transmission DODGE RAM 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: RAM, Model: DODGE RAM 1999Pages: 1691, PDF Size: 40.34 MB

Page 1 of 1691

ABBREVIATIONS

1999 Dodge Pickup R1500

GENERAL INFORMATION

COMMONLY USED ABBREVIATION

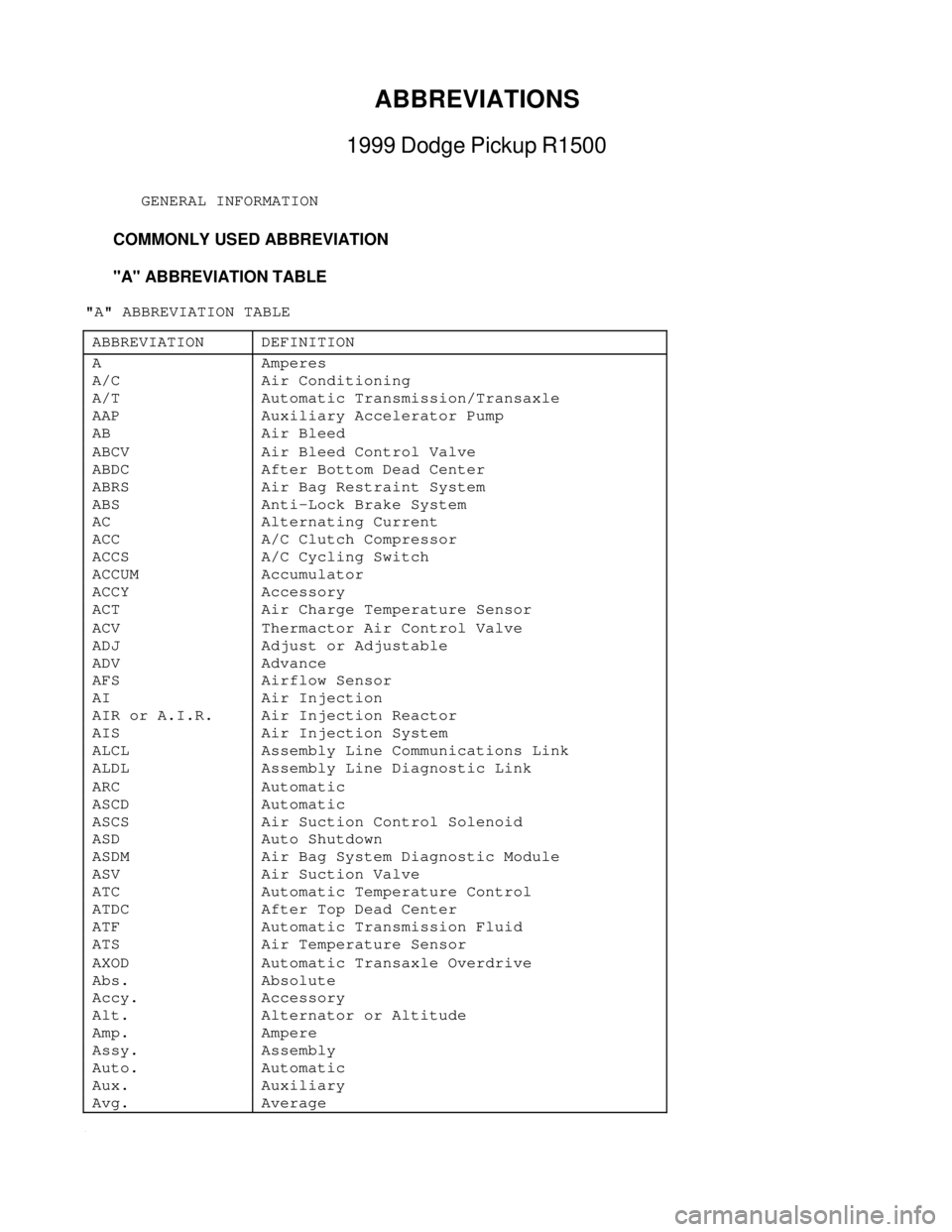

"A" ABBREVIATION TABLE

"A" ABBREVIATION TABLE

ABBREVIATION DEFINITION A Amperes A/C Air Conditioning A/T Automatic Transmission/Transaxle AAP Auxiliary Accelerator Pump AB Air Bleed ABCV Air Bleed Control Valve ABDC After Bottom Dead Center ABRS Air Bag Restraint System ABS Anti-Lock Brake System AC Alternating Current ACC A/C Clutch Compressor ACCS A/C Cycling Switch ACCUM Accumulator ACCY Accessory ACT Air Charge Temperature Sensor ACV Thermactor Air Control Valve ADJ Adjust or Adjustable ADV Advance AFS Airflow Sensor AI Air Injection AIR or A.I.R. Air Injection Reactor AIS Air Injection System ALCL Assembly Line Communications Link ALDL Assembly Line Diagnostic Link ARC Automatic ASCD Automatic ASCS Air Suction Control Solenoid ASD Auto Shutdown ASDM Air Bag System Diagnostic Module ASV Air Suction Valve ATC Automatic Temperature Control ATDC After Top Dead Center ATF Automatic Transmission Fluid ATS Air Temperature Sensor AXOD Automatic Transaxle Overdrive Abs. Absolute Accy. Accessory Alt. Alternator or Altitude Amp. Ampere Assy. Assembly Auto. Automatic Aux. Auxiliary Avg. Average

