sensor DODGE RAM 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: RAM, Model: DODGE RAM 1999Pages: 1691, PDF Size: 40.34 MB

Page 960 of 1691

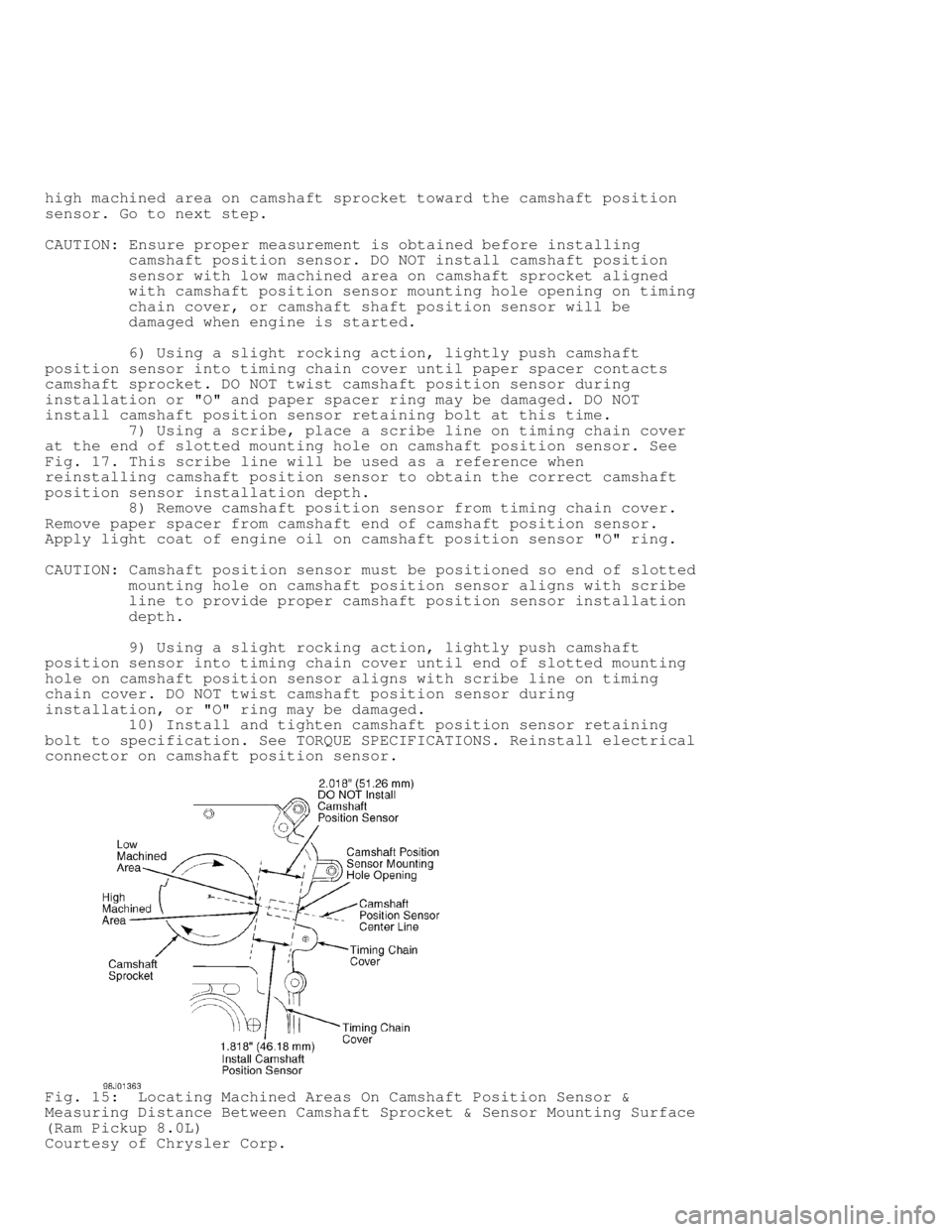

high machined area on camshaft sprocket toward the camshaft position

sensor. Go to next step.

CAUTION: Ensure proper measurement is obtained before installing

camshaft position sensor. DO NOT install camshaft position

sensor with low machined area on camshaft sprocket aligned

with camshaft position sensor mounting hole opening on timing

chain cover, or camshaft shaft position sensor will be

damaged when engine is started.

6) Using a slight rocking action, lightly push camshaft

position sensor into timing chain cover until paper spacer contacts

camshaft sprocket. DO NOT twist camshaft position sensor during

installation or "O" and paper spacer ring may be damaged. DO NOT

install camshaft position sensor retaining bolt at this time.

