driver seat adjustment DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 178 of 2889

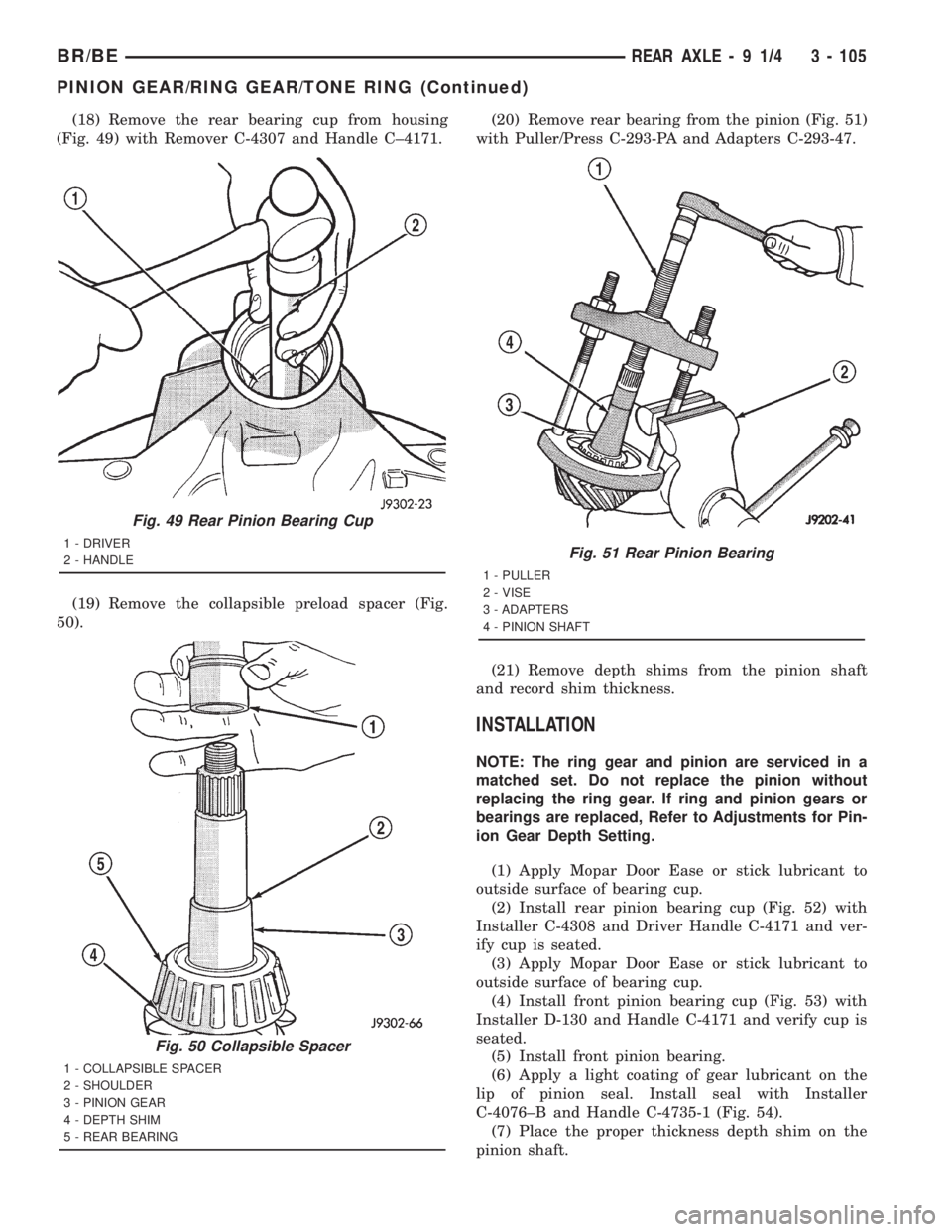

(18) Remove the rear bearing cup from housing

(Fig. 49) with Remover C-4307 and Handle C±4171.

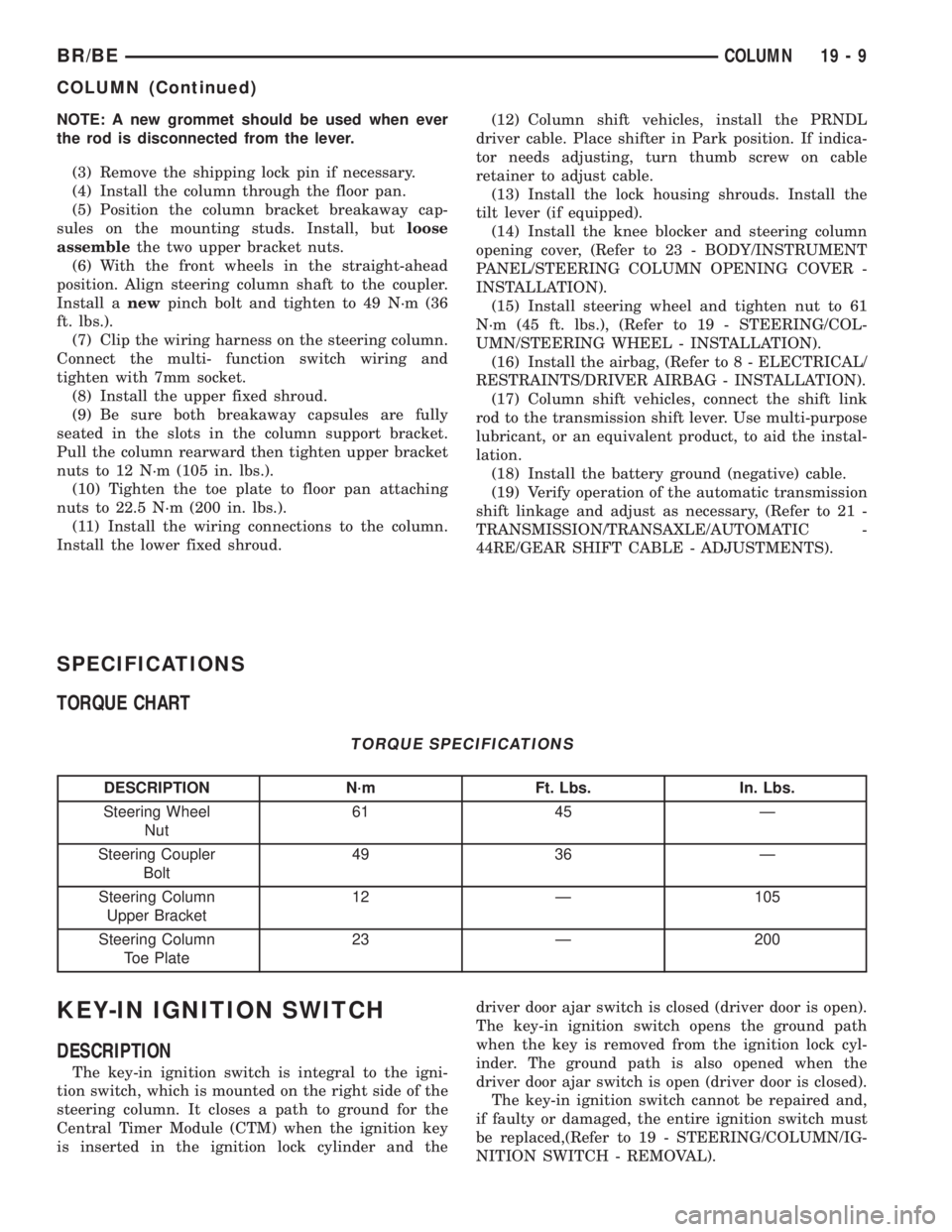

(19) Remove the collapsible preload spacer (Fig.

