clock setting DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 425 of 2889

Refer to Electrical, Restraints for more information

on the clockspring. Refer to Electrical, Body Control/

Central Control Module for more information on the

Central Timer Module. Refer to the appropriate wir-

ing information. The wiring information includes wir-

ing diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds. Following are general descriptions of

the remaining major components in the standard and

optional factory-installed audio systems.

OPERATION

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of each of the available audio systems.

CENTRAL TIMER MODULE

The high-line or premium Central Timer Module

(CTM) can also control some features of the audio

system when the vehicle is equipped with the

optional RAZ radio receiver and remote radio

switches. A high-line CTM is used on high-line ver-

sions of this vehicle. A premium CTM is used on

vehicles equipped with the optional heated seats. The

CTM combines the functions of a chime/buzzer mod-

ule, an intermittent wipe module, an illuminated

entry module, a remote keyless entry module, and a

vehicle theft security system module in a single unit.

The high-line or premium CTM also controls and

integrates many of the additional electronic functions

and features included on models with this option.The RAZ radio receiver with a remote radio switch

option is one of the features that the CTM controls.

The CTM is programmed to send switch status mes-

sages over the Chrysler Collision Detection (CCD)

data bus to control the volume, seek, and pre-set sta-

tion advance functions of the RAZ radio receiver. The

CTM monitors the status of the remote radio

switches located on the steering wheel through a

hard wired circuit. The CTM then sends the proper

switch status messages to the radio receiver. The

electronic circuitry within the radio receiver responds

to the switch status messages it receives by adjusting

the radio settings as requested.

Refer to Electrical, Body Control/Central Timer

Module for more information on the high-line CTM.

Refer to Remote Radio Switch in Description and

Operation for more information on this component.

In addition, radio receivers connected to the CCD

data bus have several audio system functions that

can be diagnosed using a DRBIIItscan tool. Refer to

the proper Diagnostic Procedures manual for more

information on DRBIIIttesting of the audio systems.

DIAGNOSIS AND TESTING - AUDIO

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

8A - 2 AUDIOBR/BE

AUDIO (Continued)

Page 433 of 2889

(7) Remove the radio receiver from the instrument

panel. Refer to Audio, Radio for the procedures.

(8) Pull the antenna cable out through the radio

receiver opening in the instrument panel.

(9) Untie the cord or twine from the instrument

panel antenna cable connector, leaving the cord or

twine in place of the cable in the instrument panel.

(10) Remove the antenna cable from the instru-

ment panel.

INSTALLATION

(1) Tie the end of the cord or twine that was used

during instrument panel antenna cable removal

securely to the connector on the end of the antenna

cable being installed into the instrument panel. This

cord will be used to pull or ªfishº the cable back into

position.

(2) Using the cord or twine, pull the antenna cable

through the radio receiver opening from under the

instrument panel.

(3) Install the radio receiver onto the instrument

panel. Refer to Audio, Radio for the procedures.

(4) Reach through the glove box opening to engage

the antenna cable with the retainer clips on the back

of the instrument panel.

(5) Install the glove box onto the instrument panel.

Refer to Body, Instrument Panel for the procedures.

(6) Untie the cord or twine from the instrument

panel antenna cable connector.

(7) Reach under the passenger side of the instru-

ment panel near the right cowl side inner panel to

reconnect the two halves of the radio antenna coaxial

cable connector. Wrap the connection with a piece of

foam tape.

(8) Engage the coaxial cable connector with the

retainer clip located on the bottom of the heater-A/C

housing.

(9) Reconnect the battery negative cable.

RADIO

DESCRIPTION

Available factory-installed radio receivers for this

model include an AM/FM/cassette (RAS sales code),

an AM/FM/cassette/5-band graphic equalizer with CD

changer control feature (RBN sales code), an AM/FM/

CD/3-band graphic equalizer (RBR sales code), or an

AM/FM/CD/cassette/3-band graphic equalizer (RAZ

sales code). The factory-installed RAZ sales code

radio receivers can also communicate on the Chrysler

Collision Detection (CCD) data bus network through

a separate two-way wire harness connector. All facto-

ry-installed receivers are stereo Electronically Tuned

Radios (ETR) and include an electronic digital clock

function.These radio receivers can only be serviced by an

authorized radio repair station. See the latest War-

ranty Policies and Procedures manual for a current

listing of authorized radio repair stations.

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed when the vehicle is

shipped from the factory. This fuse feeds various

accessories that require battery current when the

ignition switch is in the Off position, including the

clock. The IOD fuse is removed to prevent battery

discharge during vehicle storage.

When removing or installing the IOD fuse, it is

important that the ignition switch be in the Off posi-

tion. Failure to place the ignition switch in the Off

position can cause the radio display to become scram-

bled when the IOD fuse is removed and replaced.

Removing and replacing the IOD fuse again, with the

ignition switch in the Off position, will correct the

scrambled display condition.

The IOD fuse should be checked if the radio or

clock displays are inoperative. The IOD fuse is

located in the junction block. Refer to the fuse layout

label on the back of the instrument panel fuse access

panel for IOD fuse identification and location.

