drain bolt DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 127 of 2627

DIFFERENTIAL

REMOVAL

(1) Remove differential housing cover and drain

fluid.

(2) Remove axle shafts.

(3) Loosen bearing cap bolts.

NOTE: Differential bearing cap reference numbers

are stamped on caps and machined flat on the

housing. If reference numbers cannot be found,

make new marks for later reference.

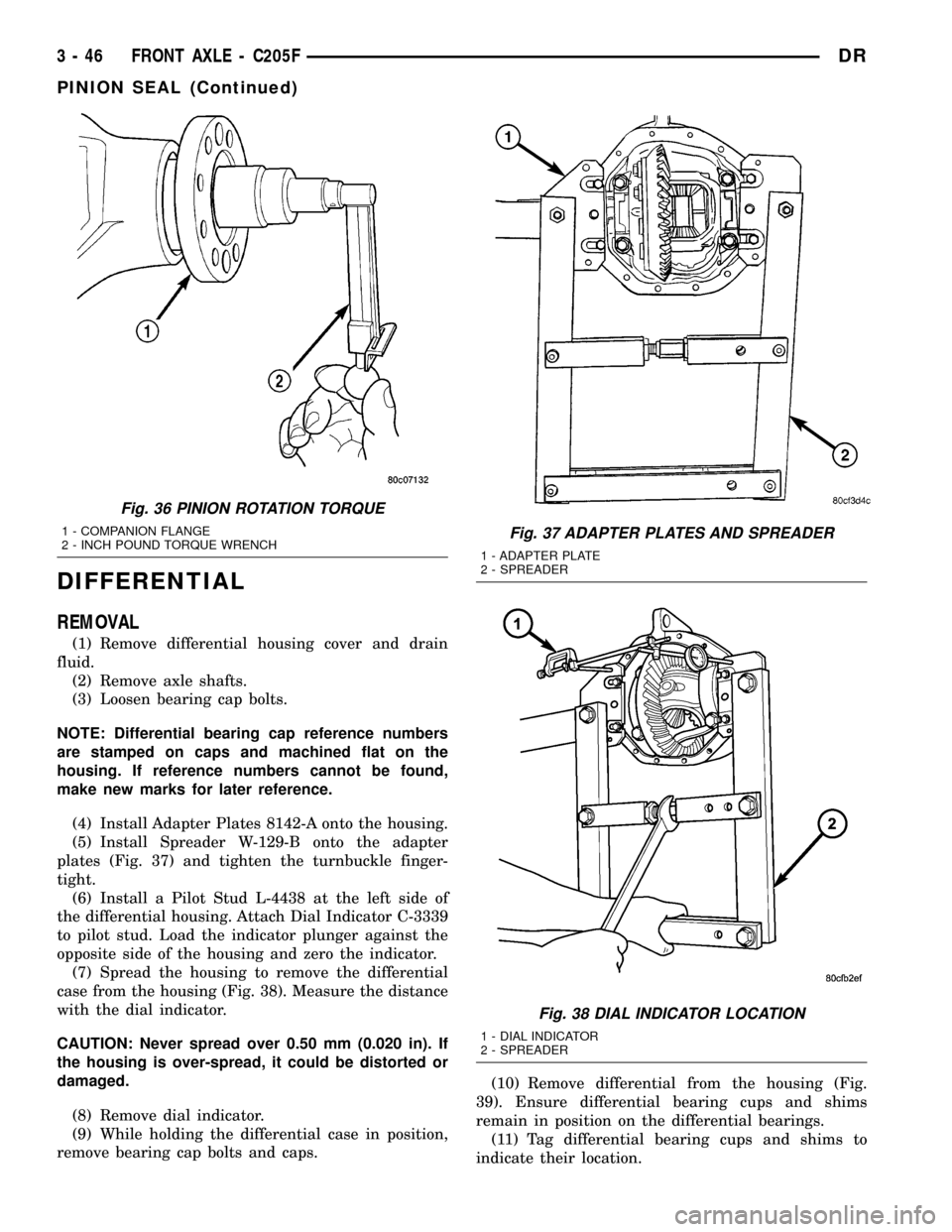

(4) Install Adapter Plates 8142-A onto the housing.

(5) Install Spreader W-129-B onto the adapter

plates (Fig. 37) and tighten the turnbuckle finger-

tight.

(6) Install a Pilot Stud L-4438 at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the indicator.

(7) Spread the housing to remove the differential

case from the housing (Fig. 38). Measure the distance

with the dial indicator.

CAUTION: Never spread over 0.50 mm (0.020 in). If

the housing is over-spread, it could be distorted or

damaged.

(8) Remove dial indicator.

(9) While holding the differential case in position,

remove bearing cap bolts and caps.(10) Remove differential from the housing (Fig.

39). Ensure differential bearing cups and shims

remain in position on the differential bearings.

(11) Tag differential bearing cups and shims to

indicate their location.

Fig. 36 PINION ROTATION TORQUE

1 - COMPANION FLANGE

2 - INCH POUND TORQUE WRENCHFig. 37 ADAPTER PLATES AND SPREADER

1 - ADAPTER PLATE

2 - SPREADER

Fig. 38 DIAL INDICATOR LOCATION

1 - DIAL INDICATOR

2 - SPREADER

3 - 46 FRONT AXLE - C205FDR

PINION SEAL (Continued)

Page 153 of 2627

DIFFERENTIAL

REMOVAL

(1) Remove differential housing cover and drain

lubricant from the housing.

(2) Remove hub bearings and axle shafts.

(3) Remove adjuster lock bolts and adjuster locks

(Fig. 34).

(4) Mark bearing caps left and right for installa-

tion reference.

(5) Remove bearing cap bolts and remove bearing

caps.

(6) Loosen differential bearing adjusters (Fig. 35)

with Spanner Wrench 8883.

(7) Remove differential case from the housing.

(8) Remove bearing cups and tag them left and

right for installation reference.