50).(20) Remove rear bearing from the pinion (Fig. 51)

with Puller/Press C-293-PA and Adapters C-293-47.

(21) Remove depth shims from the pinion shaft

and record shim thickness.

INSTALLATION

NOTE: The ring gear and pinion are serviced in a

matched set. Do not replace the pinion without

replacing the ring gear. If ring and pinion gears or

bearings are replaced, Refer to Adjustments for Pin-

ion Gear Depth Setting.

(1) Apply Mopar Door Ease or stick lubricant to

outside surface of bearing cup.

(2) Install rear pinion bearing cup (Fig. 52) with

Installer C-4308 and Driver Handle C-4171 and ver-

ify cup is seated.

(3) Apply Mopar Door Ease or stick lubricant to

outside surface of bearing cup.

(4) Install front pinion bearing cup (Fig. 53) with

Installer D-130 and Handle C-4171 and verify cup is

seated.

(5) Install front pinion bearing.

(6) Apply a light coating of gear lubricant on the

lip of pinion seal. Install seal with Installer

C-4076±B and Handle C-4735-1 (Fig. 54).

(7) Place the proper thickness depth shim on the

pinion shaft.

Fig. 49 Rear Pinion Bearing Cup

1 - DRIVER

2 - HANDLE

Fig. 50 Collapsible Spacer

1 - COLLAPSIBLE SPACER

2 - SHOULDER

3 - PINION GEAR

4 - DEPTH SHIM

5 - REAR BEARING

Fig. 51 Rear Pinion Bearing

1 - PULLER

2 - VISE

3 - ADAPTERS

4 - PINION SHAFT

BR/BEREAR AXLE - 9 1/4 3 - 105

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 1602 of 2889

NOTE: A new grommet should be used when ever

the rod is disconnected from the lever.

(3) Remove the shipping lock pin if necessary.

(4) Install the column through the floor pan.

(5) Position the column bracket breakaway cap-

sules on the mounting studs. Install, butloose

assemblethe two upper bracket nuts.

(6) With the front wheels in the straight-ahead

position. Align steering column shaft to the coupler.

Install anewpinch bolt and tighten to 49 N´m (36

ft. lbs.).

(7) Clip the wiring harness on the steering column.

Connect the multi- function switch wiring and

tighten with 7mm socket.

(8) Install the upper fixed shroud.

(9) Be sure both breakaway capsules are fully

seated in the slots in the column support bracket.

Pull the column rearward then tighten upper bracket

nuts to 12 N´m (105 in. lbs.).

(10) Tighten the toe plate to floor pan attaching

nuts to 22.5 N´m (200 in. lbs.).

(11) Install the wiring connections to the column.

Install the lower fixed shroud.(12) Column shift vehicles, install the PRNDL

driver cable. Place shifter in Park position. If indica-

tor needs adjusting, turn thumb screw on cable

retainer to adjust cable.

(13) Install the lock housing shrouds. Install the

tilt lever (if equipped).

(14) Install the knee blocker and steering column

opening cover, (Refer to 23 - BODY/INSTRUMENT

PANEL/STEERING COLUMN OPENING COVER -

INSTALLATION).

(15) Install steering wheel and tighten nut to 61

N´m (45 ft. lbs.), (Refer to 19 - STEERING/COL-

UMN/STEERING WHEEL - INSTALLATION).

(16) Install the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(17) Column shift vehicles, connect the shift link

rod to the transmission shift lever. Use multi-purpose

lubricant, or an equivalent product, to aid the instal-

lation.

(18) Install the battery ground (negative) cable.

(19) Verify operation of the automatic transmission

shift linkage and adjust as necessary, (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

44RE/GEAR SHIFT CABLE - ADJUSTMENTS).

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Steering Wheel

Nut61 45 Ð

Steering Coupler

Bolt49 36 Ð

Steering Column

Upper Bracket12 Ð 105

Steering Column

Toe Plate23 Ð 200

KEY-IN IGNITION SWITCH

DESCRIPTION

The key-in ignition switch is integral to the igni-

tion switch, which is mounted on the right side of the

steering column. It closes a path to ground for the

Central Timer Module (CTM) when the ignition key

is inserted in the ignition lock cylinder and thedriver door ajar switch is closed (driver door is open).

The key-in ignition switch opens the ground path

when the key is removed from the ignition lock cyl-

inder. The ground path is also opened when the

driver door ajar switch is open (driver door is closed).

The key-in ignition switch cannot be repaired and,

if faulty or damaged, the entire ignition switch must

be replaced,(Refer to 19 - STEERING/COLUMN/IG-

NITION SWITCH - REMOVAL).

BR/BECOLUMN 19 - 9

COLUMN (Continued)

Page 1616 of 2889

INSTALLATION

(1) Install pitman shaft bearing into housing with

a bearing driver and handle.

(2) Coat the oil seal and washer withspecial

greasesupplied with the new seal.

(3) Install the oil seal with a driver and handle.

(4) Install backup washer.

(5) Install the retainer ring with snap ring pliers.

(6) Coat the dust seal withspecial greasesup-

plied with the new seal.

(7) Install dust seal with a driver and handle.

(8) Install pitman shaft to side cover by screwing

shaft in until it fully seats to side cover.

(9) Install preload adjuster nut.Do not tighten

nut until after Over-Center Rotation Torque

adjustment has been made.

(10) Install gasket to side cover and bend tabs

around edges of side cover (Fig. 11).

(11) Install pitman shaft assembly and side cover

to housing.

(12) Install side cover bolts and tighten to 60 N´m

(44 ft. lbs.).

(13) Perform over-center rotation torque adjust-

ment, (Refer to 19 - STEERING/GEAR - ADJUST-

MENTS).

