run flat DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 84 of 2627

(10) Start engine and check vibration. If there is

little or no change move the clamp to the next posi-

tions. Repeat the vibration test.

NOTE: If there is no difference in vibration at this

positions, the vibration may not be the propeller

shaft.

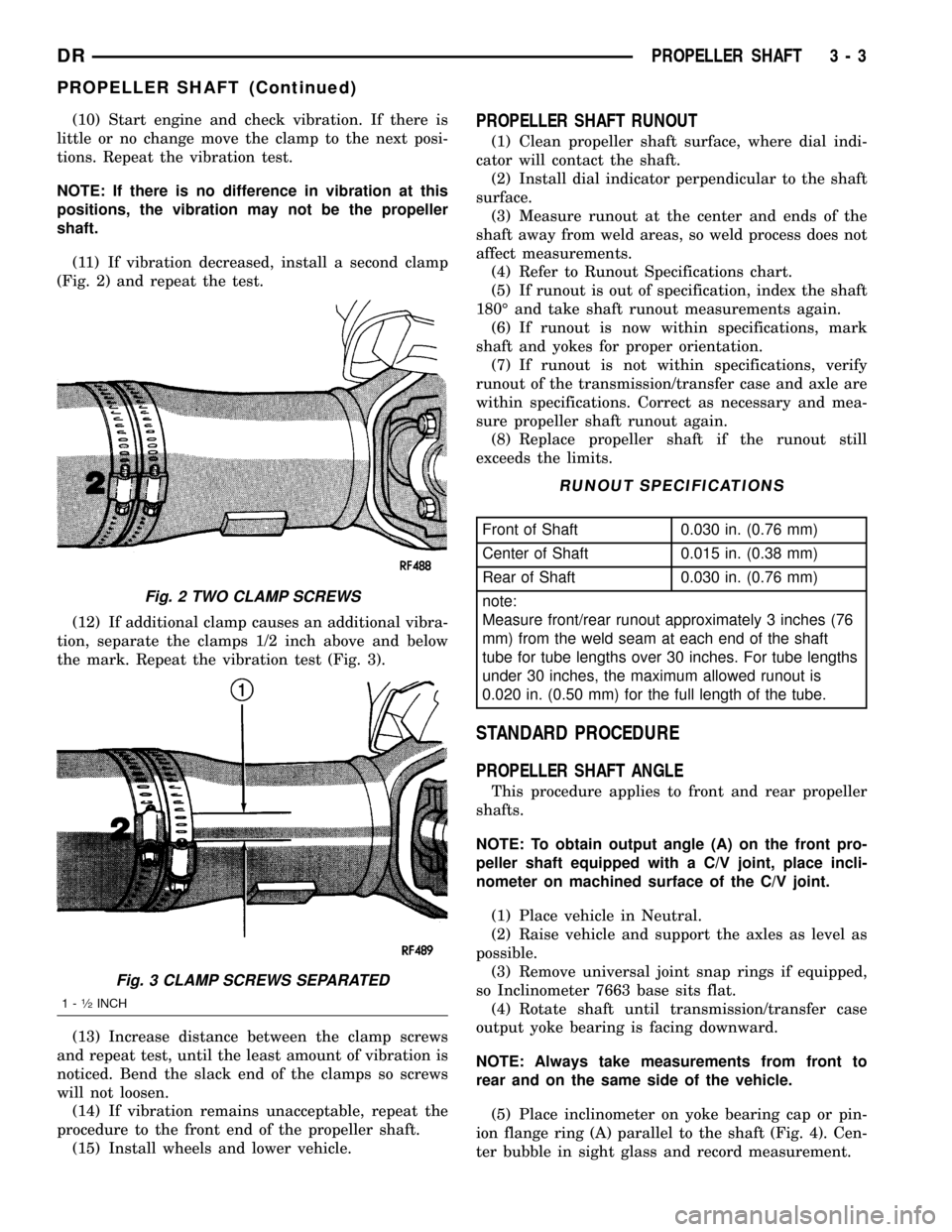

(11) If vibration decreased, install a second clamp

(Fig. 2) and repeat the test.

(12) If additional clamp causes an additional vibra-

tion, separate the clamps 1/2 inch above and below

the mark. Repeat the vibration test (Fig. 3).

(13) Increase distance between the clamp screws

and repeat test, until the least amount of vibration is

noticed. Bend the slack end of the clamps so screws

will not loosen.

(14) If vibration remains unacceptable, repeat the

procedure to the front end of the propeller shaft.

(15) Install wheels and lower vehicle.PROPELLER SHAFT RUNOUT

(1) Clean propeller shaft surface, where dial indi-

cator will contact the shaft.

(2) Install dial indicator perpendicular to the shaft

surface.

(3) Measure runout at the center and ends of the

shaft away from weld areas, so weld process does not

affect measurements.

(4) Refer to Runout Specifications chart.

(5) If runout is out of specification, index the shaft

180É and take shaft runout measurements again.

(6) If runout is now within specifications, mark

shaft and yokes for proper orientation.

(7) If runout is not within specifications, verify

runout of the transmission/transfer case and axle are

within specifications. Correct as necessary and mea-

sure propeller shaft runout again.

(8) Replace propeller shaft if the runout still

exceeds the limits.

RUNOUT SPECIFICATIONS

Front of Shaft 0.030 in. (0.76 mm)

Center of Shaft 0.015 in. (0.38 mm)

Rear of Shaft 0.030 in. (0.76 mm)

note:

Measure front/rear runout approximately 3 inches (76

mm) from the weld seam at each end of the shaft

tube for tube lengths over 30 inches. For tube lengths

under 30 inches, the maximum allowed runout is

0.020 in. (0.50 mm) for the full length of the tube.

STANDARD PROCEDURE

PROPELLER SHAFT ANGLE

This procedure applies to front and rear propeller

shafts.

NOTE: To obtain output angle (A) on the front pro-

peller shaft equipped with a C/V joint, place incli-

nometer on machined surface of the C/V joint.

(1) Place vehicle in Neutral.

(2) Raise vehicle and support the axles as level as

possible.

(3) Remove universal joint snap rings if equipped,

so Inclinometer 7663 base sits flat.

(4) Rotate shaft until transmission/transfer case

output yoke bearing is facing downward.

NOTE: Always take measurements from front to

rear and on the same side of the vehicle.

(5) Place inclinometer on yoke bearing cap or pin-

ion flange ring (A) parallel to the shaft (Fig. 4). Cen-

ter bubble in sight glass and record measurement.

Fig. 2 TWO CLAMP SCREWS

Fig. 3 CLAMP SCREWS SEPARATED

1-1¤2INCH

DRPROPELLER SHAFT 3 - 3

PROPELLER SHAFT (Continued)

Page 612 of 2627

DRIVER POWER SEAT SWITCH TEST TABLE

DRIVER SWITCH

POSITIONCONTINUITY BETWEEN

HORIZONTAL

FORWARDA-L, B-K

HORIZONTAL

REARWARDA-K, B-L

FRONT TILT UP A-M, B-N

FRONT TILT DOWN A-N, B-M

REAR TILT UP A-E, B-J

REAR TILT DOWN A-J, B-E

LUMBAR OFF O-P, O-R, P-R

LUMPAR UP (INFLATE) O-P, Q-R

LUMBAR DOWN

(DEFLATE)O-R, P-Q

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the seat cushion side shield from the

seat. Refer to the Body section of the service manual

for the procedure.

(3) Pull the switch bezel or side shield unit out

from the seat far enough to access the switch wire

harness connector. Gently pry the locking tabs of the

switch away from the wire harness connector and

carefully unplug the connector from the power seat

switch module.

(4) Remove the screws that secure the power seat

switch.

INSTALLATION

(1) Position the power seat switch on the seat

cushion side shield and install the screws that secure

the power seat switch to seat cushion side shield.

