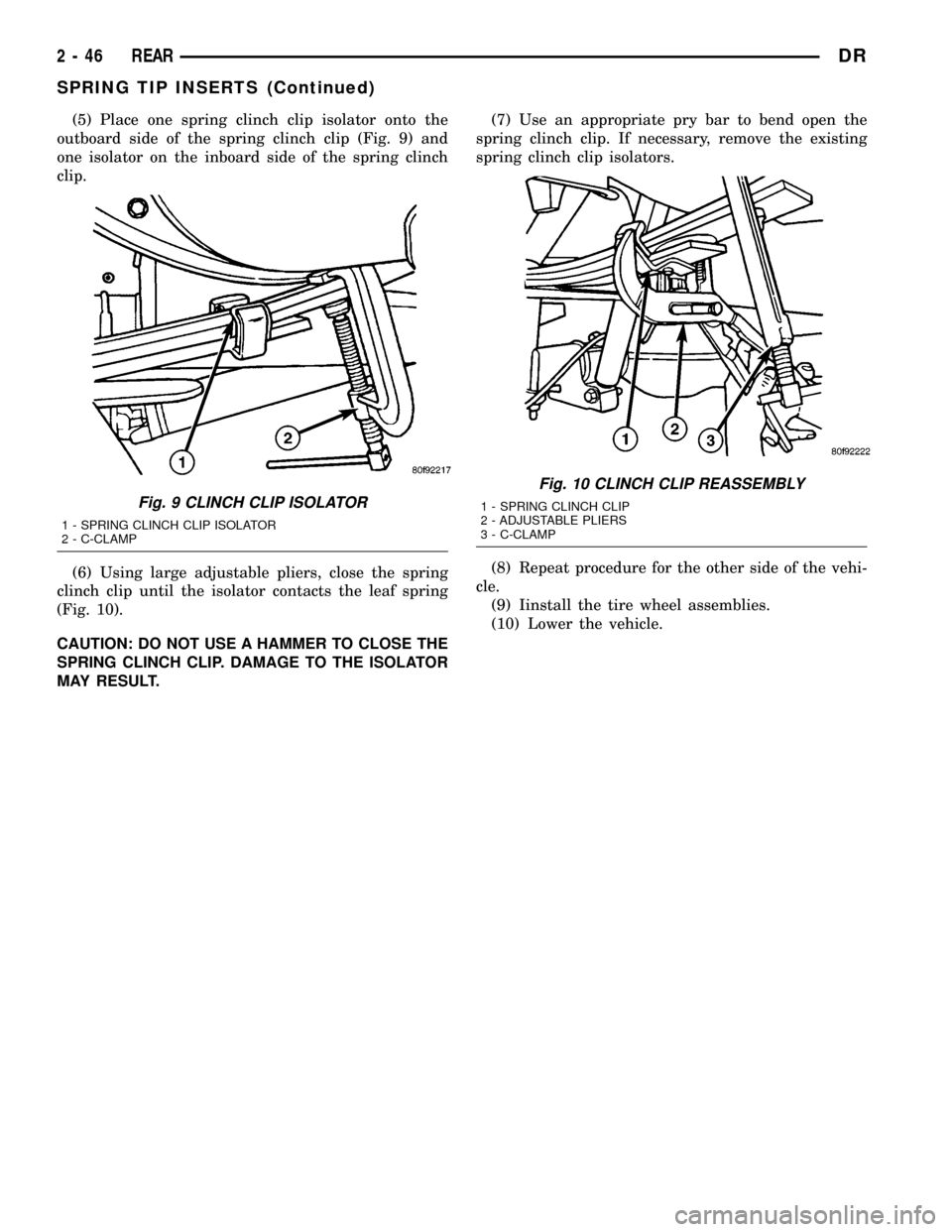

CAUTION: When working on the front leaf spring

clinch clamps finish the front before starting on the

rear to prevent personal injury.

(4) Use an appropriate pry bar to bend open the

spring clinch clip (Fig. 5). If necessary, remove the

existing spring clinch clip isolators.

(5) Use the pry bar to spread apart the leaf (Fig.

6). The clearance between the leaves should be

enough to remove the old liner (if necessary) and

install the replacement liner.

(6) If necessary, remove the old spring tip liner

(Fig. 7).

INSTALLATION

(1) With the prybar still inserted between the

leaves, install a new spring tip liner onto the leaf.

(2) Firmly seat the spring tip liner onto the leaf. A

C-Clamp can be used to compress the adjacent leaves

together (Fig. 8) which will seat the liner retaining

pin into the hole.

