Fuel lines DODGE RAM 1999 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: RAM, Model: DODGE RAM 1999Pages: 1691, PDF Size: 40.34 MB

Page 931 of 1691

2) Disconnect drain tube from drain valve. Disconnect

electrical connector for Water-In-Fuel (WIF) sensor at bottom of fuel

filter/water separator. See Fig. 3.

3) Support canister for fuel filter/water separator and

remove canister nut from top of filter mounting head. See Fig. 3.

Remove canister with fuel filter/water separator and seal ring from

filter mounting head. Remove fuel filter/water separator from

canister.

4) Remove "O" ring from top of shaft inside the canister.

Remove bolts and drain valve from canister (if necessary).

5) Check the 2 probes inside the canister on end of WIF

sensor for contamination. Clean probes if contaminated. If

contamination cannot be removed from the probes, replace WIF sensor.

If replacing WIF sensor, remove WIF sensor and "O" ring from canister.

6) Fuel heater is located inside fuel filter housing. Heater

mounting plate, heating element, temperature sensor, and wiring

harness are serviced as an assembly. Disconnect heater electrical

connector from engine wiring harness near upper rear part of filter.

7) Disconnect electrical connector at end of 2-wire harness

before attempting to pass harness through filter header. Remove clip

retaining wires to connector. Remove wires from connector. Remove 3

fuel heater screws. Press on heater sealing grommet to remove heater

from filter canister header. Pass wire through hole in filter header.

Remove fuel heater.

Installation

1) Ensure inside of canister is clean. Using NEW "O" ring,

install WIF sensor on canister (if removed). Tighten WIF sensor to

specification. See TORQUE SPECIFICATIONS.

2) Install drain valve on canister (if removed). Tighten

drain valve-to-canister bolts to specification. See TORQUE

SPECIFICATIONS.

3) Install NEW "O" ring on shaft inside canister. Coat "O"

ring with diesel fuel. Install NEW fuel filter/water separator and NEW

seal ring in canister. Coat seal ring with diesel fuel.

NOTE: Canister for fuel filter/water separator should be filled

with diesel fuel before installing. If canister cannot be

filled with diesel fuel, low-pressure fuel lines must be bled

after installation.

CAUTION: When installing canister on filter mounting head, ensure tab

areas on outside of canister align with tabs on filter

mounting head. This must be done to prevent damage to

canister and filter mounting head.

4) Fill canister for fuel filter/water separator with diesel

fuel. Install canister with fuel filter/water separator on filter

mounting head. Ensure canister fully engages with filter mounting head

and tab areas on outside of canister align with tabs on filter

mounting head.

5) Install and tighten canister nut to specification. See

TORQUE SPECIFICATIONS.

6) To install remaining components, reverse removal

procedure. If canister was not filled with diesel fuel, bleed low-

pressure fuel lines before starting engine. See FUEL LINE BLEEDING

under FUEL SYSTEM. Start engine and check for fuel leaks.

