clock DODGE RAM 1500 GAS 2004 3.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: RAM 1500 GAS, Model: DODGE RAM 1500 GAS 2004 3.GPages: 429, PDF Size: 7.52 MB

Page 186 of 429

NOTE:To improve your selection choices, the system

allows you to operate at intermediate positions between

the major modes. These intermediate positions are iden-

tified by the small dots.

Panel

Outside air flows through the outlets located in the

instrument panel.

Recirculation Modes (Panel or Bi-Level )

Select the recirculation modes when

the outside air contains smoke or

odors. This feature allows for recircu-

lation of interior air only. Air flows

through the panel outlets in this mode.

Bi-Level

Outside air flows through the outlets located in the

instrument panel and at the floor.

Mix

Outside air flows in equal proportions through the

floor and defroster outlets.

Defrost

Outside air is primarily directed to the windshield

through the defroster outlets located at the base of

the windshield, and the demister outlets located at the

edge of each side of the instrument panel.

Blower Control

The rotary knob on the left of

the control panel is the

blower control. Turn the knob

clockwise to one of the four

positions to obtain the blower

speed you desire. To turn the

blower off, turn the knob to

the far left position.

186 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 189 of 429

Floor

Outside air flows primarily through the floor out-

lets located under the instrument panel.

Mix

Outside air flows in equal proportions through the

floor and defroster outlets, and the air conditioning

may be on.

Defrost

Outside air is primarily directed to the windshield

through the defroster outlets located at the base of

the windshield, and the demister outlets located at the

edge of each side of the instrument panel, and the air

conditioning may be on.

Blower Control

The rotary knob on the left of

the control panel is the

blower control. Turn the knob

clockwise to one of the four

positions to obtain the blower

speed you desire. To turn the

blower off, turn the knob to

the far left position.

UNDERSTANDING YOUR INSTRUMENT PANEL 189

4

Page 194 of 429

Mix

Outside air flows in equal proportions through the

floor and defroster outlets.

Defrost

Outside air is primarily directed to the windshield

through the defroster outlets located at the base of

the windshield and side window demist outlets.

NOTE:The air conditioning compressor operates in

both Mix and Defrost or a blend of these modes, even if

the A/C button has not been pressed. This dehumidifies

the air to help dry the windshield.

Blower Control

The rotary knob on the left of

the control panel is the

blower control. Turn the knob

clockwise to one of the four

positions to obtain the blower

speed you desire. To turn the

blower off, turn the knob to

the far left position.

