42re DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2 of 2889

INTRODUCTION

TABLE OF CONTENTS

page page

BODY CODE PLATE

DESCRIPTION............................1

FASTENER IDENTIFICATION

DESCRIPTION............................3

FASTENER USAGE

DESCRIPTION............................6

INTERNATIONAL VEHICLE CONTROL &

DISPLAY SYMBOLS

DESCRIPTION............................6

METRIC SYSTEM

DESCRIPTION............................6TORQUE REFERENCES

DESCRIPTION............................9

VECI LABEL

DESCRIPTION...........................10

OPERATION.............................10

VEHICLE IDENTIFICATION NUMBER

DESCRIPTION...........................10

VEHICLE SAFETY CERTIFICATION LABEL

DESCRIPTION...........................12

EQUIPMENT IDENTIFICATION PLATE

DESCRIPTION...........................12

BODY CODE PLATE

DESCRIPTION

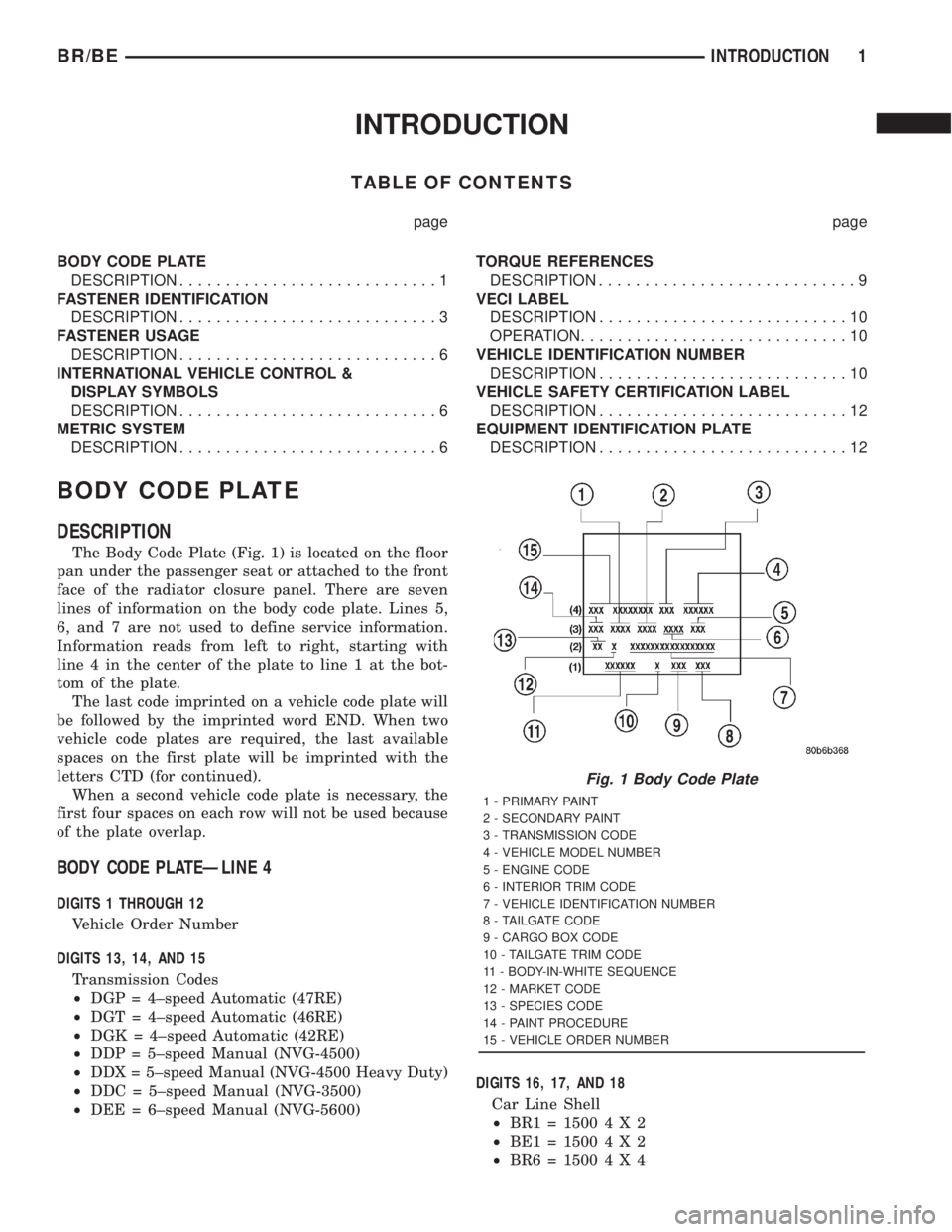

The Body Code Plate (Fig. 1) is located on the floor

pan under the passenger seat or attached to the front

face of the radiator closure panel. There are seven

lines of information on the body code plate. Lines 5,

6, and 7 are not used to define service information.

Information reads from left to right, starting with

line 4 in the center of the plate to line 1 at the bot-

tom of the plate.

The last code imprinted on a vehicle code plate will

be followed by the imprinted word END. When two

vehicle code plates are required, the last available

spaces on the first plate will be imprinted with the

letters CTD (for continued).

When a second vehicle code plate is necessary, the

first four spaces on each row will not be used because

of the plate overlap.

BODY CODE PLATEÐLINE 4

DIGITS 1 THROUGH 12

Vehicle Order Number

DIGITS 13, 14, AND 15

Transmission Codes

²DGP = 4±speed Automatic (47RE)

²DGT = 4±speed Automatic (46RE)

²DGK = 4±speed Automatic (42RE)

²DDP = 5±speed Manual (NVG-4500)

²DDX = 5±speed Manual (NVG-4500 Heavy Duty)

²DDC = 5±speed Manual (NVG-3500)