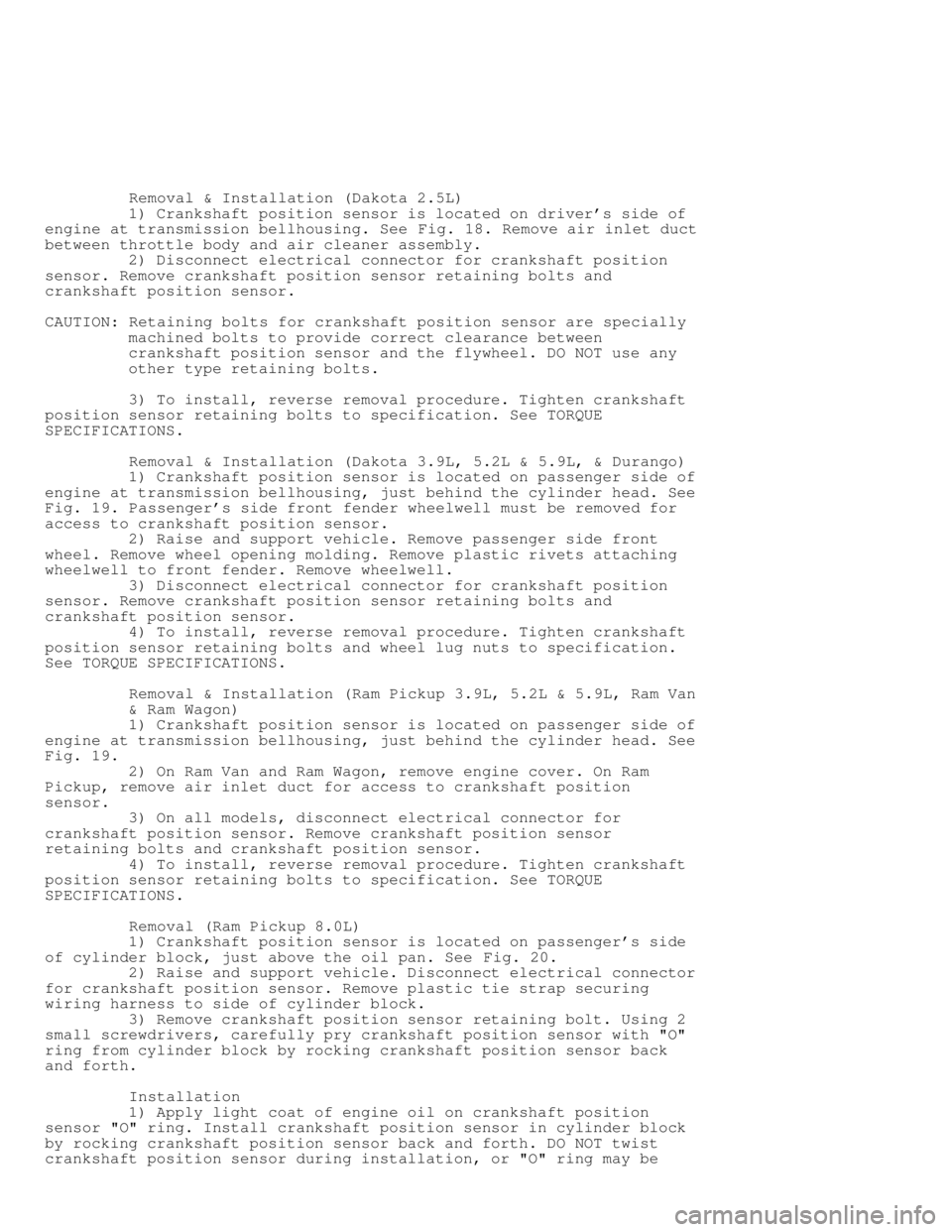

7) Using a scribe, place a scribe line on timing chain cover

at the end of slotted mounting hole on camshaft position sensor. See

Fig. 17 . This scribe line will be used as a reference when

reinstalling camshaft position sensor to obtain the correct camshaft

position sensor installation depth.

8) Remove camshaft position sensor from timing chain cover.

Remove paper spacer from camshaft end of camshaft position sensor.

Apply light coat of engine oil on camshaft position sensor "O" ring.

CAUTION: Camshaft position sensor must be positioned so end of slotted

mounting hole on camshaft position sensor aligns with scribe

line to provide proper camshaft position sensor installation

depth.

9) Using a slight rocking action, lightly push camshaft

position sensor into timing chain cover until end of slotted mounting

hole on camshaft position sensor aligns with scribe line on timing

chain cover. DO NOT twist camshaft position sensor during

installation, or "O" ring may be damaged.

10) Install and tighten camshaft position sensor retaining

bolt to specification. See TORQUE SPECIFICATIONS. Reinstall electrical

connector on camshaft position sensor.

Fig. 15: Locating Machined Areas On Camshaft Position Sensor &

Measuring Distance Between Camshaft Sprocket & Sensor Mounting Surface

(Ram Pickup 8.0L)

Courtesy of Chrysler Corp.