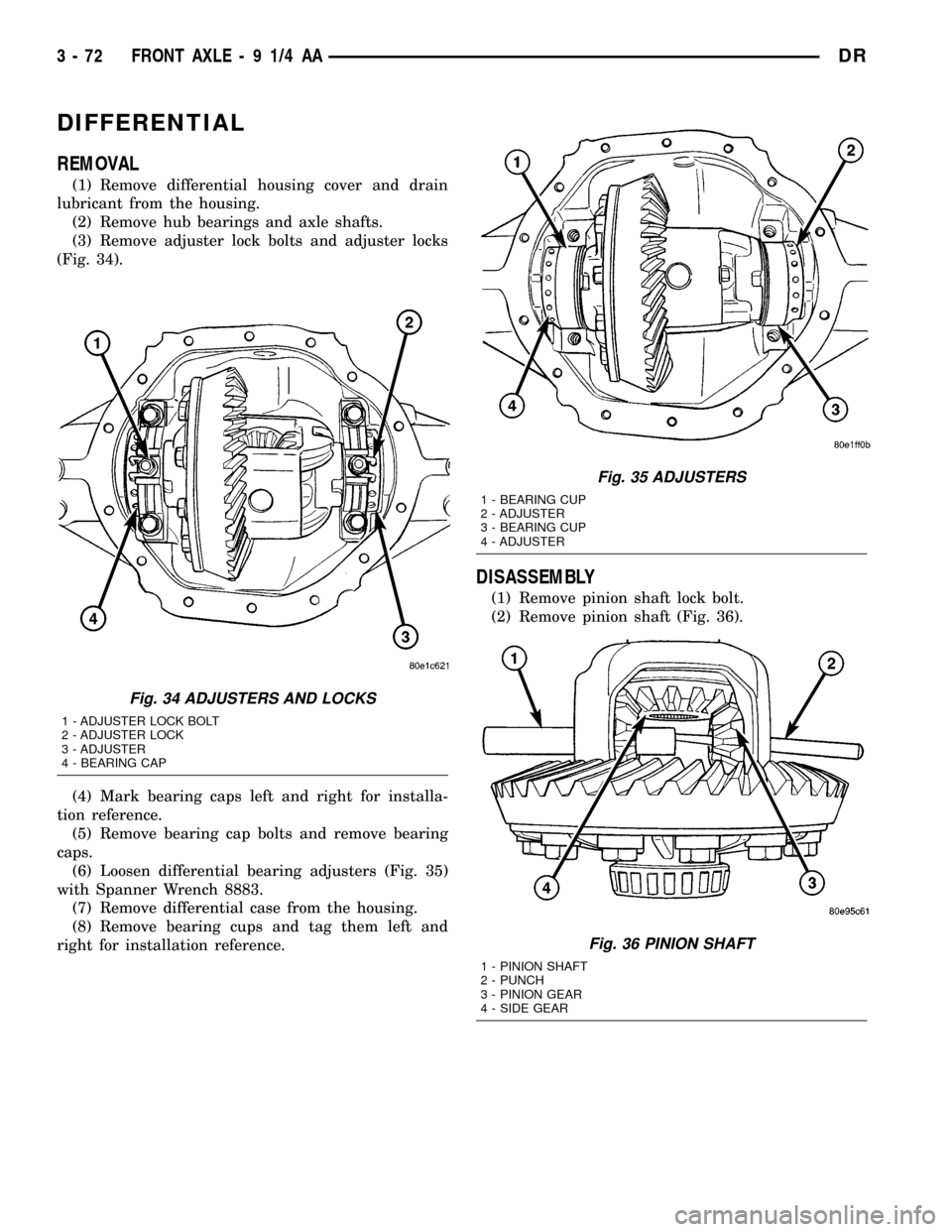

DISASSEMBLY

(1) Remove pinion shaft lock bolt.

(2) Remove pinion shaft (Fig. 36).

Fig. 34 ADJUSTERS AND LOCKS

1 - ADJUSTER LOCK BOLT

2 - ADJUSTER LOCK

3 - ADJUSTER

4 - BEARING CAP

Fig. 35 ADJUSTERS

1 - BEARING CUP

2 - ADJUSTER

3 - BEARING CUP

4 - ADJUSTER

Fig. 36 PINION SHAFT

1 - PINION SHAFT

2 - PUNCH

3 - PINION GEAR

4 - SIDE GEAR

3 - 72 FRONT AXLE - 9 1/4 AADR

Page 178 of 2627

(10) If rotating torque is low, use Holder 6719 to

hold the companion flange and tighten pinion nut in

6.8 N´m (5 ft. lbs.) increments until proper rotating

torque is achieved.

NOTE: The bearing rotating torque should be con-

stant during a complete revolution of the pinion. If

the rotating torque varies, this indicates a binding

condition.

NOTE: The seal replacement is unacceptable if the

final pinion nut torque is less than 285 N´m (210 ft.

lbs.).

(11) Install propeller shaft with the installation

reference marks aligned.

(12) Tighten the companion flange bolts to 108

N´m (80 ft. lbs.).

(13) Install brake rotors.

(14) Check the differential lubricant level.

DIFFERENTIAL COVER

REMOVAL

(1) With vehicle in neutral, position vehicle on

hoist.

(2) Remove drain plug.

(3) Remove cover bolts.

(4) Remove cover and drain lubricant.

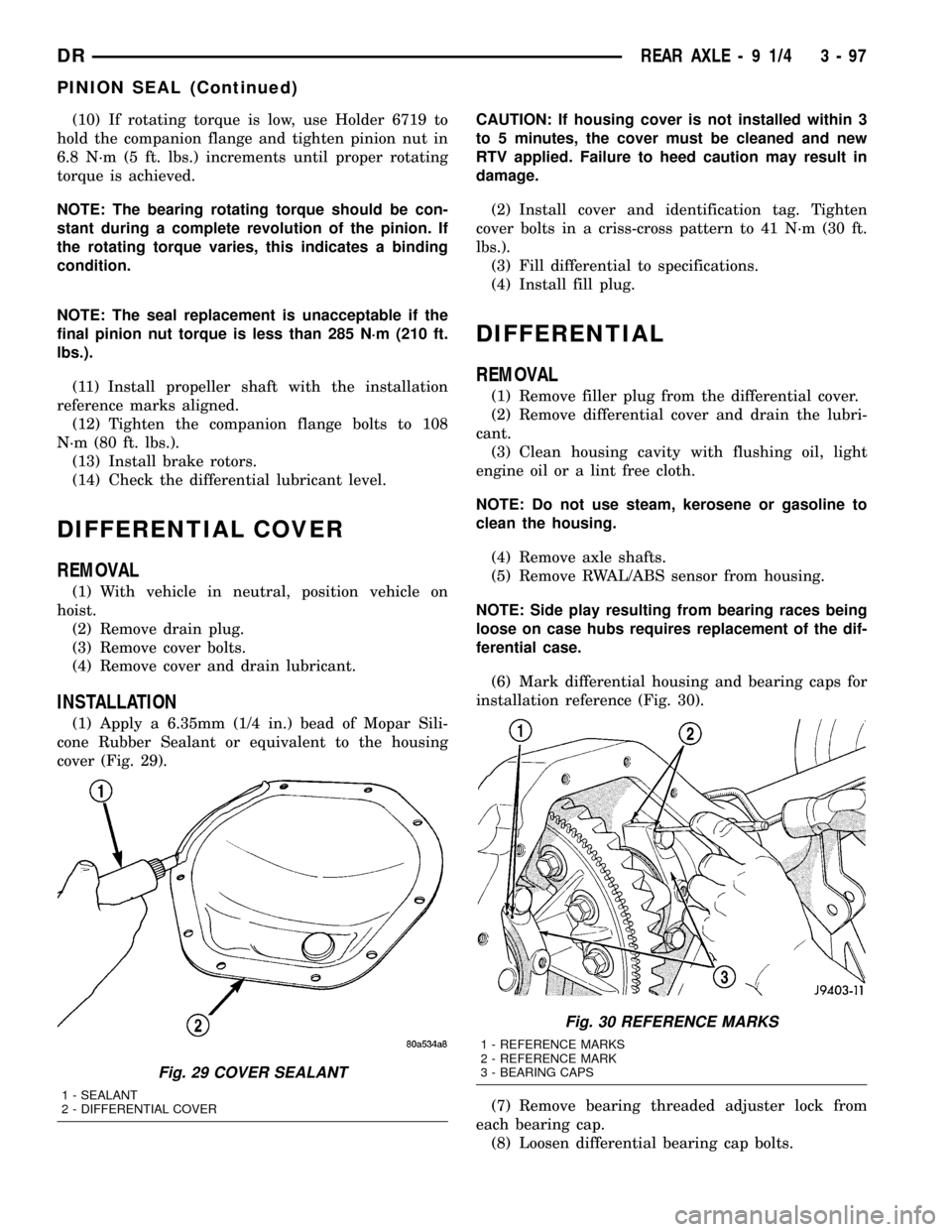

INSTALLATION

(1) Apply a 6.35mm (1/4 in.) bead of Mopar Sili-

cone Rubber Sealant or equivalent to the housing

cover (Fig. 29).CAUTION: If housing cover is not installed within 3

to 5 minutes, the cover must be cleaned and new

RTV applied. Failure to heed caution may result in

damage.

