wiring diagram window DODGE RAM 1500 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: RAM 1500, Model: DODGE RAM 1500 1998 2.GPages: 2627

Page 471 of 2627

DIAGNOSIS AND TESTING - REAR WINDOW

DEFOGGER SYSTEM

For circuit descriptions and diagrams, refer to Rear

Window Defogger in Wiring Diagrams. The operation

of the electrically heated rear window defogger sys-

tem can be confirmed in one of the following man-

ners:

1. Turn the ignition switch to the On position.

While monitoring the instrument panel voltmeter, set

the defogger switch in the On position. When the

defogger switch is turned On, a distinct voltmeter

needle deflection should be noted.

2. Turn the ignition switch to the On position. Set

the defogger switch in the On position. The rear win-

dow defogger operation can be checked by feeling the

rear window or outside rear view mirror glass. A dis-

tinct difference in temperature between the grid lines

and the adjacent clear glass or the mirror glass can

be detected within three to four minutes of operation.

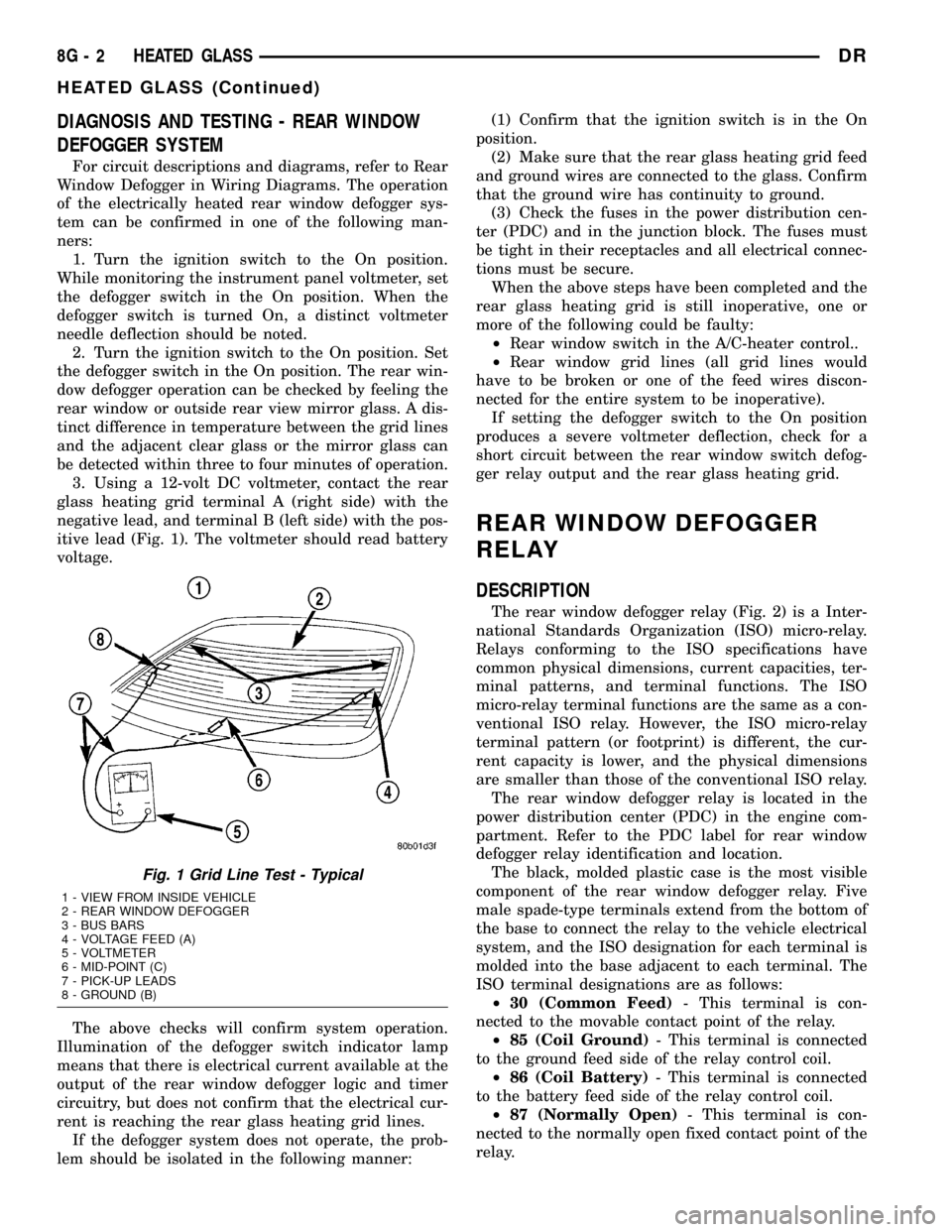

3. Using a 12-volt DC voltmeter, contact the rear

glass heating grid terminal A (right side) with the

negative lead, and terminal B (left side) with the pos-

itive lead (Fig. 1). The voltmeter should read battery

voltage.