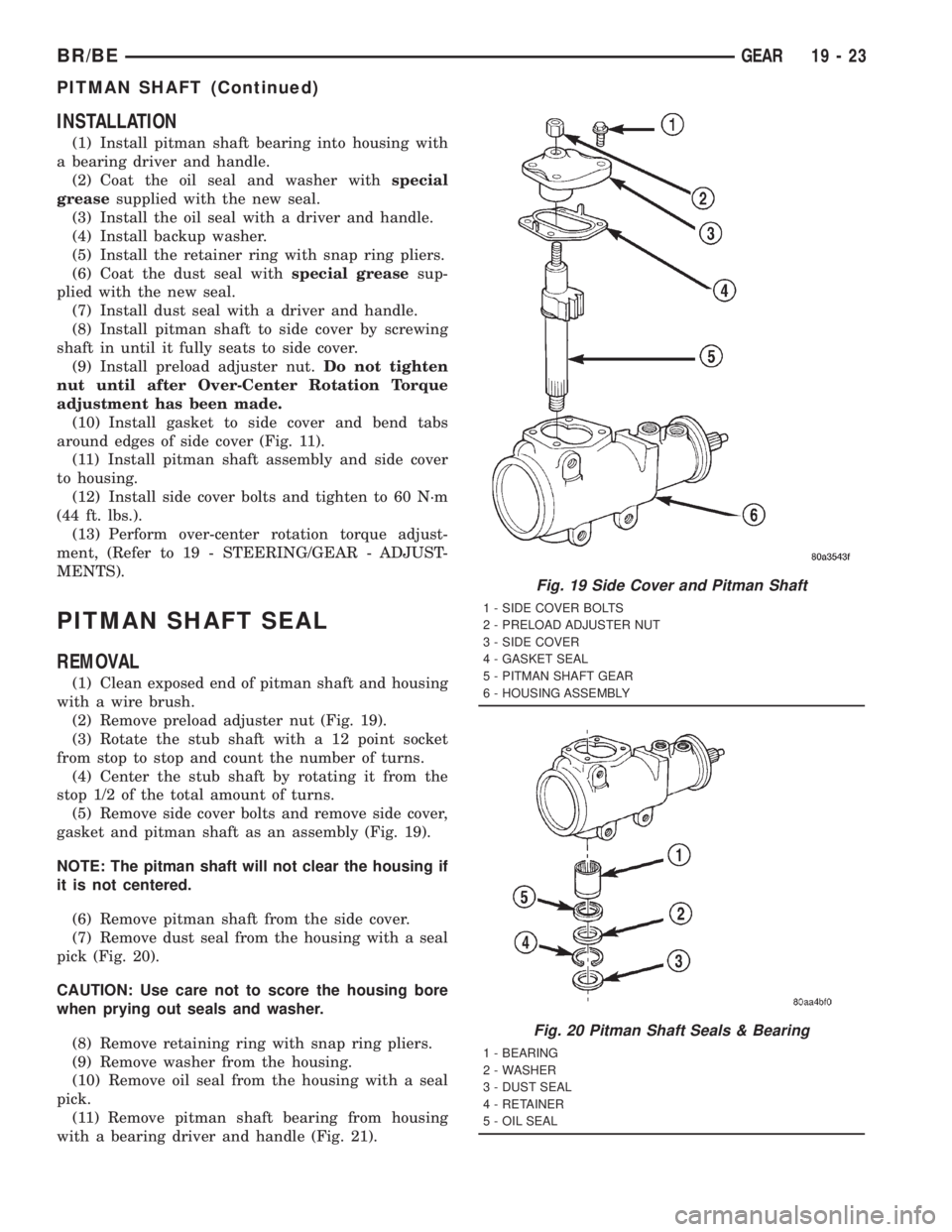

PITMAN SHAFT SEAL

REMOVAL

(1) Clean exposed end of pitman shaft and housing

with a wire brush.

(2) Remove preload adjuster nut (Fig. 19).

(3) Rotate the stub shaft with a 12 point socket

from stop to stop and count the number of turns.

(4) Center the stub shaft by rotating it from the

stop 1/2 of the total amount of turns.

(5) Remove side cover bolts and remove side cover,

gasket and pitman shaft as an assembly (Fig. 19).

NOTE: The pitman shaft will not clear the housing if

it is not centered.

(6) Remove pitman shaft from the side cover.

(7) Remove dust seal from the housing with a seal

pick (Fig. 20).

CAUTION: Use care not to score the housing bore

when prying out seals and washer.

(8) Remove retaining ring with snap ring pliers.

(9) Remove washer from the housing.

(10) Remove oil seal from the housing with a seal

pick.

(11) Remove pitman shaft bearing from housing

with a bearing driver and handle (Fig. 21).

Fig. 19 Side Cover and Pitman Shaft

1 - SIDE COVER BOLTS

2 - PRELOAD ADJUSTER NUT

3 - SIDE COVER

4 - GASKET SEAL

5 - PITMAN SHAFT GEAR

6 - HOUSING ASSEMBLY

Fig. 20 Pitman Shaft Seals & Bearing

1 - BEARING

2 - WASHER

3 - DUST SEAL

4 - RETAINER

5 - OIL SEAL

BR/BEGEAR 19 - 23

PITMAN SHAFT (Continued)

Page 2859 of 2889

DOOR CYLINDER LOCK SWITCH -

OPERATION..........................8N-5

DOOR CYLINDER LOCK SWITCH -

REMOVAL...........................8N-6

DOOR FORE/AFT - ADJUSTMENT, FRONT . . 23-68

DOOR GLASS - INSTALLATION..........23-69

DOOR GLASS - REMOVAL.............23-69

DOOR GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT...............23-154

DOOR GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT...................23-153