(2) Install cover and identification tag. Tighten

cover bolts in a criss-cross pattern to 41 N´m (30 ft.

lbs.).

(3) Fill differential to specifications.

(4) Install fill plug.

DIFFERENTIAL

REMOVAL

(1) Remove filler plug from the differential cover.

(2) Remove differential cover and drain the lubri-

cant.

(3) Clean housing cavity with flushing oil, light

engine oil or a lint free cloth.

NOTE: Do not use steam, kerosene or gasoline to

clean the housing.

(4) Remove axle shafts.

(5) Remove RWAL/ABS sensor from housing.

NOTE: Side play resulting from bearing races being

loose on case hubs requires replacement of the dif-

ferential case.

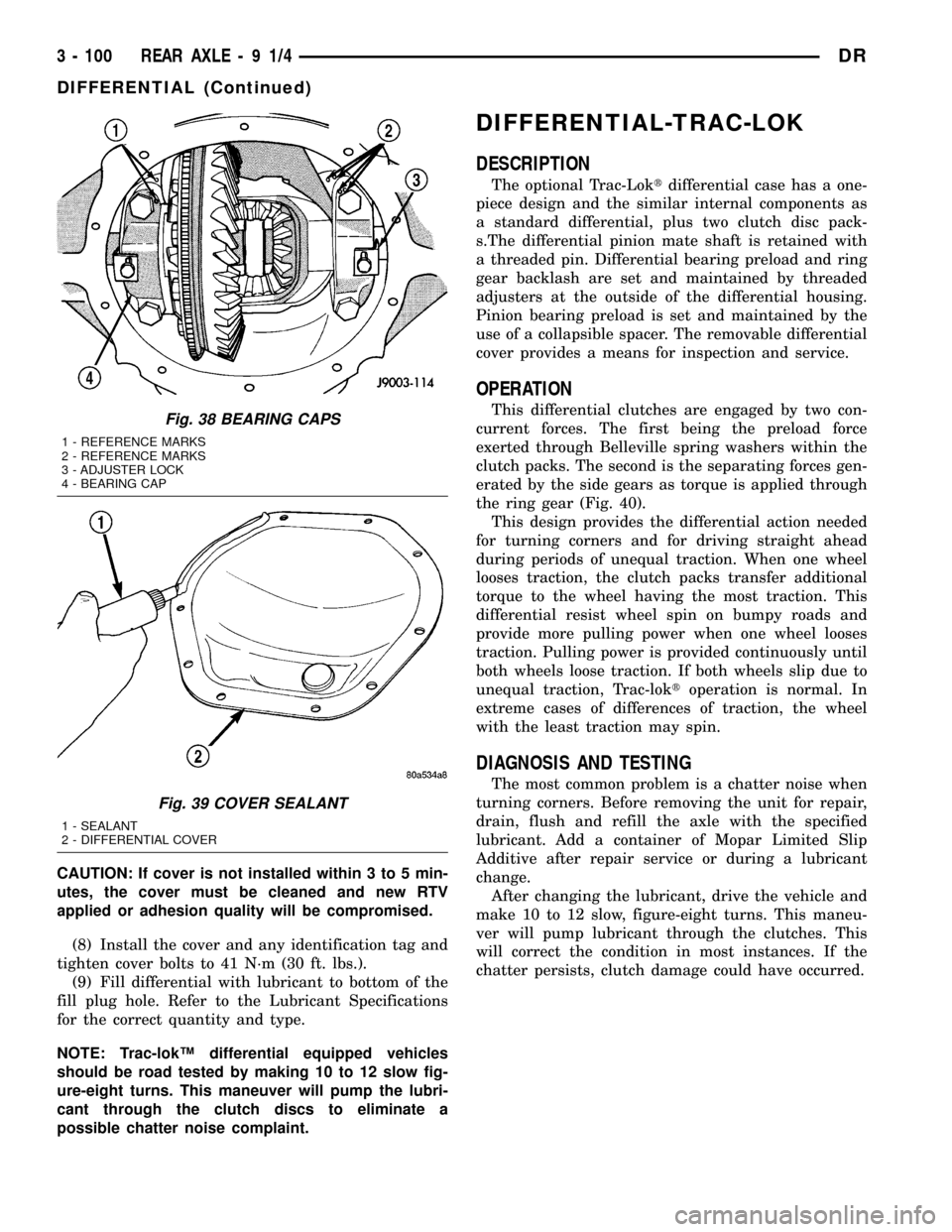

(6) Mark differential housing and bearing caps for

installation reference (Fig. 30).

(7) Remove bearing threaded adjuster lock from

each bearing cap.

(8) Loosen differential bearing cap bolts.

Fig. 29 COVER SEALANT

1 - SEALANT

2 - DIFFERENTIAL COVER

Fig. 30 REFERENCE MARKS

1 - REFERENCE MARKS

2 - REFERENCE MARK

3 - BEARING CAPS

DRREAR AXLE - 9 1/4 3 - 97

PINION SEAL (Continued)

Page 181 of 2627

CAUTION: If cover is not installed within 3 to 5 min-

utes, the cover must be cleaned and new RTV

applied or adhesion quality will be compromised.

(8) Install the cover and any identification tag and

tighten cover bolts to 41 N´m (30 ft. lbs.).

(9) Fill differential with lubricant to bottom of the

fill plug hole. Refer to the Lubricant Specifications

for the correct quantity and type.

NOTE: Trac-lokŸ differential equipped vehicles

should be road tested by making 10 to 12 slow fig-

ure-eight turns. This maneuver will pump the lubri-

cant through the clutch discs to eliminate a

possible chatter noise complaint.

DIFFERENTIAL-TRAC-LOK

DESCRIPTION

The optional Trac-Loktdifferential case has a one-

piece design and the similar internal components as

a standard differential, plus two clutch disc pack-

s.The differential pinion mate shaft is retained with

a threaded pin. Differential bearing preload and ring

gear backlash are set and maintained by threaded

adjusters at the outside of the differential housing.

Pinion bearing preload is set and maintained by the

use of a collapsible spacer. The removable differential

cover provides a means for inspection and service.