194 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 301 of 429

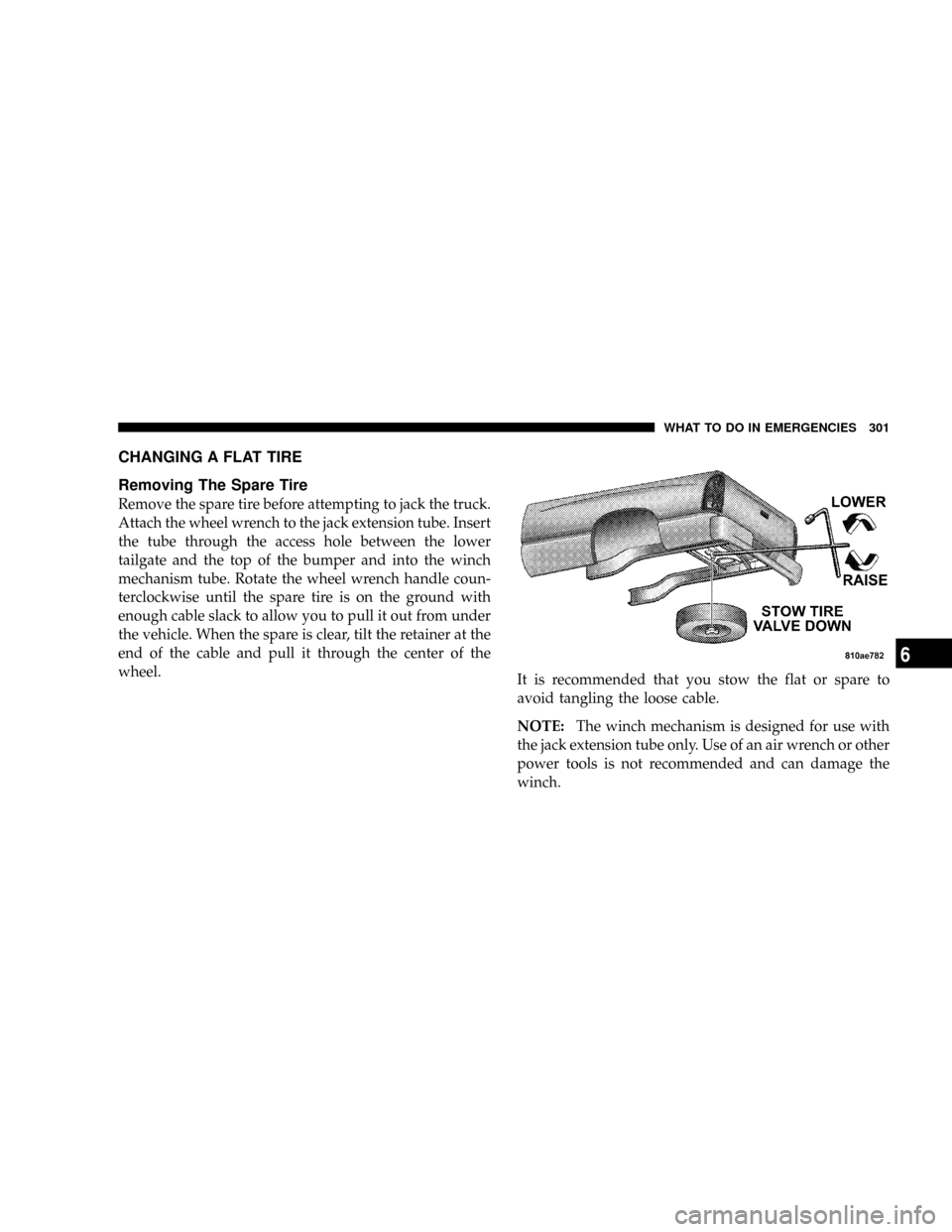

CHANGING A FLAT TIRE

Removing The Spare Tire

Remove the spare tire before attempting to jack the truck.

Attach the wheel wrench to the jack extension tube. Insert

the tube through the access hole between the lower

tailgate and the top of the bumper and into the winch

mechanism tube. Rotate the wheel wrench handle coun-

terclockwise until the spare tire is on the ground with

enough cable slack to allow you to pull it out from under

the vehicle. When the spare is clear, tilt the retainer at the

end of the cable and pull it through the center of the

wheel.

It is recommended that you stow the flat or spare to

avoid tangling the loose cable.

NOTE:The winch mechanism is designed for use with

the jack extension tube only. Use of an air wrench or other

power tools is not recommended and can damage the

winch.

WHAT TO DO IN EMERGENCIES 301

6

Page 304 of 429

1. Remove the spare wheel, jack, and tools from storage.

2. Using the wheel wrench, loosen, but do not remove,

the wheel nuts by turning them counterclockwise one

turn while the wheel is still on the ground.