Page 961 of 1691

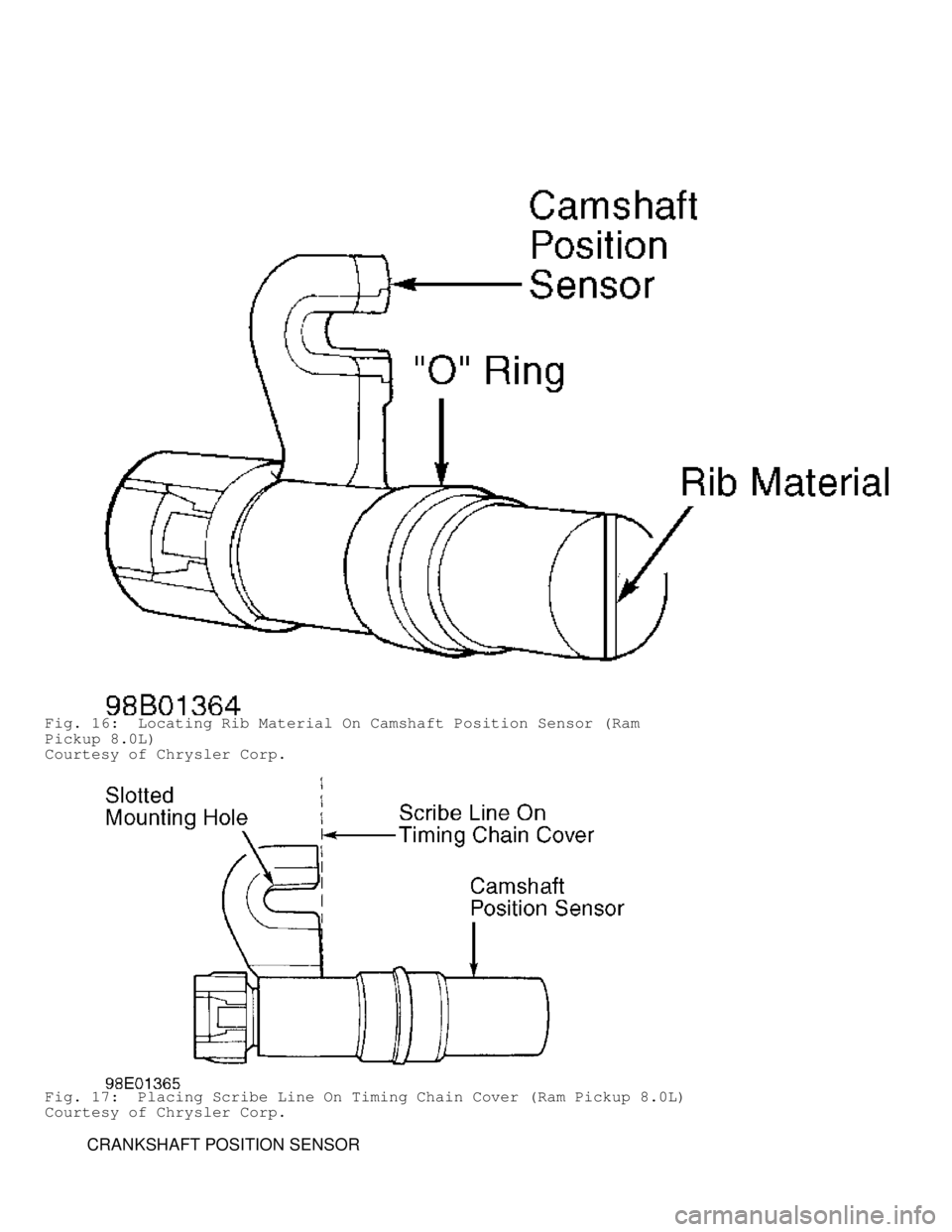

Fig. 16: Locating Rib Material On Camshaft Position Sensor (Ram

Pickup 8.0L)

Courtesy of Chrysler Corp.

Fig. 17: Placing Scribe Line On Timing Chain Cover (Ram Pickup 8.0L)

Courtesy of Chrysler Corp.

CRANKSHAFT POSITION SENSOR

Page 962 of 1691

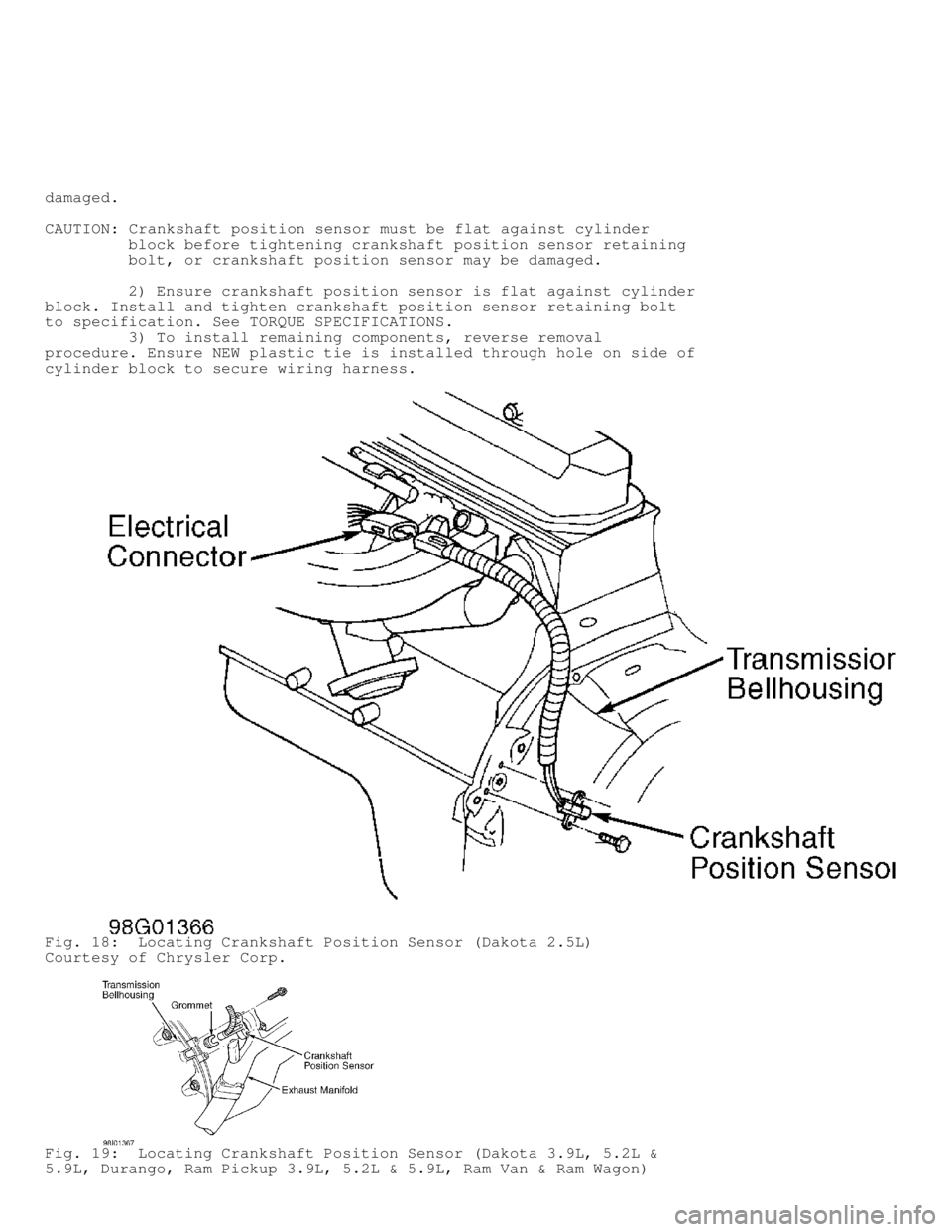

Removal & Installation (Dakota 2.5L)

1) Crankshaft position sensor is located on driver's side of

engine at transmission bellhousing. See Fig. 18. Remove air inlet duct

between throttle body and air cleaner assembly.

2) Disconnect electrical connector for crankshaft position

sensor. Remove crankshaft position sensor retaining bolts and

crankshaft position sensor.

CAUTION: Retaining bolts for crankshaft position sensor are specially

machined bolts to provide correct clearance between

crankshaft position sensor and the flywheel. DO NOT use any

other type retaining bolts.

3) To install, reverse removal procedure. Tighten crankshaft

position sensor retaining bolts to specification. See TORQUE

SPECIFICATIONS.

Removal & Installation (Dakota 3.9L, 5.2L & 5.9L, & Durango)

1) Crankshaft position sensor is located on passenger side of

engine at transmission bellhousing, just behind the cylinder head. See

Fig. 19 . Passenger's side front fender wheelwell must be removed for

access to crankshaft position sensor.

2) Raise and support vehicle. Remove passenger side front

wheel. Remove wheel opening molding. Remove plastic rivets attaching

wheelwell to front fender. Remove wheelwell.

3) Disconnect electrical connector for crankshaft position

sensor. Remove crankshaft position sensor retaining bolts and

crankshaft position sensor.

