brake light DODGE RAM 1500 GAS 2006 3.G User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM 1500 GAS, Model: DODGE RAM 1500 GAS 2006 3.GPages: 536, PDF Size: 20.73 MB

Page 328 of 536

WARNING!

On vehicles equipped with a limited-slip differen-

tial, never run the engine with one rear wheel off the

ground, since the vehicle may drive through the rear

wheel remaining on the ground. You could lose

control of the vehicle.

Care should be taken to avoid sudden accelerations when

both rear wheels are on a slippery surface. This could

cause both rear wheels to spin, and allow the vehicle to

slide sideways on the crowned surface of a road or in a

turn.

PARKING BRAKE

The foot operated parking brake is positioned below the

lower left corner of the instrument panel. To release the

parking brake, pull the parking brake release handle.

NOTE: The instrument cluster red brake warning light

will come on and flash to indicate that the parking brake

is applied. You must be sure that the parking brake is

fully applied before leaving the vehicle.

328 STARTING AND OPERATING

Page 331 of 536

also contribute to the noise condition. Repeated or con-

tinuous noises during braking may be an indication that

the brake linings are worn and in need of replacement.

Rear Wheel Anti-Lock Brake System — RWAL

The Anti-lock Brake System provides increased vehicle

stability and brake performance under most braking

conditions. The system automatically controls the opera-

tion of the rear brakes to prevent rear wheel lockup.

The system remains operational in the four-wheel drive

mode. The level of performance is reduced when the

front brakes are locked up. This may cause the rear

brakes to lockup through the drivetrain, which may

reduce the effectiveness of the Anti-lock Brake System.

During severe braking conditions, particularly with

changing road surfaces, such as ice to concrete, a slight

drop or minor pulsation may be felt in the brake pedal.

WARNING!

Both Anti-Lock Brake Systems contain sophisticated

electronic equipment. It may be susceptible to inter-

ference caused by improperly installed or high out-

put radio transmitting equipment. This interference

can cause possible loss of anti-lock braking capabil-

ity. Installation of such equipment should be per-

formed by qualified professionals.

Four-Wheel Anti-Lock Brake System — If

Equipped

This Anti-lock Brake System is designed to aid the driver

in maintaining vehicle control under adverse braking

conditions. The system operates with a separate com-

puter to modulate hydraulic pressure to prevent wheel

lockup and help avoid skidding on slippery surfaces.

STARTING AND OPERATING 331

5

Page 332 of 536

The system’s pump motor runs during an ABS stop to

provide regulated hydraulic pressure. The pump motor

makes a low humming noise during operation. This is

normal.

When you are in a severe braking condition involving

use of the Anti-lock Brake System, you will experience

some pedal drop as the vehicle comes to a complete stop.

This is the result of the system reverting to the base brake

system and is normal.

Engagement of the Anti-lock Brake System may be

accompanied by a pulsing sensation. You may also hear a

clicking noise. These occurrences are normal, and indi-

cate that the system is functioning.

ABS Warning Light

The Anti-lock Brake System includes an amber warning

light. When the light is illuminated, the Anti-lock Brake

System is not functioning. The system reverts to standard

non-anti-lock brakes.

WARNING!

Pumping of the anti-lock brakes will diminish their

effectiveness and may lead to an accident. Pumping

makes the stopping distance longer. Just press firmly

on your brake pedal when you need to slow down or

stop.

332 STARTING AND OPERATING

Page 378 of 536

WARNING!

Do not connect trailer brakes to your vehicle’s hy-

draulic brake lines. It can overload your brake sys-

tem and cause it to fail. You might not have brakes

when you need them and could have an accident.

Towing any trailer will increase your stopping dis-

tance. When towing you should allow for additional

space between your vehicle and the vehicle in front

of you. Failure to do so could result in an accident.