3

Page 7 of 1691

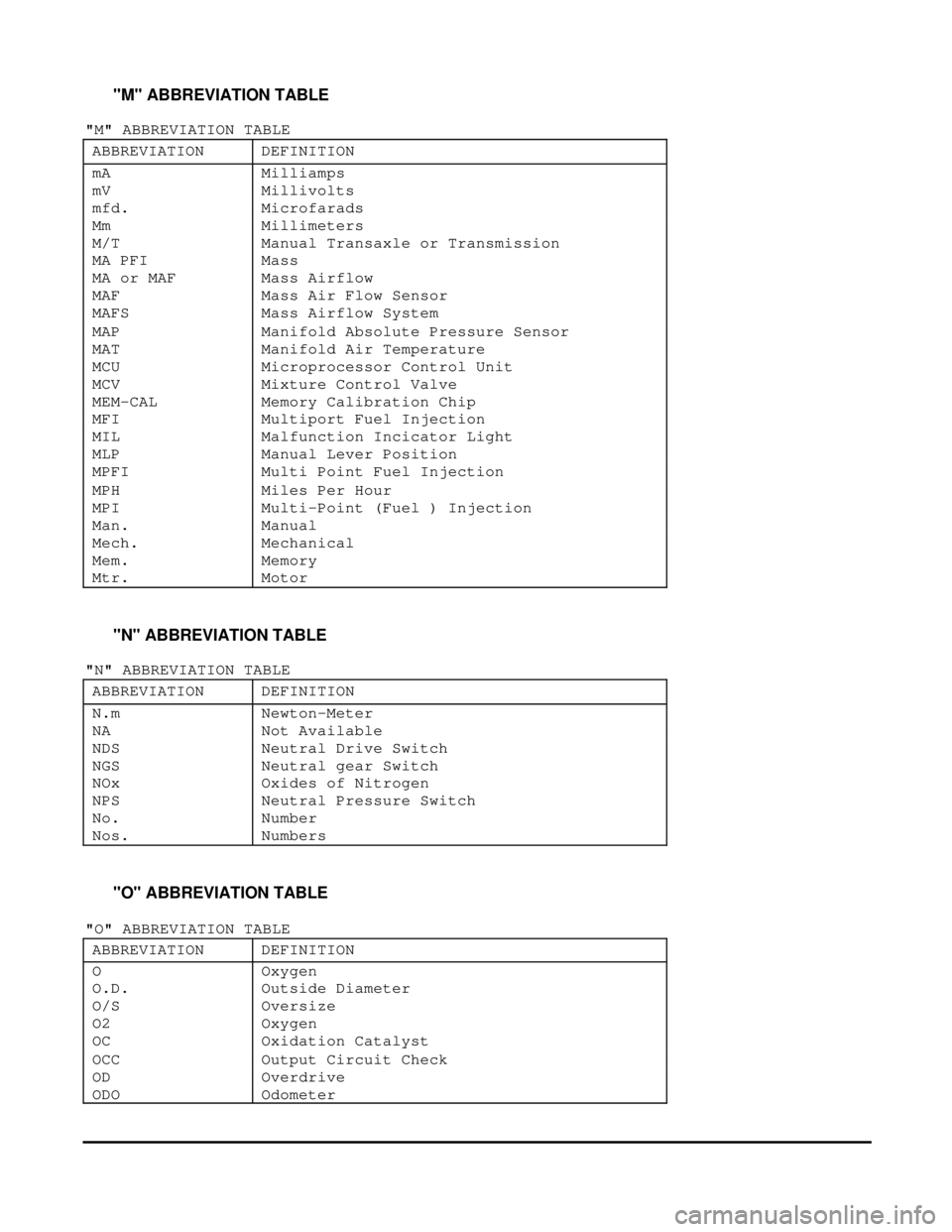

"M" ABBREVIATION TABLE

"M" ABBREVIATION TABLE

ABBREVIATION DEFINITION mA Milliamps mV Millivolts mfd. Microfarads Mm Millimeters M/T Manual Transaxle or Transmission MA PFI Mass MA or MAF Mass Airflow MAF Mass Air Flow Sensor MAFS Mass Airflow System MAP Manifold Absolute Pressure Sensor MAT Manifold Air Temperature MCU Microprocessor Control Unit MCV Mixture Control Valve MEM-CAL Memory Calibration Chip MFI Multiport Fuel Injection MIL Malfunction Incicator Light MLP Manual Lever Position MPFI Multi Point Fuel Injection MPH Miles Per Hour MPI Multi-Point (Fuel ) Injection Man. Manual Mech. Mechanical Mem. Memory Mtr. Motor