4) To install, reverse removal procedure. Tighten crankshaft

position sensor retaining bolts and wheel lug nuts to specification.

See TORQUE SPECIFICATIONS.

Removal & Installation (Ram Pickup 3.9L, 5.2L & 5.9L, Ram Van

& Ram Wagon)

1) Crankshaft position sensor is located on passenger side of

engine at transmission bellhousing, just behind the cylinder head. See

Fig. 19 .

2) On Ram Van and Ram Wagon, remove engine cover. On Ram

Pickup, remove air inlet duct for access to crankshaft position

sensor.

3) On all models, disconnect electrical connector for

crankshaft position sensor. Remove crankshaft position sensor

retaining bolts and crankshaft position sensor.

4) To install, reverse removal procedure. Tighten crankshaft

position sensor retaining bolts to specification. See TORQUE

SPECIFICATIONS.

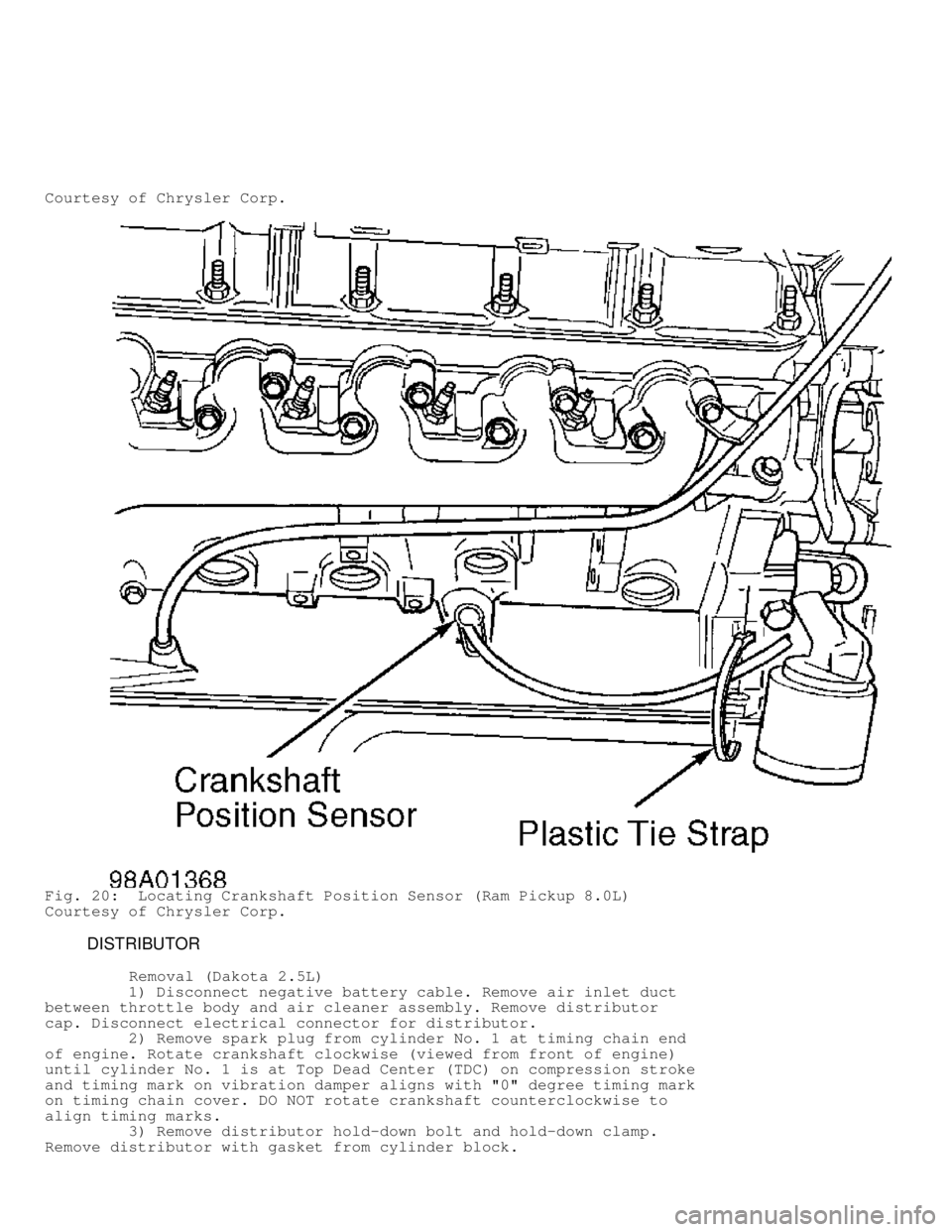

Removal (Ram Pickup 8.0L)

1) Crankshaft position sensor is located on passenger's side

of cylinder block, just above the oil pan. See Fig. 20.

2) Raise and support vehicle. Disconnect electrical connector

for crankshaft position sensor. Remove plastic tie strap securing

wiring harness to side of cylinder block.

3) Remove crankshaft position sensor retaining bolt. Using 2

small screwdrivers, carefully pry crankshaft position sensor with "O"

ring from cylinder block by rocking crankshaft position sensor back

and forth.

Installation

1) Apply light coat of engine oil on crankshaft position

sensor "O" ring. Install crankshaft position sensor in cylinder block

by rocking crankshaft position sensor back and forth. DO NOT twist

crankshaft position sensor during installation, or "O" ring may be

Page 963 of 1691

damaged.

CAUTION: Crankshaft position sensor must be flat against cylinder

block before tightening crankshaft position sensor retaining

bolt, or crankshaft position sensor may be damaged.

2) Ensure crankshaft position sensor is flat against cylinder

block. Install and tighten crankshaft position sensor retaining bolt

to specification. See TORQUE SPECIFICATIONS.

3) To install remaining components, reverse removal

procedure. Ensure NEW plastic tie is installed through hole on side of

cylinder block to secure wiring harness.

Fig. 18: Locating Crankshaft Position Sensor (Dakota 2.5L)

Courtesy of Chrysler Corp.

Fig. 19: Locating Crankshaft Position Sensor (Dakota 3.9L, 5.2L &

5.9L, Durango, Ram Pickup 3.9L, 5.2L & 5.9L, Ram Van & Ram Wagon)

Page 964 of 1691

Courtesy of Chrysler Corp.