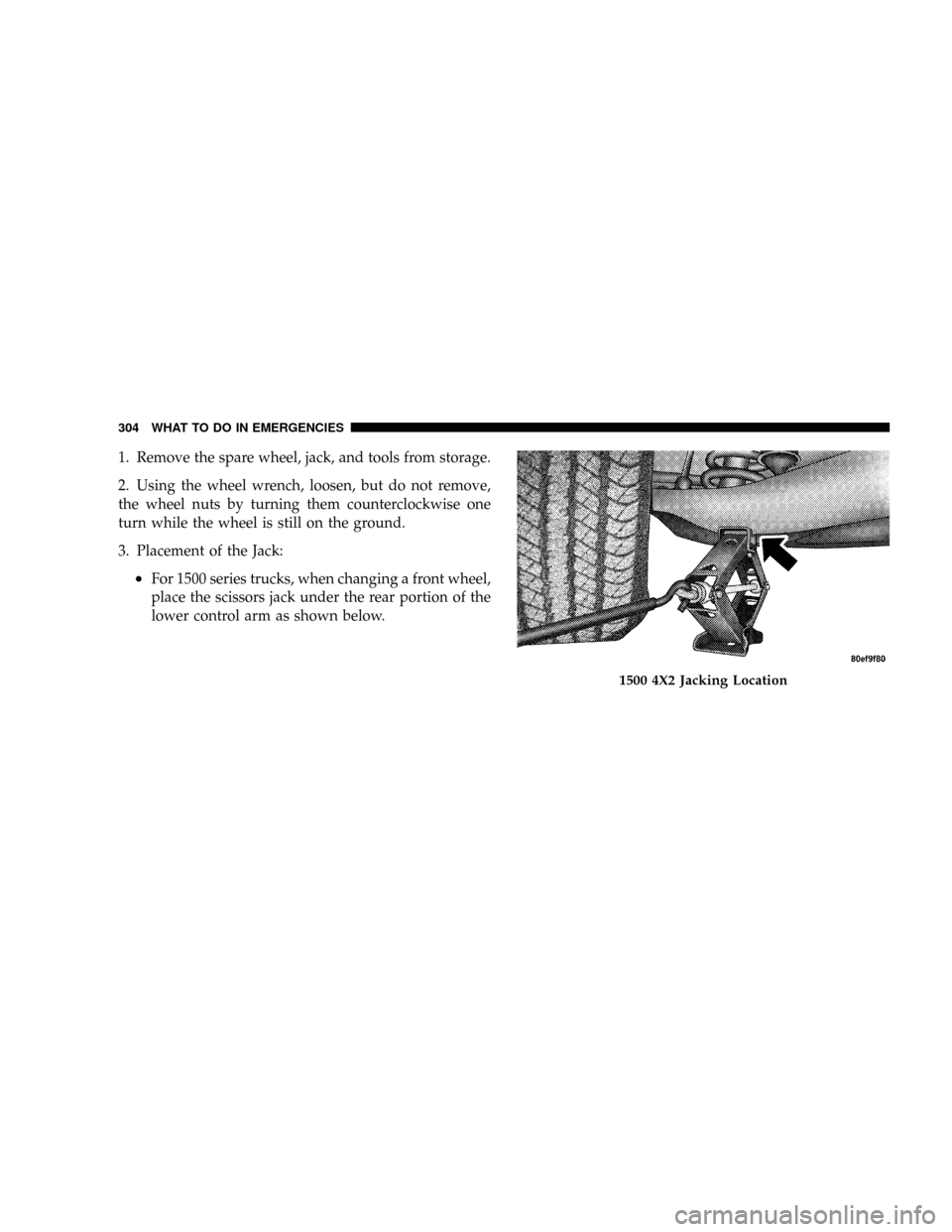

3. Placement of the Jack:

²For 1500 series trucks, when changing a front wheel,

place the scissors jack under the rear portion of the

lower control arm as shown below.