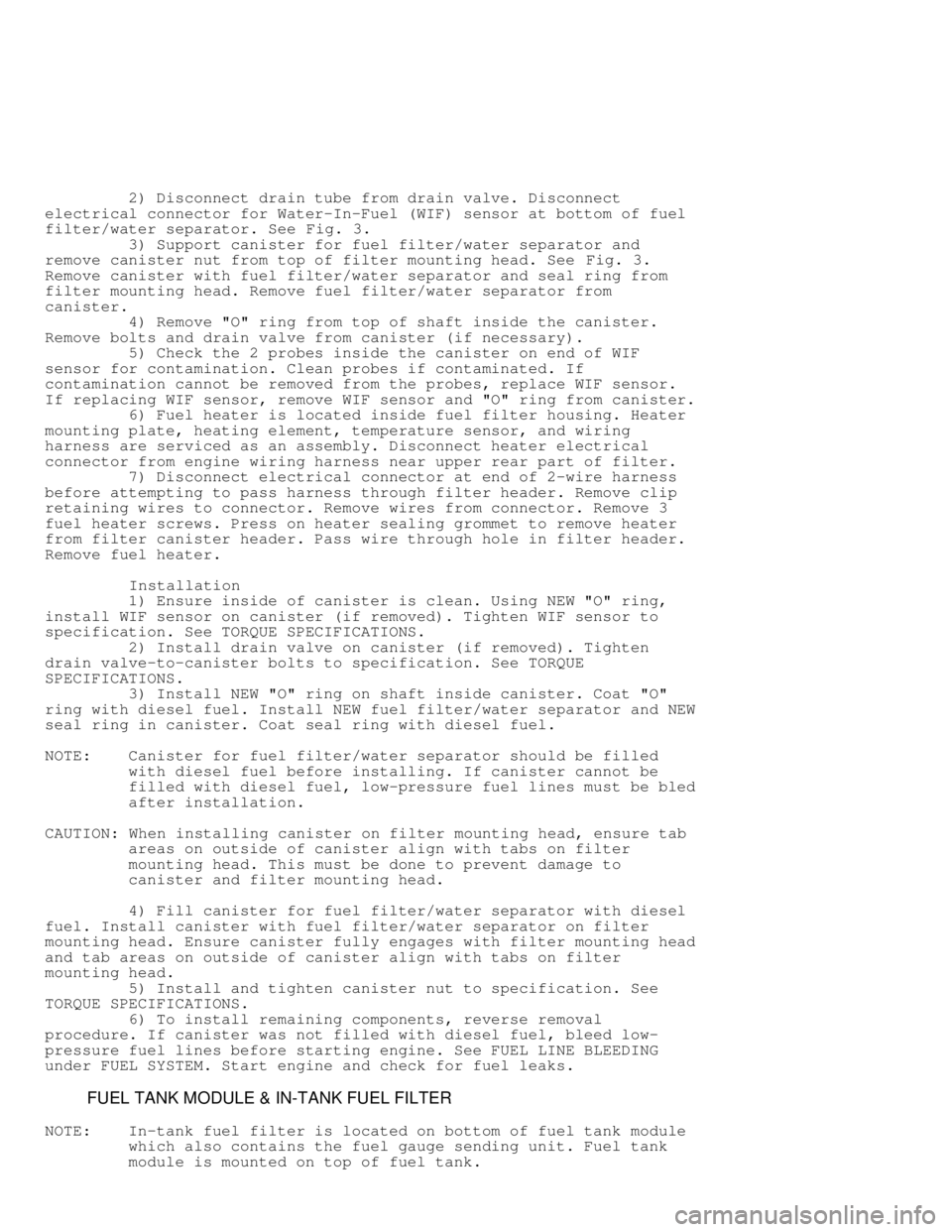

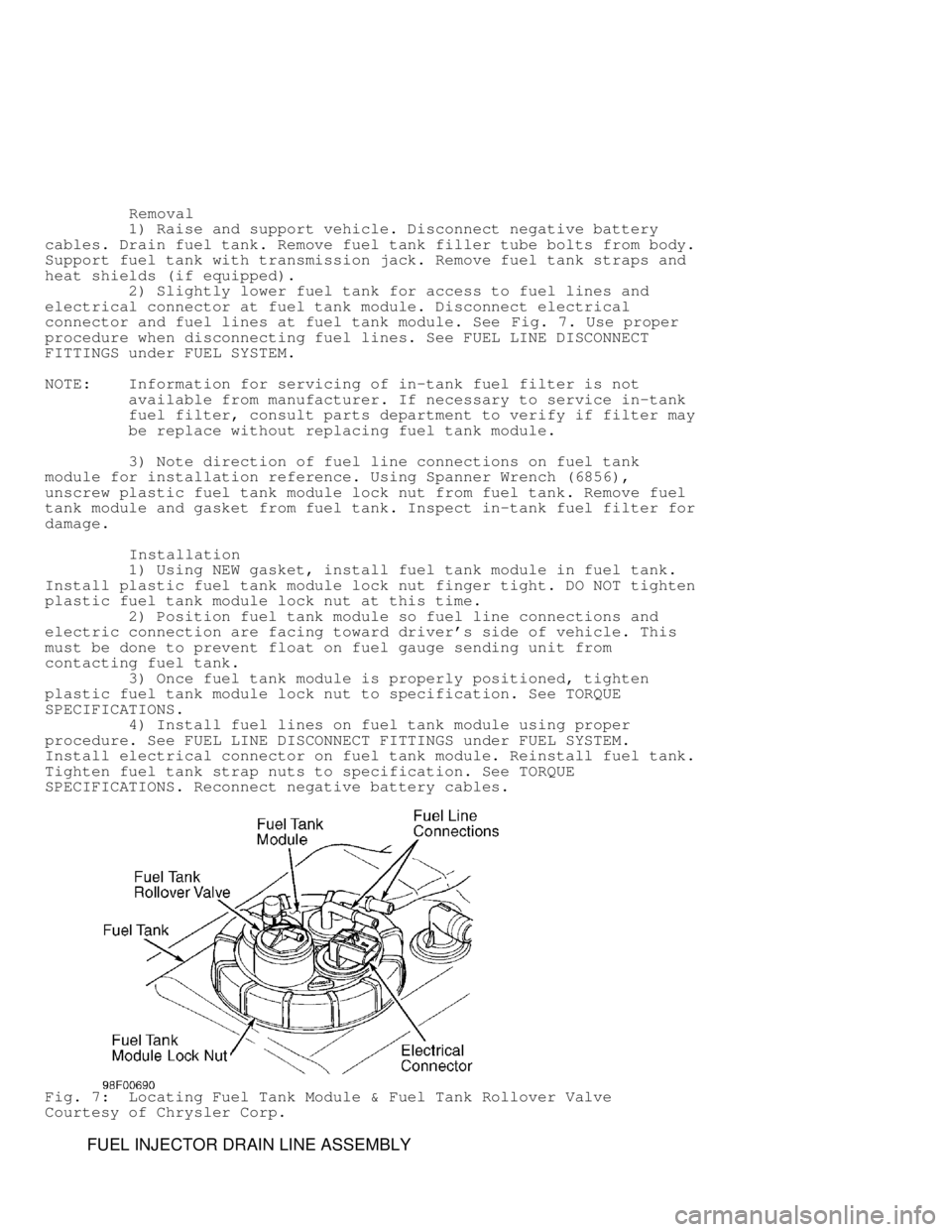

FUEL TANK MODULE & IN-TANK FUEL FILTER

NOTE: In-tank fuel filter is located on bottom of fuel tank module

which also contains the fuel gauge sending unit. Fuel tank

module is mounted on top of fuel tank.