The above checks will confirm system operation.

Illumination of the defogger switch indicator lamp

means that there is electrical current available at the

output of the rear window defogger logic and timer

circuitry, but does not confirm that the electrical cur-

rent is reaching the rear glass heating grid lines.

If the defogger system does not operate, the prob-

lem should be isolated in the following manner:(1) Confirm that the ignition switch is in the On

position.

(2) Make sure that the rear glass heating grid feed

and ground wires are connected to the glass. Confirm

that the ground wire has continuity to ground.

(3) Check the fuses in the power distribution cen-

ter (PDC) and in the junction block. The fuses must

be tight in their receptacles and all electrical connec-

tions must be secure.

When the above steps have been completed and the

rear glass heating grid is still inoperative, one or

more of the following could be faulty:

²Rear window switch in the A/C-heater control..

²Rear window grid lines (all grid lines would

have to be broken or one of the feed wires discon-

nected for the entire system to be inoperative).

If setting the defogger switch to the On position

produces a severe voltmeter deflection, check for a

short circuit between the rear window switch defog-

ger relay output and the rear glass heating grid.

REAR WINDOW DEFOGGER

RELAY

DESCRIPTION

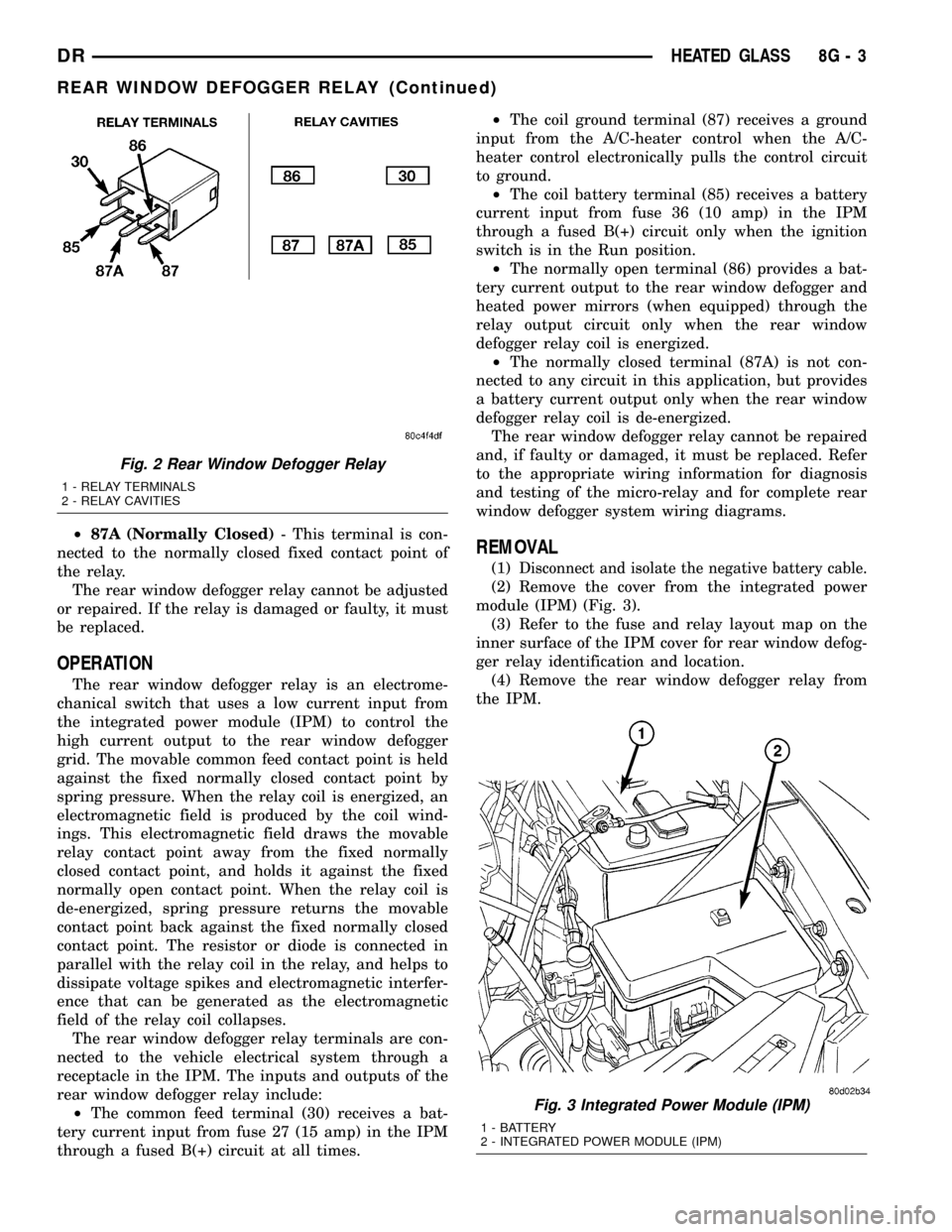

The rear window defogger relay (Fig. 2) is a Inter-

national Standards Organization (ISO) micro-relay.

Relays conforming to the ISO specifications have

common physical dimensions, current capacities, ter-

minal patterns, and terminal functions. The ISO

micro-relay terminal functions are the same as a con-

ventional ISO relay. However, the ISO micro-relay

terminal pattern (or footprint) is different, the cur-

rent capacity is lower, and the physical dimensions

are smaller than those of the conventional ISO relay.

The rear window defogger relay is located in the

power distribution center (PDC) in the engine com-

partment. Refer to the PDC label for rear window

defogger relay identification and location.

The black, molded plastic case is the most visible

component of the rear window defogger relay. Five

male spade-type terminals extend from the bottom of

the base to connect the relay to the vehicle electrical

system, and the ISO designation for each terminal is

molded into the base adjacent to each terminal. The

ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

Fig. 1 Grid Line Test - Typical

1 - VIEW FROM INSIDE VEHICLE

2 - REAR WINDOW DEFOGGER