"N" ABBREVIATION TABLE

"N" ABBREVIATION TABLE

ABBREVIATION DEFINITION N.m Newton-Meter NA Not Available NDS Neutral Drive Switch NGS Neutral gear Switch NOx Oxides of Nitrogen NPS Neutral Pressure Switch No. Number Nos. Numbers

"O" ABBREVIATION TABLE

"O" ABBREVIATION TABLE

ABBREVIATION DEFINITION O Oxygen O.D. Outside Diameter O/S Oversize O2 Oxygen OC Oxidation Catalyst OCC Output Circuit Check OD Overdrive ODO Odometer

Page 10 of 1691

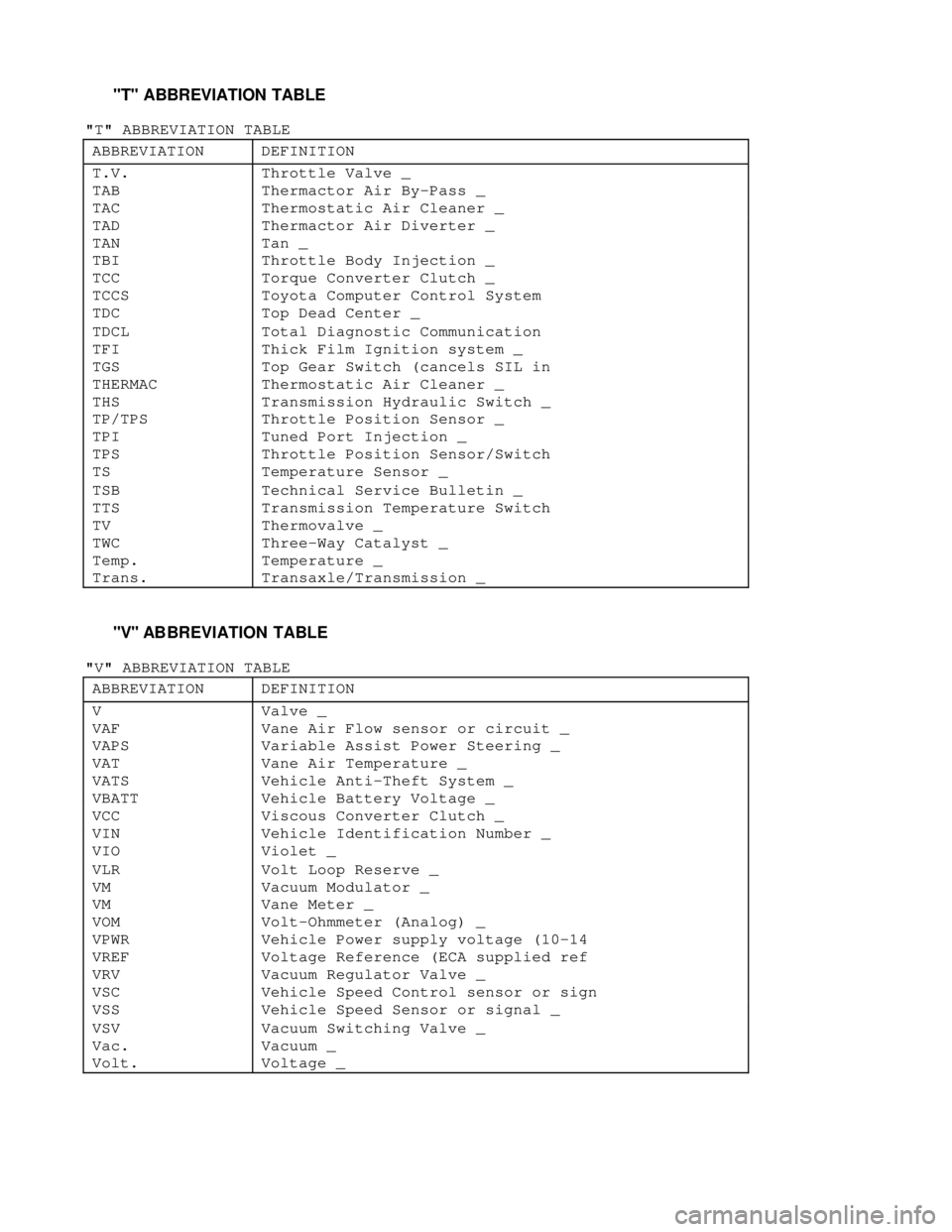

"T" ABBREVIATION TABLE

"T" ABBREVIATION TABLE

ABBREVIATION DEFINITION T.V. Throttle Valve _ TAB Thermactor Air By-Pass _ TAC Thermostatic Air Cleaner _ TAD Thermactor Air Diverter _ TAN Tan _ TBI Throttle Body Injection _ TCC Torque Converter Clutch _ TCCS Toyota Computer Control System TDC Top Dead Center _ TDCL Total Diagnostic Communication TFI Thick Film Ignition system _ TGS Top Gear Switch (cancels SIL in THERMAC Thermostatic Air Cleaner _ THS Transmission Hydraulic Switch _ TP/TPS Throttle Position Sensor _ TPI Tuned Port Injection _ TPS Throttle Position Sensor/Switch TS Temperature Sensor _ TSB Technical Service Bulletin _ TTS Transmission Temperature Switch TV Thermovalve _ TWC Three-Way Catalyst _ Temp. Temperature _ Trans. Transaxle/Transmission _