OPERATION

The radio receiver operates on fused battery cur-

rent that is available only when the ignition switch is

in the On or Accessory positions. The electronic digi-

tal clock function of the radio operates on fused bat-

tery current supplied through the IOD fuse,

regardless of the ignition switch position.

For more information on the features, setting pro-

cedures, and control functions for each of the avail-

able factory-installed radio receivers, see the owner's

manual in the vehicle glove box. For complete circuit

diagrams, refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - RADIO

If the vehicle is equipped with the optional remote

radio switches located on the steering wheel and the

problem being diagnosed is related to one of the

symptoms listed below, be certain to check the

remote radio switches and circuits. Refer to Audio,

Remote Radio Switch prior to attempting radio diag-

nosis or repair.

²Stations changing with no remote radio switch

input

8A - 10 AUDIOBR/BE

INSTRUMENT PANEL ANTENNA CABLE (Continued)

Page 438 of 2889

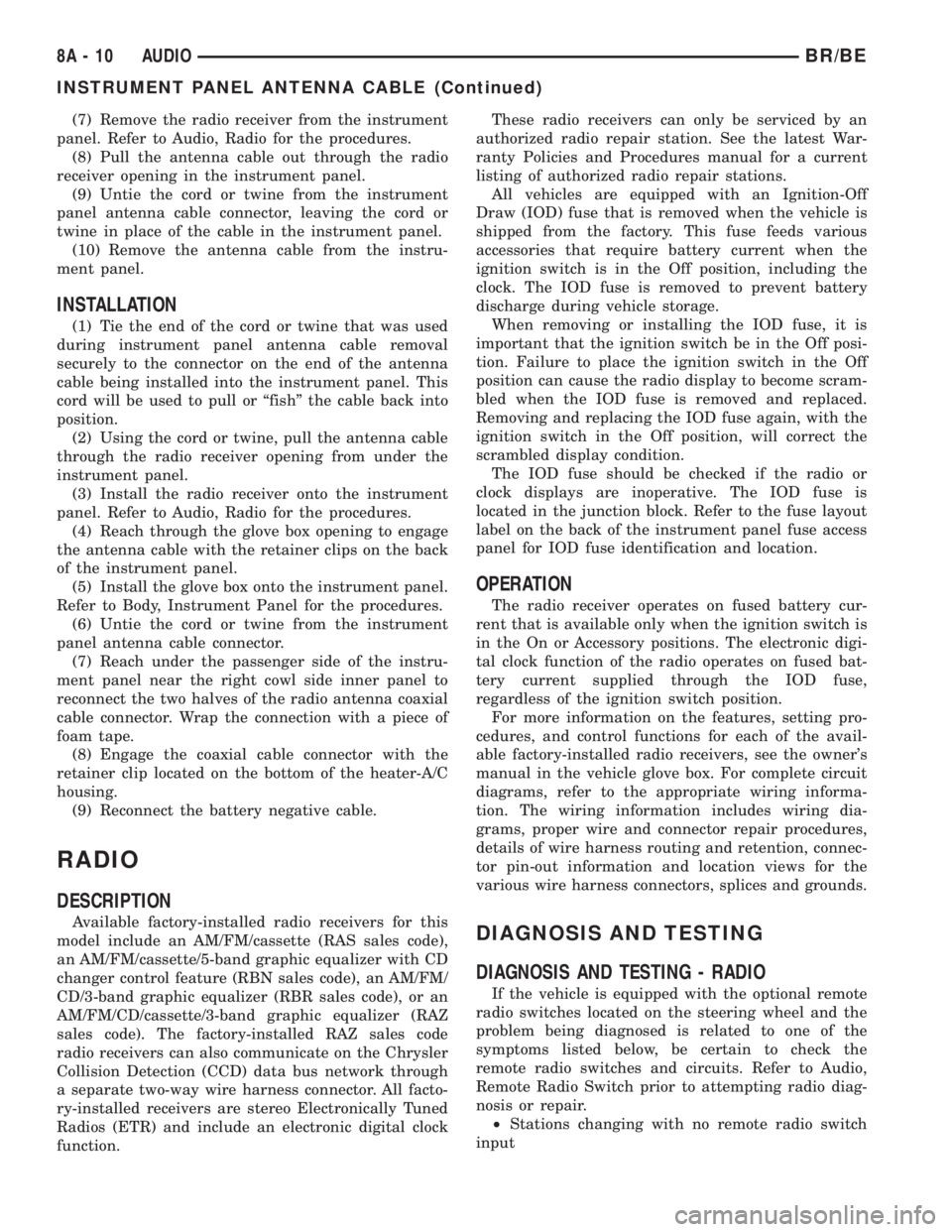

(6) Remove the heater core ground strap from the

top of the heater-A/C housing.

INSTALLATION

(1) Position the heater core ground strap and the

heater core tube retaining strap to the top of the

heater-A/C housing.

(2) Install and tighten the screw that secures the

heater core ground strap eyelet and the heater core

tube retaining strap to the top of the heater-A/C

housing. Tighten the screw to 2.2 N´m (20 in. lbs.).