3 - BUS BARS

4 - VOLTAGE FEED (A)

5 - VOLTMETER

6 - MID-POINT (C)

7 - PICK-UP LEADS

8 - GROUND (B)

8G - 2 HEATED GLASSDR

HEATED GLASS (Continued)

Page 472 of 2627

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The rear window defogger relay cannot be adjusted

or repaired. If the relay is damaged or faulty, it must

be replaced.

OPERATION

The rear window defogger relay is an electrome-

chanical switch that uses a low current input from

the integrated power module (IPM) to control the

high current output to the rear window defogger

grid. The movable common feed contact point is held

against the fixed normally closed contact point by

spring pressure. When the relay coil is energized, an

electromagnetic field is produced by the coil wind-

ings. This electromagnetic field draws the movable

relay contact point away from the fixed normally

closed contact point, and holds it against the fixed

normally open contact point. When the relay coil is

de-energized, spring pressure returns the movable

contact point back against the fixed normally closed

contact point. The resistor or diode is connected in

parallel with the relay coil in the relay, and helps to

dissipate voltage spikes and electromagnetic interfer-

ence that can be generated as the electromagnetic

field of the relay coil collapses.

The rear window defogger relay terminals are con-

nected to the vehicle electrical system through a

receptacle in the IPM. The inputs and outputs of the

rear window defogger relay include:

²The common feed terminal (30) receives a bat-

tery current input from fuse 27 (15 amp) in the IPM

through a fused B(+) circuit at all times.²The coil ground terminal (87) receives a ground

input from the A/C-heater control when the A/C-

heater control electronically pulls the control circuit

to ground.

²The coil battery terminal (85) receives a battery

current input from fuse 36 (10 amp) in the IPM

through a fused B(+) circuit only when the ignition

switch is in the Run position.

²The normally open terminal (86) provides a bat-

tery current output to the rear window defogger and

heated power mirrors (when equipped) through the

relay output circuit only when the rear window

defogger relay coil is energized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the rear window

defogger relay coil is de-energized.

The rear window defogger relay cannot be repaired

and, if faulty or damaged, it must be replaced. Refer

to the appropriate wiring information for diagnosis

and testing of the micro-relay and for complete rear

window defogger system wiring diagrams.