Fig. 20: Locating Crankshaft Position Sensor (Ram Pickup 8.0L)

Courtesy of Chrysler Corp.

DISTRIBUTOR

Removal (Dakota 2.5L)

1) Disconnect negative battery cable. Remove air inlet duct

between throttle body and air cleaner assembly. Remove distributor

cap. Disconnect electrical connector for distributor.

2) Remove spark plug from cylinder No. 1 at timing chain end

of engine. Rotate crankshaft clockwise (viewed from front of engine)

until cylinder No. 1 is at Top Dead Center (TDC) on compression stroke\

and timing mark on vibration damper aligns with "0" degree timing mark

on timing chain cover. DO NOT rotate crankshaft counterclockwise to

align timing marks.

3) Remove distributor hold-down bolt and hold-down clamp.

Remove distributor with gasket from cylinder block.

Page 966 of 1691

rotate crankshaft clockwise (viewed from front of engine) until

cylinder No. 1 is at Top Dead Center (TDC) on compression stroke and

timing mark on vibration damper aligns with "0" degree timing mark on

timing chain cover. DO NOT rotate crankshaft counterclockwise to align

timing marks. Go to next step.

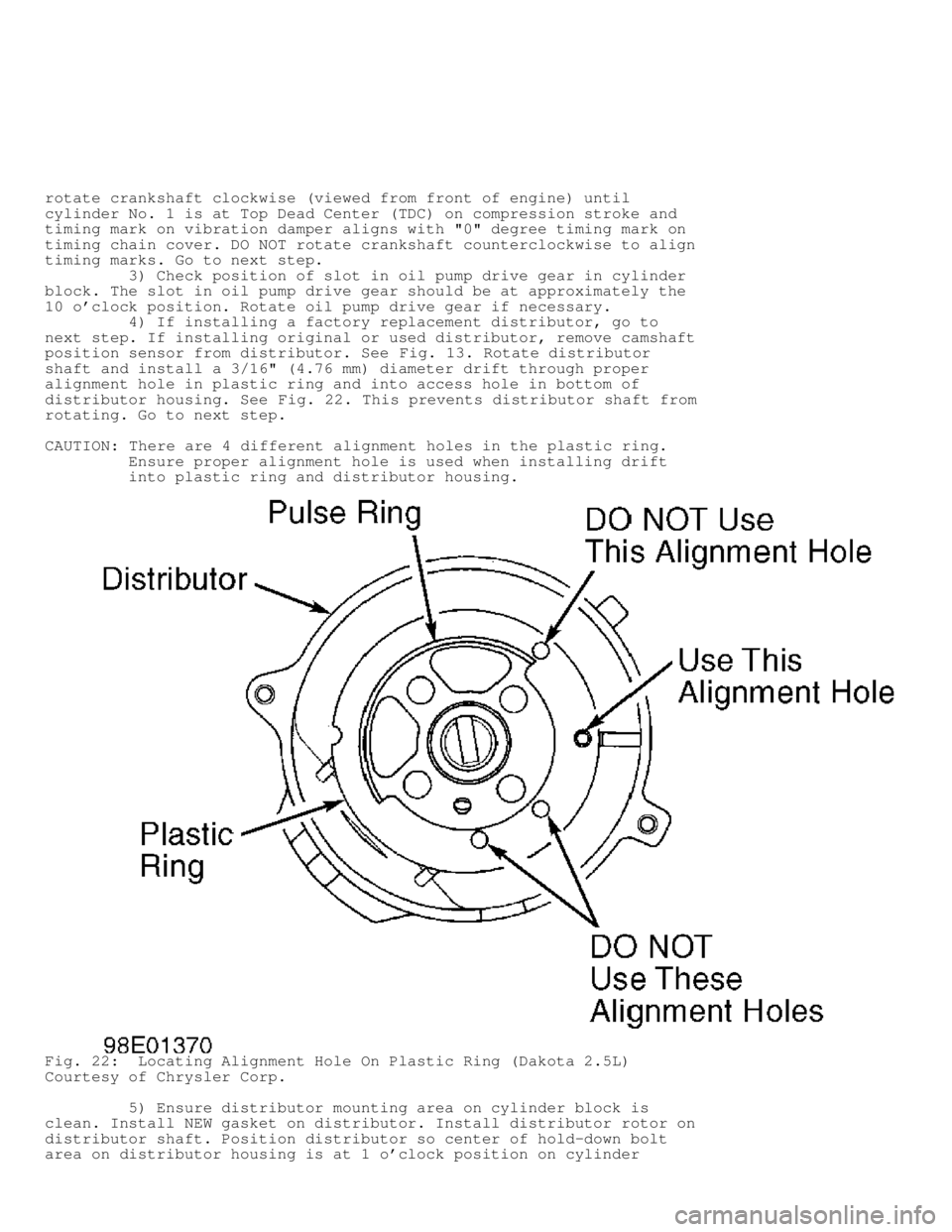

3) Check position of slot in oil pump drive gear in cylinder

block. The slot in oil pump drive gear should be at approximately the

10 o'clock position. Rotate oil pump drive gear if necessary.

4) If installing a factory replacement distributor, go to

next step. If installing original or used distributor, remove camshaft

position sensor from distributor. See Fig. 13. Rotate distributor

shaft and install a 3/16" (4.76 mm) diameter drift through proper

alignment hole in plastic ring and into access hole in bottom of

distributor housing. See Fig. 22. This prevents distributor shaft from

rotating. Go to next step.

CAUTION: There are 4 different alignment holes in the plastic ring.

Ensure proper alignment hole is used when installing drift

into plastic ring and distributor housing.

Fig. 22: Locating Alignment Hole On Plastic Ring (Dakota 2.5L)

Courtesy of Chrysler Corp.

5) Ensure distributor mounting area on cylinder block is

clean. Install NEW gasket on distributor. Install distributor rotor on

distributor shaft. Position distributor so center of hold-down bolt

area on distributor housing is at 1 o'clock position on cylinder

Page 967 of 1691

block. Install distributor so distributor shaft engages with slot in

oil pump drive gear. It may be necessary to slightly rotate

distributor during installation.

6) When distributor is fully seated, the distributor rotor

should be at 3 o'clock position and center of hold-down bolt area on

distributor housing should align with distributor hold-down bolt area

on cylinder block.

