power DODGE RAM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 447 of 2255

B(+) to heated seat module circuit to the heated seat

module as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is connected to bat-

tery voltage and should be hot at all times. Check for

battery voltage at the cavity for relay terminal 86. If

OK, go to Step 5. If not OK, repair the open circuit to

the fused B(+) fuse in the PDC as required.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. It is grounded by the

premium version of the Central Timer Module (CTM)

in response to an engine speed message received over

the Chrysler Collision Detection (CCD) data bus from

the Powertrain Control Module (PCM) when the

engine is running. Check for continuity between the

cavity for relay terminal 85 and the heated seat relay

control circuit cavity of the CTM wire harness con-

nector. There should be continuity at all times. If OK,

use a DRBIIItscan tool and the proper diagnostic

procedures manual to test the operation of the CTM

and CCD data bus. If not OK, repair the open heated

seat relay control circuit as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse access panel by inserting a

finger in the finger recess molded into the panel and

then pulling the panel sharply away from the left

outboard end of the instrument panel.

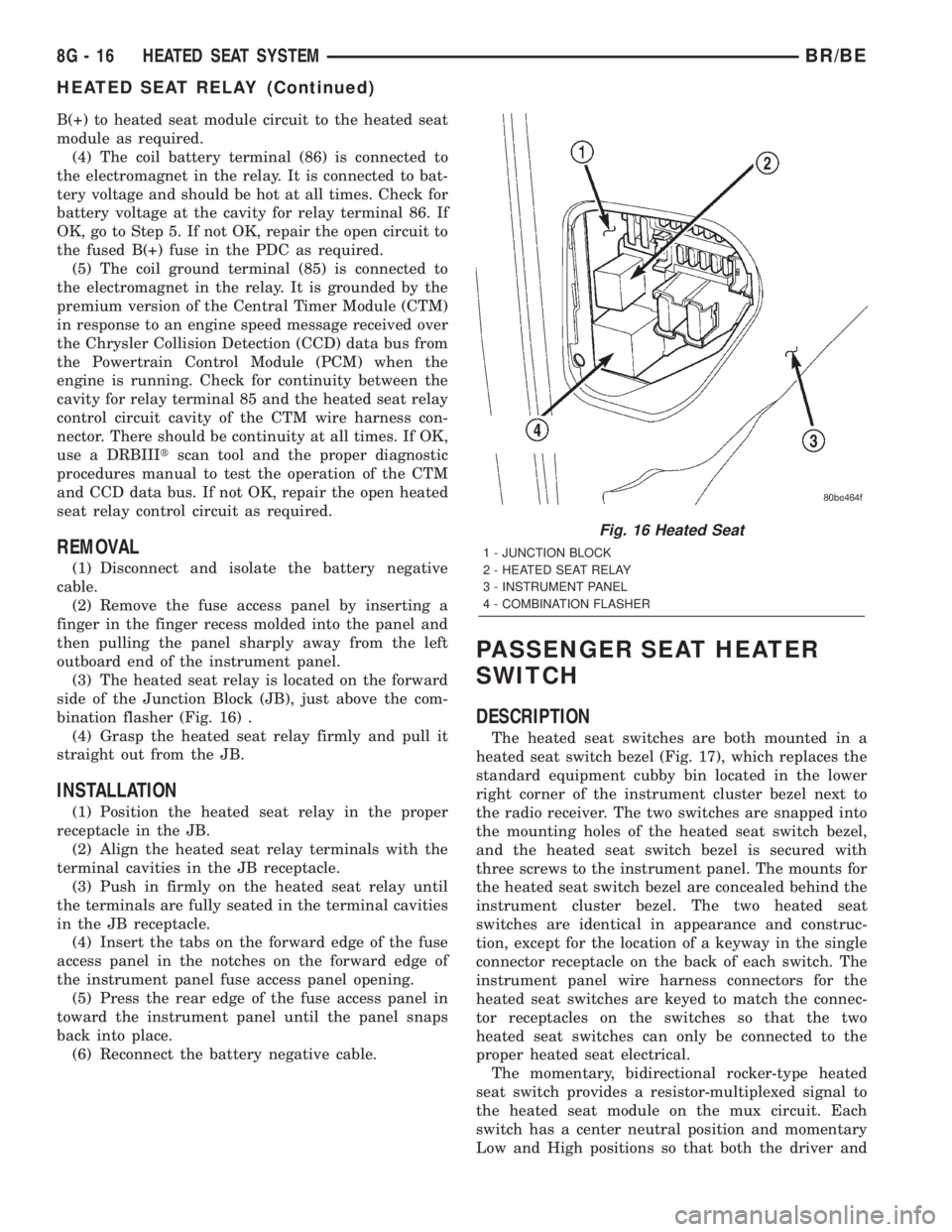

(3) The heated seat relay is located on the forward

side of the Junction Block (JB), just above the com-

bination flasher (Fig. 16) .

(4) Grasp the heated seat relay firmly and pull it

straight out from the JB.

INSTALLATION

(1) Position the heated seat relay in the proper

receptacle in the JB.

(2) Align the heated seat relay terminals with the

terminal cavities in the JB receptacle.

(3) Push in firmly on the heated seat relay until

the terminals are fully seated in the terminal cavities

in the JB receptacle.

(4) Insert the tabs on the forward edge of the fuse

access panel in the notches on the forward edge of

the instrument panel fuse access panel opening.

(5) Press the rear edge of the fuse access panel in

toward the instrument panel until the panel snaps

back into place.

(6) Reconnect the battery negative cable.