²DEE = 6±speed Manual (NVG-5600)DIGITS 16, 17, AND 18

Car Line Shell

²BR1=15004X2

²BE1=15004X2

²BR6=15004X4

Fig. 1 Body Code Plate

1 - PRIMARY PAINT

2 - SECONDARY PAINT

3 - TRANSMISSION CODE

4 - VEHICLE MODEL NUMBER

5 - ENGINE CODE

6 - INTERIOR TRIM CODE

7 - VEHICLE IDENTIFICATION NUMBER

8 - TAILGATE CODE

9 - CARGO BOX CODE

10 - TAILGATE TRIM CODE

11 - BODY-IN-WHITE SEQUENCE

12 - MARKET CODE

13 - SPECIES CODE

14 - PAINT PROCEDURE

15 - VEHICLE ORDER NUMBER

BR/BEINTRODUCTION 1

Page 19 of 2889

FLUID CAPACITIES

SPECIFICATIONS

FLUID CAPACITIES

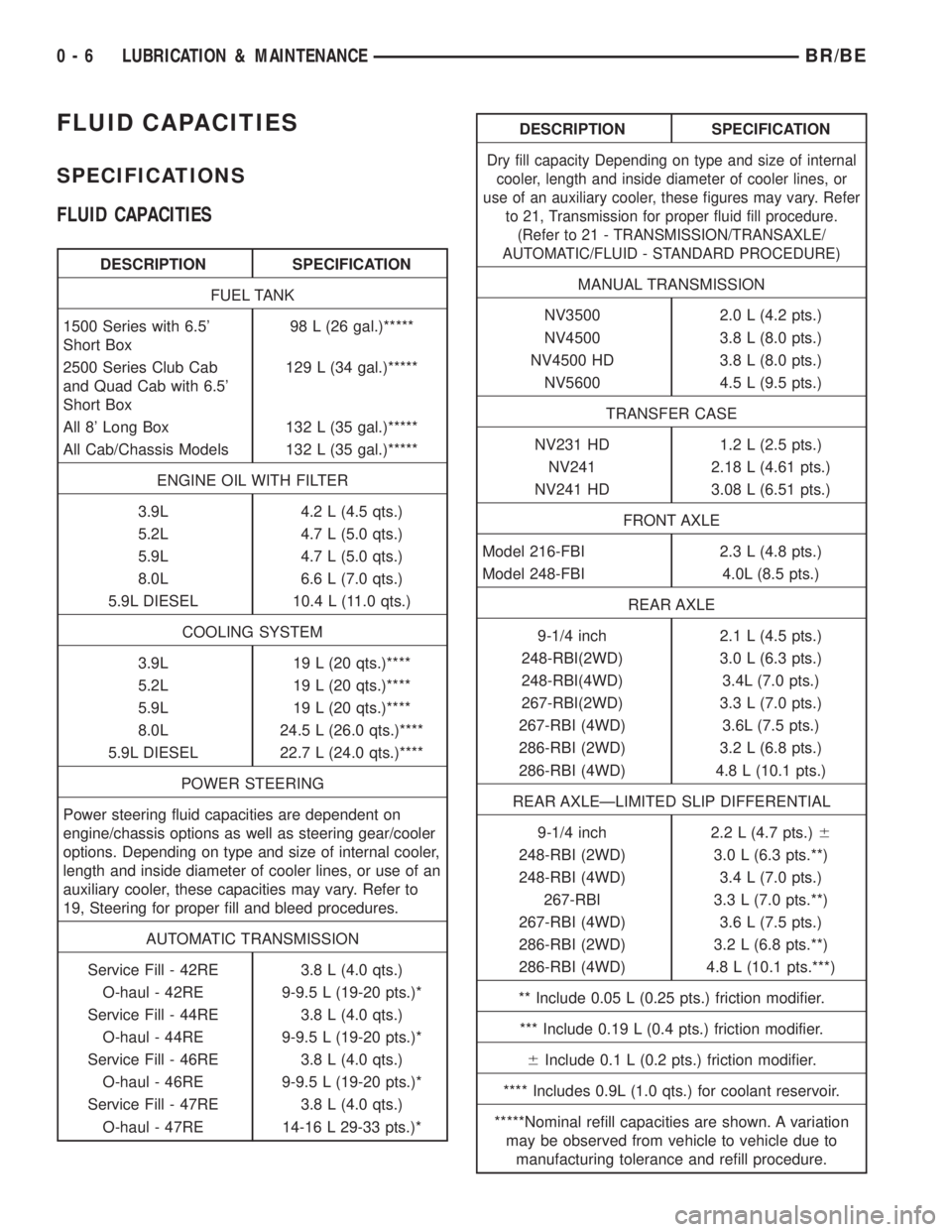

DESCRIPTION SPECIFICATION

FUEL TANK

1500 Series with 6.5'

Short Box98 L (26 gal.)*****

2500 Series Club Cab

and Quad Cab with 6.5'

Short Box129 L (34 gal.)*****

All 8' Long Box 132 L (35 gal.)*****

All Cab/Chassis Models 132 L (35 gal.)*****

ENGINE OIL WITH FILTER

3.9L 4.2 L (4.5 qts.)

5.2L 4.7 L (5.0 qts.)

5.9L 4.7 L (5.0 qts.)

8.0L 6.6 L (7.0 qts.)

5.9L DIESEL 10.4 L (11.0 qts.)

COOLING SYSTEM

3.9L 19 L (20 qts.)****

5.2L 19 L (20 qts.)****

5.9L 19 L (20 qts.)****

8.0L 24.5 L (26.0 qts.)****

5.9L DIESEL 22.7 L (24.0 qts.)****

POWER STEERING

Power steering fluid capacities are dependent on

engine/chassis options as well as steering gear/cooler

options. Depending on type and size of internal cooler,

length and inside diameter of cooler lines, or use of an

auxiliary cooler, these capacities may vary. Refer to

19, Steering for proper fill and bleed procedures.

AUTOMATIC TRANSMISSION

Service Fill - 42RE 3.8 L (4.0 qts.)

O-haul - 42RE 9-9.5 L (19-20 pts.)*

Service Fill - 44RE 3.8 L (4.0 qts.)

O-haul - 44RE 9-9.5 L (19-20 pts.)*

Service Fill - 46RE 3.8 L (4.0 qts.)

O-haul - 46RE 9-9.5 L (19-20 pts.)*

Service Fill - 47RE 3.8 L (4.0 qts.)

O-haul - 47RE 14-16 L 29-33 pts.)*

DESCRIPTION SPECIFICATION

Dry fill capacity Depending on type and size of internal

cooler, length and inside diameter of cooler lines, or

use of an auxiliary cooler, these figures may vary. Refer

to 21, Transmission for proper fluid fill procedure.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

AUTOMATIC/FLUID - STANDARD PROCEDURE)

MANUAL TRANSMISSION

NV3500 2.0 L (4.2 pts.)