(3) Position the heater core ground strap eyelet

over the stud on the dash panel.

(4) Install and tighten the nut that secures the

heater core ground strap eyelet to the stud on the

dash panel. Tighten the nut to 3.9 N´m (35 in. lbs.).

(5) Install the glove box onto the instrument panel.

Refer to Body, Instrument Panel for the procedures.

(6) Reconnect the battery negative cable.

REMOTE SWITCHES

DESCRIPTION

A remote radio switch option is available on models

equipped with the AM/FM/CD/cassette/3-band

graphic equalizer (RAZ sales code) radio receiver and

the high-line Central Timer Module (CTM). Refer to

Electrical, Body Control/Central Timer Module for

more information on this component.

Two rocker-type switches (Fig. 15) are mounted in

the sides of the rear (instrument panel side) steeringwheel trim cover. The switch on the left side is the

seek switch and has seek up, seek down, and preset

station advance functions. The switch on the right

side is the volume control switch and has volume up,

and volume down functions. The two switches are

retained in mounting holes located on each side of

the rear steering wheel trim cover by four latches

that are integral to the switches.

The remote radio switches share a common steer-

ing wheel wire harness with the vehicle speed control

switches. The steering wheel wire harness is con-

nected to the instrument panel wire harness through

the clockspring. Refer to Electrical, Clockspring for

more information on this component.

OPERATION

The remote radio switches are resistor multiplexed

units that are hard wired to the high-line or pre-

mium CTM through the clockspring. The CTM mon-

itors the status of the remote radio switches and

sends the proper switch status messages on the

Chrysler Collision Detection (CCD) data bus network

to the radio receiver. The electronic circuitry within

the radio is programmed to respond to these remote

radio switch status messages by adjusting the radio

settings as requested.

For diagnosis of the CTM or the CCD data bus, the

use of a DRBIIItscan tool and the proper Diagnostic

Procedures manual are recommended. For more

information on the features and control functions for

each of the remote radio switches, see the owner's

Fig. 14 Heater Core Ground Strap Remove/Install

1 - GROUND STRAP

2 - NUT

3 - HEATER-A/C HOUSING

4 - DASH PANEL

Fig. 15 Remote Radio Switches

1 - PRESET SEEK

2-UP

3 - SEEK

4 - VOLUME

5 - DOWN

BR/BEAUDIO 8A - 15

HEATER CORE GROUND STRAP (Continued)