Page 932 of 1691

Removal

1) Raise and support vehicle. Disconnect negative battery

cables. Drain fuel tank. Remove fuel tank filler tube bolts from body.

Support fuel tank with transmission jack. Remove fuel tank straps and

heat shields (if equipped).

2) Slightly lower fuel tank for access to fuel lines and

electrical connector at fuel tank module. Disconnect electrical

connector and fuel lines at fuel tank module. See Fig. 7. Use proper

procedure when disconnecting fuel lines. See FUEL LINE DISCONNECT

FITTINGS under FUEL SYSTEM.

NOTE: Information for servicing of in-tank fuel filter is not

available from manufacturer. If necessary to service in-tank

fuel filter, consult parts department to verify if filter may

be replace without replacing fuel tank module.

3) Note direction of fuel line connections on fuel tank

module for installation reference. Using Spanner Wrench (6856),

unscrew plastic fuel tank module lock nut from fuel tank. Remove fuel

tank module and gasket from fuel tank. Inspect in-tank fuel filter for

damage.

Installation

1) Using NEW gasket, install fuel tank module in fuel tank.

Install plastic fuel tank module lock nut finger tight. DO NOT tighten

plastic fuel tank module lock nut at this time.

2) Position fuel tank module so fuel line connections and

electric connection are facing toward driver's side of vehicle. This

must be done to prevent float on fuel gauge sending unit from

contacting fuel tank.

3) Once fuel tank module is properly positioned, tighten

plastic fuel tank module lock nut to specification. See TORQUE

SPECIFICATIONS.

4) Install fuel lines on fuel tank module using proper

procedure. See FUEL LINE DISCONNECT FITTINGS under FUEL SYSTEM.

Install electrical connector on fuel tank module. Reinstall fuel tank.

Tighten fuel tank strap nuts to specification. See TORQUE

SPECIFICATIONS. Reconnect negative battery cables.

Fig. 7: Locating Fuel Tank Module & Fuel Tank Rollover Valve

Courtesy of Chrysler Corp.

FUEL INJECTOR DRAIN LINE ASSEMBLY

Page 933 of 1691

Removal

1) Remove nameplate located above rocker lever covers. Remove

fuel injector drain line-to-fuel injector banjo bolt and seal washer

from each fuel injector. Plug all fuel openings.

2) Remove fuel injector drain line assembly retaining clamp

at rear of intake manifold. Remove fuel injector drain line bolt with

seal washers at filter mounting head. See Fig. 3. Remove fuel injector

drain line assembly.

Installation

To install, reverse removal procedure using NEW seal washers.

Tighten bolts to specification. See TORQUE SPECIFICATIONS.

FUEL HEATER

Removal & Installation

Fuel heater is located in FUEL FILTER/WATER SEPARATOR &

WATER-IN-FUEL SENSOR. See FUEL FILTER/WATER SEPARATOR & WATER-IN-FUEL

SENSOR.