"V" ABBREVIATION TABLE

"V" ABBREVIATION TABLE

ABBREVIATION DEFINITION V Valve _ VAF Vane Air Flow sensor or circuit _ VAPS Variable Assist Power Steering _ VAT Vane Air Temperature _ VATS Vehicle Anti-Theft System _ VBATT Vehicle Battery Voltage _ VCC Viscous Converter Clutch _ VIN Vehicle Identification Number _ VIO Violet _ VLR Volt Loop Reserve _ VM Vacuum Modulator _ VM Vane Meter _ VOM Volt-Ohmmeter (Analog) _ VPWR Vehicle Power supply voltage (10-14 VREF Voltage Reference (ECA supplied ref VRV Vacuum Regulator Valve _ VSC Vehicle Speed Control sensor or sign VSS Vehicle Speed Sensor or signal _ VSV Vacuum Switching Valve _ Vac. Vacuum _ Volt. Voltage _

Page 54 of 1691

are continually republished. In addition to these, standards for Drive

Train and Transmissions have recently been promulgated. Participating

shops utilize these Uniform Inspection & Communication Standards as

part of the inspection process and for communicating their findings to

their customers.

The Motorist Assurance Program continues to work

cooperatively and proactively with government agencies and consumer

groups toward solutions that both benefit the customer and are

mutually acceptable to both regulators and industry. We maintain the

belief that industry must retain control over how we conduct our

business, and we must be viewed as part of the solution and not part

of the problem. Meetings with state and other government officials

(and their representatives), concerned with auto repair and/or

consumer protection, are conducted. Feedback from these sessions is

brought back to the association, and the program adjusted as needed.

To assure auto repair customers recourse if they were not

satisfied with a repair transaction, the Motorist Assurance Program

offers mediation and arbitration through MAP/BBB-CARE and other non-

profit organizations. MAP conducted pilot programs in twelve states

before announcing the program nationally in October, 1998. During the

pilots, participating repair shops demonstrated their adherence to the

Pledge and Standards and agreed to follow the UICS in communicating

the results of their inspection to their customers. To put some

"teeth" in the program, an accreditation requirement for shops was

initiated. The requirements are stringent, and a self-policing method

has been incorporated which includes the "mystery shopping" of

outlets.

We welcome you to join us as we continue our outreach... with

your support, both the automotive repair industry and your customers

will reap the benefits. Please visit MAP at our Internet site www.

motorist.org or contact us at:

1444 I Street, NW Suite 700

Washington, DC 20005

Phone (202) 712-9042 Fax (202) 216-9646

January 1999

MAP UNIFORM INSPECTION GENERAL GUIDELINES

OVERVIEW OF SERVICE REQUIREMENTS & SUGGESTIONS

It is MAP policy that all exhaust, brake, steering,

suspension, wheel alignment, drive-line, engine performance and

maintenance, and heating, ventilation and air conditioning, and

electrical services be offered and performed under the standards and

procedures specified in these sections.

Before any service is performed on a vehicle, an inspection

of the appropriate system must be performed. The results of this

inspection must be explained to the customer and documented on an

inspection form. The condition of the vehicle and its components will

indicate what services/part replacements may be "Required" or

"Suggested". In addition, suggestions may be made to satisfy the

requests expressed by the customer.

When a component is suggested or required to be repaired or

replaced, the decision to repair or replace must be made in the

customer's best interest, and at his or her choice given the options

available.

This section lists the various parts and conditions that

indicate a required or suggested service or part replacement.

Although this list is extensive, it is not fully inclusive. In

addition to this list, a technician may make a suggestion. However,

any suggestions must be based on substantial and informed experience,

Page 104 of 1691

assembly towards right side of vehicle and remove rear A/C-heater

assembly.

5) To install, reverse removal procedure. Ensure all wiring

and hoses are clear and not pinched. Tighten bolts and nuts to

specification. See TORQUE SPECIFICATIONS .

Removal (Ram Pickup - Front)

1) Disconnect negative battery cable. Drain cooling system.

In engine compartment, remove coolant hoses from heater core tubes.

Remove coolant overflow bottle.

2) Discharge A/C system, using approved refrigerant

recovery/recycling equipment. Disconnect refrigerant lines from

evaporator and plug or cover all openings in A/C system. Remove

instrument panel. See INSTRUMENT PANEL. Remove Powertrain Control

Module (PCM) and position aside. DO NOT disconnect 60-pin connector

from PCM.

3) Remove attaching nuts from studs on engine compartment

side of dash panel. Remove defrost duct. Disconnect electrical

connectors. Remove attaching nuts from studs in passenger compartment

side of dash panel. Remove A/C-heater assembly from vehicle. See

Fig. 5 .