(2) Connect the electrical connector.

(3) Install the seat cushion side shield on the seat.

Refer to the Body section of the service manual for

the procedure.

(4) If equipped, install the screw that secures the

recliner lever to the recliner mechanism release shaft

on the outboard side of the front seat.

(5) Connect the battery negative cable.

PASSENGER SEAT SWITCH

DESCRIPTION

The power seat on this model can be adjusted in

eight different directions, up, down, front up, front

down, rear up, rear down, rearward and forward.

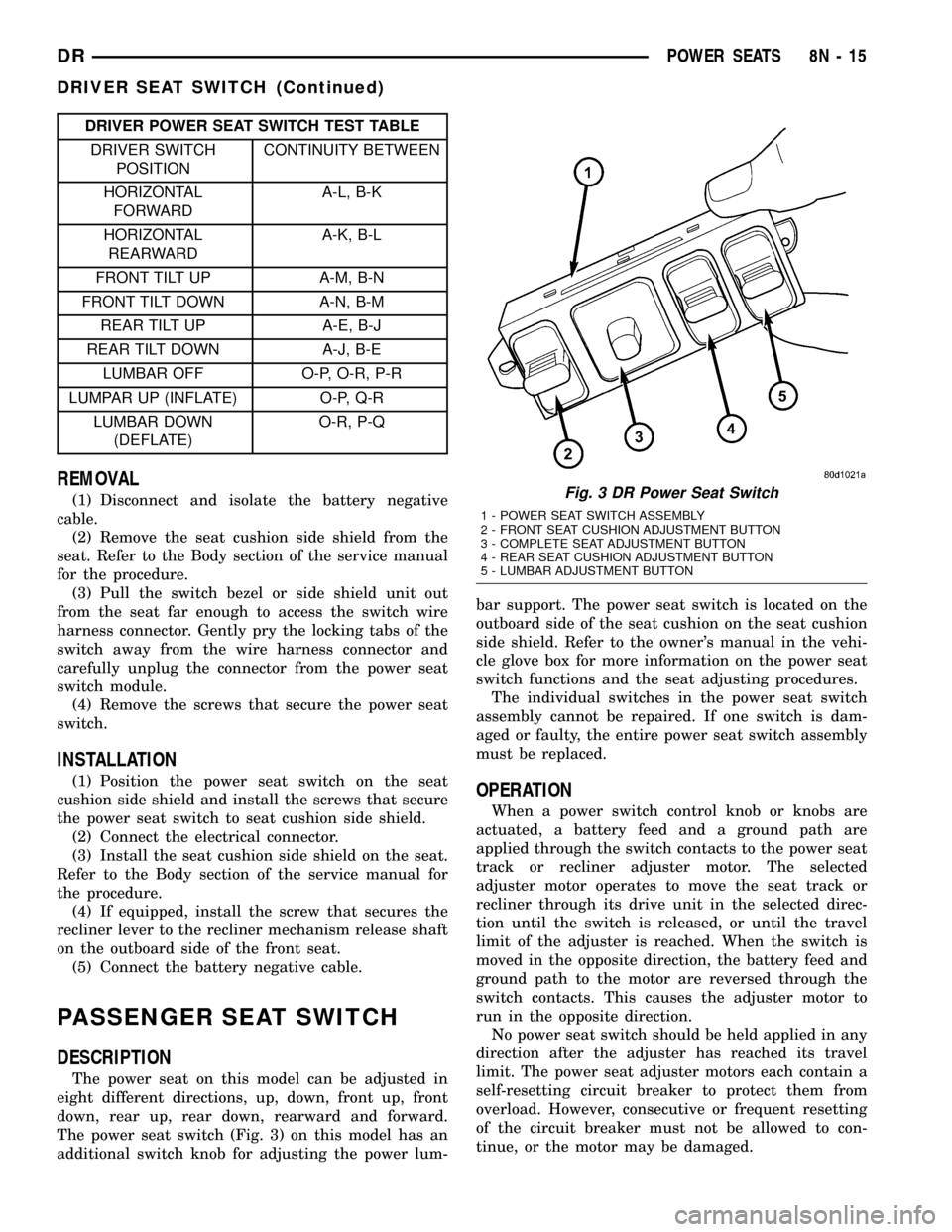

The power seat switch (Fig. 3) on this model has an

additional switch knob for adjusting the power lum-bar support. The power seat switch is located on the

outboard side of the seat cushion on the seat cushion

side shield. Refer to the owner's manual in the vehi-

cle glove box for more information on the power seat

switch functions and the seat adjusting procedures.

The individual switches in the power seat switch

assembly cannot be repaired. If one switch is dam-

aged or faulty, the entire power seat switch assembly

must be replaced.

OPERATION

When a power switch control knob or knobs are

actuated, a battery feed and a ground path are

applied through the switch contacts to the power seat

track or recliner adjuster motor. The selected

adjuster motor operates to move the seat track or

recliner through its drive unit in the selected direc-

tion until the switch is released, or until the travel

limit of the adjuster is reached. When the switch is

moved in the opposite direction, the battery feed and

ground path to the motor are reversed through the

switch contacts. This causes the adjuster motor to

run in the opposite direction.

No power seat switch should be held applied in any

direction after the adjuster has reached its travel

limit. The power seat adjuster motors each contain a

self-resetting circuit breaker to protect them from

overload. However, consecutive or frequent resetting

of the circuit breaker must not be allowed to con-

tinue, or the motor may be damaged.

Fig. 3 DR Power Seat Switch

1 - POWER SEAT SWITCH ASSEMBLY

2 - FRONT SEAT CUSHION ADJUSTMENT BUTTON

3 - COMPLETE SEAT ADJUSTMENT BUTTON

4 - REAR SEAT CUSHION ADJUSTMENT BUTTON

5 - LUMBAR ADJUSTMENT BUTTON

DRPOWER SEATS 8N - 15

DRIVER SEAT SWITCH (Continued)

Page 627 of 2627

AIRBAG SQUIB STATUS

IF the Active DTC is: Conditions Squib Status

Driver or Passenger Squib 1

openANDthe stored DTC minutes for both Driver or

Passenger squibs are within 15 minutes of each

otherBoth Squib 1 and 2 were

used.

Driver or Passenger Squib 2

open

Driver or Passenger Squib 1

openANDthe stored DTC minutes for Driver or

Passenger Squib 2 open is GREATER than the

stored DTC minutes for Driver or Passenger

Squib 1 by 15 minutes or moreSquib 1 was used; Squib 2 is

live.

Driver or Passenger Squib 2

open

Driver or Passenger Squib 1

openANDthe stored DTC minutes for Driver or

Passenger Squib 1 open is GREATER than the

stored DTC minutes for Driver or Passenger

Squib 2 by 15 minutes or moreSquib 1 is live; Squib 2 was

used.

Driver or Passenger Squib 2

open

Driver or Passenger Squib 1

openANDDriver or Passenger Squib 2 open is NOT

an active codeSquib 1 was used; Squib 2 is

live.

Driver or Passenger Squib 2

openANDDriver or Passenger Squib 1 open is NOT

an active codeSquib 1 is live; Squib 2 was

used.

Ifnone of the Driver or Passenger Squib 1 or 2

open are active codes, the status of the airbag squibs

is unknown. In this case the airbag should be han-

dled and disposed of as if the squibs were both live.