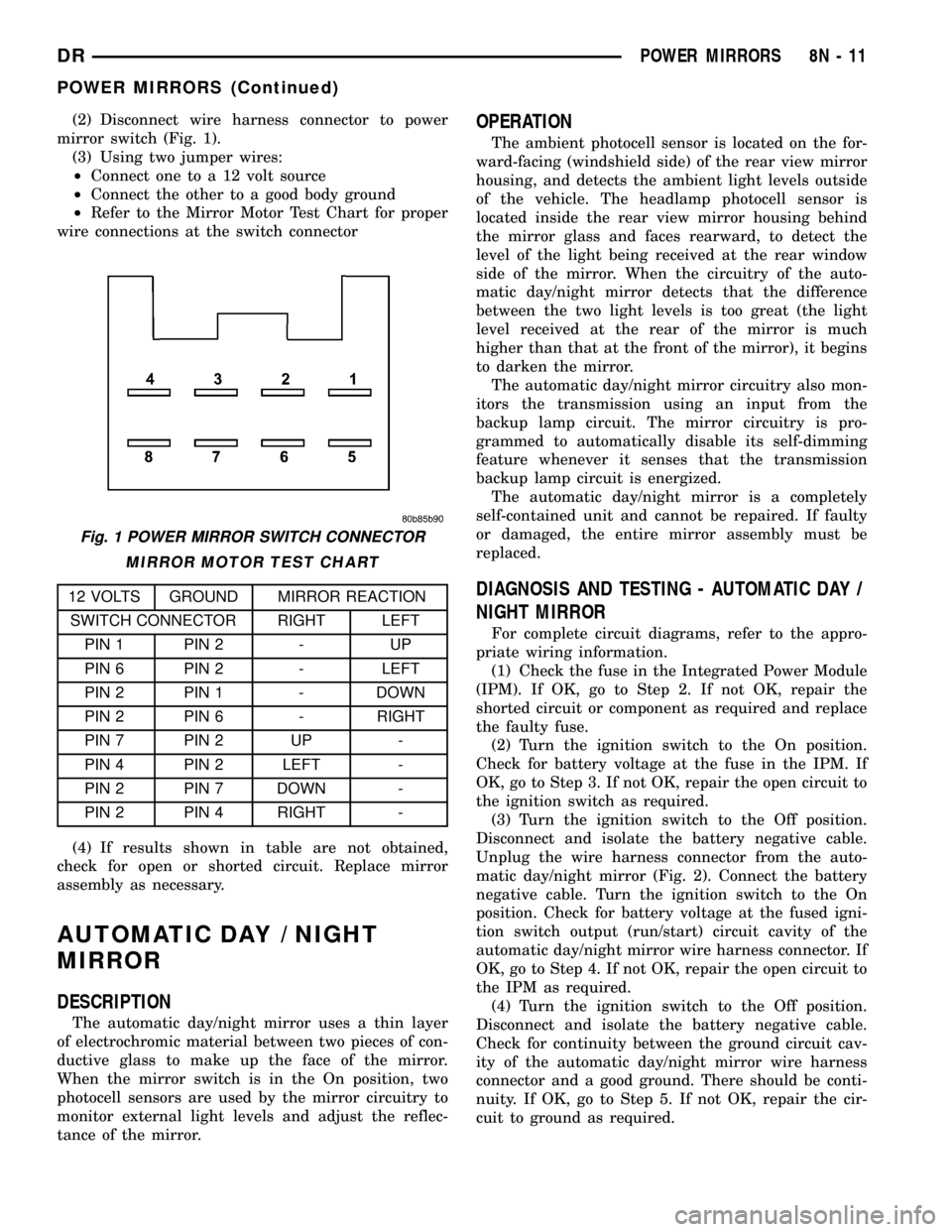

REMOVAL

(1)Disconnect and isolate the negative battery cable.

(2) Remove the cover from the integrated power

module (IPM) (Fig. 3).

(3) Refer to the fuse and relay layout map on the

inner surface of the IPM cover for rear window defog-

ger relay identification and location.

(4) Remove the rear window defogger relay from

the IPM.

Fig. 2 Rear Window Defogger Relay

1 - RELAY TERMINALS

2 - RELAY CAVITIES

Fig. 3 Integrated Power Module (IPM)

1 - BATTERY

2 - INTEGRATED POWER MODULE (IPM)

DRHEATED GLASS 8G - 3

REAR WINDOW DEFOGGER RELAY (Continued)

Page 608 of 2627

(2) Disconnect wire harness connector to power

mirror switch (Fig. 1).