7) Install hold-down clamp and distributor hold-down bolt.

Tighten distributor hold-down bolt to specification. See TORQUE

SPECIFICATIONS.

8) If installing a factory replacement distributor, remove

plastic alignment pin from distributor housing. If installing original

or used distributor, remove drift from distributor housing and

reinstall camshaft position sensor. On all applications, install

distributor cap and remaining components. Base ignition timing is

nonadjustable, as ignition timing and timing advance are controlled by

the Powertrain Control Module (PCM).

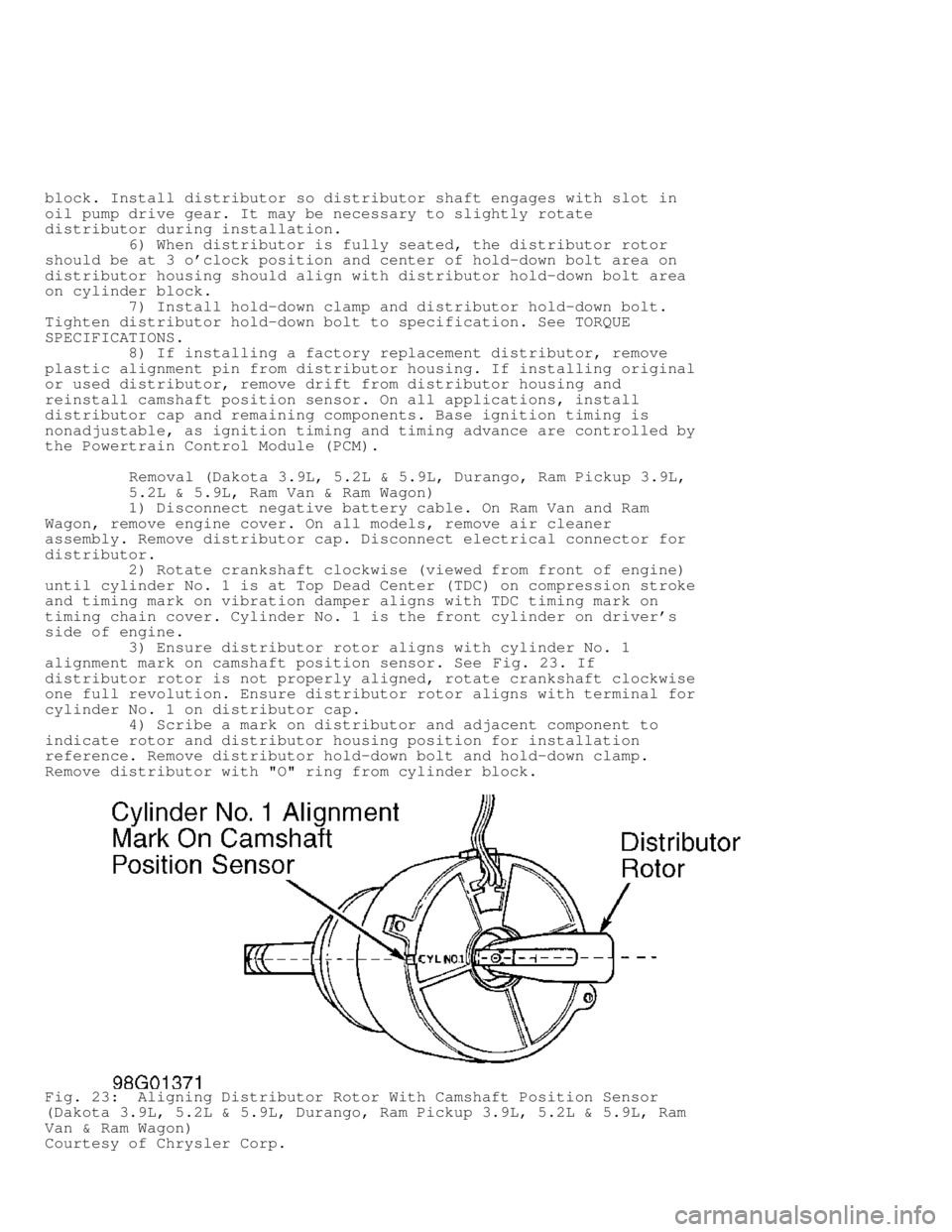

Removal (Dakota 3.9L, 5.2L & 5.9L, Durango, Ram Pickup 3.9L,

5.2L & 5.9L, Ram Van & Ram Wagon)

1) Disconnect negative battery cable. On Ram Van and Ram

Wagon, remove engine cover. On all models, remove air cleaner

assembly. Remove distributor cap. Disconnect electrical connector for

distributor.

2) Rotate crankshaft clockwise (viewed from front of engine)\

until cylinder No. 1 is at Top Dead Center (TDC) on compression stroke\

and timing mark on vibration damper aligns with TDC timing mark on

timing chain cover. Cylinder No. 1 is the front cylinder on driver's

side of engine.

3) Ensure distributor rotor aligns with cylinder No. 1

alignment mark on camshaft position sensor. See Fig. 23. If

distributor rotor is not properly aligned, rotate crankshaft clockwise

one full revolution. Ensure distributor rotor aligns with terminal for

cylinder No. 1 on distributor cap.

4) Scribe a mark on distributor and adjacent component to

indicate rotor and distributor housing position for installation

reference. Remove distributor hold-down bolt and hold-down clamp.

Remove distributor with "O" ring from cylinder block.

Fig. 23: Aligning Distributor Rotor With Camshaft Position Sensor

(Dakota 3.9L, 5.2L & 5.9L, Durango, Ram Pickup 3.9L, 5.2L & 5.9L, Ram

Van & Ram Wagon)

Courtesy of Chrysler Corp.

Page 968 of 1691

Installation

1) If engine has not been rotated after removing distributor,

go to next step. If engine was rotated after removing distributor,

rotate crankshaft clockwise (viewed from front of engine) until

cylinder No. 1 is at Top Dead Center (TDC) on compression stroke and

timing mark on vibration damper aligns with TDC timing mark on timing

chain cover. Go to next step.

2) Ensure distributor mounting area on cylinder block is

clean. Install NEW "O" ring on distributor if necessary. Apply light

coat of engine oil on "O" ring.