1500 4X2 Jacking Location

304 WHAT TO DO IN EMERGENCIES

Page 307 of 429

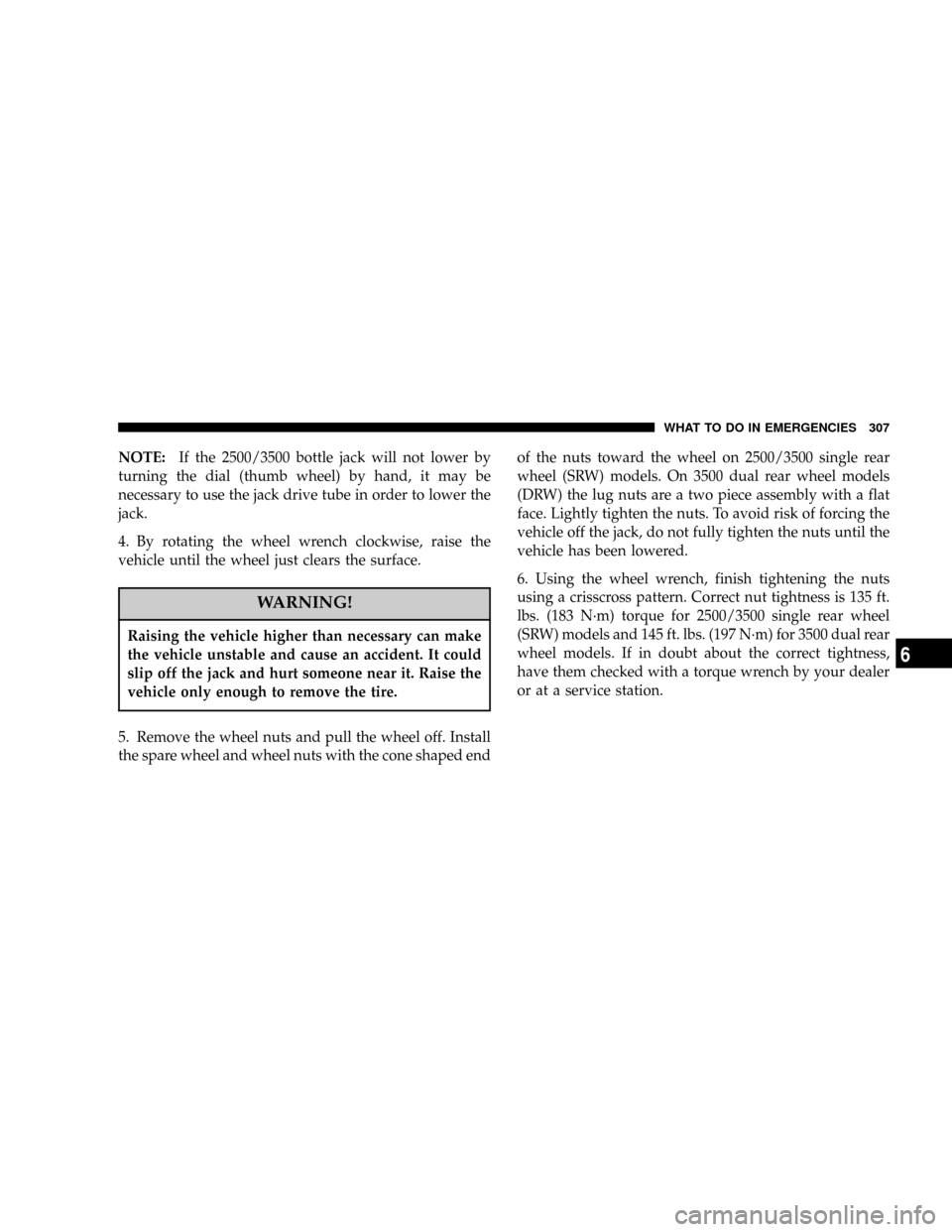

NOTE:If the 2500/3500 bottle jack will not lower by

turning the dial (thumb wheel) by hand, it may be

necessary to use the jack drive tube in order to lower the

jack.

4. By rotating the wheel wrench clockwise, raise the

vehicle until the wheel just clears the surface.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause an accident. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

5. Remove the wheel nuts and pull the wheel off. Install

the spare wheel and wheel nuts with the cone shaped endof the nuts toward the wheel on 2500/3500 single rear

wheel (SRW) models. On 3500 dual rear wheel models

(DRW) the lug nuts are a two piece assembly with a flat

face. Lightly tighten the nuts. To avoid risk of forcing the

vehicle off the jack, do not fully tighten the nuts until the

vehicle has been lowered.

6. Using the wheel wrench, finish tightening the nuts

using a crisscross pattern. Correct nut tightness is 135 ft.

lbs. (183 N´m) torque for 2500/3500 single rear wheel

(SRW) models and 145 ft. lbs. (197 N´m) for 3500 dual rear

wheel models. If in doubt about the correct tightness,

have them checked with a torque wrench by your dealer

or at a service station.