(3) Using two jumper wires:

²Connect one to a 12 volt source

²Connect the other to a good body ground

²Refer to the Mirror Motor Test Chart for proper

wire connections at the switch connector

MIRROR MOTOR TEST CHART

12 VOLTS GROUND MIRROR REACTION

SWITCH CONNECTOR RIGHT LEFT

PIN 1 PIN 2 - UP

PIN 6 PIN 2 - LEFT

PIN 2 PIN 1 - DOWN

PIN 2 PIN 6 - RIGHT

PIN 7 PIN 2 UP -

PIN 4 PIN 2 LEFT -

PIN 2 PIN 7 DOWN -

PIN 2 PIN 4 RIGHT -

(4) If results shown in table are not obtained,

check for open or shorted circuit. Replace mirror

assembly as necessary.

AUTOMATIC DAY / NIGHT

MIRROR

DESCRIPTION

The automatic day/night mirror uses a thin layer

of electrochromic material between two pieces of con-

ductive glass to make up the face of the mirror.

When the mirror switch is in the On position, two

photocell sensors are used by the mirror circuitry to

monitor external light levels and adjust the reflec-

tance of the mirror.

OPERATION

The ambient photocell sensor is located on the for-

ward-facing (windshield side) of the rear view mirror

housing, and detects the ambient light levels outside

of the vehicle. The headlamp photocell sensor is

located inside the rear view mirror housing behind

the mirror glass and faces rearward, to detect the

level of the light being received at the rear window

side of the mirror. When the circuitry of the auto-

matic day/night mirror detects that the difference

between the two light levels is too great (the light

level received at the rear of the mirror is much

higher than that at the front of the mirror), it begins

to darken the mirror.

The automatic day/night mirror circuitry also mon-

itors the transmission using an input from the

backup lamp circuit. The mirror circuitry is pro-

grammed to automatically disable its self-dimming

feature whenever it senses that the transmission

backup lamp circuit is energized.

The automatic day/night mirror is a completely

self-contained unit and cannot be repaired. If faulty

or damaged, the entire mirror assembly must be

replaced.

DIAGNOSIS AND TESTING - AUTOMATIC DAY /

NIGHT MIRROR

For complete circuit diagrams, refer to the appro-

priate wiring information.

(1) Check the fuse in the Integrated Power Module

(IPM). If OK, go to Step 2. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fuse in the IPM. If

OK, go to Step 3. If not OK, repair the open circuit to

the ignition switch as required.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Unplug the wire harness connector from the auto-

matic day/night mirror (Fig. 2). Connect the battery

negative cable. Turn the ignition switch to the On

position. Check for battery voltage at the fused igni-

tion switch output (run/start) circuit cavity of the

automatic day/night mirror wire harness connector. If

OK, go to Step 4. If not OK, repair the open circuit to

the IPM as required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Check for continuity between the ground circuit cav-

ity of the automatic day/night mirror wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 5. If not OK, repair the cir-

cuit to ground as required.

Fig. 1 POWER MIRROR SWITCH CONNECTOR

DRPOWER MIRRORS 8N - 11

POWER MIRRORS (Continued)

Page 726 of 2627

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION....... 8W-01-1

COMPONENT INDEX.................. 8W-02-1

POWER DISTRIBUTION............... 8W-10-1

GROUND DISTRIBUTION.............. 8W-15-1

BUS COMMUNICATIONS.............. 8W-18-1

CHARGING SYSTEM.................. 8W-20-1

STARTING SYSTEM.................. 8W-21-1

FUEL/IGNITION SYSTEM.............. 8W-30-1

TRANSMISSION CONTROL SYSTEM..... 8W-31-1

VEHICLE SPEED CONTROL............ 8W-33-1

REAR WHEEL ANTILOCK BRAKES....... 8W-34-1

ALL WHEEL ANTILOCK BRAKES........ 8W-35-1

VEHICLE THEFT SECURITY SYSTEM..... 8W-39-1

INSTRUMENT CLUSTER............... 8W-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . . 8W-41-1