4) Place A/C-heater assembly upside-down on work bench.

Remove screw securing floor duct to bottom of A/C-heater assembly and

slide floor duct off of center heat duct adapter. Unsnap center heat

duct adapter from bottom of A/C-heater assembly housing. Remove screw

hidden behind adapter. Remove remaining screws and separate A/C-heater

assembly.

Installation

Ensure mode door pivot pins are properly inserted in holes.

To complete installation, reverse removal procedure.

A/C-HEATER CONTROL PANEL R & I

Removal & Installation (Dakota & Durango)

1) Disconnect negative battery cable. On models equipped with

A/T, unlock ignition switch. Set parking brake and place gear selector

lever in "L" position. If equipped, set tilt steering column in lowest

position.

2) On all models, carefully pry bezel away from instrument

panel to disengage clips. Unplug connectors from cigarette lighter and

auxiliary power outlet. Disconnect fog light switch (if equipped).

Remove A/C-heater control panel screws.

3) Pull control panel outward enough to disconnect wiring

connector, vacuum harness, and temperature control cable. Remove A/C-

heater control panel. To install, reverse removal procedure. Adjust

temperature control cable. See TEMPERATURE CONTROL CABLE ADJUSTMENT .

Removal & Installation (Ram Pickup)

1) Disconnect negative battery cable. Reach under driver's

side of instrument panel, near transmission tunnel and unplug A/C-

heater control panel to A/C-heater assembly vacuum harness connector.

Disconnect vacuum harness from center air duct.

2) On models equipped with A/T, unlock ignition switch. Set

parking brake and place gear selector lever in "L" position. If

equipped, set tilt steering column in lowest position.

3) On all models, remove screw securing cluster bezel to

instrument panel. See Fig. 6. Carefully pry bezel away from instrument

panel to disengage clips. Unplug connectors from cigarette lighter and

auxiliary power outlet.

4) Remove 4 screws attaching A/C-heater control panel. Pull

control panel outward enough to disconnect wiring connector, vacuum

harness and temperature control cable. Remove A/C-heater control

Page 109 of 1691

6) Remove glove box. Reach through glove box opening and

disconnect antenna coaxial cable connector. Disconnect blower motor

connector located above glove box opening, near support brace for A/C-

heater housing. Disconnect radio ground strap. Loosen instrument panel

roll down bracket bolts about 2 turns, located at lower corners on

both sides of instrument panel. Remove 5 screws across top of dash

panel at base of windshield, removing center screw last.

7) Roll down instrument panel and install a temporary support

hook that is about 18" (457 mm) in length. Install hook from center

hole in instrument panel to center hole of dash panel. Pull lower

instrument panel outward until both roll down bracket bolts are in

slotted roll down position. Instrument panel should now be supported

and away from firewall.

8) Disconnect 2 door harness connectors, located on a bracket

near right end of instrument panel. Disconnect blower motor resistor.

Disconnect temperature control cable from A/C-heater housing and

remove from housing. See Fig. 5. Disconnect demister duct flexible

hose from A/C-heater housing.

9) Ensure instrument panel is free and clear for removal.

With the aid of an assistant, remove temporary support hook. Lift

instrument panel off of roll down bracket bolts and remove from

vehicle.

10) To install, reverse removal procedure. Ensure all wiring

and hoses are clear and not pinched. Tighten bolts and nuts to

specification. See TORQUE SPECIFICATIONS . Enable air bag system. See

AIR BAG SYSTEM SAFETY article.

Removal & Installation (Ram Pickup)

1) Disable air bag system. See AIR BAG SYSTEM SAFETY article.

Disconnect negative battery cable. Drain cooling system. Remove left

and right kick panel trim. Remove 5 screws and knee bolster/steering

column cover. Remove hood release and parking brake release handle

screws from lower instrument panel support. Remove 6 screws and

instrument panel support. Disconnect air bag connector at lower left

corner of instrument panel.

2) Pull PRNDL cable and twist to remove from position arm.

Push tab on bottom of cable retainer upward, then squeeze sides to

remove retainer from column. Remove tilt lever (tilt column only).

Remove both upper and lower shrouds from column. Remove lower fixed

column shroud. Loosen multifunction switch connector screw. Screw will

remain in connector.

3) Remove remaining steering column electrical connectors.

Remove air bag wiring harness from steering column wiring trough.

Remove wiring trough from steering column. Remove 3 toe plate nuts and

washers.

4) Remove 2 nuts and washers attaching steering column

bracket to instrument panel steering column support bracket. Allow

column to lower and rest on seat. Remove 2 screws from bottom of Air

Bag Control Module (ACM) cover. Remove 4 screws holding ACM to

transmission tunnel.

5) Disconnect wiring at ACM. Disconnect instrument panel left

side wiring connectors. Remove screw holding brake release to bottom

of instrument panel. Disconnect instrument panel right side wiring

connectors, which includes 2 connectors attached to A/C-heater

assembly housing, courtesy light connector, antenna cable and 2 body

connectors. Disconnect vacuum harness from A/C-heater system.