PASSENGER SEAT HEATER

SWITCH

DESCRIPTION

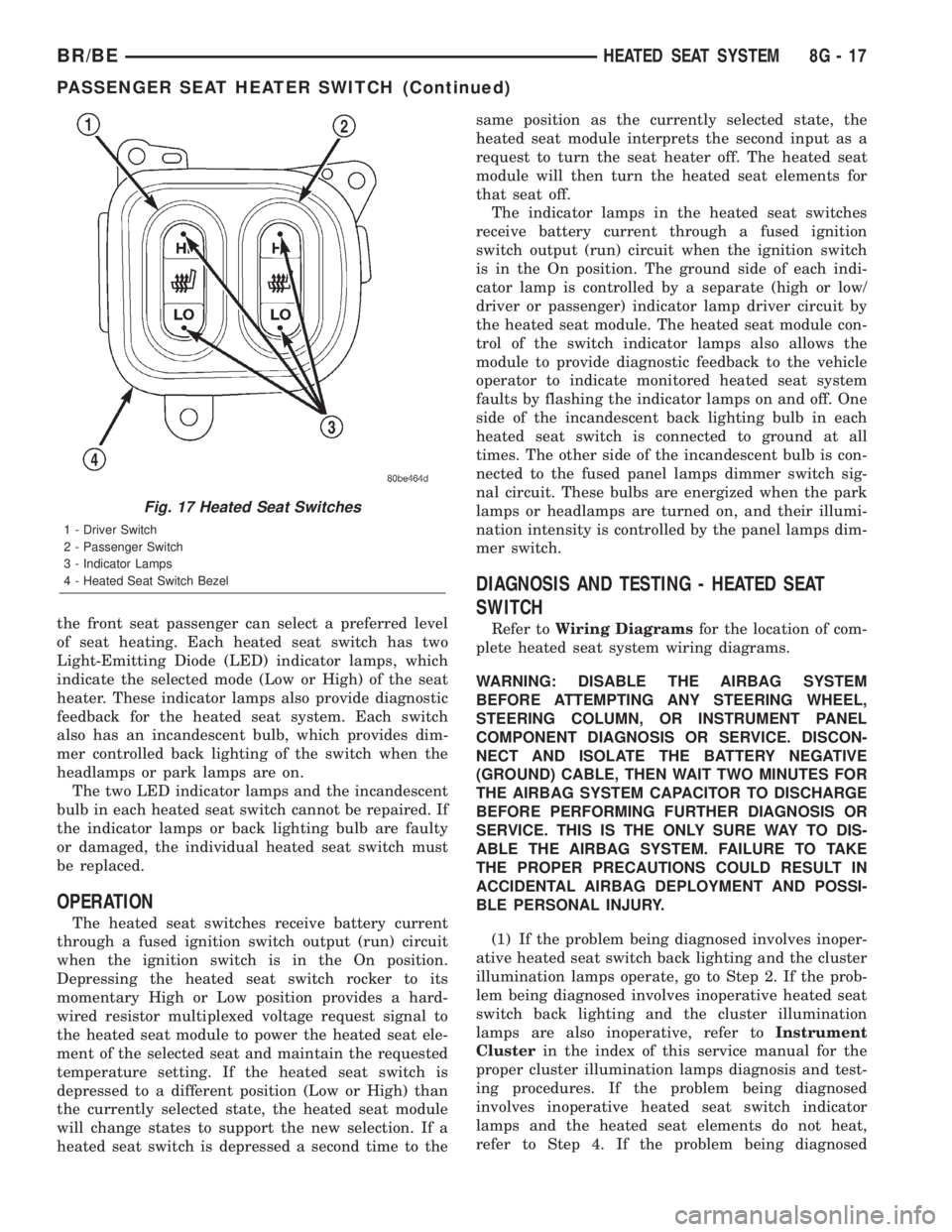

The heated seat switches are both mounted in a

heated seat switch bezel (Fig. 17), which replaces the

standard equipment cubby bin located in the lower

right corner of the instrument cluster bezel next to

the radio receiver. The two switches are snapped into

the mounting holes of the heated seat switch bezel,

and the heated seat switch bezel is secured with

three screws to the instrument panel. The mounts for

the heated seat switch bezel are concealed behind the

instrument cluster bezel. The two heated seat

switches are identical in appearance and construc-

tion, except for the location of a keyway in the single

connector receptacle on the back of each switch. The

instrument panel wire harness connectors for the

heated seat switches are keyed to match the connec-

tor receptacles on the switches so that the two

heated seat switches can only be connected to the

proper heated seat electrical.

The momentary, bidirectional rocker-type heated

seat switch provides a resistor-multiplexed signal to

the heated seat module on the mux circuit. Each

switch has a center neutral position and momentary

Low and High positions so that both the driver and

Fig. 16 Heated Seat

1 - JUNCTION BLOCK

2 - HEATED SEAT RELAY

3 - INSTRUMENT PANEL

4 - COMBINATION FLASHER

8G - 16 HEATED SEAT SYSTEMBR/BE

HEATED SEAT RELAY (Continued)

Page 448 of 2255

the front seat passenger can select a preferred level

of seat heating. Each heated seat switch has two

Light-Emitting Diode (LED) indicator lamps, which

indicate the selected mode (Low or High) of the seat

heater. These indicator lamps also provide diagnostic

feedback for the heated seat system. Each switch

also has an incandescent bulb, which provides dim-

mer controlled back lighting of the switch when the

headlamps or park lamps are on.

The two LED indicator lamps and the incandescent

bulb in each heated seat switch cannot be repaired. If

the indicator lamps or back lighting bulb are faulty

or damaged, the individual heated seat switch must

be replaced.

OPERATION

The heated seat switches receive battery current

through a fused ignition switch output (run) circuit

when the ignition switch is in the On position.

Depressing the heated seat switch rocker to its

momentary High or Low position provides a hard-

wired resistor multiplexed voltage request signal to

the heated seat module to power the heated seat ele-

ment of the selected seat and maintain the requested

temperature setting. If the heated seat switch is

depressed to a different position (Low or High) than

the currently selected state, the heated seat module

will change states to support the new selection. If a

heated seat switch is depressed a second time to thesame position as the currently selected state, the

heated seat module interprets the second input as a

request to turn the seat heater off. The heated seat

module will then turn the heated seat elements for

that seat off.

The indicator lamps in the heated seat switches

receive battery current through a fused ignition

switch output (run) circuit when the ignition switch

is in the On position. The ground side of each indi-

cator lamp is controlled by a separate (high or low/

driver or passenger) indicator lamp driver circuit by

the heated seat module. The heated seat module con-

trol of the switch indicator lamps also allows the

module to provide diagnostic feedback to the vehicle

operator to indicate monitored heated seat system

faults by flashing the indicator lamps on and off. One

side of the incandescent back lighting bulb in each

heated seat switch is connected to ground at all

times. The other side of the incandescent bulb is con-

nected to the fused panel lamps dimmer switch sig-

nal circuit. These bulbs are energized when the park

lamps or headlamps are turned on, and their illumi-

nation intensity is controlled by the panel lamps dim-

mer switch.

DIAGNOSIS AND TESTING - HEATED SEAT

SWITCH

Refer toWiring Diagramsfor the location of com-

plete heated seat system wiring diagrams.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

(1) If the problem being diagnosed involves inoper-

ative heated seat switch back lighting and the cluster

illumination lamps operate, go to Step 2. If the prob-

lem being diagnosed involves inoperative heated seat

switch back lighting and the cluster illumination

lamps are also inoperative, refer toInstrument

Clusterin the index of this service manual for the

proper cluster illumination lamps diagnosis and test-

ing procedures. If the problem being diagnosed

involves inoperative heated seat switch indicator

lamps and the heated seat elements do not heat,

refer to Step 4. If the problem being diagnosed

Fig. 17 Heated Seat Switches

1 - Driver Switch

2 - Passenger Switch

3 - Indicator Lamps

4 - Heated Seat Switch Bezel

BR/BEHEATED SEAT SYSTEM 8G - 17

PASSENGER SEAT HEATER SWITCH (Continued)

Page 453 of 2255

ELECTRICAL/VEHICLE THEFT SECURITY - GEN-

ERAL INFORMATION) for more information on the

VTSS. (Refer to 8 - ELECTRICAL/POWER LOCKS -

GENERAL INFORMATION) for more information on

the RKE system.

HORN

DESCRIPTION

The standard single, low-note, electromagnetic dia-

phragm-type horn is secured with a bracket to the

right front fender wheel house extension in the

engine compartment. The high-note horn for the

optional dual-note horn system is connected in paral-

lel with and secured with a bracket just forward of

the low-note horn. Each horn is grounded through its

wire harness connector and circuit to a ground splice

joint connector, and receives battery feed through the

closed contacts of the horn relay.

The horns cannot be repaired or adjusted and, if

faulty or damaged, they must be individually

replaced.

OPERATION

Within the two halves of the molded plastic horn

housing are a flexible diaphragm, a plunger, an elec-

tromagnetic coil and a set of contact points. The dia-

phragm is secured in suspension around its

perimeter by the mating surfaces of the horn hous-

ing. The plunger is secured to the center of the dia-

phragm and extends into the center of the

electromagnet. The contact points control the current

flow through the electromagnet.

When the horn is energized, electrical current

flows through the closed contact points to the electro-

magnet. The resulting electromagnetic field draws

the plunger and diaphragm toward it until that

movement mechanically opens the contact points.

When the contact points open, the electromagnetic

field collapses allowing the plunger and diaphragm to

return to their relaxed positions and closing the con-

tact points again. This cycle continues repeating at a

very rapid rate producing the vibration and move-

ment of air that creates the sound that is directed

through the horn outlet.

DIAGNOSIS AND TESTING - HORN

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.(1) Disconnect the wire harness connector(s) from

the horn connector receptacle(s). Measure the resis-

tance between the ground circuit cavity of the horn(s)

wire harness connector(s) and a good ground. There

should be no measurable resistance. If OK, go to Step

2. If not OK, repair the open ground circuit to ground

as required.

(2) Check for battery voltage at the horn relay out-

put circuit cavity of the horn(s) wire harness connec-

tor(s). There should be zero volts. If OK, go to Step 3.

If not OK, repair the shorted horn relay output cir-

cuit or replace the faulty horn relay as required.

(3) Depress the horn switch. There should now be

battery voltage at the horn relay output circuit cavity

of the horn(s) wire harness connector(s). If OK,

replace the faulty horn(s). If not OK, repair the open

horn relay output circuit to the horn relay as

required.