NV4500 3.8 L (8.0 pts.)

NV4500 HD 3.8 L (8.0 pts.)

NV5600 4.5 L (9.5 pts.)

TRANSFER CASE

NV231 HD 1.2 L (2.5 pts.)

NV241 2.18 L (4.61 pts.)

NV241 HD 3.08 L (6.51 pts.)

FRONT AXLE

Model 216-FBI 2.3 L (4.8 pts.)

Model 248-FBI 4.0L (8.5 pts.)

REAR AXLE

9-1/4 inch 2.1 L (4.5 pts.)

248-RBI(2WD) 3.0 L (6.3 pts.)

248-RBI(4WD) 3.4L (7.0 pts.)

267-RBI(2WD) 3.3 L (7.0 pts.)

267-RBI (4WD) 3.6L (7.5 pts.)

286-RBI (2WD) 3.2 L (6.8 pts.)

286-RBI (4WD) 4.8 L (10.1 pts.)

REAR AXLEÐLIMITED SLIP DIFFERENTIAL

9-1/4 inch 2.2 L (4.7 pts.)6

248-RBI (2WD) 3.0 L (6.3 pts.**)

248-RBI (4WD) 3.4 L (7.0 pts.)

267-RBI 3.3 L (7.0 pts.**)

267-RBI (4WD) 3.6 L (7.5 pts.)

286-RBI (2WD) 3.2 L (6.8 pts.**)

286-RBI (4WD) 4.8 L (10.1 pts.***)

** Include 0.05 L (0.25 pts.) friction modifier.

*** Include 0.19 L (0.4 pts.) friction modifier.

6Include 0.1 L (0.2 pts.) friction modifier.

**** Includes 0.9L (1.0 qts.) for coolant reservoir.

*****Nominal refill capacities are shown. A variation

may be observed from vehicle to vehicle due to

manufacturing tolerance and refill procedure.

0 - 6 LUBRICATION & MAINTENANCEBR/BE

Page 417 of 2889

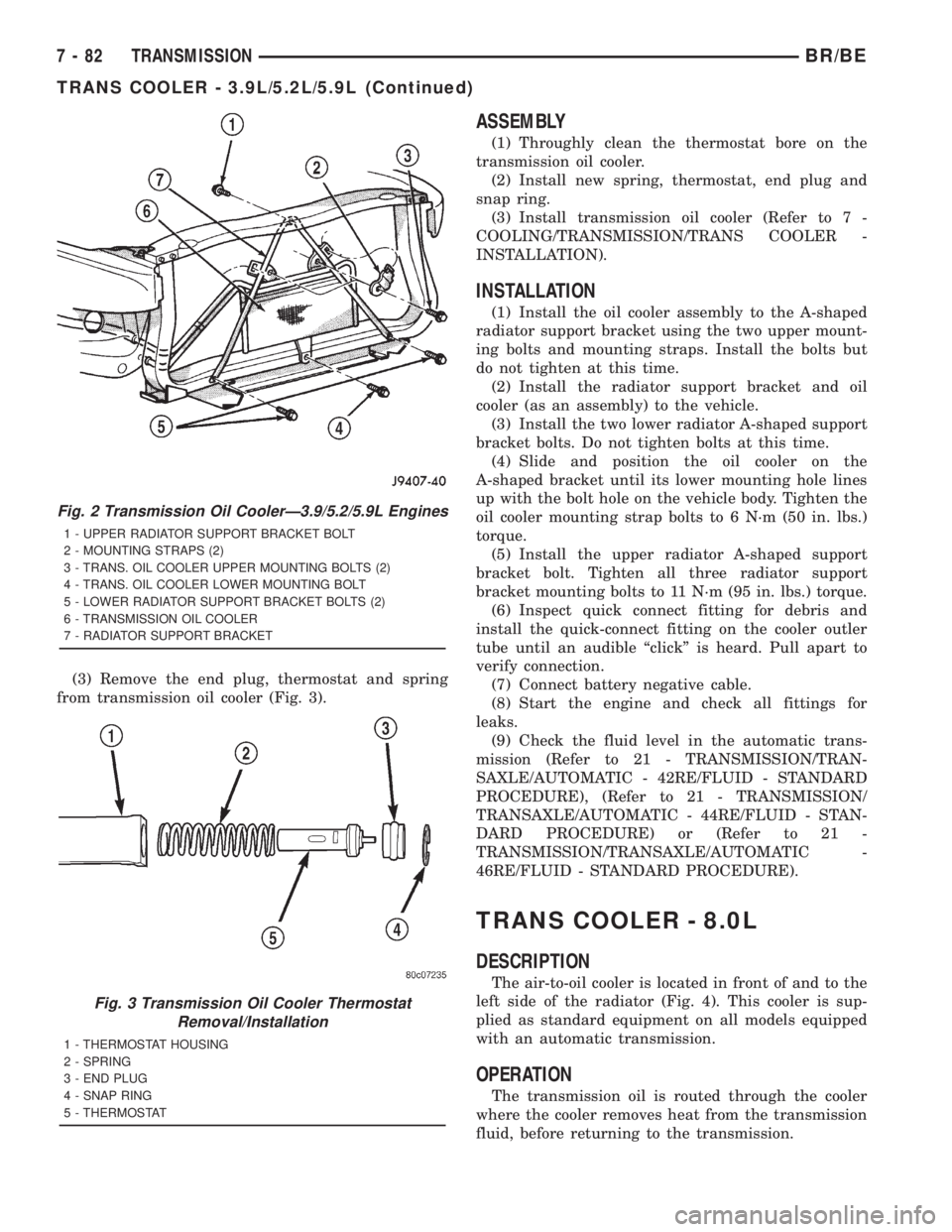

(3) Remove the end plug, thermostat and spring

from transmission oil cooler (Fig. 3).

ASSEMBLY

(1) Throughly clean the thermostat bore on the

transmission oil cooler.

(2) Install new spring, thermostat, end plug and

snap ring.

(3) Install transmission oil cooler (Refer to 7 -

COOLING/TRANSMISSION/TRANS COOLER -

INSTALLATION).

INSTALLATION

(1) Install the oil cooler assembly to the A-shaped

radiator support bracket using the two upper mount-

ing bolts and mounting straps. Install the bolts but

do not tighten at this time.