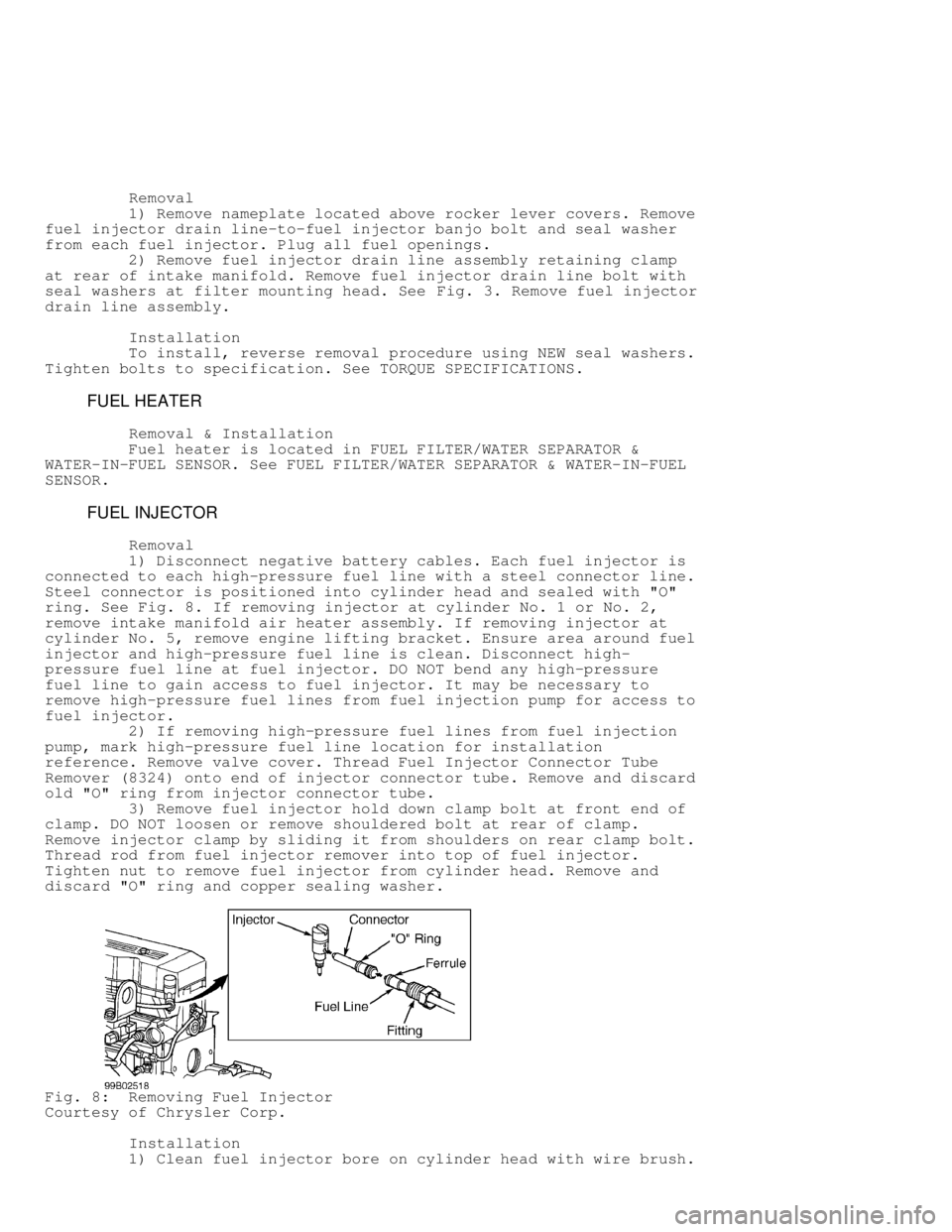

FUEL INJECTOR

Removal

1) Disconnect negative battery cables. Each fuel injector is

connected to each high-pressure fuel line with a steel connector line.

Steel connector is positioned into cylinder head and sealed with "O"

ring. See Fig. 8. If removing injector at cylinder No. 1 or No. 2,

remove intake manifold air heater assembly. If removing injector at

cylinder No. 5, remove engine lifting bracket. Ensure area around fuel

injector and high-pressure fuel line is clean. Disconnect high-

pressure fuel line at fuel injector. DO NOT bend any high-pressure

fuel line to gain access to fuel injector. It may be necessary to

remove high-pressure fuel lines from fuel injection pump for access to

fuel injector.

2) If removing high-pressure fuel lines from fuel injection

pump, mark high-pressure fuel line location for installation

reference. Remove valve cover. Thread Fuel Injector Connector Tube

Remover (8324) onto end of injector connector tube. Remove and discard\

old "O" ring from injector connector tube.

3) Remove fuel injector hold down clamp bolt at front end of

clamp. DO NOT loosen or remove shouldered bolt at rear of clamp.

Remove injector clamp by sliding it from shoulders on rear clamp bolt.

Thread rod from fuel injector remover into top of fuel injector.

Tighten nut to remove fuel injector from cylinder head. Remove and

discard "O" ring and copper sealing washer.

Fig. 8: Removing Fuel Injector

Courtesy of Chrysler Corp.

Installation

1) Clean fuel injector bore on cylinder head with wire brush.

Page 934 of 1691

Apply light coat of engine oil on NEW .060" (1.5 mm) thick Copper

sealing washer. Install NEW Copper sealing washer on spray tip of fuel

injector. Engine oil is used to aid holding sealing washer in place.

Install new "O" ring on fuel injector. Apply small amount of engine

oil to "O" ring.

2) Ensure fuel inlet hole on side of fuel injector is

positioned toward injector connector tube. Install injector into

cylinder head bore using care not to allow injector tip to touch sides

of bore. Press fuel injector into cylinder head with finger pressure

only. Install fuel injector hold down clamp into shouldered bolt while

aligning slot in top of injector into groove in bottom of clamp.

Tighten opposite clamp bolt to specification. See TORQUE

SPECIFICATIONS.

3) Apply small amount of clean engine oil to NEW "O" ring.

Install "O" ring to fuel injector connector tube. Using finger

pressure only, press injector connector tube into cylinder head.

Connect and tighten high pressure fuel lines to specification. See

TORQUE SPECIFICATIONS.

NOTE: Fuel line fitting torque is important. Mating surfaces will

not seal if fuel line fitting is under or over-torqued.

4) To install remaining components, reverse removal

procedure. Tighten bolts to specification. See TORQUE SPECIFICATIONS.

Bleed high-pressure fuel lines. See FUEL LINE BLEEDING under FUEL

SYSTEM.

FUEL INJECTION PUMP

CAUTION: High-pressure fuel lines must be clamped securely and routed

so they do not contact each other or any other components. DO

NOT weld or substitute high-pressure fuel lines. High

-pressure lines are same length and proper high-pressure fuel

line must be installed in specified area for proper engine

operation.

Removal

1) Disconnect negative battery cables. Clean fuel lines at

cylinder head and injection pump. Clean fuel injection pump and fuel

lines at side of pump. Disconnect 9-pin electrical connector at Fuel

Pump Control Module (FPCM). Place a rag around overflow valve to catch\

excess fuel. Remove overflow valve and disconnect fuel return line.

Remove banjo bolts and fuel supply line at side of injection pump and

top of fuel filter housing.

2) Remove all high pressure fuel lines, intake air tube,

accelerator pedal position sensor, air intake housing, engine oil

dipstick tube, wiring clips, electrical connectors at intake heaters,

and engine lifting bracket. Unscrew plastic access cap at front gear

cover. Remove injection pump gear-to-injection pump shaft nut and

washer.