DOOR INNER BELT WEATHERSTRIP -

INSTALLATION, FRONT...............23-154

DOOR INNER BELT WEATHERSTRIP -

REMOVAL, FRONT...................23-154

DOOR IN/OUT - ADJUSTMENT, FRONT....23-69

DOOR LATCH - ADJUSTMENT, FRONT....23-72

DOOR LOCKS - INSPECTION, DOORS.....30-11

DOOR OPENING SEAL - INSTALLATION . . 23-153

DOOR OPENING SEAL - REMOVAL......23-153

DOOR OUTER BELT WEATHERSTRIP -

INSTALLATION, FRONT...............23-154

DOOR OUTER BELT WEATHERSTRIP -

REMOVAL, FRONT...................23-154

DOOR SEAL - INSTALLATION, B-PILLAR . 23-152

DOOR SEAL - REMOVAL, B-PILLAR.....23-152

DOOR SECOND WEATHERSTRIP -

INSTALLATION, FRONT...............23-155

DOOR SECOND WEATHERSTRIP -

REMOVAL, FRONT...................23-154

DOOR SILL TRIM - INSTALLATION......23-121

DOOR SILL TRIM - REMOVAL.........23-121

DOOR SPEAKER - INSTALLATION, FRONT . 8A-20

DOOR SPEAKER - INSTALLATION, REAR . . 8A-21

DOOR SPEAKER - REMOVAL, FRONT.....8A-20

DOOR SPEAKER - REMOVAL, REAR......8A-21

DOOR UP/DOWN - ADJUSTMENT, FRONT . 23-69

DOOR UPPER CORNER SEAL -

INSTALLATION, FRONT...............23-154

DOOR UPPER CORNER SEAL -

REMOVAL, FRONT...................23-154

DOORS AND DOOR LOCKS -

INSPECTION........................30-11

DOORS AND LOCKS - INSPECTION,

WINDOWS..........................30-14

DOUBLE INVERTED FLARING -

STANDARD PROCEDURE.................5-8

DRAIN AND REFILL - STANDARD

PROCEDURE, FLUID.....21-851,21-885,21-922

DRAIN MANIFOLD - DESCRIPTION, FUEL . . 14-86

DRAIN MANIFOLD - INSTALLATION,

FUEL..............................14-86

DRAIN MANIFOLD - OPERATION, FUEL . . . 14-86

DRAIN MANIFOLD - REMOVAL, FUEL.....14-86

DRAINBACK VALVE - DESCRIPTION,

TORQUE CONVERTER....21-262,21-432,21-605,

21-778

DRAINBACK VALVE - OPERATION,

TORQUE CONVERTER....21-262,21-432,21-605,

21-778

DRAINBACK VALVE - STANDARD

PROCEDURE, TORQUE

CONVERTER.....21-262,21-432,21-606,21-778

DRAINING AT FUEL FILTER - STANDARD

PROCEDURES, WATER................14-56

DRAINING COOLING SYSTEM

3.9L/5.2L/5.9L/8.0L ENGINES -

STANDARD PROCEDURE................7-15

DRAINING COOLING SYSTEM 5.9L

DIESEL ENGINE - STANDARD

PROCEDURE.........................7-15

DRAW TEST - STANDARD PROCEDURE,

IGNITION-OFF.......................8F-15

DRIVE - DIAGNOSIS AND TESTING,

VISCOUS FAN....................7-56,7-58

DRIVE BELT - DIAGNOSIS AND TESTING,

ACCESSORY.................7-24,7-27,7-31

DRIVE BELTS - 3.9L/5.2L/5.9L -

INSTALLATION........................7-27

DRIVE BELTS - 3.9L/5.2L/5.9L -

REMOVAL...........................7-26

DRIVE BELTS - 5.9L DIESEL -

INSTALLATION

........................7-34

DRIVE BELTS - 5.9L DIESEL - REMOVAL

. . . 7-33

DRIVE BELTS - 8.0L - INSTALLATION

......7-30

DRIVE BELTS - 8.0L - REMOVAL

.........7-30

DRIVE INDICATOR - DIAGNOSIS AND

TESTING, FOUR-WHEEL

...............8J-29DRIVE VISCOUS CLUTCH - 3.9L/5.2L/

5.9L/8.0L - DESCRIPTION, FAN...........7-56

DRIVE VISCOUS CLUTCH - 3.9L/5.2L/

5.9L/8.0L - OPERATION, FAN............7-56

DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - DESCRIPTION, FAN............7-57