AIR CONDITIONING.................. 8W-42-1

AIRBAG SYSTEM.................... 8W-43-1

INTERIOR LIGHTING.................. 8W-44-1AUDIO SYSTEM..................... 8W-47-1

REAR WINDOW DEFOGGER............ 8W-48-1

OVERHEAD CONSOLE................. 8W-49-1

FRONT LIGHTING.................... 8W-50-1

REAR LIGHTING..................... 8W-51-1

TURN SIGNALS...................... 8W-52-1

WIPERS............................ 8W-53-1

TRAILER TOW....................... 8W-54-1

NAVIGATION/TELECOMMUNICATION..... 8W-55-1

POWER WINDOWS................... 8W-60-1

POWER DOOR LOCKS................ 8W-61-1

POWER MIRRORS................... 8W-62-1

POWER SEATS...................... 8W-63-1

SPLICE INFORMATION................ 8W-70-1

CONNECTOR PIN-OUTS............... 8W-80-1

CONNECTOR/GROUND/SPLICE

LOCATION........................ 8W-91-1

POWER DISTRIBUTION............... 8W-97-1 DRWIRING 8W - 1

Page 2535 of 2627

After the system has been tested for leaks and

evacuated, a refrigerant (R-134a) charge can be

injected into the system.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) If using a separate vacuum pump close all

valves before disconnecting pump. Connect manifold

gauge set to the A/C service ports.

NOTE: Always refer to the underhood HVAC Speci-

fication label for the refrigerant fill level of the vehi-

cle being serviced.

(2) Measure refrigerant (refer to capacities). Refer

to the instructions provided with the equipment

being used.

(3) Verify engine is shut off. Open the suction and

discharge valves. Open the charge valve to allow the

refrigerant to flow into the system. When the trans-

fer of refrigerant has stopped, close the suction and

discharge valve.

(4) If all of the charge did not transfer from the

dispensing device, put vehicle controls into the fol-

lowing mode:

²Automatic transmission in park or manual

transmission in neutral

²Engine at idle

²A/C mode control set to outside air

²A/C mode control set to panel mode

²A/C temperature control set to full cool

²Blower motor control set on highest speed

²Vehicle windows closed

If the A/C compressor does not engage, test the

compressor clutch control circuit and correct any fail-

ure (Refer to 8 - ELECTRICAL/WIRING DIAGRAM

INFORMATION - DIAGNOSIS AND TESTING).

(5) Open the suction valve to allow the remaining

refrigerant to transfer to the system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH-PRESSURE) VALVE AT THIS TIME.

(6) Close all valves and test the A/C system perfor-

mance.

(7) Disconnect the charging station or manifold

gauge set. Install the service port caps.

REFRIGERANT CHARGE CAPACITY

The R-134a refrigerant system charge capacity for

this vehicle can be found on the underhood HVAC

specfication tag.

A/C COMPRESSOR

DESCRIPTION

DESCRIPTION - A/C COMPRESSOR

The A/C system on models equipped with the 5.9L

engine use a Sanden SD-7 reciprocating swash plate-

type compressor. This compressor has a fixed dis-

placement of 165 cubic centimeter (10.068 cubic

inches) and has both the suction and discharge ports

located on the cylinder head.

The A/C system on models equipped with the 3.7L,

4.7L and 5.7L engines use a Denso 10S17 reciprocat-

ing swash plate-type compressor. This compressor

has a fixed displacement of 170 cubic centimeter and

has both the suction and discharge ports located on

the cylinder head.

A label identifying the use of R-134a refrigerant is

located on both A/C compressors.

DESCRIPTION - HIGH PRESSURE RELIEF

VALVE

A high pressure relief valve is located on the com-

pressor cylinder head, which is on the rear of the

compressor. This mechanical valve is designed to

vent refrigerant from the system to protect against

damage to the compressor and other system compo-

nents, caused by condenser air flow restriction or an

overcharge of refrigerant.

OPERATION

OPERATION - A/C COMPRESSOR

The A/C compressor is driven by the engine

through an electric clutch, drive pulley and belt

arrangement. The compressor is lubricated by refrig-

erant oil that is circulated throughout the refrigerant

system with the refrigerant.

The compressor draws in low-pressure refrigerant

vapor from the evaporator through its suction port. It

then compresses the refrigerant into a high-pressure,

high-temperature refrigerant vapor, which is then

pumped to the condenser through the compressor dis-

charge port.

The compressor cannot be repaired. If faulty or

damaged, the entire compressor assembly must be

replaced. The compressor clutch, pulley and clutch

coil are available for service.