(2) Install the radiator support bracket and oil

cooler (as an assembly) to the vehicle.

(3) Install the two lower radiator A-shaped support

bracket bolts. Do not tighten bolts at this time.

(4) Slide and position the oil cooler on the

A-shaped bracket until its lower mounting hole lines

up with the bolt hole on the vehicle body. Tighten the

oil cooler mounting strap bolts to 6 N´m (50 in. lbs.)

torque.

(5) Install the upper radiator A-shaped support

bracket bolt. Tighten all three radiator support

bracket mounting bolts to 11 N´m (95 in. lbs.) torque.

(6) Inspect quick connect fitting for debris and

install the quick-connect fitting on the cooler outler

tube until an audible ªclickº is heard. Pull apart to

verify connection.

(7) Connect battery negative cable.

(8) Start the engine and check all fittings for

leaks.

(9) Check the fluid level in the automatic trans-

mission (Refer to 21 - TRANSMISSION/TRAN-

SAXLE/AUTOMATIC - 42RE/FLUID - STANDARD

PROCEDURE), (Refer to 21 - TRANSMISSION/

TRANSAXLE/AUTOMATIC - 44RE/FLUID - STAN-

DARD PROCEDURE) or (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

46RE/FLUID - STANDARD PROCEDURE).

TRANS COOLER - 8.0L

DESCRIPTION

The air-to-oil cooler is located in front of and to the

left side of the radiator (Fig. 4). This cooler is sup-

plied as standard equipment on all models equipped

with an automatic transmission.

OPERATION

The transmission oil is routed through the cooler

where the cooler removes heat from the transmission

fluid, before returning to the transmission.

Fig. 2 Transmission Oil CoolerÐ3.9/5.2/5.9L Engines

1 - UPPER RADIATOR SUPPORT BRACKET BOLT

2 - MOUNTING STRAPS (2)

3 - TRANS. OIL COOLER UPPER MOUNTING BOLTS (2)

4 - TRANS. OIL COOLER LOWER MOUNTING BOLT

5 - LOWER RADIATOR SUPPORT BRACKET BOLTS (2)

6 - TRANSMISSION OIL COOLER

7 - RADIATOR SUPPORT BRACKET

Fig. 3 Transmission Oil Cooler Thermostat

Removal/Installation

1 - THERMOSTAT HOUSING

2 - SPRING

3 - END PLUG

4 - SNAP RING

5 - THERMOSTAT

7 - 82 TRANSMISSIONBR/BE

TRANS COOLER - 3.9L/5.2L/5.9L (Continued)

Page 1604 of 2889

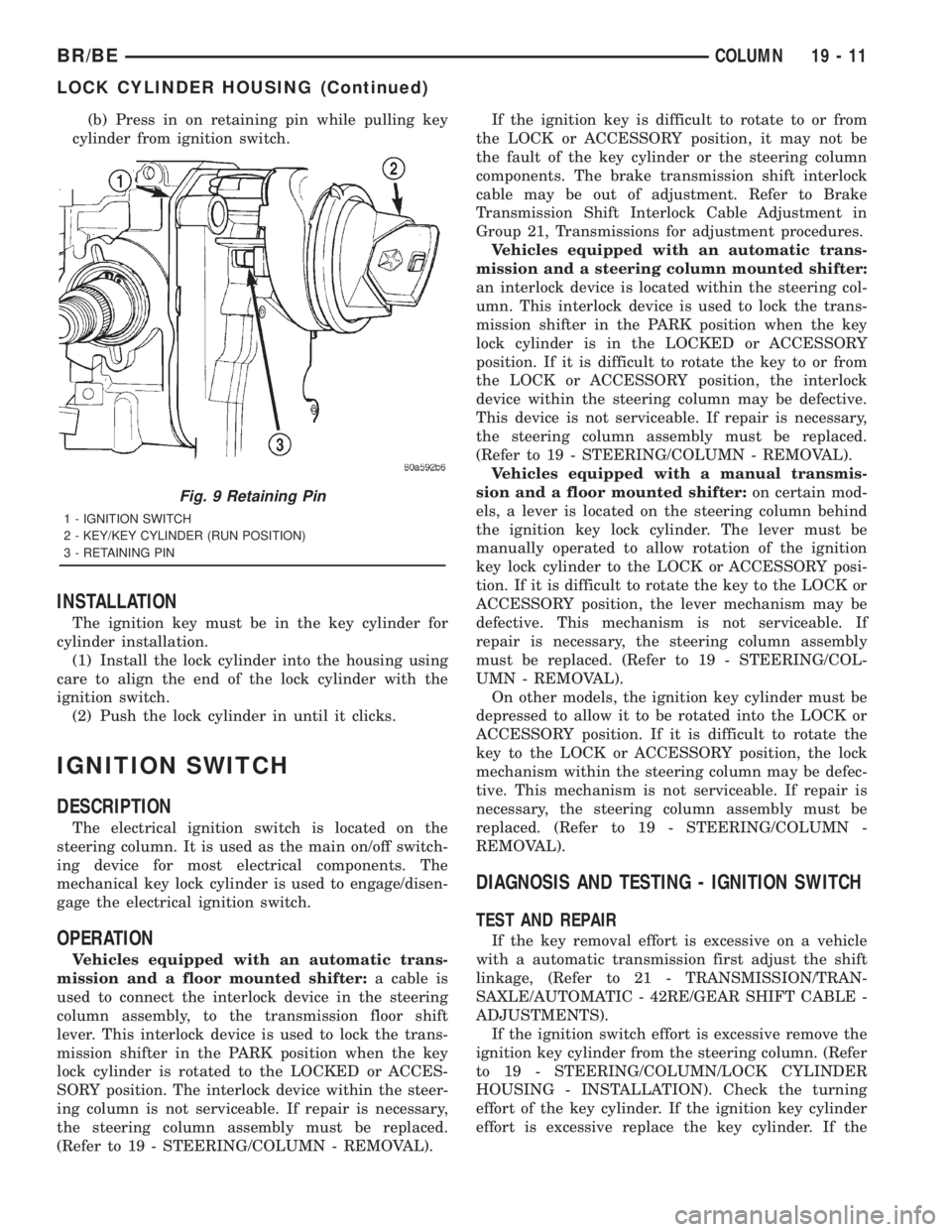

(b) Press in on retaining pin while pulling key

cylinder from ignition switch.