OPERATION

This differential clutches are engaged by two con-

current forces. The first being the preload force

exerted through Belleville spring washers within the

clutch packs. The second is the separating forces gen-

erated by the side gears as torque is applied through

the ring gear (Fig. 40).

This design provides the differential action needed

for turning corners and for driving straight ahead

during periods of unequal traction. When one wheel

looses traction, the clutch packs transfer additional

torque to the wheel having the most traction. This

differential resist wheel spin on bumpy roads and

provide more pulling power when one wheel looses

traction. Pulling power is provided continuously until

both wheels loose traction. If both wheels slip due to

unequal traction, Trac-loktoperation is normal. In

extreme cases of differences of traction, the wheel

with the least traction may spin.

DIAGNOSIS AND TESTING

The most common problem is a chatter noise when

turning corners. Before removing the unit for repair,

drain, flush and refill the axle with the specified

lubricant. Add a container of Mopar Limited Slip

Additive after repair service or during a lubricant

change.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches. This

will correct the condition in most instances. If the

chatter persists, clutch damage could have occurred.

Fig. 38 BEARING CAPS

1 - REFERENCE MARKS

2 - REFERENCE MARKS

3 - ADJUSTER LOCK

4 - BEARING CAP

Fig. 39 COVER SEALANT

1 - SEALANT

2 - DIFFERENTIAL COVER

3 - 100 REAR AXLE-91/4DR

DIFFERENTIAL (Continued)

Page 208 of 2627

(5) Hold flange with Flange Wrench 8979 (Fig. 26)

and tighten pinion nut until pinion end play is taken

up.

(6) Rotate pinion several times to seat bearings.

(7) Measure pinion rotating torque with an inch

pound torque wrench and compare it to recorded

measurement.

(8) Tighten pinion nut in small increments, until

pinion rotating torque is 0.40-0.57 N´m (3-5 in. lbs.)

greater than recorded measurement.

(9) Rotate pinion several times then verify pinion

rotating torque again.

(10) Install axle shafts.

(11) Install propeller shaft with reference marks

aligned.

(12) Check and fill differential if necessary.

DIFFERENTIAL

REMOVAL

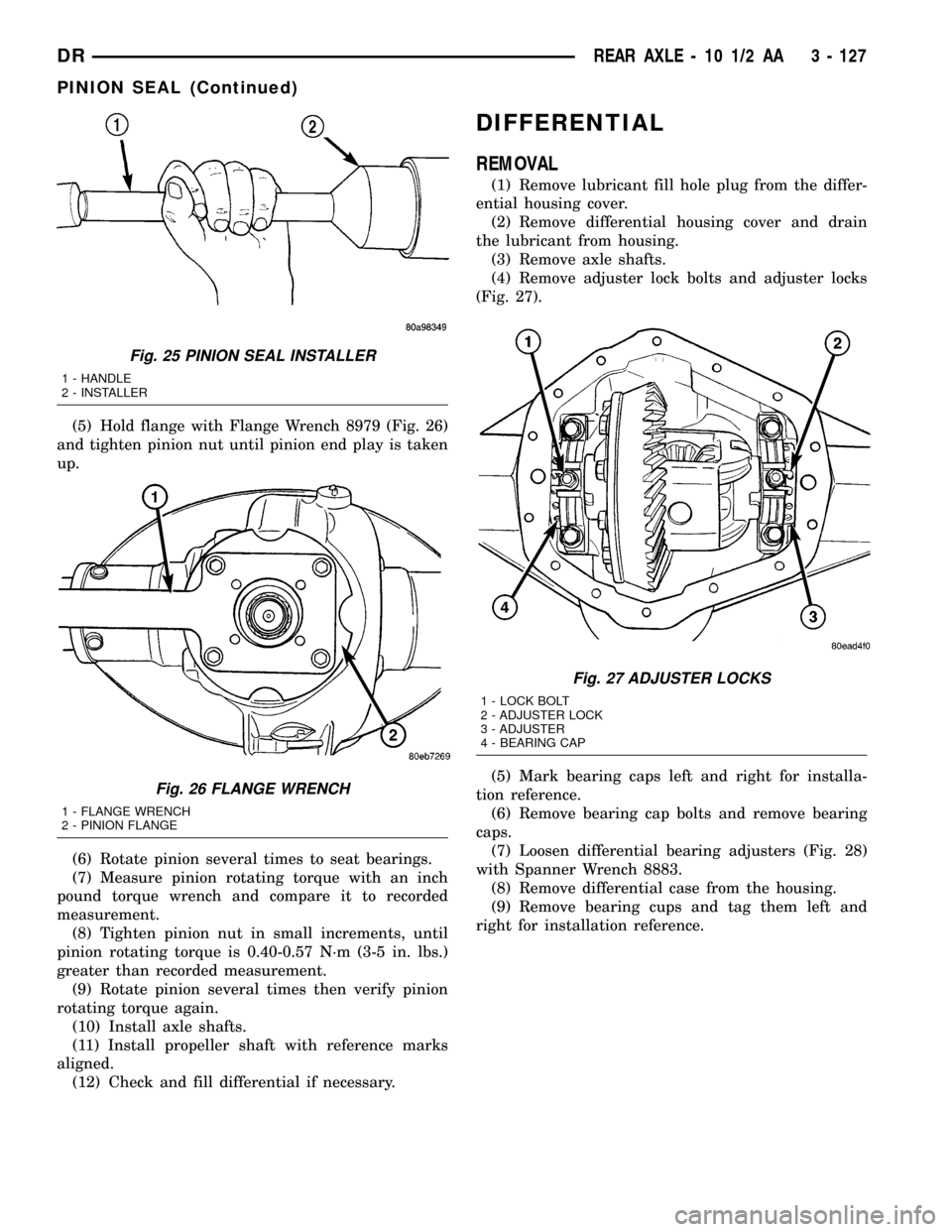

(1) Remove lubricant fill hole plug from the differ-

ential housing cover.

(2) Remove differential housing cover and drain

the lubricant from housing.

(3) Remove axle shafts.

(4) Remove adjuster lock bolts and adjuster locks

(Fig. 27).

(5) Mark bearing caps left and right for installa-

tion reference.

(6) Remove bearing cap bolts and remove bearing

caps.

(7) Loosen differential bearing adjusters (Fig. 28)

with Spanner Wrench 8883.

(8) Remove differential case from the housing.

(9) Remove bearing cups and tag them left and

right for installation reference.