WHAT TO DO IN EMERGENCIES 307

6

Page 376 of 429

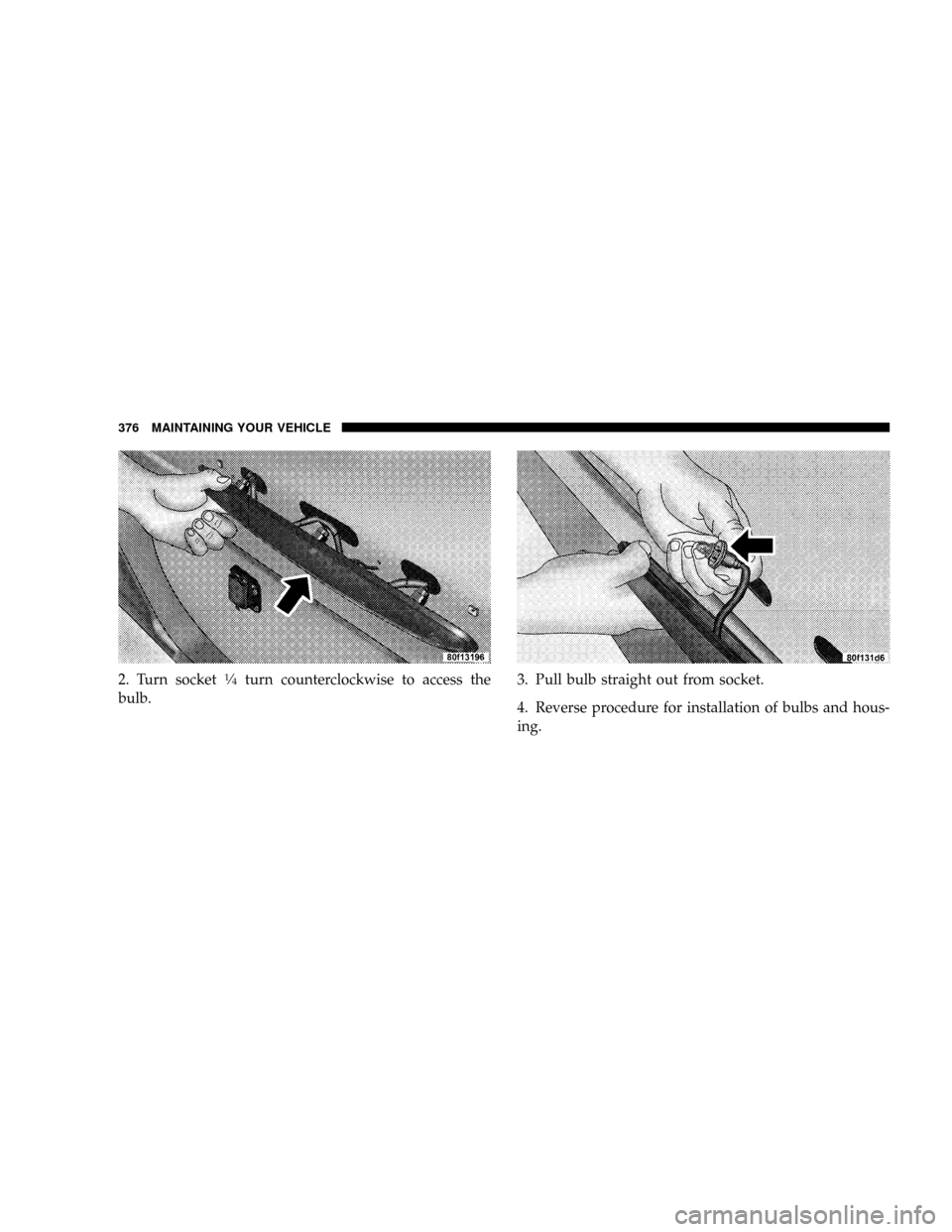

2. Turn socket1¤4turn counterclockwise to access the

bulb.3. Pull bulb straight out from socket.

4. Reverse procedure for installation of bulbs and hous-

ing.