3) Engine may be rotated by removing dust plug from

transmission adapter plate and installing Engine Barring Tool (Snap-On

SP371) in transmission adapter plate. See Fig. 9. Rotate engine until

keyway is at 12 o'clock position.

Page 938 of 1691

gear. When installing pump, ensure dowel on mounting flange must align

with hole in front of pump. Ensure fuel injection pump is flat against

gear housing. Install 4 fuel injection pump-to-gear housing nuts

finger tight. DO NOT tighten nuts at this time.

CAUTION: DO NOT tighten pump to gear cover using mounting nuts. Damage

to pump or gear cover may result. Pump must be positioned

flat to mounting flange before attempting to tighten mounting

nuts.

4) Install fuel injection pump shaft washer and nut to pump

shaft finger tight. Position lower pump bracket and install 3 bolts

finger tight. Tighten fuel injection pump drive gear nut to

preliminary torque of 22 ft. lbs. (30 N.m). Tighten 4 fuel injection

pump nuts and 3 lower pump bracket-to-pump bolts to specification.

Tighten 2 engine bracket-to-engine bolts to specification. See TORQUE

SPECIFICATIONS Final tighten injection pump shaft nut. Use barring

tool to prevent engine from rotating.

5) Install plastic access cap to front gear cover. Using new

gaskets, install fuel return line and overflow valve to side of

injection pump. Tighten overflow valve to specification. See TORQUE

SPECIFICATIONS Using new gaskets, install fuel supply line to side of

injection pump and top of fuel filter housing. Tighten banjo bolts to

specification. TORQUE SPECIFICATIONS.

6) To complete installation, reverse removal procedure. Bleed

air from fuel system. See FUEL LINE BLEEDING.

FUEL TANK ROLLOVER VALVE

Removal

1) Fuel tank rollover valve is pressed into rubber grommet on

top of fuel tank module. See Fig. 7. Manufacturer recommends removing

fuel tank for access to fuel tank rollover valve.

NOTE: It may be necessary to disconnect fuel lines and electrical

connector from fuel tank module so fuel tank may be lowered

for access to fuel tank rollover valve.

2) Raise and support vehicle. Disconnect negative battery

cables. Drain fuel tank. Remove fuel tank filler tube bolts from body.

Support fuel tank with transmission jack. Remove fuel tank straps and

heat shields (if equipped).

NOTE: Manufacturer recommends replacing rubber grommet on fuel tank

module when servicing fuel tank rollover valve.

3) Slightly lower fuel tank for access to fuel tank rollover

valve. Disconnect electrical connector and fuel lines from fuel tank

module if necessary to gain access to fuel tank rollover valve. Use

proper procedure when disconnecting fuel lines. See FUEL LINE

DISCONNECT FITTINGS under FUEL SYSTEM.

4) Disconnect hose from fuel tank rollover valve. Pry one

side of fuel tank rollover valve from rubber grommet. Remove fuel tank

rollover valve. Remove rubber grommet.

Installation

1) To install, reverse removal procedure using NEW rubber

grommet. If fuel lines were disconnected, install fuel lines on fuel

tank module using proper procedure. See FUEL LINE DISCONNECT FITTINGS

under FUEL SYSTEM.

2) Reinstall fuel tank. Tighten fuel tank strap nuts to

specification. See TORQUE SPECIFICATIONS. Reconnect negative battery

cables.

Page 939 of 1691

FUEL TRANSFER PUMP

Removal

1) Disconnect negative battery cables. Clean area around

transfer pump and fuel lines. Remove starter. Place a drain pan below

pump. Disconnect fuel line fitting at fuel supply line. Remove support

bracket bolt at top of pump. Remove banjo bolts at front and rear of

pump.

2) Disconnect pigtail harness electrical connector from main

engine wiring harness. Remove 3 pump bracket nuts. Remove fuel

transfer pump.

Installation

1) Install new gaskets to fuel supply line, support bracket,

and banjo bolt at rear of pump. Install banjo bolt finger tight.

Install new gaskets to fuel line and banjo bolt at front of pump.

Position 3 pump studs into pump mounting bracket and install 3 nuts

finger tight. Install support bracket bolt finger tight.

2) Tighten bolts and nuts evenly to specification. See TORQUE

SPECIFICATIONS. Reconnect electrical connectors. Tighten fuel lines to

specification. Install starter and negative battery cables. Bleed low-

pressure fuel lines. See FUEL LINE BLEEDING under FUEL SYSTEM.

HIGH-PRESSURE FUEL LINES

CAUTION: High-pressure fuel lines must be clamped securely and routed

so they do not contact each other or any other components. DO

NOT weld or substitute high-pressure fuel lines. High

-pressure lines are same length and proper high-pressure fuel

line must be installed in specified area for proper engine

operation.

Removal

1) Disconnect negative battery cables. Remove nameplate

located above rocker lever covers. Disconnect necessary clamps from

high-pressure fuel lines.

2) Ensure area around each high-pressure fuel line nut is

clean. Mark high-pressure fuel line location for installation

reference. Remove high-pressure fuel line from fuel injector.

3) Remove high-pressure fuel lines from fuel injection pump.

Remove high-pressure fuel lines from engine, using care not to bend

the fuel line.