3) Position distributor rotor so it aligns with terminal for

cylinder No. 1 on distributor cap. Install distributor. Ensure

distributor engages with slot in oil pump drive gear. Install hold-

down clamp and distributor hold-down bolt. DO NOT tighten distributor

hold-down bolt at this time.

4) Rotate distributor until distributor rotor aligns with

cylinder No. 1 alignment mark on camshaft position sensor. See Fig. 23

. Tighten distributor hold-down bolt to specification. See TORQUE

SPECIFICATIONS. To install remaining components, reverse removal

procedure.

5) Base ignition timing is nonadjustable. Base ignition

timing and timing advance are controlled by the Powertrain Control

Module (PCM). Distributor position is used to determine the fuel

system synchronization. To check for correct distributor position and

fuel system synchronization, see FUEL SYSTEM SYNCHRONIZATION under

FUEL SYSTEM in ON-VEHICLE ADJUSTMENTS article.

IGNITION COIL

Removal & Installation (Dakota 2.5L)

Ignition coil is located on side of engine, near distributor.

Service procedure is primarily an unbolt and bolt-on procedure.

Tighten ignition coil retaining bolts or nuts to specification. See

TORQUE SPECIFICATIONS.

Removal & Installation (Dakota 3.9L, 5.2L & 5.9L, Durango &

Ram Van/Wagon)

1) Ignition coil is located on front of passenger's side

cylinder head. Disconnect spark plug wires and electrical connector

from ignition coil.

CAUTION: Ignition coil-to-cylinder head mounting bracket bolts hold

the idler pulley for the accessory drive belt, as these bolts

are under tension. If necessary to remove these bolts,

accessory drive belt must be removed first.

2) Remove ignition coil retaining bolts or nuts with ignition

coil from the ignition coil mounting bracket. DO NOT remove ignition

coil-to-cylinder head mounting bracket bolts, as these bolts are under

tension.

3) To install, reverse removal procedure. Tighten ignition

coil retaining bolts or nuts to specification. See TORQUE

SPECIFICATIONS.

Removal & Installation (Ram Pickup 3.9L, 5.2L & 5.9L)

1) On 3.9L, 5.2L and 5.9L with light-duty emissions, ignition

coil is located on front of passenger's side cylinder head. On 5.9L

with heavy-duty emissions, ignition coil is located on top of air

injection pump. On all models, disconnect spark plug wires and

electrical connector from ignition coil.

CAUTION: On 3.9L, 5.2L and 5.9L with light-duty emissions, ignition

coil-to-cylinder head mounting bracket bolts hold the idler

Page 976 of 1691

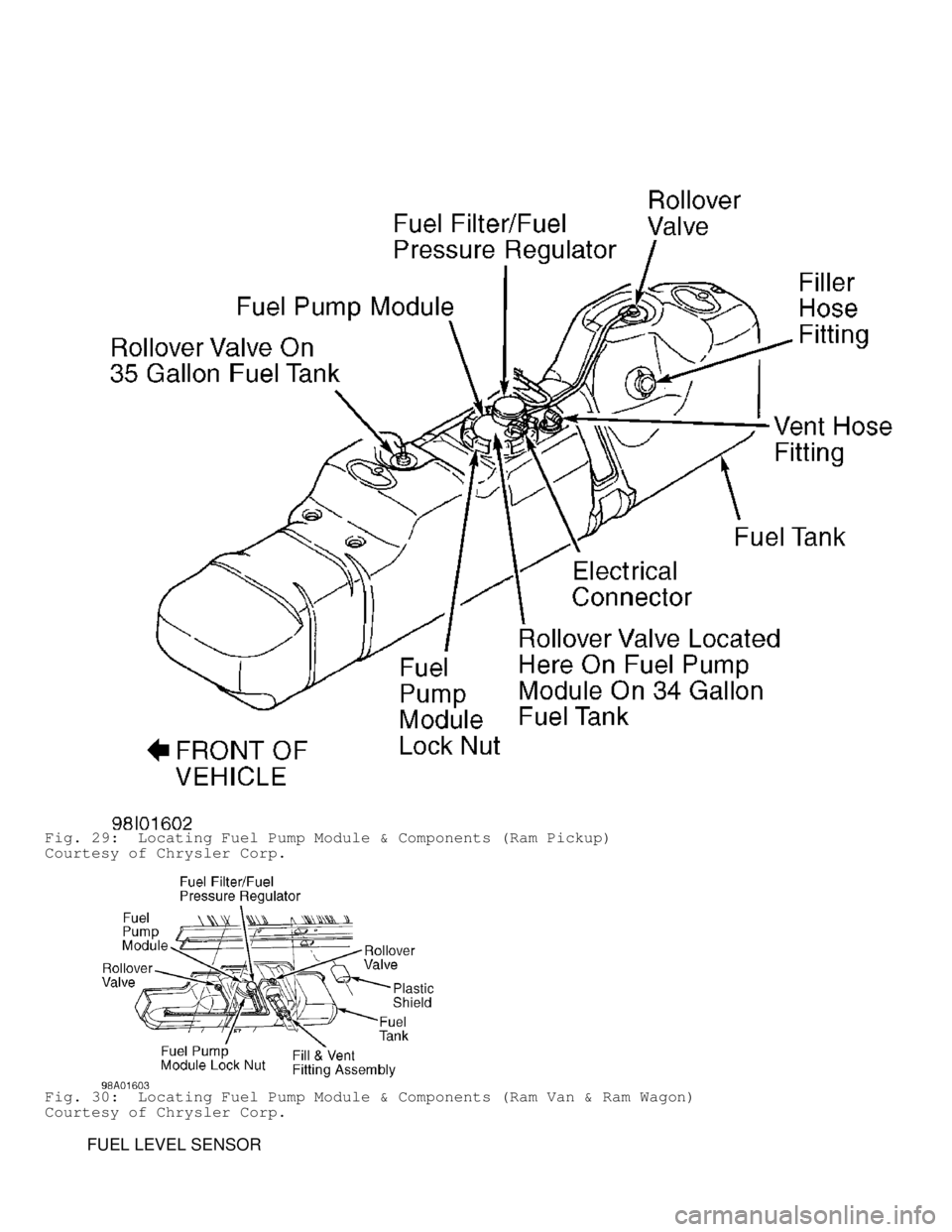

Fig. 29: Locating Fuel Pump Module & Components (Ram Pickup)

Courtesy of Chrysler Corp.