OPERATION - HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents the system

when a discharge pressure of 3445 to 4135 kPa (500

to 600 psi) or above is reached. The valve closes

24 - 48 PLUMBINGDR

PLUMBING (Continued)

Page 2624 of 2627

WATER PUMP BYPASS - DESCRIPTION....7-59

WATER PUMP BYPASS - OPERATION......7-60

WATER SEPARATOR - DESCRIPTION,

FUEL FILTER........................14-50

WATER SEPARATOR - INSTALLATION,

FUEL FILTER........................14-50

WATER SEPARATOR - OPERATION, FUEL

FILTER.............................14-50

WATER SEPARATOR - REMOVAL, FUEL

FILTER.............................14-50

WATER TO OIL COOLER - REMOVAL......7-69

WATERDAM - INSTALLATION......23-25,23-34

WATERDAM - REMOVAL..........23-25,23-34

WATER-IN-FUEL INDICATOR -

DESCRIPTION.......................8J-45

WATER-IN-FUEL INDICATOR -

OPERATION.........................8J-45

WATER-TO-AIR COOLER - INSTALLATION . . 7-70

WEAR - STANDARD PROCEDURE,

MEASURING TIMING CHAIN............9-167

WEAR INDICATORS - DIAGNOSIS AND

TESTING, TREAD......................22-8

WEAR PATTERNS - DIAGNOSIS AND

TESTING, TIRE.......................22-8

WEAR, STANDARD PROCEDURE -

MEASURING TIMING CHAIN.............9-77

WEATHERSTRIP - INSTALLATION, DRIP

RAIL..............................23-91

WEATHERSTRIP - INSTALLATION, FRONT

DOOR GLASS RUN...................23-92

WEATHERSTRIP - INSTALLATION, REAR

DOOR GLASS RUN.....................23-93

WEATHERSTRIP - REMOVAL, DRIP RAIL . . 23-91

WEATHERSTRIP - REMOVAL, FRONT

DOOR GLASS RUN...................23-92

WEATHERSTRIP - REMOVAL, REAR

DOOR GLASS RUN...................23-93

WEATHERSTRIP RETAINER -

INSTALLATION, A-PILLAR..............23-91

WEATHERSTRIP RETAINER -

INSTALLATION, DRIP RAIL.............23-92

WEATHERSTRIP RETAINER - REMOVAL,

A-PILLAR...........................23-91

WEATHERSTRIP RETAINER - REMOVAL,

DRIP RAIL..........................23-92

WELD LOCATIONS - SPECIFICATIONS . . . 23-120

WELD PROCESS - SPECIFICATIONS......13-15

WHEEL - INSTALLATION, STEERING

......19-15

WHEEL - REMOVAL, STEERING

.........19-15

WHEEL ALIGNMENT - DESCRIPTION

.......2-1

WHEEL ALIGNMENT - OPERATION

.........2-2

WHEEL ALIGNMENT, SPECIAL TOOLS

......2-7

WHEEL ANTILOCK - DIAGNOSIS AND

TESTING, REAR

.......................5-48

WHEEL BALANCE - STANDARD

PROCEDURE, TIRE

....................22-4

WHEEL COVER - REMOVAL

............22-14WHEEL INSPECTION, DIAGNOSIS AND

TESTING...........................22-11

WHEEL INSTALLATION - STANDARD

PROCEDURE, DUAL REAR.............22-12

WHEEL REPLACEMENT - STANDARD

PROCEDURE........................22-12

WHEEL RUNOUT - DIAGNOSIS AND

TESTING, TIRE.......................22-1

WHEEL SPEED SENSOR - DESCRIPTION,

FRONT..............................5-47

WHEEL SPEED SENSOR - DIAGNOSIS

AND TESTING, REAR...................5-49

WHEEL SPEED SENSOR -

INSTALLATION, FRONT.................5-48

WHEEL SPEED SENSOR -

INSTALLATION, REAR..................5-48

WHEEL SPEED SENSOR - OPERATION,

FRONT..............................5-47

WHEEL SPEED SENSOR - REMOVAL,

FRONT..............................5-48

WHEEL SPEED SENSOR - REMOVAL,

REAR...............................5-48

WHEEL WITH MATCHING TIRE -

DESCRIPTION, FULL SIZE, SPARE.......22-15

WHEELHOUSE SPLASH SHIELD -

INSTALLATION, FRONT................23-41