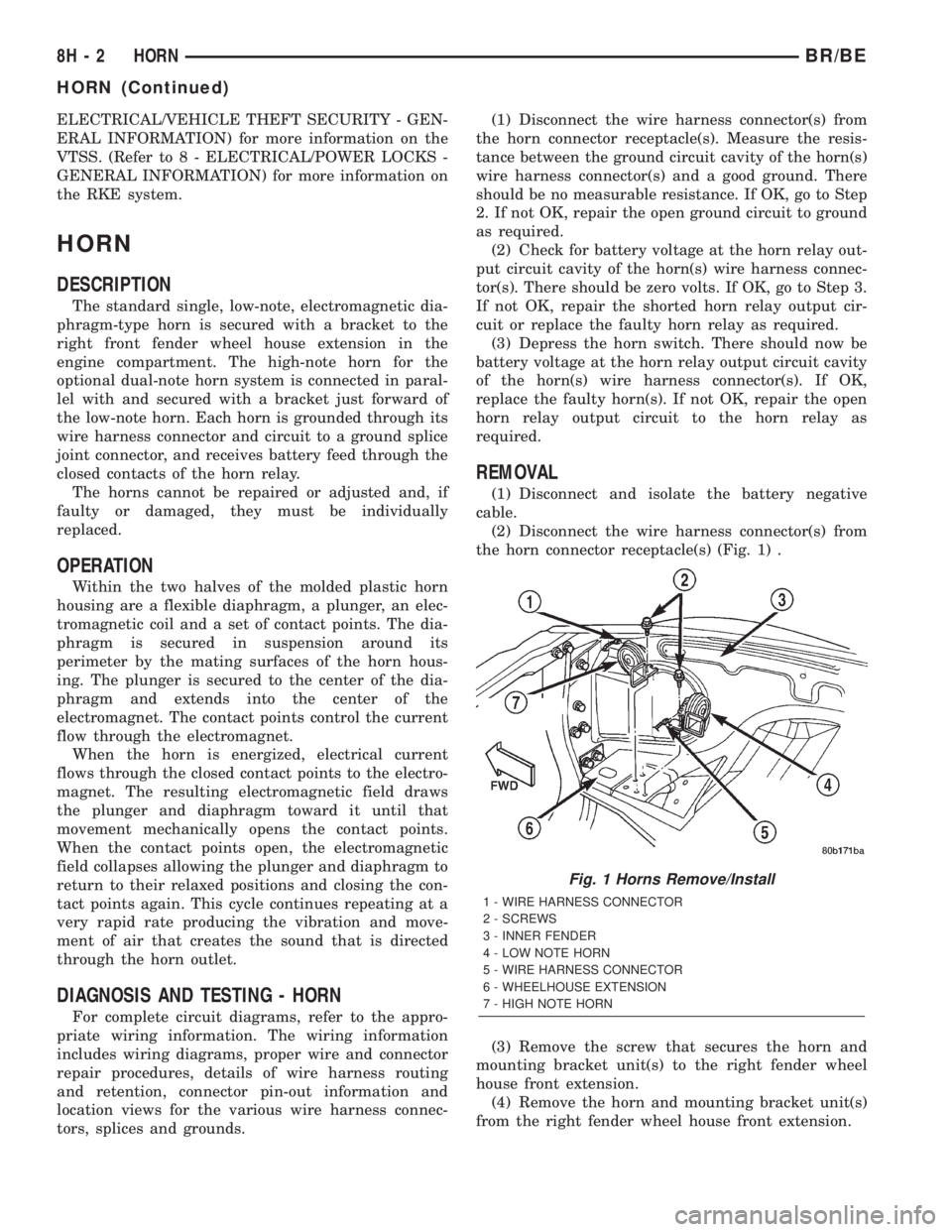

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the wire harness connector(s) from

the horn connector receptacle(s) (Fig. 1) .

(3) Remove the screw that secures the horn and

mounting bracket unit(s) to the right fender wheel

house front extension.

(4) Remove the horn and mounting bracket unit(s)

from the right fender wheel house front extension.

Fig. 1 Horns Remove/Install

1 - WIRE HARNESS CONNECTOR

2 - SCREWS

3 - INNER FENDER

4 - LOW NOTE HORN

5 - WIRE HARNESS CONNECTOR

6 - WHEELHOUSE EXTENSION

7 - HIGH NOTE HORN

8H - 2 HORNBR/BE

HORN (Continued)

Page 454 of 2255

INSTALLATION

(1) Position the horn and mounting bracket unit(s)

onto the right fender wheel house front extension.

(2) Install and tighten the screw that secures the

horn and mounting bracket unit(s) to the right

fender wheel house front extension. Tighten the

screw to 11 N´m (95 in. lbs.).

(3) Reconnect the wire harness connector(s) to the

horn connector receptacle(s).

(4) Reconnect the battery negative cable.

HORN RELAY

DESCRIPTION

The horn relay is a electromechanical device that

switches battery current to the horn when the horn

switch grounds the relay coil. The horn relay is

located in the Power Distribution Center (PDC) in

the engine compartment. If a problem is encountered

with a continuously sounding horn, it can usually be

quickly resolved by removing the horn relay from the

PDC until further diagnosis is completed. See the

fuse and relay layout label affixed to the inside sur-

face of the PDC cover for horn relay identification

and location.

The horn relay is a International Standards Orga-

nization (ISO) micro-relay. Relays conforming to the

ISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions. The ISO micro-relay terminal functions

are the same as a conventional ISO relay. However,

the ISO micro-relay terminal pattern (or footprint) is

different, the current capacity is lower, and the phys-

ical dimensions are smaller than those of the conven-

tional ISO relay.

The horn relay cannot be repaired or adjusted and,

if faulty or damaged, it must be replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