Fig. 30: Locating Fuel Pump Module & Components (Ram Van & Ram Wagon)\

Courtesy of Chrysler Corp.

FUEL LEVEL SENSOR

Page 977 of 1691

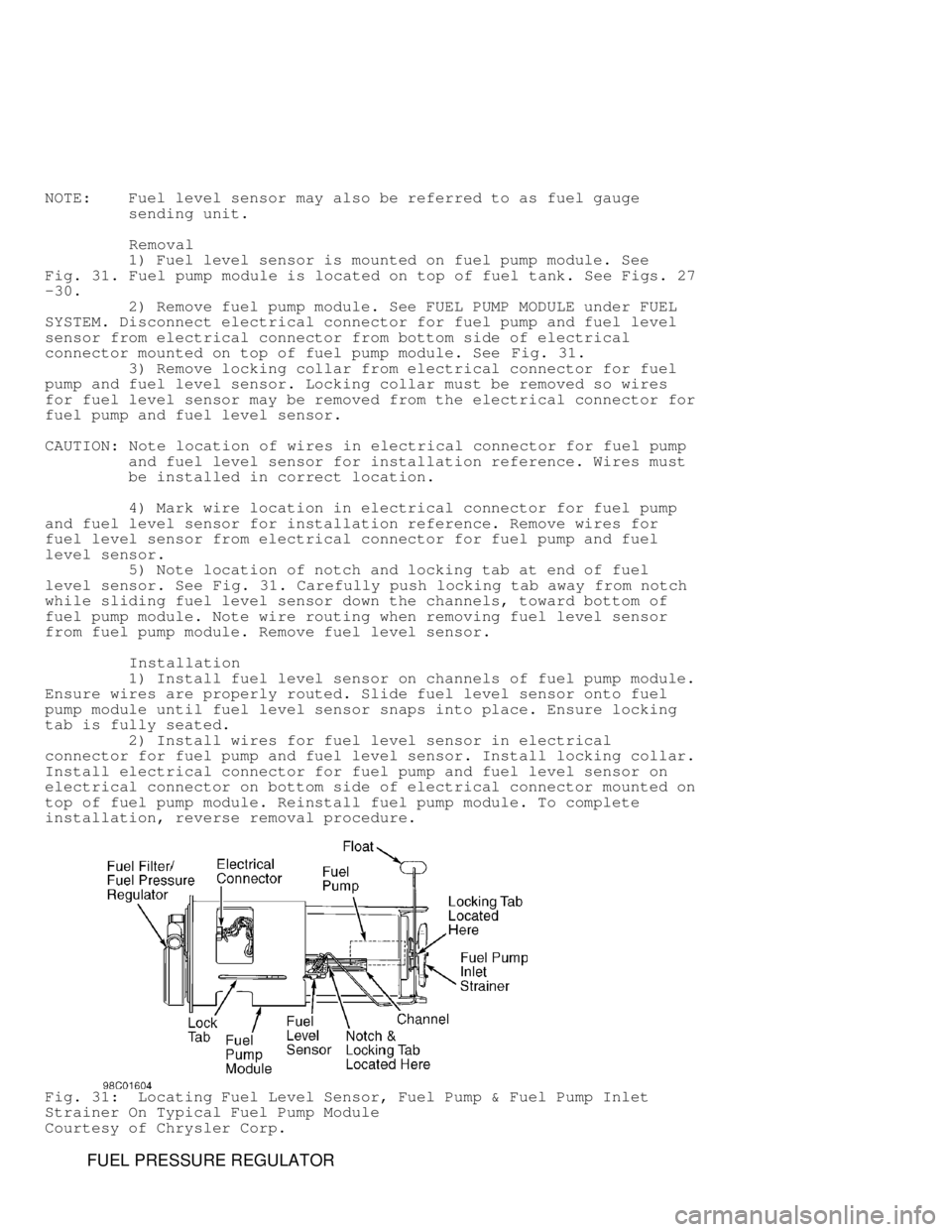

NOTE: Fuel level sensor may also be referred to as fuel gauge

sending unit.

Removal

1) Fuel level sensor is mounted on fuel pump module. See

Fig. 31 . Fuel pump module is located on top of fuel tank. See Figs. 27

-30.

2) Remove fuel pump module. See FUEL PUMP MODULE under FUEL

SYSTEM. Disconnect electrical connector for fuel pump and fuel level

sensor from electrical connector from bottom side of electrical

connector mounted on top of fuel pump module. See Fig. 31.

3) Remove locking collar from electrical connector for fuel

pump and fuel level sensor. Locking collar must be removed so wires

for fuel level sensor may be removed from the electrical connector for

fuel pump and fuel level sensor.

CAUTION: Note location of wires in electrical connector for fuel pump

and fuel level sensor for installation reference. Wires must

be installed in correct location.

4) Mark wire location in electrical connector for fuel pump

and fuel level sensor for installation reference. Remove wires for

fuel level sensor from electrical connector for fuel pump and fuel

level sensor.

5) Note location of notch and locking tab at end of fuel

level sensor. See Fig. 31. Carefully push locking tab away from notch

while sliding fuel level sensor down the channels, toward bottom of

fuel pump module. Note wire routing when removing fuel level sensor

from fuel pump module. Remove fuel level sensor.

Installation

1) Install fuel level sensor on channels of fuel pump module.

Ensure wires are properly routed. Slide fuel level sensor onto fuel

pump module until fuel level sensor snaps into place. Ensure locking

tab is fully seated.

2) Install wires for fuel level sensor in electrical

connector for fuel pump and fuel level sensor. Install locking collar.

Install electrical connector for fuel pump and fuel level sensor on

electrical connector on bottom side of electrical connector mounted on

top of fuel pump module. Reinstall fuel pump module. To complete

installation, reverse removal procedure.

Fig. 31: Locating Fuel Level Sensor, Fuel Pump & Fuel Pump Inlet

Strainer On Typical Fuel Pump Module

Courtesy of Chrysler Corp.

FUEL PRESSURE REGULATOR