6) Remove 5 screws holding instrument panel to dash. Loosen

lower instrument panel pivot bolts. Roll instrument panel downward.

Remove instrument panel from vehicle.

7) To install, reverse removal procedure. Ensure all wiring

and hoses are clear and not pinched. Tighten bolts and nuts to

specification. See TORQUE SPECIFICATIONS . Enable air bag system. See

AIR BAG SYSTEM SAFETY article.

Page 174 of 1691

protective cover is fitted to front of air bag module bearing the SRS

air bag logo. Air bag module contains air bag cushion, inflator and

supporting components. Air bag module is a sealed unit and is not

serviceable. The module inflator assembly produces nitrogen gas to

fill air bag cushion when a small amount of current from ACM is

applied to the ignitor assembly. Gas pressure builds and discharges

from inflator through a diffuser and screen assembly, forcing steering

wheel cover to burst along its seams until air bag is fully inflated.

Once air bag cushion is fully inflated, gas escapes from bag through

vents, away from driver.

Passenger-Side

Air bag module is mounted to instrument panel mounting

bracket. Module is covered by a protective door bearing the SRS air

bag logo. When supplied an electrical signal, inflator will discharge

argon gas directly into air bag. When air bag inflates, protective

door will pivot aside allowing air bag to deploy.

AIR BAG CONTROL MODULE (ACM)

ACM is located under instrument panel, on transmission

tunnel. Impact sensor, energy reserve capacitor and On-Board

Diagnostics (OBD) are an integral part of ACM. ACM monitors critical

input and output circuits within air bag system, ensuring they are

operating correctly. Some circuits are tested continuously; others are

checked only under certain conditions. ACM provides information about

air bag system through AIR BAG warning light and Data Link Connector

(DLC). When diagnostic trouble code (fault message) is stored, AIR B\

AG

warning light will be activated for 12 seconds or more.

DATA LINK CONNECTOR (DLC)

DLC is located under left side of instrument panel, left of

steering column. DLC is used to access SRS on-board diagnostics.