Fig. 25 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

Fig. 26 FLANGE WRENCH

1 - FLANGE WRENCH

2 - PINION FLANGE

Fig. 27 ADJUSTER LOCKS

1 - LOCK BOLT

2 - ADJUSTER LOCK

3 - ADJUSTER

4 - BEARING CAP

DRREAR AXLE - 10 1/2 AA 3 - 127

PINION SEAL (Continued)

Page 236 of 2627

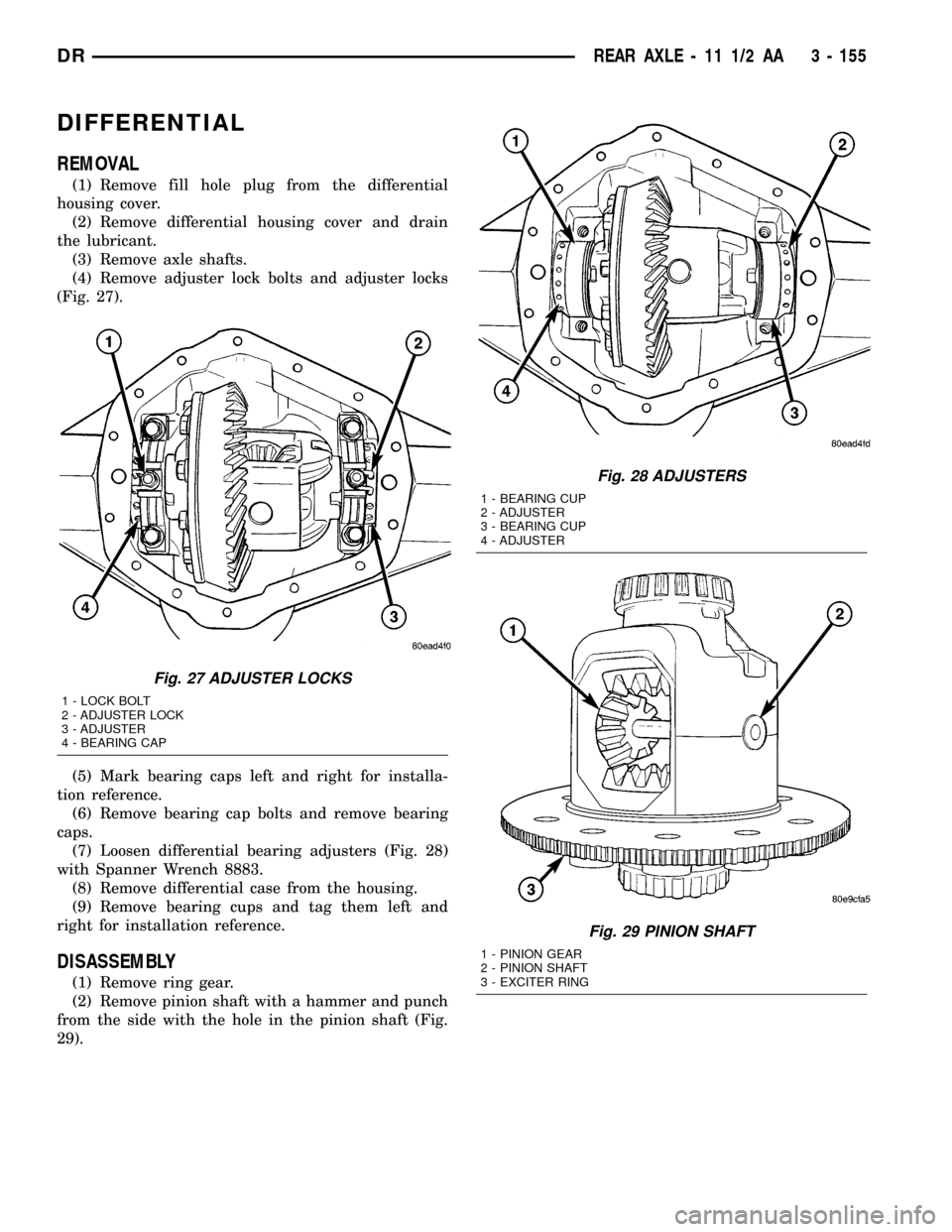

DIFFERENTIAL

REMOVAL

(1) Remove fill hole plug from the differential

housing cover.

(2) Remove differential housing cover and drain

the lubricant.

(3) Remove axle shafts.

(4) Remove adjuster lock bolts and adjuster locks

(Fig. 27).

(5) Mark bearing caps left and right for installa-

tion reference.

(6) Remove bearing cap bolts and remove bearing

caps.

(7) Loosen differential bearing adjusters (Fig. 28)

with Spanner Wrench 8883.

(8) Remove differential case from the housing.

(9) Remove bearing cups and tag them left and

right for installation reference.

DISASSEMBLY

(1) Remove ring gear.

(2) Remove pinion shaft with a hammer and punch

from the side with the hole in the pinion shaft (Fig.

29).