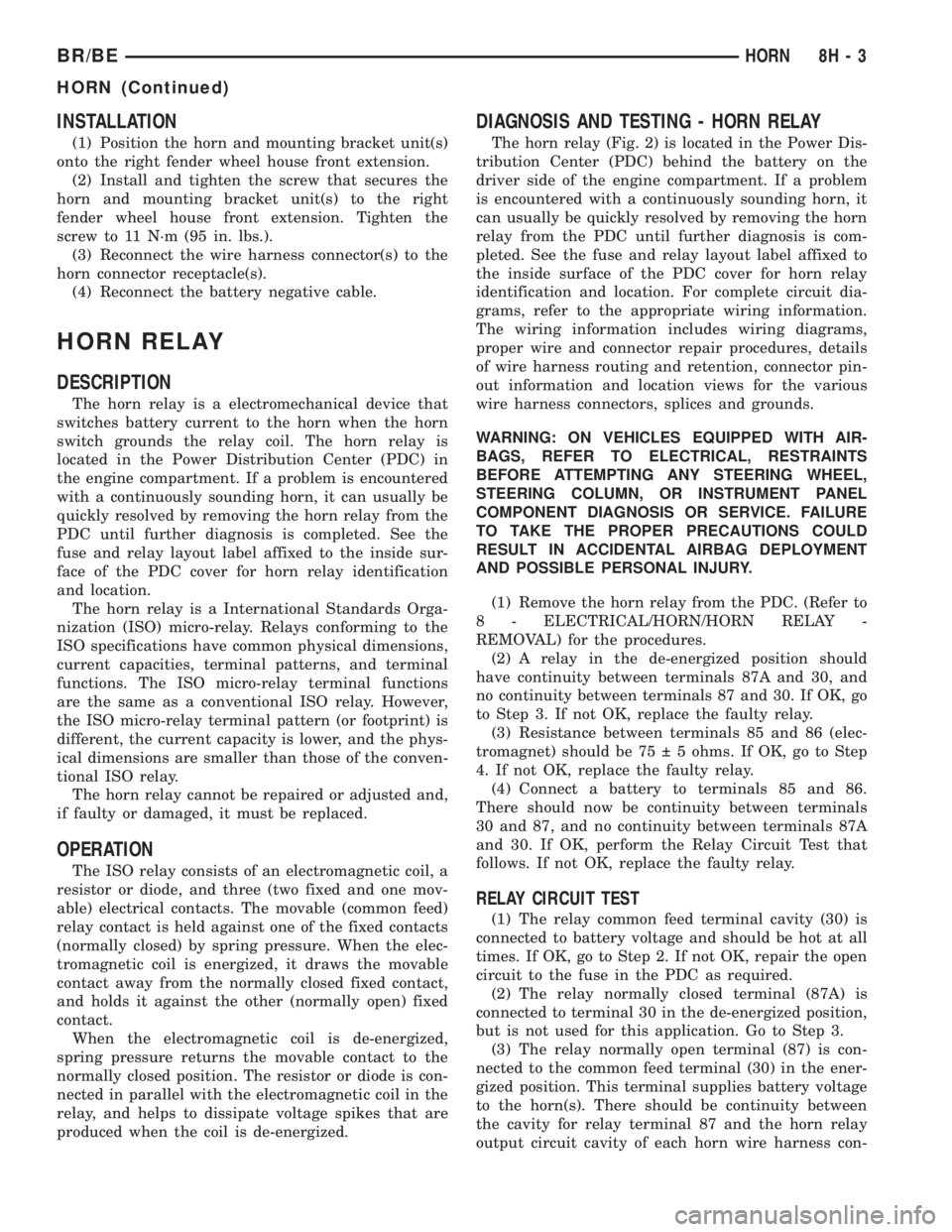

DIAGNOSIS AND TESTING - HORN RELAY

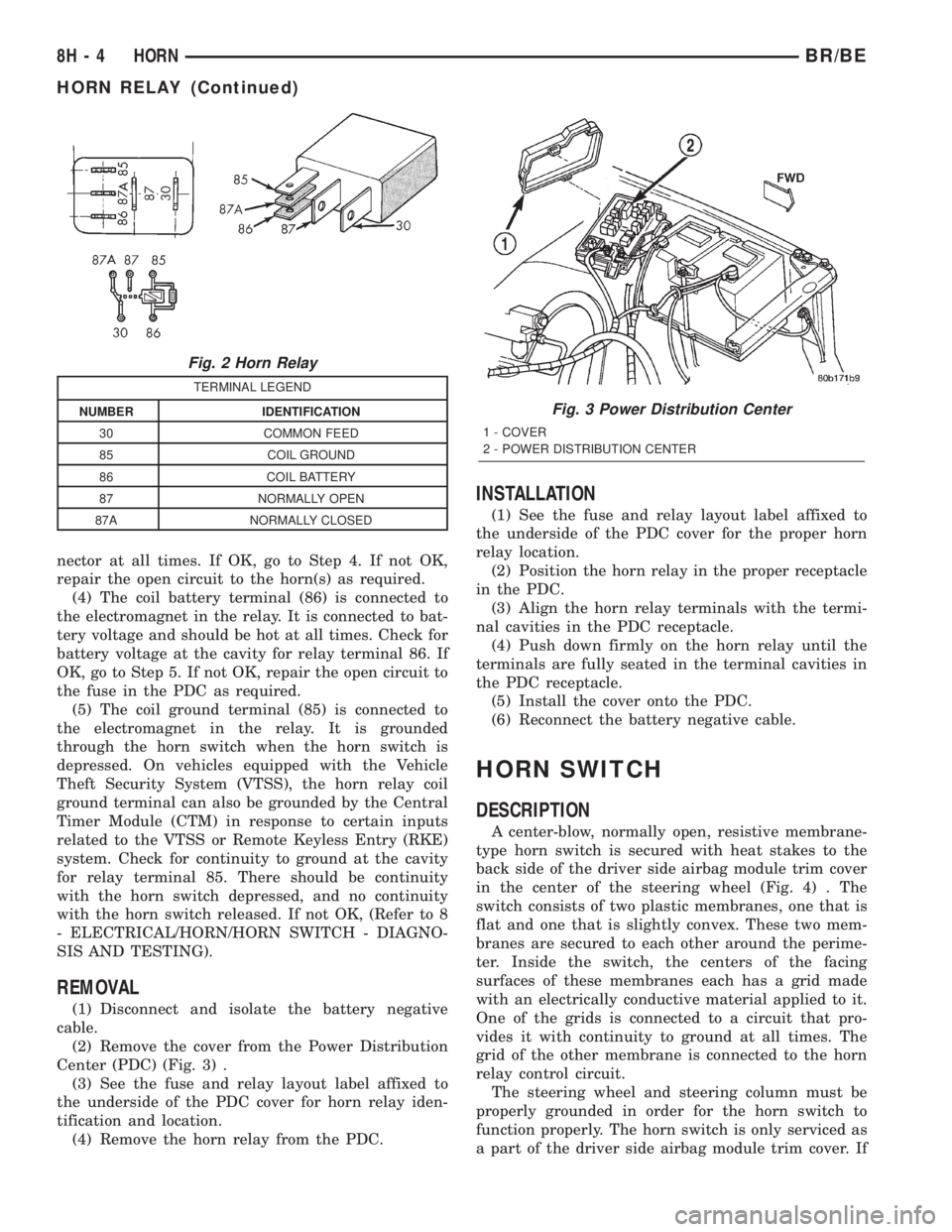

The horn relay (Fig. 2) is located in the Power Dis-

tribution Center (PDC) behind the battery on the

driver side of the engine compartment. If a problem

is encountered with a continuously sounding horn, it

can usually be quickly resolved by removing the horn

relay from the PDC until further diagnosis is com-

pleted. See the fuse and relay layout label affixed to

the inside surface of the PDC cover for horn relay

identification and location. For complete circuit dia-

grams, refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Remove the horn relay from the PDC. (Refer to

8 - ELECTRICAL/HORN/HORN RELAY -

REMOVAL) for the procedures.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the horn(s). There should be continuity between

the cavity for relay terminal 87 and the horn relay

output circuit cavity of each horn wire harness con-

BR/BEHORN 8H - 3

HORN (Continued)

Page 455 of 2255

nector at all times. If OK, go to Step 4. If not OK,

repair the open circuit to the horn(s) as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is connected to bat-

tery voltage and should be hot at all times. Check for

battery voltage at the cavity for relay terminal 86. If

OK, go to Step 5. If not OK, repair the open circuit to

the fuse in the PDC as required.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. It is grounded

through the horn switch when the horn switch is

depressed. On vehicles equipped with the Vehicle

Theft Security System (VTSS), the horn relay coil

ground terminal can also be grounded by the Central

Timer Module (CTM) in response to certain inputs

related to the VTSS or Remote Keyless Entry (RKE)

system. Check for continuity to ground at the cavity

for relay terminal 85. There should be continuity

with the horn switch depressed, and no continuity

with the horn switch released. If not OK, (Refer to 8

- ELECTRICAL/HORN/HORN SWITCH - DIAGNO-

SIS AND TESTING).