Installation

To install, reverse removal procedure. Ensure all high-

pressure fuel line nuts are tightened to specification at fuel

injector and fuel injection pump before tightening clamp bolts to

specification. Bleed high-pressure fuel lines. See FUEL LINE BLEEDING

under FUEL SYSTEM.

OVERFLOW VALVE

Removal & Installation

1) Disconnect negative battery cables. Ensure area around

overflow valve is clean. Remove valve from pump and banjo fitting.

Discard gaskets.

2) To install, reverse removal procedure using NEW gaskets.

Tighten overflow valve to specification. See TORQUE SPECIFICATIONS.

EMISSION SYSTEMS & SUB-SYSTEMS

Page 970 of 1691

CAUTION: DO NOT apply battery voltage to fuel injector for extended

periods, or fuel injector may be damaged.

7) Momentarily touch remaining end of jumper wire to negative

battery terminal in short intervals to energize fuel injector and

release remaining fuel pressure.

8) Remove jumper wires. Reinstall electrical connector and

fuel pump relay. Fuel system components may now be serviced. Cover

fuel lines with shop towel before disconnecting, as some residual fuel

pressure may exist.

9) Diagnostic Trouble Code (DTCs) may have been stored in

Powertrain Control Module (PCM) due to the removal of fuel pump relay.\

Using scan tool, clear DTCs from PCM. See appropriate SELF-DIAGNOSTICS

article for clearing of DTCs.

FUEL LINE DISCONNECT FITTINGS

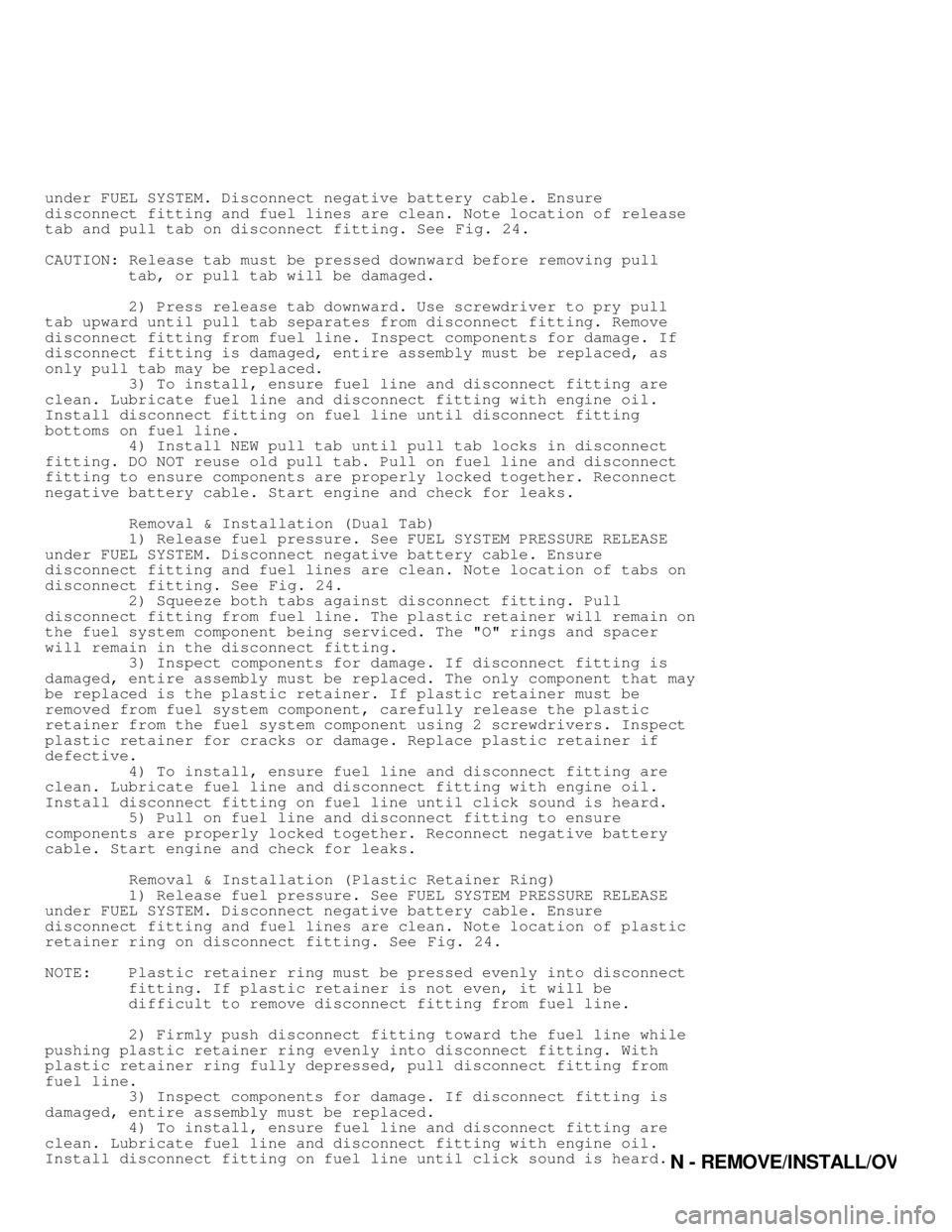

NOTE: Fuel lines may contain single tab, dual tab or plastic

retainer ring disconnect fitting. See Fig. 24. Determine type

of disconnect fitting used and use proper procedure for

proper disconnect fitting.