Page 1404 of 2889

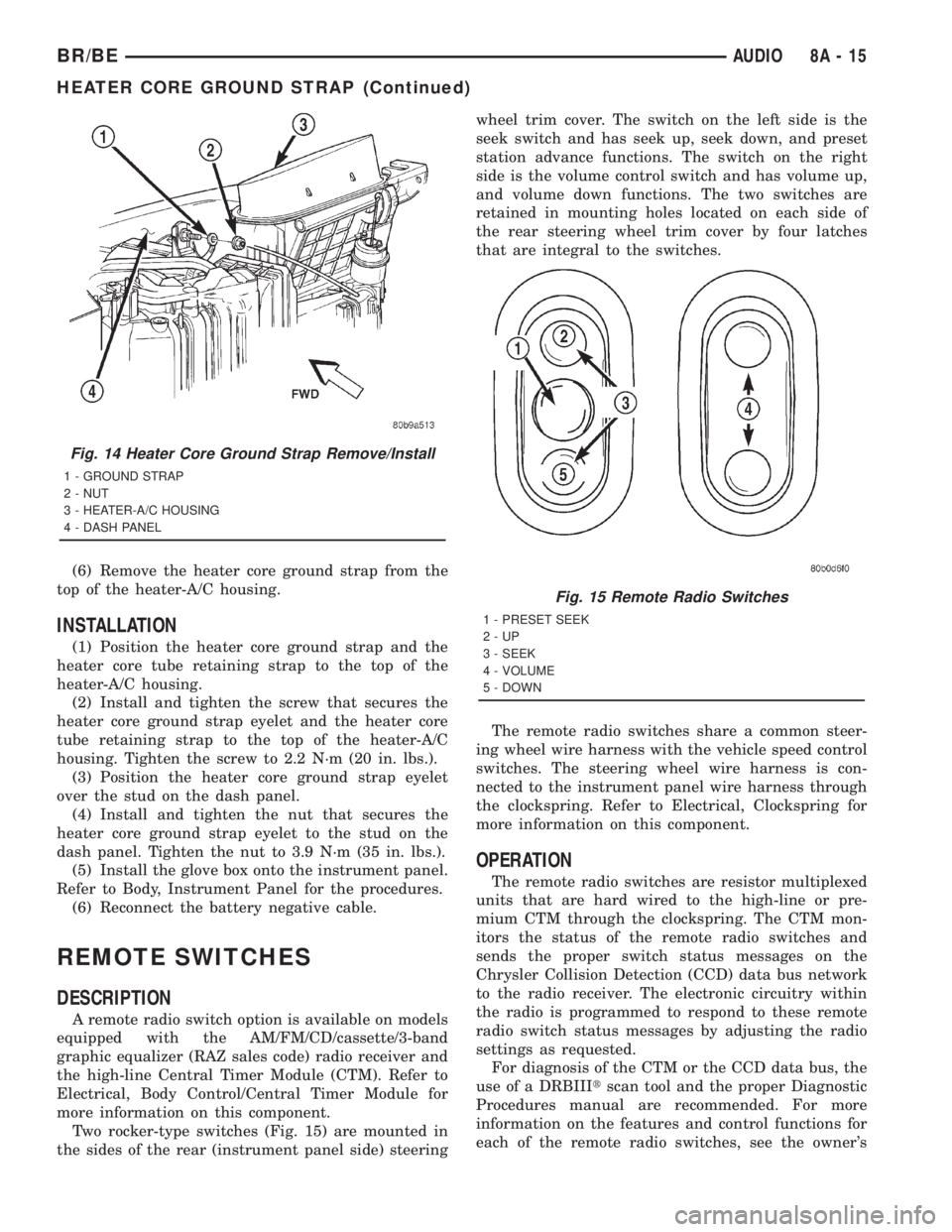

(2) Remove cylinder head cover (Fig. 47) (Refer to

9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(3) Remove the crankcase breather and vapor can-

ister (Fig. 48).

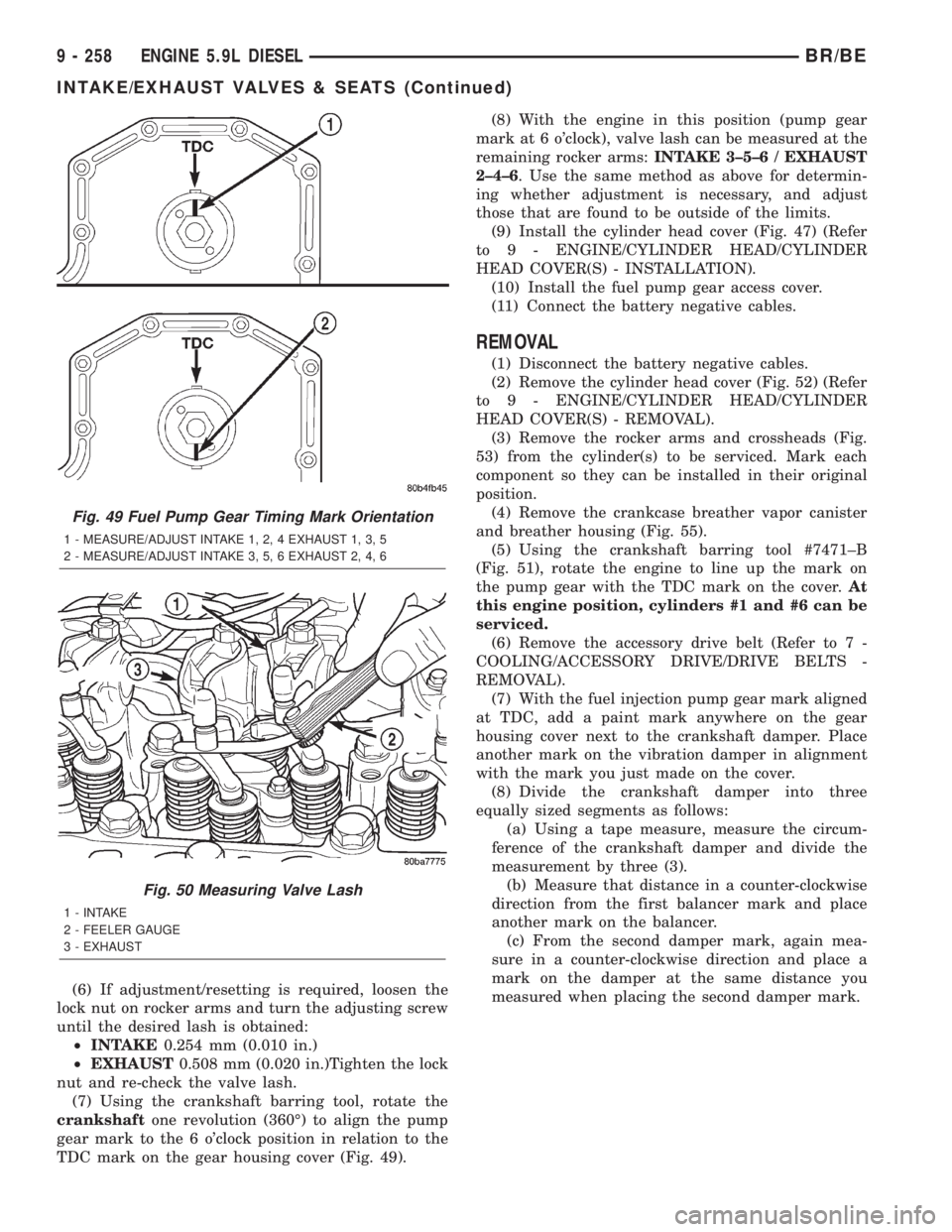

(4) Using the crankshaft barring tool #7471±B,

rotate the engine and align the pump gear mark with

the top dead center (TDC) mark on the gear housing

cover (Fig. 49).