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

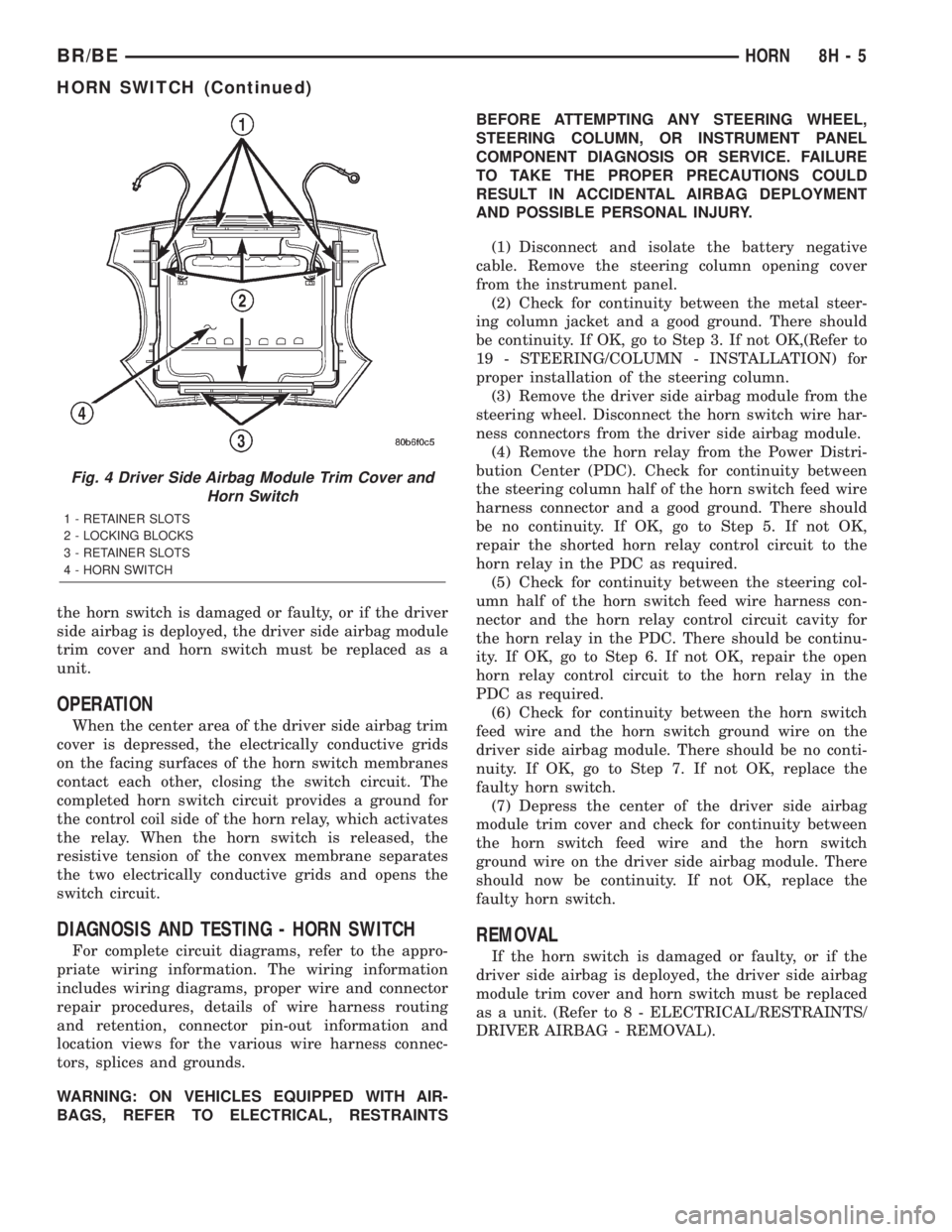

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 3) .

(3) See the fuse and relay layout label affixed to

the underside of the PDC cover for horn relay iden-

tification and location.

(4) Remove the horn relay from the PDC.

INSTALLATION

(1) See the fuse and relay layout label affixed to

the underside of the PDC cover for the proper horn

relay location.

(2) Position the horn relay in the proper receptacle

in the PDC.

(3) Align the horn relay terminals with the termi-

nal cavities in the PDC receptacle.

(4) Push down firmly on the horn relay until the

terminals are fully seated in the terminal cavities in

the PDC receptacle.

(5) Install the cover onto the PDC.

(6) Reconnect the battery negative cable.

HORN SWITCH

DESCRIPTION

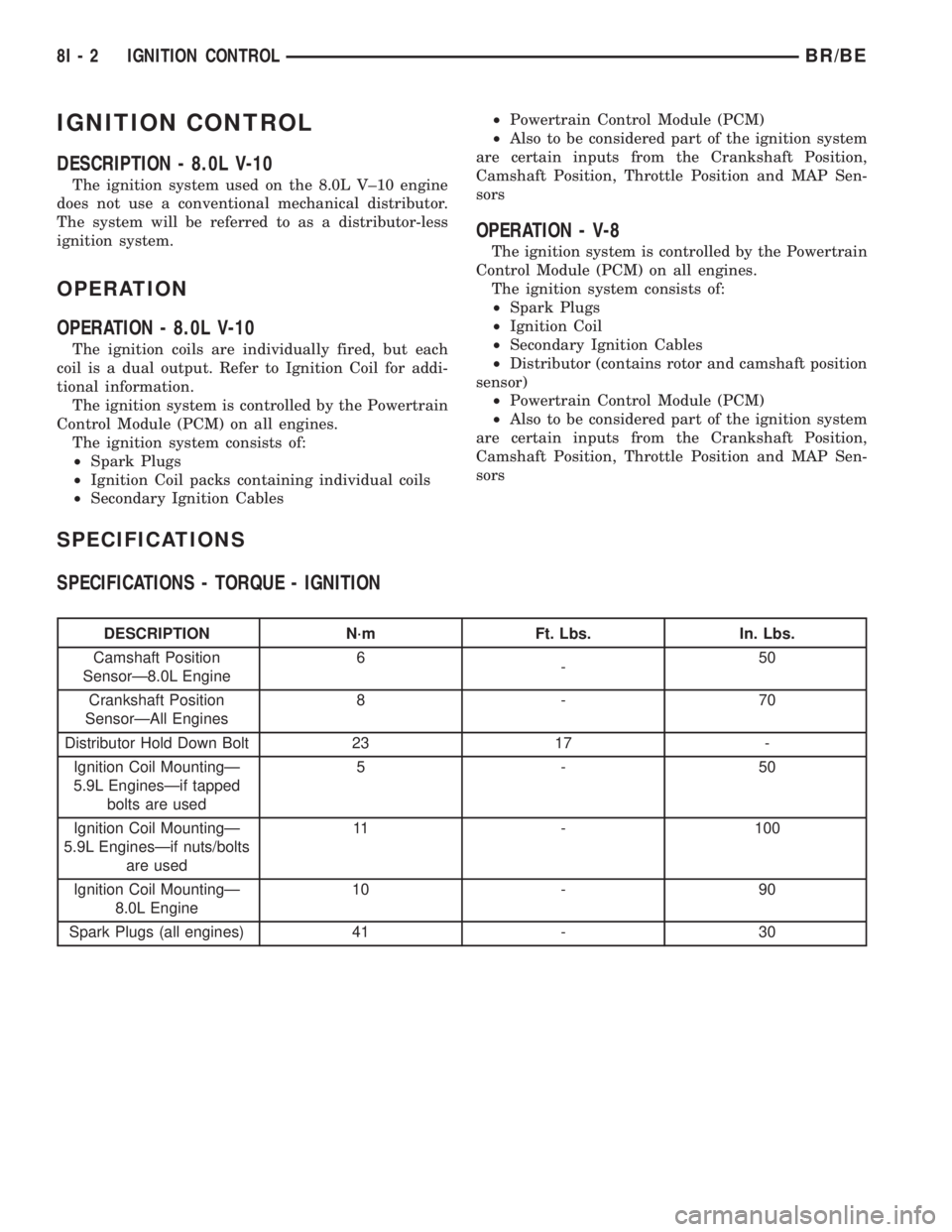

A center-blow, normally open, resistive membrane-

type horn switch is secured with heat stakes to the

back side of the driver side airbag module trim cover

in the center of the steering wheel (Fig. 4) . The

switch consists of two plastic membranes, one that is

flat and one that is slightly convex. These two mem-

branes are secured to each other around the perime-

ter. Inside the switch, the centers of the facing

surfaces of these membranes each has a grid made

with an electrically conductive material applied to it.

One of the grids is connected to a circuit that pro-

vides it with continuity to ground at all times. The

grid of the other membrane is connected to the horn

relay control circuit.

The steering wheel and steering column must be

properly grounded in order for the horn switch to

function properly. The horn switch is only serviced as

a part of the driver side airbag module trim cover. If

Fig. 2 Horn Relay

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 3 Power Distribution Center

1 - COVER

2 - POWER DISTRIBUTION CENTER

8H - 4 HORNBR/BE

HORN RELAY (Continued)

Page 456 of 2255

the horn switch is damaged or faulty, or if the driver

side airbag is deployed, the driver side airbag module

trim cover and horn switch must be replaced as a

unit.