Fig. 24: Identifying Fuel Line Disconnect Fitting

Courtesy of Chrysler Corp.

Removal & Installation (Single Tab)

1) Release fuel pressure. See FUEL SYSTEM PRESSURE RELEASE

Page 971 of 1691

N - R EM OVE /IN STA LL/O VER HAU L

under FUEL SYSTEM. Disconnect negative battery cable. Ensure disconnect fitting and fuel lines are clean. Note location of releasetab and pull tab on disconnect fitting. See Fig. 24.

CAUTION: Release tab must be pressed downward before removing pull

tab, or pull tab will be damaged. 2) Press release tab downward. Use screwdriver to pry pull tab upward until pull tab separates from disconnect fitting. Removedisconnect fitting from fuel line. Inspect components for damage. Ifdisconnect fitting is damaged, entire assembly must be replaced, asonly pull tab may be replaced. 3) To install, ensure fuel line and disconnect fitting areclean. Lubricate fuel line and disconnect fitting with engine oil.Install disconnect fitting on fuel line until disconnect fittingbottoms on fuel line. 4) Install NEW pull tab until pull tab locks in disconnectfitting. DO NOT reuse old pull tab. Pull on fuel line and disconnectfitting to ensure components are properly locked together. Reconnectnegative battery cable. Start engine and check for leaks. Removal & Installation (Dual Tab)

1) Release fuel pressure. See FUEL SYSTEM PRESSURE RELEASE under FUEL SYSTEM. Disconnect negative battery cable. Ensuredisconnect fitting and fuel lines are clean. Note location of tabs ondisconnect fitting. See Fig. 24.

2) Squeeze both tabs against disconnect fitting. Pulldisconnect fitting from fuel line. The plastic retainer will remain onthe fuel system component being serviced. The "O" rings and spacerwill remain in the disconnect fitting. 3) Inspect components for damage. If disconnect fitting isdamaged, entire assembly must be replaced. The only component that maybe replaced is the plastic retainer. If plastic retainer must beremoved from fuel system component, carefully release the plasticretainer from the fuel system component using 2 screwdrivers. Inspectplastic retainer for cracks or damage. Replace plastic retainer ifdefective. 4) To install, ensure fuel line and disconnect fitting areclean. Lubricate fuel line and disconnect fitting with engine oil.Install disconnect fitting on fuel line until click sound is heard. 5) Pull on fuel line and disconnect fitting to ensurecomponents are properly locked together. Reconnect negative batterycable. Start engine and check for leaks. Removal & Installation (Plastic Retainer Ring)

1) Release fuel pressure. See FUEL SYSTEM PRESSURE RELEASE under FUEL SYSTEM. Disconnect negative battery cable. Ensuredisconnect fitting and fuel lines are clean. Note location of plasticretainer ring on disconnect fitting. See Fig. 24.

NOTE: Plastic retainer ring must be pressed evenly into disconnect fitting. If plastic retainer is not even, it will be difficult to remove disconnect fitting from fuel line. 2) Firmly push disconnect fitting toward the fuel line while pushing plastic retainer ring evenly into disconnect fitting. Withplastic retainer ring fully depressed, pull disconnect fitting fromfuel line. 3) Inspect components for damage. If disconnect fitting isdamaged, entire assembly must be replaced. 4) To install, ensure fuel line and disconnect fitting areclean. Lubricate fuel line and disconnect fitting with engine oil.Install disconnect fitting on fuel line until click sound is heard.

Page 985 of 1691

1) To install, reverse removal procedure. If installing small

vent tube and large fill tube on fuel tank, ensure fuel tank fittings

are clean.

2) Install disconnect fitting on fuel tank fitting until

disconnect fitting snaps onto fuel tank fitting. Pull on small vent

tube or and large fill tube to ensure disconnect fitting is locked on

fuel tank fitting. To verify proper installation of disconnect

fitting, ensure the distance between release sleeve and top of fuel

tank fitting is .50" (12.7 mm) on small vent tube or .25" (6.4 mm) o\

n

large fill tube. See Fig. 37.

3) Install fuel lines on fuel filter/fuel pressure regulator

on fuel pump module using proper procedure. See FUEL LINE DISCONNECT

FITTINGS under FUEL SYSTEM.

CAUTION: DO NOT overtighten fuel tank strap retaining nuts during

installation.

4) Tighten fuel tank strap retaining nuts to specification.

See TORQUE SPECIFICATIONS. To install remaining components, reverse

removal procedure. Start engine and check for fuel leaks.

Removal (Durango)

1) Fuel tank may be drained by removing vent hose from rear

of fuel tank, or by pumping fuel from fuel tank using the fuel pump if

fuel pump is operating. If removing vent hose from fuel tank to drain

the fuel, go to step 4). If using fuel pump to drain the fuel tank, go

to next step.

2) Disconnect fuel line from fuel rail. See FUEL LINE AT FUEL

RAIL under FUEL SYSTEM. Connect Fuel Hose (6541, 6539, 6631 or 6923)

for proper engine application at fuel line fitting on fuel rail. Place

remaining end of fuel hose in an approved gasoline container.