Fig. 27 ADJUSTER LOCKS

1 - LOCK BOLT

2 - ADJUSTER LOCK

3 - ADJUSTER

4 - BEARING CAP

Fig. 28 ADJUSTERS

1 - BEARING CUP

2 - ADJUSTER

3 - BEARING CUP

4 - ADJUSTER

Fig. 29 PINION SHAFT

1 - PINION GEAR

2 - PINION SHAFT

3 - EXCITER RING

DRREAR AXLE - 11 1/2 AA 3 - 155

Page 266 of 2627

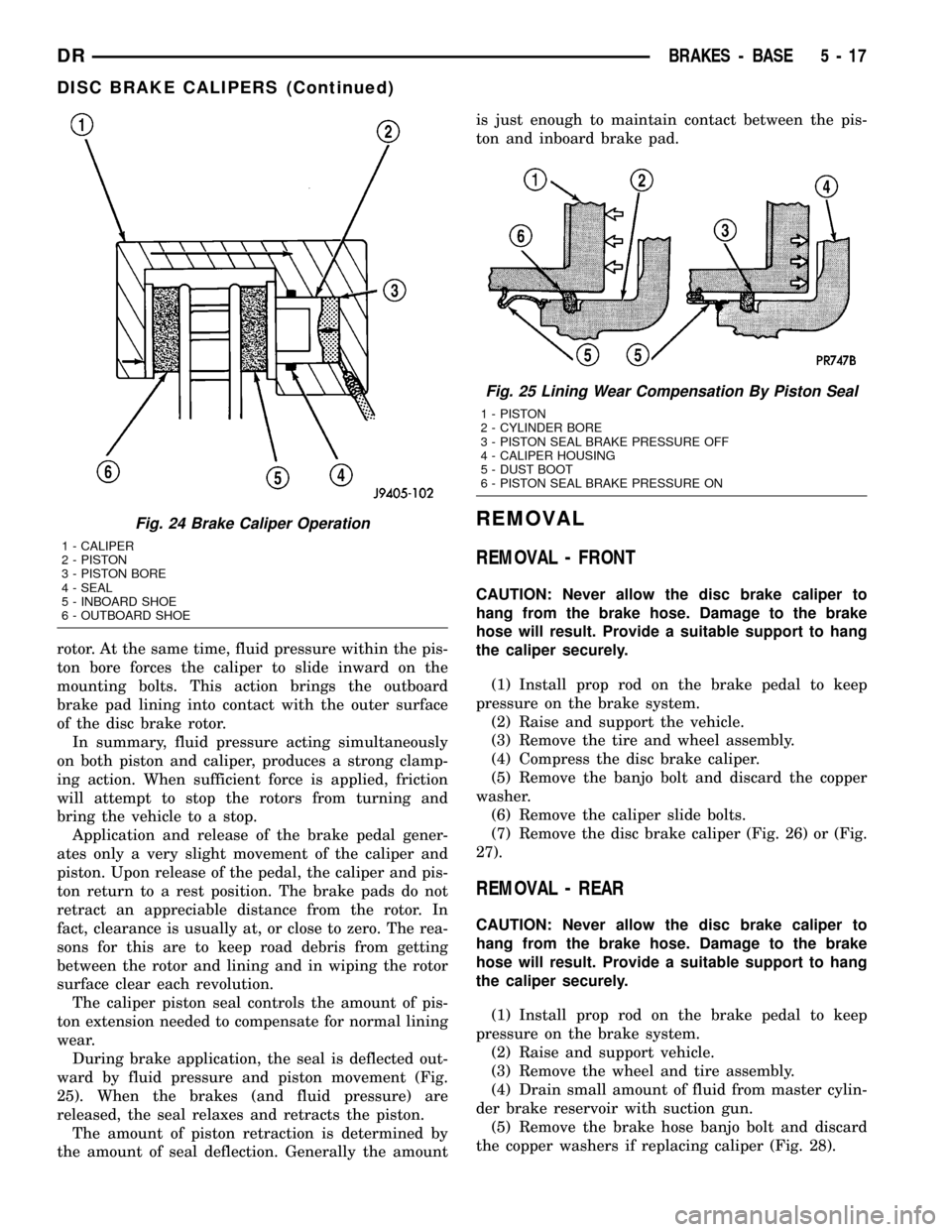

rotor. At the same time, fluid pressure within the pis-

ton bore forces the caliper to slide inward on the

mounting bolts. This action brings the outboard

brake pad lining into contact with the outer surface

of the disc brake rotor.

In summary, fluid pressure acting simultaneously

on both piston and caliper, produces a strong clamp-

ing action. When sufficient force is applied, friction

will attempt to stop the rotors from turning and

bring the vehicle to a stop.

Application and release of the brake pedal gener-

ates only a very slight movement of the caliper and

piston. Upon release of the pedal, the caliper and pis-

ton return to a rest position. The brake pads do not

retract an appreciable distance from the rotor. In

fact, clearance is usually at, or close to zero. The rea-

sons for this are to keep road debris from getting

between the rotor and lining and in wiping the rotor

surface clear each revolution.

The caliper piston seal controls the amount of pis-

ton extension needed to compensate for normal lining

wear.

During brake application, the seal is deflected out-

ward by fluid pressure and piston movement (Fig.

25). When the brakes (and fluid pressure) are

released, the seal relaxes and retracts the piston.

The amount of piston retraction is determined by

the amount of seal deflection. Generally the amountis just enough to maintain contact between the pis-

ton and inboard brake pad.

REMOVAL

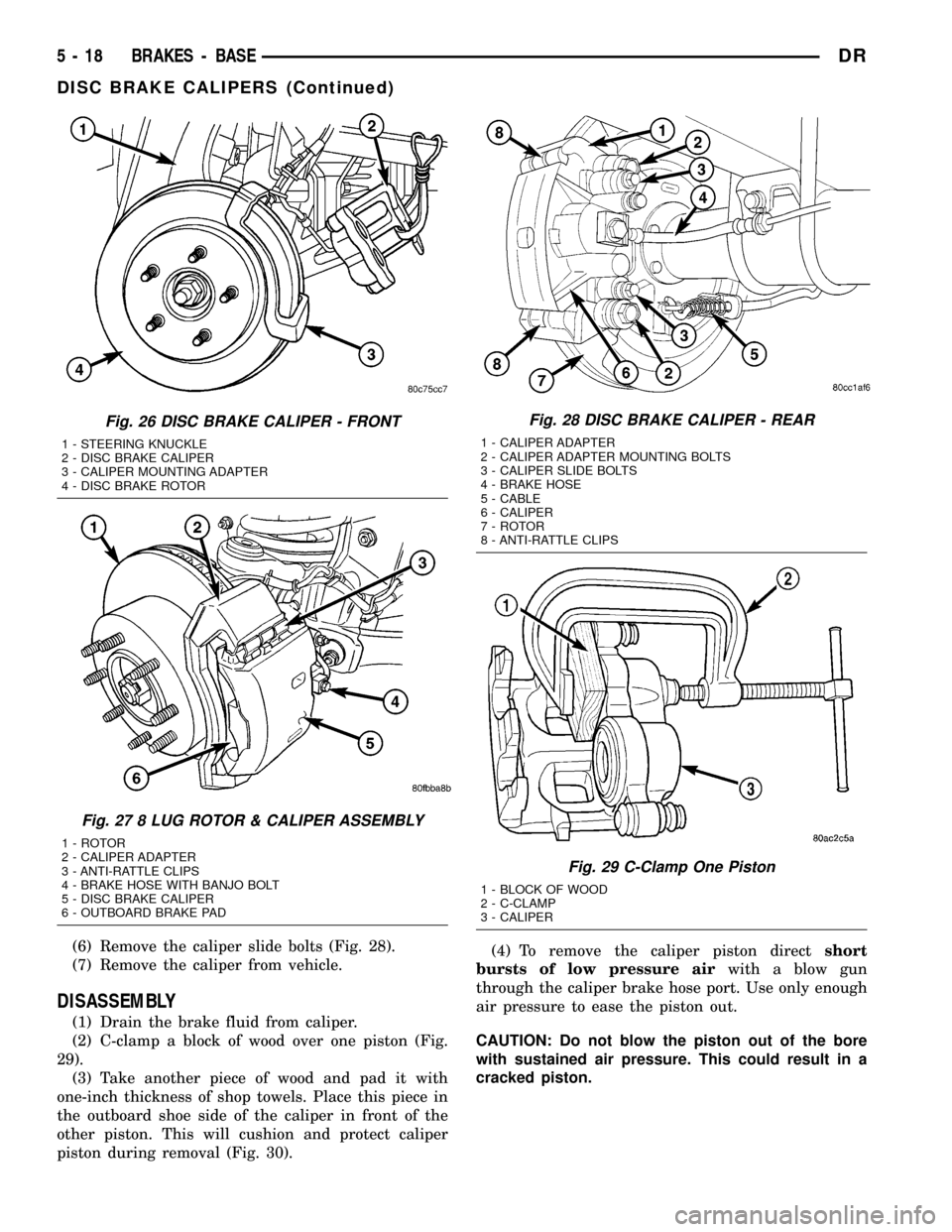

REMOVAL - FRONT

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose will result. Provide a suitable support to hang

the caliper securely.

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support the vehicle.

(3) Remove the tire and wheel assembly.

(4) Compress the disc brake caliper.

(5) Remove the banjo bolt and discard the copper

washer.

(6) Remove the caliper slide bolts.

(7) Remove the disc brake caliper (Fig. 26) or (Fig.

27).

REMOVAL - REAR

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose will result. Provide a suitable support to hang

the caliper securely.

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support vehicle.

(3) Remove the wheel and tire assembly.

(4) Drain small amount of fluid from master cylin-

der brake reservoir with suction gun.

(5) Remove the brake hose banjo bolt and discard

the copper washers if replacing caliper (Fig. 28).