INSTALLATION

The ignition key must be in the key cylinder for

cylinder installation.

(1) Install the lock cylinder into the housing using

care to align the end of the lock cylinder with the

ignition switch.

(2) Push the lock cylinder in until it clicks.

IGNITION SWITCH

DESCRIPTION

The electrical ignition switch is located on the

steering column. It is used as the main on/off switch-

ing device for most electrical components. The

mechanical key lock cylinder is used to engage/disen-

gage the electrical ignition switch.

OPERATION

Vehicles equipped with an automatic trans-

mission and a floor mounted shifter:a cable is

used to connect the interlock device in the steering

column assembly, to the transmission floor shift

lever. This interlock device is used to lock the trans-

mission shifter in the PARK position when the key

lock cylinder is rotated to the LOCKED or ACCES-

SORY position. The interlock device within the steer-

ing column is not serviceable. If repair is necessary,

the steering column assembly must be replaced.

(Refer to 19 - STEERING/COLUMN - REMOVAL).If the ignition key is difficult to rotate to or from

the LOCK or ACCESSORY position, it may not be

the fault of the key cylinder or the steering column

components. The brake transmission shift interlock

cable may be out of adjustment. Refer to Brake

Transmission Shift Interlock Cable Adjustment in

Group 21, Transmissions for adjustment procedures.

Vehicles equipped with an automatic trans-

mission and a steering column mounted shifter:

an interlock device is located within the steering col-

umn. This interlock device is used to lock the trans-

mission shifter in the PARK position when the key

lock cylinder is in the LOCKED or ACCESSORY

position. If it is difficult to rotate the key to or from

the LOCK or ACCESSORY position, the interlock

device within the steering column may be defective.

This device is not serviceable. If repair is necessary,

the steering column assembly must be replaced.

(Refer to 19 - STEERING/COLUMN - REMOVAL).

Vehicles equipped with a manual transmis-

sion and a floor mounted shifter:on certain mod-

els, a lever is located on the steering column behind

the ignition key lock cylinder. The lever must be

manually operated to allow rotation of the ignition

key lock cylinder to the LOCK or ACCESSORY posi-

tion. If it is difficult to rotate the key to the LOCK or

ACCESSORY position, the lever mechanism may be

defective. This mechanism is not serviceable. If

repair is necessary, the steering column assembly

must be replaced. (Refer to 19 - STEERING/COL-

UMN - REMOVAL).

On other models, the ignition key cylinder must be

depressed to allow it to be rotated into the LOCK or

ACCESSORY position. If it is difficult to rotate the

key to the LOCK or ACCESSORY position, the lock

mechanism within the steering column may be defec-

tive. This mechanism is not serviceable. If repair is

necessary, the steering column assembly must be

replaced. (Refer to 19 - STEERING/COLUMN -

REMOVAL).

DIAGNOSIS AND TESTING - IGNITION SWITCH

TEST AND REPAIR

If the key removal effort is excessive on a vehicle

with a automatic transmission first adjust the shift

linkage, (Refer to 21 - TRANSMISSION/TRAN-

SAXLE/AUTOMATIC - 42RE/GEAR SHIFT CABLE -

ADJUSTMENTS).

If the ignition switch effort is excessive remove the

ignition key cylinder from the steering column. (Refer

to 19 - STEERING/COLUMN/LOCK CYLINDER

HOUSING - INSTALLATION). Check the turning

effort of the key cylinder. If the ignition key cylinder

effort is excessive replace the key cylinder. If the

Fig. 9 Retaining Pin

1 - IGNITION SWITCH

2 - KEY/KEY CYLINDER (RUN POSITION)

3 - RETAINING PIN

BR/BECOLUMN 19 - 11

LOCK CYLINDER HOUSING (Continued)

Page 1636 of 2889

TRANSMISSION AND TRANSFER CASE

TABLE OF CONTENTS

page page

MANUAL - NV3500........................1

MANUAL - NV4500.......................44

MANUAL - NV5600.......................91

AUTOMATIC TRANSMISSION - 42RE........134

AUTOMATIC TRANSMISSION - 44RE........305AUTOMATIC TRANSMISSION - 46RE........477

AUTOMATIC TRANSMISSION - 47RE........648

TRANSFER CASE - NV231HD..............820

TRANSFER CASE - NV241LD..............855

TRANSFER CASE - NV241HD..............890

MANUAL - NV3500

TABLE OF CONTENTS

page page

MANUAL - NV3500

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................3

MANUAL TRANSMISSION.................3

REMOVAL...............................3

DISASSEMBLY............................5CLEANING..............................15

INSPECTION............................15

ASSEMBLY.............................17

INSTALLATION...........................40

SPECIFICATIONS........................41

SPECIAL TOOLS.........................41

MANUAL - NV3500

DESCRIPTION

The NV3500 is a medium-duty 5-speed, constant

mesh fully synchronized manual transmission. Fifth

gear is an overdrive range with a ratio of 0.73:1. The

NV3500 is available in two and four-wheel drive con-

figurations.

The transmission gear case consists of two alumi-

num housings (Fig. 1). The clutch housing is not a

removable component. It is an integral part of the

transmission front housing.

A combination of roller and ball bearings are used

to support the transmission shafts in the two hous-

ings. The transmission gears all rotate on caged type

needle bearings. A roller bearing is used between the

input and output shaft.

The transmission has a single shaft shift mecha-

nism with three shift forks all mounted on the shaft.

The shaft is supported in the front and rear housings

by bushings and one linear ball bearing. Internal

shift components consist of the forks, shaft, shift

lever socket, and detent components

GEAR RATIOS

Gear ratios is as follows:

GEAR RATIO

FIRST 4.02:1

SECOND 2.32:1

THIRD 1.40:1

FOURTH 1:1

FIFTH 0.73:1

REVERSE 3.55:1

OPERATION

The manual transmission receives power through

the clutch assembly from the engine. The clutch disc

is splined to the transmission input shaft and is

turned at engine speed at all times that the clutch is

engaged. The input shaft is connected to the trans-

mission countershaft through the mesh of fourth

speed gear on the input shaft and the fourth counter-

shaft gear. At this point, all the transmission gears

are spinning.