CLEANUP PROCEDURE

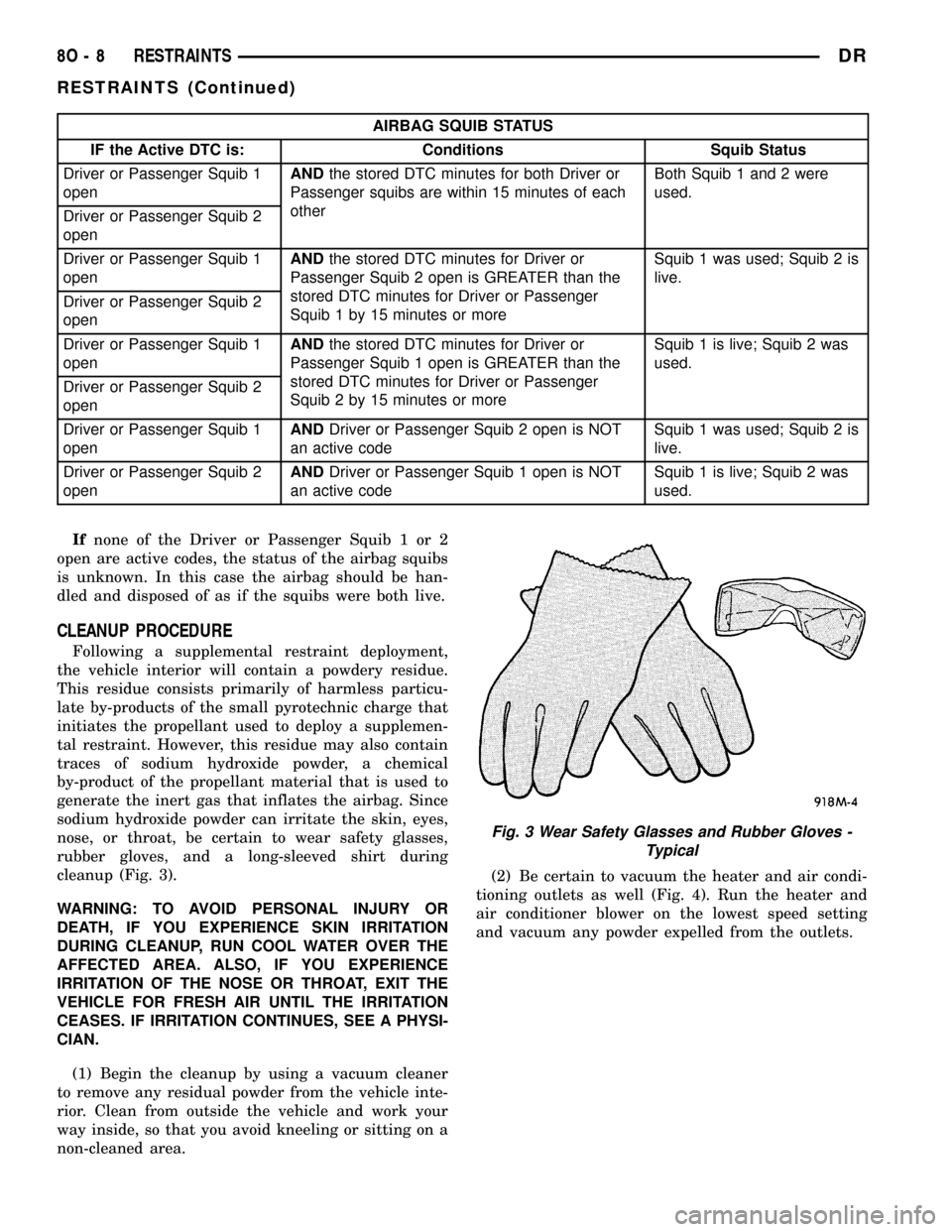

Following a supplemental restraint deployment,

the vehicle interior will contain a powdery residue.

This residue consists primarily of harmless particu-

late by-products of the small pyrotechnic charge that

initiates the propellant used to deploy a supplemen-

tal restraint. However, this residue may also contain

traces of sodium hydroxide powder, a chemical

by-product of the propellant material that is used to

generate the inert gas that inflates the airbag. Since

sodium hydroxide powder can irritate the skin, eyes,

nose, or throat, be certain to wear safety glasses,

rubber gloves, and a long-sleeved shirt during

cleanup (Fig. 3).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, IF YOU EXPERIENCE SKIN IRRITATION

DURING CLEANUP, RUN COOL WATER OVER THE

AFFECTED AREA. ALSO, IF YOU EXPERIENCE

IRRITATION OF THE NOSE OR THROAT, EXIT THE

VEHICLE FOR FRESH AIR UNTIL THE IRRITATION

CEASES. IF IRRITATION CONTINUES, SEE A PHYSI-

CIAN.

(1) Begin the cleanup by using a vacuum cleaner

to remove any residual powder from the vehicle inte-

rior. Clean from outside the vehicle and work your

way inside, so that you avoid kneeling or sitting on a

non-cleaned area.(2) Be certain to vacuum the heater and air condi-

tioning outlets as well (Fig. 4). Run the heater and

air conditioner blower on the lowest speed setting

and vacuum any powder expelled from the outlets.

Fig. 3 Wear Safety Glasses and Rubber Gloves -

Typical

8O - 8 RESTRAINTSDR

RESTRAINTS (Continued)

Page 1238 of 2627

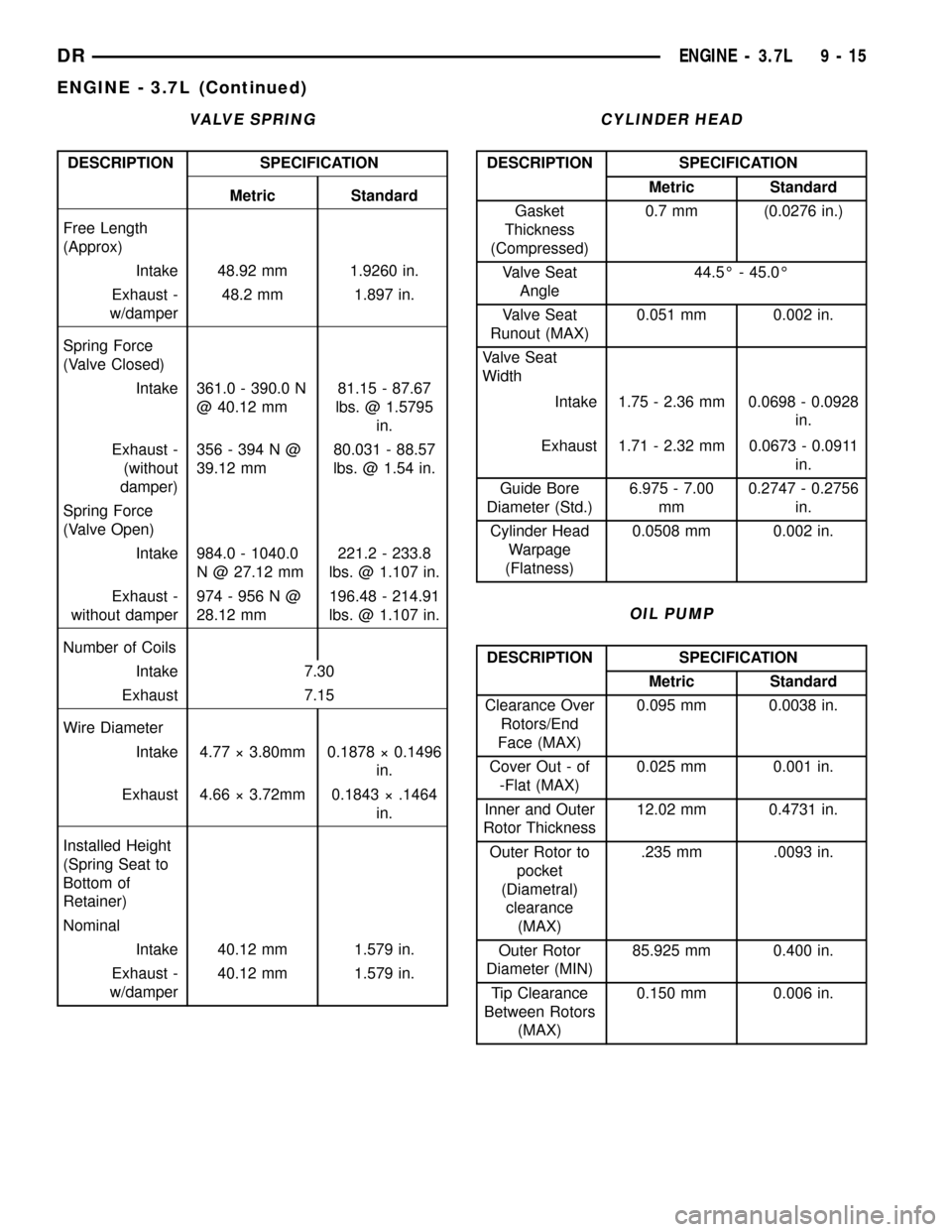

VALVE SPRING

DESCRIPTION SPECIFICATION

Metric Standard

Free Length

(Approx)

Intake 48.92 mm 1.9260 in.