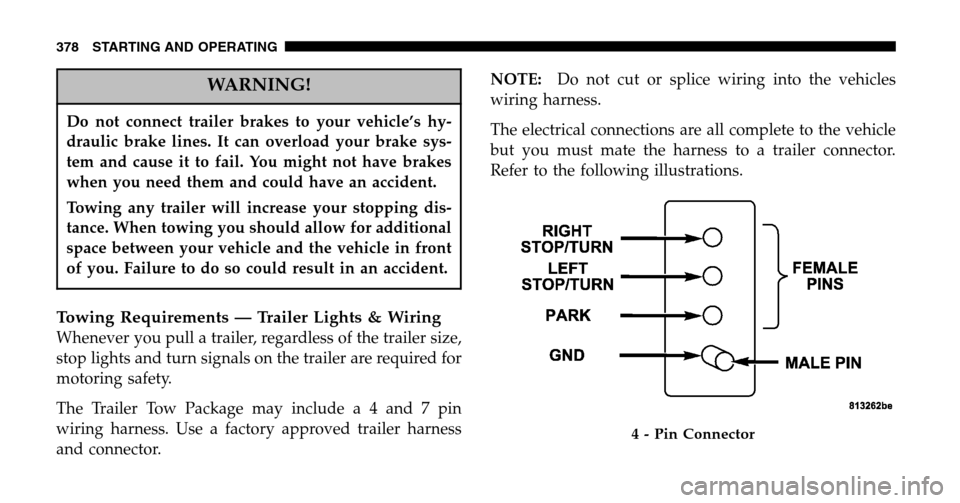

Towing Requirements — Trailer Lights & Wiring

Whenever you pull a trailer, regardless of the trailer size,

stop lights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may includ ea4and7pin

wiring harness. Use a factory approved trailer harness

and connector. NOTE:

Do not cut or splice wiring into the vehicles

wiring harness.

The electrical connections are all complete to the vehicle

but you must mate the harness to a trailer connector.

Refer to the following illustrations.

4 - Pin Connector

378 STARTING AND OPERATING

Page 391 of 536

6. Using the point of a ballpoint pen or similar object,

depress the recessed transfer case Neutral (N) button for

4 seconds.

7. After shift is completed and the Neutral (N) light

comes on release Neutral (N) button.

8. Start engine.

9. Shift automatic transmission into Reverse (R).

10. Release brake pedal for five seconds and ensure that

there is no vehicle movement.

11. Repeat steps 9 and 10 with the transmission in Drive

(D).

12. Shut engine OFF and place ignition key to the

unlocked OFF position.

13. Shift automatic transmission into Park (P).

14. Apply parking brake. 15. Attach vehicle to tow vehicle with tow bar.

16. Release parking brake.

NOTE:

Items 1 through 5 are requirements that must be

met prior to depressing the Neutral (N) selection button,

and must continue to be met until the 4 seconds elapses

and the shift has been completed. If any of these require-

ments (with the exception o f 3 - Key ON) are not met

prior to depressing the Neutral (N) button or are no

longer met during the 4 second timer, then the Neutral

(N) indicator light will flash continuously until all re-

quirements are met or until the Neutral (N) button is

released.

NOTE: The ignition key must be ON for a shift to take

place and for the position indicator lights to be operable.

If the key in not ON, the shift will not take place and no

position indicator lights will be on or flashing.

STARTING AND OPERATING 391

5

Page 392 of 536

NOTE:Flashing neutral (N) position indicator light

indicates that shift requirements have not been met.

CAUTION!

Damage to the transmission may occur if the trans-

mission is shifted into Park (P) with the transfer case

in Neutral (N) and the engine RUNNING. With the

transfer case in Neutral (N) ensure that the engine is

OFF prior to shifting the transmission into Park (P).

Returning to Normal Operation — Electronic Shift

Transfer Case

Use the following procedure to prepare your vehicle for

normal usage.

1. Bring vehicle to a complete stop.

2. Shut OFF the engine. 3. Turn the ignition key to the ON position, but do not

start the engine.

4. Depress the brake pedal.

5. Shift automatic transmission to Neutral (N) or depress

clutch on manual transmission.

6. Using the point of a ballpoint pen or similar object,

depress the recessed transfer case Neutral (N) button for

1 second.

7. After the Neutral (N) indicator light turns off release

the Neutral (N) button.

8. After the Neutral (N) button has been released the

transfer case will shift to the position identified by the

selector switch.

9. Shift automatic transmission into P (Park).

NOTE:

The transfer case can not be shifted into Neutral

(N) from the 4Auto (if equipped) position.

392 STARTING AND OPERATING

Page 393 of 536

NOTE:Items 1 through 5 are requirements that must be

met prior to depressing the Neutral (N) selection button,

and must continue to be met until 1 second elapses and

the shift has been completed. If any of these requirements

(with the exception o f 3 - key ON) are not met prior to

depressing the Neutral (N) button or are no longer met

during the 1 second time, then all of the mode position

indicator lights will flash continuously until all require-

ments are met or until the Neutral (N) button is released.

NOTE: The ignition key must be ON for a shift to take

place and for the position indicator lights to be operable.

If the key is not ON, the shift will not take place and no

position indicator lights will be on or flashing.

NOTE: Flashing neutral (N) position indicator light

indicates that shift requirements have not been met.WARNING!