BR/BETRANSMISSION AND TRANSFER CASE 21 - 1

Page 1769 of 2889

AUTOMATIC TRANSMISSION - 42RE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 42RE

DESCRIPTION..........................135

OPERATION............................137

DIAGNOSIS AND TESTING................143

AUTOMATIC TRANSMISSION.............143

PRELIMINARY........................143

ROAD TESTING.......................143

HYDRAULIC PRESSURE TEST...........144

AIR CHECKING TRANSMISSION CLUTCH

AND BAND OPERATION.................147

CONVERTER HOUSING FLUID LEAK......148

DIAGNOSIS CHARTS...................149

STANDARD PROCEDURE.................159

ALUMINUM THREAD REPAIR.............159

REMOVAL.............................159

DISASSEMBLY..........................160

CLEANING.............................165

INSPECTION...........................165

ASSEMBLY............................166

INSTALLATION..........................173

SCHEMATICS AND DIAGRAMS.............174

SPECIFICATIONS........................186

SPECIAL TOOLS........................188

ACCUMULATOR

DESCRIPTION..........................191

OPERATION............................191

INSPECTION...........................192

BANDS

DESCRIPTION..........................192

OPERATION............................192

ADJUSTMENTS.........................193

ELECTRONIC GOVERNOR

DESCRIPTION..........................194

OPERATION............................194

REMOVAL.............................196

INSTALLATION..........................197

EXTENSION HOUSING BUSHING

REMOVAL.............................198

INSTALLATION..........................198

EXTENSION HOUSING SEAL

REMOVAL.............................198

INSTALLATION..........................198

FLUID AND FILTER

DIAGNOSIS AND TESTING................199

EFFECTS OF INCORRECT FLUID LEVEL . . . 199

CAUSES OF BURNT FLUID..............199

FLUID CONTAMINATION................199

STANDARD PROCEDURE.................199

FLUID LEVEL CHECK...................199FLUID AND FILTER REPLACEMENT.......201

TRANSMISSION FILL...................201

FRONT CLUTCH

DESCRIPTION..........................202

OPERATION............................202

DISASSEMBLY..........................202

INSPECTION...........................205

ASSEMBLY............................206

FRONT SERVO

DESCRIPTION..........................206

OPERATION............................207

DISASSEMBLY..........................207

CLEANING.............................207

INSPECTION...........................207

ASSEMBLY............................208

OIL PUMP

DESCRIPTION..........................208

OPERATION............................208

STANDARD PROCEDURE.................209

OIL PUMP VOLUME CHECK..............209

DISASSEMBLY..........................209

CLEANING.............................211

INSPECTION...........................211

ASSEMBLY............................212

OUTPUT SHAFT FRONT BEARING

REMOVAL.............................213

INSTALLATION..........................213

OUTPUT SHAFT REAR BEARING

REMOVAL.............................213

INSTALLATION..........................213

OVERDRIVE CLUTCH

DESCRIPTION..........................214

OPERATION............................214

OVERDRIVE OFF SWITCH

DESCRIPTION..........................215

OPERATION............................215

DIAGNOSIS AND TESTING................215

OVERDRIVE ELECTRICAL CONTROLS.....215

REMOVAL.............................215

INSTALLATION..........................215

OVERDRIVE UNIT

REMOVAL.............................216

DISASSEMBLY..........................217

CLEANING.............................224

INSPECTION...........................224

ASSEMBLY............................225

INSTALLATION..........................234

21 - 134 AUTOMATIC TRANSMISSION - 42REBR/BE

Page 1770 of 2889

OVERRUNNING CLUTCH CAM/OVERDRIVE

PISTON RETAINER

DESCRIPTION..........................235

OPERATION............................235

DISASSEMBLY..........................235

CLEANING.............................236

INSPECTION...........................236

ASSEMBLY............................236

PARK/NEUTRAL POSITION SWITCH

DIAGNOSIS AND TESTING................237

PARK/NEUTRAL POSITION SWITCH.......237

REMOVAL.............................238

INSTALLATION..........................238

PISTONS

DESCRIPTION..........................238

OPERATION............................238

PLANETARY GEARTRAIN/OUTPUT SHAFT

DESCRIPTION..........................240

OPERATION............................240

DISASSEMBLY..........................240

INSPECTION...........................241

ASSEMBLY............................241

REAR CLUTCH

DESCRIPTION..........................246

OPERATION............................246

DISASSEMBLY..........................247

CLEANING.............................247

INSPECTION...........................248

ASSEMBLY............................248

REAR SERVO

DESCRIPTION..........................250

OPERATION............................250

DISASSEMBLY..........................251

CLEANING.............................251

ASSEMBLY............................251

SHIFT MECHANISM

DESCRIPTION..........................251OPERATION............................251

ADJUSTMENTS.........................252

SOLENOID

DESCRIPTION..........................252

OPERATION............................253

SPEED SENSOR

DESCRIPTION..........................253

OPERATION............................253

THROTTLE VALVE CABLE

DESCRIPTION..........................253

ADJUSTMENTS.........................254

TORQUE CONVERTER

DESCRIPTION..........................256

OPERATION............................260

REMOVAL.............................261

INSTALLATION..........................261

TORQUE CONVERTER DRAINBACK VALVE

DESCRIPTION..........................262

OPERATION............................262

STANDARD PROCEDURE.................262

TORQUE CONVERTER DRAINBACK VALVE . 262

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION..........................262

OPERATION............................262

VALVE BODY

DESCRIPTION..........................263

OPERATION............................267

REMOVAL.............................281

DISASSEMBLY..........................282

CLEANING.............................293

INSPECTION...........................293

ASSEMBLY............................294

INSTALLATION..........................303

ADJUSTMENTS.........................304

AUTOMATIC TRANSMISSION -

42RE

DESCRIPTION

The 42RE is a four speed fully automatic transmis-

sion (Fig. 1) with an electronic governor. The 42RE is

equipped with a lock-up clutch in the torque con-

verter. First through third gear ranges are provided

by the clutches, bands, overrunning clutch, and plan-

etary gear sets in the transmission. Fourth gear

range is provided by the overdrive unit that contains

an overdrive clutch, direct clutch, planetary gear set,

and overrunning clutch.

The transmission contains a front, rear, and direct

clutch which function as the input driving compo-

nents. It also contains the kickdown (front) and thelow/reverse (rear) bands which, along with the over-

running clutch and overdrive clutch, serve as the

holding components. The driving and holding compo-

nents combine to select the necessary planetary gear

components, in the front, rear, or overdrive planetary

gear set, transfer the engine power from the input

shaft through to the output shaft.