Exhaust -

w/damper48.2 mm 1.897 in.

Spring Force

(Valve Closed)

Intake 361.0 - 390.0 N

@ 40.12 mm81.15 - 87.67

lbs. @ 1.5795

in.

Exhaust -

(without

damper)356-394N@

39.12 mm80.031 - 88.57

lbs. @ 1.54 in.

Spring Force

(Valve Open)

Intake 984.0 - 1040.0

N @ 27.12 mm221.2 - 233.8

lbs. @ 1.107 in.

Exhaust -

without damper974-956N@

28.12 mm196.48 - 214.91

lbs. @ 1.107 in.

Number of Coils

Intake 7.30

Exhaust 7.15

Wire Diameter

Intake 4.77 ý 3.80mm 0.1878 ý 0.1496

in.

Exhaust 4.66 ý 3.72mm 0.1843 ý .1464

in.

Installed Height

(Spring Seat to

Bottom of

Retainer)

Nominal

Intake 40.12 mm 1.579 in.

Exhaust -

w/damper40.12 mm 1.579 in.

CYLINDER HEAD

DESCRIPTION SPECIFICATION

Metric Standard

Gasket

Thickness

(Compressed)0.7 mm (0.0276 in.)

Valve Seat

Angle44.5É - 45.0É

Valve Seat

Runout (MAX)0.051 mm 0.002 in.

Valve Seat

Width

Intake 1.75 - 2.36 mm 0.0698 - 0.0928

in.

Exhaust 1.71 - 2.32 mm 0.0673 - 0.0911

in.

Guide Bore

Diameter (Std.)6.975 - 7.00

mm0.2747 - 0.2756

in.

Cylinder Head

Warpage

(Flatness)0.0508 mm 0.002 in.

OIL PUMP

DESCRIPTION SPECIFICATION

Metric Standard

Clearance Over

Rotors/End

Face (MAX)0.095 mm 0.0038 in.

Cover Out - of

-Flat (MAX)0.025 mm 0.001 in.

Inner and Outer

Rotor Thickness12.02 mm 0.4731 in.

Outer Rotor to

pocket

(Diametral)

clearance

(MAX).235 mm .0093 in.

Outer Rotor

Diameter (MIN)85.925 mm 0.400 in.

Tip Clearance

Between Rotors

(MAX)0.150 mm 0.006 in.

DRENGINE - 3.7L 9 - 15

ENGINE - 3.7L (Continued)

Page 1325 of 2627

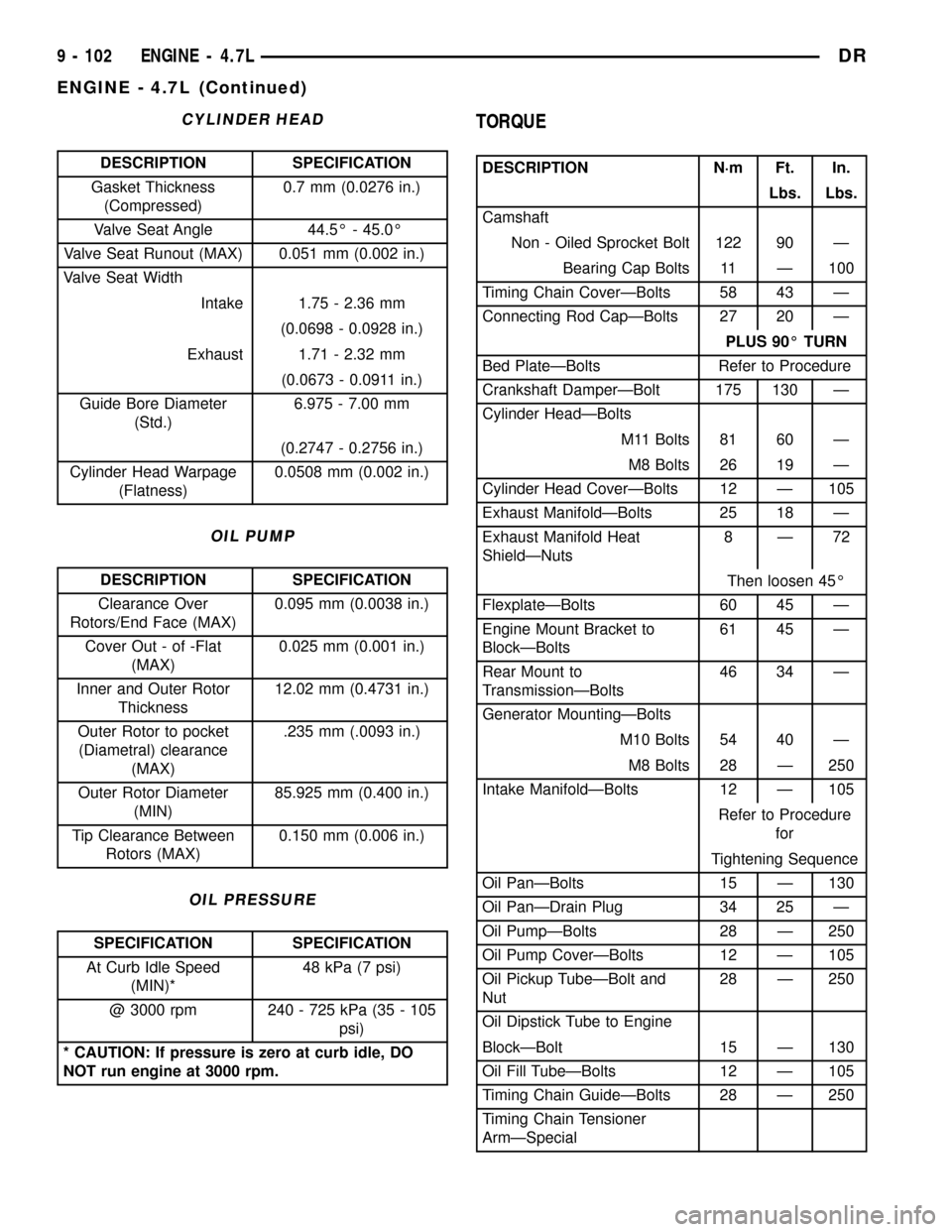

CYLINDER HEAD

DESCRIPTION SPECIFICATION

Gasket Thickness

(Compressed)0.7 mm (0.0276 in.)

Valve Seat Angle 44.5É - 45.0É

Valve Seat Runout (MAX) 0.051 mm (0.002 in.)

Valve Seat Width

Intake 1.75 - 2.36 mm

(0.0698 - 0.0928 in.)

Exhaust 1.71 - 2.32 mm

(0.0673 - 0.0911 in.)

Guide Bore Diameter

(Std.)6.975 - 7.00 mm

(0.2747 - 0.2756 in.)