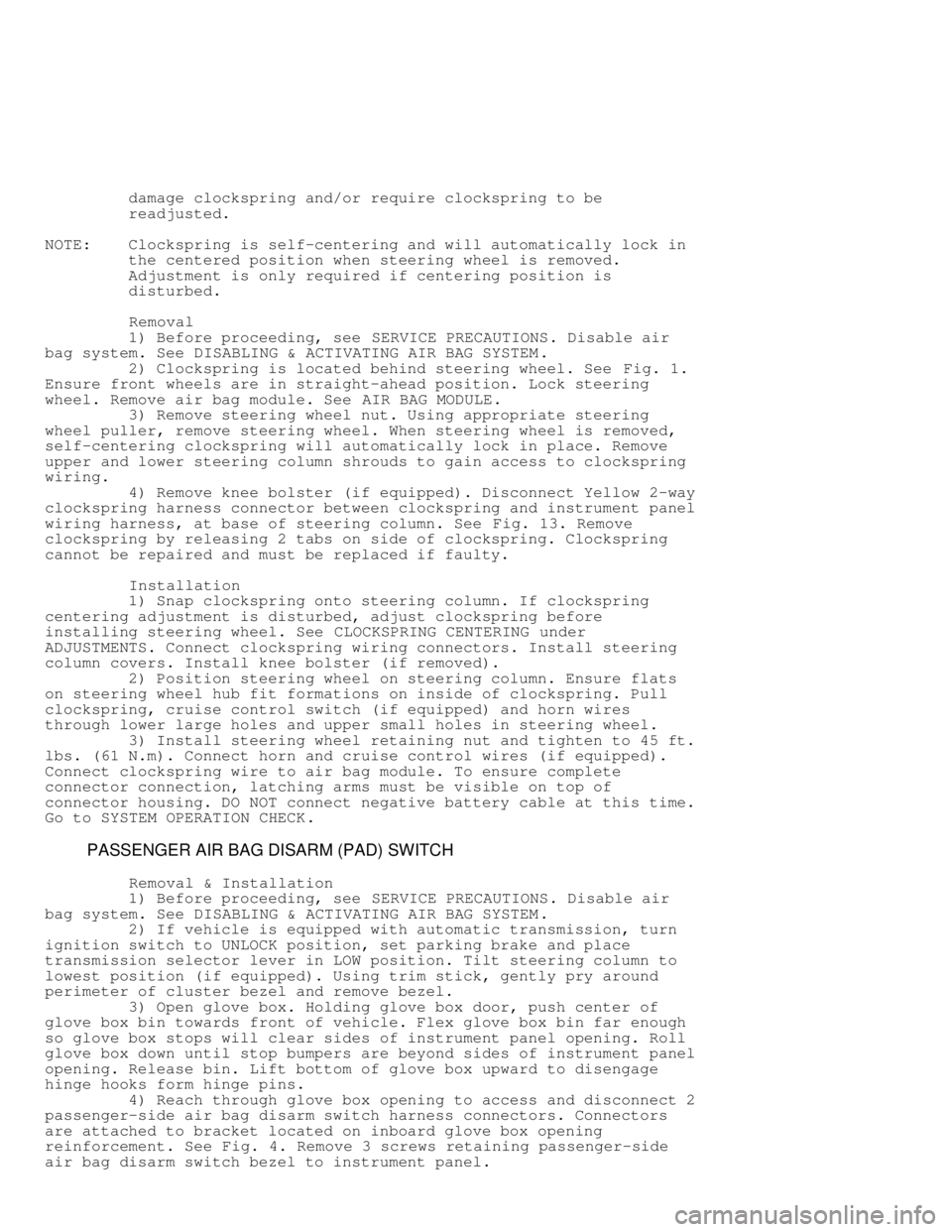

CLOCKSPRING

Clockspring connects air bag module to steering column

wiring, completing air bag system circuit. See Fig. 1. Inside

clockspring is a flat, ribbon-like tape of conductive material, which

winds and unwinds with steering wheel movement. Clockspring is the

most fragile part of air bag system. Clockspring must be centered

properly to allow 1 1/2 steering wheel turns in either direction. If

clockspring is not centered properly, it can break from stretching or

fatigue.

Fig. 1: Identifying Clockspring Assembly

Courtesy of DaimlerChrysler Corp.

Page 178 of 1691

foot wires to terminals of a 12-volt battery. After air bag module

deploys, let module cool off and allow dust to settle before

approaching.

POST-COLLISION INSPECTION

When a vehicle has been involved in a collision, certain

components of the passive restraint system must be inspected or

replaced. See PASSIVE RESTRAINT SYSTEM INSPECTION article in the

GENERAL INFORMATION section for post-collision inspection information.

REMOVAL & INSTALLATION

* PLEASE READ THIS FIRST *

WARNING: Failure to follow air bag service precautions may

result in air bag deployment and personal injury. See

SERVICE PRECAUTIONS . After component replacement,

ensure proper system operation. See SYSTEM OPERATION CHECK.

CAUTION: When battery is disconnected, vehicle computer and memory

systems may lose memory data. Driveability problems may

exist until computer systems have completed a relearn cycle.

See COMPUTER RELEARN PROCEDURES in GENERAL INFORMATION

before disconnecting battery.

AIR BAG CONTROL MODULE (ACM)

WARNING: ACM contains impact sensor, which enables SRS to activate air

bag. To avoid accidental air bag deployment, DO NOT connect

ACM electrically to system unless it is bolted to vehicle.

Removal

1) Before proceeding, see SERVICE PRECAUTIONS. Disable air

bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM . Remove bottom

of center console (ACM trim cover).

2) On M/T models, remove center console from floor panel

transmission tunnel. On A/T models, remove screws securing trim cover

to ACM mounting bracket. See Fig. 2. Pull top of trim cover rearward

to release snap clips from instrument panel support bracket.

3) On all models, loosen but do not remove screws on sides

that secure instrument panel support bracket to ACM mounting bracket.

See Fig. 3 .

4) Remove nuts securing support bracket to studs on lower

instrument panel. Disconnect wire harness retainer from hole in

support bracket. Pull top of support bracket away from instrument

panel studs and fold down over ACM until it is laying on floor panel.

Unplug wire harness connector from ACM.

CAUTION: Always replace ACM and ACM mounting bracket as an assembly.

Replacement ACM includes a NEW mounting bracket. DO NOT mount

NEW ACM to old mounting bracket.

5) Remove screws securing mounting bracket to floor panel

transmission tunnel. Remove ACM, mounting bracket and support bracket

as a unit from floor panel.

Installation

To complete installation, reverse removal procedure. Install

ACM with arrow pointing toward front of vehicle. Connect ACM

connectors, ensuring connectors are locked into position. Tighten ACM

Page 181 of 1691

damage clockspring and/or require clockspring to be

readjusted.

NOTE: Clockspring is self-centering and will automatically lock in

the centered position when steering wheel is removed.

Adjustment is only required if centering position is

disturbed.

Removal

1) Before proceeding, see SERVICE PRECAUTIONS. Disable air

bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM .

2) Clockspring is located behind steering wheel. See Fig. 1.

Ensure front wheels are in straight-ahead position. Lock steering

wheel. Remove air bag module. See AIR BAG MODULE.

3) Remove steering wheel nut. Using appropriate steering

wheel puller, remove steering wheel. When steering wheel is removed,

self-centering clockspring will automatically lock in place. Remove

upper and lower steering column shrouds to gain access to clockspring

wiring.

4) Remove knee bolster (if equipped). Disconnect Yellow 2-wa\

y

clockspring harness connector between clockspring and instrument panel

wiring harness, at base of steering column. See Fig. 13. Remove

clockspring by releasing 2 tabs on side of clockspring. Clockspring

cannot be repaired and must be replaced if faulty.