The valve body is mounted to the lower side of the

transmission and contains the valves to control pres-

sure regulation, fluid flow control, and clutch/band

application. The oil pump is mounted at the front of

the transmission and is driven by the torque con-

verter hub. The pump supplies the oil pressure nec-

essary for clutch/band actuation and transmission

lubrication.

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 135

Page 1771 of 2889

Fig. 1 42RE Transmission

21 - 136 AUTOMATIC TRANSMISSION - 42REBR/BE

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1772 of 2889

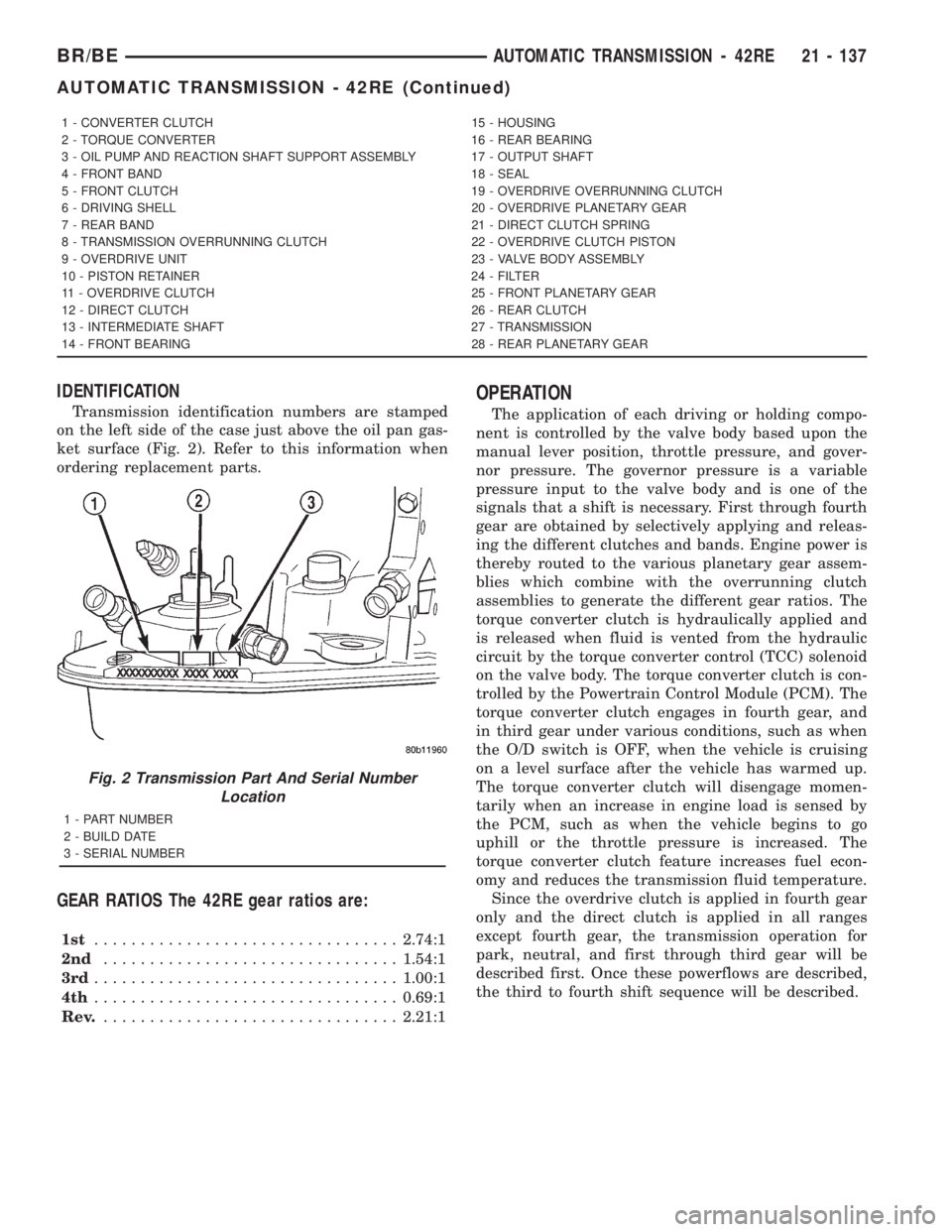

IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan gas-

ket surface (Fig. 2). Refer to this information when

ordering replacement parts.

GEAR RATIOS The 42RE gear ratios are:

1st.................................2.74:1

2nd................................1.54:1

3rd.................................1.00:1

4th.................................0.69:1

Rev.................................2.21:1

OPERATION

The application of each driving or holding compo-

nent is controlled by the valve body based upon the

manual lever position, throttle pressure, and gover-

nor pressure. The governor pressure is a variable

pressure input to the valve body and is one of the

signals that a shift is necessary. First through fourth

gear are obtained by selectively applying and releas-

ing the different clutches and bands. Engine power is

thereby routed to the various planetary gear assem-

blies which combine with the overrunning clutch

assemblies to generate the different gear ratios. The

torque converter clutch is hydraulically applied and

is released when fluid is vented from the hydraulic

circuit by the torque converter control (TCC) solenoid

on the valve body. The torque converter clutch is con-

trolled by the Powertrain Control Module (PCM). The

torque converter clutch engages in fourth gear, and

in third gear under various conditions, such as when

the O/D switch is OFF, when the vehicle is cruising

on a level surface after the vehicle has warmed up.

The torque converter clutch will disengage momen-

tarily when an increase in engine load is sensed by

the PCM, such as when the vehicle begins to go

uphill or the throttle pressure is increased. The

torque converter clutch feature increases fuel econ-

omy and reduces the transmission fluid temperature.

Since the overdrive clutch is applied in fourth gear

only and the direct clutch is applied in all ranges

except fourth gear, the transmission operation for

park, neutral, and first through third gear will be

described first. Once these powerflows are described,

the third to fourth shift sequence will be described.