Cylinder Head Warpage

(Flatness)0.0508 mm (0.002 in.)

OIL PUMP

DESCRIPTION SPECIFICATION

Clearance Over

Rotors/End Face (MAX)0.095 mm (0.0038 in.)

Cover Out - of -Flat

(MAX)0.025 mm (0.001 in.)

Inner and Outer Rotor

Thickness12.02 mm (0.4731 in.)

Outer Rotor to pocket

(Diametral) clearance

(MAX).235 mm (.0093 in.)

Outer Rotor Diameter

(MIN)85.925 mm (0.400 in.)

Tip Clearance Between

Rotors (MAX)0.150 mm (0.006 in.)

OIL PRESSURE

SPECIFICATION SPECIFICATION

At Curb Idle Speed

(MIN)*48 kPa (7 psi)

@ 3000 rpm 240 - 725 kPa (35 - 105

psi)

* CAUTION: If pressure is zero at curb idle, DO

NOT run engine at 3000 rpm.

TORQUE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Camshaft

Non - Oiled Sprocket Bolt 122 90 Ð

Bearing Cap Bolts 11 Ð 100

Timing Chain CoverÐBolts 58 43 Ð

Connecting Rod CapÐBolts 27 20 Ð

PLUS 90É TURN

Bed PlateÐBolts Refer to Procedure

Crankshaft DamperÐBolt 175 130 Ð

Cylinder HeadÐBolts

M11 Bolts 81 60 Ð

M8 Bolts 26 19 Ð

Cylinder Head CoverÐBolts 12 Ð 105

Exhaust ManifoldÐBolts 25 18 Ð

Exhaust Manifold Heat

ShieldÐNuts8Ð72

Then loosen 45É

FlexplateÐBolts 60 45 Ð

Engine Mount Bracket to

BlockÐBolts61 45 Ð

Rear Mount to

TransmissionÐBolts46 34 Ð

Generator MountingÐBolts

M10 Bolts 54 40 Ð

M8 Bolts 28 Ð 250

Intake ManifoldÐBolts 12 Ð 105

Refer to Procedure

for

Tightening Sequence

Oil PanÐBolts 15 Ð 130

Oil PanÐDrain Plug 34 25 Ð

Oil PumpÐBolts 28 Ð 250

Oil Pump CoverÐBolts 12 Ð 105

Oil Pickup TubeÐBolt and

Nut28 Ð 250

Oil Dipstick Tube to Engine

BlockÐBolt 15 Ð 130

Oil Fill TubeÐBolts 12 Ð 105

Timing Chain GuideÐBolts 28 Ð 250

Timing Chain Tensioner

ArmÐSpecial

9 - 102 ENGINE - 4.7LDR

ENGINE - 4.7L (Continued)

Page 2031 of 2627

specification, the reaction plate, all the friction discs,

and steels must be replaced.

(16) Remove the 4C retainer/bulkhead and all of

the 2C clutch components from the transmission

case.

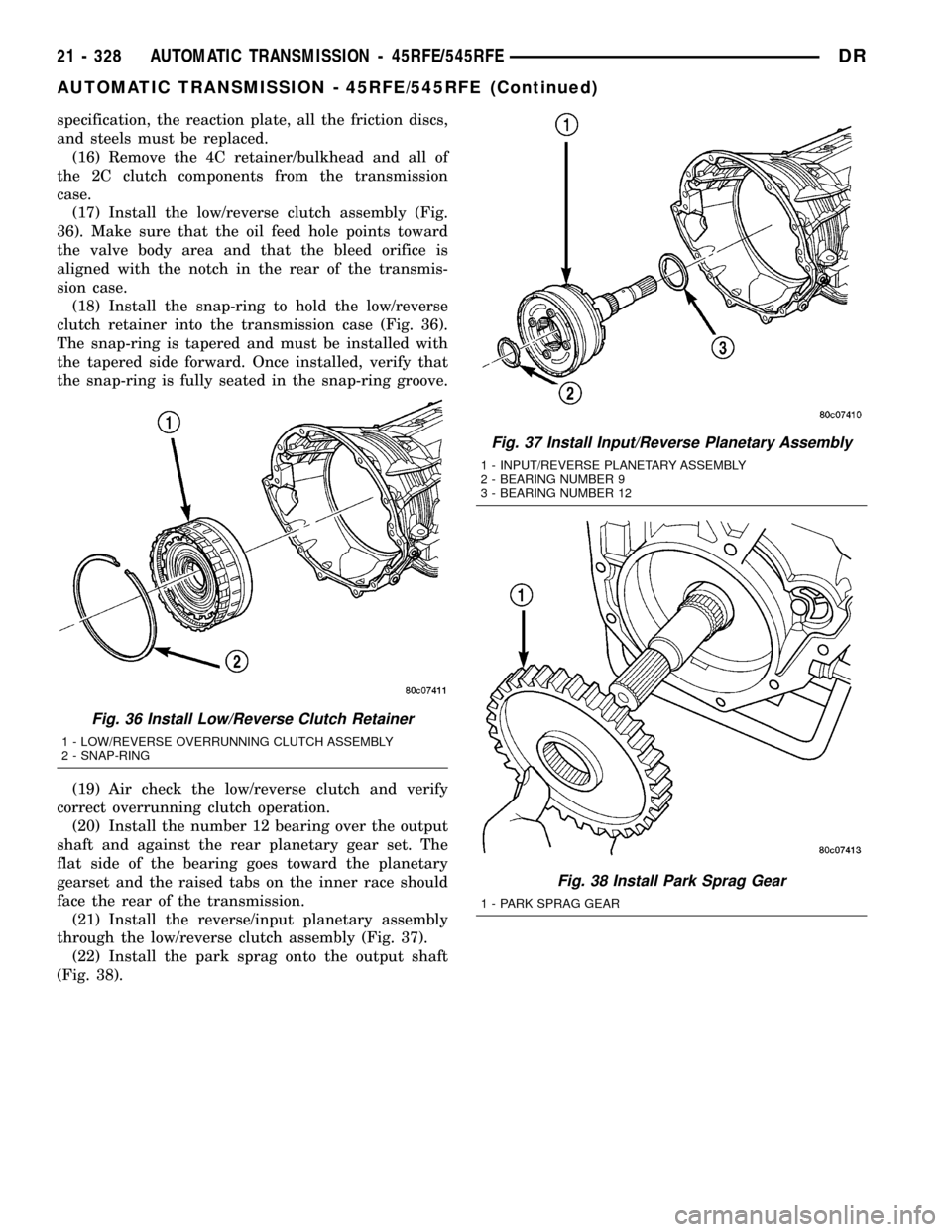

(17) Install the low/reverse clutch assembly (Fig.

36). Make sure that the oil feed hole points toward

the valve body area and that the bleed orifice is

aligned with the notch in the rear of the transmis-

sion case.

(18) Install the snap-ring to hold the low/reverse

clutch retainer into the transmission case (Fig. 36).

The snap-ring is tapered and must be installed with

the tapered side forward. Once installed, verify that

the snap-ring is fully seated in the snap-ring groove.

(19) Air check the low/reverse clutch and verify

correct overrunning clutch operation.

(20) Install the number 12 bearing over the output

shaft and against the rear planetary gear set. The

flat side of the bearing goes toward the planetary

gearset and the raised tabs on the inner race should

face the rear of the transmission.

(21) Install the reverse/input planetary assembly

through the low/reverse clutch assembly (Fig. 37).

(22) Install the park sprag onto the output shaft

(Fig. 38).