(5) With the engine in this position (pump gear

mark at 12 o'clock), valve lash can be measured at

the following rocker arms:INTAKE 1±2±4 /

EXHAUST 1±3±5. Measure the valve lash by insert-

ing a feeler gauge between the rocker arm socket and

crosshead (Fig. 50). Refer to VALVE LASH LIMIT

CHART for the correct specifications. If the measure-

ment fallswithinthe limits, adjustment/resettingis

notnecessary. If measurement finds the lashout-

sideof the limits, adjustment/resettingisrequired.

VALVE LASH LIMIT CHART

INTAKE EXHAUST

0.152 mm ( 0.006 in.)

MIN.0.381 mm (0.015 in.)

MIN.

0.381 mm (0.015 in.)

MAX.0.762 mm (0.030 in.)

MAX.

note:

If measured valve lash falls within these

specifications, no adjustment/reset is necessary.

Engine operation within these ranges has no

adverse affect on performance, emissions, fuel

economy or level of engine noise.

Fig. 47 Cylinder Head Cover and Gasket

1 - BOLT (5)

2 - GASKET

3 - ªTOP FRONTº

4 - ISOLATOR (5)

Fig. 48 Crankcase Breather Vapor Canister

1 - ENGINE FRONT COVER STUD

2 - STRAP

3 - VAPOR CANISTER

4 - NUT

5 - CAP

6 - CRANKCASE BREATHER

7 - CLAMP

8 - HOSE

BR/BEENGINE 5.9L DIESEL 9 - 257

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1405 of 2889

(6) If adjustment/resetting is required, loosen the

lock nut on rocker arms and turn the adjusting screw

until the desired lash is obtained:

²INTAKE0.254 mm (0.010 in.)

²EXHAUST0.508 mm (0.020 in.)Tighten the lock

nut and re-check the valve lash.

(7) Using the crankshaft barring tool, rotate the

crankshaftone revolution (360É) to align the pump

gear mark to the 6 o'clock position in relation to the

TDC mark on the gear housing cover (Fig. 49).(8) With the engine in this position (pump gear

mark at 6 o'clock), valve lash can be measured at the

remaining rocker arms:INTAKE 3±5±6 / EXHAUST

2±4±6. Use the same method as above for determin-

ing whether adjustment is necessary, and adjust

those that are found to be outside of the limits.

(9) Install the cylinder head cover (Fig. 47) (Refer

to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - INSTALLATION).

(10) Install the fuel pump gear access cover.

(11) Connect the battery negative cables.

REMOVAL

(1) Disconnect the battery negative cables.

(2) Remove the cylinder head cover (Fig. 52) (Refer

to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - REMOVAL).

(3) Remove the rocker arms and crossheads (Fig.

53) from the cylinder(s) to be serviced. Mark each

component so they can be installed in their original

position.

(4) Remove the crankcase breather vapor canister

and breather housing (Fig. 55).

(5) Using the crankshaft barring tool #7471±B

(Fig. 51), rotate the engine to line up the mark on

the pump gear with the TDC mark on the cover.At

this engine position, cylinders #1 and #6 can be

serviced.

(6) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) With the fuel injection pump gear mark aligned

at TDC, add a paint mark anywhere on the gear

housing cover next to the crankshaft damper. Place

another mark on the vibration damper in alignment

with the mark you just made on the cover.

(8) Divide the crankshaft damper into three

equally sized segments as follows:

(a) Using a tape measure, measure the circum-

ference of the crankshaft damper and divide the

measurement by three (3).

(b) Measure that distance in a counter-clockwise

direction from the first balancer mark and place

another mark on the balancer.

(c) From the second damper mark, again mea-

sure in a counter-clockwise direction and place a

mark on the damper at the same distance you

measured when placing the second damper mark.

Fig. 49 Fuel Pump Gear Timing Mark Orientation

1 - MEASURE/ADJUST INTAKE 1, 2, 4 EXHAUST 1, 3, 5

2 - MEASURE/ADJUST INTAKE 3, 5, 6 EXHAUST 2, 4, 6

Fig. 50 Measuring Valve Lash

1 - INTAKE

2 - FEELER GAUGE

3 - EXHAUST

9 - 258 ENGINE 5.9L DIESELBR/BE

INTAKE/EXHAUST VALVES & SEATS (Continued)