NOTE: THE SPRING TIP LINER IS PROPERLY

INSTALLED WHEN THE RETAINING PIN IS POINT-

ING TOWARD THE PAVEMENT AND THE WEAR PAD

IS CONTACTING THE LEAF SPRING.

(3) Apply a small amount of lubricant oil onto the

tip liner wear pad.

(4) Install all the spring tip liners.

Fig. 5 C-CLAMP AND PRY BAR

1 - REAR LEAF SPRING CLINCH CLAMP

2-PRYBAR

3 - C-CLAMP

Fig. 6 SPRING SEPARATION

1 - REAR LEAF SPRING

2-PRYBAR

Fig. 7 SPRING TIP LINER REMOVAL

1 - SPRING TIP LINER

2 - RUBBER MALLET

Fig. 8 CLINCH CLIP

1 - C-CLAMP

2 - SPRING CLINCH CLAMP

DRREAR 2 - 45

SPRING TIP INSERTS (Continued)

Page 81 of 2627

(5) Place one spring clinch clip isolator onto the

outboard side of the spring clinch clip (Fig. 9) and

one isolator on the inboard side of the spring clinch

clip.

(6) Using large adjustable pliers, close the spring

clinch clip until the isolator contacts the leaf spring

(Fig. 10).

CAUTION: DO NOT USE A HAMMER TO CLOSE THE

SPRING CLINCH CLIP. DAMAGE TO THE ISOLATOR

MAY RESULT.(7) Use an appropriate pry bar to bend open the

spring clinch clip. If necessary, remove the existing

spring clinch clip isolators.

(8) Repeat procedure for the other side of the vehi-

cle.

(9) Iinstall the tire wheel assemblies.

(10) Lower the vehicle.

Fig. 9 CLINCH CLIP ISOLATOR

1 - SPRING CLINCH CLIP ISOLATOR

2 - C-CLAMP

Fig. 10 CLINCH CLIP REASSEMBLY

1 - SPRING CLINCH CLIP

2 - ADJUSTABLE PLIERS

3 - C-CLAMP

2 - 46 REARDR

SPRING TIP INSERTS (Continued)