Fig. 38 Install Park Sprag Gear

1 - PARK SPRAG GEAR

Fig. 36 Install Low/Reverse Clutch Retainer

1 - LOW/REVERSE OVERRUNNING CLUTCH ASSEMBLY

2 - SNAP-RING

Fig. 37 Install Input/Reverse Planetary Assembly

1 - INPUT/REVERSE PLANETARY ASSEMBLY

2 - BEARING NUMBER 9

3 - BEARING NUMBER 12

21 - 328 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

AUTOMATIC TRANSMISSION - 45RFE/545RFE (Continued)

Page 2087 of 2627

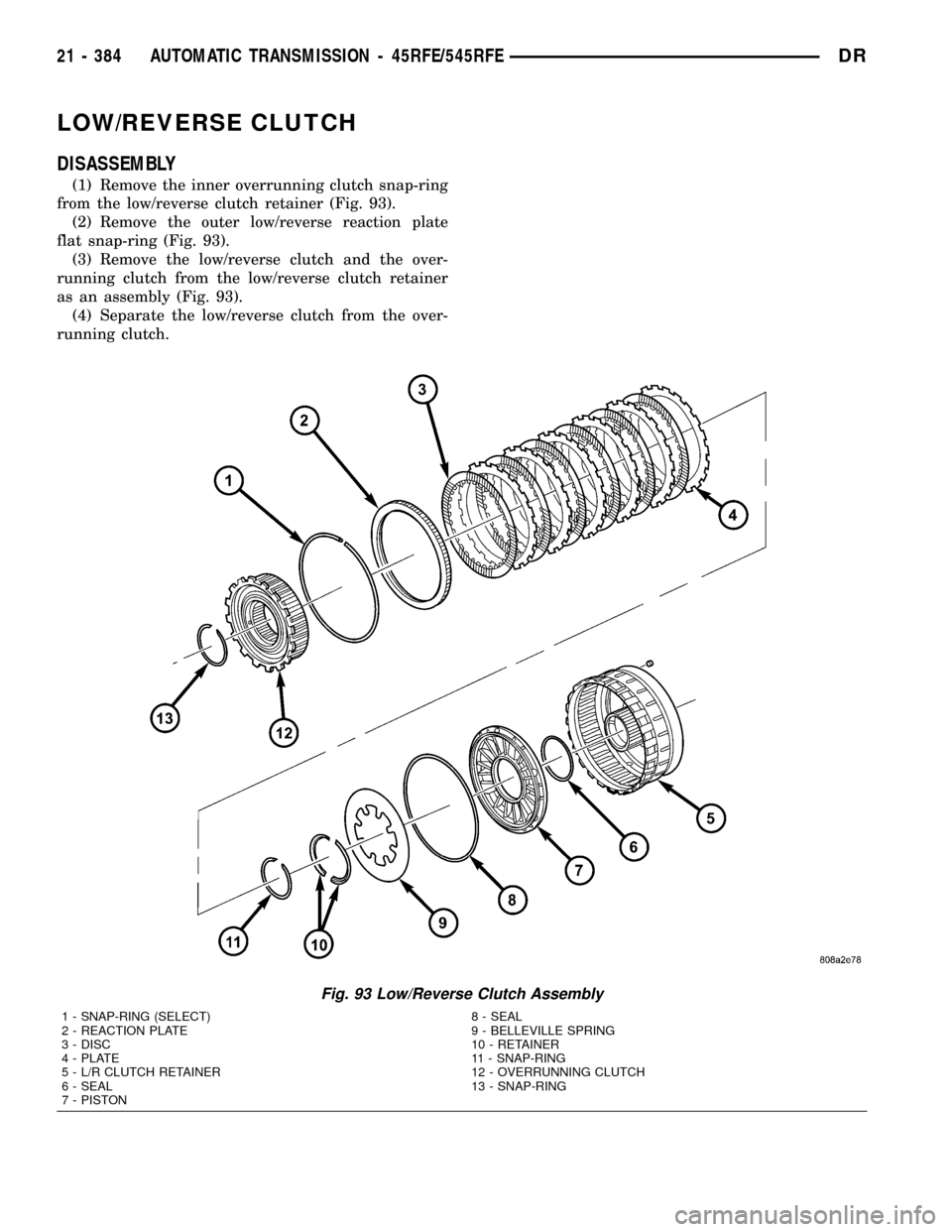

LOW/REVERSE CLUTCH

DISASSEMBLY

(1) Remove the inner overrunning clutch snap-ring

from the low/reverse clutch retainer (Fig. 93).

(2) Remove the outer low/reverse reaction plate

flat snap-ring (Fig. 93).

(3) Remove the low/reverse clutch and the over-

running clutch from the low/reverse clutch retainer

as an assembly (Fig. 93).

(4) Separate the low/reverse clutch from the over-

running clutch.

Fig. 93 Low/Reverse Clutch Assembly

1 - SNAP-RING (SELECT) 8 - SEAL

2 - REACTION PLATE 9 - BELLEVILLE SPRING

3 - DISC 10 - RETAINER

4 - PLATE 11 - SNAP-RING

5 - L/R CLUTCH RETAINER 12 - OVERRUNNING CLUTCH

6 - SEAL 13 - SNAP-RING

7 - PISTON

21 - 384 AUTOMATIC TRANSMISSION - 45RFE/545RFEDR

Page 2088 of 2627

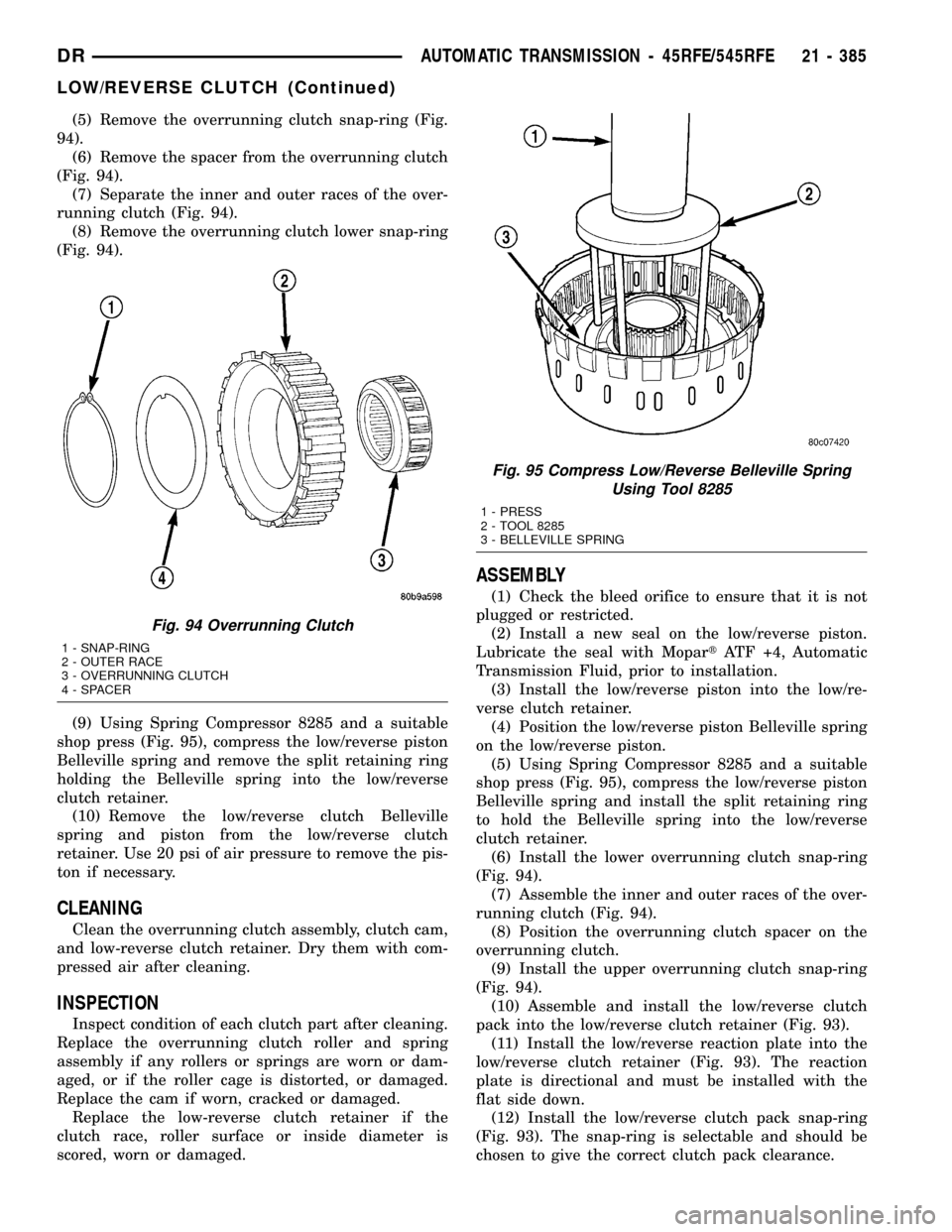

(5) Remove the overrunning clutch snap-ring (Fig.