Page 1939 of 2889

ADJUSTMENTS - VALVE BODY

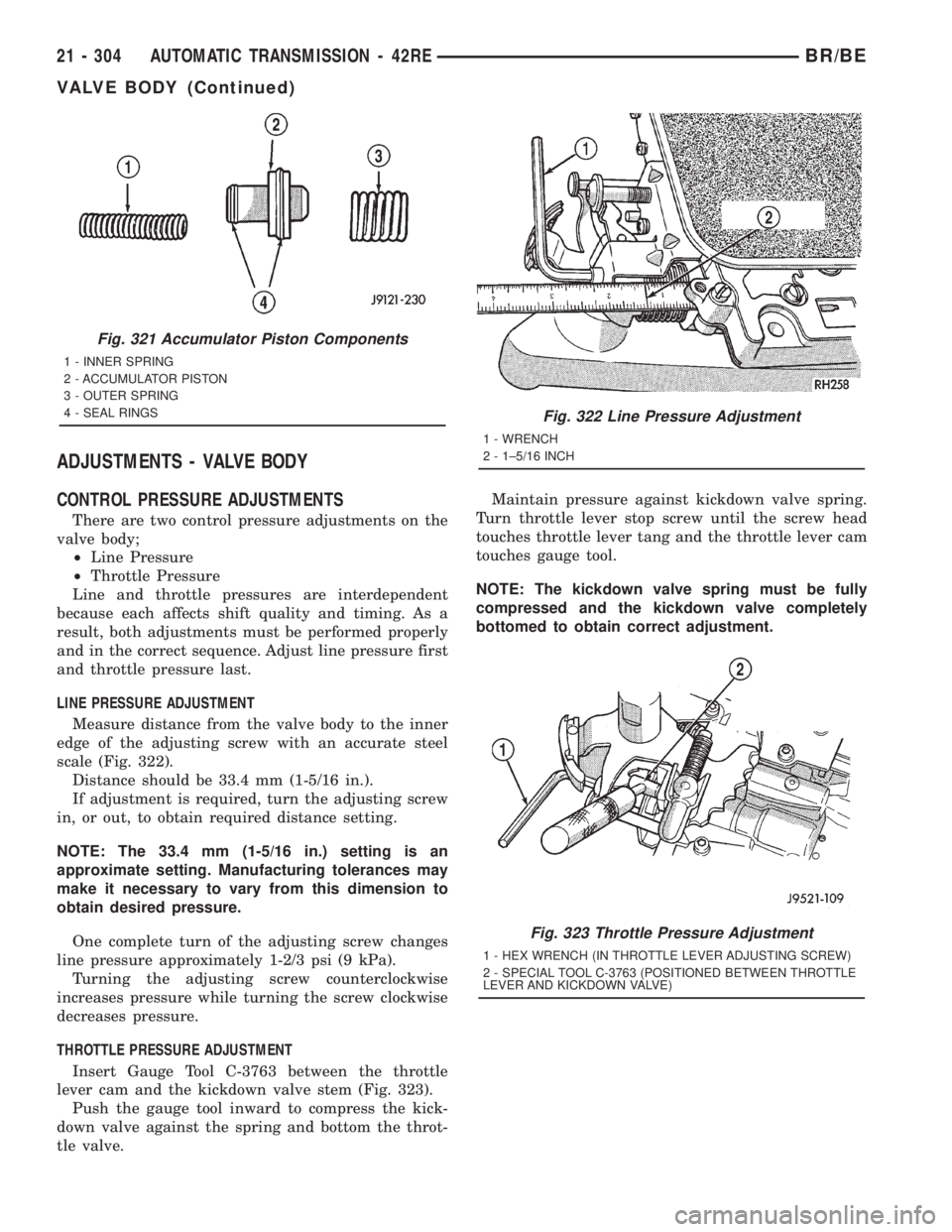

CONTROL PRESSURE ADJUSTMENTS

There are two control pressure adjustments on the

valve body;

²Line Pressure

²Throttle Pressure

Line and throttle pressures are interdependent

because each affects shift quality and timing. As a

result, both adjustments must be performed properly

and in the correct sequence. Adjust line pressure first

and throttle pressure last.

LINE PRESSURE ADJUSTMENT

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 322).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

NOTE: The 33.4 mm (1-5/16 in.) setting is an

approximate setting. Manufacturing tolerances may

make it necessary to vary from this dimension to

obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa).

Turning the adjusting screw counterclockwise

increases pressure while turning the screw clockwise

decreases pressure.

THROTTLE PRESSURE ADJUSTMENT

Insert Gauge Tool C-3763 between the throttle

lever cam and the kickdown valve stem (Fig. 323).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

NOTE: The kickdown valve spring must be fully

compressed and the kickdown valve completely

bottomed to obtain correct adjustment.

Fig. 321 Accumulator Piston Components

1 - INNER SPRING

2 - ACCUMULATOR PISTON

3 - OUTER SPRING

4 - SEAL RINGS

Fig. 322 Line Pressure Adjustment

1 - WRENCH

2 - 1±5/16 INCH

Fig. 323 Throttle Pressure Adjustment

1 - HEX WRENCH (IN THROTTLE LEVER ADJUSTING SCREW)

2 - SPECIAL TOOL C-3763 (POSITIONED BETWEEN THROTTLE

LEVER AND KICKDOWN VALVE)

21 - 304 AUTOMATIC TRANSMISSION - 42REBR/BE

VALVE BODY (Continued)