OPERATION

When the center area of the driver side airbag trim

cover is depressed, the electrically conductive grids

on the facing surfaces of the horn switch membranes

contact each other, closing the switch circuit. The

completed horn switch circuit provides a ground for

the control coil side of the horn relay, which activates

the relay. When the horn switch is released, the

resistive tension of the convex membrane separates

the two electrically conductive grids and opens the

switch circuit.

DIAGNOSIS AND TESTING - HORN SWITCH

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTSBEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable. Remove the steering column opening cover

from the instrument panel.

(2) Check for continuity between the metal steer-

ing column jacket and a good ground. There should

be continuity. If OK, go to Step 3. If not OK,(Refer to

19 - STEERING/COLUMN - INSTALLATION) for

proper installation of the steering column.

(3) Remove the driver side airbag module from the

steering wheel. Disconnect the horn switch wire har-

ness connectors from the driver side airbag module.

(4) Remove the horn relay from the Power Distri-

bution Center (PDC). Check for continuity between

the steering column half of the horn switch feed wire

harness connector and a good ground. There should

be no continuity. If OK, go to Step 5. If not OK,

repair the shorted horn relay control circuit to the

horn relay in the PDC as required.

(5) Check for continuity between the steering col-

umn half of the horn switch feed wire harness con-

nector and the horn relay control circuit cavity for

the horn relay in the PDC. There should be continu-

ity. If OK, go to Step 6. If not OK, repair the open

horn relay control circuit to the horn relay in the

PDC as required.

(6) Check for continuity between the horn switch

feed wire and the horn switch ground wire on the

driver side airbag module. There should be no conti-

nuity. If OK, go to Step 7. If not OK, replace the

faulty horn switch.

(7) Depress the center of the driver side airbag

module trim cover and check for continuity between

the horn switch feed wire and the horn switch

ground wire on the driver side airbag module. There

should now be continuity. If not OK, replace the

faulty horn switch.REMOVAL

If the horn switch is damaged or faulty, or if the

driver side airbag is deployed, the driver side airbag

module trim cover and horn switch must be replaced

as a unit. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - REMOVAL).

Fig. 4 Driver Side Airbag Module Trim Cover and

Horn Switch

1 - RETAINER SLOTS

2 - LOCKING BLOCKS

3 - RETAINER SLOTS

4 - HORN SWITCH

BR/BEHORN 8H - 5

HORN SWITCH (Continued)

Page 459 of 2255

IGNITION CONTROL

DESCRIPTION - 8.0L V-10

The ignition system used on the 8.0L V±10 engine

does not use a conventional mechanical distributor.

The system will be referred to as a distributor-less

ignition system.

OPERATION

OPERATION - 8.0L V-10

The ignition coils are individually fired, but each

coil is a dual output. Refer to Ignition Coil for addi-

tional information.

The ignition system is controlled by the Powertrain

Control Module (PCM) on all engines.

The ignition system consists of:

²Spark Plugs

²Ignition Coil packs containing individual coils

²Secondary Ignition Cables²Powertrain Control Module (PCM)

²Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position and MAP Sen-

sors

OPERATION - V-8

The ignition system is controlled by the Powertrain

Control Module (PCM) on all engines.

The ignition system consists of:

²Spark Plugs

²Ignition Coil

²Secondary Ignition Cables

²Distributor (contains rotor and camshaft position

sensor)

²Powertrain Control Module (PCM)

²Also to be considered part of the ignition system

are certain inputs from the Crankshaft Position,

Camshaft Position, Throttle Position and MAP Sen-

sors

SPECIFICATIONS

SPECIFICATIONS - TORQUE - IGNITION

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Camshaft Position

SensorÐ8.0L Engine6

-50

Crankshaft Position

SensorÐAll Engines8-70

Distributor Hold Down Bolt 23 17 -

Ignition Coil MountingÐ

5.9L EnginesÐif tapped

bolts are used5-50

Ignition Coil MountingÐ

5.9L EnginesÐif nuts/bolts

are used11 - 100

Ignition Coil MountingÐ

8.0L Engine10 - 90

Spark Plugs (all engines) 41 - 30

8I - 2 IGNITION CONTROLBR/BE

Page 461 of 2255

IGNITION COIL RESISTANCEÐ8.0L V-10

ENGINE

Primary Resistance: 0.53-0.65 Ohms. Test across the

primary connector. Refer to text for test procedures.

Secondary Resistance: 10.9-14.7K Ohms. Test

across the individual coil towers. Refer to text for test

procedures.

IGNITION TIMING

Ignition timing is not adjustable on any engine.

AUTOMATIC SHUT DOWN

RELAY

DESCRIPTION - PCM OUTPUT

The 5±pin, 12±volt, Automatic Shutdown (ASD)

relay is located in the Power Distribution Center

(PDC). Refer to label on PDC cover for relay location.

OPERATION

OPERATION - PCM OUTPUT

The ASD relay supplies battery voltage (12+ volts)

to the fuel injectors and ignition coil(s). With certain

emissions packages it also supplies 12±volts to the

oxygen sensor heating elements.

The ground circuit for the coil within the ASD

relay is controlled by the Powertrain Control Module

(PCM). The PCM operates the ASD relay by switch-

ing its ground circuit on and off.

The ASD relay will be shut±down, meaning the

12±volt power supply to the ASD relay will be de-ac-

tivated by the PCM if:

²the ignition key is left in the ON position. This

is if the engine has not been running for approxi-

mately 1.8 seconds.

²there is a crankshaft position sensor signal to

the PCM that is lower than pre-determined values.

OPERATION - ASD SENSE - PCM INPUT

A 12 volt signal at this input indicates to the PCM

that the ASD has been activated. The relay is used to

connect the oxygen sensor heater element, ignition

coil and fuel injectors to 12 volt + power supply.

This input is used only to sense that the ASD relay

is energized. If the Powertrain Control Module

(PCM) does not see 12 volts at this input when the

ASD should be activated, it will set a Diagnostic

Trouble Code (DTC).