94).

(6) Remove the spacer from the overrunning clutch

(Fig. 94).

(7) Separate the inner and outer races of the over-

running clutch (Fig. 94).

(8) Remove the overrunning clutch lower snap-ring

(Fig. 94).

(9) Using Spring Compressor 8285 and a suitable

shop press (Fig. 95), compress the low/reverse piston

Belleville spring and remove the split retaining ring

holding the Belleville spring into the low/reverse

clutch retainer.

(10) Remove the low/reverse clutch Belleville

spring and piston from the low/reverse clutch

retainer. Use 20 psi of air pressure to remove the pis-

ton if necessary.

CLEANING

Clean the overrunning clutch assembly, clutch cam,

and low-reverse clutch retainer. Dry them with com-

pressed air after cleaning.

INSPECTION

Inspect condition of each clutch part after cleaning.

Replace the overrunning clutch roller and spring

assembly if any rollers or springs are worn or dam-

aged, or if the roller cage is distorted, or damaged.

Replace the cam if worn, cracked or damaged.

Replace the low-reverse clutch retainer if the

clutch race, roller surface or inside diameter is

scored, worn or damaged.

ASSEMBLY

(1) Check the bleed orifice to ensure that it is not

plugged or restricted.

(2) Install a new seal on the low/reverse piston.

Lubricate the seal with MopartATF +4, Automatic

Transmission Fluid, prior to installation.

(3) Install the low/reverse piston into the low/re-

verse clutch retainer.

(4) Position the low/reverse piston Belleville spring

on the low/reverse piston.

(5) Using Spring Compressor 8285 and a suitable

shop press (Fig. 95), compress the low/reverse piston

Belleville spring and install the split retaining ring

to hold the Belleville spring into the low/reverse

clutch retainer.

(6) Install the lower overrunning clutch snap-ring

(Fig. 94).

(7) Assemble the inner and outer races of the over-

running clutch (Fig. 94).

(8) Position the overrunning clutch spacer on the

overrunning clutch.

(9) Install the upper overrunning clutch snap-ring

(Fig. 94).

(10) Assemble and install the low/reverse clutch

pack into the low/reverse clutch retainer (Fig. 93).

(11) Install the low/reverse reaction plate into the

low/reverse clutch retainer (Fig. 93). The reaction

plate is directional and must be installed with the

flat side down.

(12) Install the low/reverse clutch pack snap-ring

(Fig. 93). The snap-ring is selectable and should be

chosen to give the correct clutch pack clearance.

Fig. 94 Overrunning Clutch

1 - SNAP-RING

2 - OUTER RACE

3 - OVERRUNNING CLUTCH

4 - SPACER

Fig. 95 Compress Low/Reverse Belleville Spring

Using Tool 8285

1 - PRESS

2 - TOOL 8285

3 - BELLEVILLE SPRING

DRAUTOMATIC TRANSMISSION - 45RFE/545RFE 21 - 385

LOW/REVERSE CLUTCH (Continued)

Page 2280 of 2627

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND

WHEEL RUNOUT......................1

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE ROTATION . 3

STANDARD PROCEDURE - MATCH

MOUNTING...........................3

STANDARD PROCEDURE - TIRE AND

WHEEL BALANCE......................4

TIRES

DESCRIPTION

DESCRIPTION - SPARE TIRE /

TEMPORARY.........................6

DESCRIPTION - TIRES..................6

DESCRIPTION - RADIAL ± PLY TIRES......6

DESCRIPTION - TIRE PRESSURE FOR

HIGH SPEEDS.........................7

DESCRIPTION - REPLACEMENT TIRES.....7

DESCRIPTION - TIRE INFLATION

PRESSURES..........................7

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRESSURE

GAUGES.............................7

DIAGNOSIS AND TESTING - TIRE NOISE

OR VIBRATION........................7

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS..........................8

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS...........................8