Installation

1) Snap clockspring onto steering column. If clockspring

centering adjustment is disturbed, adjust clockspring before

installing steering wheel. See CLOCKSPRING CENTERING under

ADJUSTMENTS. Connect clockspring wiring connectors. Install steering

column covers. Install knee bolster (if removed).

2) Position steering wheel on steering column. Ensure flats

on steering wheel hub fit formations on inside of clockspring. Pull

clockspring, cruise control switch (if equipped) and horn wires

through lower large holes and upper small holes in steering wheel.

3) Install steering wheel retaining nut and tighten to 45 ft.

lbs. (61 N.m). Connect horn and cruise control wires (if equipped).

Connect clockspring wire to air bag module. To ensure complete

connector connection, latching arms must be visible on top of

connector housing. DO NOT connect negative battery cable at this time.

Go to SYSTEM OPERATION CHECK .

PASSENGER AIR BAG DISARM (PAD) SWITCH

Removal & Installation

1) Before proceeding, see SERVICE PRECAUTIONS. Disable air

bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM .

2) If vehicle is equipped with automatic transmission, turn

ignition switch to UNLOCK position, set parking brake and place

transmission selector lever in LOW position. Tilt steering column to

lowest position (if equipped). Using trim stick, gently pry around

perimeter of cluster bezel and remove bezel.

3) Open glove box. Holding glove box door, push center of

glove box bin towards front of vehicle. Flex glove box bin far enough

so glove box stops will clear sides of instrument panel opening. Roll

glove box down until stop bumpers are beyond sides of instrument panel

opening. Release bin. Lift bottom of glove box upward to disengage

hinge hooks form hinge pins.

4) Reach through glove box opening to access and disconnect 2

passenger-side air bag disarm switch harness connectors. Connectors

are attached to bracket located on inboard glove box opening

reinforcement. See Fig. 4. Remove 3 screws retaining passenger-side

air bag disarm switch bezel to instrument panel.

Page 195 of 1691

NOTE: All active codes must be resolved before diagnosing store

codes.

1) Raise and support vehicle. Start engine and let idle with

transmission in PARK position. Wiggle wiring harness and connectors of

air bag system and rotate steering wheel from stop to stop.

2) Visually inspect related wire harness connectors. Look for

broken, bent, pushed out, spread, corroded or contaminated terminals.

Also, look for chafed, pierced, pinched or partially broken wires.

3) Check for trouble codes as you work through system. If

stored trouble code becomes active, perform appropriate diagnostic

test. If stored code is reproducible, repair or replace wiring

harness, harness connector or terminals or replace component as

necessary.

CLUSTER MESSAGE MISMATCH

NOTE: Perform AIR BAG VERIFICATION TEST after

all repairs. Each time a connector is disconnected, inspect

it to ensure it is in good condition. Always focus on circuit

being tested. Dirt, water and corrosion, are most common

problems in connectors. Due to manufacturer changes in wire

colors, use terminal identification whenever possible.

1) If AIR BAG warning light is on, go to next step. If AIR

BAG warning light is not on, go to step 5).

2) Using DRB, select PASSIVE RESTRAINTS, AIRBAG and MONITOR

DISPLAY. Read WARNING LAMP STATUS. If DRB does not display MIC LAMP

STATUS ON, replace instrument cluster. If DRB displays MIC LAMP STATUS

ON, go to next step.

3) If DRB displays ACM LAMP REQUEST: ON, go to next step. If

DRB does not display ACM LAMP REQUEST: ON, replace instrument cluster.

4) If there are no potential causes for this DTC remaining,

ACM is assumed to be defective. Replace ACM. See

AIR BAG CONTROL MODULE (ACM) under REMOVAL & INSTALLATION.

NOTE: If AIR BAG warning light is defective, instrument cluster

will flash seat belt light for 30 seconds starting 10 seconds

after bulb check stops.

5) Using DRB, read air bag control module active codes

(messages). If CLUSTER MISMATCH is only active message, go to next

step. If other messages are present, go to appropriate diagnostic test

to continue diagnosis.

6) If seat belt warning light flashes for 30 seconds after

bulb check is complete, replace instrument cluster. If seat belt

warning light does not flashes for 30 seconds after bulb check is

complete, go to next step.

7) Using DRB, select PASSIVE RESTRAINTS, AIRBAG and MONITOR

DISPLAY. Read WARNING LAMP STATUS. If DRB displays ACM LAMP REQUEST:

OFF, go to next step. If DRB does not display ACM LAMP REQUEST: OFF,

replace instrument cluster.

8) If DRB displays MIC LAMP REQUEST: OFF, go to next step. If

DRB does not display MIC LAMP REQUEST: OFF, replace instrument

cluster.

9) If there are no potential causes for this DTC remaining,

ACM is assumed to be defective. Replace ACM. See

AIR BAG CONTROL MODULE (ACM) under REMOVAL & INSTALLATION.

DRIVER SQUIB CIRCUIT OPEN

NOTE: Perform AIR BAG VERIFICATION TEST after

all repairs. Each time a connector is disconnected, inspect