Page 2111 of 2889

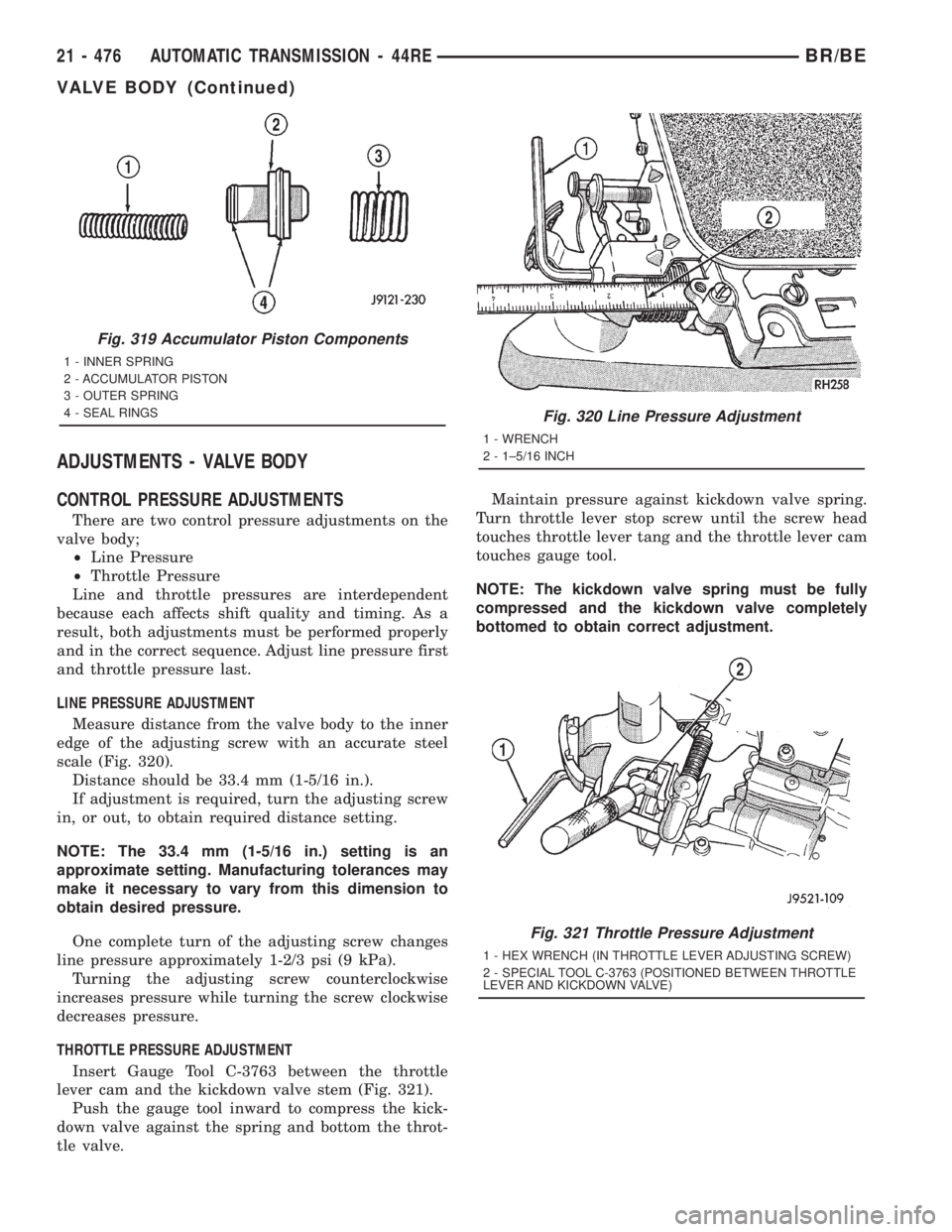

ADJUSTMENTS - VALVE BODY

CONTROL PRESSURE ADJUSTMENTS

There are two control pressure adjustments on the

valve body;

²Line Pressure

²Throttle Pressure

Line and throttle pressures are interdependent

because each affects shift quality and timing. As a

result, both adjustments must be performed properly

and in the correct sequence. Adjust line pressure first

and throttle pressure last.

LINE PRESSURE ADJUSTMENT

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 320).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

NOTE: The 33.4 mm (1-5/16 in.) setting is an

approximate setting. Manufacturing tolerances may

make it necessary to vary from this dimension to

obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa).

Turning the adjusting screw counterclockwise

increases pressure while turning the screw clockwise

decreases pressure.

THROTTLE PRESSURE ADJUSTMENT

Insert Gauge Tool C-3763 between the throttle

lever cam and the kickdown valve stem (Fig. 321).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

NOTE: The kickdown valve spring must be fully

compressed and the kickdown valve completely

bottomed to obtain correct adjustment.

Fig. 319 Accumulator Piston Components

1 - INNER SPRING

2 - ACCUMULATOR PISTON

3 - OUTER SPRING

4 - SEAL RINGS

Fig. 320 Line Pressure Adjustment

1 - WRENCH

2 - 1±5/16 INCH

Fig. 321 Throttle Pressure Adjustment

1 - HEX WRENCH (IN THROTTLE LEVER ADJUSTING SCREW)

2 - SPECIAL TOOL C-3763 (POSITIONED BETWEEN THROTTLE

LEVER AND KICKDOWN VALVE)

21 - 476 AUTOMATIC TRANSMISSION - 44REBR/BE

VALVE BODY (Continued)