376 MAINTAINING YOUR VEHICLE

Page 377 of 429

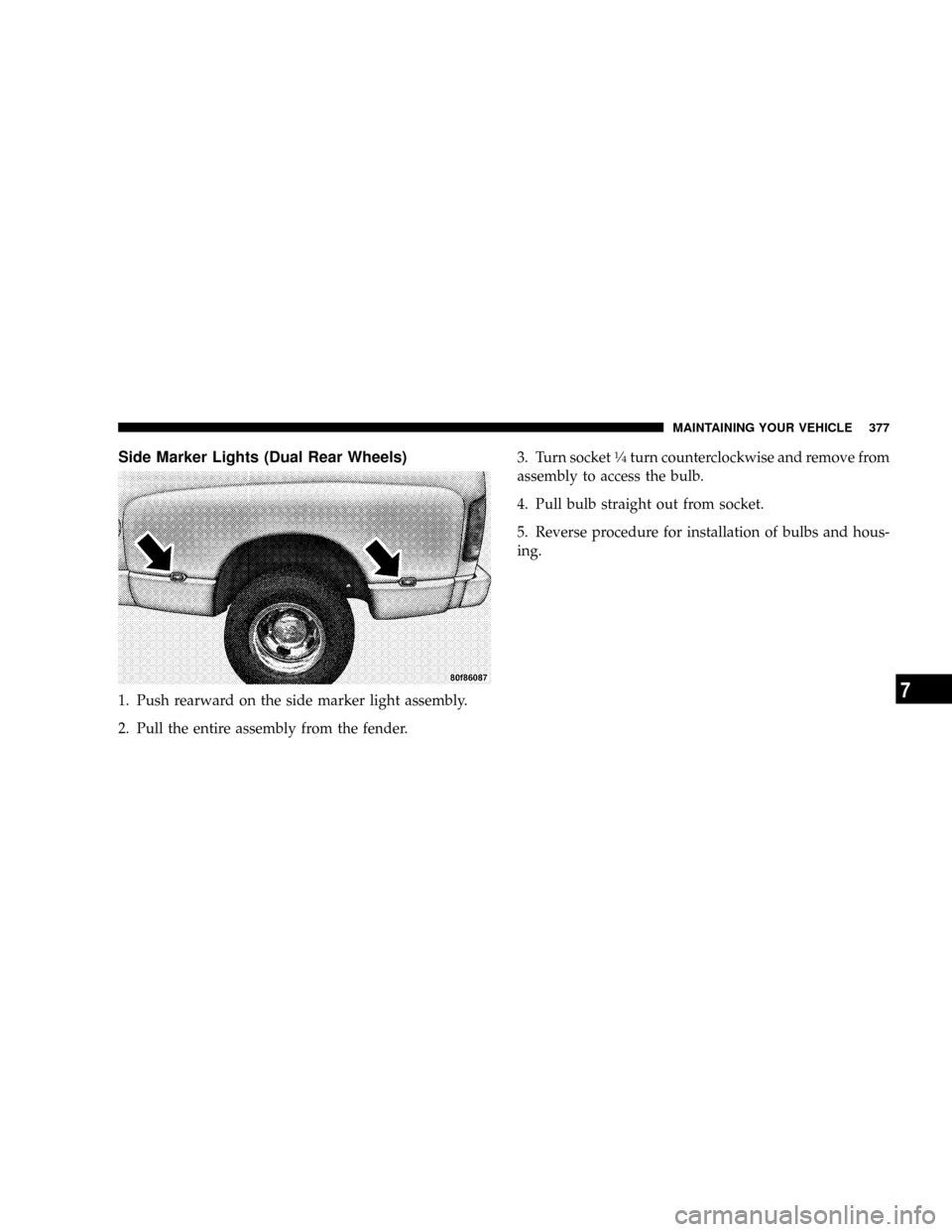

Side Marker Lights (Dual Rear Wheels)

1. Push rearward on the side marker light assembly.

2. Pull the entire assembly from the fender.3. Turn socket

1¤4turn counterclockwise and remove from

assembly to access the bulb.

4. Pull bulb straight out from socket.

5. Reverse procedure for installation of bulbs and hous-

ing.