WHEELHOUSE SPLASH SHIELD -

INSTALLATION, REAR.................23-41

WHEELHOUSE SPLASH SHIELD -

REMOVAL, FRONT....................23-41

WHEELHOUSE SPLASH SHIELD -

REMOVAL, REAR.....................23-41

WHEELS - DESCRIPTION..............22-11

WHEELS - INSTALLATION, REAR DUAL....5-35

WHEELS - OPERATION................22-11

WHEELS - REMOVAL, REAR DUAL........5-34

WIND NOISE - DIAGNOSIS AND TESTING . . 23-2

WINDOW DEFOGGER RELAY -

DESCRIPTION, REAR..................8G-2

WINDOW DEFOGGER RELAY -

INSTALLATION, REAR..................8G-4

WINDOW DEFOGGER RELAY -

OPERATION, REAR....................8G-3

WINDOW DEFOGGER RELAY -

REMOVAL, REAR.....................8G-3

WINDOW DEFOGGER SWITCH -

DESCRIPTION, REAR..................8G-4

WINDOW DEFOGGER SWITCH -

OPERATION, REAR....................8G-4

WINDOW DEFOGGER SYSTEM -

DIAGNOSIS AND TESTING, REAR.........8G-2

WINDOW MOTOR - REMOVAL..........8N-20

WINDOW REGULATOR - MANUAL -

INSTALLATION..................23-27,23-35

WINDOW REGULATOR - MANUAL -

REMOVAL.....................23-26,23-35

WINDOW REGULATOR - POWER -

INSTALLATION..................23-26,23-34WINDOW REGULATOR - POWER -

REMOVAL.....................23-25,23-34

WINDOW SWITCH - DIAGNOSIS AND

TESTING...........................8N-20

WINDOW SWITCH - INSTALLATION......8N-21

WINDOW SWITCH - REMOVAL..........8N-20

WINDOWS - DESCRIPTION, POWER.....8N-19

WINDOWS - DIAGNOSIS AND TESTING,

POWER............................8N-19

WINDOWS - OPERATION, POWER.......8N-19

WINDSHIELD SAFETY PRECAUTIONS,

WARNING..........................23-88

WIPER & WASHER SYSTEM - CLEANING . . 8R-6

WIPER & WASHER SYSTEM -

DIAGNOSIS AND TESTING..............8R-6

WIPER & WASHER SYSTEM -

INSPECTION.........................8R-7

WIPER ARM - DESCRIPTION...........8R-17

WIPER ARM - INSTALLATION...........8R-18

WIPER ARM - OPERATION.............8R-18

WIPER ARM - REMOVAL..............8R-18

WIPER BLADE - DESCRIPTION..........8R-18

WIPER BLADE - INSTALLATION.........8R-20

WIPER BLADE - OPERATION...........8R-19

WIPER BLADE - REMOVAL.............8R-19

WIPER HIGH/LOW RELAY -

DESCRIPTION.......................8R-20

WIPER HIGH/LOW RELAY - DIAGNOSIS

AND TESTING.......................8R-21

WIPER HIGH/LOW RELAY -

INSTALLATION......................8R-22

WIPER HIGH/LOW RELAY - OPERATION . . 8R-20

WIPER HIGH/LOW RELAY - REMOVAL....8R-21

WIPER MODULE - DESCRIPTION........8R-22

WIPER MODULE - INSTALLATION.......8R-23

WIPER MODULE - OPERATION..........8R-23

WIPER MODULE - REMOVAL...........8R-23

WIPER ON/OFF RELAY - DESCRIPTION . . . 8R-24

WIPER ON/OFF RELAY - DIAGNOSIS AND

TESTING...........................8R-25

WIPER ON/OFF RELAY - INSTALLATION . . . 8R-26

WIPER ON/OFF RELAY - OPERATION.....8R-25

WIPER ON/OFF RELAY - REMOVAL......8R-26

WIPERS/WASHERS - DESCRIPTION

.......8R-1

WIPERS/WASHERS - OPERATION

........8R-4

WIRE SPLICING - STANDARD

PROCEDURE

.....................8W-01-15

WIRING - DESCRIPTION, TRAILER TOW

. . 8L-24

WIRING DIAGRAMS - DESCRIPTION,

HOW TO USE

.....................8W-01-1

WIRING HARNESS - DIAGNOSIS AND

TESTING

.........................8W-01-7

WIRING/TERMINAL, SPECIAL TOOLS

. . 8W-01-10

WORN THREADS - STANDARD

PROCEDURE, REPAIR

DAMAGED OR

...........9-190,9-240,9-9,9-94

DRINDEX 37

Description Group-Page Description Group-Page Description Group-Page