1 - CONVERTER CLUTCH 15 - HOUSING

2 - TORQUE CONVERTER 16 - REAR BEARING

3 - OIL PUMP AND REACTION SHAFT SUPPORT ASSEMBLY 17 - OUTPUT SHAFT

4 - FRONT BAND 18 - SEAL

5 - FRONT CLUTCH 19 - OVERDRIVE OVERRUNNING CLUTCH

6 - DRIVING SHELL 20 - OVERDRIVE PLANETARY GEAR

7 - REAR BAND 21 - DIRECT CLUTCH SPRING

8 - TRANSMISSION OVERRUNNING CLUTCH 22 - OVERDRIVE CLUTCH PISTON

9 - OVERDRIVE UNIT 23 - VALVE BODY ASSEMBLY

10 - PISTON RETAINER 24 - FILTER

11 - OVERDRIVE CLUTCH 25 - FRONT PLANETARY GEAR

12 - DIRECT CLUTCH 26 - REAR CLUTCH

13 - INTERMEDIATE SHAFT 27 - TRANSMISSION

14 - FRONT BEARING 28 - REAR PLANETARY GEAR

Fig. 2 Transmission Part And Serial Number

Location

1 - PART NUMBER

2 - BUILD DATE

3 - SERIAL NUMBER

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 137

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1773 of 2889

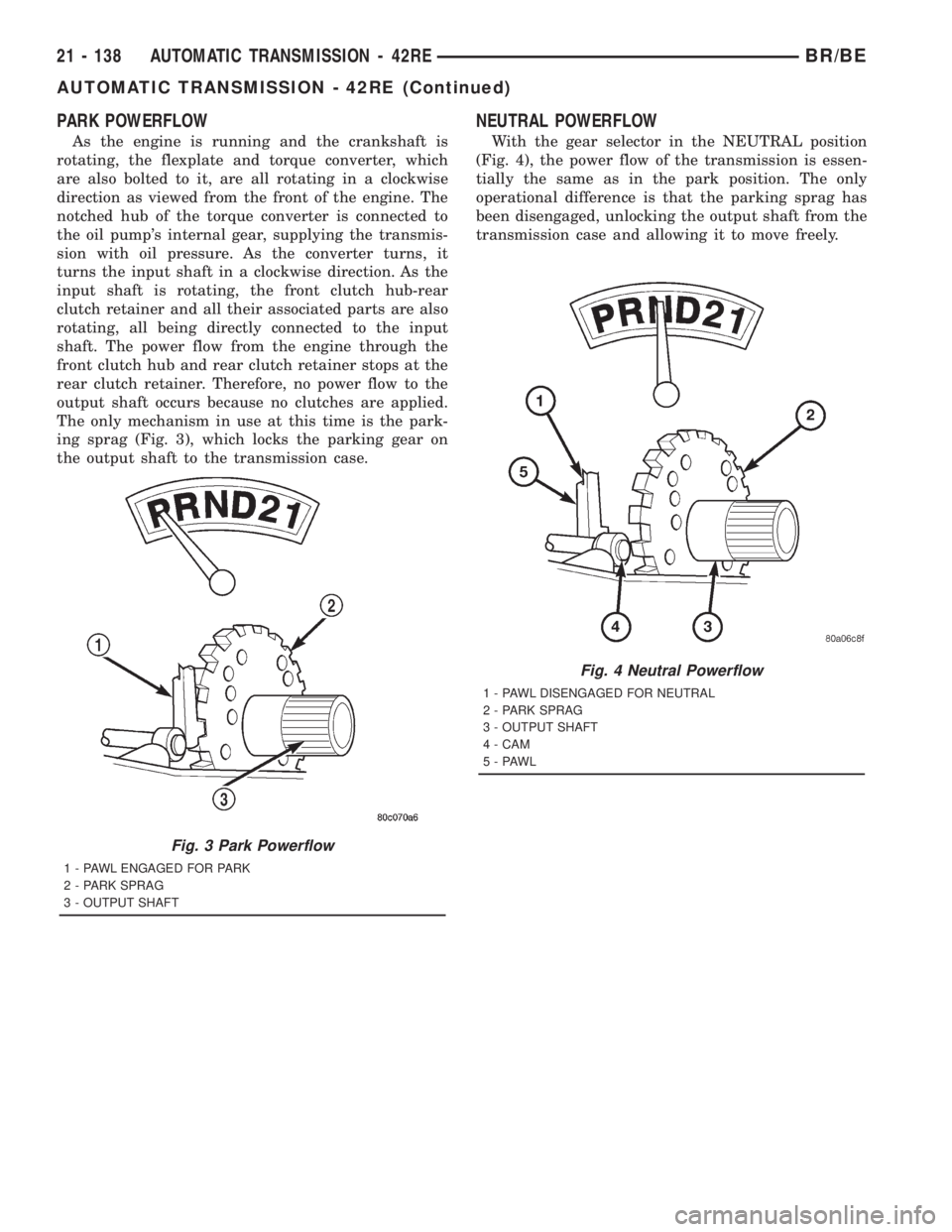

PARK POWERFLOW

As the engine is running and the crankshaft is

rotating, the flexplate and torque converter, which

are also bolted to it, are all rotating in a clockwise

direction as viewed from the front of the engine. The

notched hub of the torque converter is connected to

the oil pump's internal gear, supplying the transmis-

sion with oil pressure. As the converter turns, it

turns the input shaft in a clockwise direction. As the

input shaft is rotating, the front clutch hub-rear

clutch retainer and all their associated parts are also

rotating, all being directly connected to the input

shaft. The power flow from the engine through the

front clutch hub and rear clutch retainer stops at the

rear clutch retainer. Therefore, no power flow to the

output shaft occurs because no clutches are applied.

The only mechanism in use at this time is the park-

ing sprag (Fig. 3), which locks the parking gear on

the output shaft to the transmission case.

NEUTRAL POWERFLOW

With the gear selector in the NEUTRAL position

(Fig. 4), the power flow of the transmission is essen-

tially the same as in the park position. The only

operational difference is that the parking sprag has

been disengaged, unlocking the output shaft from the

transmission case and allowing it to move freely.

Fig. 3 Park Powerflow

1 - PAWL ENGAGED FOR PARK

2 - PARK SPRAG

3 - OUTPUT SHAFT

Fig. 4 Neutral Powerflow

1 - PAWL DISENGAGED FOR NEUTRAL

2 - PARK SPRAG

3 - OUTPUT SHAFT

4 - CAM

5-PAWL

21 - 138 AUTOMATIC TRANSMISSION - 42REBR/BE

AUTOMATIC TRANSMISSION - 42RE (Continued)