MAINTAINING YOUR VEHICLE 377

7

Page 378 of 429

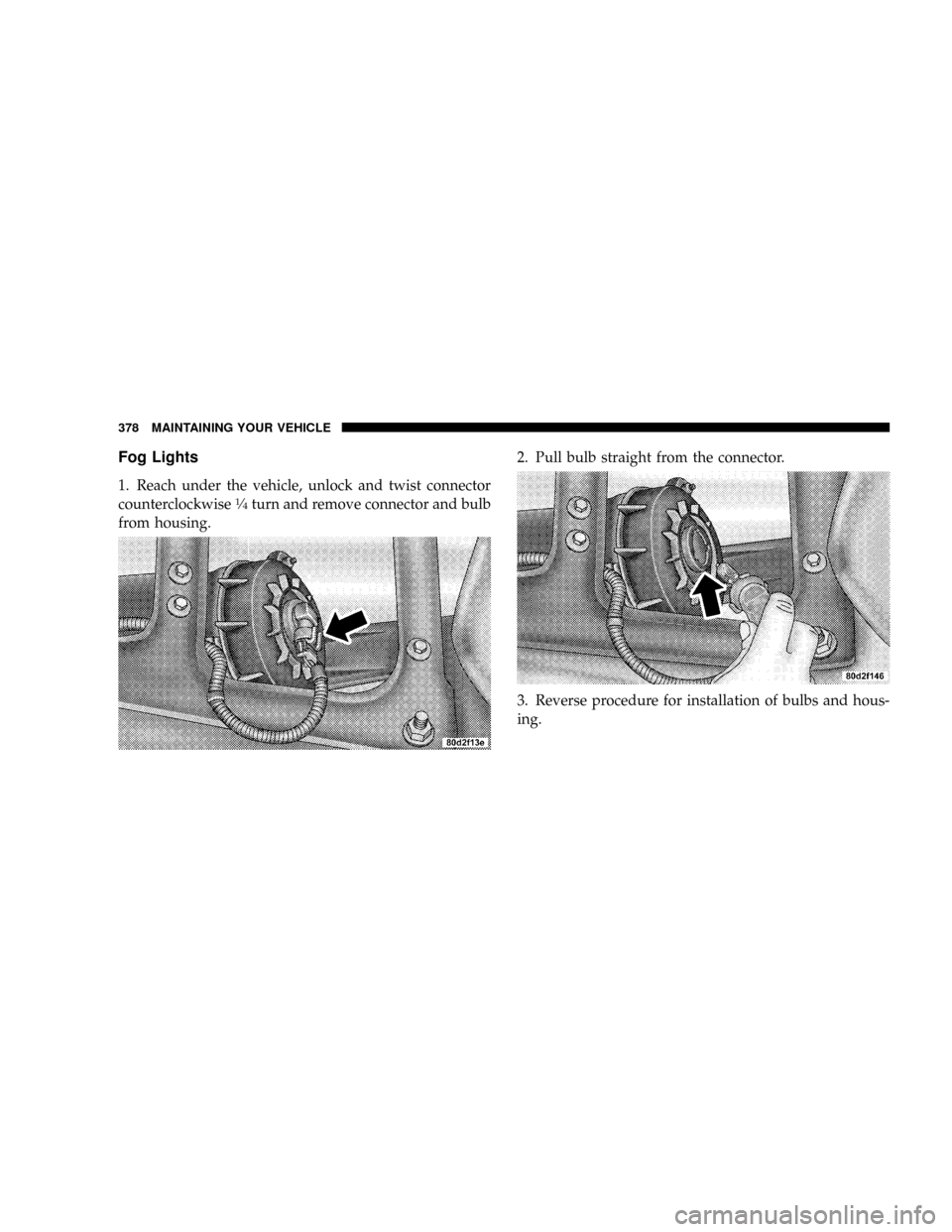

Fog Lights

1. Reach under the vehicle, unlock and twist connector

counterclockwise1¤4turn and remove connector and bulb

from housing.2. Pull bulb straight from the connector.

3. Reverse procedure for installation of bulbs and hous-

ing.

378 MAINTAINING YOUR VEHICLE

Page 416 of 429

Climate Control......................... 185

Clock................................ 151

Clutch............................... 349

Clutch Linkage Maintenance................ 350

Compact Disc Maintenance................. 184

Compact Disc Player..................158,164

Compact Spare Tire...................... 247

Compass.............................. 117

Compass Calibration..................... 117

Compass Variance....................... 118

Computer, Trip/Travel.................... 114

Console, Overhead....................... 113

Contract, Service........................ 406

Converter, Catalytic...................... 266

Cooling System......................... 344

Coolant Capacity...................... 379

Coolant Level......................... 344

Disposal of Used Coolant................ 347

Drain, Flush, and Refill.................. 345Inspection........................... 344

Radiator Cap......................344,347

Selection of Coolant...............346,379,381

Temperature Gauge..................... 146

Cruise Control.......................... 109

Cup Holder............................ 128

Customer Assistance..................... 404

Daytime Running Lights................... 102

Dealer Service.......................... 326

Defroster, Rear Window..............78,191,195

Defroster, Windshield..................186,189

Delay Wipers........................... 105

Differential, Limited-Slip.................. 228

Dipsticks

Automatic Transmission................. 352

Power Steering........................ 339

Disc Brakes............................ 348

416 INDEX