DRIVE VISCOUS CLUTCH - 5.9L

DIESEL - OPERATION, FAN..............7-57

DRIVER AIRBAG - ASSEMBLY..........8O-17

DRIVER AIRBAG - DESCRIPTION........8O-14

DRIVER AIRBAG - DISASSEMBLY........8O-15

DRIVER AIRBAG - INSTALLATION.......8O-18

DRIVER AIRBAG - OPERATION..........8O-14

DRIVER AIRBAG - REMOVAL...........8O-14

DRIVER POWER SEAT SWITCH -

DESCRIPTION.......................8N-16

DRIVER POWER SEAT SWITCH -

DIAGNOSIS & TESTING...............8N-16

DRIVER POWER SEAT SWITCH -

INSTALLATION......................8N-17

DRIVER POWER SEAT SWITCH -

OPERATION.........................8N-16

DRIVER POWER SEAT SWITCH -

REMOVAL..........................8N-17

DRIVER SEAT HEATER SWITCH -

DESCRIPTION........................8G-7

DRIVER SEAT HEATER SWITCH -

INSTALLATION.......................8G-9

DRIVER SEAT HEATER SWITCH -

OPERATION..........................8G-7

DRIVER SEAT HEATER SWITCH -

REMOVAL.............................8G-9

DROP - STANDARD PROCEDURE,

TESTING FOR A VOLTAGE............8W-01-7

DRUM - ADJUSTMENT, REAR BRAKE......5-34

DRUM - CLEANING....................5-33

DRUM - DESCRIPTION.................5-32

DRUM - DIAGNOSIS AND TESTING,

BRAKE..............................5-33

DRUM - INSPECTION..................5-33

DRUM - OPERATION...................5-32

DRUM BRAKES - INSTALLATION, REAR

PARK BRAKE CABLE 2500/3500

SERIES WITH........................5-39

DRUM BRAKES - REMOVAL, REAR PARK

BRAKE CABLES 2500/3500 SERIES

WITH...............................5-38

DRUM IN HAT PARK BRAKE SHOES -

2500/3500 - INSTALLATION, REAR........5-42

DRUM IN HAT PARK BRAKE SHOES -

2500/3500 - REMOVAL, REAR...........5-41

DRUM MACHINING - STANDARD

PROCEDURE, BRAKE...................5-33

DUAL REAR WHEEL INSTALLATION -

STARDARD PROCEDURE...............22-10

DUCT ADAPTER - INSTALLATION,

DEFROSTER AND DEMISTER

...........24-35

DUCT ADAPTER - REMOVAL,

DEFROSTER AND DEMISTER

...........24-35

DUCTS - INSTALLATION, DEFROSTER

AND DEMISTER

......................24-35

DUCTS - REMOVAL, DEFROSTER AND

DEMISTER

..........................24-34

DUCTS - REMOVAL, INSTRUMENT

PANEL

.............................24-37

DUCTS - REMOVAL, INSTRUMENT

PANEL DEMISTER

....................24-37

DUTY ENGINE (1500 AND 2500 MODELS

EXCEPT 8.0L) MAINTENANCE

SCHEDULES, MAINTENANCE

SCHEDULES - LIGHT

....................0-7

DUTY ENGINE (FEDERAL ONLY - 2500

8.0L HD AND 3500 5.9L& 8.0L

MODELS) MAINTENANCE SCHEDULES

- DESCRIPTION, HEAVY

................0-17

DUTY TRUCK MAINTENANCE SCHEDULE

(8.0L 2500 & 3500 MODELS -

CALIFORNIA ONLY) - DESCRIPTION,

MEDIUM

............................0-13

DUTY/8.0L - DESCRIPTION, CATALYTIC

CONVERTER - 5.9L HEAVY

..............11-6

DUTY/8.0L - INSPECTION, CATALYTIC

CONVERTER - 5.9L HEAVY

..............11-7

DUTY/8.0L - INSPECTION, EXHAUST

PIPE - 5.9L HEAVY

....................11-9

DUTY/8.0L - INSPECTION, TAILPIPE -

5.9L HEAVY

.........................11-12DUTY/8.0L - INSTALLATION, CATALYTIC

CONVERTER - 5.9L HEAVY..............11-7

DUTY/8.0L - INSTALLATION, EXHAUST

PIPE - 5.9L HEAVY....................11-9

DUTY/8.0L - INSTALLATION, TAILPIPE -

5.9L HEAVY.........................11-12

DUTY/8.0L - OPERATION, CATALYTIC

CONVERTER - 5.9L HEAVY..............11-6

DUTY/8.0L - REMOVAL, CATALYTIC

CONVERTER - 5.9L HEAVY..............11-6

DUTY/8.0L - REMOVAL, EXHAUST PIPE -

5.9L HEAVY..........................11-8

DUTY/8.0L - REMOVAL, TAILPIPE - 5.9L

HEAVY .............................11-12

EASY ENTRY SEAT TRACK -

INSTALLATION......................23-142

EASY ENTRY SEAT TRACK - REMOVAL . . 23-142

ECM - DESCRIPTION..................8E-13

ECM - OPERATION...................8E-13

EFFECTS OF INCORRECT FLUID LEVEL -

DIAGNOSIS AND TESTING......21-199,21-370,

21-545,21-715

ELECTRICAL CONTROLS - DIAGNOSIS

AND TESTING, OVERDRIVE.....21-215,21-386,

21-579,21-732

ELECTROLYTE LEVEL - STANDARD

PROCEDURE, CHECKING BATTERY........8F-8

ELECTRONIC FEATURES - DESCRIPTION,

PROGRAMMABLE....................30-20

ELECTRONIC FEATURES - OPERATION,

PROGRAMMABLE....................30-20

ELECTRONIC GOVERNOR -

DESCRIPTION....21-194,21-365,21-540,21-710

ELECTRONIC GOVERNOR -

INSTALLATION....21-197,21-367,21-543,21-713

ELECTRONIC GOVERNOR - OPERATION

. 21-194,

21-365,21-541,21-711

ELECTRONIC GOVERNOR - REMOVAL

. . . 21-196,

21-367,21-542,21-712

ELEMENT - DESCRIPTION, HEATED

SEAT

..............................8G-10

ELEMENT - INSTALLATION, AIR

CLEANER

...........................9-245

ELEMENT - OPERATION, HEATED SEAT

. . . 8G-10

ELEMENT - REMOVAL, AIR CLEANER

.....9-244

ELEMENT AND SENSOR - DIAGNOSIS &

TESTING, HEATED SEAT

...............8G-11

EMERGENCY SIGNALS - INSPECTION,

TURN

..............................30-19

END SPLASH SHIELDS - INSTALLATION,

FRONT

.............................23-92

END SPLASH SHIELDS - REMOVAL,

FRONT

.............................23-92

ENGINE - DESCRIPTION, COOLING

SYSTEM FLOW - 3.9L/5.2L/5.9L

...........7-1

ENGINE - DESCRIPTION, FUEL

REQUIREMENTS - DIESEL

...............0-2

ENGINE - DIAGNOSIS AND TESTING,

COOLING SYSTEM DIESEL

..............7-12

ENGINE - DIAGNOSIS AND TESTING,

COOLING SYSTEM GAS

.................7-7

ENGINE - DIAGNOSIS AND TESTING,

DIESEL

.............................11-4

ENGINE - DIAGNOSIS AND TESTING,

GAS

................................11-4

ENGINE - ENGINE FIRING ORDER, 3.9L

V-6

.................................8I-2

ENGINE - IGNITION COIL RESISTANCE,

8.0L V-10

............................8I-3

ENGINE - INSTALLATION

...............9-241

ENGINE - INSTALLATION, DIESEL

........19-35

ENGINE - INSTALLATION, GASOLINE

.....19-35

ENGINE - REMOVAL

..................9-238

ENGINE - REMOVAL, DIESEL

...........19-33

ENGINE - REMOVAL, GASOLINE

.........19-33

ENGINE - SPARK PLUG CABLE ORDER,

8.0L V-10

............................8I-2

ENGINE - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM 5.9L

DIESEL

.............................7-15

ENGINE - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM 5.9L

DIESEL

.............................7-15

ENGINE - TORQUE, DIESEL

.............14-90

ENGINE - VISUAL INSPECTION, 8.0L

.....14-32

12 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2864 of 2889

HEAD - INSPECTION, CYLINDER . . . 9-137,9-193,

9-23,9-250,9-80

HEAD - INSTALLATION, CYLINDER . 9-137,9-193,

9-23,9-250,9-80

HEAD - OPERATION, CYLINDER . 9-136,9-22,9-79

HEAD - REMOVAL, CYLINDER . 9-137,9-192,9-23,

9-246,9-80

HEAD COVER GASKET - DESCRIPTION,

CYLINDER...........................9-22

HEAD COVER GASKET - OPERATION,

CYLINDER...........................9-22

HEAD COVER(S) - CLEANING, CYLINDER . 9-138,

9-194,9-24,9-253,9-81

HEAD COVER(S) - DESCRIPTION,

CYLINDER..........................9-194

HEAD COVER(S) - INSPECTION,

CYLINDER........9-138,9-194,9-24,9-253,9-81

HEAD COVER(S) - INSTALLATION,

CYLINDER........9-138,9-194,9-24,9-253,9-81

HEAD COVER(S) - REMOVAL, CYLINDER . 9-138,

9-194,9-24,9-253,9-81

HEAD GASKET FAILURE - DIAGNOSIS

AND TESTING, CYLINDER . 9-136,9-191,9-22,9-79

HEAD RESTRAINTS - INSPECTION, SEAT

BELTS, SHOULDER BELTS,

RETRACTORS.......................30-12

HEADLAMP - DESCRIPTION............8L-13