You or others could be injured if you leave the

vehicle unattended with the transfer case in the

Neutral (N) position without first fully engaging the

parking brake. The transfer case Neutral (N) position

disengages both the front and rear driveshafts from

the powertrain and will allow the vehicle to move

despite the transmission position. The parking

brake should always be applied when the driver is

not in the vehicle.

STARTING AND OPERATING 393

5

Page 455 of 536

5. Remove the dipstick, wipe it clean and reinsert it until

seated.

6. Remove the dipstick again and note the fluid level on

both sides. The fluid level should be between the “HOT”

(upper) reference holes on the dipstick at normal operat-

ing temperature. Verify that solid coating of oil is seen on

both sides of the dipstick. If the fluid is low, add as

required into the dipstick tube. Do not overfill.After

adding any quantity of oil through the oil fill tube, wait

a minimum of two (2) minutes for the oil to fully drain

into the transmission before rechecking the fluid level.

NOTE: If it is necessary to check the transmission below

the operating temperature, the fluid level should be

between the two “COLD” (lower) holes on the dipstick

with the fluid at approximately 70°F (21°C) (room tem-

perature). If the fluid level is correctly established at

room temperature, it should be between the “HOT” (upper) reference holes when the transmission reaches

180°F (82°C). Remember it is best to check the level at the

normal operating temperature.

CAUTION!

Be aware that if the fluid temperature is below 50°F

(10°C) it may not register on the dipstick. Do not add

fluid until the temperature is elevated enough to

produce an accurate reading.

7. Check for leaks. Release parking brake.

To prevent dirt and water from entering the transmission

after checking or replenishing fluid, make certain that the

dipstick cap is properly reseated. It is normal for the

dipstick cap to spring back slightly from its fully seated

position, as long as its seal remains engaged in the

dipstick tube.

MAINTAINING YOUR VEHICLE 455

7

Page 490 of 536

At Each Stop for Fuel

•Check the engine oil level about 5 minutes after a fully

warmed engine is shut off. Checking the oil level while

the vehicle is on level ground will improve the accu-

racy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

•Check the windshield washer solvent and add if

required. When refilling the washer fluid reservoir,

take some washer fluid and apply it to a cloth or towel

and wipe clean the wiper blades, this will help blade

performance.

Once a Month

•Check tire pressure and look for unusual wear or

damage.

•Inspect the battery and clean and tighten the terminals

as required.

•Check the fluid levels of coolant bottle, brake master

cylinder, and transmission and add as needed.

•Check all lights and all other electrical items for correct

operation.

At Each Oil Change

•Change the engine oil filter.

•Lubricate Drivetrain/Steering/Suspension Grease Fit-

tings (if equipped)

•Inspect the exhaust system.

•Inspect the brake hoses.

•Inspect the CV joints/U— joints (if equipped) and

front suspension components.

•Check the automatic transmission fluid level.

•Check the manual transmission fluid level.

•Check the coolant level, hoses, and clamps.

•Lubricate Front Drive Shaft Fitting (2500/3500, 4X4).

490 MAINTENANCE SCHEDULES

8

M A I

N T

E

N A

N C E

S

C

H E

D

U L

E

S

Page 518 of 536

Adding Fuel........................... 360

Air Cleaner, Engine

(Engine Air Cleaner Filter) ..............436,459

Air Conditioner Maintenance ............... 440

Air Conditioning Refrigerant .............440,441

Air Conditioning System ................277,440

Air Conditioning System, Zone Control ........ 280

Air Pressure, Tires .................... 344,352

Airbag .......................... 43,50,80,86

Airbag Light ...................... 53,109,220

Airbag On/Off Switch ................... 50,86

Airbag, Side ............................ 89

Alarm (Security Alarm) .................26,222

Alignment and Balance ................... 351

Alterations/Modifications, Vehicle ............. 7

Antenna, Satellite Radio ................... 269

Antifreeze (Engine Coolant) ..............448,483

Anti-Lock Brake System (ABS) .............. 331

Anti-Lock Warning Light ...............224,332 Anti-Theft System

..................... 26,222

Appearance Care ........................ 462

Ashtray ............................... 194

Automatic Transmission Adding Fluid ......................... 455

Fluid and Filter Changes ................. 456

Fluid Level Check ...................... 454

Fluid Type ........................ 456,486

Shift Indicator ........................ 222

Shifting ............................. 299

Special Additives ...................... 456

Axle Fluid .......................... 452,486

Axle Lubrication (Axle Fluid) ............... 452

Ball Joints ............................. 441

Battery ............................... 439

Emergency Starting ..................... 416

Saving Feature (Protection) ............... 163

Bearings .............................. 457

518 INDEX