Page 2454 of 2889

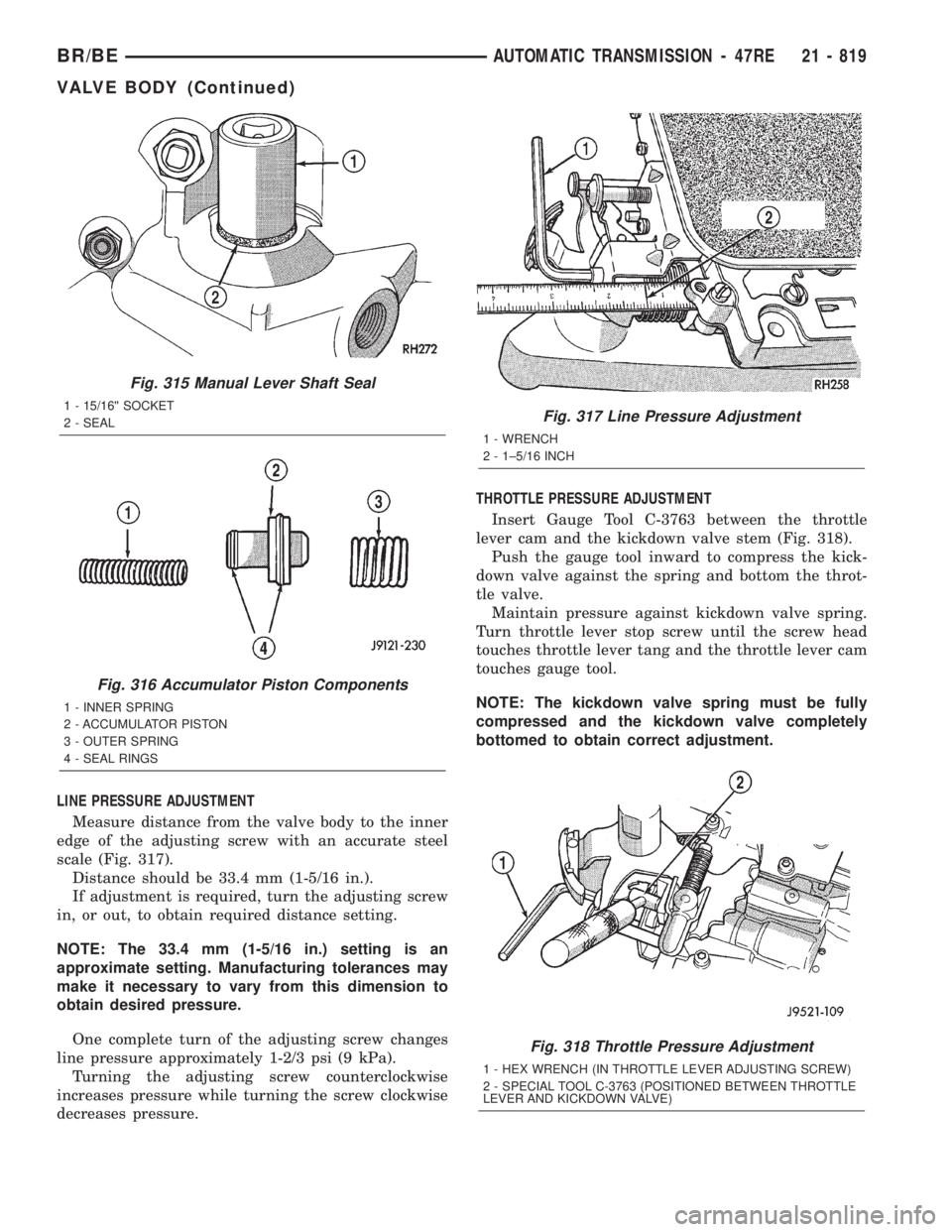

LINE PRESSURE ADJUSTMENT

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 317).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

NOTE: The 33.4 mm (1-5/16 in.) setting is an

approximate setting. Manufacturing tolerances may

make it necessary to vary from this dimension to

obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa).

Turning the adjusting screw counterclockwise

increases pressure while turning the screw clockwise

decreases pressure.THROTTLE PRESSURE ADJUSTMENT

Insert Gauge Tool C-3763 between the throttle

lever cam and the kickdown valve stem (Fig. 318).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.

Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

NOTE: The kickdown valve spring must be fully

compressed and the kickdown valve completely

bottomed to obtain correct adjustment.

Fig. 315 Manual Lever Shaft Seal

1 - 15/16©© SOCKET

2 - SEAL

Fig. 316 Accumulator Piston Components

1 - INNER SPRING

2 - ACCUMULATOR PISTON

3 - OUTER SPRING

4 - SEAL RINGS

Fig. 317 Line Pressure Adjustment

1 - WRENCH

2 - 1±5/16 INCH

Fig. 318 Throttle Pressure Adjustment

1 - HEX WRENCH (IN THROTTLE LEVER ADJUSTING SCREW)

2 - SPECIAL TOOL C-3763 (POSITIONED BETWEEN THROTTLE

LEVER AND KICKDOWN VALVE)

BR/BEAUTOMATIC TRANSMISSION - 47RE 21 - 819

VALVE BODY (Continued)