HEADLAMP - DIAGNOSIS AND TESTING . . 8L-13

HEADLAMP - INSTALLATION............8L-16

HEADLAMP - OPERATION..............8L-13

HEADLAMP - REMOVAL...............8L-16

HEADLAMP ALIGNMENT, SPECIAL

TOOLS..............................8L-4

HEADLAMP RELAY - DESCRIPTION......8L-16

HEADLAMP RELAY - DIAGNOSIS AND

TESTING...........................8L-17

HEADLAMP RELAY - INSTALLATION......8L-18

HEADLAMP RELAY - OPERATION........8L-17

HEADLAMP RELAY - REMOVAL.........8L-18

HEADLAMP SWITCH - DESCRIPTION.....8L-18

HEADLAMP SWITCH - DIAGNOSIS AND

TESTING...........................8L-18

HEADLAMP SWITCH - INSTALLATION....8L-20

HEADLAMP SWITCH - OPERATION.......8L-18

HEADLAMP SWITCH - REMOVAL........8L-19

HEADLAMP UNIT - ADJUSTMENTS......8L-21

HEADLAMP UNIT - INSTALLATION.......8L-20

HEADLAMP UNIT - REMOVAL...........8L-20

HEADLINER - INSTALLATION..........23-125

HEADLINER - REMOVAL..............23-125

HEAT SHIELDS - DESCRIPTION.........11-10

HEAT SHIELDS - INSTALLATION.........11-10

HEAT SHIELDS - REMOVAL.............11-10

HEAT/DEFROST DOOR - INSTALLATION . . . 24-39

HEAT/DEFROST DOOR - REMOVAL.......24-38

HEAT/DEFROST DOOR ACTUATOR -

INSTALLATION.......................24-27

HEAT/DEFROST DOOR ACTUATOR -

REMOVAL..........................24-26

HEATED MIRROR GRID - DESCRIPTION . . . 8G-4

HEATED MIRROR GRID - DIAGNOSIS

AND TESTING........................8G-4

HEATED MIRROR GRID - OPERATION.....8G-4

HEATED MIRROR SWITCH - DIAGNOSIS

AND TESTING........................8G-3

HEATED MIRROR SYSTEM -

DESCRIPTION........................8G-1

HEATED MIRROR SYSTEM - DIAGNOSIS

AND TESTING........................8G-2

HEATED MIRROR SYSTEM - OPERATION . . . 8G-2

HEATED SEAT ELEMENT - DESCRIPTION . . 8G-10

HEATED SEAT ELEMENT - OPERATION....8G-10

HEATED SEAT ELEMENT AND SENSOR -

DIAGNOSIS & TESTING...............8G-11

HEATED SEAT RELAY - DESCRIPTION....8G-11

HEATED SEAT RELAY - DIAGNOSIS &

TESTING...........................8G-12

HEATED SEAT RELAY - INSTALLATION....8G-13

HEATED SEAT RELAY - OPERATION......8G-12

HEATED SEAT RELAY - REMOVAL.......8G-13

HEATED SEAT SWITCH - DIAGNOSIS &

TESTING

.......................8G-14,8G-8

HEATED SEAT SYSTEM - DESCRIPTION

....8G-5

HEATED SEAT SYSTEM - DIAGNOSIS &

TESTING

............................8G-6

HEATED SEAT SYSTEM - OPERATION

.....8G-6

HEATER - 3.9L/5.2L/5.9L -

DESCRIPTION, ENGINE BLOCK

...........7-45HEATER - 3.9L/5.2L/5.9L -

INSTALLATION, ENGINE BLOCK..........7-45

HEATER - 3.9L/5.2L/5.9L - OPERATION,

ENGINE BLOCK.......................7-45

HEATER - 3.9L/5.2L/5.9L - REMOVAL,

ENGINE BLOCK.......................7-45

HEATER - 5.9L DIESEL - DESCRIPTION,

ENGINE BLOCK.......................7-47

HEATER - 5.9L DIESEL - INSTALLATION,

ENGINE BLOCK.......................7-47

HEATER - 5.9L DIESEL - OPERATION,

ENGINE BLOCK.......................7-47

HEATER - 5.9L DIESEL - REMOVAL,

ENGINE BLOCK.......................7-47

HEATER - 8.0L - DESCRIPTION, ENGINE

BLOCK..............................7-46

HEATER - 8.0L - INSTALLATION, ENGINE

BLOCK..............................7-46

HEATER - 8.0L - OPERATION, ENGINE

BLOCK..............................7-46

HEATER - 8.0L - REMOVAL, ENGINE

BLOCK..............................7-46

HEATER - DESCRIPTION, FUEL..........14-62

HEATER - DESCRIPTION, INTAKE AIR....14-100

HEATER - DIAGNOSIS AND TESTING,

FUEL..............................14-62

HEATER - INSTALLATION, INTAKE AIR . . . 14-101

HEATER - OPERATION, FUEL............14-62

HEATER - OPERATION, INTAKE AIR.....14-100

HEATER - REMOVAL, INTAKE AIR.......14-100

HEATER - REMOVAL/INSTALLATION,

FUEL................................14-63

HEATER AND AIR CONDITIONER -

DESCRIPTION........................24-1

HEATER AND AIR CONDITIONER -

OPERATION..........................24-1

HEATER CONTROL - DESCRIPTION, A/C . . . 24-18

HEATER CONTROL - DIAGNOSIS AND

TESTING, A/C.......................24-19

HEATER CONTROL - INSTALLATION, A/C . . 24-20

HEATER CONTROL - OPERATION, A/C....24-18

HEATER CONTROL - REMOVAL, A/C......24-19

HEATER CORE - DESCRIPTION..........24-55

HEATER CORE - INSTALLATION.........24-56

HEATER CORE - OPERATION............24-55

HEATER CORE - REMOVAL.............24-56

HEATER CORE GROUND STRAP -

INSTALLATION.......................8A-15

HEATER CORE GROUND STRAP -

REMOVAL..........................8A-14

HEATER PERFORMANCE - DIAGNOSIS

AND TESTING........................24-6

HEATER RELAY - DESCRIPTION, FUEL....14-63

HEATER RELAY - DESCRIPTION, INTAKE

AIR ..............................14-101

HEATER RELAY - DIAGNOSIS AND

TESTING, FUEL......................14-64

HEATER RELAY - INSTALLATION, FUEL . . . 14-65

HEATER RELAY - INSTALLATION, INTAKE

AIR ..............................14-102

HEATER RELAY - OPERATION, FUEL......14-63

HEATER RELAY - OPERATION, INTAKE

AIR

..............................14-102

HEATER RELAY - REMOVAL, FUEL

.......14-65

HEATER RELAY - REMOVAL, INTAKE AIR

. 14-102

HEATER SWITCH - DESCRIPTION,

DRIVER SEAT

........................8G-7

HEATER SWITCH - DESCRIPTION,

PASSENGER SEAT

....................8G-13

HEATER SWITCH - INSTALLATION,

DRIVER SEAT

........................8G-9

HEATER SWITCH - INSTALLATION,

PASSENGER SEAT

....................8G-16

HEATER SWITCH - OPERATION, DRIVER

SEAT

...............................8G-7

HEATER SWITCH - OPERATION,

PASSENGER SEAT

....................8G-14

HEATER SWITCH - REMOVAL, DRIVER

SEAT

...............................8G-9

HEATER SWITCH - REMOVAL,

PASSENGER SEAT

....................8G-15

HEATER/AIR CONDITIONER -

INSPECTION

........................30-17

HEAVY DUTY ENGINE (FEDERAL ONLY -

2500 8.0L HD AND 3500 5.9L& 8.0L

MODELS) MAINTENANCE SCHEDULES

- DESCRIPTION

.......................0-17HEAVY DUTY/8.0L - DESCRIPTION,

CATALYTIC CONVERTER - 5.9L...........11-6

HEAVY DUTY/8.0L - INSPECTION,

CATALYTIC CONVERTER - 5.9L...........11-7

HEAVY DUTY/8.0L - INSPECTION,

EXHAUST PIPE - 5.9L..................11-9

HEAVY DUTY/8.0L - INSPECTION,

TAILPIPE - 5.9L......................11-12

HEAVY DUTY/8.0L - INSTALLATION,

CATALYTIC CONVERTER - 5.9L...........11-7

HEAVY DUTY/8.0L - INSTALLATION,

EXHAUST PIPE - 5.9L..................11-9

HEAVY DUTY/8.0L - INSTALLATION,

TAILPIPE - 5.9L......................11-12

HEAVY DUTY/8.0L - OPERATION,

CATALYTIC CONVERTER - 5.9L...........11-6

HEAVY DUTY/8.0L - REMOVAL,

CATALYTIC CONVERTER - 5.9L...........11-6

HEAVY DUTY/8.0L - REMOVAL,

EXHAUST PIPE - 5.9L..................11-8

HEAVY DUTY/8.0L - REMOVAL, TAILPIPE

- 5.9L..............................11-12

HEIGHT ADJUSTER KNOB -

INSTALLATION, TURNING LOOP.........8O-30

HEIGHT ADJUSTER KNOB - REMOVAL,

TURNING LOOP.....................8O-30

HIGH BEAM INDICATOR - DESCRIPTION . . 8J-21

HIGH BEAM INDICATOR - DIAGNOSIS

AND TESTING.......................8J-22

HIGH BEAM INDICATOR - OPERATION....8J-22

HIGH MOUNTED STOP LAMP -

INSTALLATION, CENTER................8L-6

HIGH MOUNTED STOP LAMP -

REMOVAL, CENTER....................8L-6

HIGH MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER................8L-6

HIGH MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER....................8L-6