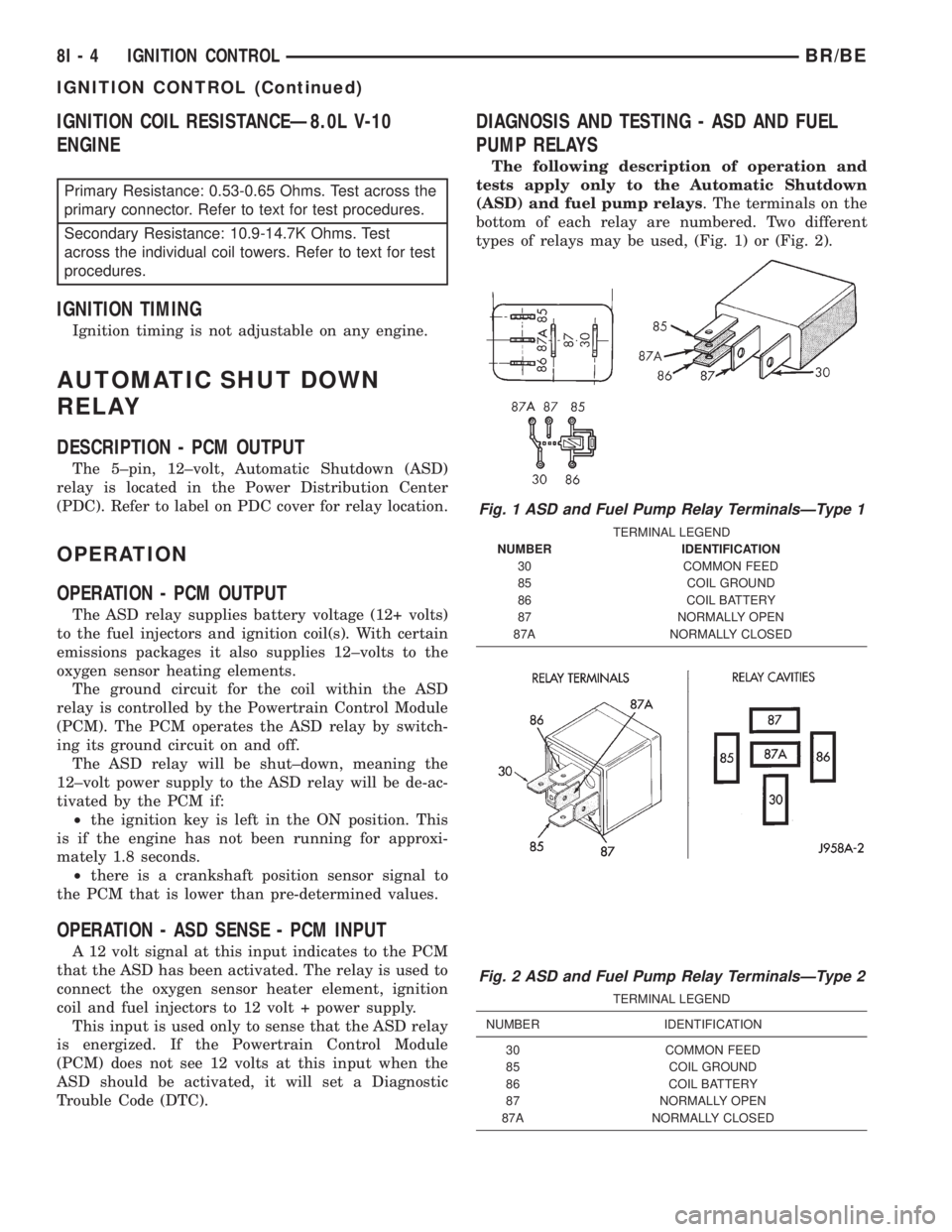

DIAGNOSIS AND TESTING - ASD AND FUEL

PUMP RELAYS

The following description of operation and

tests apply only to the Automatic Shutdown

(ASD) and fuel pump relays. The terminals on the

bottom of each relay are numbered. Two different

types of relays may be used, (Fig. 1) or (Fig. 2).

Fig. 1 ASD and Fuel Pump Relay TerminalsÐType 1

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 2 ASD and Fuel Pump Relay TerminalsÐType 2

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

8I - 4 IGNITION CONTROLBR/BE

IGNITION CONTROL (Continued)

Page 462 of 2255

²Terminal number 30 is connected to battery volt-

age. For both the ASD and fuel pump relays, termi-

nal 30 is connected to battery voltage at all times.

²The PCM grounds the coil side of the relay

through terminal number 85.

²Terminal number 86 supplies voltage to the coil

side of the relay.

²When the PCM de-energizes the ASD and fuel

pump relays, terminal number 87A connects to termi-

nal 30. This is the Off position. In the off position,

voltage is not supplied to the rest of the circuit. Ter-

minal 87A is the center terminal on the relay.

²When the PCM energizes the ASD and fuel

pump relays, terminal 87 connects to terminal 30.

This is the On position. Terminal 87 supplies voltage

to the rest of the circuit.

The following procedure applies to the ASD and

fuel pump relays.

(1) Remove relay from connector before testing.

(2) With the relay removed from the vehicle, use

an ohmmeter to check the resistance between termi-

nals 85 and 86. The resistance should be 75 ohms +/-

5 ohms.

(3) Connect the ohmmeter between terminals 30

and 87A. The ohmmeter should show continuity

between terminals 30 and 87A.

(4) Connect the ohmmeter between terminals 87

and 30. The ohmmeter should not show continuity at

this time.

(5) Connect one end of a jumper wire (16 gauge or

smaller) to relay terminal 85. Connect the other end

of the jumper wire to the ground side of a 12 volt

power source.

(6) Connect one end of another jumper wire (16

gauge or smaller) to the power side of the 12 volt

power source.Do not attach the other end of the

jumper wire to the relay at this time.

WARNING: DO NOT ALLOW OHMMETER TO CON-

TACT TERMINALS 85 OR 86 DURING THIS TEST.

DAMAGE TO OHMMETER MAY RESULT.

(7) Attach the other end of the jumper wire to

relay terminal 86. This activates the relay. The ohm-

meter should now show continuity between relay ter-

minals 87 and 30. The ohmmeter should not show

continuity between relay terminals 87A and 30.

(8) Disconnect jumper wires.(9) Replace the relay if it did not pass the continu-

ity and resistance tests. If the relay passed the tests,

it operates properly. Check the remainder of the ASD

and fuel pump relay circuits. Refer to 8, Wiring Dia-

grams.

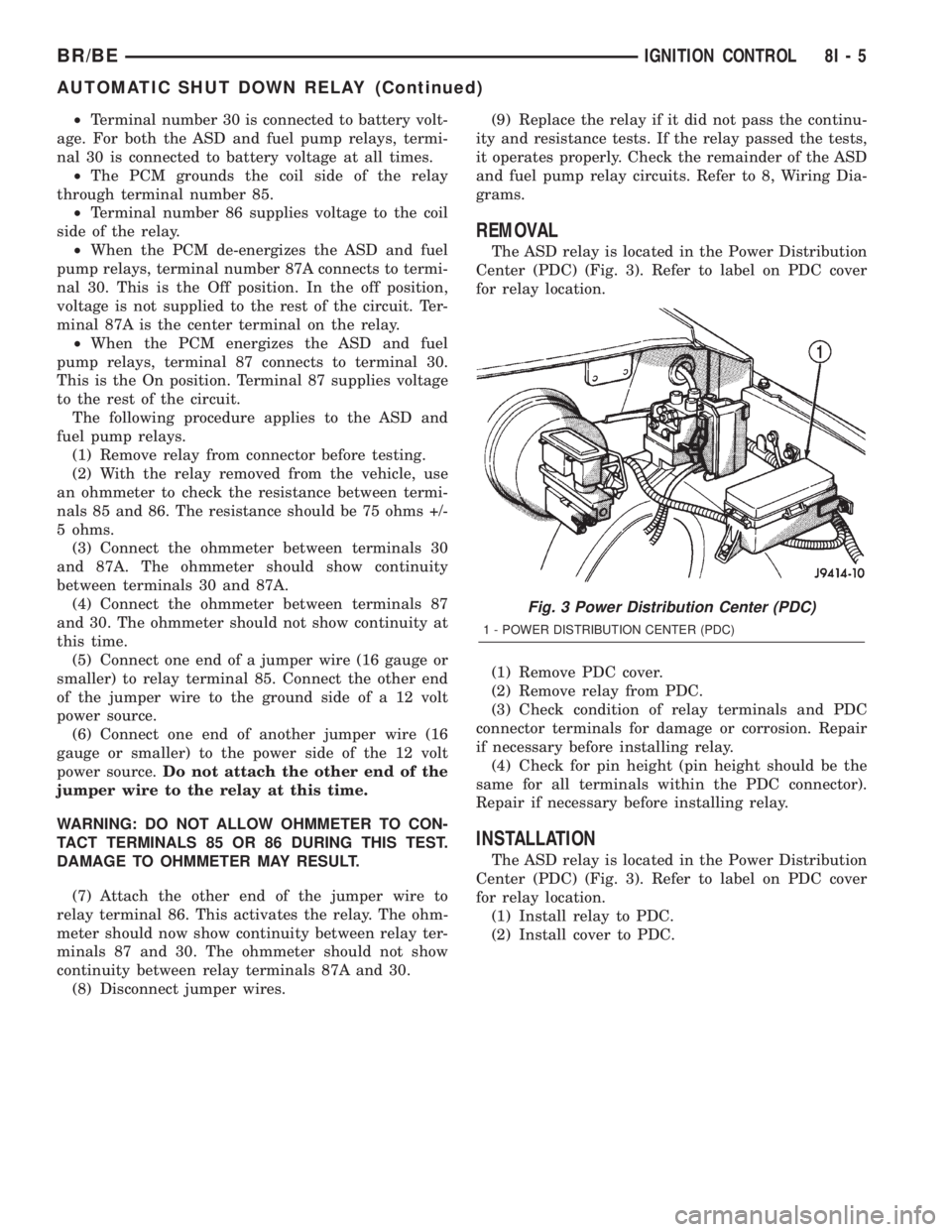

REMOVAL

The ASD relay is located in the Power Distribution

Center (PDC) (Fig. 3). Refer to label on PDC cover

for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The ASD relay is located in the Power Distribution