Page 164 of 2627

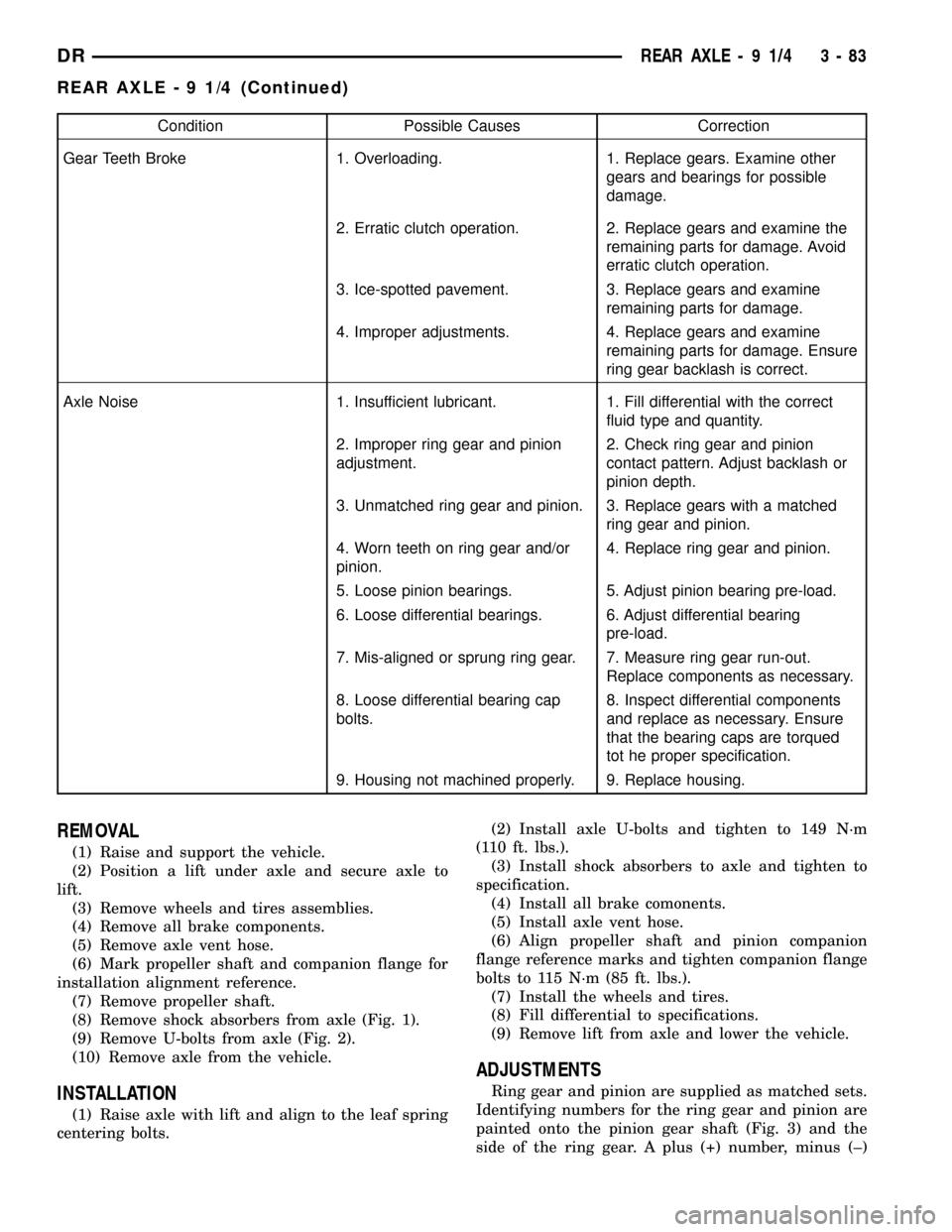

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern. Adjust backlash or

pinion depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

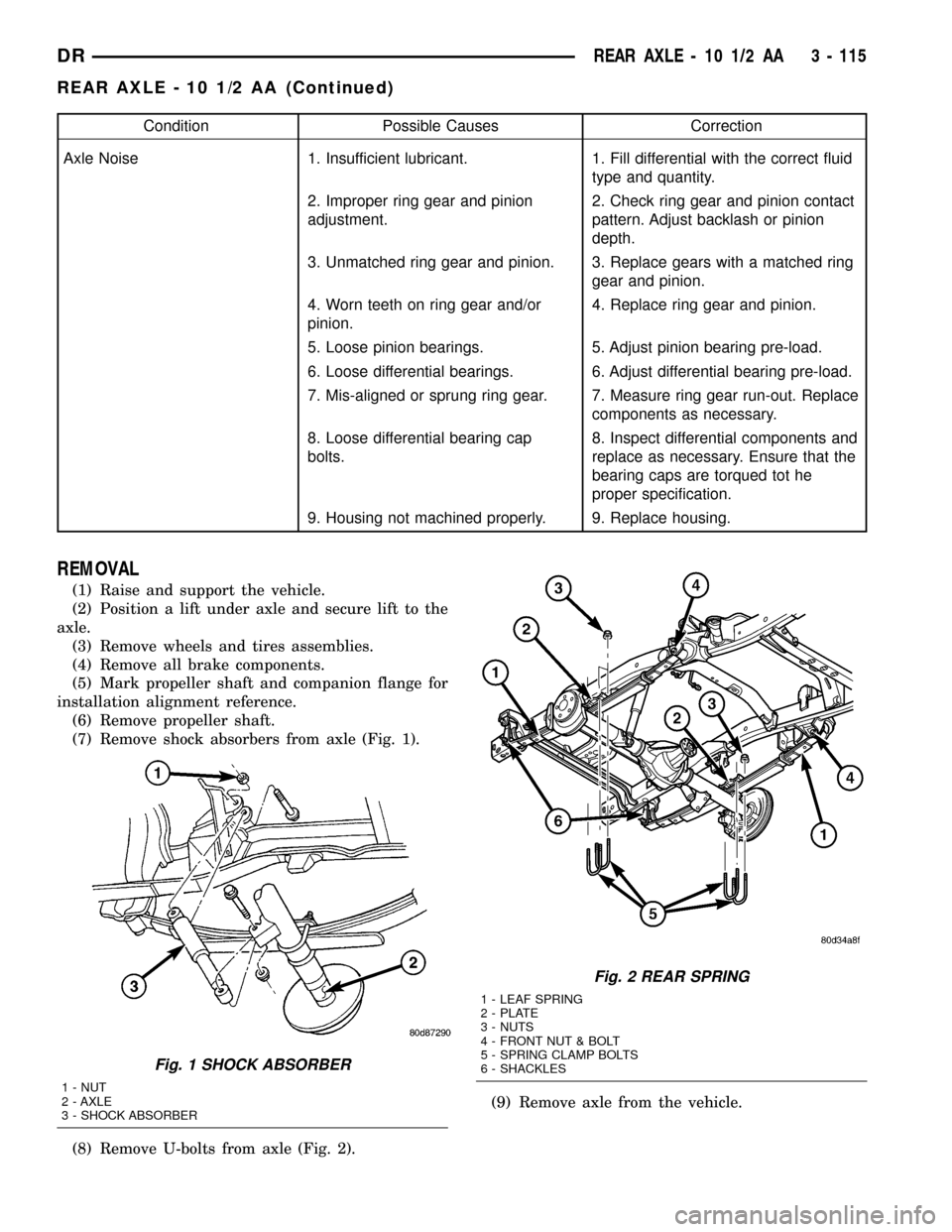

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lift under axle and secure axle to

lift.