DIAGNOSIS AND TESTING - TIRE/VEHICLE

LEAD................................8STANDARD PROCEDURE - REPAIRING

LEAKS..............................10

SPECIFICATIONS

TIRE REVOLUTIONS PER MILE..........10

WHEELS

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING

WHEEL INSPECTION..................11

STANDARD PROCEDURE

STANDARD PROCEDURE - WHEEL

REPLACEMENT.......................12

STANDARD PROCEDURE - DUAL REAR

WHEEL INSTALLATION.................12

SPECIFICATIONS

TORQUE CHART......................13

STUDS

REMOVAL.............................14

INSTALLATION.........................14

WHEEL COVER

REMOVAL.............................14

INSTALLATION

INSTALLATION - REAR.................14

INSTALLATION - FRONT................14

SPARE TIRE

DESCRIPTION

DESCRIPTION - SPARE / TEMPORARY

TIRE...............................15

DESCRIPTION - FULL SIZE, SPARE WHEEL

WITH MATCHING TIRE.................15

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND WHEEL

RUNOUT

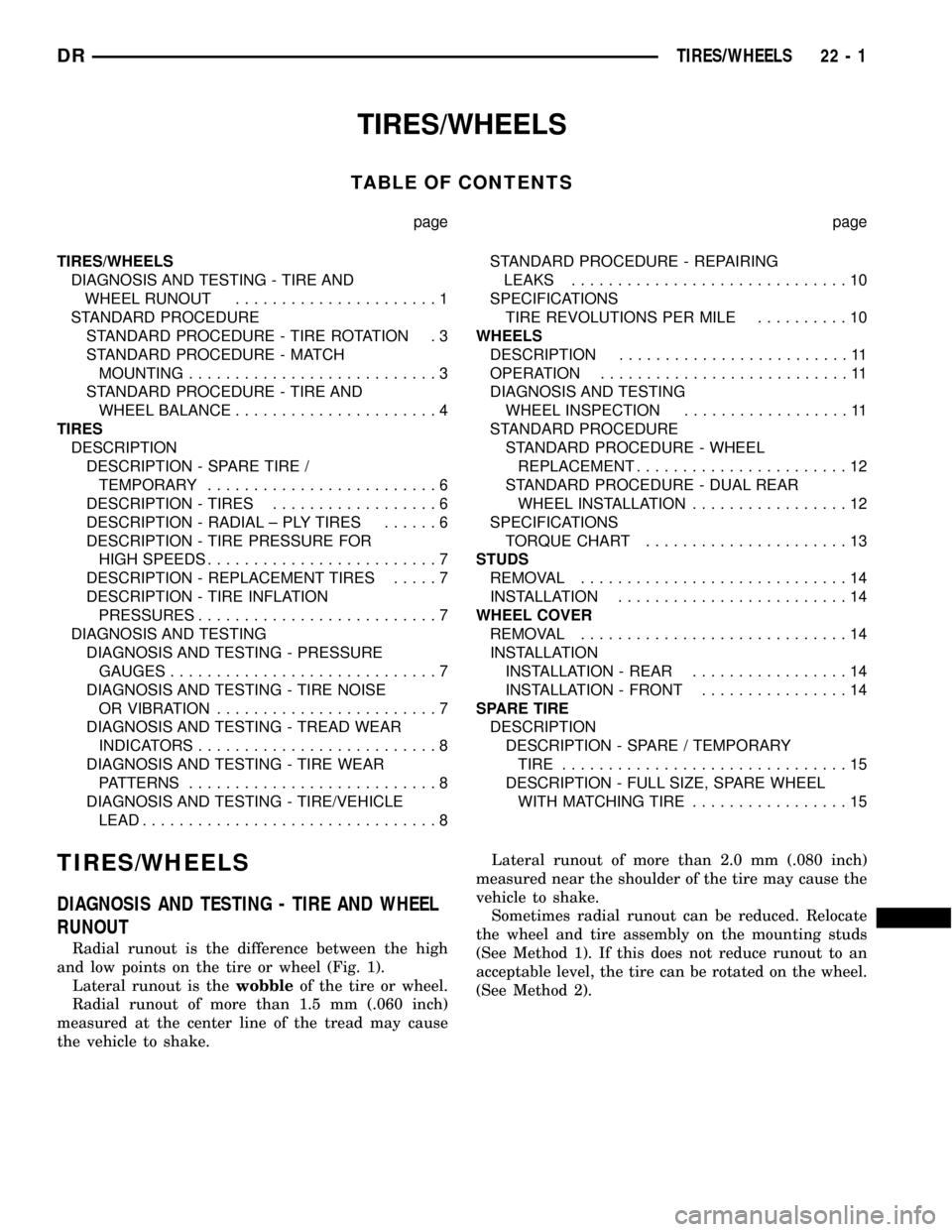

Radial runout is the difference between the high

and low points on the tire or wheel (Fig. 1).

Lateral runout is thewobbleof the tire or wheel.

Radial runout of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake.Lateral runout of more than 2.0 mm (.080 inch)

measured near the shoulder of the tire may cause the

vehicle to shake.

Sometimes radial runout can be reduced. Relocate

the wheel and tire assembly on the mounting studs

(See Method 1). If this does not reduce runout to an

acceptable level, the tire can be rotated on the wheel.

(See Method 2).

DRTIRES/WHEELS 22 - 1

Page 2281 of 2627

METHOD 1 (RELOCATE WHEEL ON HUB)

(1) Drive vehicle a short distance to eliminate tire

flat spotting from a parked position.

(2) Check wheel bearings and adjust if adjustable

or replace if necessary.

(3) Check the wheel mounting surface.

(4) Relocate wheel on the mounting, two studs

over from the original position.

(5) Tighten wheel nuts until all are properly

torqued, to eliminate brake distortion.

(6) Check radial runout. If still excessive, mark

tire sidewall, wheel, and stud at point of maximum

runout and proceed to Method 2.

METHOD 2 (RELOCATE TIRE ON WHEEL)

NOTE: Rotating the tire on wheel is particularly

effective when there is runout in both tire and

wheel.

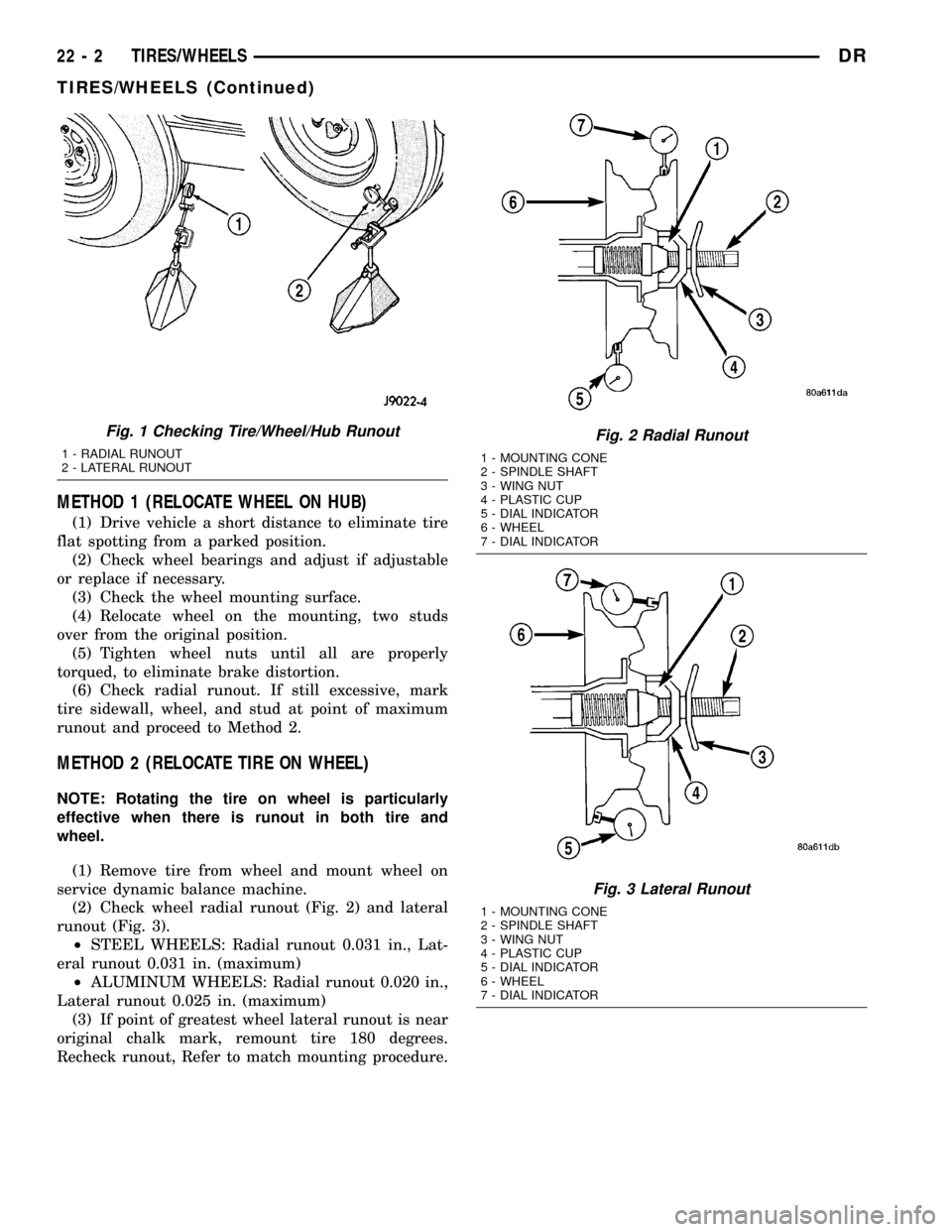

(1) Remove tire from wheel and mount wheel on

service dynamic balance machine.

(2) Check wheel radial runout (Fig. 2) and lateral

runout (Fig. 3).

²STEEL WHEELS: Radial runout 0.031 in., Lat-

eral runout 0.031 in. (maximum)

²ALUMINUM WHEELS: Radial runout 0.020 in.,

Lateral runout 0.025 in. (maximum)

(3) If point of greatest wheel lateral runout is near

original chalk mark, remount tire 180 degrees.

Recheck runout, Refer to match mounting procedure.

Fig. 1 Checking Tire/Wheel/Hub Runout

1 - RADIAL RUNOUT

2 - LATERAL RUNOUT

Fig. 2 Radial Runout

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

Fig. 3 Lateral Runout

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

22 - 2 TIRES/WHEELSDR

TIRES/WHEELS (Continued)