Center (PDC) (Fig. 3). Refer to label on PDC cover

for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

Fig. 3 Power Distribution Center (PDC)

1 - POWER DISTRIBUTION CENTER (PDC)

BR/BEIGNITION CONTROL 8I - 5

AUTOMATIC SHUT DOWN RELAY (Continued)

Page 464 of 2255

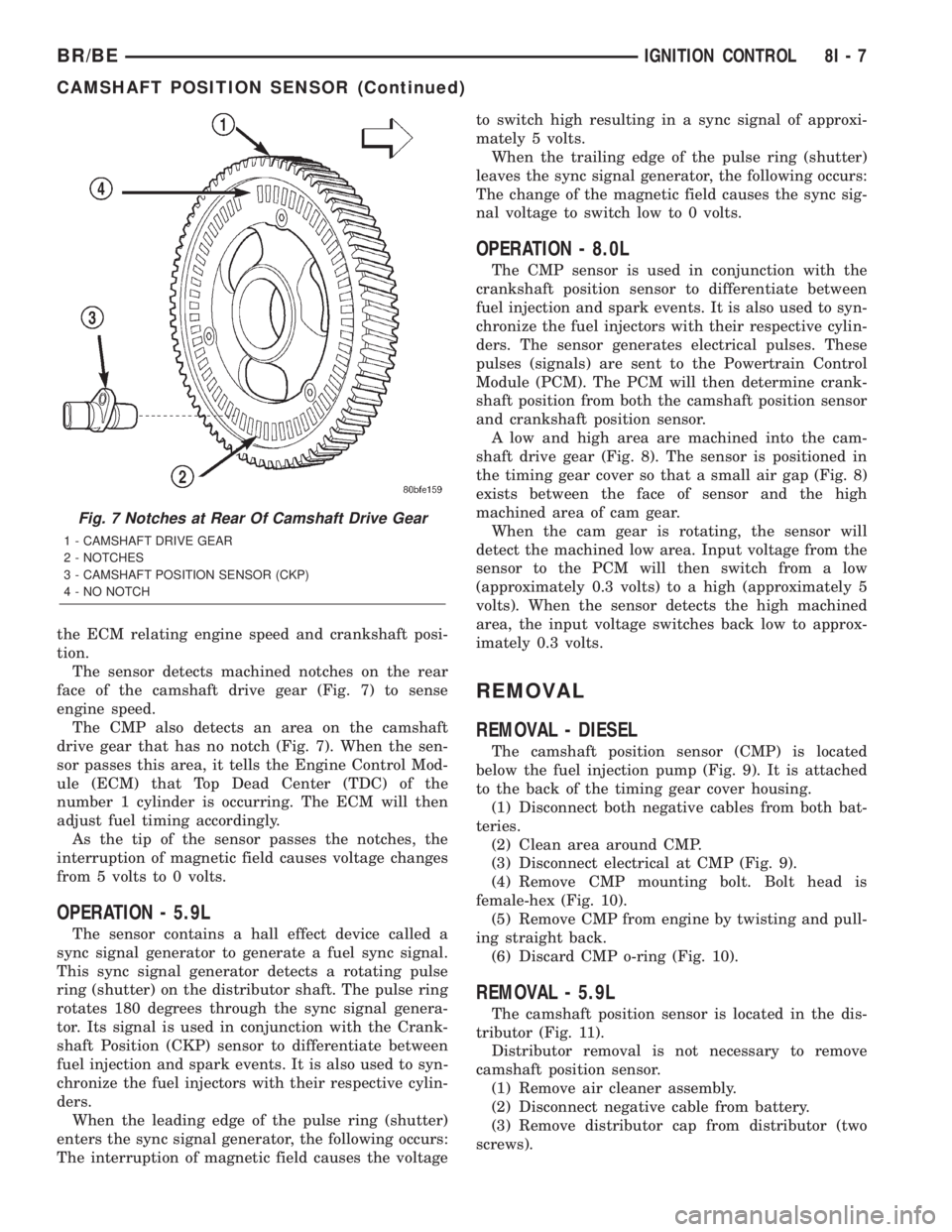

the ECM relating engine speed and crankshaft posi-

tion.

The sensor detects machined notches on the rear

face of the camshaft drive gear (Fig. 7) to sense

engine speed.

The CMP also detects an area on the camshaft

drive gear that has no notch (Fig. 7). When the sen-

sor passes this area, it tells the Engine Control Mod-

ule (ECM) that Top Dead Center (TDC) of the

number 1 cylinder is occurring. The ECM will then

adjust fuel timing accordingly.

As the tip of the sensor passes the notches, the

interruption of magnetic field causes voltage changes

from 5 volts to 0 volts.

OPERATION - 5.9L

The sensor contains a hall effect device called a

sync signal generator to generate a fuel sync signal.

This sync signal generator detects a rotating pulse

ring (shutter) on the distributor shaft. The pulse ring

rotates 180 degrees through the sync signal genera-

tor. Its signal is used in conjunction with the Crank-

shaft Position (CKP) sensor to differentiate between

fuel injection and spark events. It is also used to syn-

chronize the fuel injectors with their respective cylin-

ders.

When the leading edge of the pulse ring (shutter)

enters the sync signal generator, the following occurs:

The interruption of magnetic field causes the voltageto switch high resulting in a sync signal of approxi-

mately 5 volts.

When the trailing edge of the pulse ring (shutter)

leaves the sync signal generator, the following occurs:

The change of the magnetic field causes the sync sig-

nal voltage to switch low to 0 volts.

OPERATION - 8.0L

The CMP sensor is used in conjunction with the

crankshaft position sensor to differentiate between

fuel injection and spark events. It is also used to syn-

chronize the fuel injectors with their respective cylin-

ders. The sensor generates electrical pulses. These

pulses (signals) are sent to the Powertrain Control

Module (PCM). The PCM will then determine crank-

shaft position from both the camshaft position sensor

and crankshaft position sensor.

A low and high area are machined into the cam-

shaft drive gear (Fig. 8). The sensor is positioned in

the timing gear cover so that a small air gap (Fig. 8)

exists between the face of sensor and the high

machined area of cam gear.

When the cam gear is rotating, the sensor will

detect the machined low area. Input voltage from the

sensor to the PCM will then switch from a low

(approximately 0.3 volts) to a high (approximately 5

volts). When the sensor detects the high machined

area, the input voltage switches back low to approx-

imately 0.3 volts.

REMOVAL

REMOVAL - DIESEL

The camshaft position sensor (CMP) is located

below the fuel injection pump (Fig. 9). It is attached

to the back of the timing gear cover housing.

(1) Disconnect both negative cables from both bat-

teries.

(2) Clean area around CMP.

(3) Disconnect electrical at CMP (Fig. 9).

(4) Remove CMP mounting bolt. Bolt head is

female-hex (Fig. 10).

(5) Remove CMP from engine by twisting and pull-

ing straight back.

(6) Discard CMP o-ring (Fig. 10).

REMOVAL - 5.9L

The camshaft position sensor is located in the dis-

tributor (Fig. 11).

Distributor removal is not necessary to remove

camshaft position sensor.

(1) Remove air cleaner assembly.

(2) Disconnect negative cable from battery.

(3) Remove distributor cap from distributor (two

screws).

Fig. 7 Notches at Rear Of Camshaft Drive Gear

1 - CAMSHAFT DRIVE GEAR

2 - NOTCHES

3 - CAMSHAFT POSITION SENSOR (CKP)

4 - NO NOTCH

BR/BEIGNITION CONTROL 8I - 7

CAMSHAFT POSITION SENSOR (Continued)