HIGH PRESSURE FUEL LINES -

DESCRIPTION.......................14-74

HIGH PRESSURE FUEL LINES -

OPERATION.........................14-74

HIGH PRESSURE RELIEF VALVE -

DESCRIPTION.......................24-46

HIGH PRESSURE RELIEF VALVE -

OPERATION.........................24-46

HIGH PRESSURE SWITCH -

DESCRIPTION, A/C...................24-20

HIGH PRESSURE SWITCH - DIAGNOSIS

AND TESTING, A/C...................24-20

HIGH PRESSURE SWITCH -

INSTALLATION, A/C...................24-21

HIGH PRESSURE SWITCH - OPERATION,

A/C................................24-20

HIGH PRESSURE SWITCH - REMOVAL,

A/C................................24-21

HIGH-PRESSURE FUEL LINE LEAKS -

DIAGNOSIS AND TESTING.............14-74

HINGE - INSTALLATION......23-71,23-79,23-99

HINGE - REMOVAL.........23-70,23-79,23-99

HITCH - INSTALLATION, TRAILER........13-10

HITCH - REMOVAL, TRAILER...........13-10

HOISTING - STANDARD PROCEDURE......0-28

HOLDDOWN - DESCRIPTION, BATTERY . . . 8F-18

HOLDDOWN - INSTALLATION, BATTERY . . . 8F-18

HOLDDOWN - OPERATION, BATTERY.....8F-18

HOLDDOWN - REMOVAL, BATTERY......8F-18

HOLDER - INSTALLATION, CUP........23-111

HOLDER - REMOVAL, CUP............23-110

HOLE REPAIR - DESCRIPTION,

THREADED........................Intro.-6

HONING - STANDARD PROCEDURE,

CYLINDER BORE........9-10,9-126,9-180,9-69

HOOD - ADJUSTMENT

...............23-100

HOOD - INSTALLATION

...............23-100

HOOD - REMOVAL

...................23-100

HOOD LATCH/SAFETY CATCH -

INSPECTION

.........................30-4

HOOK - INSTALLATION, COAT

..........23-125

HOOK - INSTALLATION, FRONT TOW

.....13-10

HOOK - REMOVAL, COAT

.............23-124

HOOK - REMOVAL, FRONT TOW

..........13-9

HORN - DESCRIPTION

.............8H-1,8H-2

HORN - DIAGNOSIS AND TESTING

.......8H-2

HORN - INSPECTION

..................30-19

HORN - OPERATION

...............8H-1,8H-2

HORN RELAY - DESCRIPTION

...........8H-3

BR/BEINDEX 17

Description Group-Page Description Group-Page Description Group-Page

Page 2880 of 2889

SPECIFICATIONS, SPECIFICATIONS -

TORQUE............................23-61

SPECIFICATIONS, SPECIFICATIONS -

TORQUE............................13-9

SPECIFICATIONS, SPECIFICATIONS -

TORQUE............................24-8

SPECIFICATIONS, TORQUE - FUEL

DELIVERY...........................14-4

SPECIFICATIONS, TORQUE - GAS FUEL

INJECTION..........................14-35

SPECIFICATIONS, TORQUE -

GENERATOR/CHARGING SYSTEM........8F-28

SPECIFICATIONS, TORQUE - IGNITION.....8I-2

SPECIFICATIONS, TORQUE - STARTING

SYSTEM............................8F-38

SPEED CONTROL - INSPECTION.........30-17

SPEED CONTROL SERVO - DESCRIPTION . . 8P-5

SPEED CONTROL SERVO -

INSTALLATION.......................8P-10

SPEED CONTROL SERVO - OPERATION....8P-5

SPEED CONTROL SERVO - REMOVAL.....8P-6

SPEED CONTROL SYSTEM -

DESCRIPTION........................8P-1

SPEED CONTROL SYSTEM - OPERATION . . . 8P-2

SPEED CONTROL SYSTEM - TORQUE.....8P-4

SPEED INPUT - DESCRIPTION, VEHICLE . . . 8P-1

SPEED SENSOR - DESCRIPTION . 21-253,21-424,

21-597,21-770

SPEED SENSOR - OPERATION . . . 21-253,21-424,

21-597,21-770

SPEEDOMETER - DESCRIPTION...........8J-30

SPEEDOMETER - OPERATION...........8J-30

SPLASH SHIELD - INSTALLATION, REAR . . 23-96

SPLASH SHIELD - REMOVAL, REAR......23-96

SPLASH SHIELDS - INSTALLATION,

FRONT END.........................23-92

SPLASH SHIELDS - REMOVAL, FRONT

END ...............................23-92

SPLICE LOCATIONS - DESCRIPTION . . . 8W-95-1

SPLICING - STANDARD PROCEDURE,

WIRE...........................8W-01-12

SPLIT BENCH - INSTALLATION, SEAT....23-134

SPLIT BENCH - INSTALLATION, SEAT

BACK.............................23-136

SPLIT BENCH - INSTALLATION, SEAT

BACK COVER.......................23-138

SPLIT BENCH - INSTALLATION, SEAT

CUSHION COVER....................23-140

SPLIT BENCH - INSTALLATION, SEAT

TRACK............................23-142

SPLIT BENCH - REMOVAL, SEAT.......23-134

SPLIT BENCH - REMOVAL, SEAT BACK . . 23-135

SPLIT BENCH - REMOVAL, SEAT BACK

COVER............................23-137

SPLIT BENCH - REMOVAL, SEAT

CUSHION COVER....................23-139

SPLIT BENCH - REMOVAL, SEAT TRACK . 23-142

SPOOL VALVE - INSTALLATION..........19-26

SPOOL VALVE - REMOVAL.............19-24

SPRING - DESCRIPTION........2-11,2-22,2-28

SPRING - INSTALLATION.......2-12,2-22,2-29

SPRING - OPERATION..........2-11,2-22,2-28

SPRING - REMOVAL...........2-11,2-22,2-28

SPRING AND SHOCK - DIAGNOSIS AND

TESTING............................2-26

SPRINGS - INSTALLATION, VALVES AND

VALVE .............................9-199

SPRINGS - REMOVAL, VALVES AND

VALVE .............................9-197

SPRINGS - STANDARD PROCEDURE,

VALVES, GUIDES.............9-138,9-25,9-82

SPRINGS, INTAKE/EXHAUST VALVES &

SEATS - STANDARD PROCEDURE-

VALVES,GUIDES.....................9-253

SPROCKETS - INSTALLATION, TIMING

BELT/CHAIN...........9-115,9-170,9-227,9-58

SPROCKETS - REMOVAL, TIMING

BELT/CHAIN...........9-114,9-170,9-226,9-57

SQUEAKS, RATTLES AND WIND NOISE -

INSPECTION........................30-15

STABILIZER BAR - DESCRIPTION . 2-12,2-22,2-30

STABILIZER BAR - INSTALLATION....2-12,2-23,

2-30

STABILIZER BAR - OPERATION

. . 2-12,2-22,2-30

STABILIZER BAR - REMOVAL

....2-12,2-22,2-30

STANCHION COVER - INSTALLATION

....23-143

STANCHION COVER - REMOVAL

........23-143

STANDARD CAB - INSTALLATION

........8O-19STANDARD CAB - REMOVAL...........8O-18

STARTER MOTOR - DESCRIPTION,

ENGINE............................8F-39

STARTER MOTOR - DIAGNOSIS AND

TESTING...........................8F-39

STARTER MOTOR - INSTALLATION,

ENGINE............................8F-41

STARTER MOTOR - OPERATION, ENGINE . . 8F-39

STARTER MOTOR - REMOVAL, ENGINE . . . 8F-40

STARTER MOTOR RELAY -

DESCRIPTION, ENGINE................8F-42

STARTER MOTOR RELAY -

INSTALLATION, ENGINE................8F-43

STARTER MOTOR RELAY - OPERATION,

ENGINE............................8F-42

STARTER MOTOR RELAY - REMOVAL,