(3) Remove wheels and tires assemblies.

(4) Remove all brake components.

(5) Remove axle vent hose.

(6) Mark propeller shaft and companion flange for

installation alignment reference.

(7) Remove propeller shaft.

(8) Remove shock absorbers from axle (Fig. 1).

(9) Remove U-bolts from axle (Fig. 2).

(10) Remove axle from the vehicle.

INSTALLATION

(1) Raise axle with lift and align to the leaf spring

centering bolts.(2) Install axle U-bolts and tighten to 149 N´m

(110 ft. lbs.).

(3) Install shock absorbers to axle and tighten to

specification.

(4) Install all brake comonents.

(5) Install axle vent hose.

(6) Align propeller shaft and pinion companion

flange reference marks and tighten companion flange

bolts to 115 N´m (85 ft. lbs.).

(7) Install the wheels and tires.

(8) Fill differential to specifications.

(9) Remove lift from axle and lower the vehicle.

ADJUSTMENTS

Ring gear and pinion are supplied as matched sets.

Identifying numbers for the ring gear and pinion are

painted onto the pinion gear shaft (Fig. 3) and the

side of the ring gear. A plus (+) number, minus (±)

DRREAR AXLE - 9 1/4 3 - 83

REAR AXLE - 9 1/4 (Continued)

Page 165 of 2627

number or zero (0) along with the gear set sequence

number (01 to 99) is on each gear. This first number

is the amount (in thousandths of an inch) the depth

varies from the standard depth setting of a pinion

marked with a (0). The next two numbers are the

sequence number of the gear set. The standard depth

provides the best teeth contact pattern.Compensation for pinion depth variance is

achieved with select shims. The shims are placed

behind the rear pinion bearing. (Fig. 4).

If installing a new gear, note the depth variance

number of the original and replacement pinion. Add

or subtract this number from the original depth

shim/oil slinger to compensate for the difference in

the depth variances. The numbers represent thou-

sands of an inch deviation from the standard. If the

number is negative, add that value to the required

thickness of the depth shims. If the number is posi-

tive, subtract that value from the thickness of the

depth shim.

Pinion Gear Depth Variance Chart: Note where

Old and New Pinion Marking columns intersect.

Intersecting figure represents plus or minus the

amount needed.

Fig. 1 SHOCK ABSORBER

1 - NUT

2 - AXLE

3 - SHOCK ABSORBER

Fig. 2 REAR SPRING

1 - LEAF SPRING

2 - PLATE

3 - NUTS

4 - FRONT NUT & BOLT

5 - SPRING CLAMP BOLTS

6 - SHACKLES

Fig. 3 PINION ID NUMBER

1 - VARIANCE NUMBER

2 - SEQUENCE NUMBER

Fig. 4 ADJUSTMENT SHIM LOCATIONS

1 - DIFFERENTIAL HOUSING

2 - COLLAPSIBLE SPACER

3 - PINION BEARING

4 - PINION DEPTH SHIM

5 - PINION GEAR

6 - BEARING CUP

3 - 84 REAR AXLE-91/4DR

REAR AXLE - 9 1/4 (Continued)

Page 196 of 2627

Condition Possible Causes Correction

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct fluid

type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion contact

pattern. Adjust backlash or pinion

depth.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched ring

gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out. Replace

components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components and

replace as necessary. Ensure that the

bearing caps are torqued tot he

proper specification.

9. Housing not machined properly. 9. Replace housing.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lift under axle and secure lift to the

axle.

(3) Remove wheels and tires assemblies.

(4) Remove all brake components.

(5) Mark propeller shaft and companion flange for

installation alignment reference.

(6) Remove propeller shaft.

(7) Remove shock absorbers from axle (Fig. 1).

(8) Remove U-bolts from axle (Fig. 2).(9) Remove axle from the vehicle.

Fig. 1 SHOCK ABSORBER

1 - NUT

2 - AXLE

3 - SHOCK ABSORBER

Fig. 2 REAR SPRING

1 - LEAF SPRING

2 - PLATE

3 - NUTS

4 - FRONT NUT & BOLT

5 - SPRING CLAMP BOLTS

6 - SHACKLES

DRREAR AXLE - 10 1/2 AA 3 - 115

REAR AXLE - 10 1/2 AA (Continued)