Fig. 24 Brake Caliper Operation

1 - CALIPER

2 - PISTON

3 - PISTON BORE

4 - SEAL

5 - INBOARD SHOE

6 - OUTBOARD SHOE

Fig. 25 Lining Wear Compensation By Piston Seal

1 - PISTON

2 - CYLINDER BORE

3 - PISTON SEAL BRAKE PRESSURE OFF

4 - CALIPER HOUSING

5 - DUST BOOT

6 - PISTON SEAL BRAKE PRESSURE ON

DRBRAKES - BASE 5 - 17

DISC BRAKE CALIPERS (Continued)

Page 267 of 2627

(6) Remove the caliper slide bolts (Fig. 28).

(7) Remove the caliper from vehicle.

DISASSEMBLY

(1) Drain the brake fluid from caliper.

(2) C-clamp a block of wood over one piston (Fig.

29).

(3) Take another piece of wood and pad it with

one-inch thickness of shop towels. Place this piece in

the outboard shoe side of the caliper in front of the

other piston. This will cushion and protect caliper

piston during removal (Fig. 30).(4) To remove the caliper piston directshort

bursts of low pressure airwith a blow gun

through the caliper brake hose port. Use only enough

air pressure to ease the piston out.

CAUTION: Do not blow the piston out of the bore

with sustained air pressure. This could result in a

cracked piston.

Fig. 26 DISC BRAKE CALIPER - FRONT

1 - STEERING KNUCKLE

2 - DISC BRAKE CALIPER

3 - CALIPER MOUNTING ADAPTER

4 - DISC BRAKE ROTOR

Fig. 27 8 LUG ROTOR & CALIPER ASSEMBLY

1 - ROTOR

2 - CALIPER ADAPTER

3 - ANTI-RATTLE CLIPS

4 - BRAKE HOSE WITH BANJO BOLT

5 - DISC BRAKE CALIPER

6 - OUTBOARD BRAKE PAD

Fig. 28 DISC BRAKE CALIPER - REAR

1 - CALIPER ADAPTER

2 - CALIPER ADAPTER MOUNTING BOLTS

3 - CALIPER SLIDE BOLTS

4 - BRAKE HOSE

5 - CABLE

6 - CALIPER

7 - ROTOR

8 - ANTI-RATTLE CLIPS

Fig. 29 C-Clamp One Piston

1 - BLOCK OF WOOD

2 - C-CLAMP

3 - CALIPER

5 - 18 BRAKES - BASEDR

DISC BRAKE CALIPERS (Continued)

Page 270 of 2627

INSTALLATION

INSTALLATION - FRONT

NOTE: Install a new copper washers on the banjo

bolt when installing

(1) Install the disc brake caliper (Fig. 26) or (Fig.

27).

CAUTION: Verify brake hose is not twisted or

kinked before tightening fitting bolt.

(2) Install the banjo bolt with new copper washers

to the caliper. Tighten to 27 N´m (20 ft. lbs.)

(3) Install the caliper slide pin bolts. tighten to 32

N´m (24 ft. lbs.)

(4) Remove the prop rod.

(5) Bleed the base brake system, (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL - STAN-

DARD PROCEDURE).

(6) Install the tire and wheel assembly, (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(7) Lower the vehicle.

INSTALLATION - REAR

(1) Install caliper to the caliper adapter.

(2) Coat the caliper mounting slide pin bolts with

silicone grease. Then install and tighten the bolts to

15 N´m (11 ft. lbs.).

(3) Install the brake hose banjo bolt if removed.

(4) Install the brake hose to the caliper withnew

seal washersand tighten fitting bolt to 27 N´m (245

in. lbs.).CAUTION: Verify brake hose is not twisted or

kinked before tightening fitting bolt.

(5) Remove the prop rod from the vehicle.

(6) Bleed the base brake system,(Refer to 5 -

BRAKES - STANDARD PROCEDURE) OR (Refer to

5 - BRAKES - STANDARD PROCEDURE).

(7) Install the wheel and tire assemblies (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(8) Remove the supports and lower the vehicle.

(9) Verify a firm pedal before moving the vehicle.

DISC BRAKE CALIPER

ADAPTER

REMOVAL

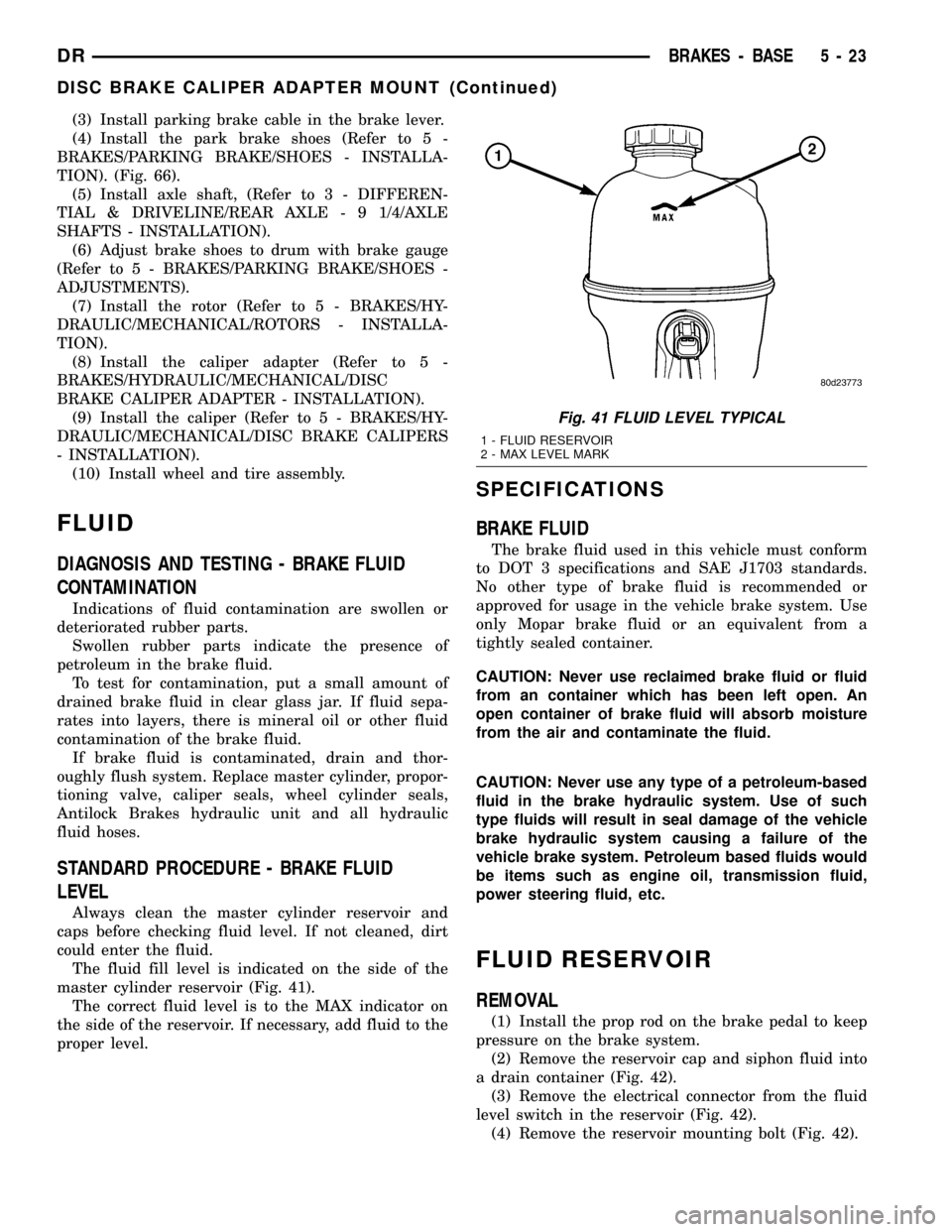

REMOVAL - FRONT

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Remove the disc brake caliper (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPERS - REMOVAL).