ENGINE............................8F-43

STARTER RELAY - DIAGNOSIS AND

TESTING...........................8F-42

STARTING - DESCRIPTION.............8F-32

STARTING - OPERATION...............8F-32

STARTING - STANDARD PROCEDURE,

JUMP...............................0-27

STARTING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-33

STARTING SYSTEM - SPECIFICATIONS,

TORQUE............................8F-38

STARTING SYSTEM, SPECIFICATIONS.....8F-38

STATE DISPLAY TEST MODE -

DESCRIPTION........................25-1

STATIONARY GLASS - DESCRIPTION....23-145

STATIONARY GLASS - OPERATION......23-145

STEERING - DESCRIPTION..............19-1

STEERING - OPERATION................19-1

STEERING AND HANDLING -

INSPECTION........................30-15

STEERING COLUMN OPENING COVER -

INSTALLATION......................23-116

STEERING COLUMN OPENING COVER -

REMOVAL.........................23-115

STEERING FLOW AND PRESSURE -

DIAGNOSIS AND TESTING, POWER.......19-4

STEERING GEAR HOUSING PLUG -

INSTALLATION.......................19-27

STEERING GEAR HOUSING PLUG -

REMOVAL..........................19-27

STEERING GEAR LEAKAGE - DIAGNOSIS

AND TESTING, POWER................19-14

STEERING GEAR, SPECIAL TOOLS -

POWER............................19-20

STEERING GEAR, SPECIFICATIONS -

POWER............................19-19

STEERING LINKAGE, SPECIAL TOOLS....19-39,

19-42

STEERING PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER.......19-31

STEERING PUMP, SPECIAL TOOLS -

POWER............................19-36

STEERING SYSTEM - DIAGNOSIS AND

TESTING, POWER.....................19-2

STEERING SYSTEM - STANDARD

PROCEDURE, FLUSHING POWER........19-32

STEERING WHEEL - INSTALLATION......19-13

STEERING WHEEL - REMOVAL..........19-13

STEM SEAL - INSTALLATION, VALVE.....9-198

STEM SEALS - REMOVAL, VALVE........9-197

STEPS - NEW VEHICLE PREPARATION

FORM, FINAL........................30-22

STOP LAMP - INSTALLATION, CENTER

HIGH MOUNTED......................8L-6

STOP LAMP - REMOVAL, CENTER HIGH

MOUNTED...........................8L-6

STOP LAMP UNIT - INSTALLATION,

CENTER HIGH MOUNTED...............8L-6

STOP LAMP UNIT - REMOVAL, CENTER

HIGH MOUNTED......................8L-6

STORAGE - DESCRIPTION, PRE

DELIVERY..........................30-19

STORAGE - STANDARD PROCEDURE,

PRE DELIVERY......................30-20

STORAGE BIN - INSTALLATION

.........23-116

STORAGE BIN - REMOVAL

............23-116

STOWAGE TRAY - INSTALLATION, REAR

FLOOR

............................23-121

STOWAGE TRAY - REMOVAL, REAR

FLOOR

............................23-121

STRAP - INSTALLATION, CAB-TO- BED

GROUND

...........................8A-14STRAP - INSTALLATION, ENGINE-TO-

BODY GROUND......................8A-13

STRAP - INSTALLATION, HEATER CORE

GROUND...........................8A-15

STRAP - REMOVAL, CAB-TO- BED

GROUND...........................8A-14

STRAP - REMOVAL, ENGINE-TO-BODY

GROUND...........................8A-13

STRAP - REMOVAL, HEATER CORE

GROUND...........................8A-14

STRETCH - INSPECTION, MEASURING

TIMING CHAIN........9-114,9-170,9-227,9-58

STRIKER - ADJUSTMENT, LATCH.......23-102

STRIKER - INSTALLATION, GLOVE BOX

LATCH ............................23-113

STRIKER - INSTALLATION, LATCH . 23-102,23-65,

23-73

STRIKER - LOWER - INSTALLATION,

LATCH .............................23-82

STRIKER - LOWER - REMOVAL, LATCH . . . 23-82

STRIKER - REMOVAL, GLOVE BOX

LATCH ............................23-113

STRIKER - REMOVAL, LATCH....23-102,23-65,

23-73

STRIKER - UPPER - INSTALLATION,

LATCH .............................23-82

STRIKER - UPPER - REMOVAL, LATCH . . . 23-82

STRIPE - INSTALLATION, TAPE..........23-88

STRIPE - REMOVAL, TAPE.............23-88

STRIPES AND DECALS - INSTALLATION,

BODY..............................23-87

STRIPES AND DECALS - REMOVAL,

BODY..............................23-87

STRUCTURAL ADHESIVE LOCATIONS,

SPECIFICATIONS.....................23-44

STUDS - INSTALLATION...............22-12

STUDS - REMOVAL...................22-12

SUCTION AND DISCHARGE LINE -

INSTALLATION.......................24-51

SUCTION AND DISCHARGE LINE -

REMOVAL..........................24-50

SUN VISOR - INSTALLATION..........23-127

SUN VISOR - REMOVAL..............23-127

SUPPLIES - DESCRIPTION, 5 VOLT......8E-17

SUPPLIES - OPERATION, 5 VOLT........8E-19

SUPPLY - DIAGNOSIS AND TESTING,

VACUUM............................8P-2

SUPPLY RESTRICTIONS - DIAGNOSIS

AND TESTING, FUEL..................14-56

SUPPORT - INSTALLATION, LUMBAR....23-133

SUPPORT - REMOVAL, LUMBAR.......23-133

SUPPORT BRACKET - INSTALLATION,

REARVIEW MIRROR.................23-126

SUPPORT PLATE - INSTALLATION........5-32

SUPPORT PLATE - REMOVAL............5-32

SUPPRESSION COMPONENTS -

DESCRIPTION, RADIO NOISE...........8A-12

SUPPRESSION COMPONENTS -

DIAGNOSIS AND TESTING, RADIO

NOISE.............................8A-12

SUSPENSION - STANDARD

PROCEDURES, ALIGNMENT LINK/COIL.....2-5

SUSPENSION, SPECIAL TOOLS -

INDEPENDENT FRONT...................2-9

SUSPENSION, SPECIAL TOOLS -

LINK/COIL...........................2-16

SUSPENSION-REAR, SPECIAL TOOLS.....2-28

SWITCH - DESCRIPTION

...............8P-12

SWITCH - DESCRIPTION, A/C HIGH

PRESSURE

.........................24-20

SWITCH - DESCRIPTION, A/C LOW

PRESSURE

.........................24-21

SWITCH - DESCRIPTION, BLOWER

MOTOR

............................24-24

SWITCH - DESCRIPTION, BRAKE LAMP

....8L-4

SWITCH - DESCRIPTION, CLUTCH

PEDAL POSITION

.....................6-22

SWITCH - DESCRIPTION, DOOR AJAR

....8L-34

SWITCH - DESCRIPTION, DOOR

CYLINDER LOCK

......................8N-5

SWITCH - DESCRIPTION, DRIVER

POWER SEAT

.......................8N-16

SWITCH - DESCRIPTION, DRIVER SEAT

HEATER

.............................8G-7

SWITCH - DESCRIPTION, HEADLAMP

....8L-18

SWITCH - DESCRIPTION, HORN

..........8H-4

SWITCH - DESCRIPTION, IGNITION

......19-11

BR/BEINDEX 33

Description Group-Page Description Group-Page Description Group-Page