3) Connect scan tool to Data Link Connector (DLC). DLC is a

16-pin connector attached to bottom of driver's side of the instrument

panel, just to the right of the brake pedal. Using scan tool

manufacturer's instructions, activate the fuel pump and pump fuel from

fuel tank. Once fuel tank is empty, remove scan tool. Reinstall fuel

line on fuel rail using proper procedure. Go to step 5).

4) Release fuel pressure from fuel system. See FUEL SYSTEM

PRESSURE RELEASE. Ensure negative battery cable is disconnected.

Remove fuel tank cap to release any residual fuel tank pressure.

5) Raise and support vehicle. Remove necessary skid plates

for access to fuel tank. Disconnect vent and filler hose from rear of

fuel tank. If fuel tank was not previously drained, place drain hose

in vent hose fitting at rear of fuel tank. Drain fuel from fuel tank

into an approved gasoline container.

6) Support fuel tank with transmission jack. Remove fuel tank

strap retaining nuts. Position fuel tank straps toward outside of

vehicle. Slightly lower fuel tank. Ensure rear of fuel tank is higher

than front of fuel tank to prevent any spilling any remaining fuel in

fuel tank.

7) Disconnect fuel line from fuel filter/fuel pressure

regulator on fuel pump module using proper procedure for fuel line

disconnect fitting. See FUEL LINE DISCONNECT FITTINGS. Fuel pump

module is located on top of fuel tank. See Fig. 28. Disconnect

electrical connector at fuel pump module. Disconnect vapor line from

rollover valves on top of fuel tank and EVAP line from fuel pump

module. Lower fuel tank from vehicle.

CAUTION: DO NOT overtighten fuel tank strap retaining nuts during

installation.

Installation

1) To install, reverse removal procedure. Install fuel lines

Page 986 of 1691

on fuel filter/fuel pressure regulator on fuel pump module using

proper procedure. See FUEL LINE DISCONNECT FITTINGS.

2) Tighten fuel tank strap retaining nuts to specification.

See TORQUE SPECIFICATIONS. Start engine and check for fuel leaks.

Removal (Ram Pickup)

1) Fuel tank may be drained by lowering fuel tank, or by

pumping fuel from fuel tank using the fuel pump if fuel pump is

operating. If lowering fuel tank to drain the fuel, go to step 4). If

using fuel pump to drain the fuel tank, go to next step.

2) Disconnect fuel line from fuel rail. See FUEL LINE AT FUEL

RAIL. Connect Fuel Hose (6541, 6539, 6631 or 6923) for proper engine

application at fuel line fitting on fuel rail. Place remaining end of

fuel hose in an approved gasoline container.

3) Connect scan tool to Data Link Connector (DLC). DLC is a

16-pin connector attached to bottom of driver's side of the instrument

panel, just straight above the accelerator pedal. Using scan tool

manufacturer's instructions, activate the fuel pump and pump fuel from

fuel tank. Once fuel tank is empty, remove scan tool. Reinstall fuel

line on fuel rail using proper procedure. Go to step 5).

4) Release fuel pressure from fuel system. See FUEL SYSTEM

PRESSURE RELEASE. Ensure negative battery cable is disconnected.

Remove fuel tank cap to release any residual fuel tank pressure.

5) Raise and support vehicle. Open fuel tank filler door.

Remove fuel tank filler tube assembly-to-body screws. Support fuel

tank with transmission jack. Remove fuel tank strap retaining nuts.

6) Slightly lower fuel tank. If fuel tank was not previously

drained, slightly rotate fuel tank so vent hose and filler hose on

fuel tank are above the fuel level in the fuel tank to prevent fuel

leakage when hoses are disconnected. Vent hose and filler hose attach

to fitting on the fuel tank. See Fig. 29.

7) Disconnect vent hose from vent hose fitting on fuel tank.

If fuel tank was previously drained, go to next step. If fuel tank was

not previously drained, place drain hose in vent hose fitting on fuel

tank. Drain fuel from fuel tank into an approved gasoline container.

Go to next step.

8) Disconnect filler hose from filler hose fitting on fuel

tank. Disconnect electrical connector at fuel pump module. Fuel pump

module is located on top of fuel tank. See Fig. 29.

9) Disconnect fuel line from fuel filter/fuel pressure

regulator on fuel pump module using proper procedure for fuel line

disconnect fitting. See FUEL LINE DISCONNECT FITTINGS under FUEL

SYSTEM.

10) Disconnect necessary vapor hoses from rollover valves on

top of fuel tank or fuel pump module. See Fig. 29. Lower fuel tank

from vehicle.

CAUTION: DO NOT overtighten fuel tank strap retaining nuts during

installation.

Installation

1) To install, reverse removal procedure. Install fuel lines

on fuel filter/fuel pressure regulator on fuel pump module using

proper procedure. See FUEL LINE DISCONNECT FITTINGS.

2) Tighten fuel tank strap retaining nuts to specification.

See TORQUE SPECIFICATIONS. Start engine and check for fuel leaks.

Removal (Ram Van & Ram Wagon)

1) Fuel tank may be drained by siphoning fuel out through

small vent hose on fuel and vent hose fitting assembly on fuel tank,

or by pumping fuel from fuel tank using the fuel pump if fuel pump is

operating. If siphoning fuel out through small vent hose on fuel and

vent hose fitting assembly on fuel tank, go to step 4). If using fuel