(4) Remove the bolts securing the caliper adapter

to the steering knuckle (Fig. 38)

(5) Remove the caliper adapter.

REMOVAL - REAR

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Drain a small amount of fluid from master cyl-

inder brake reservoir with acleansuction gun.

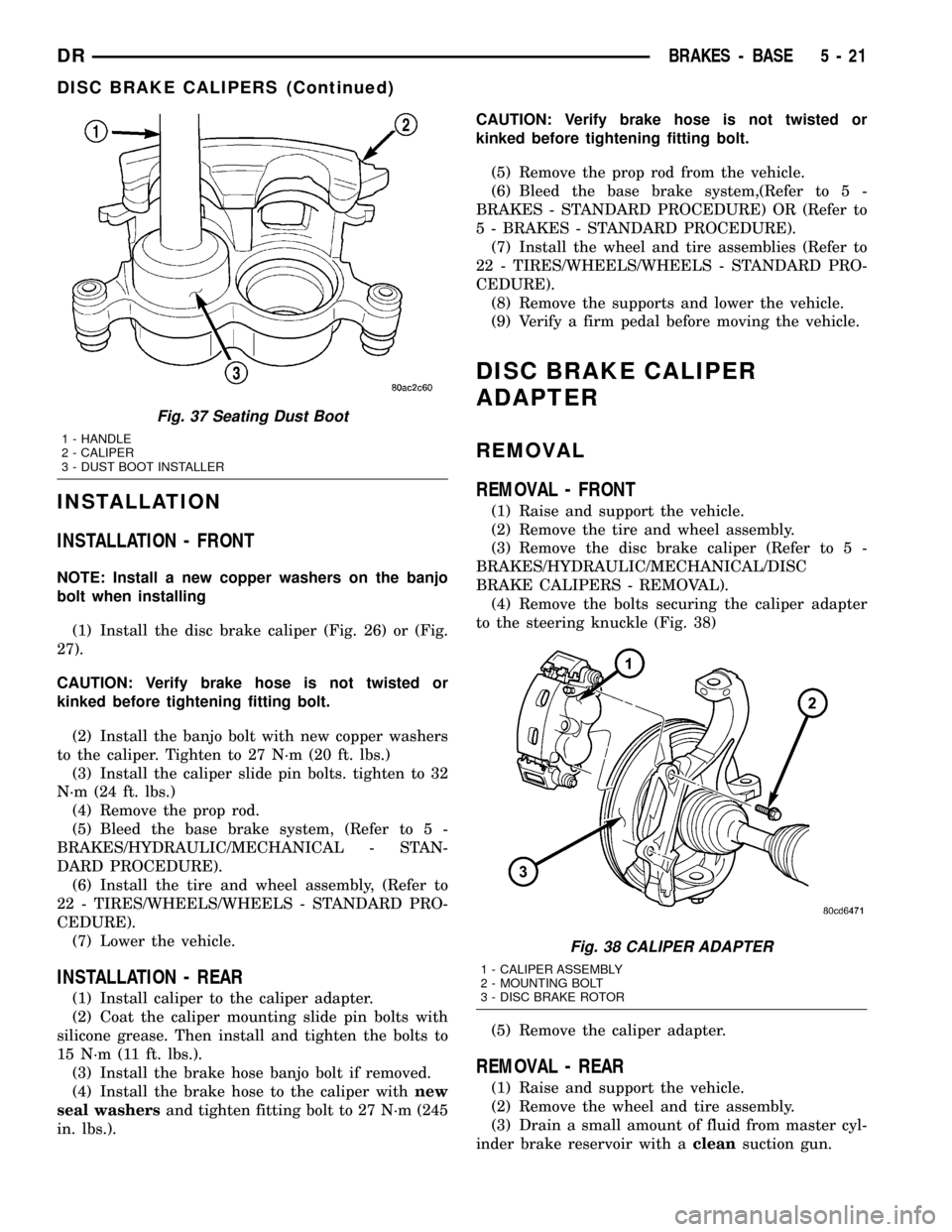

Fig. 37 Seating Dust Boot

1 - HANDLE

2 - CALIPER

3 - DUST BOOT INSTALLER

Fig. 38 CALIPER ADAPTER

1 - CALIPER ASSEMBLY

2 - MOUNTING BOLT

3 - DISC BRAKE ROTOR

DRBRAKES - BASE 5 - 21

DISC BRAKE CALIPERS (Continued)

Page 272 of 2627

(3) Install parking brake cable in the brake lever.

(4) Install the park brake shoes (Refer to 5 -

BRAKES/PARKING BRAKE/SHOES - INSTALLA-

TION). (Fig. 66).

(5) Install axle shaft, (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/REAR AXLE - 9 1/4/AXLE

SHAFTS - INSTALLATION).

(6) Adjust brake shoes to drum with brake gauge

(Refer to 5 - BRAKES/PARKING BRAKE/SHOES -

ADJUSTMENTS).

(7) Install the rotor (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - INSTALLA-

TION).

(8) Install the caliper adapter (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION).

(9) Install the caliper (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- INSTALLATION).

(10) Install wheel and tire assembly.

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts.

Swollen rubber parts indicate the presence of

petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If brake fluid is contaminated, drain and thor-

oughly flush system. Replace master cylinder, propor-

tioning valve, caliper seals, wheel cylinder seals,

Antilock Brakes hydraulic unit and all hydraulic

fluid hoses.

STANDARD PROCEDURE - BRAKE FLUID

LEVEL

Always clean the master cylinder reservoir and

caps before checking fluid level. If not cleaned, dirt

could enter the fluid.

The fluid fill level is indicated on the side of the

master cylinder reservoir (Fig. 41).

The correct fluid level is to the MAX indicator on

the side of the reservoir. If necessary, add fluid to the

proper level.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications and SAE J1703 standards.

No other type of brake fluid is recommended or

approved for usage in the vehicle brake system. Use

only Mopar brake fluid or an equivalent from a

tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

FLUID RESERVOIR

REMOVAL

(1) Install the prop rod on the brake pedal to keep

pressure on the brake system.

(2) Remove the reservoir cap and siphon fluid into

a drain container (Fig. 42).

(3) Remove the electrical connector from the fluid

level switch in the reservoir (Fig. 42).

(4) Remove the reservoir mounting bolt (Fig. 42).

Fig. 41 FLUID LEVEL TYPICAL

1 - FLUID RESERVOIR

2 - MAX LEVEL MARK

DRBRAKES - BASE 5 - 23

DISC BRAKE CALIPER ADAPTER MOUNT (Continued)